warning DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 51 of 5267

3.(K342) ASD CONTROL OUTPUT CIRCUIT

Turn the ignition off

Connect the C2 TIPM harness connector.

Ignition on, engine not running.

Back probe the C10 TIPM harness connector at the (K342) ASD Control Output circuit terminal and measure the

voltage on the (K342) ASD Control Output circuit.

Is the voltage above 10 volts?

Ye s>>

Go To 4

No>>

Go To 7

4.(K342) ASD CONTROL OUTPUT CIRCUIT VOLTAGE DROP TO THE FUEL INJECTORS

Turn the ignition off.

With a voltmeter, use Negative lead of the voltmeter along with terminal probe tool #6801, backprobe the (K342)

ASD Control Output circuit at a Fuel Injector harness connector.

With the Positive lead of the voltmeter along with terminal probe tool #6801, back probe the (K342) ASD Control

Output circuit at the C10 TIPM harness connector.

Start the engine and allow it to idle.

WARNING: When the engine is operating, do not stand in direct line with the fan. Do not put your hands

near the pulleys, belts, or fan. Do notwear loose clothing. Failure to follow these instructions can result in

personal injury or death.

Measure the voltage of the (K342) ASD Control Output circuit.

NOTE: Perform the test at every fuel injector.

Is the voltage above 0.001 of a volt (1.0mV) for any of the Fuel Injector ASD Control Output circuits?

Ye s>>

Repair the excessive resistance in the (K342) ASD Control Output circuit to the appropriate Fuel Injec-

tor.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 5

5.(K342) ASD CONTROL OUTPUT CIRCUIT VOLTAGE DRIP TO THE IGNITION COILS

Turn the Ignition off.

With a voltmeter, use Negative lead of the voltmeter along with terminal probe tool #6801, backprobe the (K342)

ASD Control Output circuit at a Ignition Coil harness connector.

With the Positive lead of the voltmeter along with terminal probe tool #6801, back probe the (K342) ASD Control

Output circuit at the C10 TIPM harness connector.

Start the engine and allow it to idle.

WARNING: When the engine is operating, do not stand in direct line with the fan. Do not put your hands

near the pulleys, belts, or fan. Do notwear loose clothing. Failure to follow these instructions can result in

personal injury or death.

Measure the voltage of the (K342) ASD Control Output circuit.

NOTE: Perform the test at every Ignition Coil.

Is the voltage above 0.001 of a volt (1.0mV) for any of the Ignition Coil ASD Control Output circuits?

Ye s>>

Repair the excessive resistance in the (K342) ASD Control Output circuit to the appropriate Ignition Coil.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 6

Page 52 of 5267

6.PCM Turn the ignition off.

Disconnect C3 NGC harness connector.

CAUTION: Do not probe the PCM harness connectors. Probing the PCM harness connectors will damage

the PCM terminals resulting in poor terminal to pin connection. Install Miller Special Tool #8815 and #8815-1

to perform diagnosis.

With a voltmeter, use Negative lead of the voltmeter along with terminal probe tool #6801, probe the (K342) ASD

Control Output circuit at the appropriate terminals of special tool #8815.

With the Positive lead of the voltmeter along with terminal probe tool #6801, back probe the (K342) ASD Control

Output circuit at the C10 TIPM harness connector.

Start the engine and allow it to idle.

WARNING: When the engine is operating, do not stand in direct line with the fan. Do not put your hands

near the pulleys, belts, or fan. Do notwear loose clothing. Failure to follow these instructions can result in

personal injury or death.

Measure the voltage of the (K342) ASD Control Output circuit.

Is the voltage above 0.001 of a volt (1.0mV) for any of the Ignition Coil ASD Control Output circuits?

Ye s>>

Repair the excessive resistance in the (K342) ASD Control Output circuit tothePCM.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace and program the Powertrain Control Module in accordance with Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

7.TOTALLY INTEGRATED POWER MODULE

NOTE: Before continuing, check the TIPM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors.

Pay particular attention to allPower and voltage circuits.

Were any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace the Totally Integrated Power Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 175 of 5267

When Monitored:

With the engine running in closed loop mode, the ambient/battery temperature above (-7°C) 20°F, altitude

below 8500 ft.

