DODGE RAM SRT-10 2006 Service Repair Manual

RAM SRT-10 2006

DODGE

DODGE

https://www.carmanualsonline.info/img/12/56917/w960_56917-0.png

DODGE RAM SRT-10 2006 Service Repair Manual

Trending: belt, parking sensors, oil viscosity, air conditioning, transmission oil, check oil, Fuel pump relay

Page 4241 of 5267

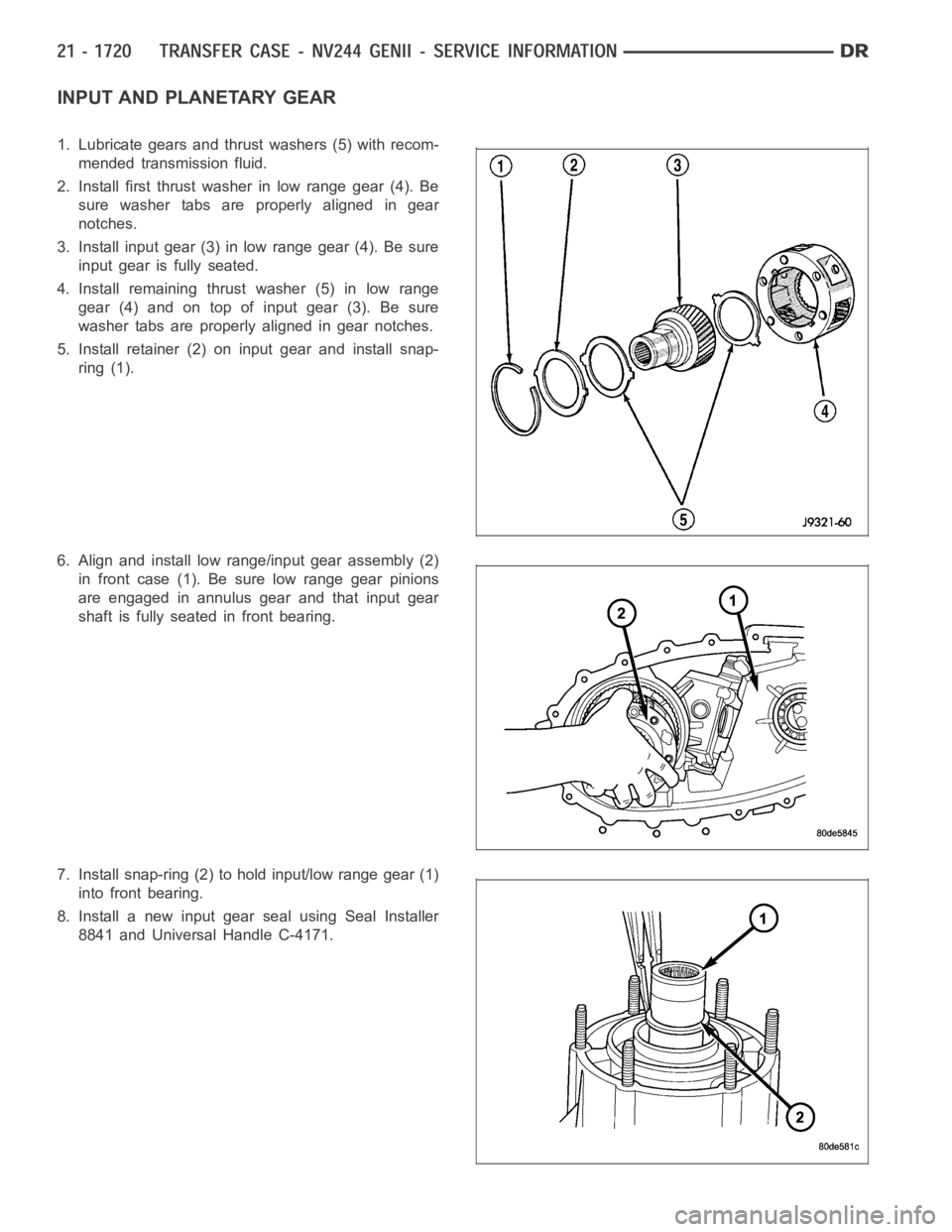

INPUT AND PLANETARY GEAR

1. Lubricate gears and thrust washers (5) with recom-

mended transmission fluid.

2. Install first thrust washer in low range gear (4). Be

sure washer tabs are properly aligned in gear

notches.

3. Install input gear (3) in low range gear (4). Be sure

input gear is fully seated.

4. Install remaining thrust washer (5) in low range

gear (4) and on top of input gear (3). Be sure

washer tabs are properly aligned in gear notches.

5. Install retainer (2) on input gear and install snap-

ring (1).

