oil type DODGE RAM SRT-10 2006 Service Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2090 of 5267

COOLER & LINES-OIL

DESCRIPTION

An engine oil cooler is used on all models. The cooler is a coolant-to-oil type and mounted on the right front inner

fender.

OPERATION

Engine oil travels from the oil pump and filter to the oil cooler via an oil supply line. The oil is cooled and returned

to the engine via an oil return line. Engine oil is then pumped into the main oil gallery. Engine coolant flows into the

cooler from the heater return hose and exits into the water pump inlet nipple.

STANDARD PROCEDURE - OIL COOLER LINE QUICK CONNECT FITTING

DISASSEMBLY/ASSEMBLY

DISASSEMBLY

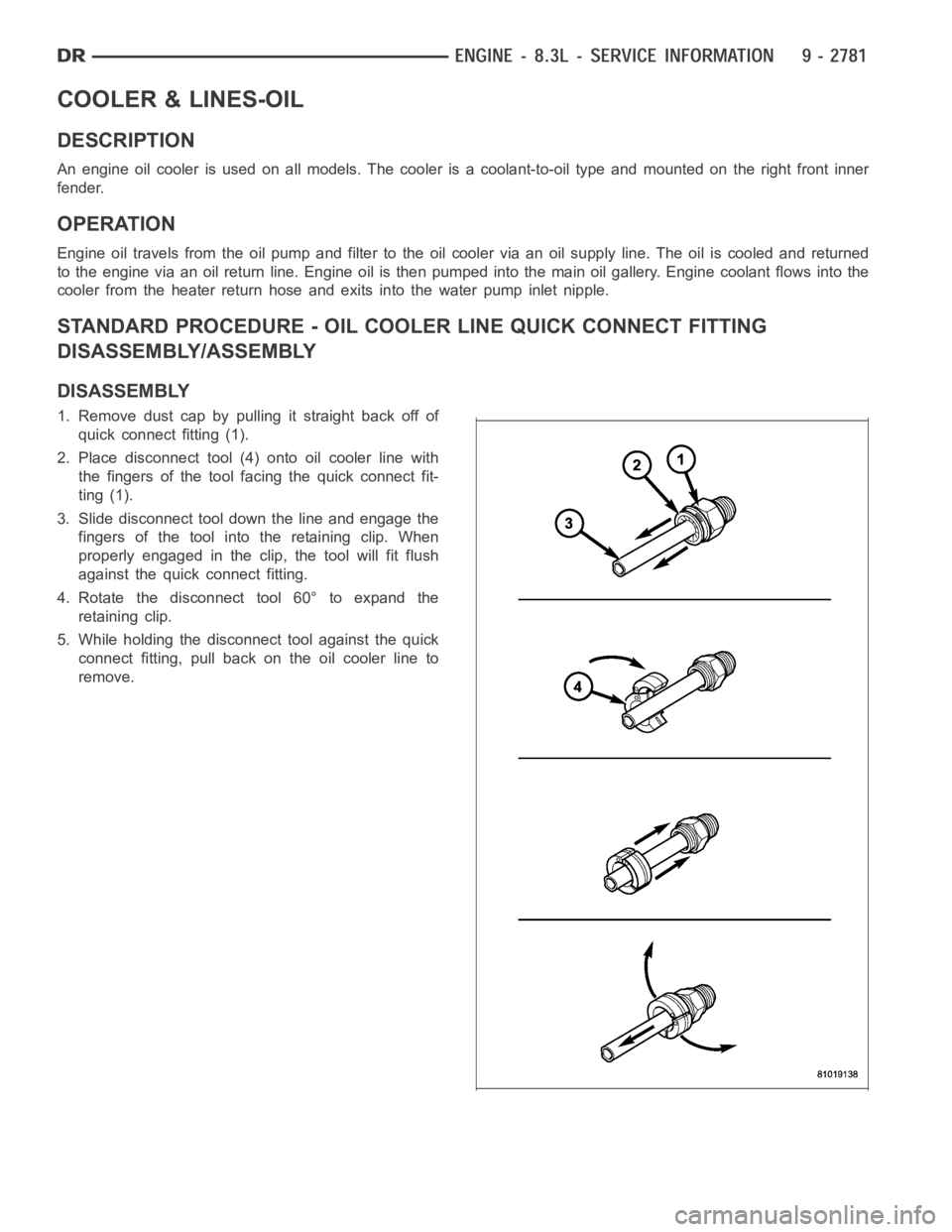

1. Remove dust cap by pulling it straight back off of

quick connect fitting (1).

2. Place disconnect tool (4) onto oil cooler line with

the fingers of the tool facing the quick connect fit-

ting (1).

3. Slide disconnect tool down the line and engage the

fingers of the tool into the retaining clip. When

properly engaged in the clip, the tool will fit flush

against the quick connect fitting.

4. Rotate the disconnect tool 60° to expand the

retaining clip.

5. While holding the disconnect tool against the quick

connect fitting, pull back on the oil cooler line to

remove.

Page 2104 of 5267

BLOCK-ENGINE

DESCRIPTION

The cylinder block is made of a sand-cast aluminum alloy. The cylinder block has interference-fit cast iron cylinder

liners. The cylinder liners are thermally installed during block manufacturing; they are not serviceable items.

Six iron main bearing caps use four bolts per cap; two vertical and two horizontal. A crankshaft oil scraper is

attached to the main bearing caps via extended main bearing cap bolts and nuts.

