lock DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2280 of 5267

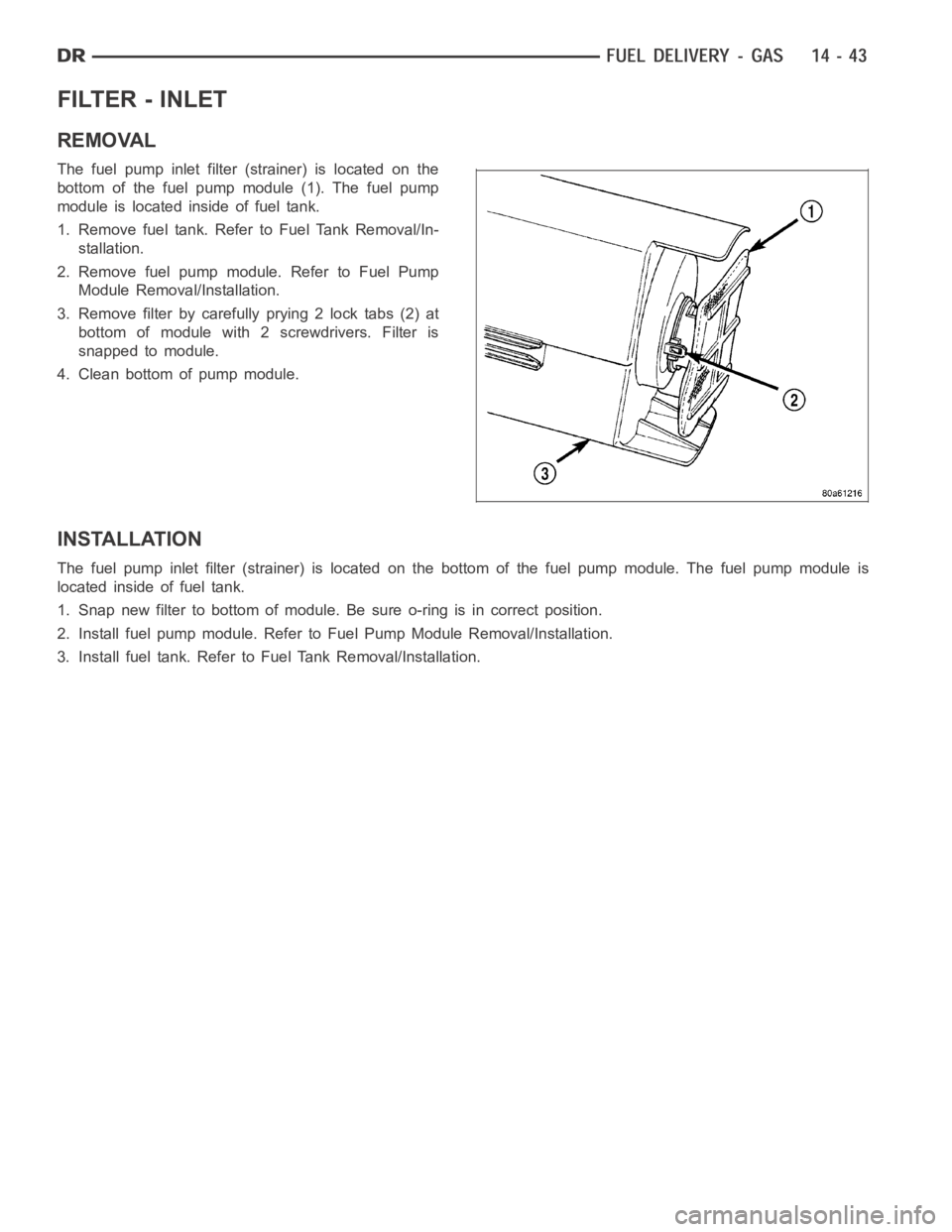

FILTER - INLET

REMOVAL

The fuel pump inlet filter (strainer) is located on the

bottom of the fuel pump module (1). The fuel pump

module is located inside of fuel tank.

1. Remove fuel tank. Refer to Fuel Tank Removal/In-

stallation.

2. Remove fuel pump module. Refer to Fuel Pump

Module Removal/Installation.

3. Remove filter by carefully prying 2 lock tabs (2) at

bottom of module with 2 screwdrivers. Filter is

snapped to module.

4. Clean bottom of pump module.

INSTALLATION

The fuel pump inlet filter (strainer) is located on the bottom of the fuel pump module. The fuel pump module is

located inside of fuel tank.

