display DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 5193 of 5267

EMISSIONS CONTROL

DESCRIPTION

STATE DISPLAY TEST MODE

The switch inputs to the Powertrain Control Module (PCM) have two recognized states; HIGH and LOW. For this

reason, the PCM cannot recognize the difference between a selected switchposition versus an open circuit, a short

circuit, or a defective switch. If the State Display screen shows the changefromHIGHtoLOWorLOWtoHIGH,

assume the entire switch circuit to the PCM functions properly. Connect the DRB scan tool to the data link con-

nector and access the state display screen. Then access either State Display Inputs and Outputs or State Display

Sensors.

CIRCUIT ACTUATION TEST MODE

The Circuit Actuation Test Mode checks for proper operation of output circuits or devices the Powertrain Control

Module (PCM) may not internally recognize. The PCM attempts to activate these outputs and allow an observer to

verify proper operation. Most of the tests provide an audible or visual indication of device operation (click of relay

contacts, fuel spray, etc.). Except for intermittent conditions, if a device functions properly during testing, assume the

device, its associated wiring, and driver circuit work correctly. Connect the DRB scan tool to the data link connector

and access the Actuators screen.

DIAGNOSTIC TROUBLE CODES

A Diagnostic Trouble Code (DTC) indicates the PCM has recognized an abnormal condition in the system.

Remember that DTC’s are the results of a system or circuit failure, but do not directly identify the failed

component or components.

BULB CHECK

Each time the ignition key is turned to the ON position, the malfunction indicator (check engine) lamp on the instru-

ment panel should illuminate for approximately 2 seconds then go out. Thisis done for a bulb check.

OBTAINING DTC’S USING DRB SCAN TOOL

1. Obtain the applicable Powertrain Diagnostic Manual.

2. Obtain the DRB Scan Tool.

3. Connect the DRB Scan Tool to the data link (diagnostic) connector. This connector is located in the passenger

compartment at the lower edge of instrument panel, and near the steering column.

4. Turn the ignition switch on and access the “Read Fault” screen.

5. Record all the DTC’s and “freeze frame” information shown on the DRB scantool.

6. To erase DTC’s, use the “Erase Trouble Code” data screen on the DRB scan tool.Do not erase any DTC’s

until problems have been investigated and repairs have been performed.

TA S K M A N A G E R

The PCM is responsible for efficiently coordinating the operation of all the emissions-related components. The PCM

is also responsible for determining if the diagnostic systems are operating properly. The software designed to carry

out these responsibilities is called the ’Task Manager’.

MONITORED SYSTEMS

There are new electronic circuit monitors that check fuel, emission, engine and ignition performance. These moni-

tors use information from various sensor circuits to indicate the overalloperation of the fuel, engine, ignition and

emission systems and thus the emissions performance of the vehicle.

The fuel, engine, ignition and emission systems monitors do not indicate aspecific component problem. They do

indicate that there is an implied problem within one of the systems and thata specific problem must be diagnosed.

If any of these monitors detect a problem affecting vehicle emissions, theMalfunction Indicator Lamp (MIL) will be

illuminated. These monitors generate Diagnostic Trouble Codes that can be displayed with the MIL or a scan tool.

Page 5197 of 5267

COMPONENT MONITORS

There are several components that will affect vehicle emissions if they malfunction. If one of these components

malfunctions the Malfunction Indicator Lamp (MIL) will illuminate.

Some of the component monitors are checking for proper operation of the part. Electrically operated components

now have input (rationality) and output (functionality) checks. Previously, a component like the Throttle Position sen-

sor (TPS) was checked by the PCM for an open or shorted circuit. If one of these conditions occurred, a DTC was

set. Now there is a check to ensure that the component is working. This is donebywatchingforaTPSindication

of a greater or lesser throttle opening than MAP and engine rpm indicate. Inthe case of the TPS, if engine vacuum

is high and engine rpm is 1600 or greater, and the TPS indicates a large throttle opening, a DTC will be set. The

same applies to low vacuum if the TPS indicates a small throttle opening.

