DODGE RAM SRT-10 2006 Service Repair Manual

RAM SRT-10 2006

DODGE

DODGE

https://www.carmanualsonline.info/img/12/56917/w960_56917-0.png

DODGE RAM SRT-10 2006 Service Repair Manual

Trending: Crank pulley bolt, traction control, headrest, OBD port, turn signal, fuses, wheelbase

Page 5241 of 5267

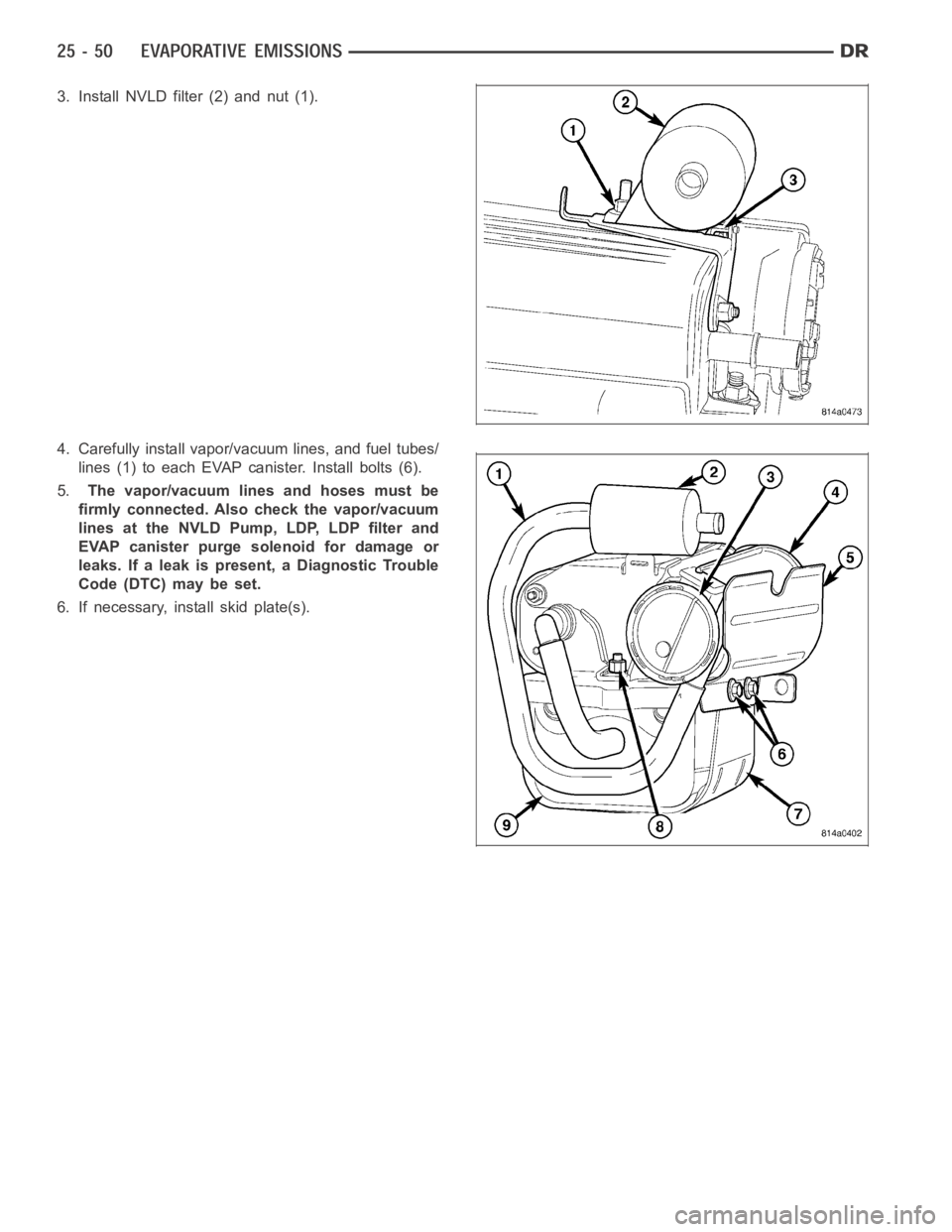

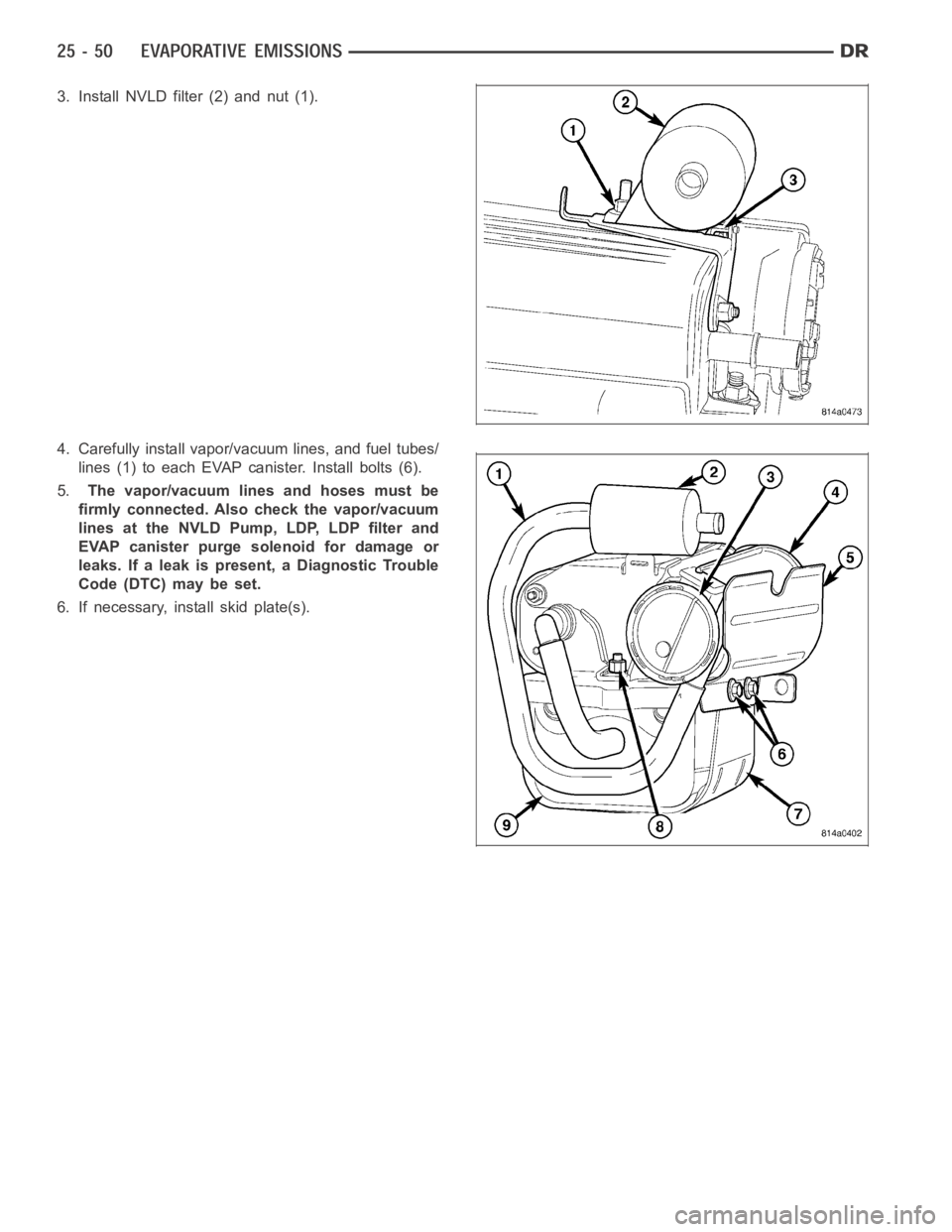