1. Snap new filter to bottom of module. Be sure o-ring is in correct position.

2. Install fuel pump module. Refer to Fuel Pump Module Removal/Installation.

3. Install fuel tank. Refer to Fuel Tank Removal/Installation.

Page 2286 of 5267

SENSOR-CRANKSHAFT POSITION

DESCRIPTION

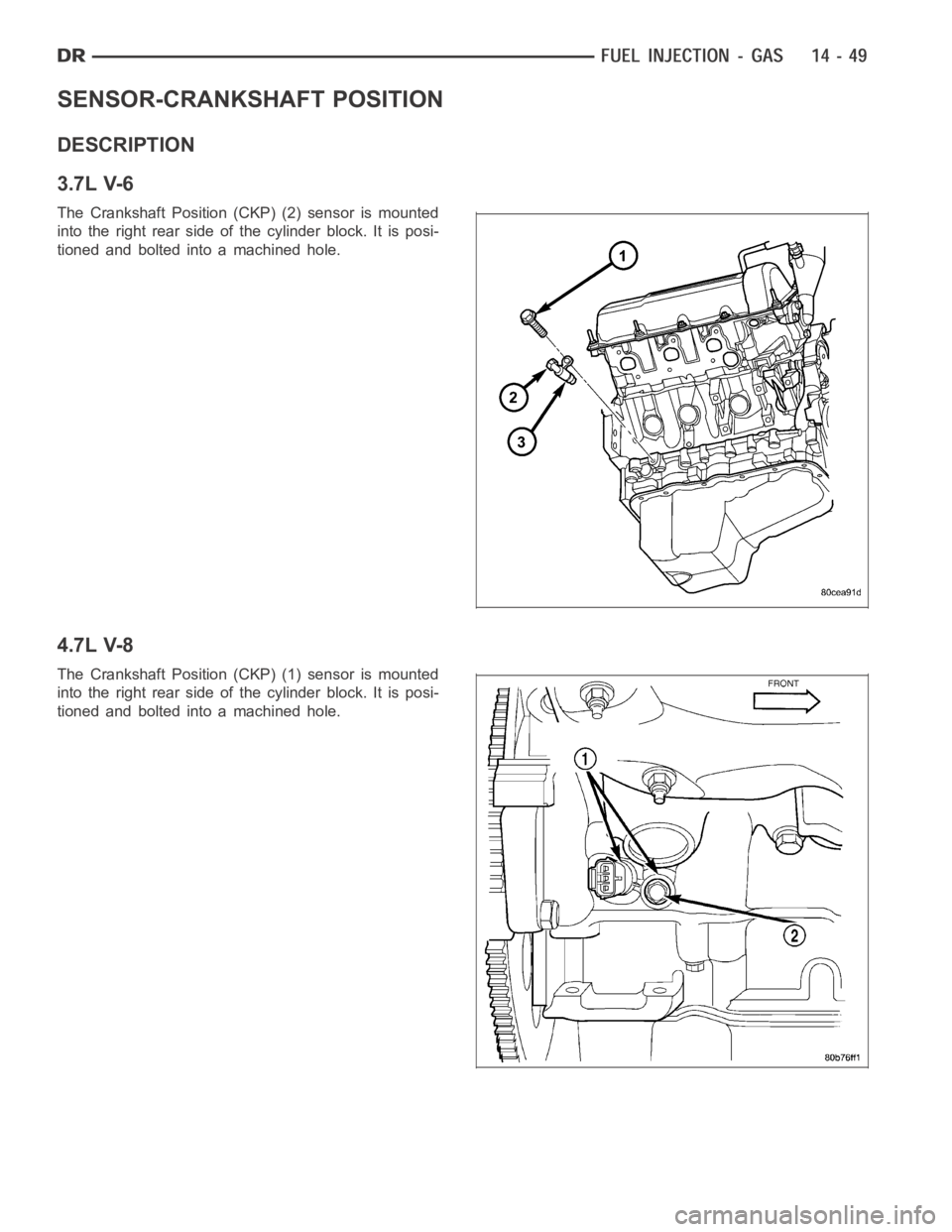

3.7L V-6

The Crankshaft Position (CKP) (2) sensor is mounted

into the right rear side of the cylinder block. It is posi-

tioned and bolted into a machined hole.

4.7L V-8

The Crankshaft Position (CKP) (1) sensor is mounted

into the right rear side of the cylinder block. It is posi-

tioned and bolted into a machined hole.

