lock DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2107 of 5267

INSTALLATION

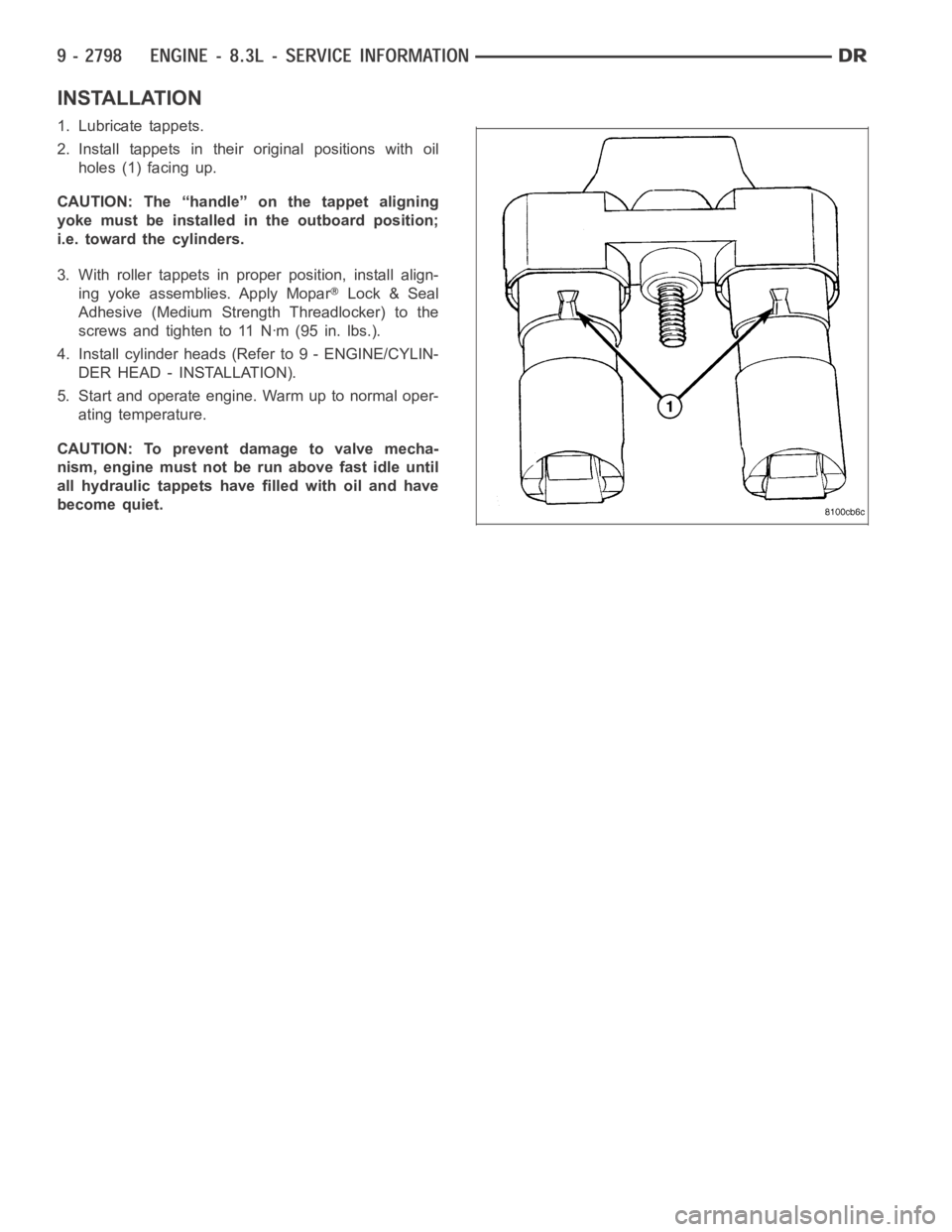

1. Lubricate tappets.

2. Install tappets in their original positions with oil

holes (1) facing up.

CAUTION: The “handle” on the tappet aligning

yoke must be installed in the outboard position;

i.e. toward the cylinders.

3. With roller tappets in proper position, install align-

ing yoke assemblies. Apply Mopar

Lock & Seal

Adhesive (Medium Strength Threadlocker) to the

screwsandtightento11Nꞏm(95in.lbs.).

4. Install cylinder heads (Refer to 9 - ENGINE/CYLIN-

DER HEAD - INSTALLATION).

5. Start and operate engine. Warm up to normal oper-

ating temperature.

CAUTION: To prevent damage to valve mecha-

nism, engine must not be run above fast idle until

all hydraulic tappets have filled with oil and have

become quiet.

Page 2108 of 5267

CAMSHAFT

REMOVAL

1. Perform the fuel pressure relief procedure (Refer to

14 - FUEL SYSTEM/FUEL DELIVERY - STAN-

DARD PROCEDURE).

2. Disconnect the negative battery cable.

3. Raise and support the vehicle.

4. Remove the front engine shield.

5. Drain the cooling system

6. Drain the power steering fluid.

7. Remove the oil pan (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - REMOVAL).

8. Lower the vehicle.

9. Remove the radiator and radiator fan assembly

(Refer to 7 - COOLING/ENGINE/RADIATOR -

REMOVAL).

10. Remove intake manifold (Refer to 9 - ENGINE/

MANIFOLDS/INTAKE MANIFOLD - REMOVAL).

11. Remove cylinder head covers (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

12. Remove timing chain cover (Refer to 9 - ENGINE/

VALVE TIMING/TIMING CHAIN COVER - REMOVAL).

13. Remove rocker arm assemblies.

NOTE: Identify each push rod to be replaced in its original location.

14. Remove push rods.

15. Remove cylinder heads (Refer to 9 - ENGINE/CYLINDER HEAD - REMOVAL).

16. Remove hydraulic tappets (Refer to 9 - ENGINE/ENGINE BLOCK/HYDRAULICTAPPETS - REMOVAL).

17. Remove timing chain and camshaft sprocket (Refer to 9 - ENGINE/VALVE TIMING/TIMING CHAIN AND

SPROCKETS - REMOVAL).