Set Condition:

If the PCM multiplies short term compensation by long term adaptive as wellas a purge fuel multiplier and the

result is below a certain value for 30 seconds over two trips, a freeze frameis stored, the MIL illuminates and

a trouble code is stored. Two Trip Fault. Three good trips to turn off the MIL.

Possible Causes

EXHAUST LEAK

ENGINE MECHANICAL

1/2O2SENSOR

(K141) O2 SENSOR 1/2 SIGNAL CIRCUIT

(K299) O2 1/2 HEATER CONTROL CIRCUIT

(K904) O2 RETURN DOWNSTREAM CIRCUIT

FUEL CONTAMINATION

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

NOTE: Check the vehicle repair history. If the 1/2 O2 has been replaced makesure that the O2 sensor was

properly installed and meets OEM specification.

NOTE: Check for contaminants that may have damaged the O2 Sensor: contaminated fuel, unapproved sil-

icone, oil and coolant.

Ignition on, engine not running.

With a scan tool, read DTCs.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.EXHAUST LEAK

Turn the ignition off.

WARNING: To avoid personal injury from the exhaust system being hot, allowthe exhaust to cool down to

a safe temperature before performing a physical inspection. Failure to follow these instructions can result in

personal injury or death.

Visually and Physically inspect the exhaust system for holes, cracks and blockage in the exhaust system.

Is the exhaust system is good condition?

Ye s>>

Go To 3

No>>

Repair or Replace as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 180 of 5267

When Monitored:

With the engine running in closed loop mode, the ambient/battery temperature above (-7°C) 20°F, altitude

below 8500 ft.

Set Condition:

If the PCM multiplies short term compensation by long term adaptive as wellas a purge fuel multiplier and the

result is below a certain value for 30 seconds over two trips, a freeze frameis stored, the MIL illuminates and

a trouble code is stored. Two Trip Fault. Three good trips to turn off the MIL.

Possible Causes

EXHAUST LEAK

ENGINE MECHANICAL

1/2O2SENSOR

(K141) O2 SENSOR 1/2 SIGNAL CIRCUIT

(K299) O2 HEATER 1/2 CONTROL CIRCUIT

(K904) O2 RETURN DOWNSTREAM CIRCUIT

FUEL CONTAMINATION

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

NOTE: Check the vehicle repair history. If the 1/2 O2 has been replaced makesure that the O2 sensor was

properly installed and meets OEM specification.

NOTE: Check for contaminants that may have damaged the O2 Sensor: contaminated fuel, unapproved sil-

icone, oil and coolant.

Ignition on, engine not running.

With a scan tool, read DTCs.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.EXHAUST LEAK

Turn the ignition off.

WARNING: To avoid personal injury from the exhaust system being hot, allowthe exhaust to cool down to

a safe temperature before performing a physical inspection. Failure to follow these instructions can result in

personal injury or death.

Visually and Physically inspect the exhaust system for holes, cracks and blockage in the exhaust system.

Is the exhaust system is good condition?

Ye s>>

Go To 3

No>>

Repair or Replace as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 186 of 5267

When Monitored:

With the engine running in closed loop mode, the ambient/battery temperature above (-7°C) 20°F, altitude

below 8500 ft and fuel level greater than 15%.

Set Condition:

If the PCM multiplies short term compensation by long term adaptive and a certain percentage is exceeded for

two trips, a freeze frame is stored, the MIL illuminates and a trouble code is stored. Two Trip Fault. Three good

trips to turn off the MIL.

Possible Causes

EXHAUST LEAK

ENGINE MECHANICAL

2/2O2SENSOR

(K243) O2 2/2 SIGNAL CIRCUIT

(K399) O2 HEATER 2/2 CONTROL CIRCUIT

(K904) O2 RETURN DOWNSTREAM CIRCUIT

FUEL CONTAMINATION

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

NOTE: Check the vehicle repair history. If the 2/2 O2 has been replaced makesure that the O2 sensor was

properly installed and meets OEM specification.

NOTE: Check for contaminants that may have damaged the O2 Sensor: contaminated fuel, unapproved sil-

icone, oil and coolant.

Ignition on, engine not running.

With a scan tool, read DTCs.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.EXHAUST LEAK

Turn the ignition off.

