display DODGE RAM SRT-10 2006 Service Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1407 of 5267

When Monitored:

With ignition key on, battery voltage above 10.4 volts, and engine RPM greater than 400.

Set Condition:

No voltage sensed at the PCM when the ASD Relay is energized.

Possible Causes

GOOD TRIP EQUAL TO ZERO

ASD RELAY

(A14) FUSED B+ CIRCUITS

(K342) ASD RELAY OUTPUT CIRCUIT OPEN

(K342) ASD OUTPUT CIRCUIT OPEN

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

1.GOOD TRIP EQUAL TO ZERO

Ignition on, engine not running.

With the scan tool, read DTCs and record the related Freeze Frame data.

Is the Good Trip Counter displayed and equal to zero?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITIONSymptom (Diagnostic Procedure).

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.ENGINE STARTING STATUS

Attempt to start the engine.

Did the engine start?

Ye s>>

Go To 3

No>>

Go To 4

3.(K342) ASD OUTPUT CIRCUIT OPEN

Turn the ignition off.

Remove the ASD Relay from the PDC.

Disconnect the PCM harness connectors.

Measure the resistance of the (K342) ASD Relay Output circuit from the ASD Relay cavity in the PDC to the PCM

harness connector.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 7

No>>

Repair the open in the (K342)ASD Relay Output circuit.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 1416 of 5267

When Monitored:

Immediately after a cold start, with battery/ambient temperature between 40 deg. F and 90 Deg. F and coolant

temperature within 10 Deg. F of battery/ambient.

Set Condition:

LDP test must pass first. If the PCM suspects a pinched hose it will not set a fault until it runs the EVAP purge

flow monitor. If the purge monitor does not pass then the pinched hose faultwill be set.

Possible Causes

EVAP CANISTER OBSTRUCTED

OBSTRUCTION IN HOSE/TUBE BETWEEN EVAP CANISTER AND PURGE SOLENOID

LDP PRESSURE HOSE OBSTRUCTED

LEAK DETECTION PUMP

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.VEHICLE HISTORY AND SERVICE BULLETIN INVESTIGATION

Ignition on, engine not running.

With a scan tool, read DTCs and record the related Freeze Frame data if any DTC(s) are present.

Whether or not any DTC(s) are present you will want to check the following items which may assist in repairing the

customer’s complaint successfully.

Check the vehicles repair history.

If the vehicle has a repair history that pertains to the customer’s currentcomplaint, review the repair.

Inspect the vehicle for any aftermarket accessories that may have been installed incorrectly.

Check for any service bulletin(s) related to the customer’s complaint or DTC(s).

If a service bulletin applies, follow the instructions per the service bulletin.

Choose the following scenario that best applies.

The service bulletin repaired the customer’s complaint.

Testing complete.

A DTC is present, no service bulletins apply, or the service bulletin didn’t repair the customer’s complaint.

Go To 2

2.GOOD TRIP EQUAL TO ZERO

Ignition on, engine not running.

With the scan tool, read DTCs.

Is the Good Trip Counter displayed and equal to zero?

Ye s>>

Go To 3

No>>

Go To 8

Page 1427 of 5267

When Monitored:

Immediately after a cold start, with battery/ambient temperature between 40 Deg. F and 90 Deg. F and coolant

temperature within 10 Deg. F of battery/ambient.

Set Condition:

The state of the switch does not change when the solenoid is energized.

Possible Causes

GOOD TRIP EQUAL TO ZERO

LDP VACUUM SUPPLY

LEAK DETECTION PUMP

(K107) LDP SWITCH SENSE CIRCUIT OPEN

(K107) LDP SWITCH SENSE CIRCUIT SHORTED TO GROUND

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.VEHICLE HISTORY AND SERVICE BULLETIN INVESTIGATION

Ignition on, engine not running.

With a scan tool, read DTCs and record the related Freeze Frame data if any DTC(s) are present.