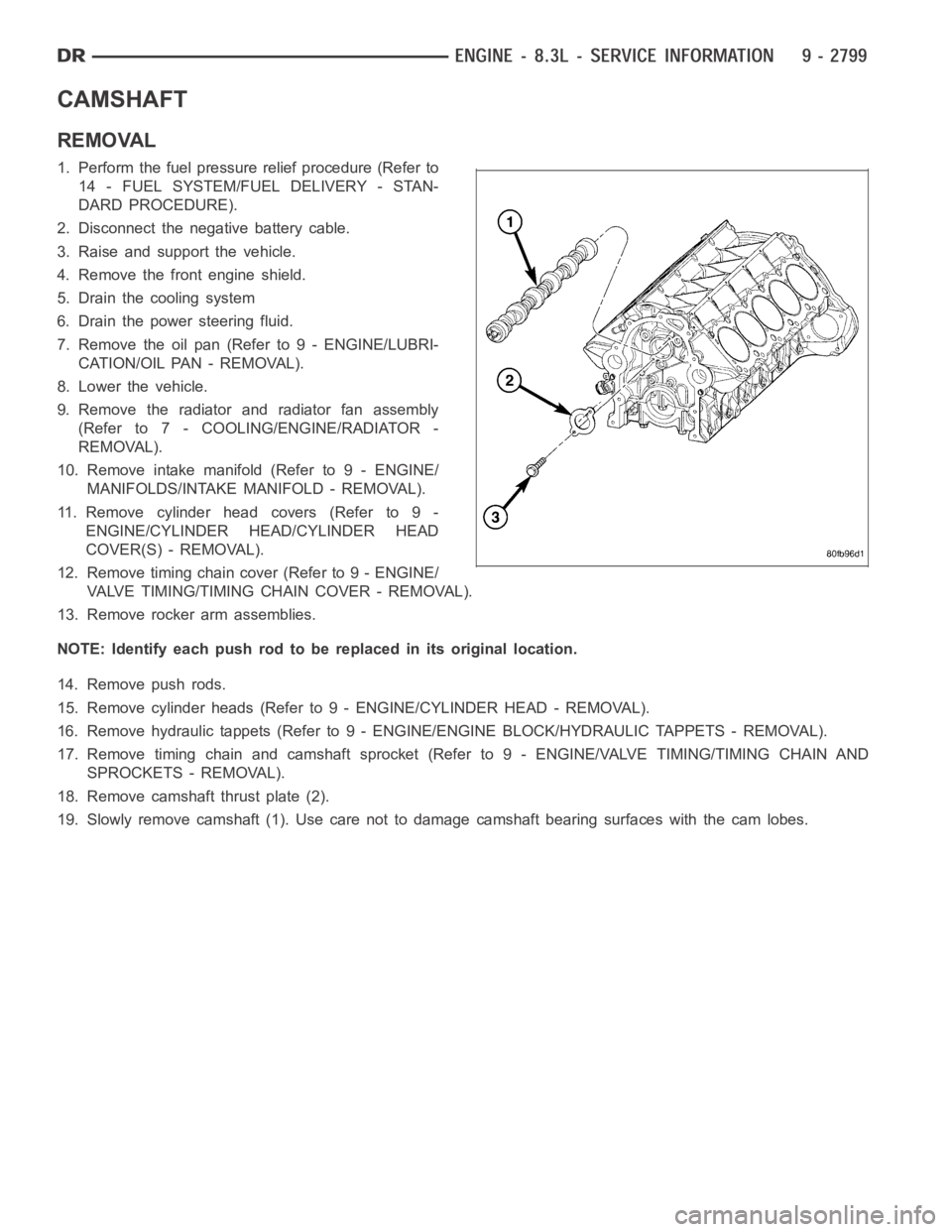

18. Remove camshaft thrust plate (2).

19. Slowly remove camshaft (1). Use care not to damage camshaft bearing surfaces with the cam lobes.

Page 2109 of 5267

INSTALLATION

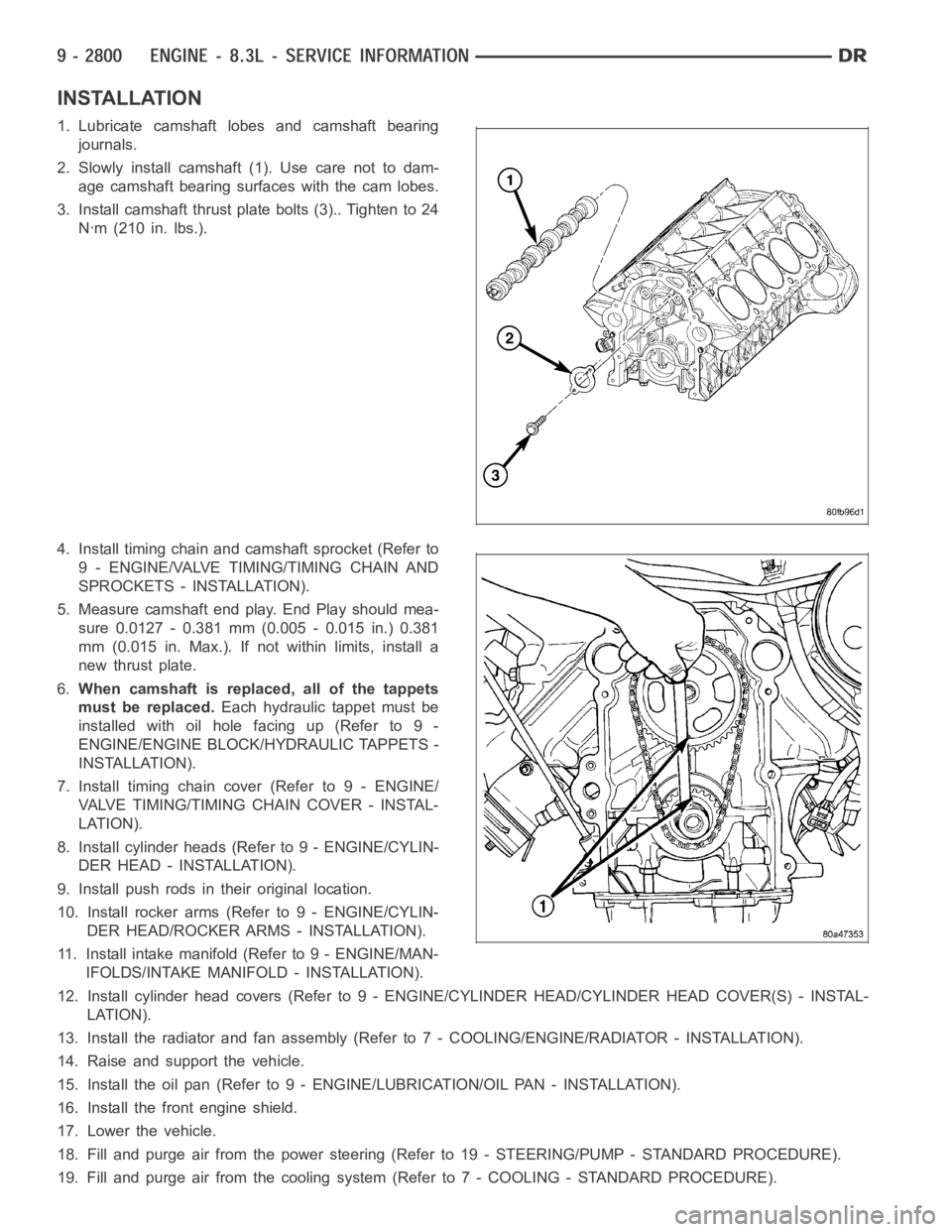

1. Lubricate camshaft lobes and camshaft bearing

journals.

2. Slowly install camshaft (1). Use care not to dam-

age camshaft bearing surfaces with the cam lobes.

3. Install camshaft thrust plate bolts (3).. Tighten to 24

Nꞏm (210 in. lbs.).

4. Install timing chain and camshaft sprocket (Refer to

9 - ENGINE/VALVE TIMING/TIMING CHAIN AND

SPROCKETS - INSTALLATION).

5. Measure camshaft end play. End Play should mea-

sure 0.0127 - 0.381 mm (0.005 - 0.015 in.) 0.381

mm (0.015 in. Max.). If not within limits, install a

new thrust plate.

6.When camshaft is replaced, all of the tappets

must be replaced.Each hydraulic tappet must be

installed with oil hole facing up (Refer to 9 -

ENGINE/ENGINE BLOCK/HYDRAULIC TAPPETS -

INSTALLATION).

7. Install timing chain cover (Refer to 9 - ENGINE/

VALVE TIMING/TIMINGCHAIN COVER - INSTAL-

LATION).