Page 2287 of 5267

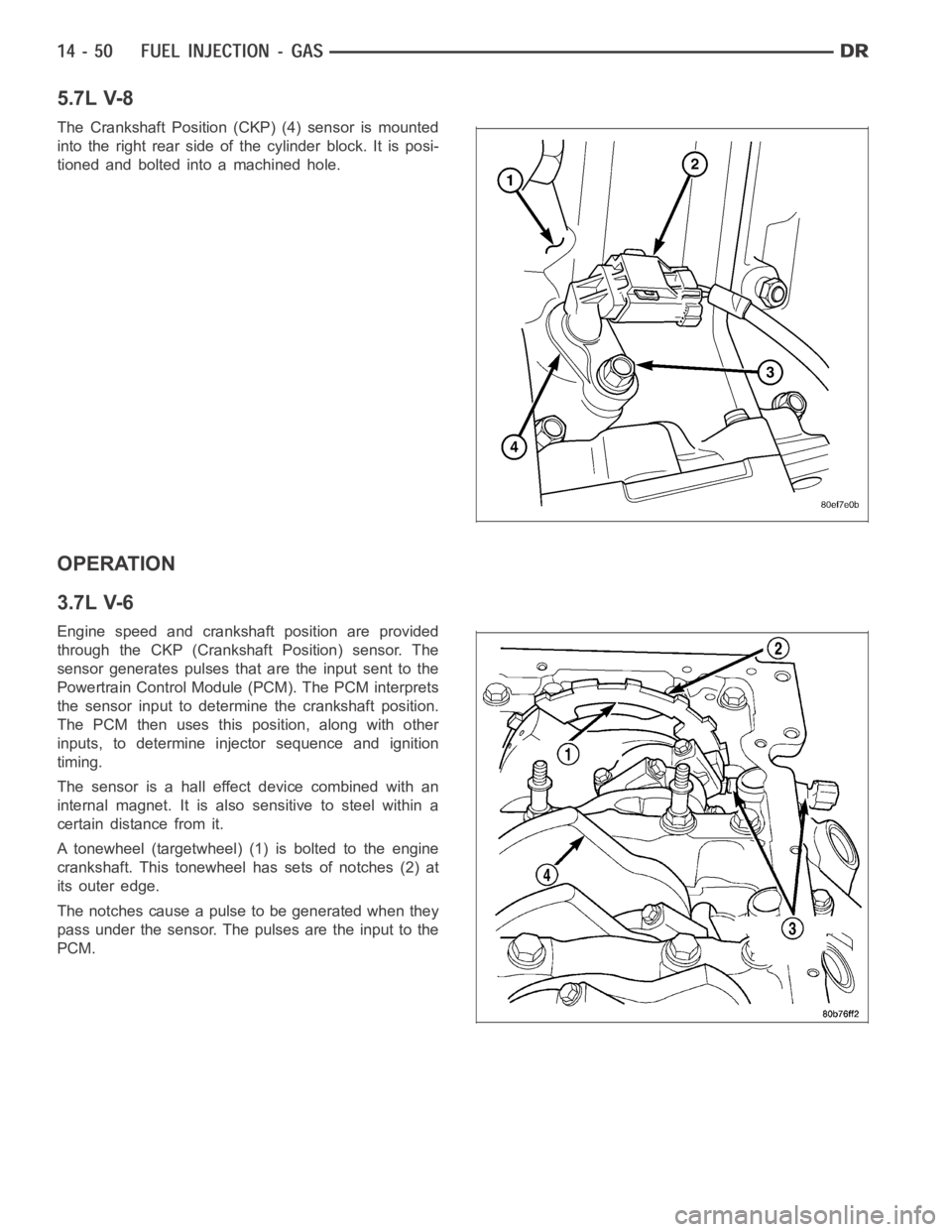

5.7L V-8

The Crankshaft Position (CKP) (4) sensor is mounted

into the right rear side of the cylinder block. It is posi-

tioned and bolted into a machined hole.

OPERATION

3.7L V-6

Engine speed and crankshaft position are provided

through the CKP (Crankshaft Position) sensor. The

sensor generates pulses that are the input sent to the

Powertrain Control Module (PCM). The PCM interprets

the sensor input to determine the crankshaft position.

The PCM then uses this position, along with other

inputs, to determine injector sequence and ignition

timing.

The sensor is a hall effect device combined with an

internal magnet. It is also sensitive to steel within a

certain distance from it.

A tonewheel (targetwheel) (1) is bolted to the engine

crankshaft. This tonewheel has sets of notches (2) at

its outer edge.

The notches cause a pulse to be generated when they

pass under the sensor. The pulses are the input to the

PCM.

Page 2289 of 5267

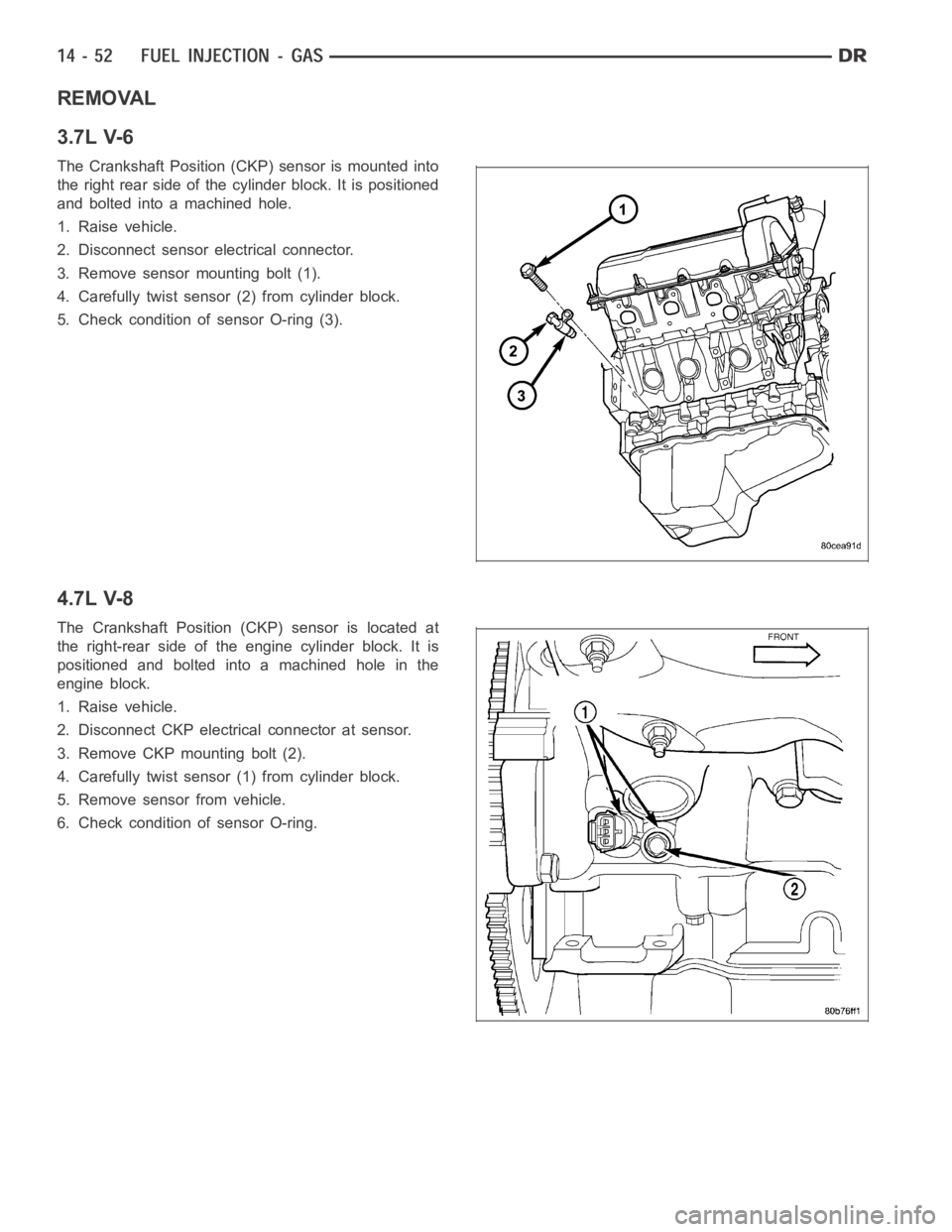

REMOVAL

3.7L V-6

The Crankshaft Position (CKP) sensor is mounted into

the right rear side of the cylinder block. It is positioned

and bolted into a machined hole.

