lock DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2311 of 5267

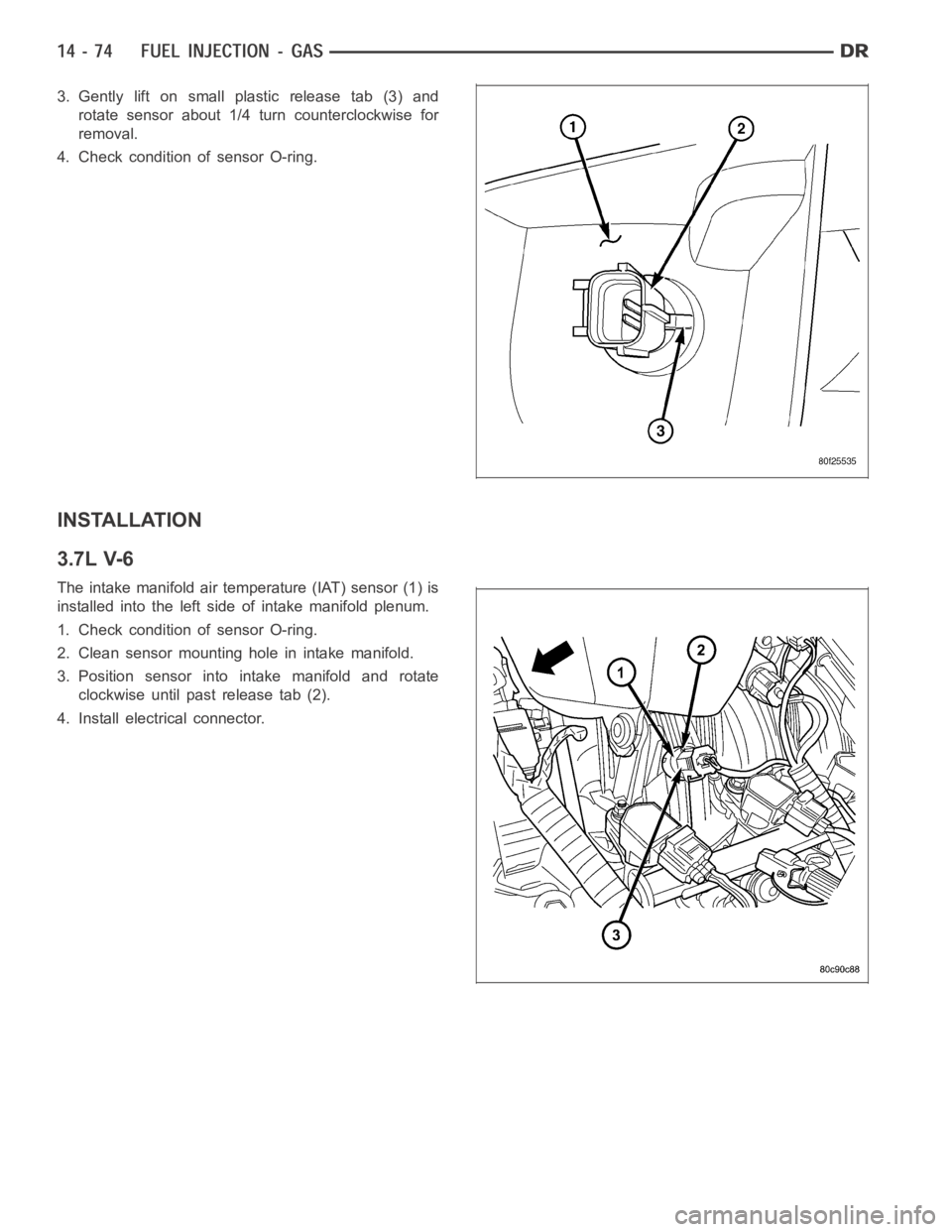

3. Gently lift on small plastic release tab (3) and

rotate sensor about 1/4 turn counterclockwise for

removal.

4. Check condition of sensor O-ring.

INSTALLATION

3.7L V-6

The intake manifold air temperature (IAT) sensor (1) is

installed into the left side of intake manifold plenum.

1. Check condition of sensor O-ring.

2. Clean sensor mounting hole in intake manifold.

3. Position sensor into intake manifold and rotate

clockwise until past release tab (2).