Whether or not any DTC(s) are present you will want to check the following items which may assist in repairing the

customer’s complaint successfully.

Check the vehicles repair history.

If the vehicle has a repair history that pertains to the customer’s currentcomplaint, review the repair.

Inspect the vehicle for any aftermarket accessories that may have been installed incorrectly.

Check for any service bulletin(s) related to the customer’s complaint or DTC(s).

If a service bulletin applies, follow the instructions per the service bulletin.

Choose the following scenario that best applies.

The service bulletin repaired the customer’s complaint.

Testing complete.

A DTC is present, no service bulletins apply, or the service bulletin didn’t repair the customer’s complaint.

Go To 2

2.GOOD TRIP EQUAL TO ZERO

Check for any related TSBs.

Ignition on, engine not running.

With the scan tool, read DTCs and record the related Freeze Frame data.

Is the Good Trip Counter displayed and equal to zero?

Ye s>>

Go To 3

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 1431 of 5267

When Monitored:

Continuously when the ignition is on and battery voltage is greater than 10.4 volts.

Set Condition:

The state of the solenoid circuit does not match the PCM’s desired state.

Possible Causes

(K125) GENERATOR SOURCE CIRCUIT OPEN

(K107) LDP SWITCH SIGNAL CIRCUIT OPEN

(K107) LDP SWITCH SIGNAL CIRCUIT SHORTED TO GROUND

(K106) LEAK DETECTION PUMP SOLENOID CONTROL CIRCUIT OPEN

(K106) LDP SOLENOID CONTROL CIRCUIT SHORTED TO GROUND

LEAK DETECTION PUMP

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.VEHICLE HISTORY AND SERVICE BULLETIN INVESTIGATION

Ignition on, engine not running.

With a scan tool, read DTCs and record the related Freeze Frame data if any DTC(s) are present.

Whether or not any DTC(s) are present you will want to check the following items which may assist in repairing the

customer’s complaint successfully.

Check the vehicles repair history.

If the vehicle has a repair history that pertains to the customer’s currentcomplaint, review the repair.

Inspect the vehicle for any aftermarket accessories that may have been installed incorrectly.

Check for any service bulletin(s) related to the customer’s complaint or DTC(s).

If a service bulletin applies, follow the instructions per the service bulletin.

Choose the following scenario that best applies.

The service bulletin repaired the customer’s complaint.

Testing complete.

A DTC is present, no service bulletins apply, or the service bulletin didn’t repair the customer’s complaint.

Go To 2

2.GOOD TRIP EQUAL TO ZERO

Ignition on, engine not running.

With the scan tool, read DTCs.

Is the Good Trip Counter displayed and equal to zero?

Ye s>>

Go To 3

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 1456 of 5267

When Monitored:

With the ignition on.

Set Condition:

The PCM has not received an expected Cluster Status Bus message from the instrument cluster within the last

20 seconds.

Possible Causes

(D25) OPEN BETWEEN PCM AND CLUSTER

(D25) SHORTED BETWEEN PCM AND CLUSTER

CLUSTER

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.NO CLUSTER BUS MESSAGE

Ignition on, engine not running.

With the scan tool, erase DTCs.

Cycle the ignition key on and off several times.

With the scan tool, read DTCs.

Does the DTC reset?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.COMMUNICATE WITH CLUSTER

Ignition on, engine not running.

With the scan tool, attempt to communicate with the Instrument cluster.

Can communication be established with the Instrument Cluster?

Ye s>>

Go To 3

No>>

Refer to the Communication Category of the Body Diagnostic Manual and perform the appropriate

symptom related to no communication with cluster.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

3.INSTRUMENT CLUSTER OPERATION

Start the engine

Allow the engine to idle.

Is the correct engine speed display in the instrument cluster (Tach)?

Ye s>>

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Refer to the Instrument Category in the Body Diagnostic Manual and performthe appropriate symptom.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 1460 of 5267

P1696-PCM FAILURE EEPROM WRITE DENIED

For a complete wiring diagramRefer to Section 8W.