1. Raise vehicle.

2. Disconnect sensor electrical connector.

3. Remove sensor mounting bolt (1).

4. Carefully twist sensor (2) from cylinder block.

5. Check condition of sensor O-ring (3).

4.7L V-8

The Crankshaft Position (CKP) sensor is located at

the right-rear side of the engine cylinder block. It is

positioned and bolted into a machined hole in the

engine block.

1. Raise vehicle.

2. Disconnect CKP electrical connector at sensor.

3. Remove CKP mounting bolt (2).

4. Carefully twist sensor (1) from cylinder block.

5. Remove sensor from vehicle.

6. Check condition of sensor O-ring.

Page 2290 of 5267

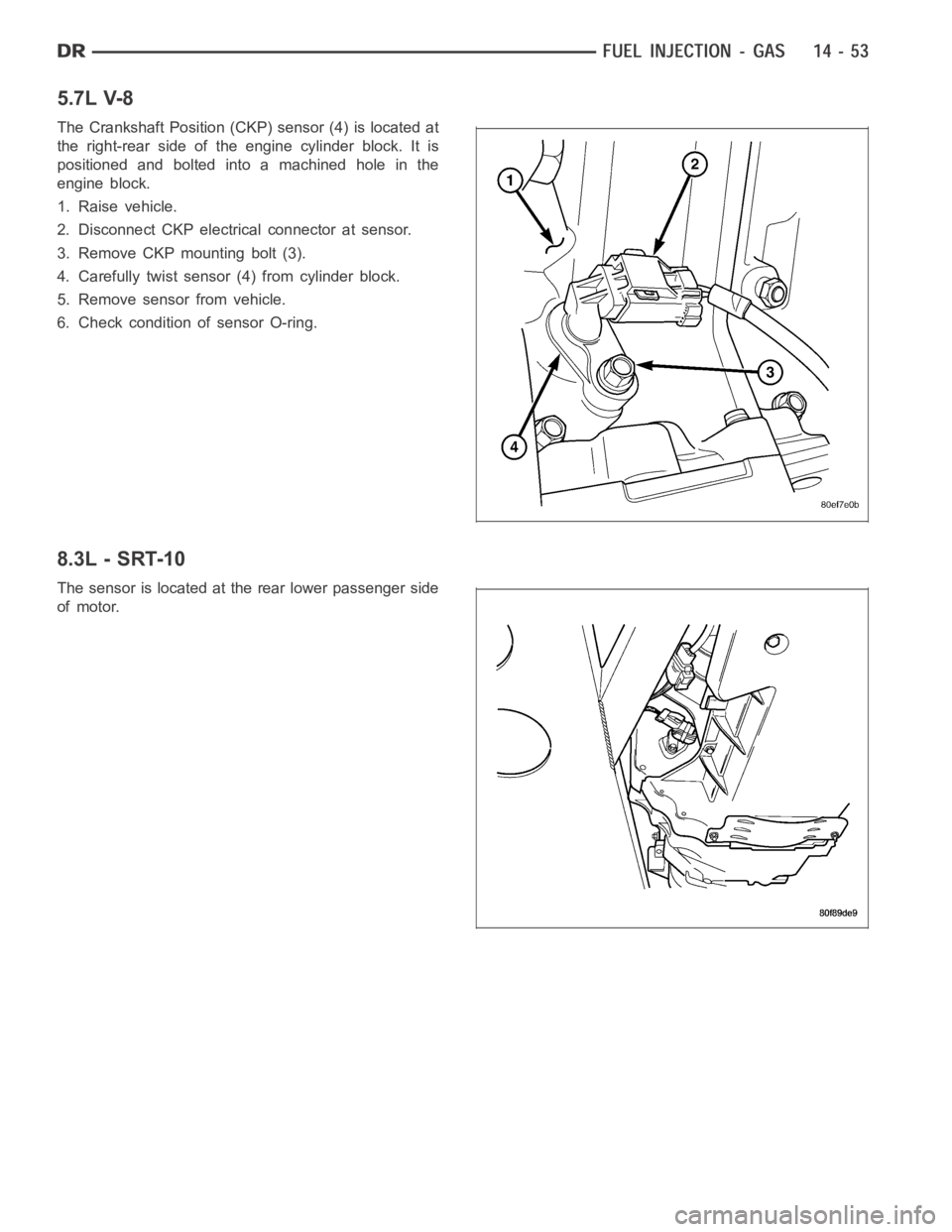

5.7L V-8

The Crankshaft Position (CKP) sensor (4) is located at

the right-rear side of the engine cylinder block. It is

positioned and bolted into a machined hole in the

engine block.

1. Raise vehicle.

2. Disconnect CKP electrical connector at sensor.

3. Remove CKP mounting bolt (3).

4. Carefully twist sensor (4) from cylinder block.

5. Remove sensor from vehicle.

6. Check condition of sensor O-ring.

8.3L - SRT-10

The sensor is located at the rear lower passenger side

of motor.

Page 2291 of 5267

1. Disconnect electrical connector from crankshaft

position sensor.

2. Remove sensor mounting bolt.

3. Pull sensor out. A light tap to top of sensor may

ease removal.