STANDARD PROCEDURE - CYLINDER BORE HONING

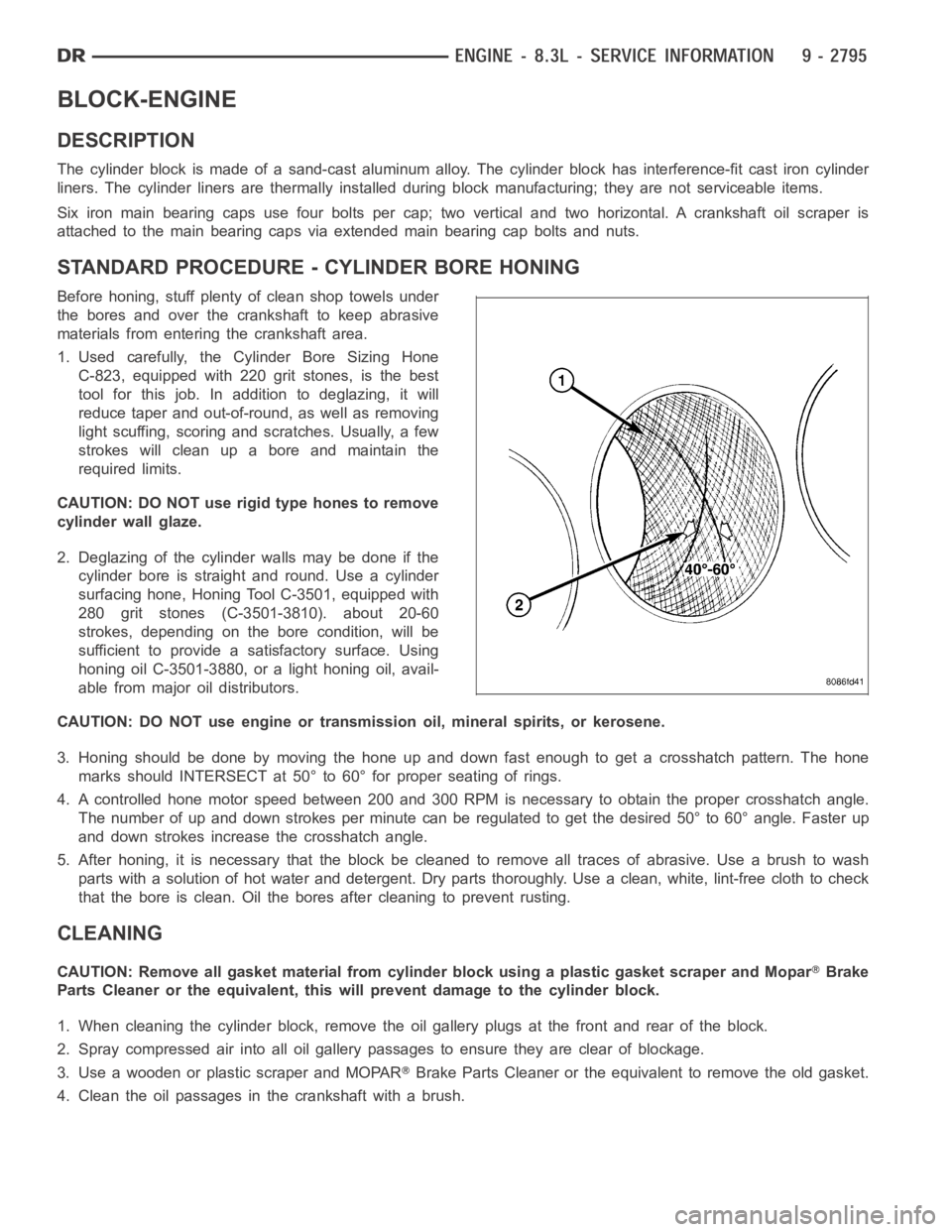

Before honing, stuff plenty of clean shop towels under

the bores and over the crankshaft to keep abrasive

materials from entering the crankshaft area.

1. Used carefully, the Cylinder Bore Sizing Hone

C-823, equipped with 220 grit stones, is the best

tool for this job. In addition to deglazing, it will

reduce taper and out-of-round, as well as removing

light scuffing, scoring and scratches. Usually, a few

strokes will clean up a bore and maintain the

required limits.

CAUTION: DO NOT use rigid type hones to remove

cylinder wall glaze.

2. Deglazing of the cylinder walls may be done if the

cylinder bore is straight and round. Use a cylinder

surfacing hone, Honing Tool C-3501, equipped with

280 grit stones (C-3501-3810). about 20-60

strokes, depending on the bore condition, will be

sufficient to provide a satisfactory surface. Using

honing oil C-3501-3880, or a light honing oil, avail-

able from major oil distributors.

CAUTION: DO NOT use engine or transmission oil, mineral spirits, or kerosene.

3. Honing should be done by moving the hone up and down fast enough to get a crosshatch pattern. The hone

marks should INTERSECT at 50° to 60° for proper seating of rings.

4. A controlled hone motor speed between 200 and 300 RPM is necessary to obtain the proper crosshatch angle.

The number of up and down strokes per minute can be regulated to get the desired 50° to 60° angle. Faster up

and down strokes increase the crosshatch angle.

5. After honing, it is necessary that the block be cleaned to remove all traces of abrasive. Use a brush to wash

parts with a solution of hot water and detergent. Dry parts thoroughly. Usea clean, white, lint-free cloth to check

that the bore is clean. Oil the bores after cleaning to prevent rusting.

CLEANING

CAUTION: Remove all gasket material from cylinder block using a plastic gasket scraper and MoparBrake

Parts Cleaner or the equivalent, this will prevent damage to the cylinder block.

1. When cleaning the cylinder block, remove the oil gallery plugs at the front and rear of the block.

2. Spray compressed air into all oil gallery passages to ensure they are clear of blockage.

3. Use a wooden or plastic scraper and MOPAR

Brake Parts Cleaner or the equivalent to remove the old gasket.