8. Install cylinder heads (Refer to 9 - ENGINE/CYLIN-

DER HEAD - INSTALLATION).

9. Install push rods in their original location.

10. Install rocker arms (Refer to 9 - ENGINE/CYLIN-

DER HEAD/ROCKER ARMS - INSTALLATION).

11. Install intake manifold (Refer to 9 - ENGINE/MAN-

IFOLDS/INTAKE MANIFOLD - INSTALLATION).

12. Install cylinder head covers (Refer to 9 - ENGINE/CYLINDER HEAD/CYLINDER HEAD COVER(S) - INSTAL-

LATION).

13. Install the radiator and fan assembly (Refer to 7 - COOLING/ENGINE/RADIATOR - INSTALLATION).

14. Raise and support the vehicle.

15. Install the oil pan (Refer to 9 - ENGINE/LUBRICATION/OIL PAN - INSTALLATION).

16. Install the front engine shield.

17. Lower the vehicle.

18. Fill and purge air from the power steering (Refer to 19 - STEERING/PUMP -STANDARD PROCEDURE).

19. Fill and purge air from the coolingsystem (Refer to 7 - COOLING - STANDARD PROCEDURE).

Page 2112 of 5267

MEASURING CONNECTING ROD SIDE CLEARANCE

1. Using a feeler gauge, check connecting rod side

clearance. (Refer to 9 - ENGINE - SPECIFICA-

TIONS) for connecting rod side clearance

specifications.