All open/short circuit checks, or any component that has an associated limp-in, will set a fault after 1 trip with the

malfunction present. Components without an associated limp-in will taketwo trips to illuminate the MIL.

OPERATION

OPERATION

The Powertrain Control Module (PCM) monitors many

different circuits in the fuel injection, ignition, emission

and engine systems. If the PCM senses a problem

withamonitoredcircuitoftenenoughtoindicatean

actual problem, it stores a Diagnostic Trouble Code

(DTC) in the PCM’s memory. If the problem is repaired

or ceases to exist, the PCM cancels the code after 40

warm-up cycles. Diagnostic trouble codes that affect

vehicle emissions illuminatethe Malfunction Indicator

Lamp (MIL). The MIL is displayed as an engine icon

(graphic) on the instrument panel. Refer to Malfunction

Indicator Lamp in this section.

Certain criteria must be met before the PCM stores a

DTC in memory. The criteria may be a specific range

of engine RPM, engine temperature, and/or input volt-

age to the PCM.

The PCM might not store a DTC for a monitored cir-

cuit even though a malfunction has occurred. This

may happen because one of the DTC criteria for the

circuit has not been met.For example,assume the diagnostic trouble code criteria requires the PCM to monitor the

circuit only when the engine operates between 750 and 2000 RPM. Suppose thesensor’s output circuit shorts to

ground when engine operates above 2400 RPM (resulting in 0 volt input to thePCM). Because the condition hap-

pens at an engine speed above the maximum threshold (2000 rpm), the PCM willnot store a DTC.

There are several operating conditions for which the PCM monitors and setsDTC’s. Refer to Monitored Systems,

Components, and Non-Monitored Circuits in this section.