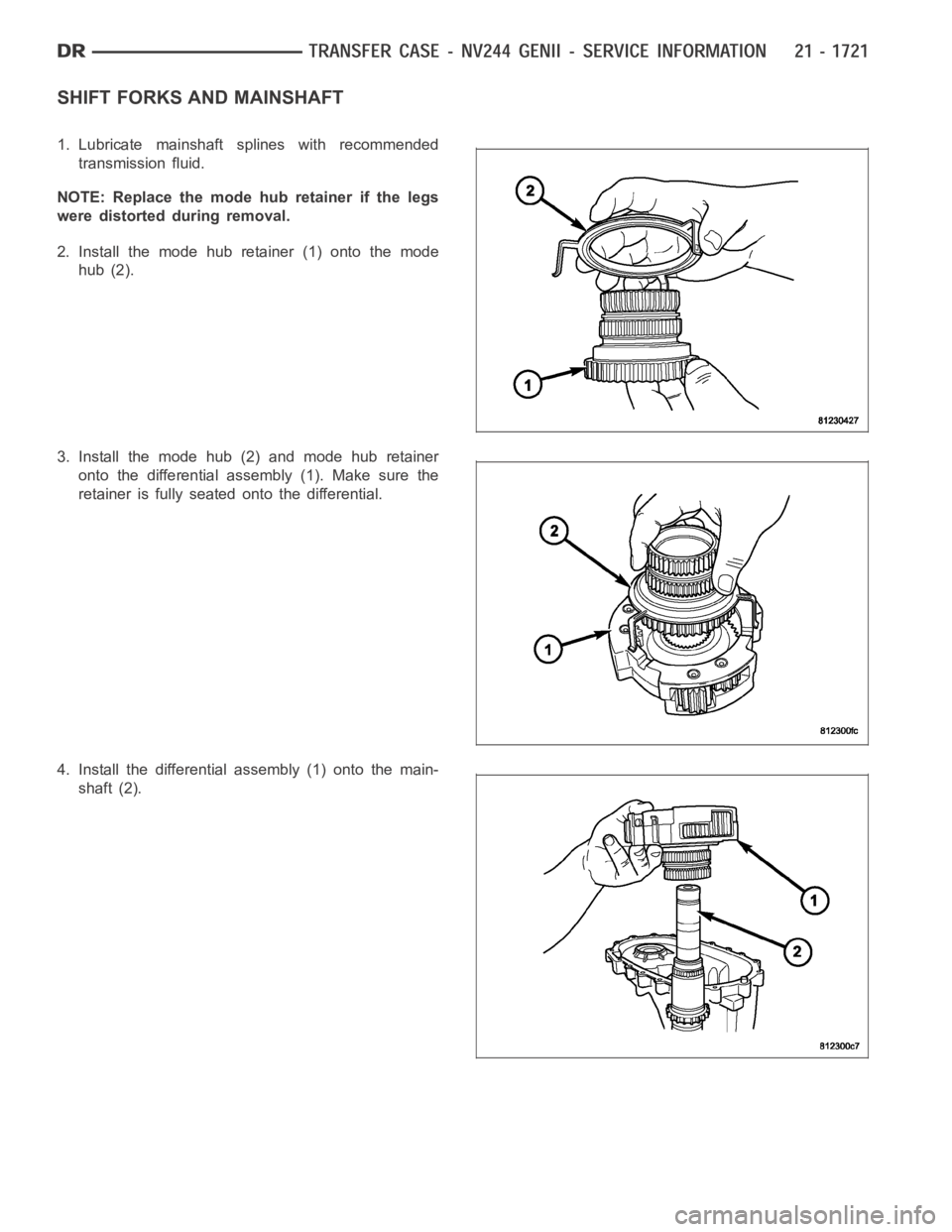

6. Align and install low range/input gear assembly (2)

in front case (1). Be sure low range gear pinions

are engaged in annulus gear and that input gear

shaft is fully seated in front bearing.

7. Install snap-ring (2) to hold input/low range gear (1)

into front bearing.

8. Install a new input gear seal using Seal Installer

8841 and Universal Handle C-4171.

Page 4242 of 5267

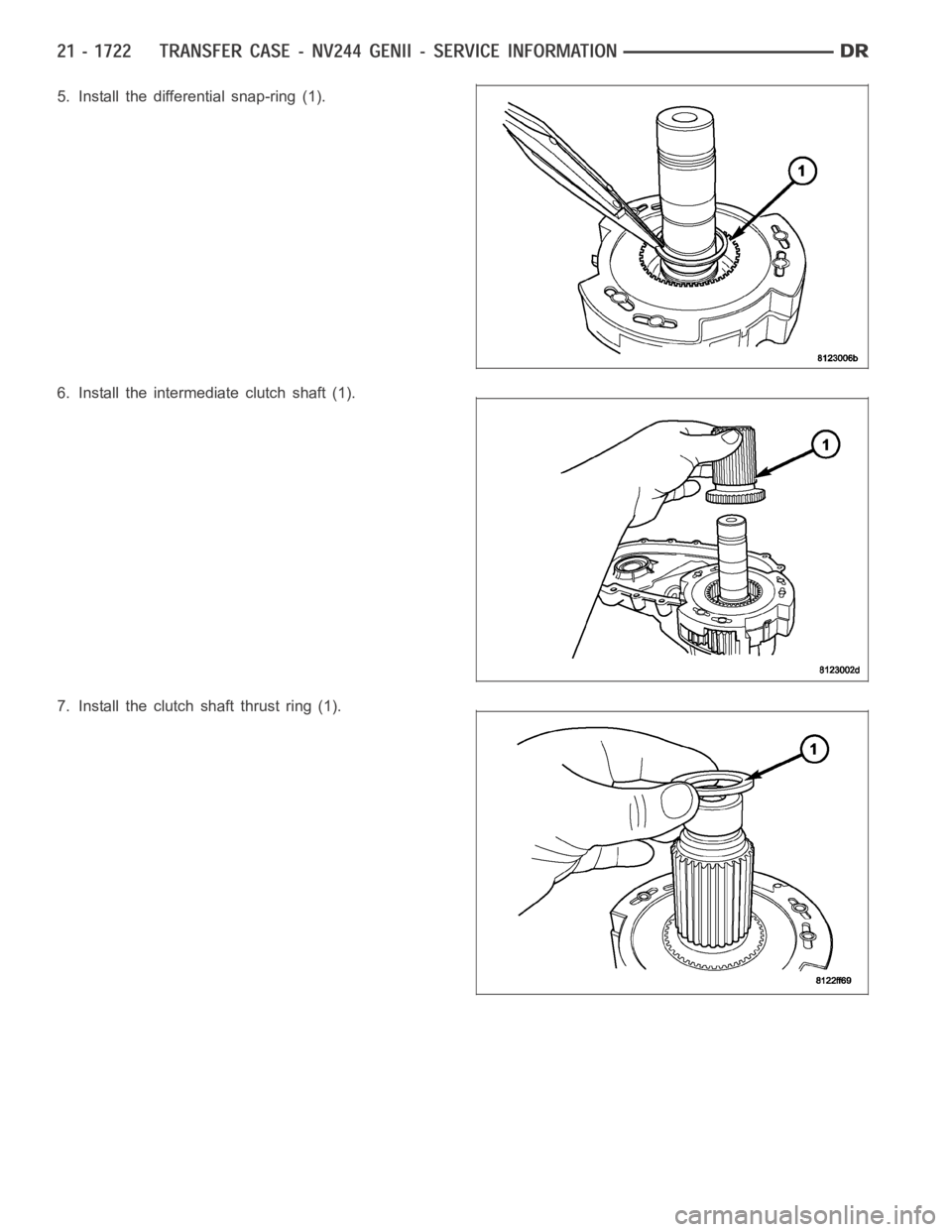

SHIFT FORKS AND MAINSHAFT

1. Lubricate mainshaft splines with recommended

transmission fluid.