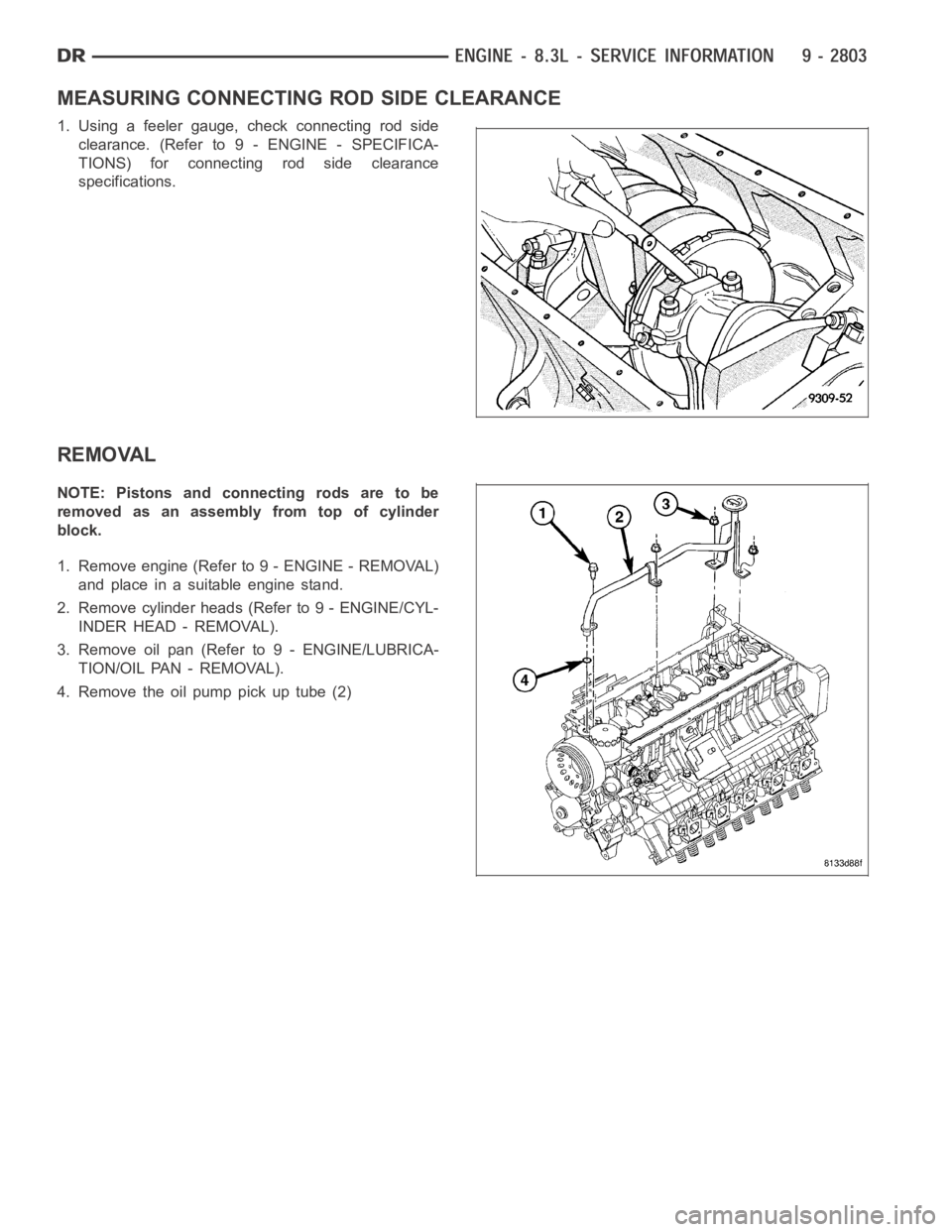

REMOVAL

NOTE: Pistons and connecting rods are to be

removed as an assembly from top of cylinder

block.

1. Remove engine (Refer to 9 - ENGINE - REMOVAL)

and place in a suitable engine stand.

2. Remove cylinder heads (Refer to 9 - ENGINE/CYL-

INDER HEAD - REMOVAL).

3. Remove oil pan (Refer to 9 - ENGINE/LUBRICA-

TION/OIL PAN - REMOVAL).

4. Remove the oil pump pick up tube (2)

Page 2113 of 5267

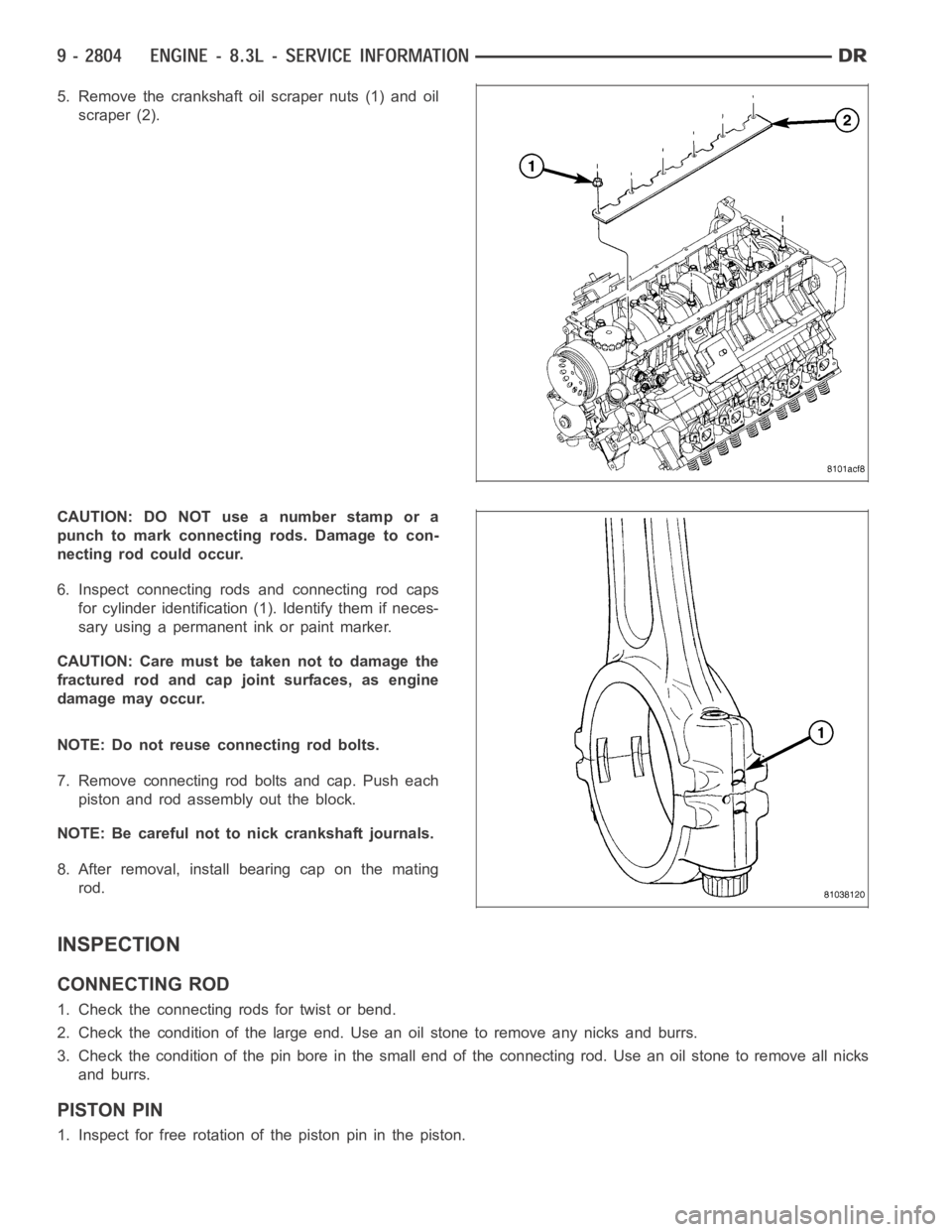

5. Remove the crankshaft oil scraper nuts (1) and oil

scraper (2).