4. Clean the oil passages in the crankshaft with a brush.

Page 2151 of 5267

HEAT SHIELDS

DESCRIPTION

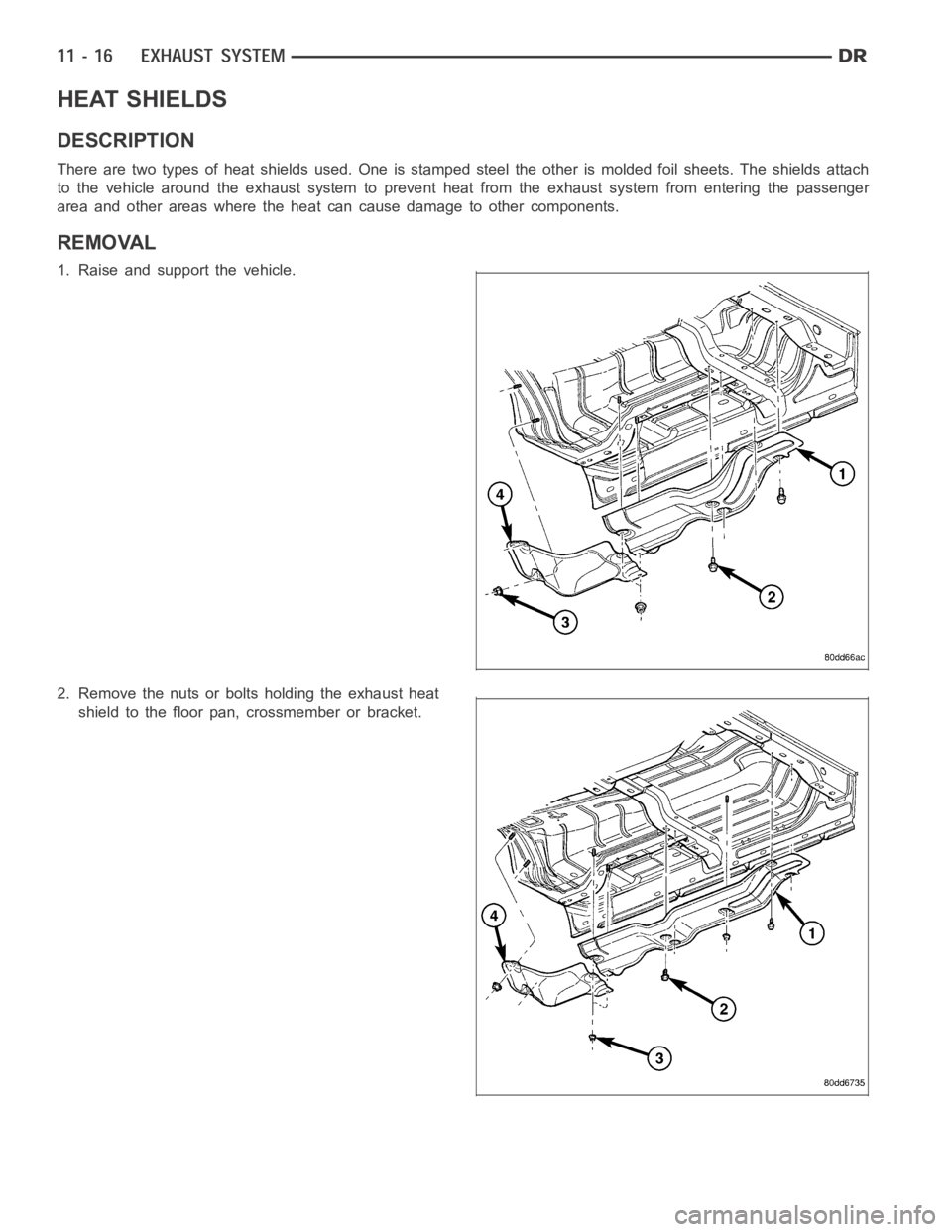

There are two types of heat shields used. One is stamped steel the other is molded foil sheets. The shields attach

to the vehicle around the exhaust system to prevent heat from the exhaust system from entering the passenger

area and other areas where the heat can cause damage to other components.

REMOVAL

1. Raise and support the vehicle.

2. Remove the nuts or bolts holding the exhaust heat

shield to the floor pan, crossmember or bracket.

Page 2163 of 5267

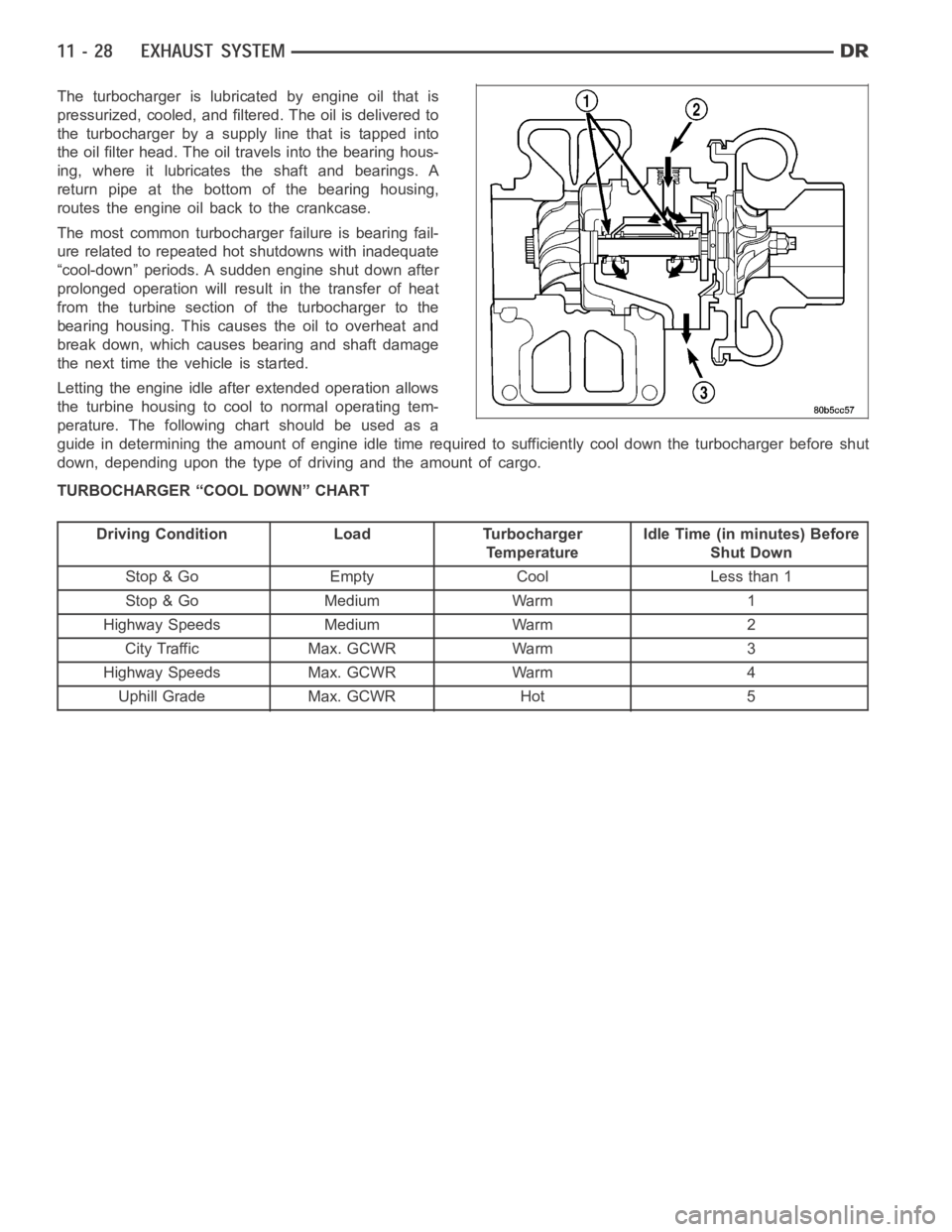

The turbocharger is lubricated by engine oil that is

pressurized, cooled, and filtered. The oil is delivered to

the turbocharger by a supply line that is tapped into

the oil filter head. The oil travels into the bearing hous-

ing, where it lubricates the shaft and bearings. A

return pipe at the bottom of the bearing housing,

routes the engine oil back to the crankcase.

