check engine light DODGE RAM SRT-10 2006 Service Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 793 of 5267

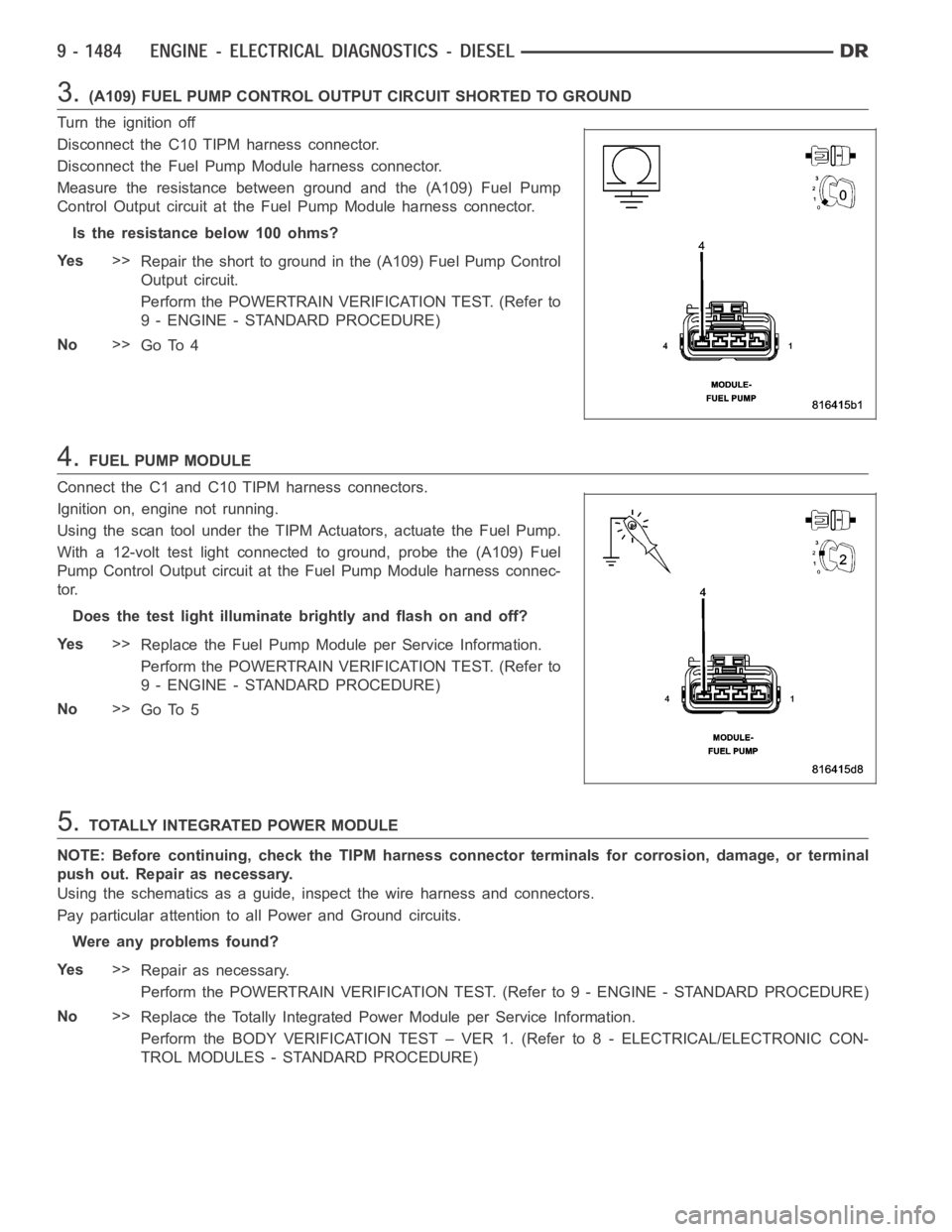

3.(A109) FUEL PUMP CONTROL OUTPUT CIRCUIT SHORTED TO GROUND

Turn the ignition off

Disconnect the C10 TIPM harness connector.

Disconnect the Fuel Pump Module harness connector.