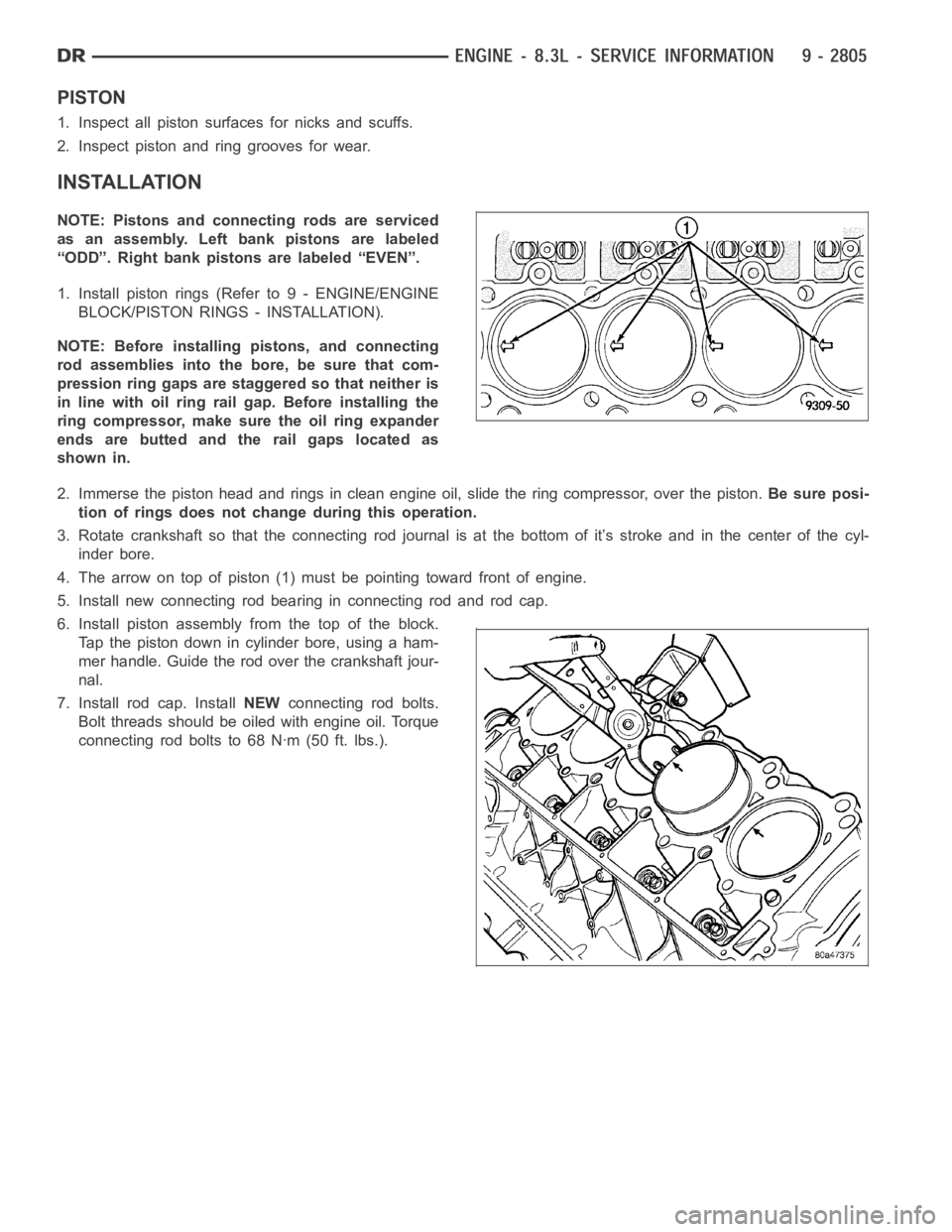

CAUTION: DO NOT use a number stamp or a

punch to mark connecting rods. Damage to con-

necting rod could occur.

6. Inspect connecting rods and connecting rod caps

for cylinder identification (1). Identify them if neces-

sary using a permanent ink or paint marker.

CAUTION: Care must be taken not to damage the

fractured rod and cap joint surfaces, as engine

damage may occur.

NOTE: Do not reuse connecting rod bolts.

7. Remove connecting rod bolts and cap. Push each

piston and rod assembly out the block.

NOTE: Be careful not to nick crankshaft journals.

8. After removal, install bearing cap on the mating

rod.

INSPECTION

CONNECTING ROD

1. Check the connecting rods for twist or bend.

2. Check the condition of the large end. Use an oil stone to remove any nicks and burrs.

3. Check the condition of the pin bore in the small end of the connecting rod.Useanoilstonetoremoveallnicks

and burrs.