INSTALLATION

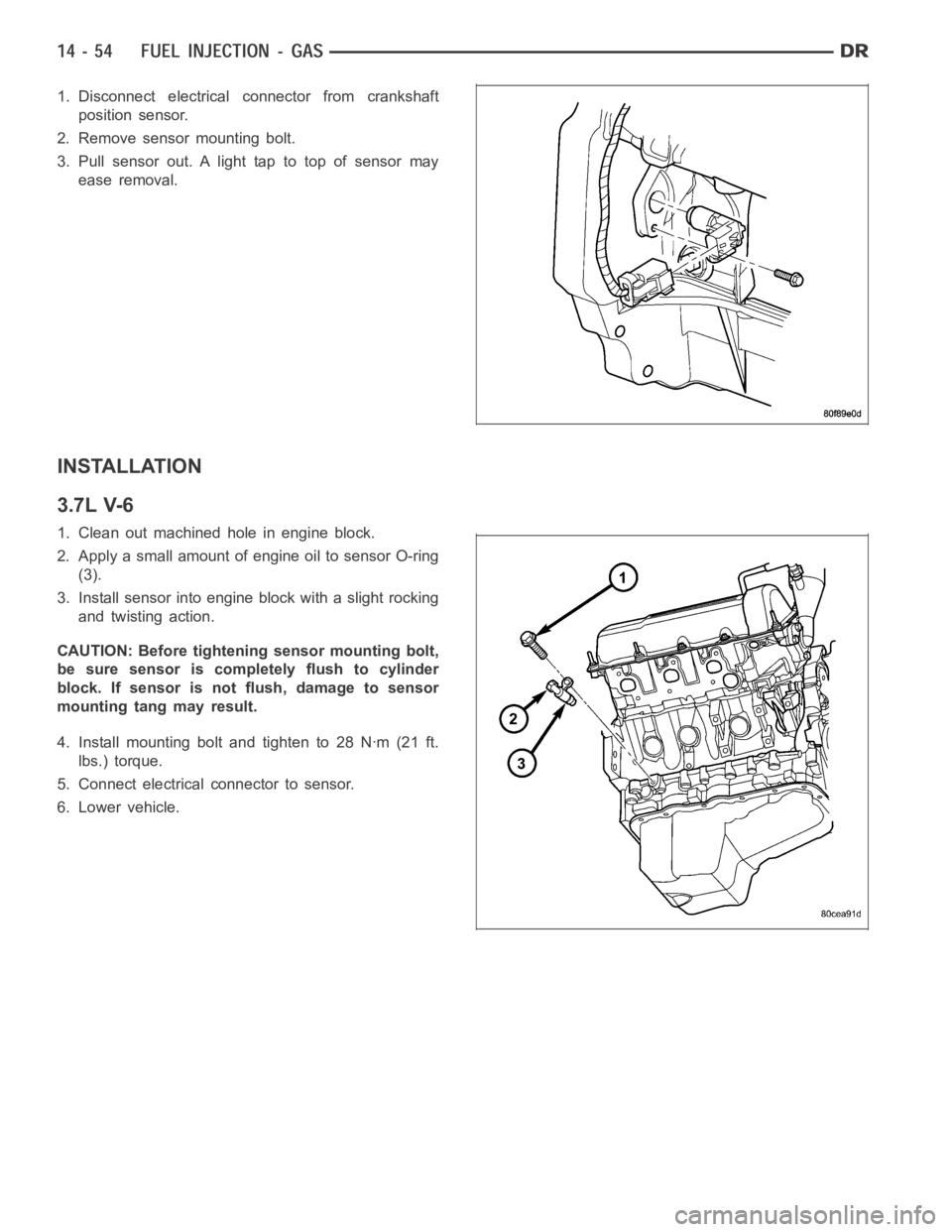

3.7L V-6

1. Clean out machined hole in engine block.

2. Apply a small amount of engine oil to sensor O-ring

(3).

3. Install sensor into engine block with a slight rocking

and twisting action.

CAUTION: Before tightening sensor mounting bolt,

be sure sensor is completely flush to cylinder

block. If sensor is not flush, damage to sensor

mounting tang may result.

4. Install mounting bolt and tighten to 28 Nꞏm (21 ft.

lbs.) torque.