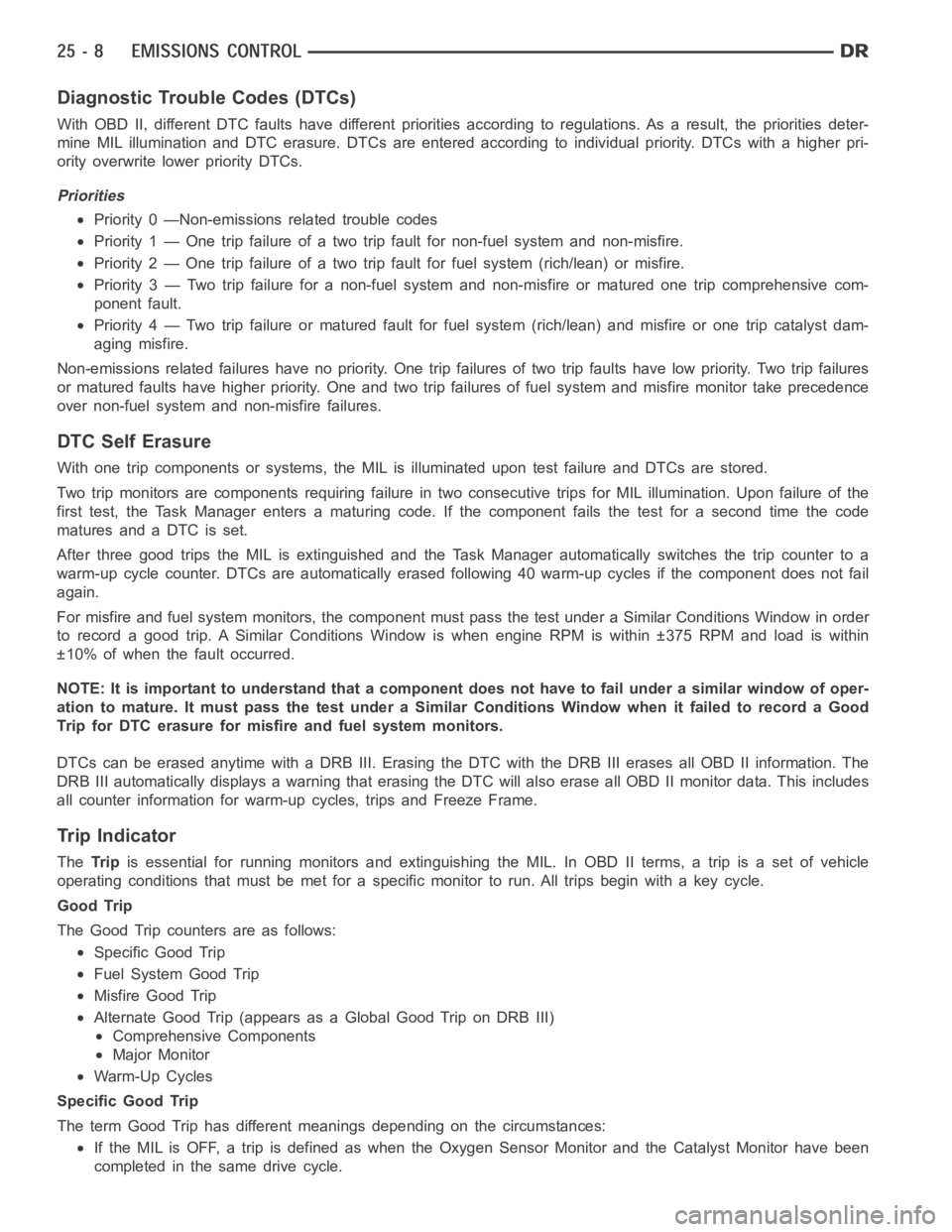

Technicians must retrieve stored DTC’s by connecting the DRB scan tool (oran equivalent scan tool) to the 16–way

data link connector. The connector is located on the bottom edge of the instrument panel near the steering column.

NOTE: Various diagnostic procedures may actually cause a diagnostic monitor to set a DTC. For instance,

pulling a spark plug wire to perform a spark test may set the misfire code. When a repair is completed and

verified, connect the DRB scan tool to the 16–way data link connector (1) toerase all DTC’s and extinguish

the MIL.

Page 5199 of 5267

Diagnostic Trouble Codes (DTCs)

With OBD II, different DTC faults have different priorities according to regulations. As a result, the priorities deter-

mine MIL illumination and DTC erasure. DTCs are entered according to individual priority. DTCs with a higher pri-

ority overwrite lower priority DTCs.

Priorities

Priority 0 —Non-emissions related trouble codes

Priority 1 — One trip failure of a two trip fault for non-fuel system and non-misfire.

Priority 2 — One trip failure of a two trip fault for fuel system (rich/lean)or misfire.

Priority 3 — Two trip failure for a non-fuel system and non-misfire or matured one trip comprehensive com-

ponent fault.

Priority 4 — Two trip failure or matured fault for fuel system (rich/lean) and misfire or one trip catalyst dam-

aging misfire.

Non-emissions related failures have no priority. One trip failures of twotrip faults have low priority. Two trip failures

or matured faults have higher priority. One and two trip failures of fuel system and misfire monitor take precedence

over non-fuel system and non-misfire failures.

DTC Self Erasure

With one trip components or systems,the MIL is illuminated upon test failure and DTCs are stored.

Two trip monitors are components requiring failure in two consecutive trips for MIL illumination. Upon failure of the

first test, the Task Manager enters a maturing code. If the component failsthe test for a second time the code

matures and a DTC is set.

After three good trips the MIL is extinguished and the Task Manager automatically switches the trip counter to a

warm-up cycle counter. DTCs are automatically erased following 40 warm-up cycles if the component does not fail

again.

For misfire and fuel system monitors, the component must pass the test under a Similar Conditions Window in order

to record a good trip. A Similar Conditions Window is when engine RPM is within ±375 RPM and load is within

±10% of when the fault occurred.

NOTE: It is important to understand that a component does not have to fail under a similar window of oper-

ation to mature. It must pass the test under a Similar Conditions Window whenitfailedtorecordaGood

Trip for DTC erasure for misfire and fuel system monitors.

DTCs can be erased anytime with a DRB III. Erasing the DTC with the DRB III erases all OBD II information. The

DRB III automatically displays a warning that erasing the DTC will also erase all OBD II monitor data. This includes

all counter information for warm-up cycles, trips and Freeze Frame.