4. Install electrical connector.

Page 2312 of 5267

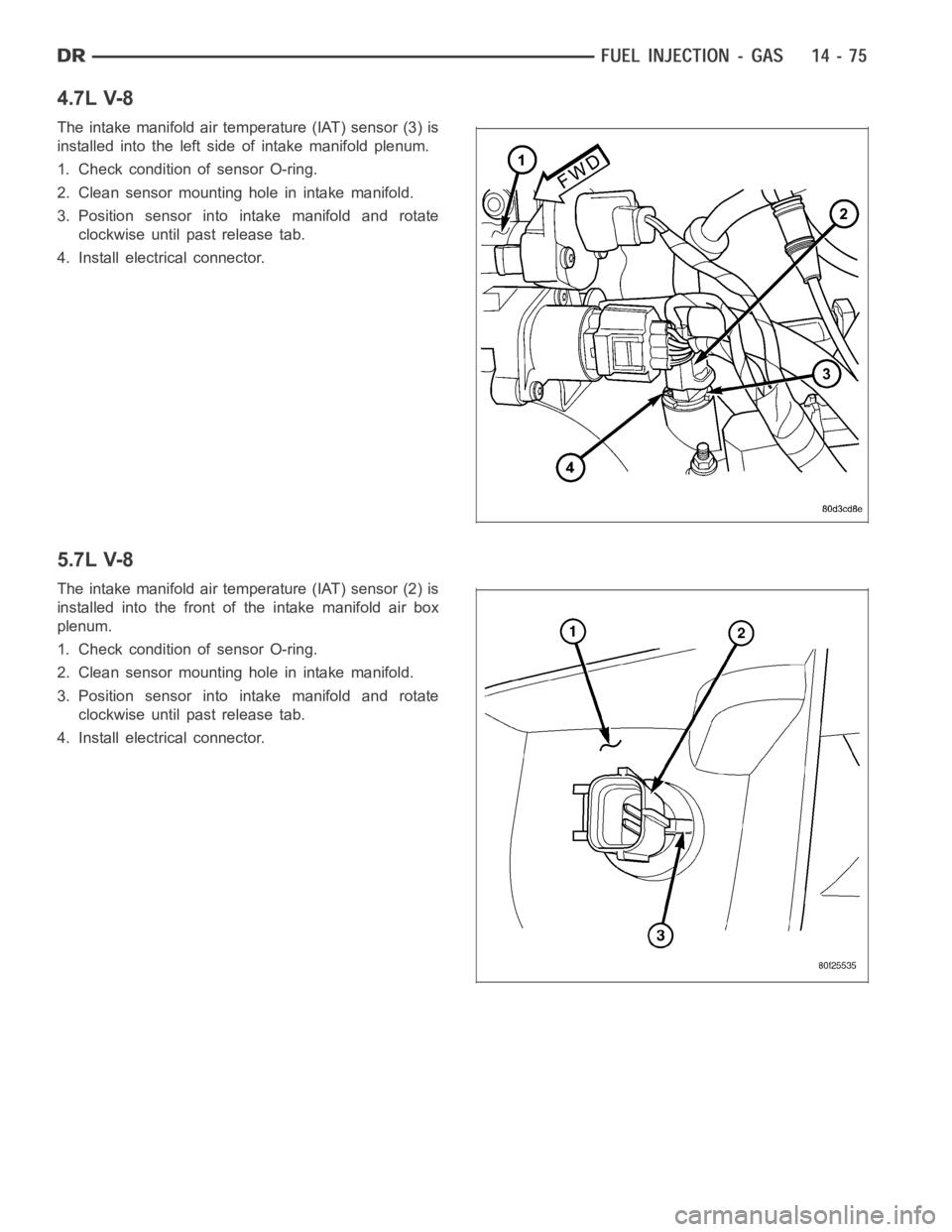

4.7L V-8

The intake manifold air temperature (IAT) sensor (3) is

installed into the left side of intake manifold plenum.

1. Check condition of sensor O-ring.

2. Clean sensor mounting hole in intake manifold.

3. Position sensor into intake manifold and rotate

clockwise until past release tab.

4. Install electrical connector.

5.7L V-8

The intake manifold air temperature (IAT) sensor (2) is

installed into the front of the intake manifold air box

plenum.

1. Check condition of sensor O-ring.

2. Clean sensor mounting hole in intake manifold.

3. Position sensor into intake manifold and rotate

clockwise until past release tab.

4. Install electrical connector.

Page 2318 of 5267

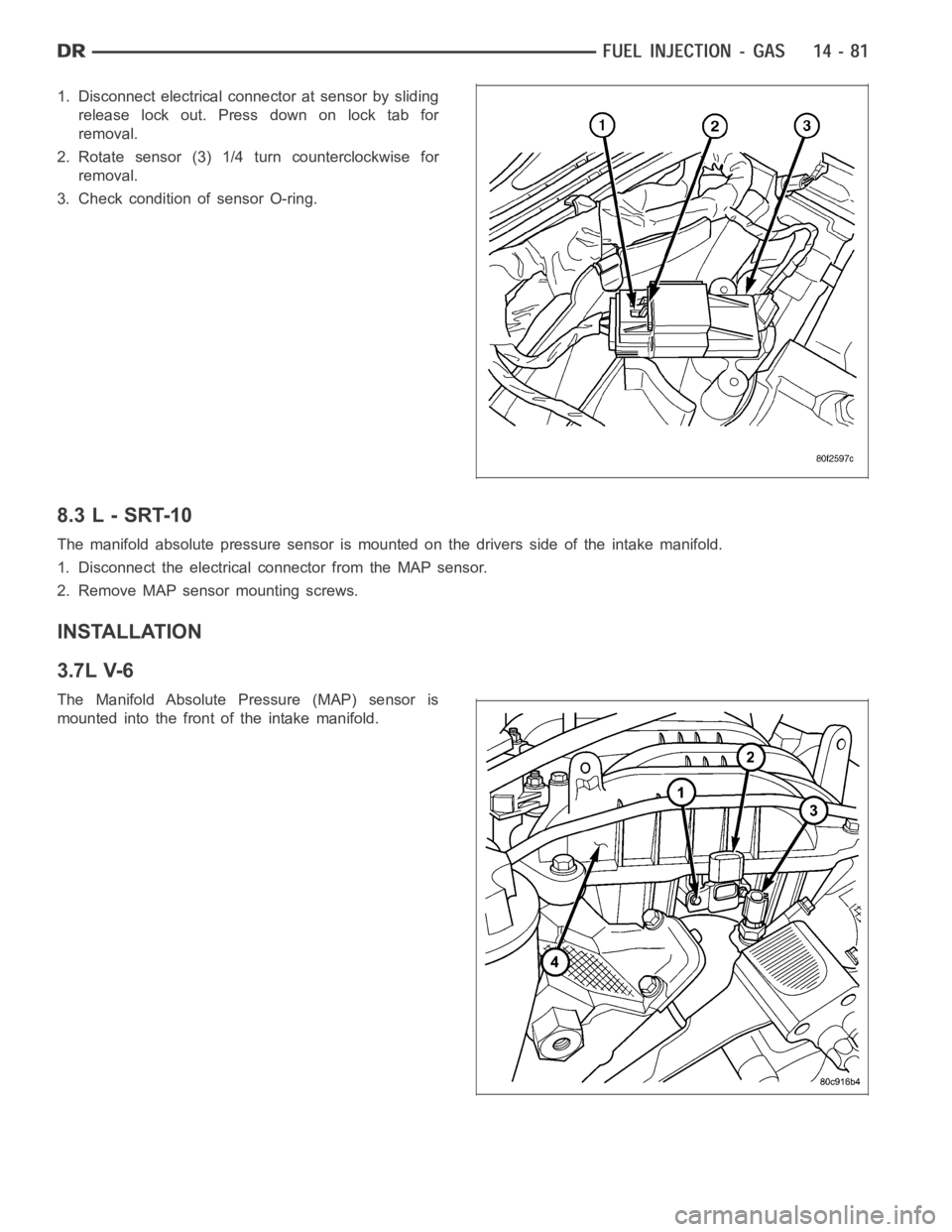

1. Disconnect electrical connector at sensor by sliding

release lock out. Press down on lock tab for

removal.