The most common turbocharger failure is bearing fail-

ure related to repeated hot shutdowns with inadequate

“cool-down” periods. A sudden engine shut down after

prolonged operation will result in the transfer of heat

from the turbine section of the turbocharger to the

bearing housing. This causes the oil to overheat and

break down, which causes bearing and shaft damage

thenexttimethevehicleisstarted.

Letting the engine idle after extended operation allows

the turbine housing to cool to normal operating tem-

perature. The following chart should be used as a

guide in determining the amount of engine idle time required to sufficiently cool down the turbocharger before shut

down, depending upon the type of driving and the amount of cargo.

TURBOCHARGER “COOL DOWN” CHART

Driving Condition Load Turbocharger

TemperatureIdle Time (in minutes) Before

Shut Down

Stop & Go Empty Cool Less than 1

Stop & Go Medium Warm 1

Highway Speeds Medium Warm 2

City Traffic Max. GCWR Warm 3

Highway Speeds Max. GCWR Warm 4

Uphill Grade Max. GCWR Hot 5

Page 2255 of 5267

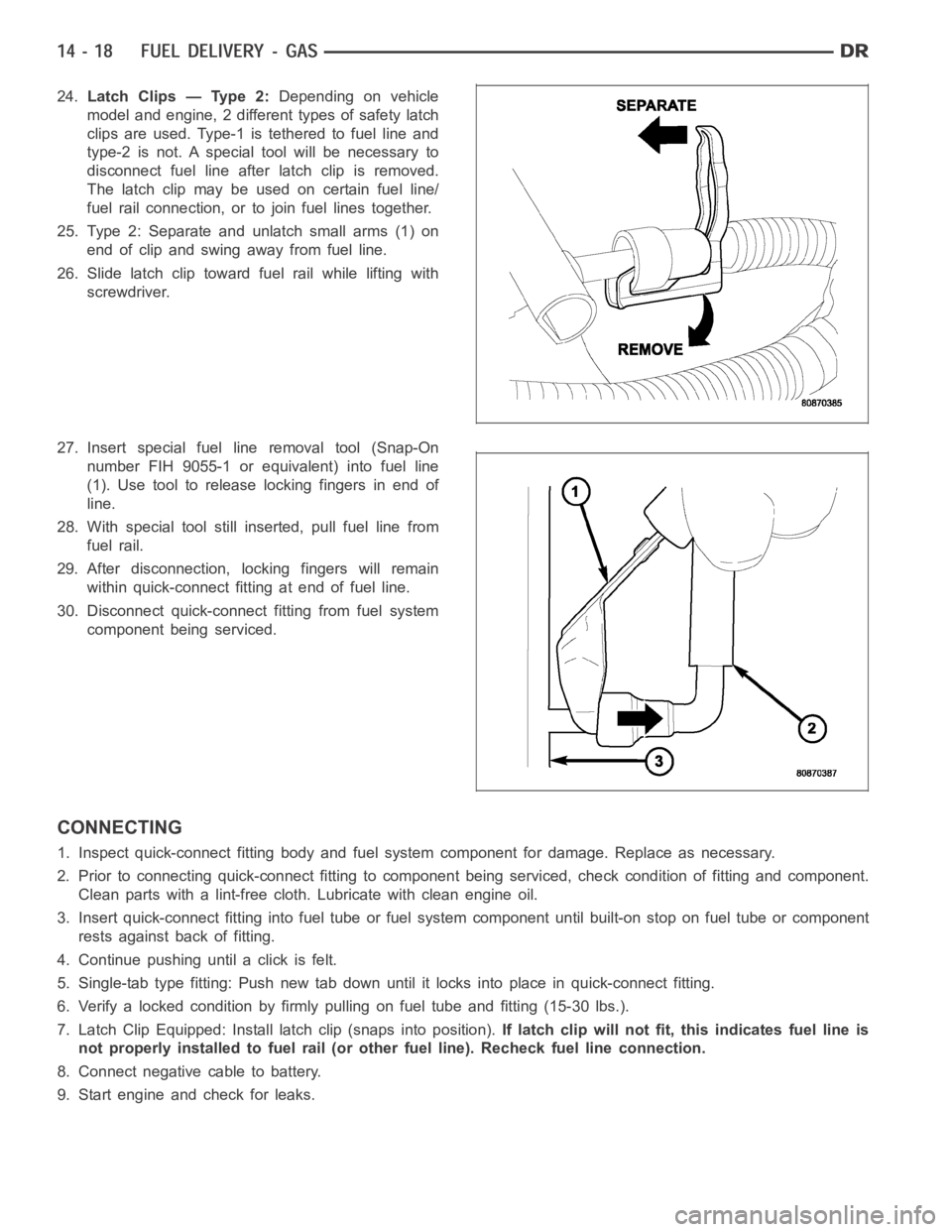

24.Latch Clips — Type 2:Depending on vehicle

model and engine, 2 different types of safety latch

clips are used. Type-1 is tethered to fuel line and

type-2 is not. A special tool will be necessary to

disconnect fuel line after latch clip is removed.

The latch clip may be used on certain fuel line/

fuel rail connection, or to join fuel lines together.

25. Type 2: Separate and unlatch small arms (1) on

end of clip and swing away from fuel line.

26. Slide latch clip toward fuel rail while lifting with

screwdriver.