Trip Indicator

TheTri pis essential for running monitors and extinguishing the MIL. In OBD II terms,atripisasetofvehicle

operating conditions that must be met for a specific monitor to run. All trips begin with a key cycle.

Good Trip

The Good Trip counters are as follows:

Specific Good Trip

Fuel System Good Trip

Misfire Good Trip

Alternate Good Trip (appears as a Global Good Trip on DRB III)

Comprehensive Components

Major Monitor

Warm-Up Cycles

Specific Good Trip

The term Good Trip has different meanings depending on the circumstances:

If the MIL is OFF, a trip is defined as when the Oxygen Sensor Monitor and the Catalyst Monitor have been

completed in the same drive cycle.

Page 5200 of 5267

If the MIL is ON and a DTC was set by the Fuel Monitor or Misfire Monitor (both continuous monitors), the

vehicle must be operated in the Similar Condition Window for a specified amount of time.

If the MIL is ON and a DTC was set by a Task Manager commanded once-per-trip monitor (such as the Oxy-

gen Sensor Monitor, Catalyst Monitor, Purge Flow Monitor, Leak DetectionPump Monitor, EGR Monitor or

Oxygen Sensor Heater Monitor), a good trip is when the monitor is passed on the next start-up.

If the MIL is ON and any other emissions DTC was set (not an OBD II monitor), a good trip occurs when the

Oxygen Sensor Monitor and Catalyst Monitor have been completed, or two minutes of engine run time if the

Oxygen Sensor Monitor and Catalyst Monitor have been stopped from running.

Fuel System Good Trip

To count a good trip (three required) and turn off the MIL, the following conditions must occur:

Engine in closed loop

Operating in Similar Conditions Window

Short Term multiplied by Long Term less than threshold

Less than threshold for a predetermined time

If all of the previous criteria are met, the PCM will count a good trip (threerequired) and turn off the MIL.

Misfire Good Trip

If the following conditions are met the PCM will count one good trip (three required) in order to turn off the MIL:

Operating in Similar Condition Window

1000 engine revolutions with no misfire

Warm-Up Cycles

Once the MIL has been extinguished by the Good Trip Counter, the PCM automatically switches to a Warm-Up

CycleCounterthatcanbeviewedontheDRBIII.Warm-UpCyclesareusedtoerase DTCs and Freeze Frames.

Forty Warm-Up cycles must occur in order for the PCM to self-erase a DTC and Freeze Frame. A Warm-Up Cycle

is defined as follows:

Engine coolant temperature must start below and rise above 160° F (71.1°C).

Engine coolant temperature must rise by 40° F (4.4°C)

No further faults occur

Freeze Frame Data Storage

Once a failure occurs, the Task Manager records several engine operating conditions and stores it in a Freeze

Frame. The Freeze Frame is considered one frame of information taken by an on-board data recorder. When a fault

occurs, the PCM stores the input data from various sensors so that technicians can determine under what vehicle

operating conditions the failure occurred.

The data stored in Freeze Frame is usually recorded when a system fails the first time for two trip faults. Freeze

Frame data will only be overwritten by a different fault with a higher priority.

CAUTION: Erasing DTCs, either with the DRB III or by disconnecting the battery, also clears all Freeze

Frame data.

Similar Conditions Window

The Similar Conditions Window displays information about engine operation during a monitor. Absolute MAP (engine

load) and Engine RPM are stored in this window when a failure occurs. There are two different Similar conditions

Windows: Fuel System and Misfire.

FUEL SYSTEM

Fuel System Similar Conditions Window— An indicator that ’Absolute MAP When Fuel Sys Fail’ and ’RPM

When Fuel Sys Failed’ are all in the same range when the failure occurred. Indicated by switching from ’NO’

to ’YES’.

Absolute MAP When Fuel Sys Fail— The stored MAP reading at the time of failure. Informs the user at

what engine load the failure occurred.

Absolute MAP— A live reading of engine load to aid the user in accessing the Similar Conditions Window.

RPM When Fuel Sys Fail— The stored RPM reading at the time of failure. Informs the user at what engine

RPM the failure occurred.