2. Rotate sensor (3) 1/4 turn counterclockwise for

removal.

3. Check condition of sensor O-ring.

8.3 L - SRT-10

The manifold absolute pressure sensor is mounted on the drivers side of theintake manifold.

1. Disconnect the electrical connector from the MAP sensor.

2. Remove MAP sensor mounting screws.

INSTALLATION

3.7L V-6

The Manifold Absolute Pressure (MAP) sensor is

mounted into the front of the intake manifold.

Page 2320 of 5267

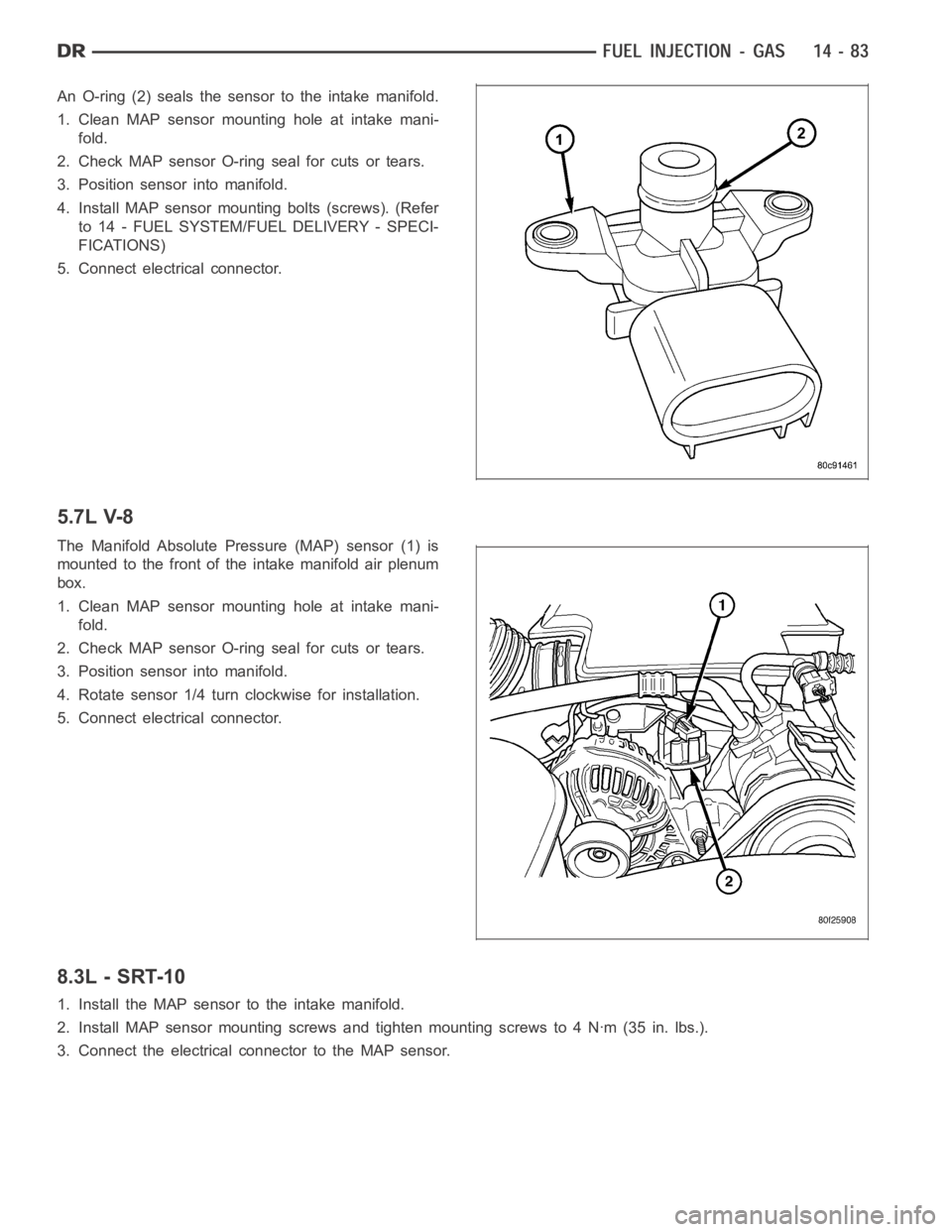

An O-ring (2) seals the sensor to the intake manifold.

1. Clean MAP sensor mounting hole at intake mani-

fold.

2. Check MAP sensor O-ring seal for cuts or tears.

3. Position sensor into manifold.

4. Install MAP sensor mounting bolts (screws). (Refer

to 14 - FUEL SYSTEM/FUEL DELIVERY - SPECI-

FICATIONS)

5. Connect electrical connector.

5.7L V-8

The Manifold Absolute Pressure (MAP) sensor (1) is

mounted to the front of the intake manifold air plenum

box.

1. Clean MAP sensor mounting hole at intake mani-

fold.