Measure the resistance between ground and the (A109) Fuel Pump

Control Output circuit at the Fuel Pump Module harness connector.

Istheresistancebelow100ohms?

Ye s>>

Repair the short to ground in the (A109) Fuel Pump Control

Output circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 4

4.FUEL PUMP MODULE

Connect the C1 and C10 TIPM harness connectors.

Ignition on, engine not running.

Using the scan tool under the TIPM Actuators, actuate the Fuel Pump.

With a 12-volt test light connected to ground, probe the (A109) Fuel

Pump Control Output circuit at the Fuel Pump Module harness connec-

tor.

Does the test light illuminate brightly and flash on and off?

Ye s>>

Replace the Fuel Pump Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 5

5.TOTALLY INTEGRATED POWER MODULE

NOTE: Before continuing, check the TIPM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors.

Pay particular attention to all Power and Ground circuits.

Were any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace the Totally Integrated Power Module per Service Information.

Perform the BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES - STANDARD PROCEDURE)

Page 857 of 5267

When Monitored:

Ignition on.

Set Condition:

Low voltage detected at the WIF signal circuit at the ECM.

Possible Causes

OTHER DTC’S PRESENT

WATER IN FUEL

ECM

INTERMITTENT CONDITION

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.OTHER DTC’S PRESENT

With the scan tool, read DTCs.

Do you have any additional water in fuel DTC’s?

Ye s>>

Repair other Water in fuel sensor DTC’s first.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 2

2.WAT E R I N F U E L

Using the service publications as a guide, drain the water in fuel separator.

Did the DTC become inactive after draining the water in fuel separator?

Ye s>>

Clear DTC, repair complete.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 3