WARNING: To avoid personal injury from the exhaust system being hot, allowthe exhaust to cool down to

a safe temperature before performing a physical inspection. Failure to follow these instructions can result in

personal injury or death.

Visually and Physically inspect the exhaust system for holes, cracks and blockage in the exhaust system.

Is the exhaust system is good condition?

Ye s>>

Go To 3

No>>

Repair or Replace as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 191 of 5267

When Monitored:

With the engine running in closed loop mode, the ambient/battery temperature above (-7°C) 20°F, altitude

below 8500 ft.

Set Condition:

If the PCM multiplies short term compensation by long term adaptive as wellas a purge fuel multiplier and the

result is below a certain value for 30 seconds over two trips, a freeze frameis stored, the MIL illuminates and

a trouble code is stored. Two Trip Fault. Three good trips to turn off the MIL.

Possible Causes

EXHAUST LEAK

ENGINE MECHANICAL

2/2O2SENSOR

(K342) O2 SENSOR 2/2 SIGNAL CIRCUIT

(K399) O2 SENSOR 2/2 HEATER CONTROL CIRCUIT

(K904) O2 RETURN DOWNSTREAM CIRCUIT

FUEL CONTAMINATION

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

NOTE: Check the vehicle repair history. If the 2/2 O2 has been replaced makesure that the O2 sensor was

properly installed and meets OEM specification.

NOTE: Check for contaminants that may have damaged the O2 Sensor: contaminated fuel, unapproved sil-

icone, oil and coolant.

Ignition on, engine not running.

With a scan tool, read DTCs.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.EXHAUST LEAK

Turn the ignition off.

WARNING: To avoid personal injury from the exhaust system being hot, allowthe exhaust to cool down to

a safe temperature before performing a physical inspection. Failure to follow these instructions can result in

personal injury or death.

Visually and Physically inspect the exhaust system for holes, cracks and blockage in the exhaust system.

Is the exhaust system is good condition?

Ye s>>

Go To 3

No>>

Repair or Replace as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 310 of 5267

When Monitored:

Ignition on, Engine running, and no ECT DTCs present.

Set Condition:

PCM recognizes that the ECT has failed its self coherence test. The coolanttemp should only change at a

certain rate, if this rate is too slow or too fast this fault will set. Two trip fault. Three good trips to clear MIL.

ETC light will illuminate on first trip failure.

Possible Causes

LOW COOLANT LEVEL

(K2) ECT SIGNAL CIRCUIT SHORTED TO BATTERY VOLTAGE

(K2) ECT SIGNAL CIRCUIT OPEN

(K900) SENSOR GROUND CIRCUIT OPEN

(K2) ECT SIGNAL CIRCUIT SHORTED TO GROUND

(K2) ECT SIGNAL CIRCUIT SHORTED TO THE (K900) SENSOR GROUND

THERMOSTAT

ECT SENSOR

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

Ignition on, engine not running.

NOTE: If this code sets during extreme ambient temperatures, improper installation of a block heater could

be the cause of this DTC.

With a scan tool, read DTCs.

Diagnose all other ECT and Cooling System codes before continuing.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.LOW COOLANT LEVEL

NOTE: If a Engine Coolant Temperature (ECT) DTC is set along with this code,diagnose the ECT DTC first.

NOTE: Inspect the ECT terminals and related PCM terminals. Ensure the terminals are free from corrosion

and damage.

NOTE: The best way to diagnose this DTC is to allow the vehicle to sit overnight outside in order to have

a totally cold soaked engine.

NOTE: Extremely cold outside ambient temperatures may have caused this DTCtoset.

NOTE: Need to make sure that no Cooling System DTCs are set or changes that would make the warm up

much slower or much faster: broken water pump can set this, addition of aftermarket auxiliary cooler can

set this DTC.

WARNING: Never open the cooling system when the engine is hot. The system isunder pressure. Failure to

follow these instructions can result in personal injury or death. Allow the engine to cool before opening the

cooling system.

Page 351 of 5267

When Monitored:

The engine running. The engine speed greater than 1157 RPM.

Set Condition:

The battery sensed voltage is 1 volt below the charging goal for 13.47 seconds. The PCM senses the battery

voltage turns off the field driver and senses the battery voltage again. Ifthe voltages are the same, the code

is set. One Trip Fault. Three good trips to turn off the MIL.