2. Check MAP sensor O-ring seal for cuts or tears.

3. Position sensor into manifold.

4. Rotate sensor 1/4 turn clockwise for installation.

5. Connect electrical connector.

8.3L - SRT-10

1. Install the MAP sensor to the intake manifold.

2. Install MAP sensor mounting screws and tighten mounting screws to 4 Nꞏm (35 in. lbs.).

3. Connect the electrical connector to the MAP sensor.

Page 2346 of 5267

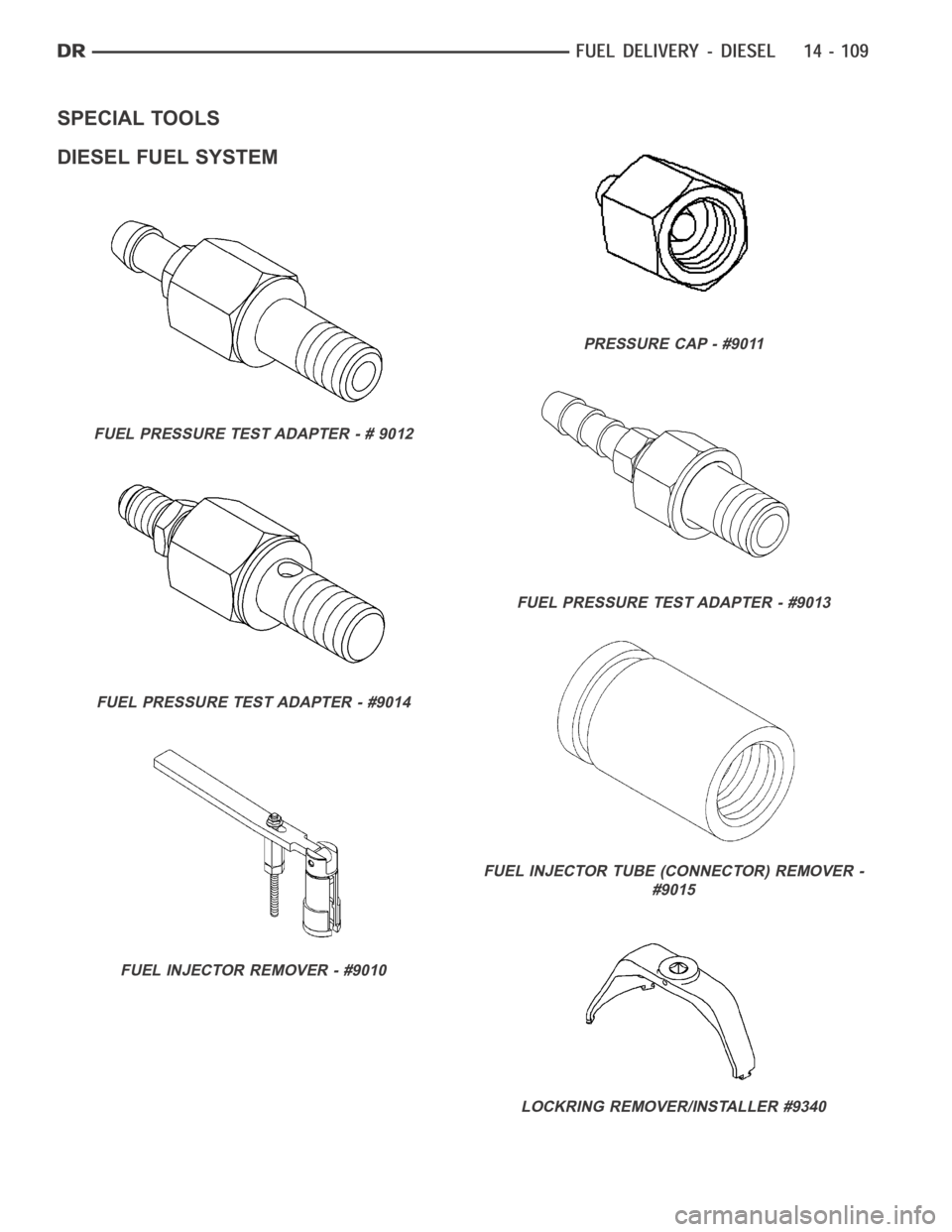

SPECIAL TOOLS

DIESELFUELSYSTEM

FUEL PRESSURE TEST ADAPTER - # 9012

FUEL PRESSURE TEST ADAPTER - #9014

FUEL INJECTOR REMOVER - #9010

PRESSURE CAP - #9011

FUEL PRESSURE TEST ADAPTER - #9013

FUEL INJECTOR TUBE (CONNECTOR) REMOVER -

#9015

LOCKRING REMOVER/INSTALLER #9340

Page 2348 of 5267

FILTER - FUEL / WATER SEPARATOR

DESCRIPTION

The fuel filter/water separator assembly is located on left side of engineabove the starter motor. The assembly also

includes the fuel heater, Water-In-Fuel (WIF) sensor and a screened banjobolt attached at the bottom of the fuel

filter canister.

OPERATION

The fuel filter/water separator protects the fuel injection pump by removing water and contaminants from the fuel.

The construction of the filter/separator allows fuel to pass through it, but helps prevent moisture (water) from doing

so. Moisture collects at the bottom of the canister.

Refer to the maintenance schedules in the owners manual for the recommended fuel filter replacement intervals.

For draining of water from canister, refer to Fuel Filter/Water SeparatorRemoval/Installation section.

There is a screened banjo bolt that is attached at the bottom of the fuel filter canister. It provides additional filtering

for the high pressure fuel system components.

A Water-In-Fuel (WIF) sensor is attached to the side of fuel filter housing. Refer to Water-In-Fuel Sensor Descrip-

tion/Operation.

The fuel heater is installed into the top of the filter/separator housing.Refer to Fuel Heater Description/Operation.