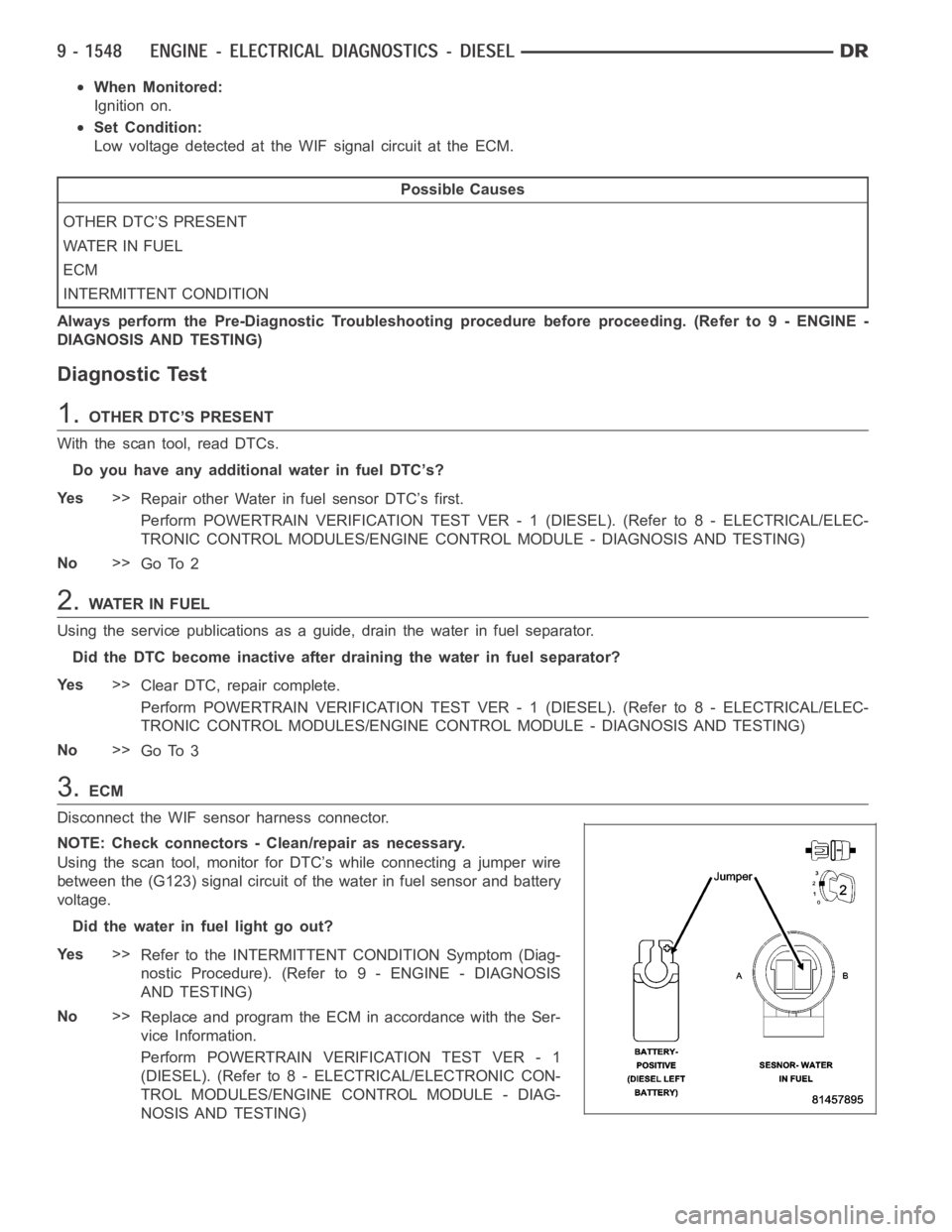

3.ECM

Disconnect the WIF sensor harness connector.

NOTE: Check connectors - Clean/repair as necessary.

Using the scan tool, monitor for DTC’s while connecting a jumper wire

between the (G123) signal circuit of the water in fuel sensor and battery

voltage.

Did the water in fuel light go out?

Ye s>>

Refer to the INTERMITTENT CONDITION Symptom (Diag-

nostic Procedure). (Refer to 9 - ENGINE - DIAGNOSIS

AND TESTING)

No>>

Replace and program the ECM in accordance with the Ser-

vice Information.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

Page 882 of 5267

*CHECKING THE ECM POWER AND GROUNDS

For a complete wiring diagramRefer to Section 8W.

Possible Causes

ECM GROUND CIRCUIT(S) OPEN

FUSED B+ CIRCUIT OPEN

FUSED IGNITION SWITCH OUTPUT CIRCUIT OPEN

Diagnostic Test

1.ECM GROUND CIRCUIT(S) OPEN

Turn the ignition off.

Disconnect the ECM harness connectors.

Using a 12-volt test light connected to 12-volts, check each of the ECM ground circuits in ECM harness connector.

Did the test light illuminate for each cavity?

Ye s>>

Go To 2

No>>

Repair the ECM Ground circuit(s) for an open.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

2.FUSED IGNITION SWITCH OUTPUT CIRCUIT OPEN

Turn the ignition off.

Disconnect the ECM harness connectors.

Turn the ignition on.

Using a 12-volt test light connected to ground, check the Fused Ignition Switch Output circuit in ECM harness con-

nector.

Is the test light on?

Ye s>>

Go To 3

No>>

Repair the Fused Ignition Switch Output circuit for an open.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

3.FUSED B+ CIRCUIT OPEN

Turn the ignition off.

Disconnect the ECM harness connectors.

Using a 12-volt test light connected to ground, check each Fused B+ circuitin the ECM harness connector.

Does the test light illuminatebrightly for each circuit?

Ye s>>

Te s t C o m p l e t e .

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Repair the Fused B+ Output circuit for an open.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 1021 of 5267