Possible Causes

EXCESSIVE RESISTANCE IN THE BATTERY POSITIVE CIRCUIT

EXCESSIVE RESISTANCE IN THE CASE GROUND

(K20) GEN FIELD CONTROL CIRCUIT SHORTED TO VOLTAGE

(K20) GEN FIELD CONTROL CIRCUIT OPEN

(K20) GEN FIELD CONTROL CIRCUIT SHORTED TO GROUND

(Z20) GEN GROUND CIRCUIT OPEN

GENERATOR

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

NOTE: Inspect the vehicle for aftermarket accessories that may exceed theGenerator System output.

Ignition on, engine not running.

NOTE: The battery must be fully charged.

NOTE: The Generator belt tension and condition must be checked before continuing.

With a scan tool, read DTCs.

With a scan tool, erase DTCs.

Start the engine.

Allow the idle to stabilize.

Ignition on, engine not running.

With the scan tool, read DTCs.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.FUSED B+ CIRCUIT HIGH RESISTANCE

WARNING: When the engine is operating, do not stand in direct line with the fan. Do not put your hands

near the pulleys, belts, or fan. Do notwear loose clothing. Failure to follow these instructions can result in

personal injury or death.

Ignition on, engine not running.

Measure the voltage between the Generator B+ Output Terminal and the Battery+ Post.

Start the engine.

Is the voltage above 0.4 of a volt?

Ye s>>

Repair the excessive resistance in the battery positive circuit between the Generator and Battery.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 3

Page 352 of 5267

3.EXCESSIVE RESISTANCE IN THE CASE GROUND

WARNING: When the engine is operating, do not stand in direct line with the fan. Do not put your hands

near the pulleys, belts, or fan. Do notwear loose clothing. Failure to follow these instructions can result in

personal injury or death.

Start the engine.

Warm the engine to operating temperature.

NOTE: Make sure all wires are clear of the engine’s moving parts.

Measure the voltage between the Generator Case and Battery ground post.

Is the voltage above 0.1 of a volt?

Ye s>>

Repair the excessive resistance in the Generator Case Ground.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 4