PISTON PIN

1. Inspect for free rotation of the piston pin in the piston.

Page 2114 of 5267

PISTON

1. Inspect all piston surfaces for nicks and scuffs.

2. Inspect piston and ring grooves for wear.

INSTALLATION

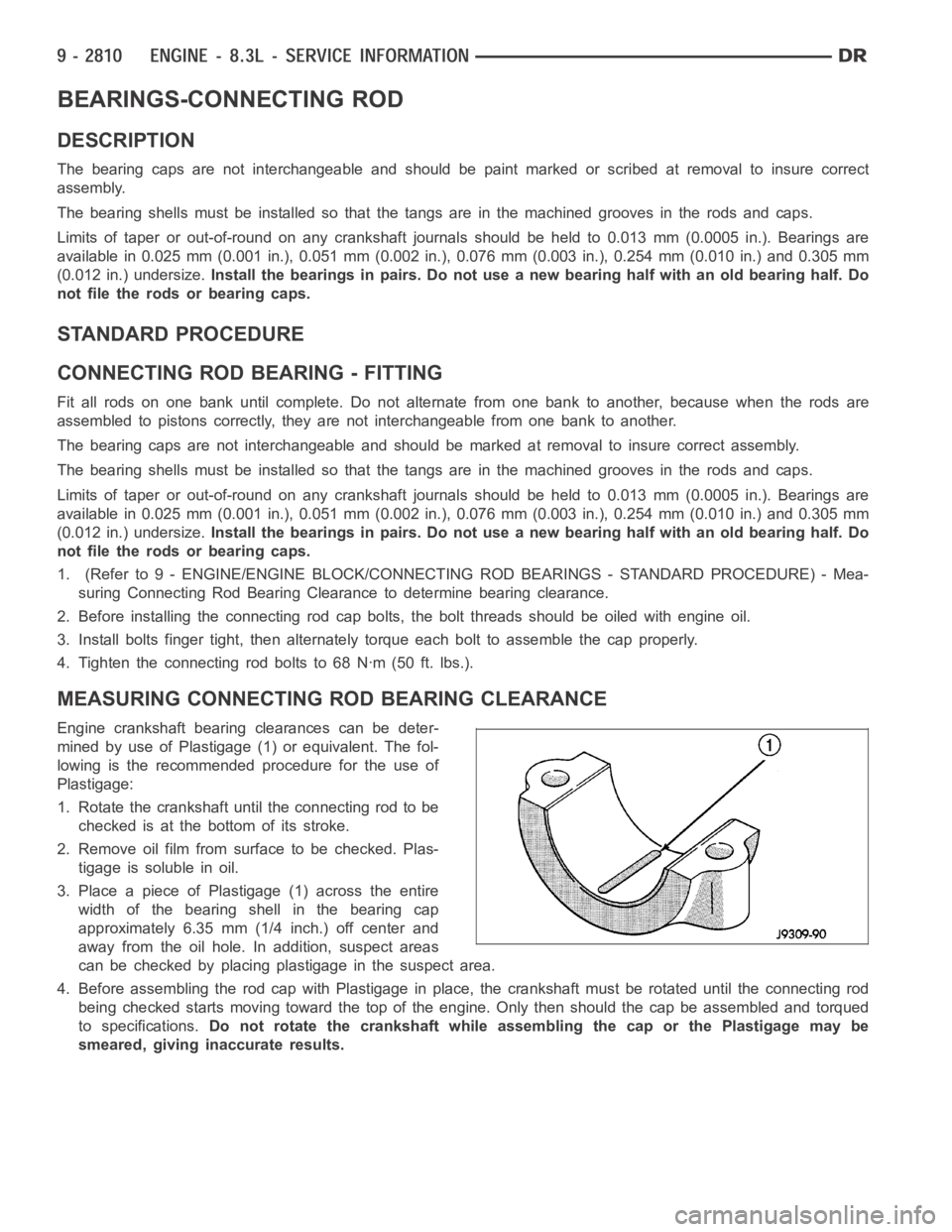

NOTE: Pistons and connecting rods are serviced

as an assembly. Left bank pistons are labeled

“ODD”. Right bank pistons are labeled “EVEN”.

1. Install piston rings (Refer to 9 - ENGINE/ENGINE

BLOCK/PISTON RINGS - INSTALLATION).

NOTE: Before installing pistons, and connecting

rod assemblies into the bore, be sure that com-

pression ring gaps are staggered so that neither is

in line with oil ring rail gap. Before installing the

ring compressor, make sure the oil ring expander

ends are butted and the rail gaps located as

shown in.

2. Immerse the piston head and rings in clean engine oil, slide the ring compressor, over the piston.Be sure posi-

tion of rings does not change during this operation.

3. Rotate crankshaft so that the connecting rod journal is at the bottom of it’s stroke and in the center of the cyl-

inder bore.

4. The arrow on top of piston (1) must be pointing toward front of engine.

5. Install new connecting rod bearing in connecting rod and rod cap.

6. Install piston assembly from the top of the block.

Tap the piston down in cylinder bore, using a ham-

mer handle. Guide the rod over the crankshaft jour-

nal.

7. Install rod cap. InstallNEWconnecting rod bolts.

Bolt threads should be oiled with engine oil. Torque

connecting rod bolts to 68 Nꞏm (50 ft. lbs.).

Page 2119 of 5267

BEARINGS-CONNECTING ROD

DESCRIPTION

The bearing caps are not interchangeable and should be paint marked or scribed at removal to insure correct

assembly.

The bearing shells must be installed so that the tangs are in the machined grooves in the rods and caps.

Limits of taper or out-of-round on any crankshaft journals should be held to 0.013 mm (0.0005 in.). Bearings are

available in 0.025 mm (0.001 in.), 0.051 mm (0.002 in.), 0.076 mm (0.003 in.), 0.254 mm (0.010 in.) and 0.305 mm

(0.012 in.) undersize.Install the bearings in pairs. Do not use a new bearing half with an old bearing half. Do

not file the rods or bearing caps.

STANDARD PROCEDURE

CONNECTING ROD BEARING - FITTING

Fit all rods on one bank until complete. Do not alternate from one bank to another, because when the rods are

assembled to pistons correctly, they are not interchangeable from one bank to another.

The bearing caps are not interchangeable and should be marked at removal toinsure correct assembly.

The bearing shells must be installed so that the tangs are in the machined grooves in the rods and caps.

Limits of taper or out-of-round on any crankshaft journals should be held to 0.013 mm (0.0005 in.). Bearings are

available in 0.025 mm (0.001 in.), 0.051 mm (0.002 in.), 0.076 mm (0.003 in.), 0.254 mm (0.010 in.) and 0.305 mm

(0.012 in.) undersize.Install the bearings in pairs. Do not use a new bearing half with an old bearing half. Do

not file the rods or bearing caps.

1. (Refer to 9 - ENGINE/ENGINE BLOCK/CONNECTING ROD BEARINGS - STANDARD PROCEDURE) - Mea-

suring Connecting Rod Bearing Clearance to determine bearing clearance.