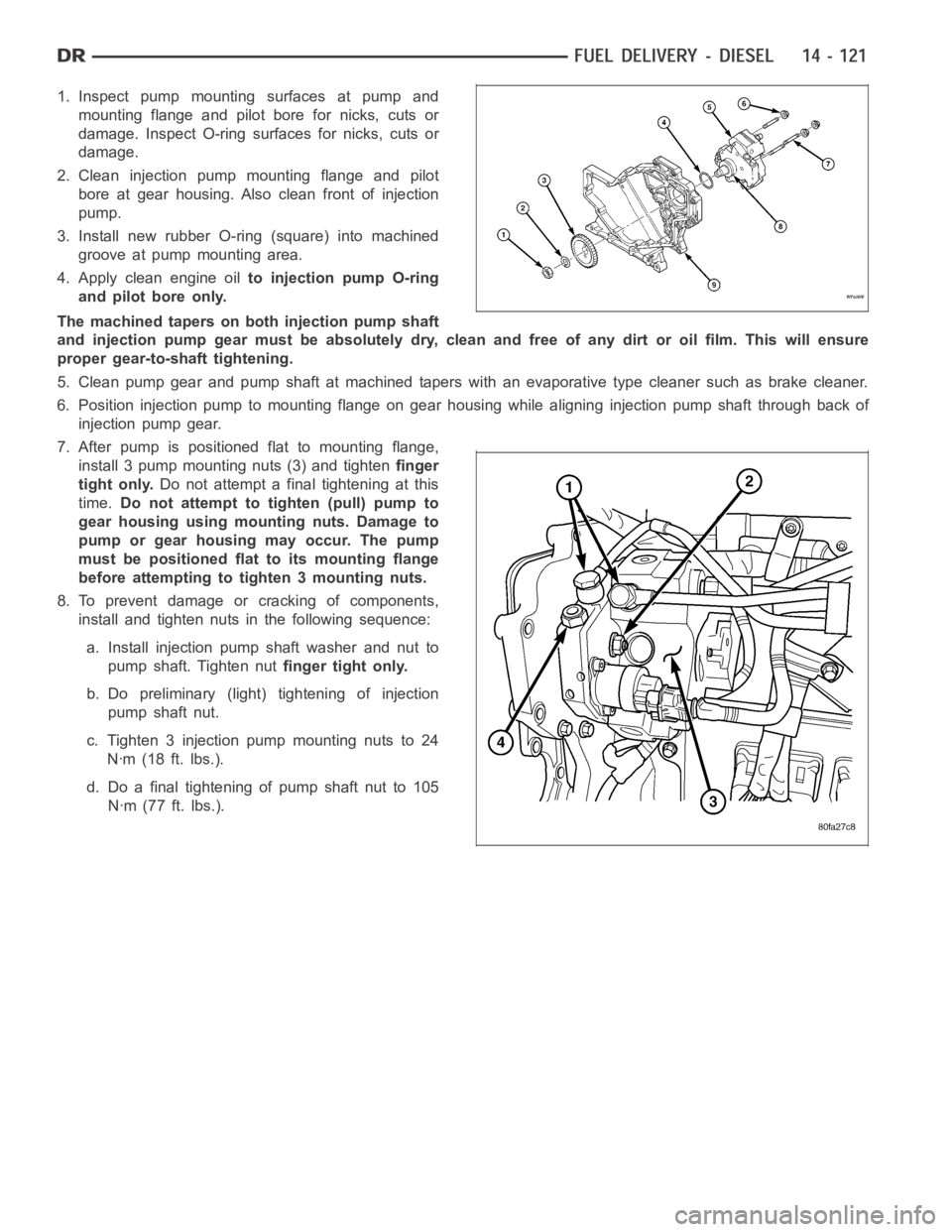

27. Insert special fuel line removal tool (Snap-On

number FIH 9055-1 or equivalent) into fuel line

(1). Use tool to release locking fingers in end of

line.

28. With special tool still inserted, pull fuel line from

fuel rail.

29. After disconnection, locking fingers will remain

within quick-connect fitting at end of fuel line.

30. Disconnect quick-connect fitting from fuel system

component being serviced.

CONNECTING

1. Inspect quick-connect fitting body and fuel system component for damage. Replace as necessary.

2. Prior to connecting quick-connect fitting to component being serviced, check condition of fitting and component.

Clean parts with a lint-free cloth. Lubricate with clean engine oil.

3. Insert quick-connect fitting intofuel tube or fuel system component until built-on stop on fuel tube or component

rests against back of fitting.

4. Continue pushing until a click is felt.

5. Single-tab type fitting: Push new tab down until it locks into place in quick-connect fitting.

6. Verify a locked condition by firmly pulling on fuel tube and fitting (15-30 lbs.).

7. Latch Clip Equipped: Install latch clip (snaps into position).If latch clip will not fit, this indicates fuel line is

not properly installed to fuel rail (or other fuel line). Recheck fuel lineconnection.