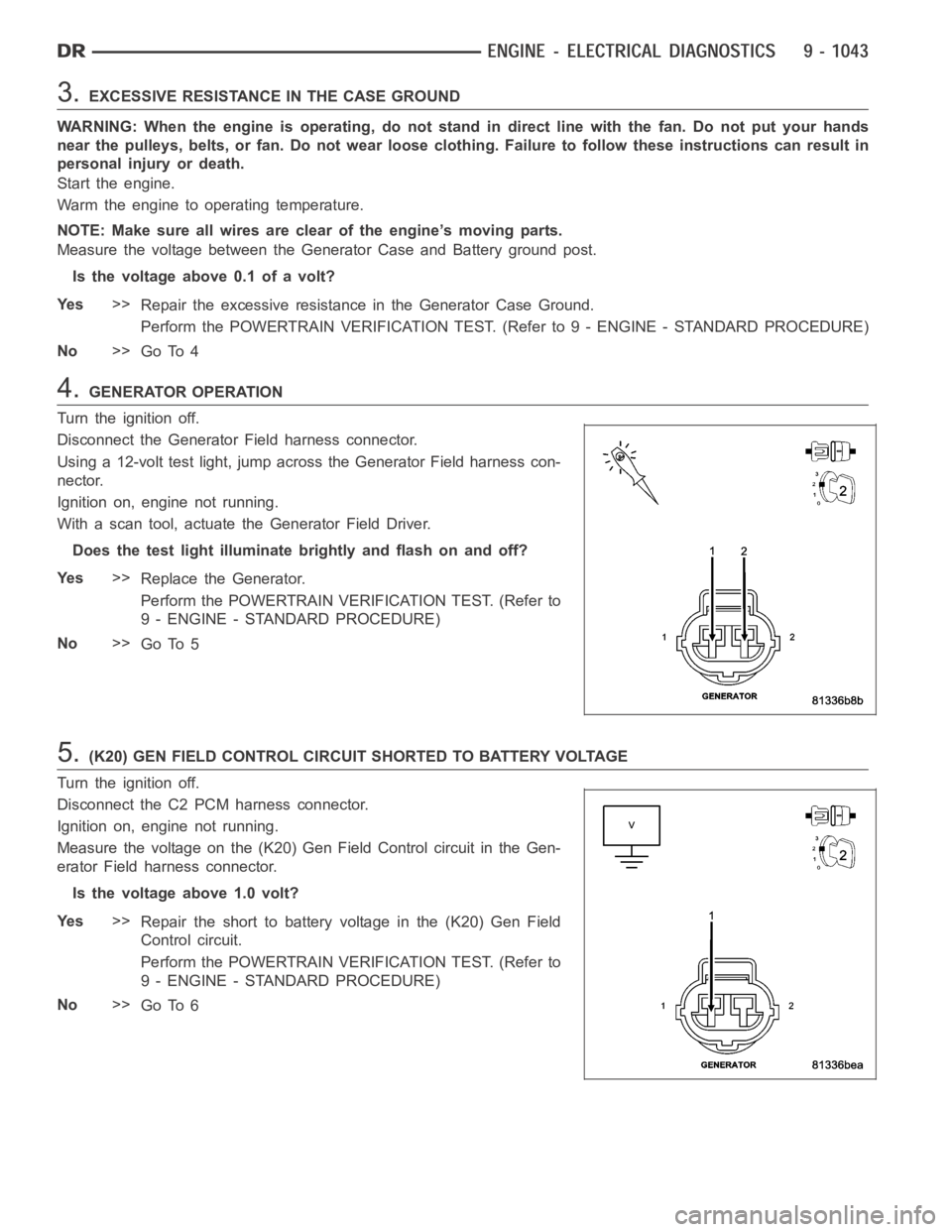

4.GENERATOR OPERATION

Turn the ignition off.

Disconnect the Generator Field harness connector.

Using a 12-volt test light, jump across the Generator Field harness con-

nector.

Ignition on, engine not running.

With a scan tool, actuate theGenerator Field Driver.

Does the test light illuminate brightly and flash on and off?