3. Install NVLD filter (2) and nut (1).

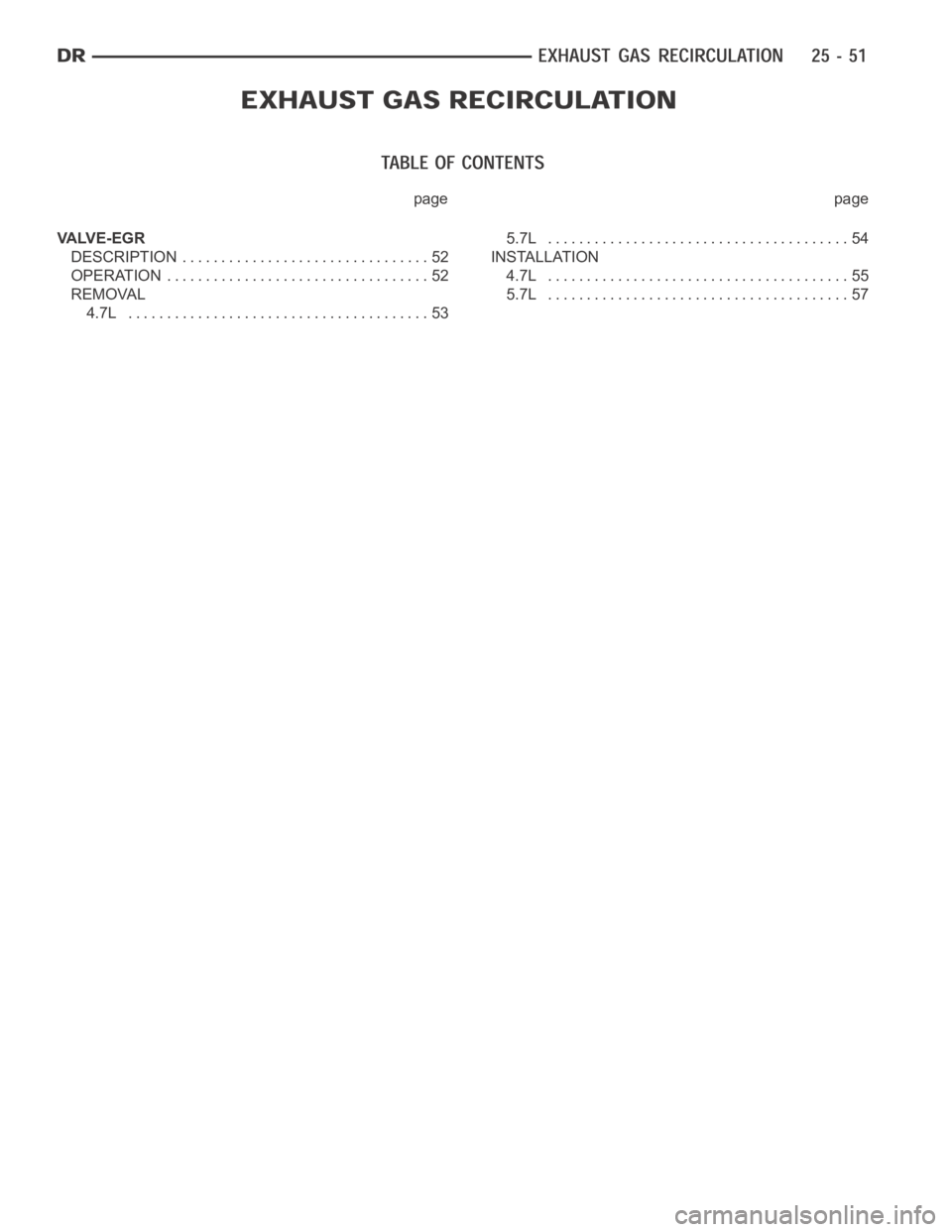

4. Carefully install vapor/vacuum lines, and fuel tubes/

lines (1) to each EVAP canister. Install bolts (6).