When Monitored:

Ignition on and battery voltage greater than 10 volts.

Set Condition:

An attempt to program/write to the internal EEPROM failed, also checks at powerdown.

Possible Causes

SRI MILEAGE INVALID

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.SCAN TOOL DISPLAYS WRITE FAILURE

Ignition on, engine not running.

With the scan tool, perform the SRI Memory Test.

Does the scan tool display Write Failure?

Ye s>>

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 2

2.SCAN TOOL DISPLAYS WRITE REFUSED

With the scan tool, perform the SRI Memory Test.

Does the scan tool display Write Refused?

Ye s>>

Go To 3

No>>

Go To 4

3.PCM REFUSED 2ND TEST

With the scan tool, perform the SRI Memory Test a second time.

NOTE: Retest the SRI Memory two more times.

Does the scan tool display Write Refused again?

Ye s>>

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Te s t C o m p l e t e .

4.SCAN TOOL DISPLAYS SRI MILEAGE INVALID

With the scan tool, perform the SRI Memory Test.

Does the scan tool display SRI Mileage Invalid?

Ye s>>

Update the mileage and retest the SRI Memory.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 5

Page 1461 of 5267

5.COMPARE SRI MILEAGE WITH ODOMETER

Compare the SRI Mileage stored with the Instrument Panel Odometer.

Is the mileage within the specified range displayed on the scan tool?

Ye s>>

Te s t C o m p l e t e .

No>>

Update the mileage and retest the SRI Memory.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 1463 of 5267

Possible Causes

(A103) FUSED B+ CIRCUIT

(Z429) BRAKE LAMP SWITCH GROUND CIRCUIT OPEN

BRAKE LAMP SWITCH

(B29) BRAKE SWITCH NO.1 SIGNAL CIRCUIT OPEN

(B29) BRAKE SWITCH NO.1 SIGNAL CIRCUIT SHORT TO GROUND

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.SCAN TOOL DOES NOT SHOW BRAKE SW PRESSED OR RELEASED

Ignition on, engine not running.

With the scan tool in Inputs/Outputs, read the Brake Switch state.

While observing the scan tool display, press and release the brake pedal several times.

Does the scan tool display Brake Switch PRESSED and RELEASED?

Ye s>>

The Brake Lamp Switch is operating properly at this time.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 2