8. Connect negative cable to battery.

9. Start engine and check for leaks.

Page 2358 of 5267

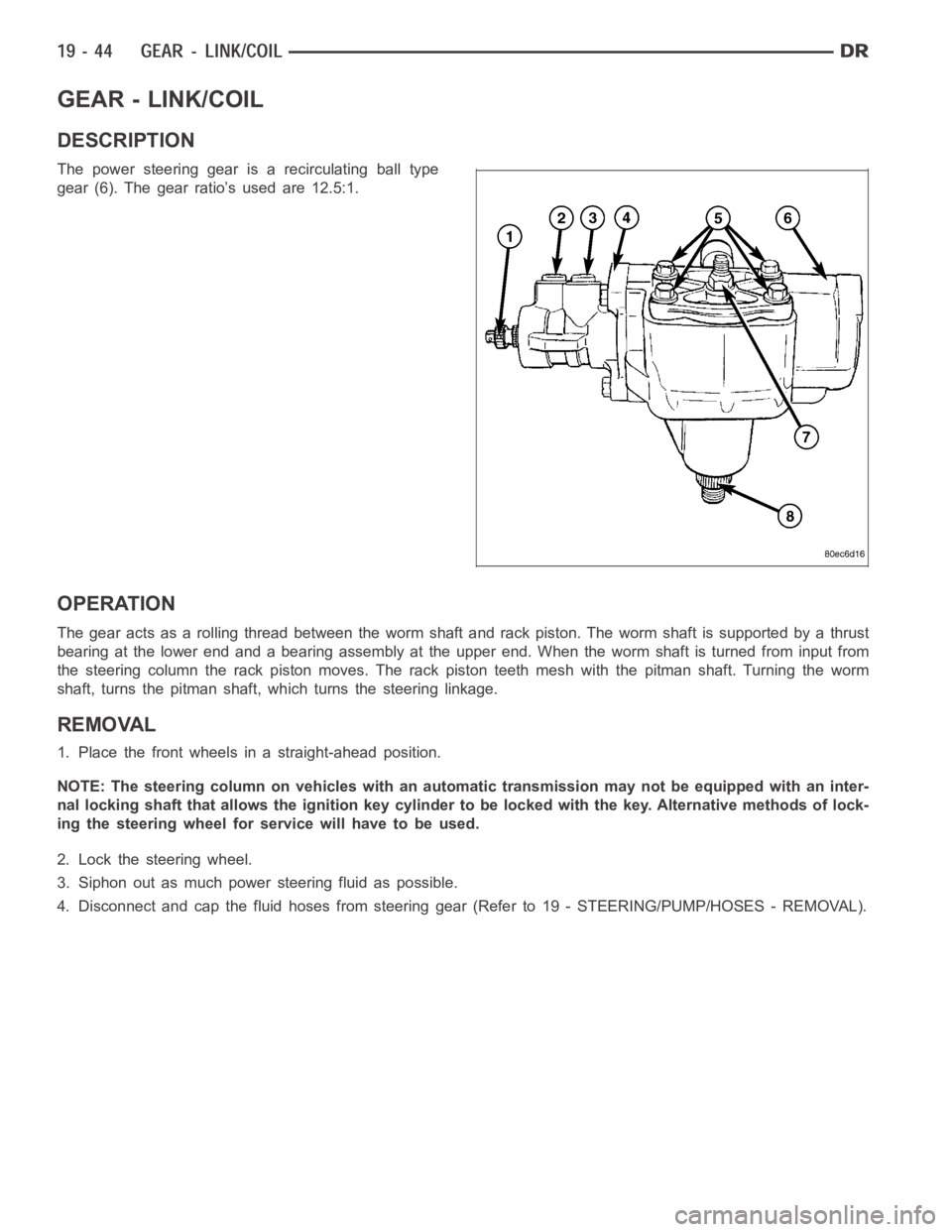

1. Inspect pump mounting surfaces at pump and

mounting flange and pilot bore for nicks, cuts or

damage. Inspect O-ring surfaces for nicks, cuts or

damage.

2. Clean injection pump mounting flange and pilot

bore at gear housing. Also clean front of injection

pump.

3. Install new rubber O-ring (square) into machined

groove at pump mounting area.

4. Apply clean engine oilto injection pump O-ring

and pilot bore only.

The machined tapers on both injection pump shaft

and injection pump gear must be absolutely dry, clean and free of any dirt oroil film. This will ensure

proper gear-to-shaft tightening.

5. Clean pump gear and pump shaft at machined tapers with an evaporative type cleaner such as brake cleaner.

6. Position injection pump to mounting flange on gear housing while aligning injection pump shaft through back of

injection pump gear.

7. After pump is positioned flat to mounting flange,

install 3 pump mounting nuts (3) and tightenfinger

tight only.Do not attempt a final tightening at this

time.Do not attempt to tighten (pull) pump to

gear housing using mounting nuts. Damage to

pump or gear housing may occur. The pump

must be positioned flat to its mounting flange

before attempting to tighten 3 mounting nuts.

8. To prevent damage or cracking of components,

install and tighten nuts in the following sequence:

a. Install injection pump shaft washer and nut to

pump shaft. Tighten nutfinger tight only.

b. Do preliminary (light) tightening of injection

pump shaft nut.

c. Tighten 3 injection pump mounting nuts to 24

Nꞏm (18 ft. lbs.).

d. Do a final tightening of pump shaft nut to 105

Nꞏm (77 ft. lbs.).