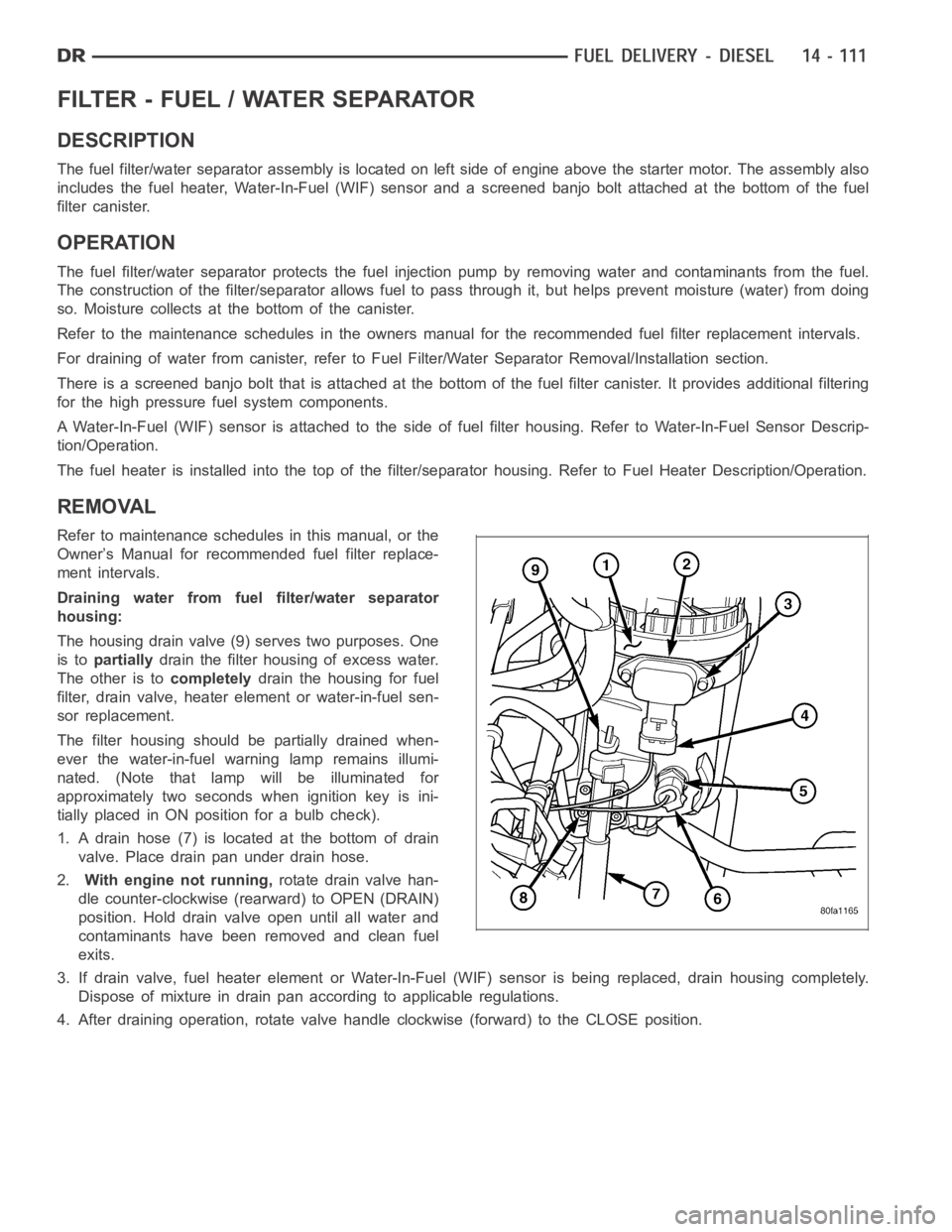

REMOVAL

Refer to maintenance schedules in this manual, or the

Owner’s Manual for recommended fuel filter replace-

ment intervals.

Draining water from fuel filter/water separator

housing:

The housing drain valve (9) serves two purposes. One

is topartiallydrain the filter housing of excess water.

The other is tocompletelydrain the housing for fuel

filter, drain valve, heater element or water-in-fuel sen-

sor replacement.

The filter housing should be partially drained when-

ever the water-in-fuel warning lamp remains illumi-

nated. (Note that lamp will be illuminated for

approximately two seconds when ignition key is ini-

tially placed in ON position for a bulb check).

1. A drain hose (7) is located at the bottom of drain

valve. Place drain pan under drain hose.

2.With engine not running,rotate drain valve han-

dle counter-clockwise (rearward) to OPEN (DRAIN)

position. Hold drain valve open until all water and

contaminants have been removed and clean fuel

exits.

3. If drain valve, fuel heater element or Water-In-Fuel (WIF) sensor is being replaced, drain housing completely.

Dispose of mixture in drain pan according to applicable regulations.