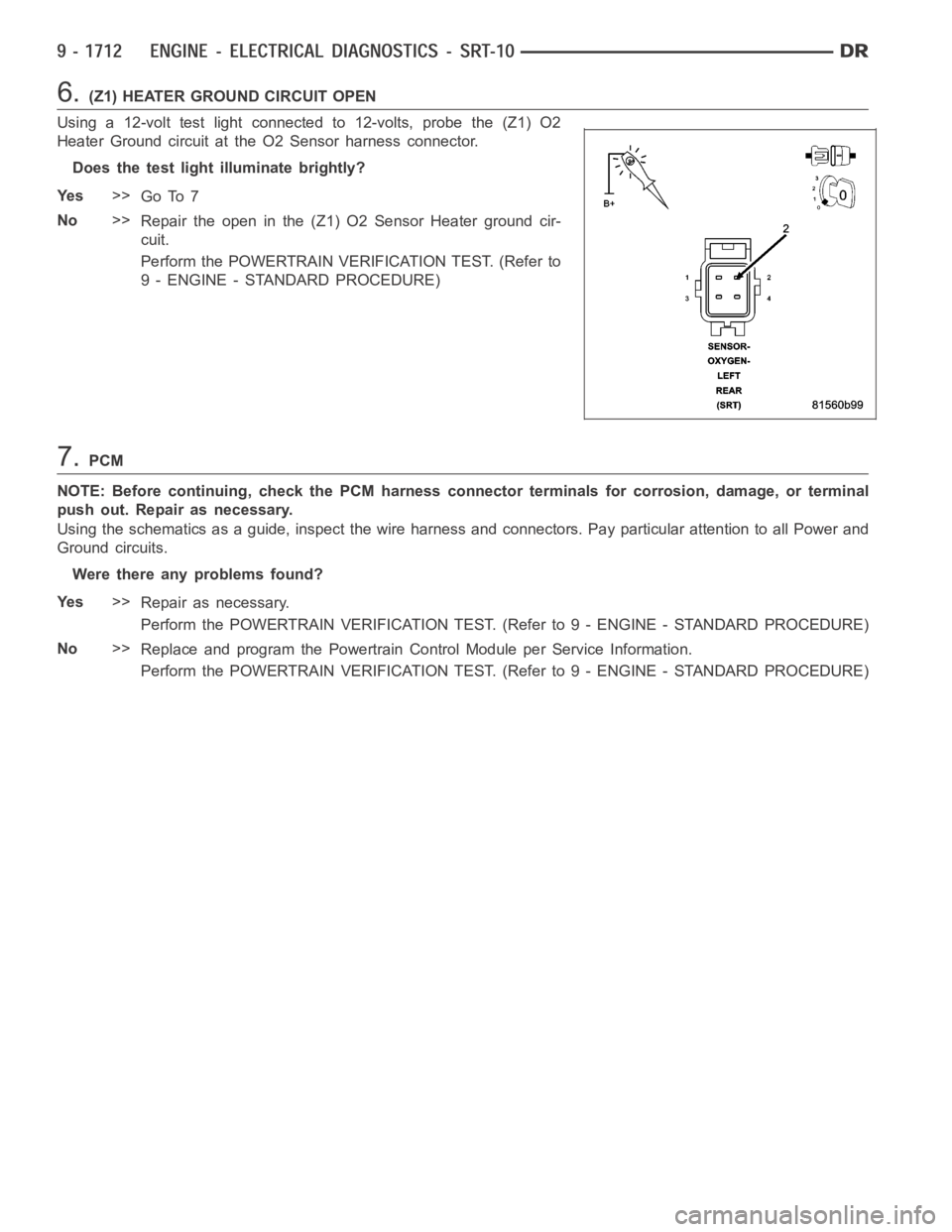

6.(Z1) HEATER GROUND CIRCUIT OPEN

Using a 12-volt test light connected to 12-volts, probe the (Z1) O2

Heater Ground circuit at the O2 Sensor harness connector.

Does the test light illuminate brightly?

Ye s>>

Go To 7

No>>

Repair the open in the (Z1) O2 Sensor Heater ground cir-

cuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

7.PCM

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 1052 of 5267

6.(Z1) HEATER GROUND CIRCUIT OPEN

Using a 12-volt test light connected to 12-volts, probe the (Z1) O2

Heater Ground circuit at the O2 Sensor harness connector.

Does the test light illuminate brightly?

Ye s>>

Go To 7

No>>

Repair the open in the (Z1) O2 Sensor Heater ground cir-

cuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

7.PCM

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 1128 of 5267

NOTE: Lightly tap the bottom of the spark plug on a solid surface. The electrode in the spark plug should

not move.