Page 2449 of 5267

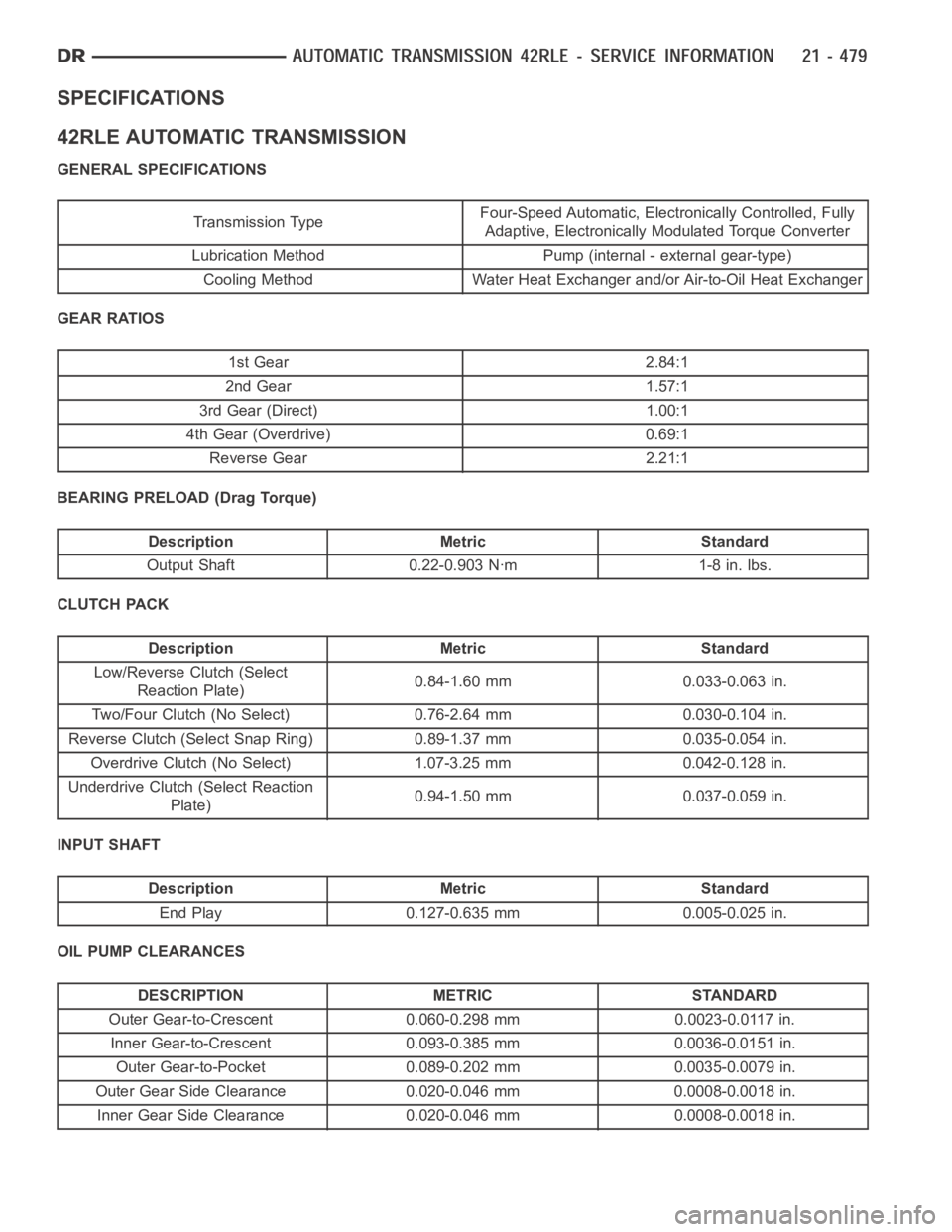

GEAR - LINK/COIL

DESCRIPTION

The power steering gear is a recirculating ball type

gear (6). The gear ratio’s used are 12.5:1.

OPERATION

The gear acts as a rolling thread between the worm shaft and rack piston. Theworm shaft is supported by a thrust

bearing at the lower end and a bearing assembly at the upper end. When the worm shaft is turned from input from

the steering column the rack piston moves. The rack piston teeth mesh with the pitman shaft. Turning the worm

shaft, turns the pitman shaft, which turns the steering linkage.

REMOVAL

1. Place the front wheels in a straight-ahead position.

NOTE: The steering column on vehicles with an automatic transmission may not be equipped with an inter-

nal locking shaft that allows the ignition key cylinder to be locked with the key. Alternative methods of lock-

ing the steering wheel for service will have to be used.

2. Lock the steering wheel.

3. Siphon out as much power steering fluid as possible.

4. Disconnect and cap the fluid hoses from steering gear (Refer to 19 - STEERING/PUMP/HOSES - REMOVAL).

Page 3000 of 5267

SPECIFICATIONS

42RLE AUTOMATIC TRANSMISSION

GENERAL SPECIFICATIONS

Transmission TypeFour-Speed Automatic, Electronically Controlled, Fully

Adaptive, Electronically Modulated Torque Converter

Lubrication Method Pump (internal - external gear-type)

Cooling Method Water Heat Exchanger and/or Air-to-Oil Heat Exchanger

GEAR RATIOS

1st Gear 2.84:1

2nd Gear 1.57:1

3rd Gear (Direct) 1.00:1

4th Gear (Overdrive) 0.69:1

Reverse Gear 2.21:1

BEARING PRELOAD (Drag Torque)

Description Metric Standard

Output Shaft 0.22-0.903 Nꞏm 1-8 in. lbs.

CLUTCH PACK

Description Metric Standard

Low/Reverse Clutch (Select

Reaction Plate)0.84-1.60 mm 0.033-0.063 in.

Two/Four Clutch (No Select) 0.76-2.64 mm 0.030-0.104 in.

Reverse Clutch (Select Snap Ring) 0.89-1.37 mm 0.035-0.054 in.

Overdrive Clutch (No Select) 1.07-3.25 mm 0.042-0.128 in.

Underdrive Clutch (Select Reaction

Plate)0.94-1.50 mm 0.037-0.059 in.

INPUT SHAFT

Description Metric Standard

End Play 0.127-0.635 mm 0.005-0.025 in.

OIL PUMP CLEARANCES

DESCRIPTION METRIC STANDARD

Outer Gear-to-Crescent 0.060-0.298 mm 0.0023-0.0117 in.

Inner Gear-to-Crescent 0.093-0.385 mm 0.0036-0.0151 in.

Outer Gear-to-Pocket 0.089-0.202 mm 0.0035-0.0079 in.

Outer Gear Side Clearance 0.020-0.046 mm 0.0008-0.0018 in.

Inner Gear Side Clearance 0.020-0.046 mm 0.0008-0.0018 in.

Page 3014 of 5267

FLUID AND FILTER

DIAGNOSIS AND TESTING

CAUSES OF BURNT FLUID

Burnt, discolored fluid is a result of overheating which has two primary causes.

1. A result of restricted fluid flow through the main and/or auxiliary cooler. This condition is usually the result of a

faulty or improperly installed drainback valve, a damaged oil cooler, or severe restrictions in the coolers and lines

caused by debris or kinked lines.

2. Heavy duty operation with a vehicle not properly equipped for this type of operation. Trailer towing or similar high

load operation will overheat the transmission fluid if the vehicle is improperly equipped. Such vehicles should

have an auxiliary transmission fluid cooler, a heavy duty cooling system,and the engine/axle ratio combination

needed to handle heavy loads.

EFFECTS OF INCORRECT FLUID LEVEL

Alowfluidlevelallowsthepumptotakeinairalongwiththefluid.Airinthe fluid will cause fluid pressures to be

low and develop slower than normal. If the transmission is overfilled, thegears churn the fluid into foam. This aer-

ates the fluid and causing the same conditions occurring with a low level. In either case, air bubbles cause fluid

overheating, oxidation, and varnish buildup which interferes with valveand clutch operation. Foaming also causes

fluid expansion which can result in fluid overflow from the transmission vent or fill tube. Fluid overflow can easily be

mistaken for a leak if inspection is not careful.

FLUID CONTAMINATION

Transmission fluid contamination is generally a result of:

adding incorrect fluid

failure to clean dipstick and fill tube when checking level

engine coolant entering the fluid

internal failure that generates debris

overheat that generates sludge (fluid breakdown)

failure to replace contaminated converter after repair

The use of non-recommended fluids can result in transmission failure. Theusual results are erratic shifts, slippage,

abnormal wear and eventual failure due to fluid breakdown and sludge formation. Avoid this condition by using rec-

ommended fluids only.