5. Connect electrical connector to sensor.

6. Lower vehicle.

Page 2292 of 5267

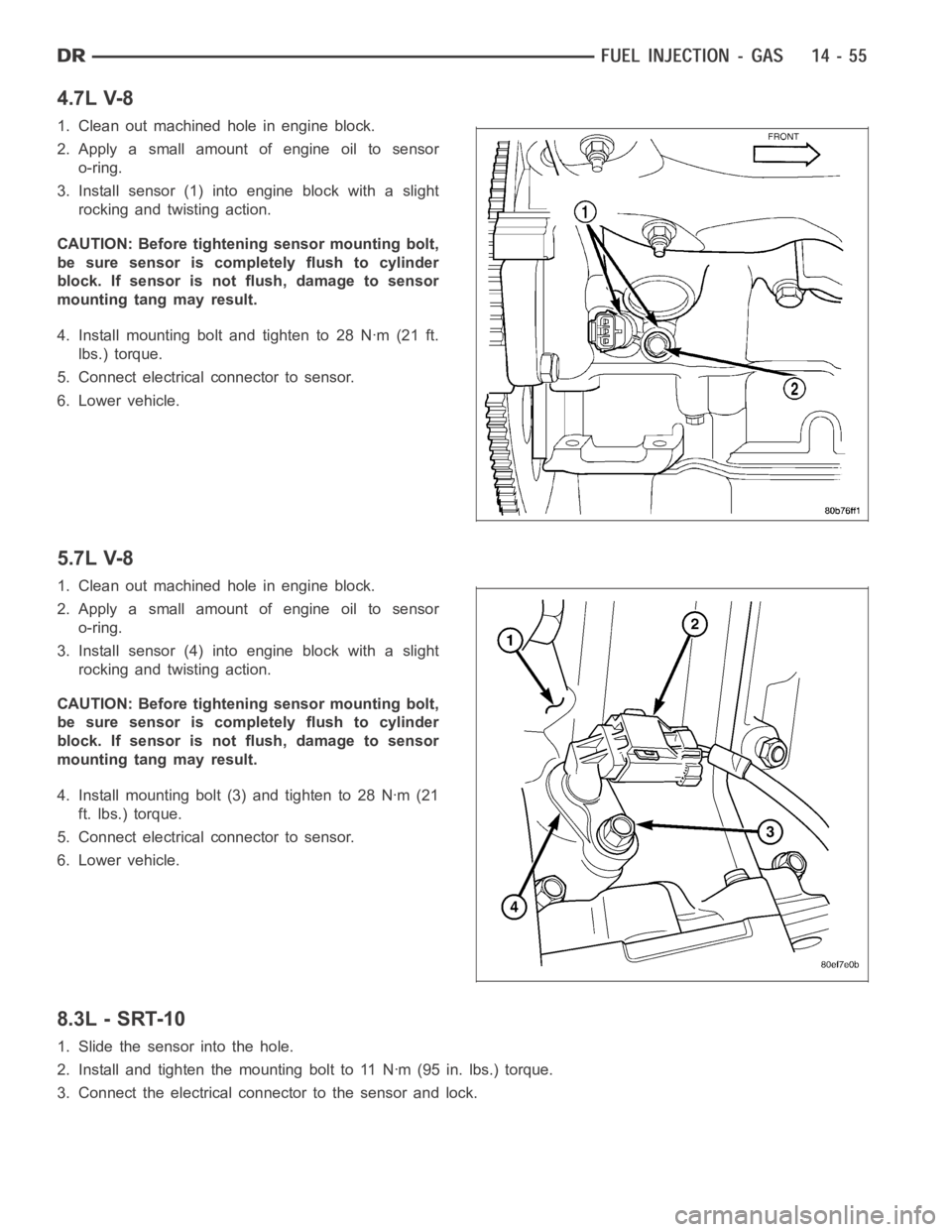

4.7L V-8

1. Clean out machined hole in engine block.

2. Apply a small amount of engine oil to sensor

o-ring.

3. Install sensor (1) into engine block with a slight

rocking and twisting action.

CAUTION: Before tightening sensor mounting bolt,

be sure sensor is completely flush to cylinder

block. If sensor is not flush, damage to sensor

mounting tang may result.

4. Install mounting bolt and tighten to 28 Nꞏm (21 ft.

lbs.) torque.

5. Connect electrical connector to sensor.

6. Lower vehicle.

5.7L V-8

1. Clean out machined hole in engine block.

2. Apply a small amount of engine oil to sensor

o-ring.

3. Install sensor (4) into engine block with a slight

rocking and twisting action.

CAUTION: Before tightening sensor mounting bolt,

be sure sensor is completely flush to cylinder

block. If sensor is not flush, damage to sensor

mounting tang may result.

4. Install mounting bolt (3) and tighten to 28 Nꞏm (21

ft. lbs.) torque.