Does the Spark Plug have any problems?

Ye s>>

Replace the Spark Plug.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 6

6.FUEL PRESSURE CHECK

WARNING: The fuel system is under a constant pressure (even with the engineoff). Before testing or ser-

vicing any fuel system hose, fitting or line, the fuel system pressure mustbe released. Failure to follow

these instructions can result in personal injury or death.

Install a fuel pressure gauge to the fuel rail.

Start the engine and observe the fuel pressure reading.

NOTE: Fuel pressure specification is 407 KPa +/- 34 KPa (59 psi +/- 5 psi).

Choose a conclusion that best matches your fuel pressure reading.

Within Specification

Go To 7

Below Specification

Go To 12

Above Specification

Replace the fuel filter/pressure regulator.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

7.FUEL PRESSURE LEAK DOWN

NOTE: Before continuing visually and physically inspect the fuel delivery system for external leaks or dam-

age. Repair / replace as necessary.

Turn the ignition off.

WARNING: The fuel system is under a constant pressure (even with the engineoff). Before testing or ser-

vicing any fuel system hose, fitting or line, the fuel system pressure mustbe released. Failure to follow

these instructions can result in personal injury or death

Installspecialtool6539(5/16

)or6631(3/8) fuel line adapter.

Install the fuel pressure gauge.

Start the engine and allow the fuel system to reach maximum pressure.

Turn the ignition off.

NOTE: Fuel specification is 407 KPa +/- 34 KPa (59 psi +/- 5 psi).

Using special tool C4390, Hose Clamp Pliers, pinch the rubber fuel line between the fuel pressure gauge and the

engine.

Monitor the fuel pressure gauge for a minimum of 5 minutes.

NOTE: The pressure should not fall below 241 KPa (35 psi)

Does the pressure fall below the listed specification?

Ye s>>

Replace the leaking Fuel Injector(s).

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 8

Page 1129 of 5267

8.FUEL INJECTOR OPERATION

WARNING: The fuel system is under a constant pressure (even with the engineoff). Before testing or ser-

vicing any fuel system hose, fitting or line, the fuel system pressure mustbe released. Failure to follow

these instructions can result in personal injury or death.

CAUTION: After each Fuel Injector actuation, start the engine to clean thecylinder of fuel. Failure to do so

could cause engine damage.

Remove special tool C4390.

Start the engine and allow the fuel pressure to reach maximum pressure.

Ignition on, engine not running.

Using the scan tool, actuate the Fuel Injector for the cylinder that indicated the misfire.

Monitor the fuel pressure gauge.

Does the fuel pressure gauge indicate a drop in fuel pressure?

Ye s>>

Go To 9

No>>

Go To 10

NOTE: Turn the ignition off, remove the Fuel Pressure gauge, and connect the fuel lines before continuing.

9.ENGINE MECHANICAL

Check for any of the following conditions/mechanical problems.

ENGINE VACUUM - must be at least 13 inches in neutral

ENGINE VALVE TIMING - must be within specifications

ENGINE COMPRESSION - must be within specifications

ENGINE EXHAUST SYSTEM - must be free of any restrictions or leaks.

ENGINE PCV SYSTEM - must flow freely

TORQUE CONVERTER STALL SPEED - must be within specifications

POWER BRAKE BOOSTER - no internal vacuum leaks

FUEL - must be free of contamination

CAM LOBES - must not be worn excessively

CYLINDER LEAKAGE TEST - must be within specifications

VALVE SPRINGS - cannot be weak or broken

Are there any engine mechanical problems?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 17

10.FUEL INJECTOR

Turn the ignition off.

Disconnect the Fuel Injector harness connector of the misfiring cylinder.

Ignition on, engine not running.

NOTE: When a Misfire is detected for a particular cylinder, the PCM will shut down that cylinders Injector

Control circuit.

With the scan tool, erase DTCs.

Using a 12-volt test light connected to 12-volts, probe the Injector Control circuit.

With the scan tool, actuate the Fuel Injector.

Does the test light blink/flicker?