2. Before installing the connecting rod cap bolts, the bolt threads shouldbe oiled with engine oil.

3. Install bolts finger tight, then alternately torque each bolt to assemble the cap properly.

4. Tighten the connecting rod bolts to 68 Nꞏm (50 ft. lbs.).

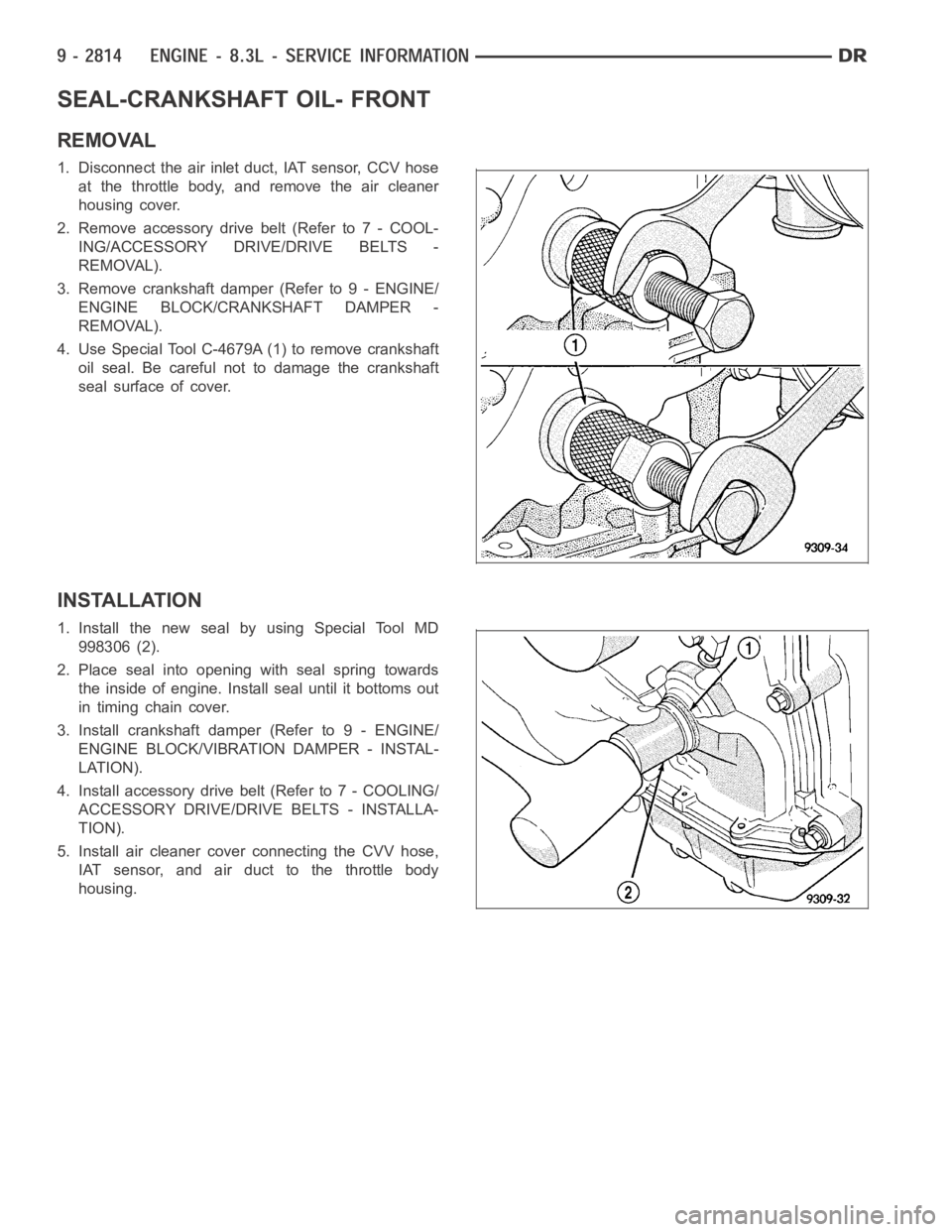

MEASURING CONNECTING ROD BEARING CLEARANCE

Engine crankshaft bearing clearances can be deter-

mined by use of Plastigage (1) or equivalent. The fol-

lowing is the recommended procedure for the use of

Plastigage:

1. Rotate the crankshaft until the connecting rod to be

checked is at the bottom of its stroke.

2. Remove oil film from surface to be checked. Plas-

tigage is soluble in oil.

3. Place a piece of Plastigage (1) across the entire

width of the bearing shell in the bearing cap

approximately 6.35 mm (1/4 inch.) off center and

away from the oil hole. In addition, suspect areas

can be checked by placing plastigage in the suspect area.

4. Before assembling the rod cap with Plastigage in place, the crankshaft must be rotated until the connecting rod

being checked starts moving toward the top of the engine. Only then should the cap be assembled and torqued

to specifications.Do not rotate the crankshaft while assembling the cap or the Plastigage maybe

smeared, giving inaccurate results.

Page 2123 of 5267

SEAL-CRANKSHAFT OIL- FRONT

REMOVAL

1. Disconnect the air inlet duct, IAT sensor, CCV hose

at the throttle body, and remove the air cleaner

housing cover.

2. Remove accessory drive belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

3. Remove crankshaft damper (Refer to 9 - ENGINE/

ENGINE BLOCK/CRANKSHAFT DAMPER -

REMOVAL).

4. Use Special Tool C-4679A (1) to remove crankshaft

oil seal. Be careful not to damage the crankshaft

seal surface of cover.

INSTALLATION

1. Install the new seal by using Special Tool MD

998306 (2).

2. Place seal into opening with seal spring towards

the inside of engine. Install seal until it bottoms out

in timing chain cover.

3. Install crankshaft damper (Refer to 9 - ENGINE/

ENGINE BLOCK/VIBRATION DAMPER - INSTAL-

LATION).

4. Install accessory drive belt (Refer to 7 - COOLING/

ACCESSORY DRIVE/DRIVE BELTS - INSTALLA-

TION).

5. Install air cleaner cover connecting the CVV hose,

IAT sensor, and air duct to the throttle body

housing.