5. Connect electrical connector to sensor.

6. Lower vehicle.

8.3L - SRT-10

1. Slide the sensor into the hole.

2. Install and tighten the mounting bolt to 11 Nꞏm (95 in. lbs.) torque.

3. Connect the electrical connector to the sensor and lock.

Page 2300 of 5267

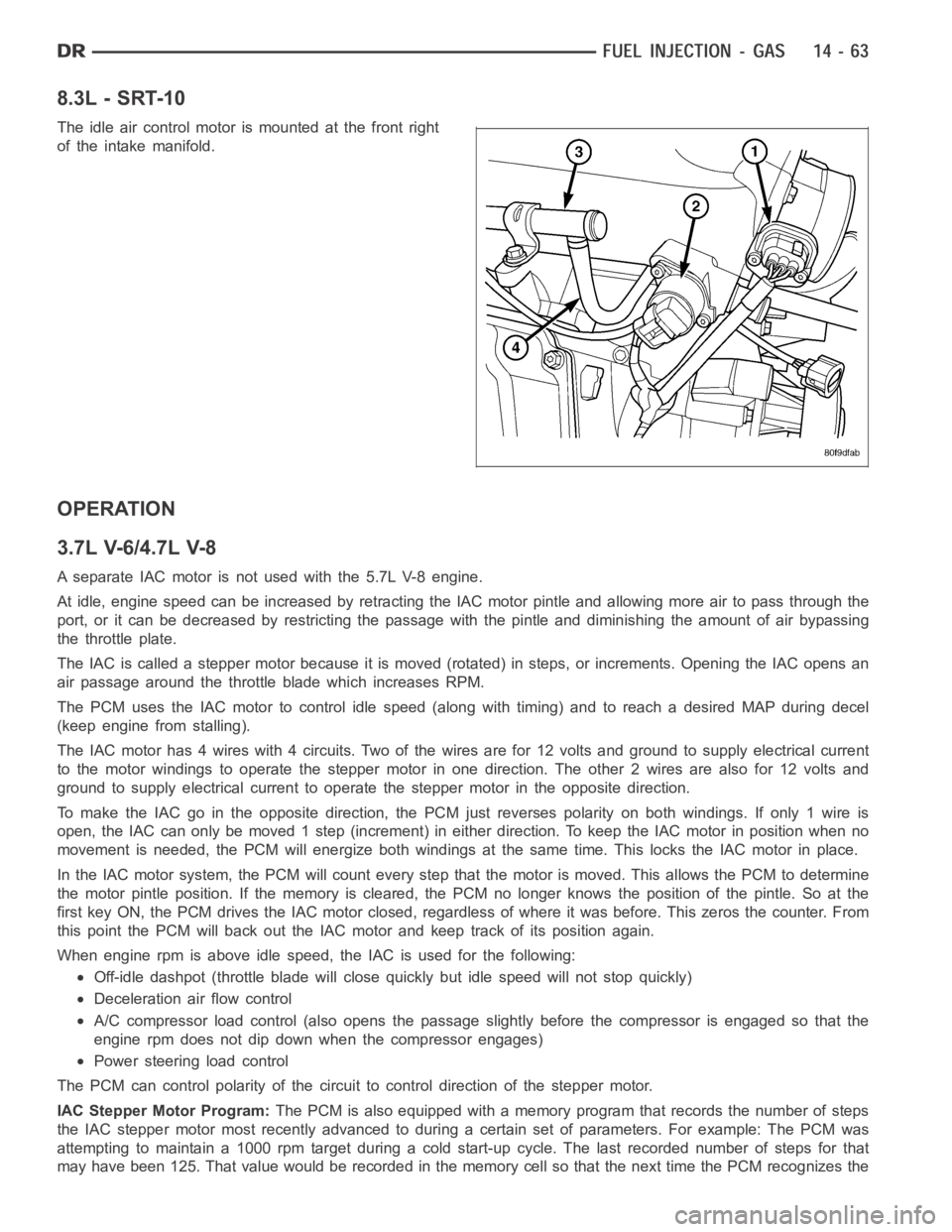

8.3L - SRT-10

The idle air control motor is mounted at the front right

of the intake manifold.

OPERATION

3.7L V-6/4.7L V-8

A separate IAC motor is not used with the 5.7L V-8 engine.

At idle, engine speed can be increased by retracting the IAC motor pintle and allowing more air to pass through the

port, or it can be decreased by restricting the passage with the pintle and diminishing the amount of air bypassing

the throttle plate.

The IAC is called a stepper motor because it is moved (rotated) in steps, or increments. Opening the IAC opens an

air passage around the throttle blade which increases RPM.

The PCM uses the IAC motor to control idle speed (along with timing) and to reach a desired MAP during decel

(keep engine from stalling).

The IAC motor has 4 wires with 4 circuits. Two of the wires are for 12 volts andground to supply electrical current

to the motor windings to operate the stepper motor in one direction. The other2wiresarealsofor12voltsand

ground to supply electrical current to operate the stepper motor in the opposite direction.

To make the IAC go in the opposite direction, the PCM just reverses polarityon both windings. If only 1 wire is

open, the IAC can only be moved 1 step (increment) in either direction. To keeptheIACmotorinpositionwhenno

movement is needed, the PCM will energize both windings at the same time. This locks the IAC motor in place.

In the IAC motor system, the PCM will count every step that the motor is moved. This allows the PCM to determine

the motor pintle position. If the memory is cleared, the PCM no longer knowsthe position of the pintle. So at the

first key ON, the PCM drives the IAC motor closed, regardless of where it wasbefore. This zeros the counter. From

this point the PCM will back out the IAC motor and keep track of its position again.

When engine rpm is above idle speed, the IAC is used for the following:

Off-idle dashpot (throttle blade will close quickly but idle speed will notstopquickly)

Deceleration air flow control

A/C compressor load control (also opens the passage slightly before the compressor is engaged so that the

engine rpm does not dip down when the compressor engages)

Power steering load control

The PCM can control polarity of the circuit to control direction of the stepper motor.

IAC Stepper Motor Program:The PCM is also equipped with a memory program that records the number of steps

the IAC stepper motor most recently advanced to during a certain set of parameters. For example: The PCM was

attempting to maintain a 1000 rpm target during a cold start-up cycle. The last recorded number of steps for that

may have been 125. That value would be recorded in the memory cell so that thenext time the PCM recognizes the