Ye s>>

Replace the Fuel Injector.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 11

Page 1131 of 5267

14.IGNITION WIRE

NOTE: If the vehicle being tested does not have an ignition wire answer YES to this test and continue.

Turn the ignition off.

Remove the ignition wire.

Measure the resistance of the ignition wire.

Is the resistance below 10K ohms?

Ye s>>

Go To 14

No>>

Replace the Ignition Wire.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

15.IGNITION COIL

Disconnect the Ignition Coil harness connector.

RemovetheFuelPumpfuseorASDfuse.

Using a 12-volt test light connected to 12-volts, probe the Ignition Coil Control circuit.

Crank the engine for 5 seconds while observing the test light.

Does the test light brightly blink/flicker?

Ye s>>

Replace the Ignition Coil.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 15

16.COIL CONTROL CIRCUIT

Turn the ignition off.

Disconnect the Ignition Coil harness connector.

Disconnect the PCM harness connectors.

CAUTION: Do not probe the PCM harness connectors. Probing the PCM harness connectors will damage

the PCM terminals resulting in poor terminal to pin connection. Install Miller Special Tool 8815 to perform

diagnosis.

Check the Coil Control circuit for an open, short to ground, and short to voltage.

Was a problem found with the Coil Control circuit?

Ye s>>

Repair the Coil Control circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 17

17.PCM

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 1135 of 5267

NOTE: Connect the Fuel Injector harness connector before continuing.

5.SPARK PLUG

Turn the ignition off.

Remove the Spark Plug.

Inspect the Spark Plug for the following conditions.

-Cracks

- Carbon Tracking

- Foreign Material

- Gap size out of specifications

- Loose or broke electrode

NOTE: Lightly tap the bottom of the spark plug on a solid surface. The electrode in the spark plug should

not move.

Were any of the above conditions present?

Ye s>>

Replace the Spark Plug.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 6

6.FUEL PRESSURE CHECK

WARNING: The fuel system is under a constant pressure (even with the engineoff). Before testing or ser-

vicing any fuel system hose, fitting or line, the fuel system pressure mustbe released. Failure to follow

these instructions can result in personal injury or death.

Install a fuel pressure gauge to the fuel rail.

Start the engine and observe the fuel pressure reading.

NOTE: Fuel pressure specification is 407 KPa +/- 34 KPa (59 psi +/- 5 psi).

Choose a conclusion that best matches your fuel pressure reading.

Within Specification

Go To 7

Below Specification

Go To 12

Above Specification

Replace the fuel filter/pressure regulator.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

7.FUEL PRESSURE LEAK DOWN

NOTE: Before continuing visually and physically inspect the fuel delivery system for external leaks or dam-

age. Repair / replace as necessary.

Turn the ignition off.

WARNING: The fuel system is under a constant pressure (even with the engineoff). Before testing or ser-

vicing any fuel system hose, fitting or line, the fuel system pressure mustbe released. Failure to follow

these instructions can result in personal injury or death

Installspecialtool6539(5/16

)or6631(3/8) fuel line adapter.

Install the fuel pressure gauge.

Start the engine and allow the fuel system to reach maximum pressure.

Turn the ignition off.

NOTE: Fuel specification is 407 KPa +/- 34 KPa (59 psi +/- 5 psi).

Using special tool C4390, Hose Clamp Pliers, pinch the rubber fuel line between the fuel pressure gauge and the

engine.

Monitor the fuel pressure gauge for a minimum of 5 minutes.