Page 2124 of 5267

SEAL-OIL-REAR-CRANK AND RETAINER

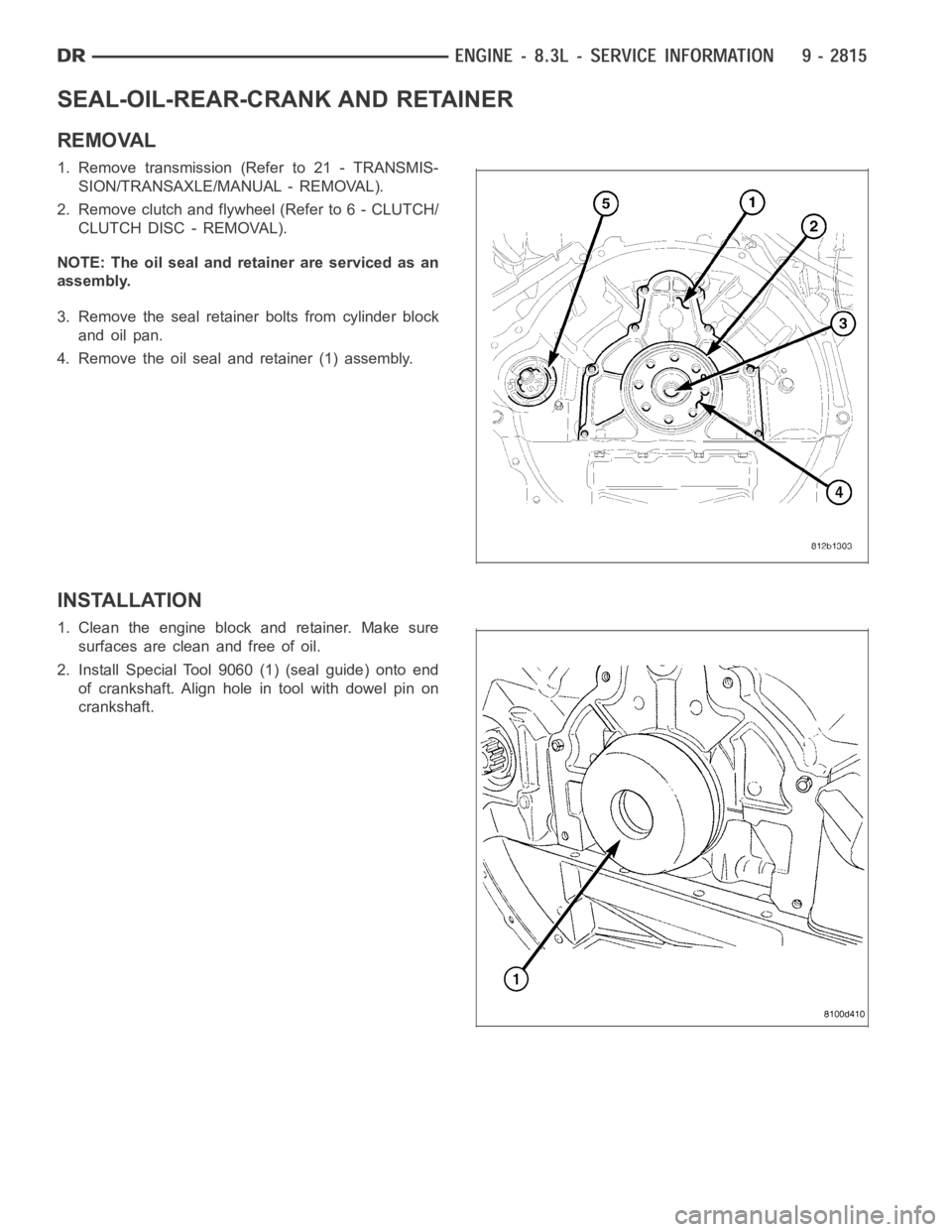

REMOVAL

1. Remove transmission (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/MANUAL - REMOVAL).

2. Remove clutch and flywheel (Refer to 6 - CLUTCH/

CLUTCH DISC - REMOVAL).

NOTE: The oil seal and retainer are serviced as an

assembly.

3. Remove the seal retainer bolts from cylinder block

and oil pan.

4. Remove the oil seal and retainer (1) assembly.

INSTALLATION

1. Clean the engine block and retainer. Make sure

surfaces are clean and free of oil.

2. Install Special Tool 9060 (1) (seal guide) onto end

of crankshaft. Align hole in tool with dowel pin on

crankshaft.

Page 2125 of 5267

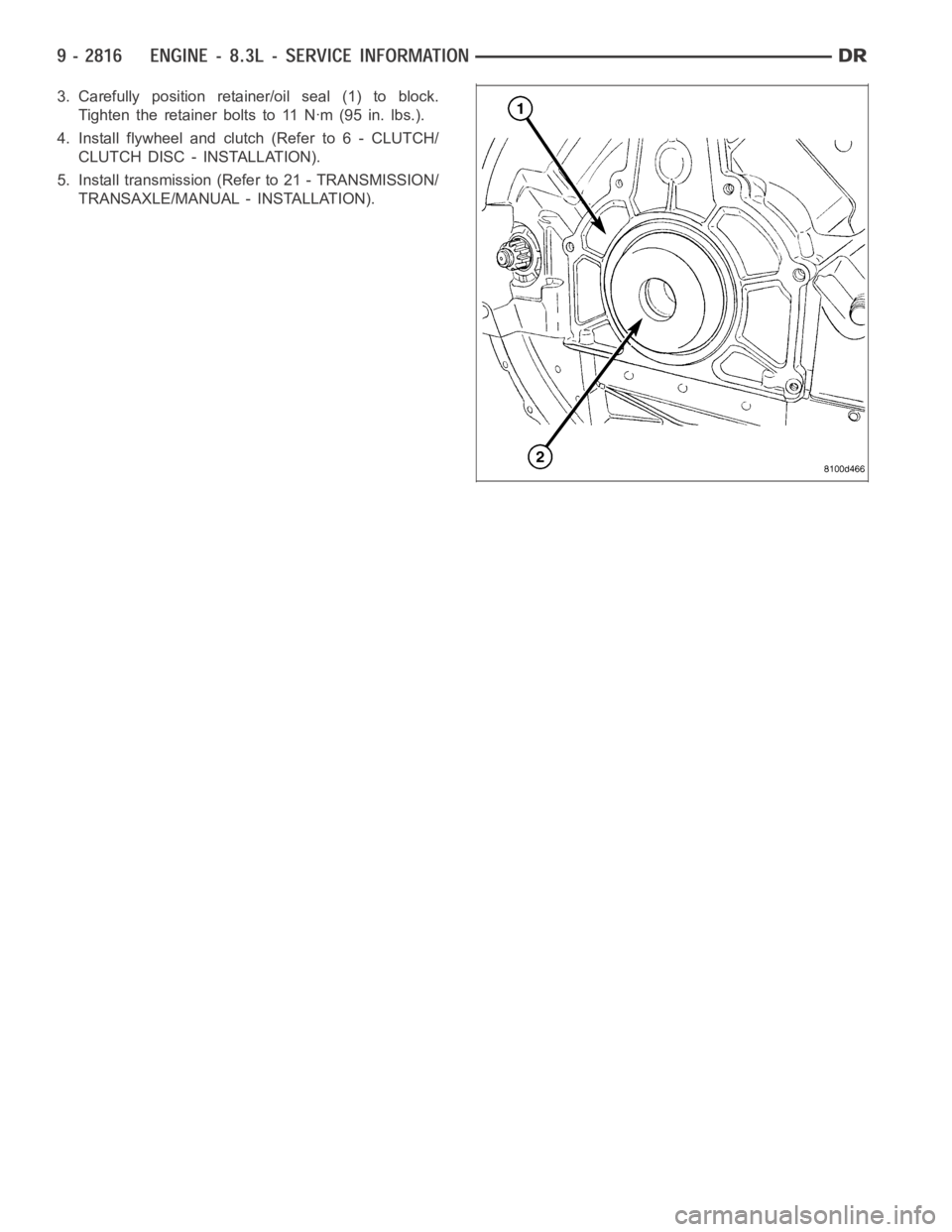

3. Carefully position retainer/oil seal (1) to block.

Tighten the retainer bolts to 11 Nꞏm (95 in. lbs.).

4. Install flywheel and clutch (Refer to 6 - CLUTCH/

CLUTCH DISC - INSTALLATION).

5. Install transmission (Refer to 21 - TRANSMISSION/

TRANSAXLE/MANUAL - INSTALLATION).