5.The vapor/vacuum lines and hoses must be

firmly connected. Also check the vapor/vacuum

lines at the NVLD Pump, LDP, LDP filter and

EVAP canister purge solenoid for damage or

leaks. If a leak is present, a Diagnostic Trouble

Code (DTC) may be set.

6. If necessary, install skid plate(s).

Page 5242 of 5267

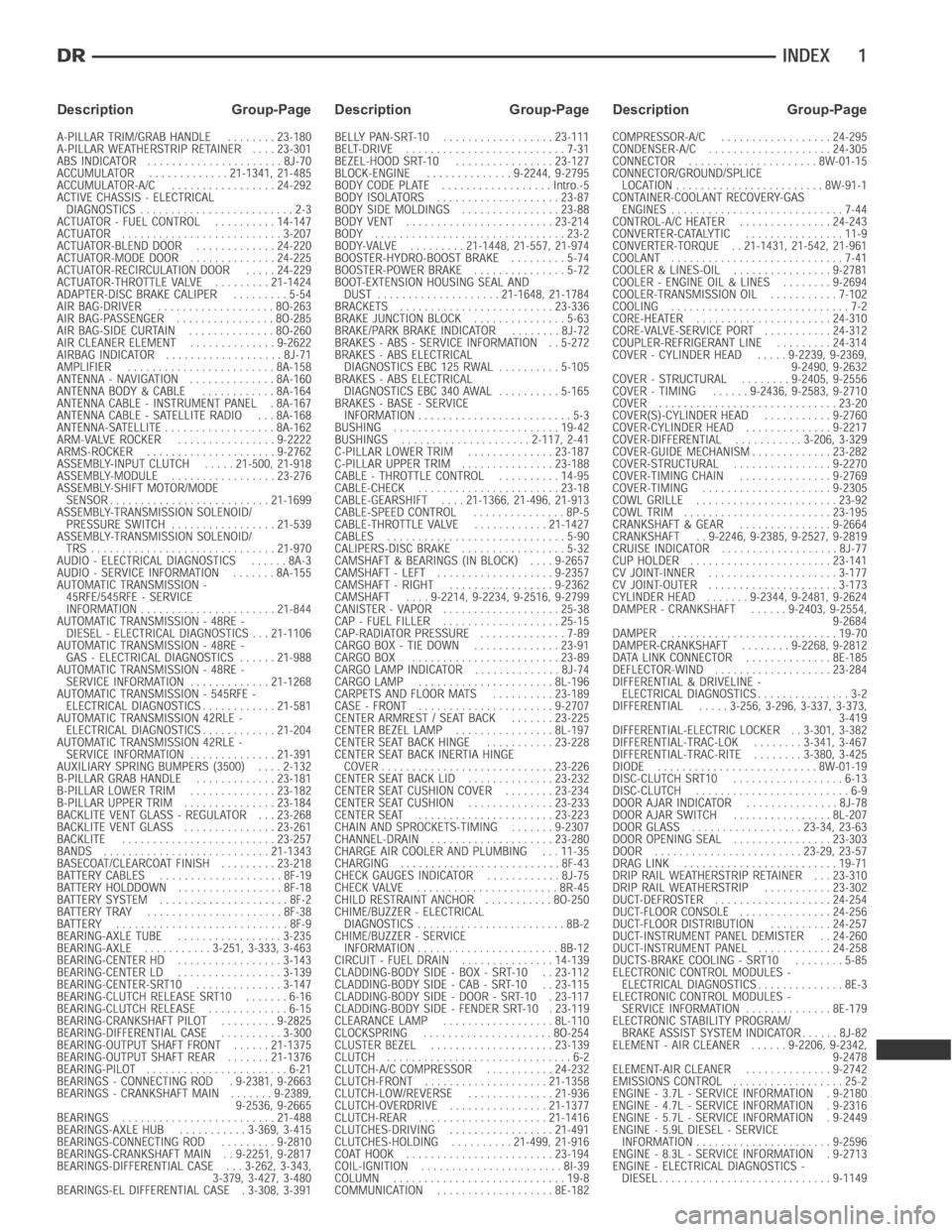

page page

VALVE-EGR

DESCRIPTION ................................ 52

OPERATION .................................. 52

REMOVAL

4.7L ....................................... 535.7L ....................................... 54