Page 1137 of 5267

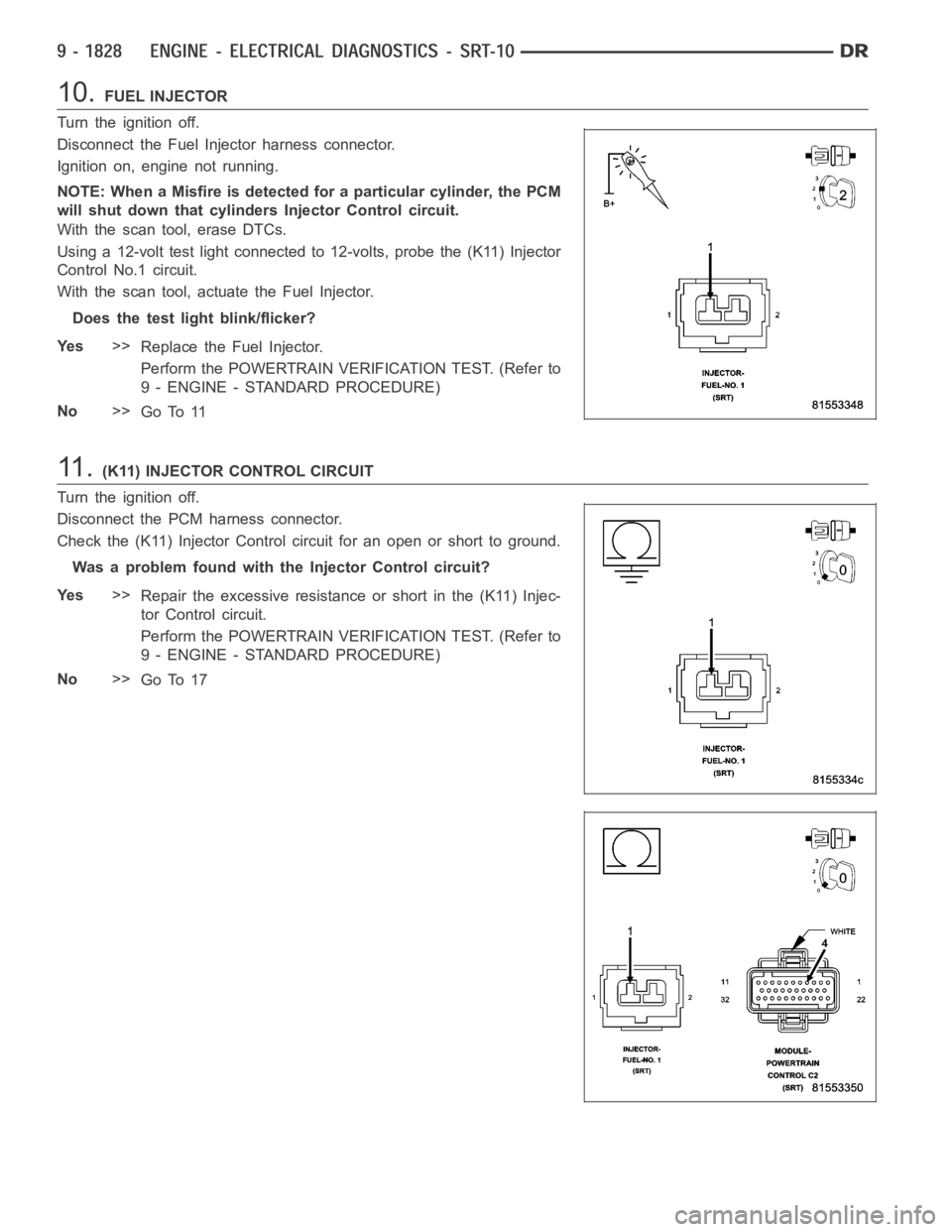

10.FUEL INJECTOR

Turn the ignition off.

Disconnect the Fuel Injector harness connector.

Ignition on, engine not running.

NOTE: When a Misfire is detected for a particular cylinder, the PCM

will shut down that cylindersInjector Control circuit.

With the scan tool, erase DTCs.

Using a 12-volt test light connected to 12-volts, probe the (K11) Injector

Control No.1 circuit.

With the scan tool, actuate the Fuel Injector.

Does the test light blink/flicker?

Ye s>>

Replace the Fuel Injector.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 11

11 .(K11) INJECTOR CONTROL CIRCUIT

Turn the ignition off.

Disconnect the PCM harness connector.

Check the (K11) Injector Control circuit for an open or short to ground.

Was a problem found with the Injector Control circuit?

Ye s>>

Repair the excessive resistanceorshortinthe(K11)Injec-

tor Control circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 17