The dipstick cap and fill tube should be wiped clean before checking fluid level. Dirt, grease and other foreign mate-

rial on the cap and tube could fall into the tube if not removed beforehand. Take the time to wipe the cap and tube

clean before withdrawing the dipstick.

Engine coolant in the transmission fluid is generally caused by a cooler malfunction. The only remedy is to replace

the radiator as the cooler in the radiator is not a serviceable part. If coolant has circulated through the transmission,

an overhaul is necessary.

The torque converter should also be replaced whenever a failure generatessludge and debris. This is necessary

because normal converter flushing procedures will not remove all contaminants.

STANDARD PROCEDURE

FLUID LEVEL CHECK

The transmission sump has a dipstick to check oil similar to most automatictransmissions. It is located on the left

side of the engine. Be sure to wipe all dirt from dipstick handle before removing.

The torque converter fills in both the PARK and NEUTRAL positions. Place the selector lever in PARK to be sure

that the fluid level check is accurate.The engine should be running at idle speed for at least one minute, with

the vehicle on level ground.At normal operating temperature (approximately 82° C or 180° F), the fluidlevel is

correct if it is in the HOT region (cross-hatched area) on the oil level indicator. The fluid level should be in COLD

region at 21° C (70° F) fluid temperature. Adjust fluid level as necessary.Use only Mopar

ATF+4, Automatic Trans-

mission Fluid.

Page 3015 of 5267

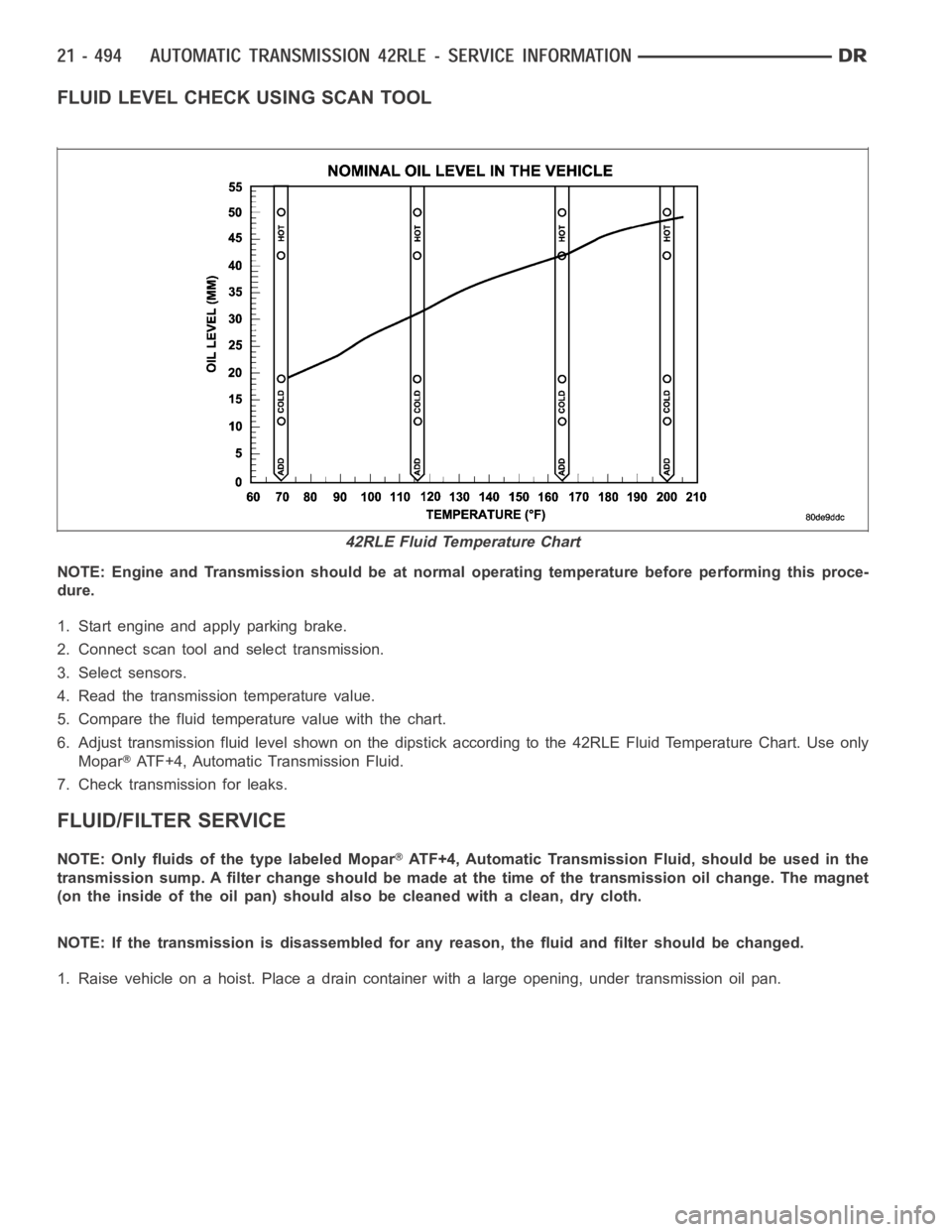

FLUID LEVEL CHECK USING SCAN TOOL

NOTE: Engine and Transmission should be at normal operating temperature before performing this proce-

dure.

1. Start engine and apply parking brake.

2. Connect scan tool and select transmission.

3. Select sensors.

4. Read the transmission temperature value.

5. Compare the fluid temperature value with the chart.

6. Adjust transmission fluid level shown on the dipstick according to the 42RLE Fluid Temperature Chart. Use only

Mopar

ATF+4, Automatic Transmission Fluid.

7. Check transmission for leaks.

FLUID/FILTER SERVICE

NOTE: Only fluids of the type labeled MoparATF+4, Automatic Transmission Fluid, should be used in the

transmission sump. A filter change should be made at the time of the transmission oil change. The magnet

(on the inside of the oil pan) should also be cleaned with a clean, dry cloth.

NOTE: If the transmission is disassembled for any reason, the fluid and filter should be changed.

1. Raise vehicle on a hoist. Place a drain container with a large opening, under transmission oil pan.

42RLE Fluid Temperature Chart