NOTE: Replace the mode hub retainer if the legs

were distorted during removal.

2. Install the mode hub retainer (1) onto the mode

hub (2).

3. Install the mode hub (2) and mode hub retainer

onto the differential assembly (1). Make sure the

retainer is fully seated onto the differential.

4. Install the differential assembly (1) onto the main-

shaft (2).

Page 4243 of 5267

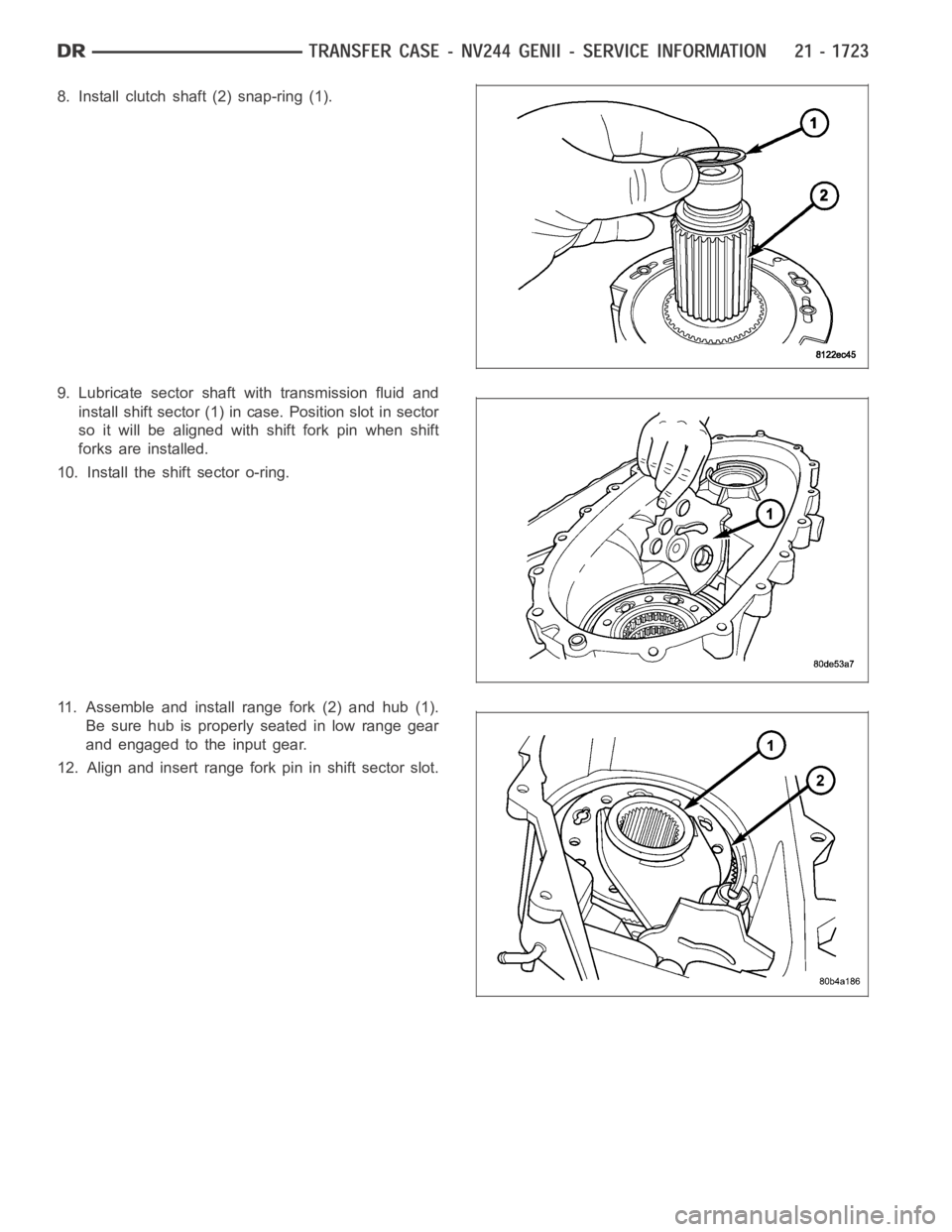

5. Install the differential snap-ring (1).

6. Install the intermediate clutch shaft (1).

7. Install the clutch shaft thrust ring (1).

Page 4244 of 5267

8. Install clutch shaft (2) snap-ring (1).

9. Lubricate sector shaft with transmission fluid and

install shift sector (1) in case. Position slot in sector

so it will be aligned with shift fork pin when shift

forks are installed.

10. Install the shift sector o-ring.

11. Assemble and install range fork (2) and hub (1).

Be sure hub is properly seated in low range gear

and engaged to the input gear.