4. After draining operation, rotate valve handle clockwise (forward) to the CLOSE position.

Page 2349 of 5267

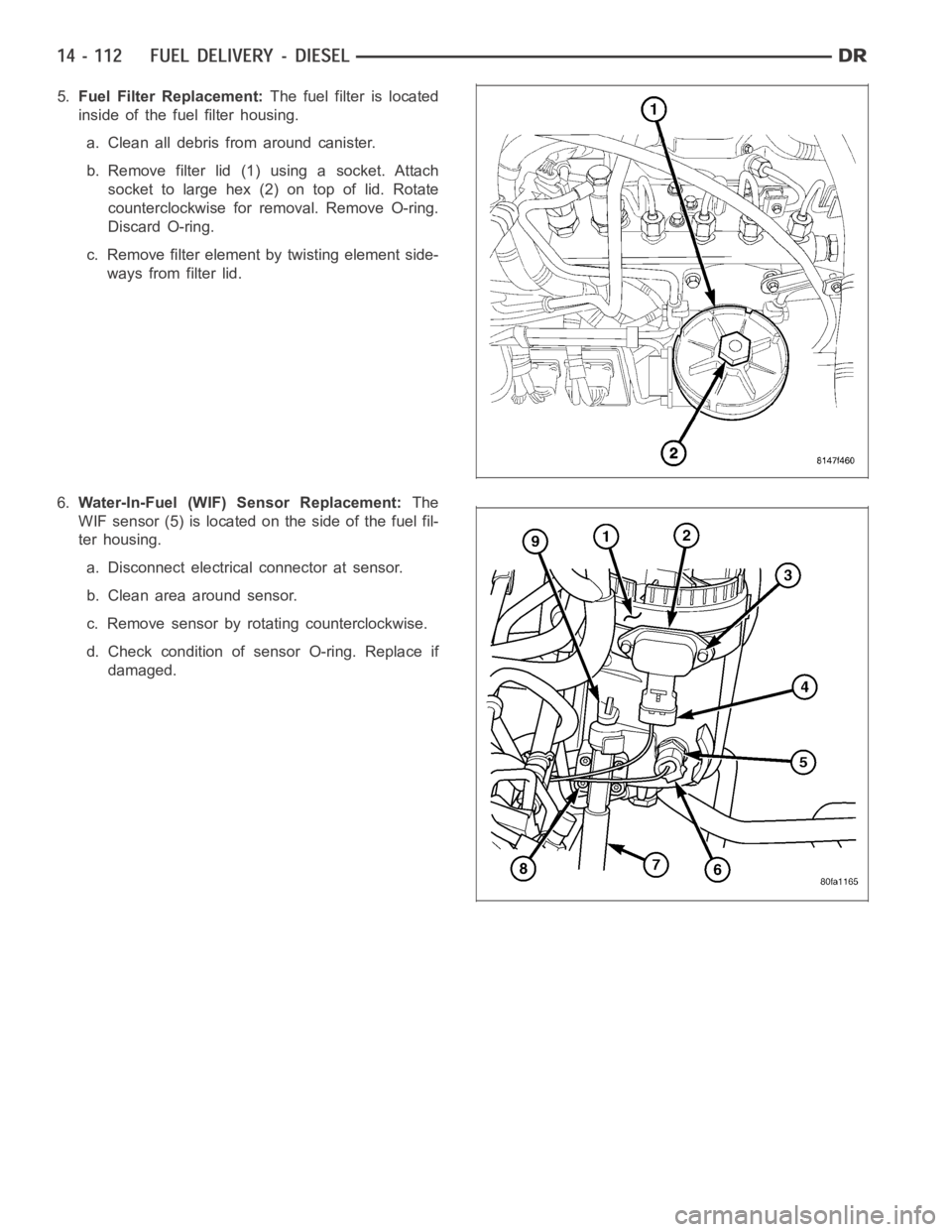

5.Fuel Filter Replacement:The fuel filter is located

inside of the fuel filter housing.

a. Clean all debris from around canister.

b. Remove filter lid (1) using a socket. Attach

socket to large hex (2) on top of lid. Rotate

counterclockwise for removal. Remove O-ring.

Discard O-ring.

c. Remove filter element by twisting element side-

ways from filter lid.

6.Water-In-Fuel (WIF) Sensor Replacement:The

WIF sensor (5) is located on the side of the fuel fil-

ter housing.

a. Disconnect electrical connector at sensor.

b. Clean area around sensor.

c. Remove sensor by rotating counterclockwise.

d. Check condition of sensor O-ring. Replace if

damaged.

Page 2350 of 5267

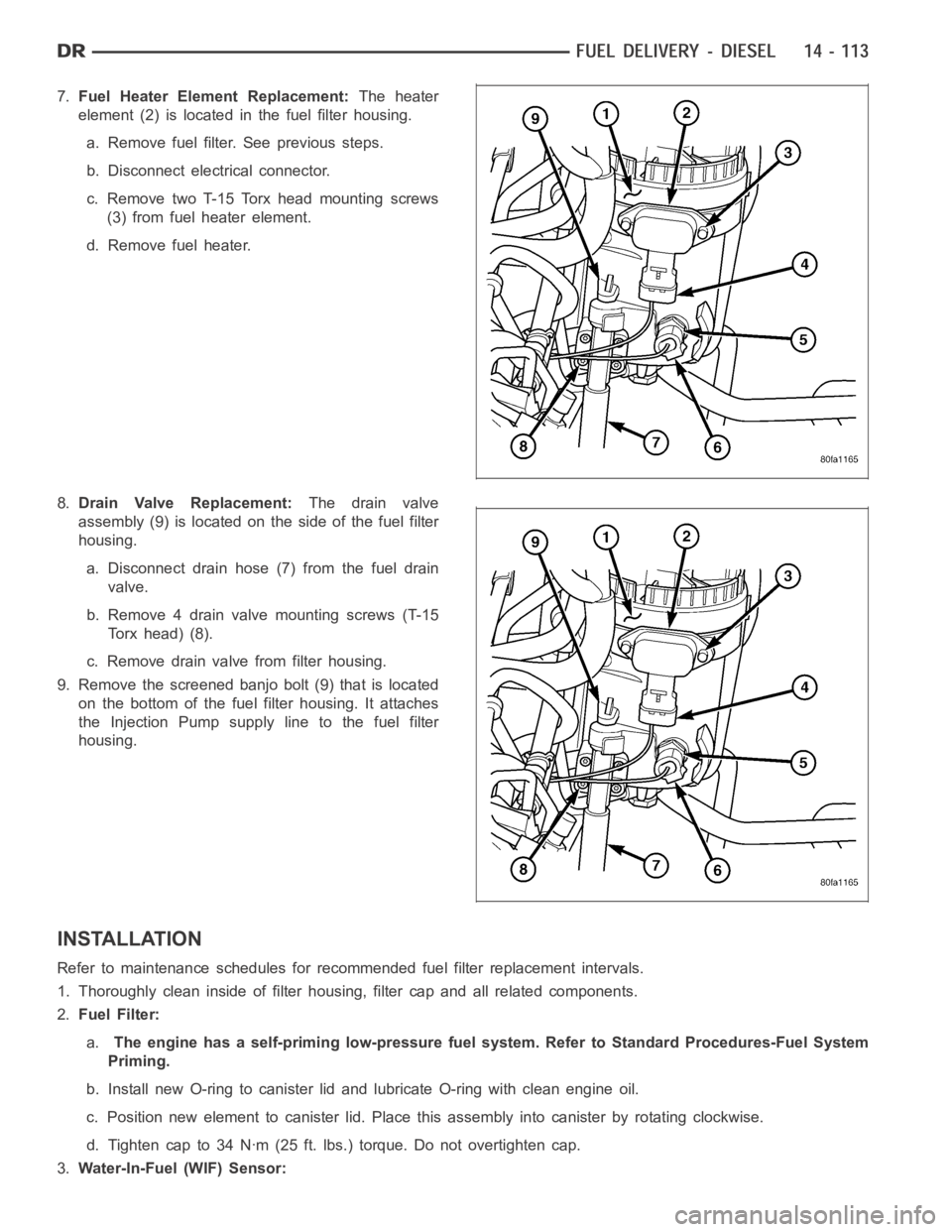

7.Fuel Heater Element Replacement:The heater

element (2) is located in the fuel filter housing.