Page 2308 of 5267

REMOVAL

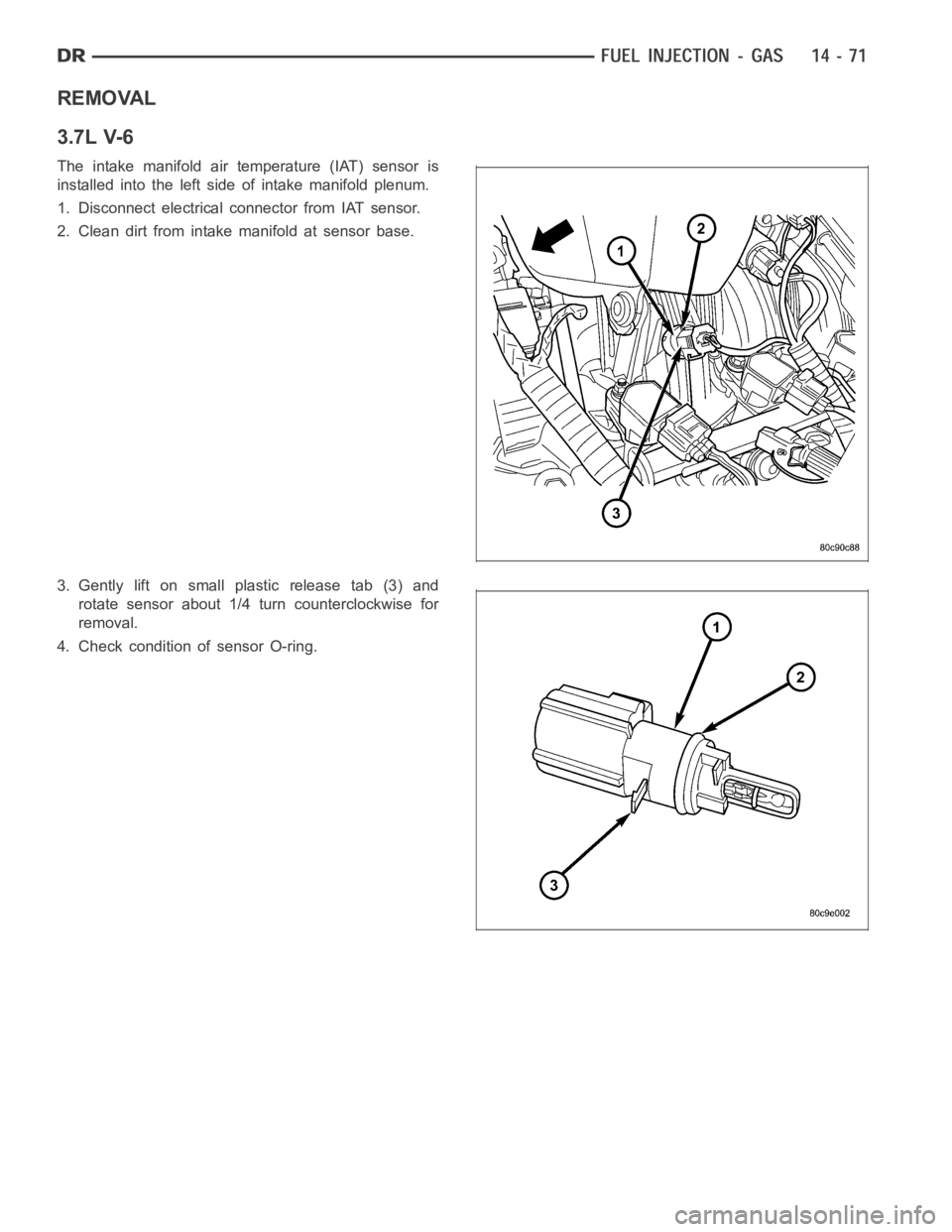

3.7L V-6

The intake manifold air temperature (IAT) sensor is

installed into the left side of intake manifold plenum.

1. Disconnect electrical connector from IAT sensor.

2. Clean dirt from intake manifold at sensor base.

3. Gently lift on small plastic release tab (3) and

rotate sensor about 1/4 turn counterclockwise for

removal.

4. Check condition of sensor O-ring.

Page 2309 of 5267

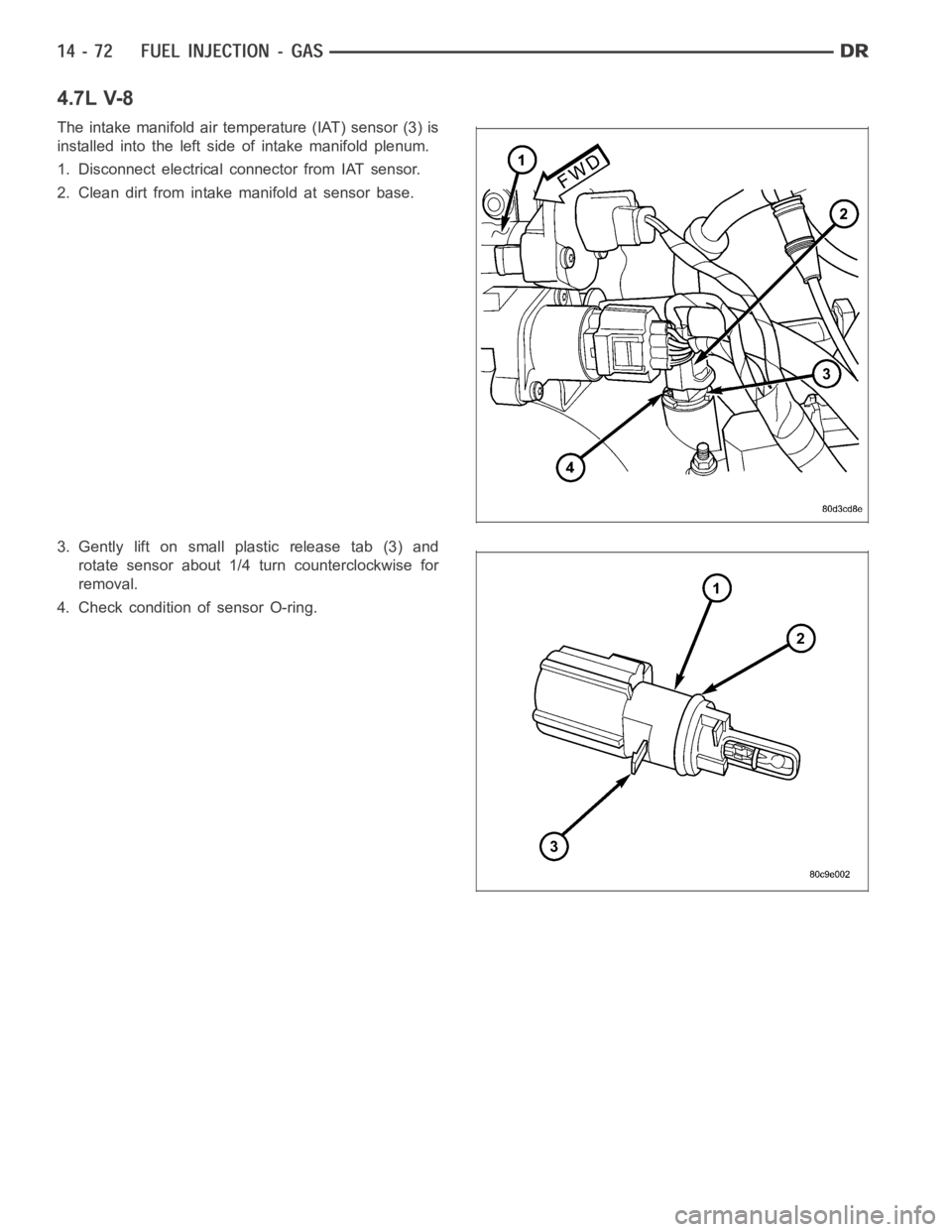

4.7L V-8

The intake manifold air temperature (IAT) sensor (3) is

installed into the left side of intake manifold plenum.

1. Disconnect electrical connector from IAT sensor.

2. Clean dirt from intake manifold at sensor base.

3. Gently lift on small plastic release tab (3) and

rotate sensor about 1/4 turn counterclockwise for

removal.

4. Check condition of sensor O-ring.