12. Align and insert range fork pin in shift sector slot.

Page 4245 of 5267

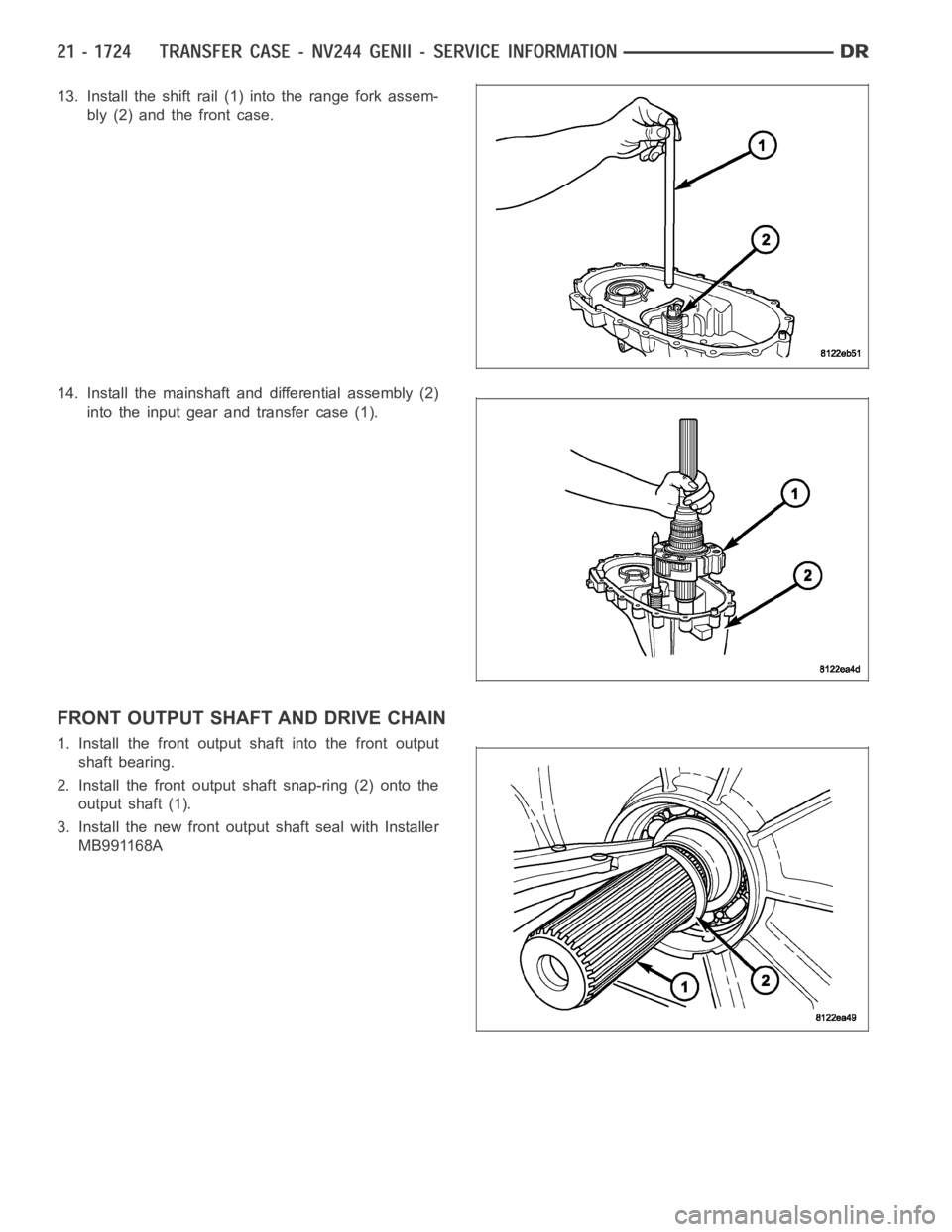

13. Install the shift rail (1) into the range fork assem-

bly (2) and the front case.

14. Install the mainshaft and differential assembly (2)

into the input gear and transfer case (1).

FRONT OUTPUT SHAFT AND DRIVE CHAIN

1. Install the front output shaft into the front output

shaft bearing.

2. Install the front output shaft snap-ring (2) onto the

output shaft (1).