a. Remove fuel filter. See previous steps.

b. Disconnect electrical connector.

c. Remove two T-15 Torx head mounting screws

(3) from fuel heater element.

d. Remove fuel heater.

8.Drain Valve Replacement:The drain valve

assembly (9) is located on the side of the fuel filter

housing.

a. Disconnect drain hose (7) from the fuel drain

valve.

b. Remove 4 drain valve mounting screws (T-15

Torx head) (8).

c. Remove drain valve from filter housing.

9. Remove the screened banjo bolt (9) that is located

on the bottom of the fuel filter housing. It attaches

the Injection Pump supply line to the fuel filter

housing.

INSTALLATION

Refer to maintenance schedules for recommended fuel filter replacement intervals.

1. Thoroughly clean inside of filter housing, filter cap and all related components.

2.Fuel Filter:

a.The engine has a self-priming low-pressure fuel system. Refer to StandardProcedures-Fuel System

Priming.

b. Install new O-ring to canister lid and lubricate O-ring with clean engine oil.

c. Position new element to canister lid. Place this assembly into canisterby rotating clockwise.

d. Tighten cap to 34 Nꞏm (25 ft. lbs.) torque. Do not overtighten cap.

3.Water-In-Fuel (WIF) Sensor:

Page 2369 of 5267

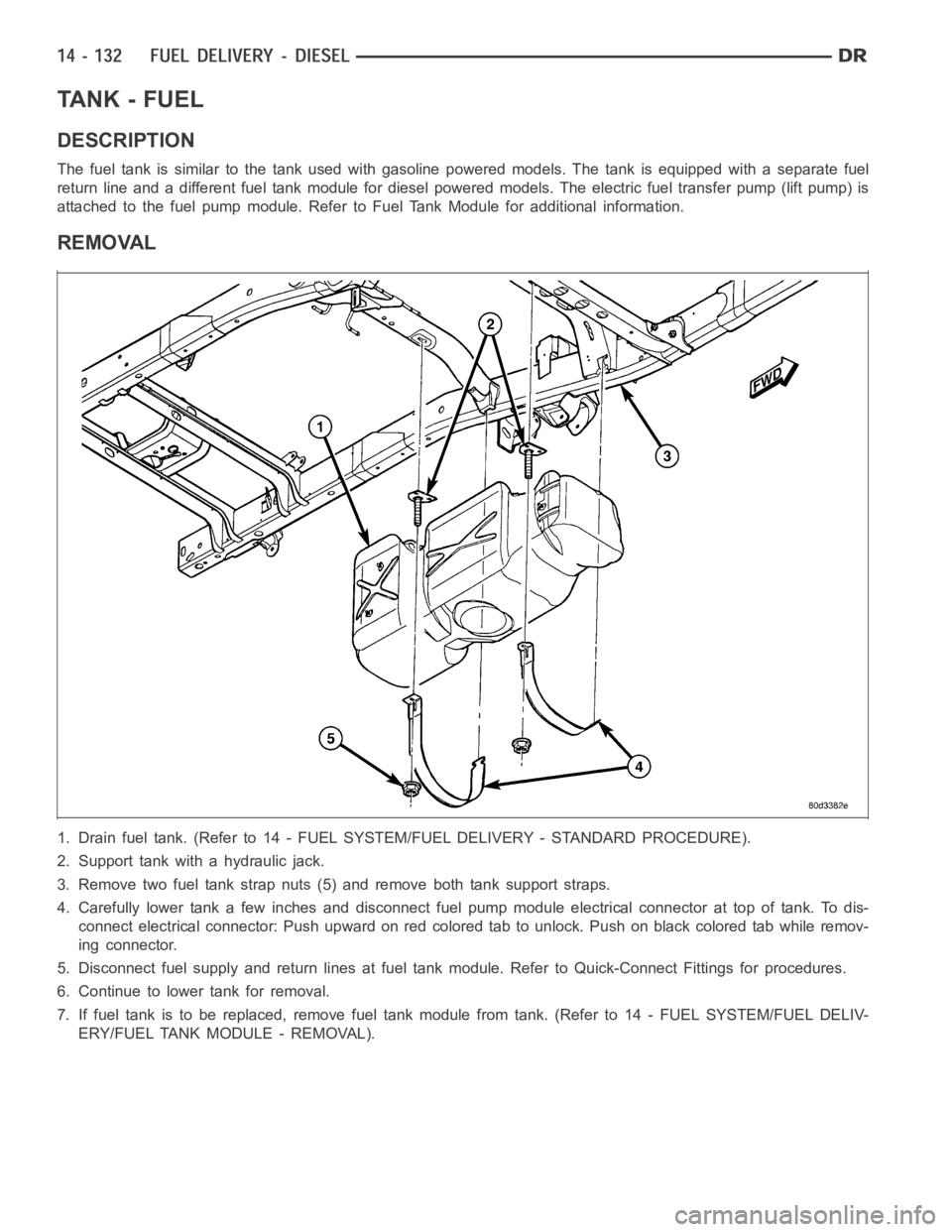

TA N K - F U E L

DESCRIPTION

The fuel tank is similar to the tank used with gasoline powered models. The tank is equipped with a separate fuel

return line and a different fuel tank module for diesel powered models. Theelectric fuel transfer pump (lift pump) is

attached to the fuel pump module. Refer to Fuel Tank Module for additional information.