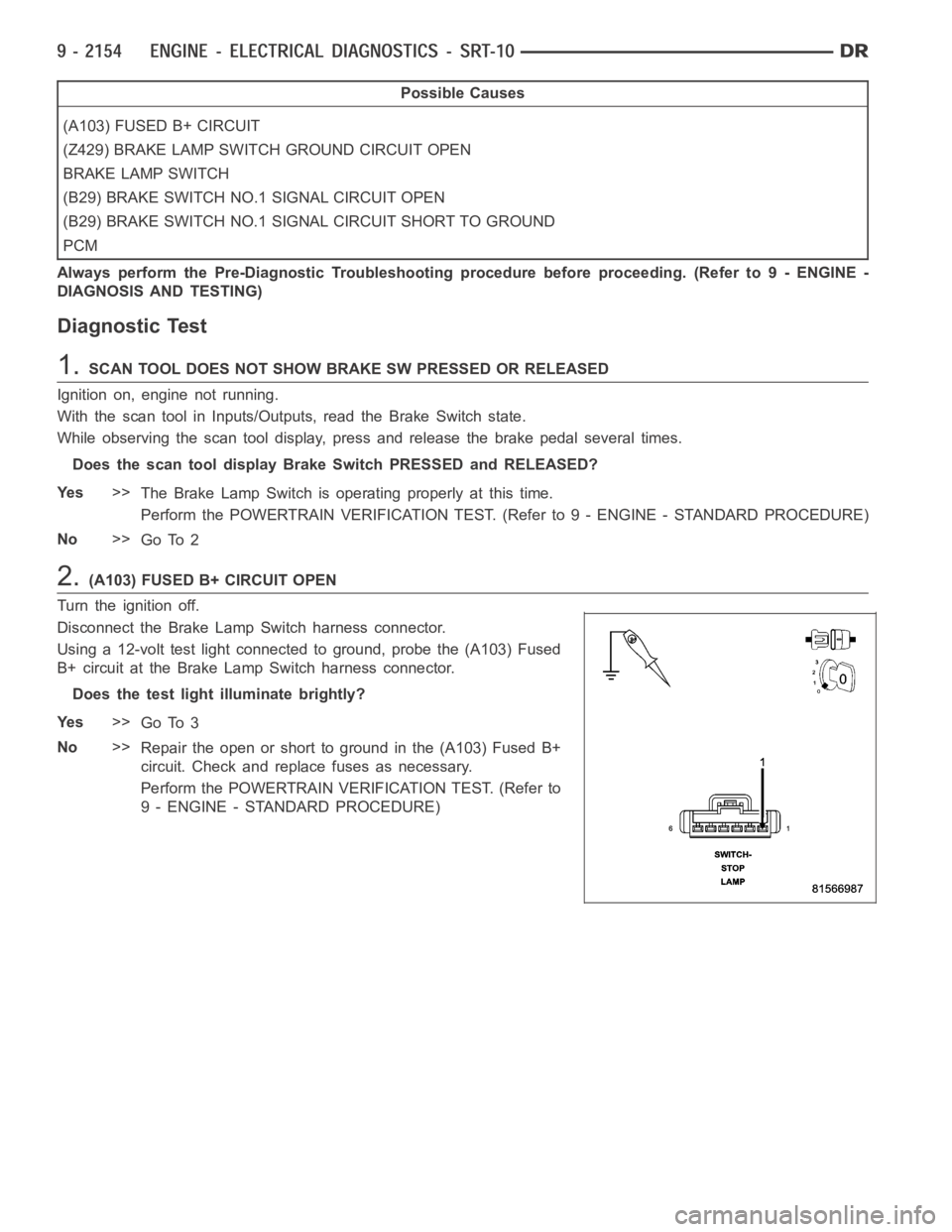

2.(A103) FUSED B+ CIRCUIT OPEN

Turn the ignition off.

Disconnect the Brake Lamp Switch harness connector.

Using a 12-volt test light connected to ground, probe the (A103) Fused

B+ circuit at the Brake Lamp Switch harness connector.

Does the test light illuminate brightly?

Ye s>>

Go To 3

No>>

Repair the open or short to ground in the (A103) Fused B+

circuit. Check and replace fuses as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

Page 2909 of 5267

42RLE TRANSMISSION VERIFICATION TEST - VER 1

1.

Perform the following after completion of a diagnostic repair:

Note: After completion of the Transmission Verification Test, the Powertrain Verification Test must be

performed. Refer to the Engine Category.

Reconnect any disconnected components.

With the scan tool, erase all Transmission and Engine DTCs.

Erase DTC P0700 under engine to turn off the MIL off after completion of transmission repairs.

Perform *PRNDL FAULT CLEARING PROCEDURE after completion of repairs for P0706-TRANSMISSION

RANGE SENSOR RATIONALITY.

If the Powertrain Control Module or the Transmission has been repaired or replaced, it is necessary to perform

the scan tool Quick Learn Procedure.

If the Torque converter has been replaced, with the scan tool perform TCC BREAK-IN.

If the Powertrain Control Module or Front Control Module has been replacedyoumustresetthePinionFactor

in the Front Control Module.

With the scan tool, display Transmission Temperature. Start and run the engine until the Transmission Tem-

perature is HOT, above 43° C or 110° F.

Check the transmission fluid and adjust if necessary. Refer to the ServiceInformation for the Fluid Fill proce-

dure.

Road test the vehicle. With the scan tool, monitor the engine RPM. Make 15 to20 1-2, 2-3, 3-4 upshifts.