3. Install the new front output shaft seal with Installer

MB991168A

Page 4246 of 5267

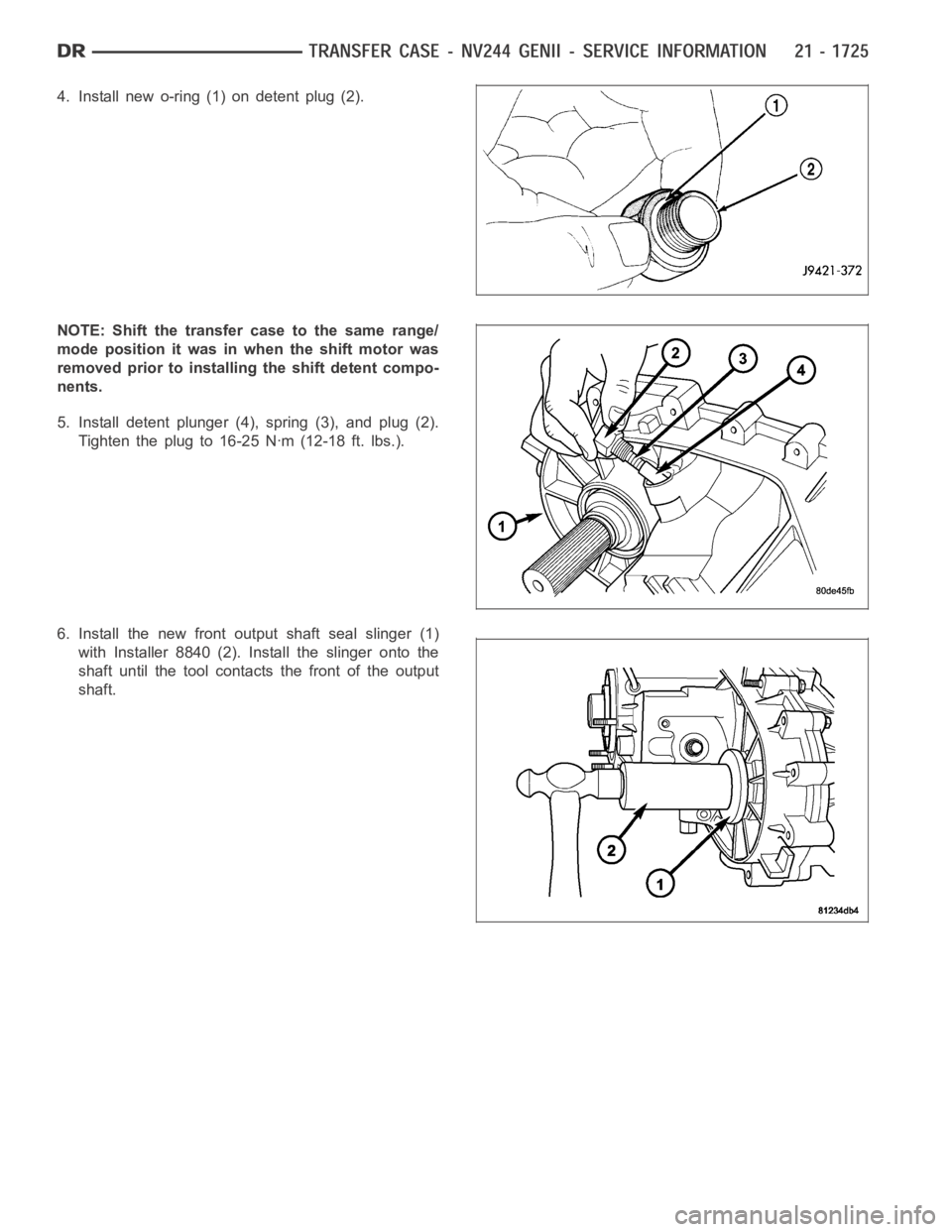

4. Install new o-ring (1) on detent plug (2).

NOTE: Shift the transfer case to the same range/

mode position it was in when the shift motor was

removed prior to installing the shift detent compo-

nents.

5. Install detent plunger (4), spring (3), and plug (2).

Tighten the plug to 16-25 Nꞏm (12-18 ft. lbs.).

6. Install the new front output shaft seal slinger (1)

with Installer 8840 (2). Install the slinger onto the

shaft until the tool contacts the front of the output

shaft.

Page 4247 of 5267

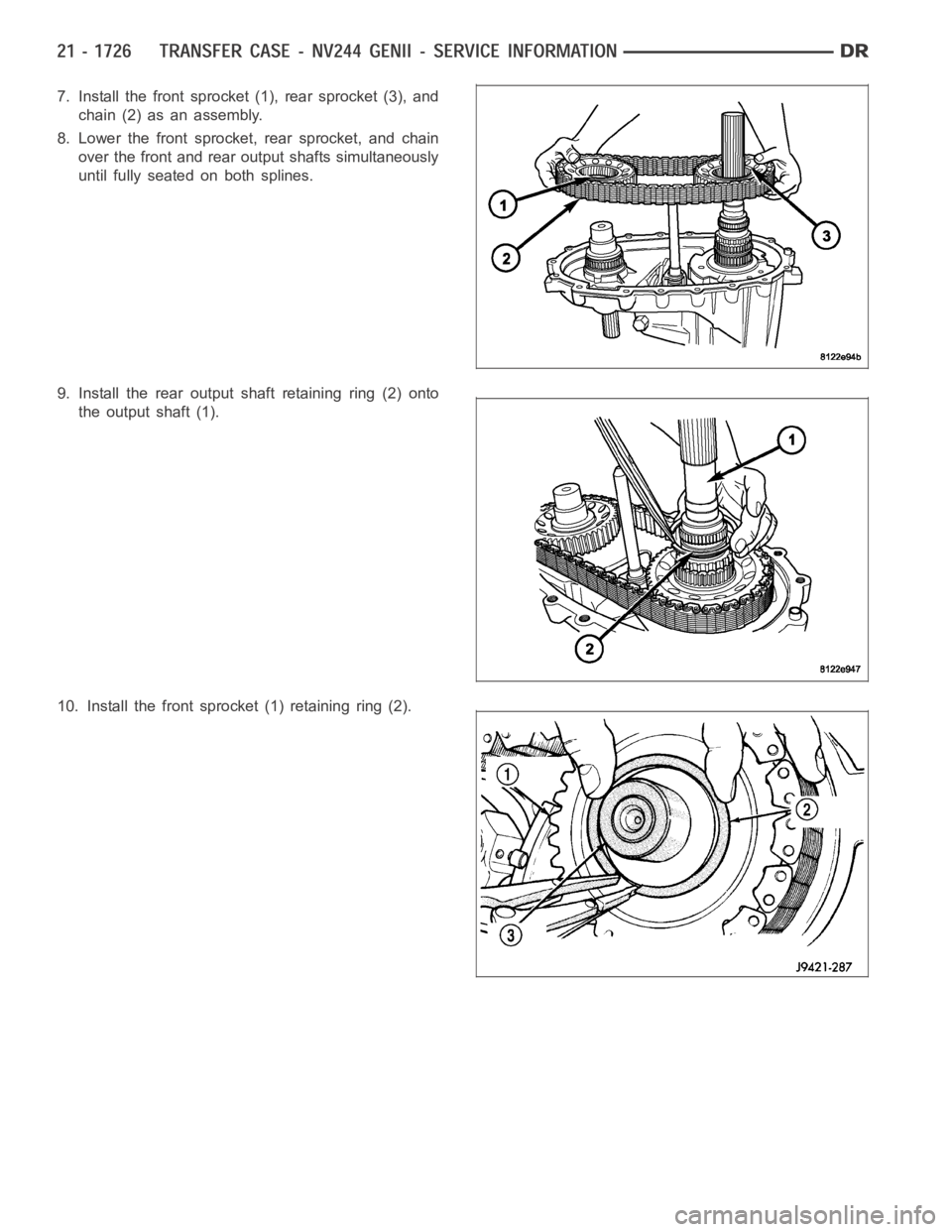

7. Install the front sprocket (1), rear sprocket (3), and

chain (2) as an assembly.