Ye s>>

Replace the Generator.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 5

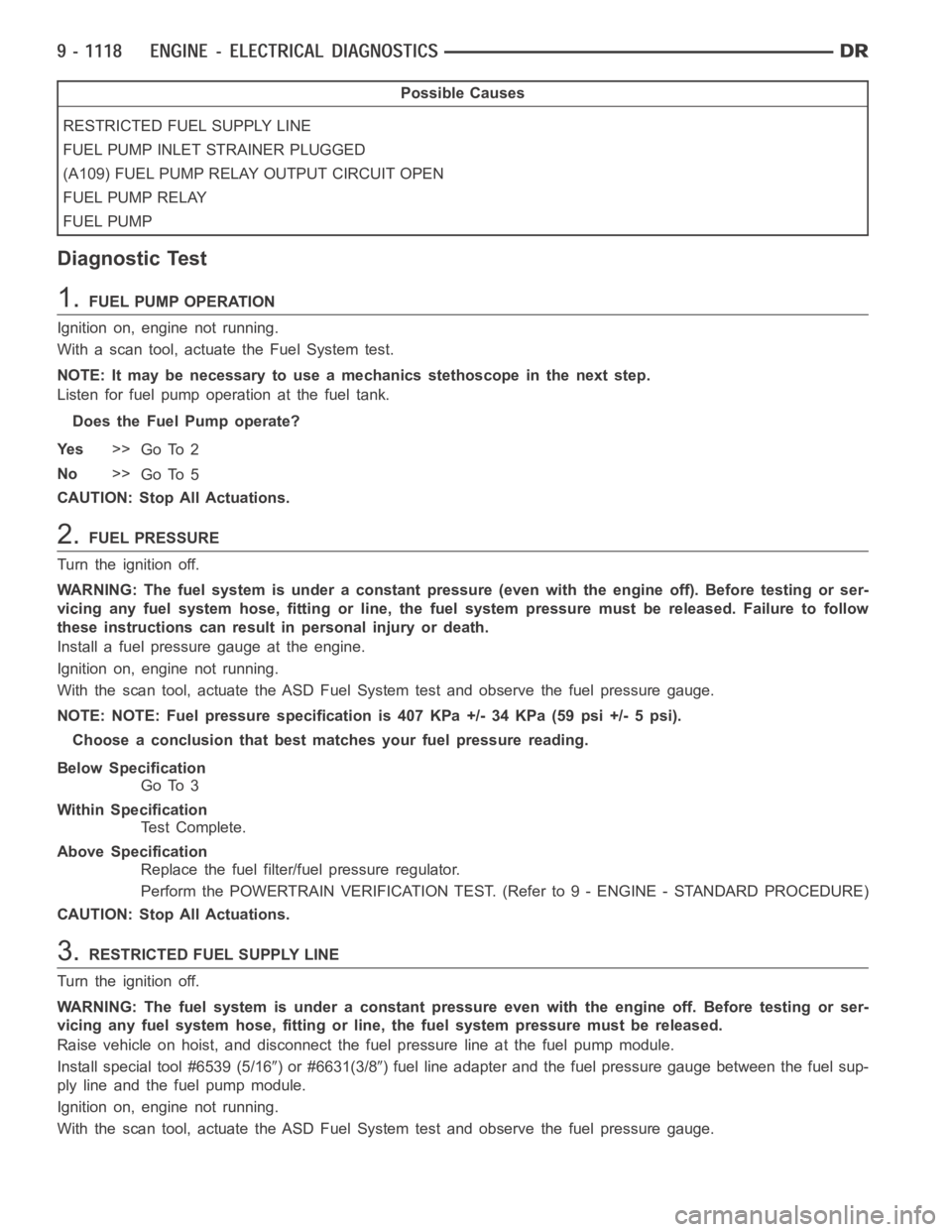

5.(K20) GEN FIELD CONTROL CIRCUIT SHORTED TO BATTERY VOLTAGE

Turn the ignition off.

Disconnect the C2 PCM harness connector.

Ignition on, engine not running.

Measure the voltage on the (K20) Gen Field Control circuit in the Gen-

erator Field harness connector.

Is the voltage above 1.0 volt?

Ye s>>

Repair the short to battery voltage in the (K20) Gen Field

Control circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 6

Page 427 of 5267

Possible Causes

RESTRICTED FUEL SUPPLY LINE

FUEL PUMP INLET STRAINER PLUGGED

(A109) FUEL PUMP RELAY OUTPUT CIRCUIT OPEN

FUEL PUMP RELAY

FUEL PUMP

Diagnostic Test

1.FUEL PUMP OPERATION

Ignition on, engine not running.

With a scan tool, actuate the Fuel System test.

NOTE: It may be necessary to use a mechanics stethoscope in the next step.

Listen for fuel pump operation at the fuel tank.

Does the Fuel Pump operate?

Ye s>>

Go To 2

No>>

Go To 5

CAUTION: Stop All Actuations.

2.FUEL PRESSURE

Turn the ignition off.

WARNING: The fuel system is under a constant pressure (even with the engineoff). Before testing or ser-

vicing any fuel system hose, fitting or line, the fuel system pressure mustbe released. Failure to follow

these instructions can result in personal injury or death.

Install a fuel pressure gauge at the engine.

Ignition on, engine not running.

With the scan tool, actuate the ASD FuelSystem test and observe the fuel pressure gauge.

NOTE: NOTE: Fuel pressure specification is 407 KPa +/- 34 KPa (59 psi +/- 5 psi).

Choose a conclusion that best matches your fuel pressure reading.

Below Specification

Go To 3

Within Specification

Te s t C o m p l e t e .

Above Specification

Replace the fuel filter/fuel pressure regulator.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

CAUTION: Stop All Actuations.

3.RESTRICTED FUEL SUPPLY LINE

Turn the ignition off.

WARNING: The fuel system is under a constant pressure even with the engine off. Before testing or ser-

vicing any fuel system hose, fitting or line, the fuel system pressure mustbe released.

Raise vehicle on hoist, and disconnect the fuel pressure line at the fuel pump module.

Install special tool #6539 (5/16

) or #6631(3/8) fuel line adapter and the fuel pressure gauge between the fuel sup-

ply line and the fuel pump module.

Ignition on, engine not running.

With the scan tool, actuate the ASD FuelSystem test and observe the fuel pressure gauge.