Perform these shifts from a standing start to 45 mph with a constant throttleopeningof20to25degrees.

With speeds below 25 MPH, make 5 to 8 wide open throttle kickdowns to 1st gear. Allow at least 5 seconds

each in 2nd and 3rd gear between each kickdown.

For a specific DTC, drive the vehicle to the Symptom’s When Monitored/WhenSet conditions to verify the DTC

is repaired.

If equipped with AutoStick, upshift and downshift several times using the AutoStickfeature during the road

test.

Note: Use the OBDII task manager to run a Good Trip in each gear, this will confirm the repair and to

ensure that the DTC has not re-matured.

Check for any Diagnostic Trouble Codes (DTCs) during and after the road test.

Did any Diagnostic Trouble Codes set during the road test?

Ye s>>

Repair is not complete. Refer to the Transmission category and perform theappropriate symptom(s).

(Refer to 21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 42RLE - DIAGNOSIS AND TESTING)

No>>

Repair is complete.

Page 2922 of 5267

TEST THREE - SELECTOR IN DRIVE (OD OFF - Third and Second Gear)

NOTE: This test checks the overdrive clutch hydraulic circuit as well as the shift schedule.

1. Attach gauge to the overdrive clutch tap.

2. Move selector lever to the DRIVE position.

3. Allow vehicle wheels to turn and increase throttle opening to achieve anindicated vehicle speed of 20 mph.

4. Overdrive clutch pressure should read 74 to 95 psi.

5. Move selector lever to the DRIVE position and increase indicated vehicle speed to 30 mph.

6. The vehicle should be in second gearand overdrive clutch pressure shouldbelessthan5psi.

TEST FOUR - SELECTOR IN DRIVE (OD ON - Fourth Gear)

NOTE: This test checks the 2/4 clutch hydraulic circuit.

1. Attach gauge to the 2/4 clutch tap.

2. Move selector lever to the DRIVE position.

3. Allow vehicle front wheels to turn and increase throttle opening to achieve an indicated vehicle speed of 30 mph.

Vehicleshouldbeinfourthgear.

4. The 2/4 clutch pressure should read 75 to 95 psi.

TEST FIVE-SELECTOR IN DRIVE (OD ON - Fourth Gear, CC on)

NOTE: These tests check the torque converter clutch hydraulic circuit.

1. Attach gauge to the torque converter clutch off pressure tap.

2. Move selector lever to the DRIVE position.

3. Allow vehicle wheels to turn and increase throttle opening to achieve anindicated vehicle speed of 50 mph.

Vehicle should be in 4th gear, CC on.

CAUTION: Both wheels must turn at the same speed.

4. Torque converter clutch off pressure should be less than 5 psi.

5. Now attach the gauge to the torque converter clutch on pressure tap.

6. Move selector to the OD position.

7. Allow vehicle wheels to turn and increase throttle opening to achieve anindicated vehicle speed of 50 mph.

8. Verify the torque converter clutch is applied mode using the RPM displayof the scan tool.

9. Torque converter clutch on pressure should be 60-90 psi.

TEST SIX-SELECTOR IN REVERSE

NOTE: This test checks the reverse clutch hydraulic circuit.

1. Attach gauge to the reverse and low/reverse clutch tap.

2. Move selector lever to the REVERSE position.

3. Read reverse clutch pressure with output stationary (foot on brake) andthrottle opened to achieve 1500 rpm.

4. Reverse and low/reverse clutch pressure should read 165 to 235 psi.

TEST RESULT INDICATIONS

1. If proper line pressure is found in any one test, the pump and pressure regulator are working properly.

2. Low pressure in all positions indicates a defective pump, a clogged filter, or a stuck pressure regulator valve.

3. Clutch circuit leaks are indicated if pressures do not fall within the specified pressure range.

4. If the overdrive clutch pressure is greater than 5 psi in Step 6 of Test Three, a worn reaction shaft seal ring or

a defective solenoid assembly is indicated.