8. Lower the front sprocket, rear sprocket, and chain

over the front and rear output shafts simultaneously

until fully seated on both splines.

9. Install the rear output shaft retaining ring (2) onto

the output shaft (1).

10. Install the front sprocket (1) retaining ring (2).

Page 4248 of 5267

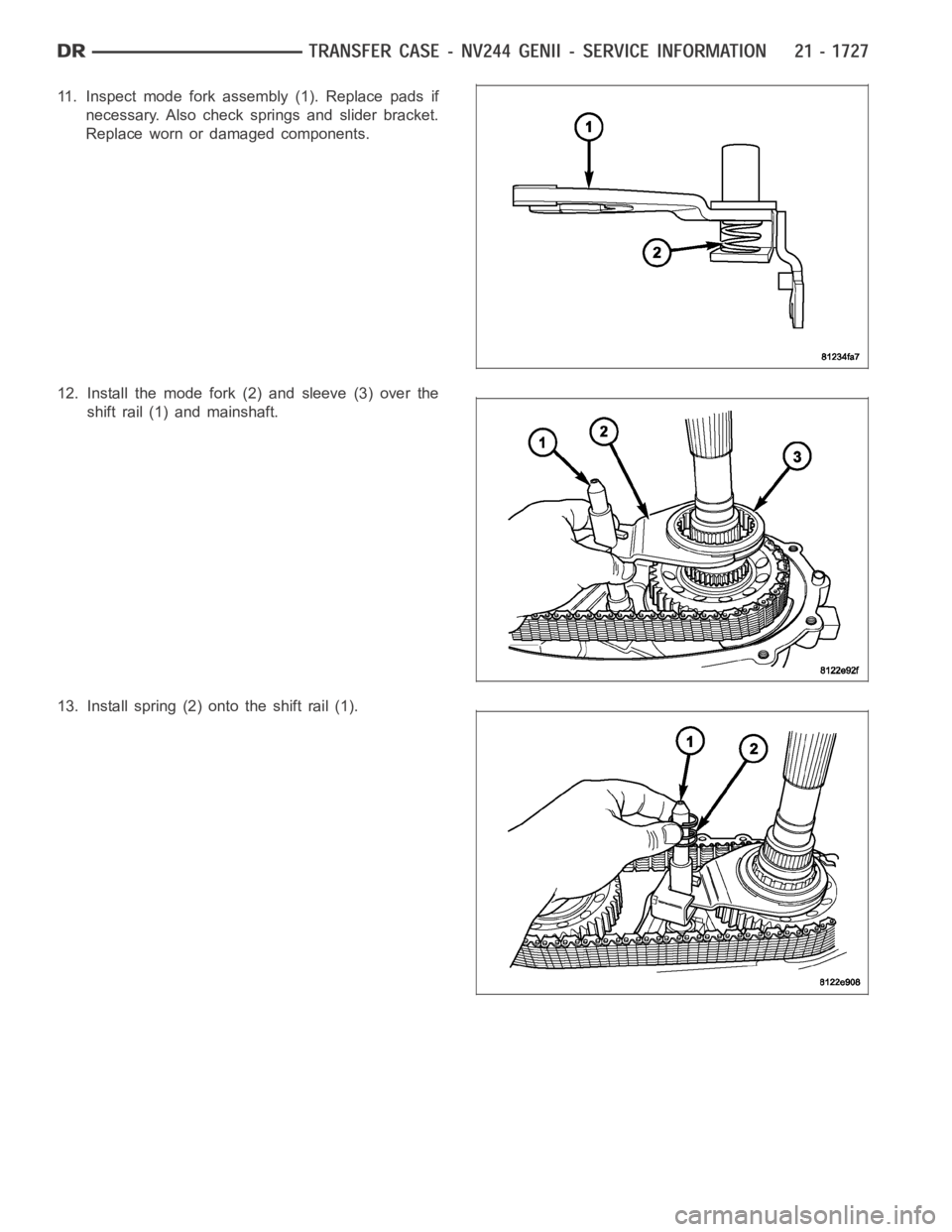

11. Inspect mode fork assembly (1). Replace pads if

necessary. Also check springs and slider bracket.

Replace worn or damaged components.

12. Install the mode fork (2) and sleeve (3) over the

shift rail (1) and mainshaft.