REMOVAL

1. Drain fuel tank. (Refer to 14 - FUEL SYSTEM/FUEL DELIVERY - STANDARD PROCEDURE).

2. Support tank with a hydraulic jack.

3. Remove two fuel tank strap nuts (5) and remove both tank support straps.

4. Carefully lower tank a few inches and disconnect fuel pump module electrical connector at top of tank. To dis-

connect electrical connector: Push upward on red colored tab to unlock. Push on black colored tab while remov-

ing connector.

5. Disconnect fuel supply and return lines at fuel tank module. Refer to Quick-Connect Fittings for procedures.

6. Continue to lower tank for removal.

7. If fuel tank is to be replaced, remove fuel tank module from tank. (Refer to 14 - FUEL SYSTEM/FUEL DELIV-

ERY/FUEL TANK MODULE - REMOVAL).

Page 2371 of 5267

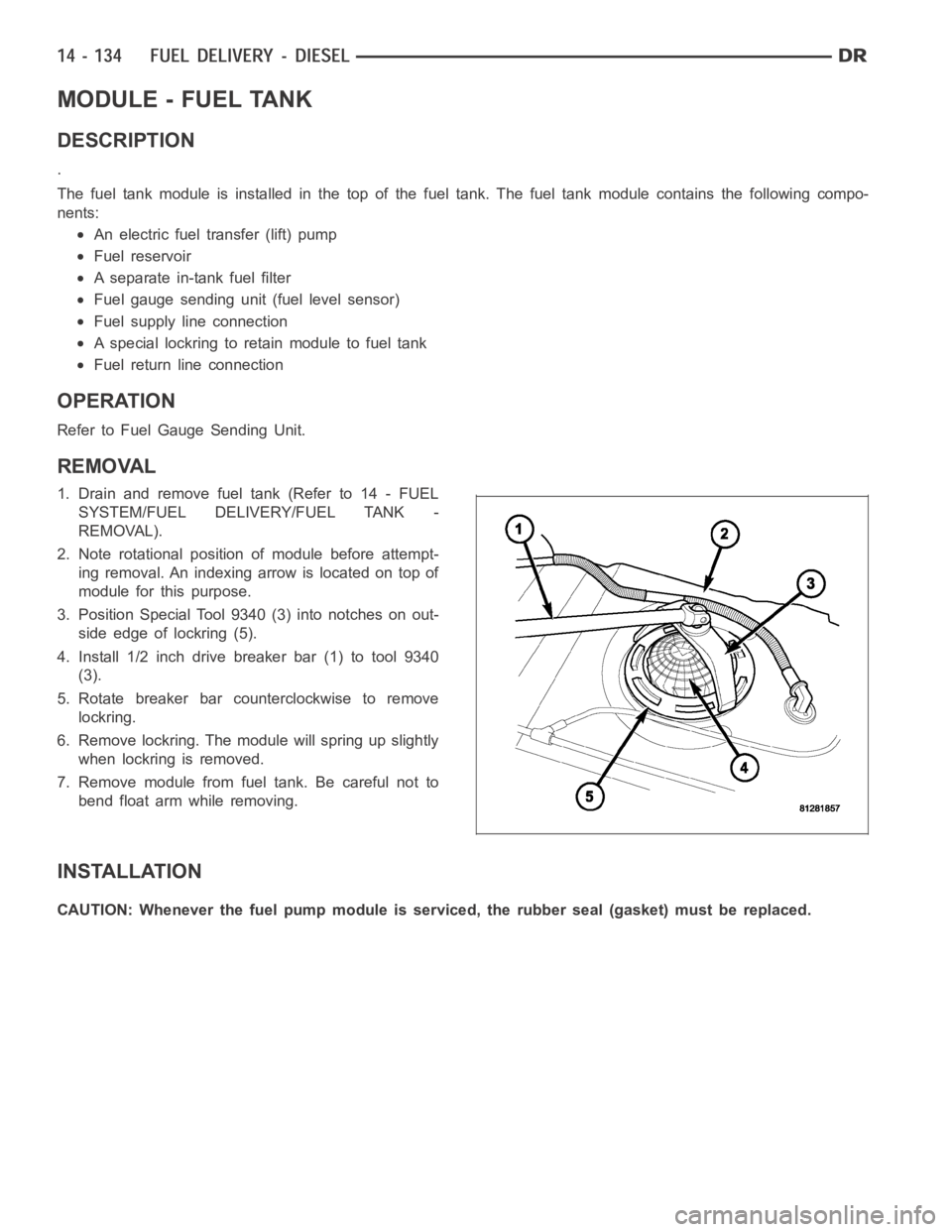

MODULE - FUEL TANK

DESCRIPTION

.

The fuel tank module is installed in the top of the fuel tank. The fuel tank module contains the following compo-

nents:

An electric fuel transfer (lift) pump

Fuel reservoir

A separate in-tank fuel filter

Fuel gauge sending unit (fuel level sensor)

Fuel supply line connection

A special lockring to retain module to fuel tank

Fuel return line connection

OPERATION

Refer to Fuel Gauge Sending Unit.

REMOVAL

1. Drain and remove fuel tank (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY/FUEL TANK -

REMOVAL).

2. Note rotational position of module before attempt-

ing removal. An indexing arrow is located on top of

module for this purpose.

3. Position Special Tool 9340 (3) into notches on out-

side edge of lockring (5).

4. Install 1/2 inch drive breaker bar (1) to tool 9340

(3).

5. Rotate breaker bar counterclockwise to remove

lockring.

6. Remove lockring. The module will spring up slightly

when lockring is removed.

7. Remove module from fuel tank. Be careful not to

bend float arm while removing.

INSTALLATION

CAUTION: Whenever the fuel pump module is serviced, the rubber seal (gasket) must be replaced.