13. Install spring (2) onto the shift rail (1).

Page 4249 of 5267

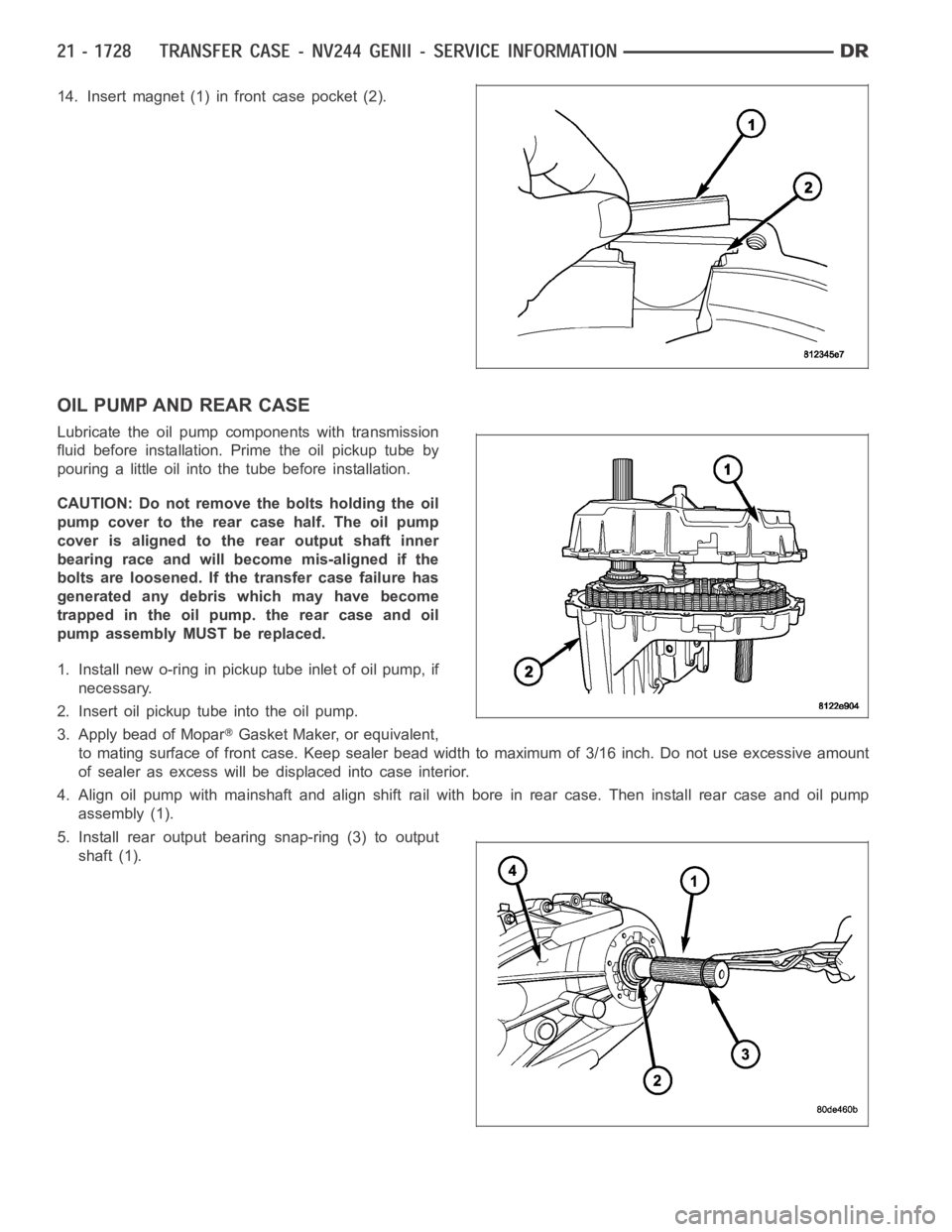

14. Insert magnet (1) in front case pocket (2).

OIL PUMP AND REAR CASE

Lubricate the oil pump components with transmission

fluid before installation. Prime the oil pickup tube by

pouring a little oil into the tube before installation.

CAUTION: Do not remove the bolts holding the oil

pump cover to the rear case half. The oil pump

cover is aligned to the rear output shaft inner

bearing race and will become mis-aligned if the

bolts are loosened. If the transfer case failure has

generated any debris which may have become

trapped in the oil pump. the rear case and oil

pump assembly MUST be replaced.

1. Install new o-ring in pickup tube inlet of oil pump, if

necessary.

2. Insert oil pickup tube into the oil pump.

3. Apply bead of Mopar

Gasket Maker, or equivalent,

to mating surface of front case. Keep sealer bead width to maximum of 3/16 inch. Do not use excessive amount

of sealer as excess will be displaced into case interior.

4. Align oil pump with mainshaft and align shift rail with bore in rear case.Then install rear case and oil pump

assembly (1).

5. Install rear output bearing snap-ring (3) to output

shaft (1).

Page 4250 of 5267

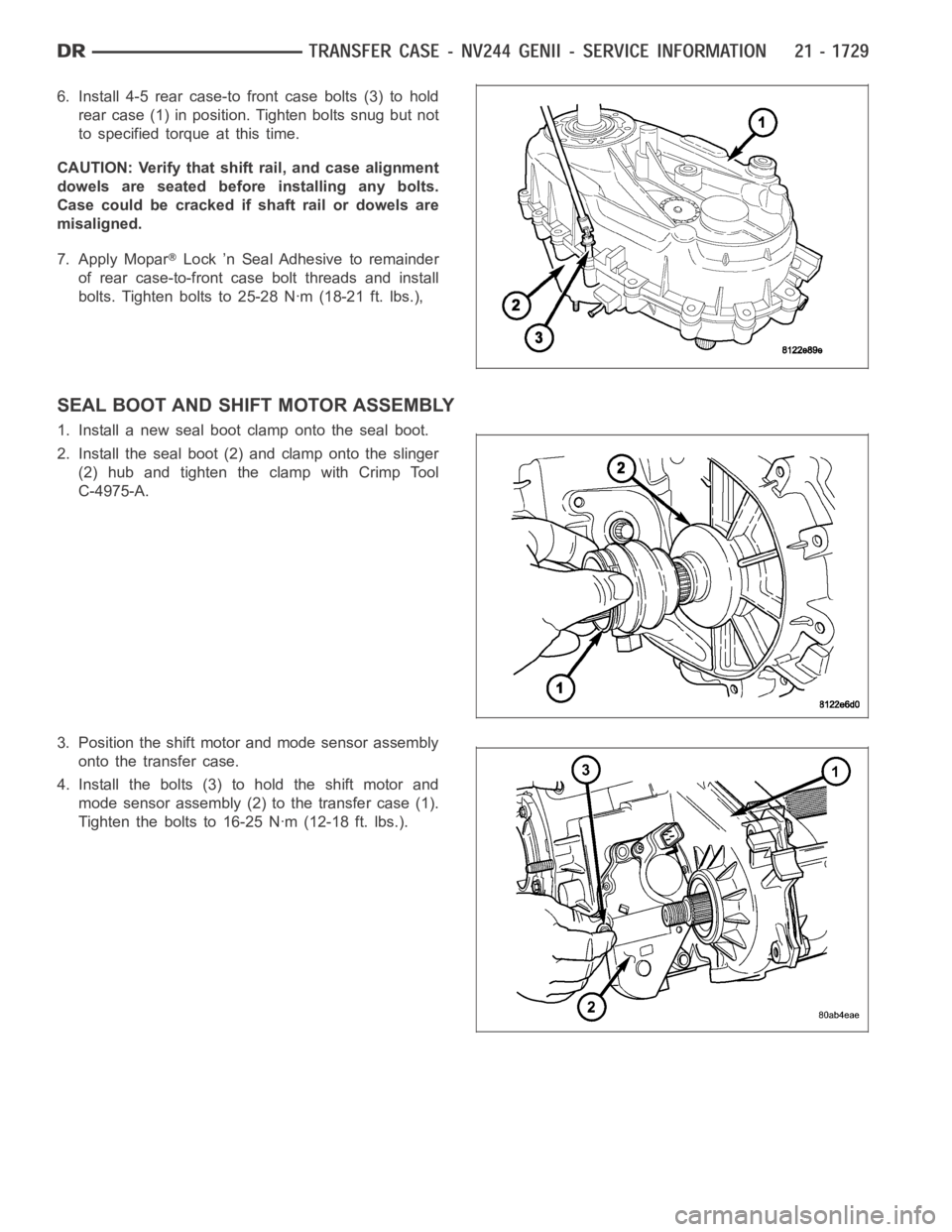

6. Install 4-5 rear case-to front case bolts (3) to hold

rear case (1) in position. Tighten bolts snug but not

to specified torque at this time.

CAUTION: Verify that shift rail, and case alignment

dowels are seated before installing any bolts.

Case could be cracked if shaft rail or dowels are

misaligned.

7. Apply Mopar

Lock ’n Seal Adhesive to remainder

of rear case-to-front case bolt threads and install

bolts. Tighten bolts to 25-28 Nꞏm (18-21 ft. lbs.),

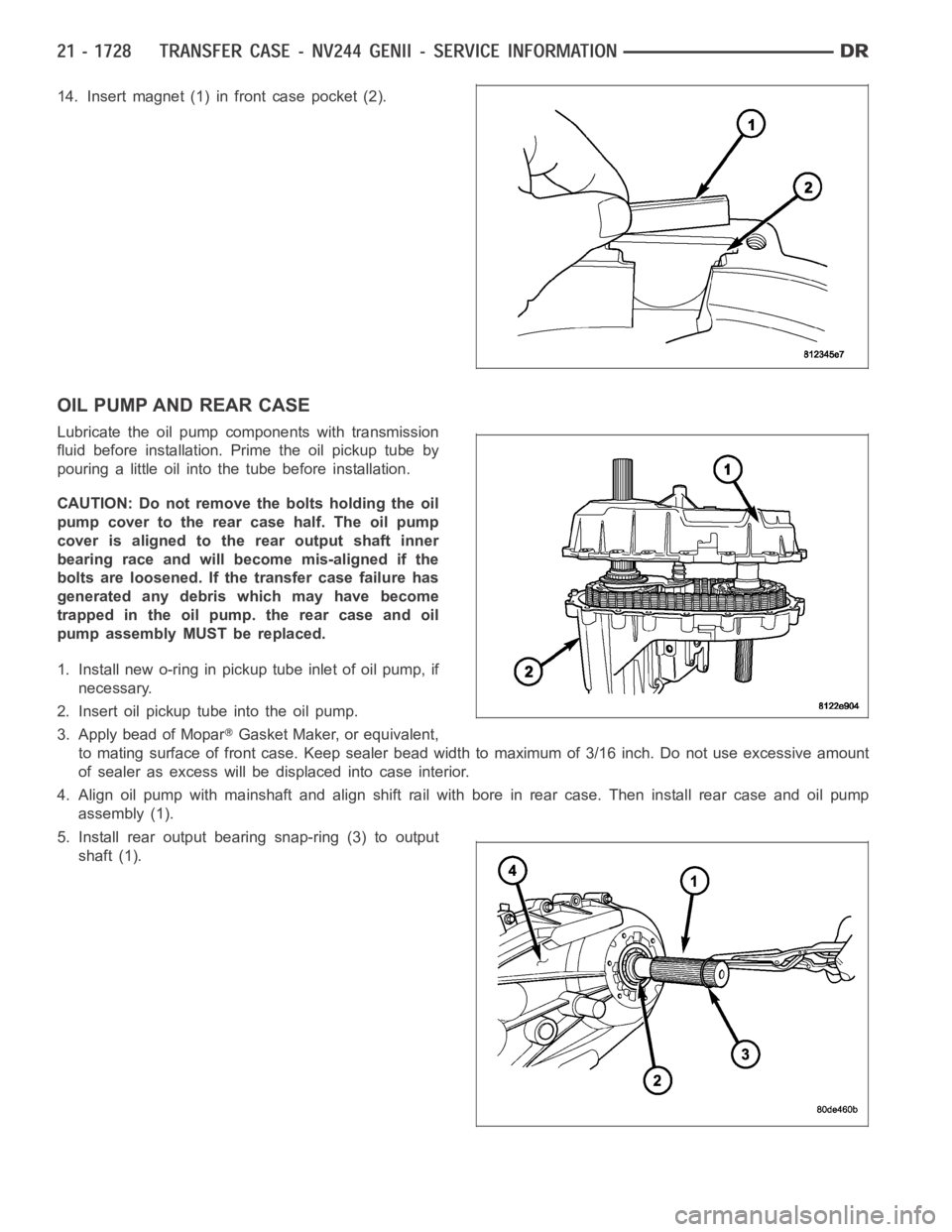

SEAL BOOT AND SHIFT MOTOR ASSEMBLY

1. Install a new seal boot clamp onto the seal boot.

2. Install the seal boot (2) and clamp onto the slinger

(2) hub and tighten the clamp with Crimp Tool

C-4975-A.

3. Position the shift motor and mode sensor assembly

onto the transfer case.

4. Install the bolts (3) to hold the shift motor and

mode sensor assembly (2) to the transfer case (1).

Tighten the bolts to 16-25 Nꞏm (12-18 ft. lbs.).

Trending: odometer, four wheel drive, ad blue, brake sensor, fuel pressure, wheel, dead battery