INSTALLATION

4.7L ....................................... 55

5.7L ....................................... 57

Page 5243 of 5267

VALVE-EGR

DESCRIPTION

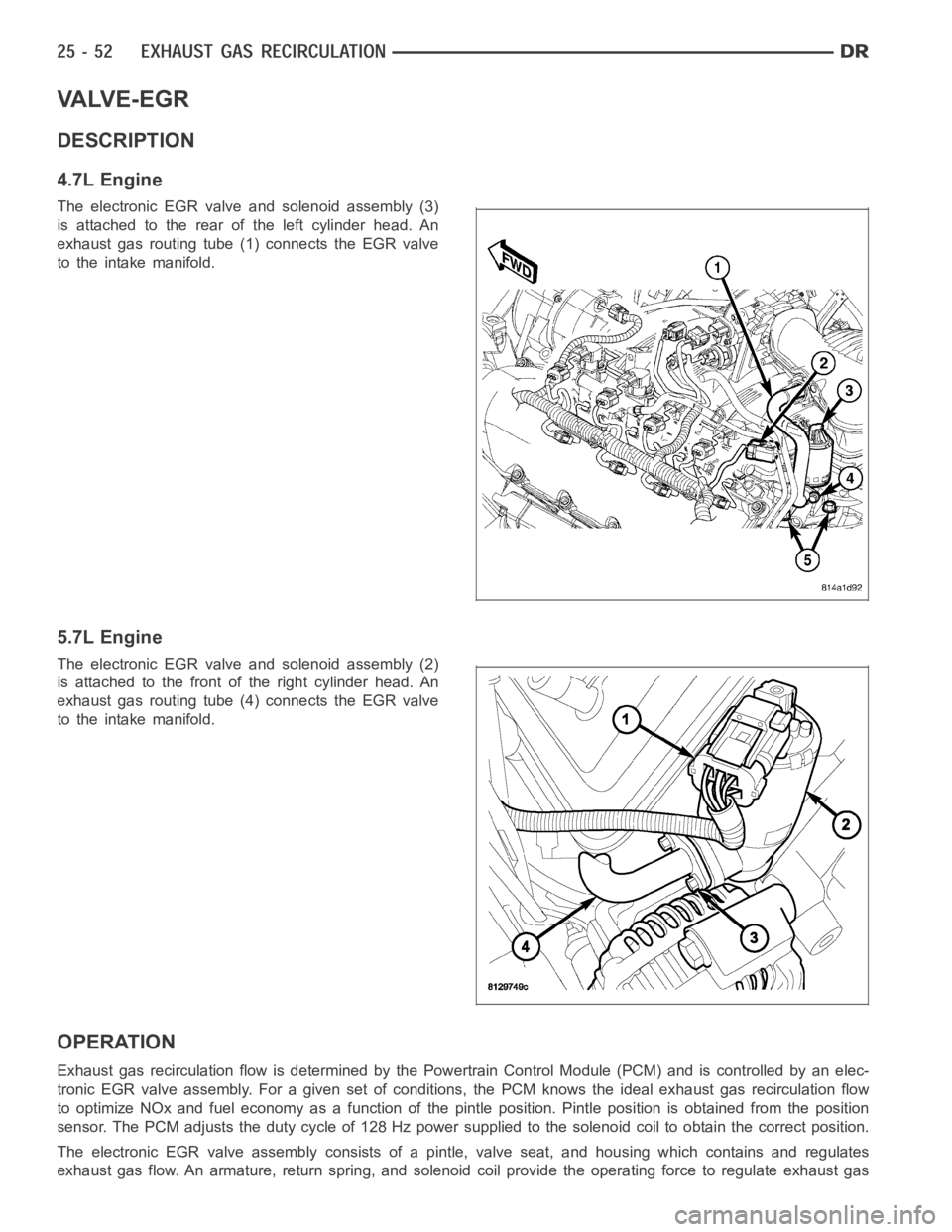

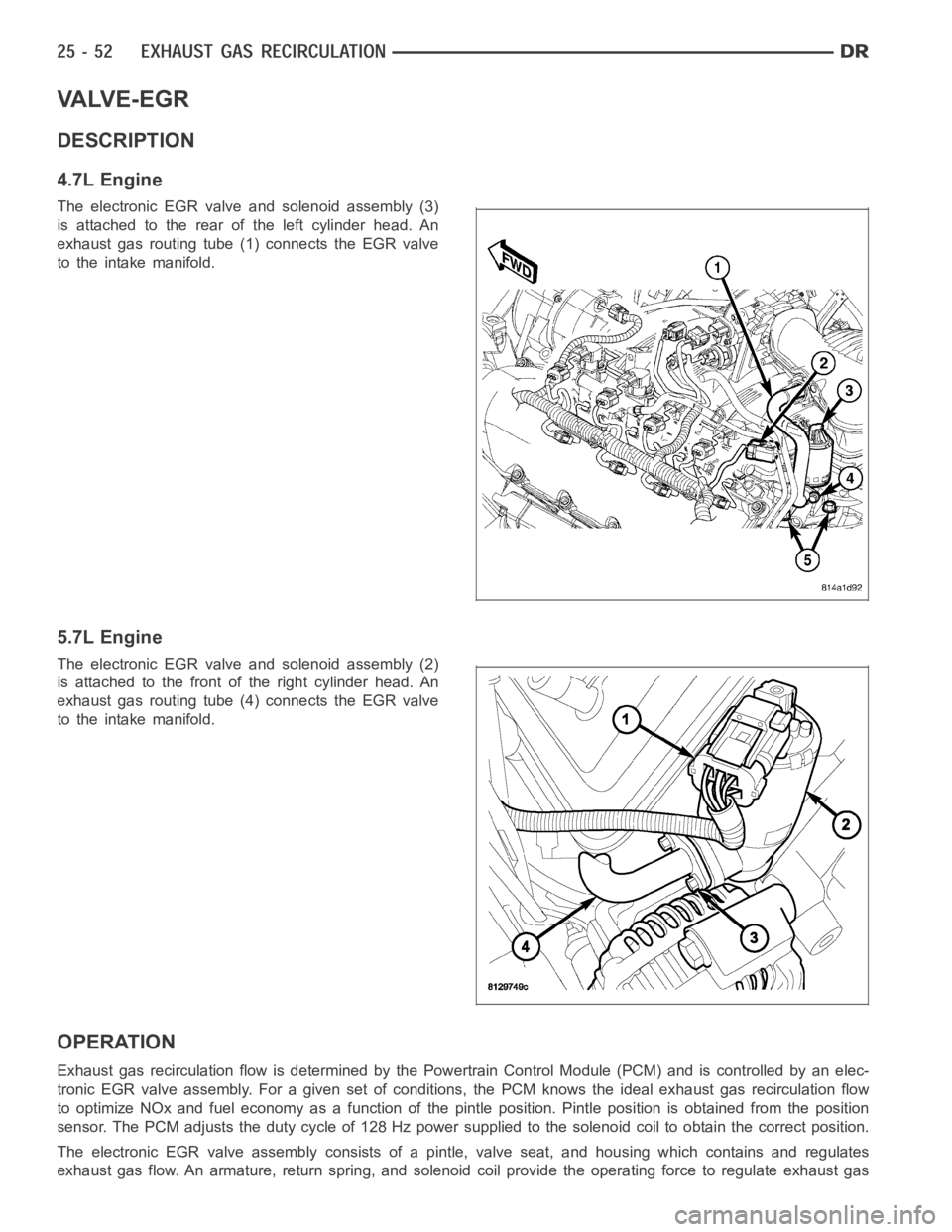

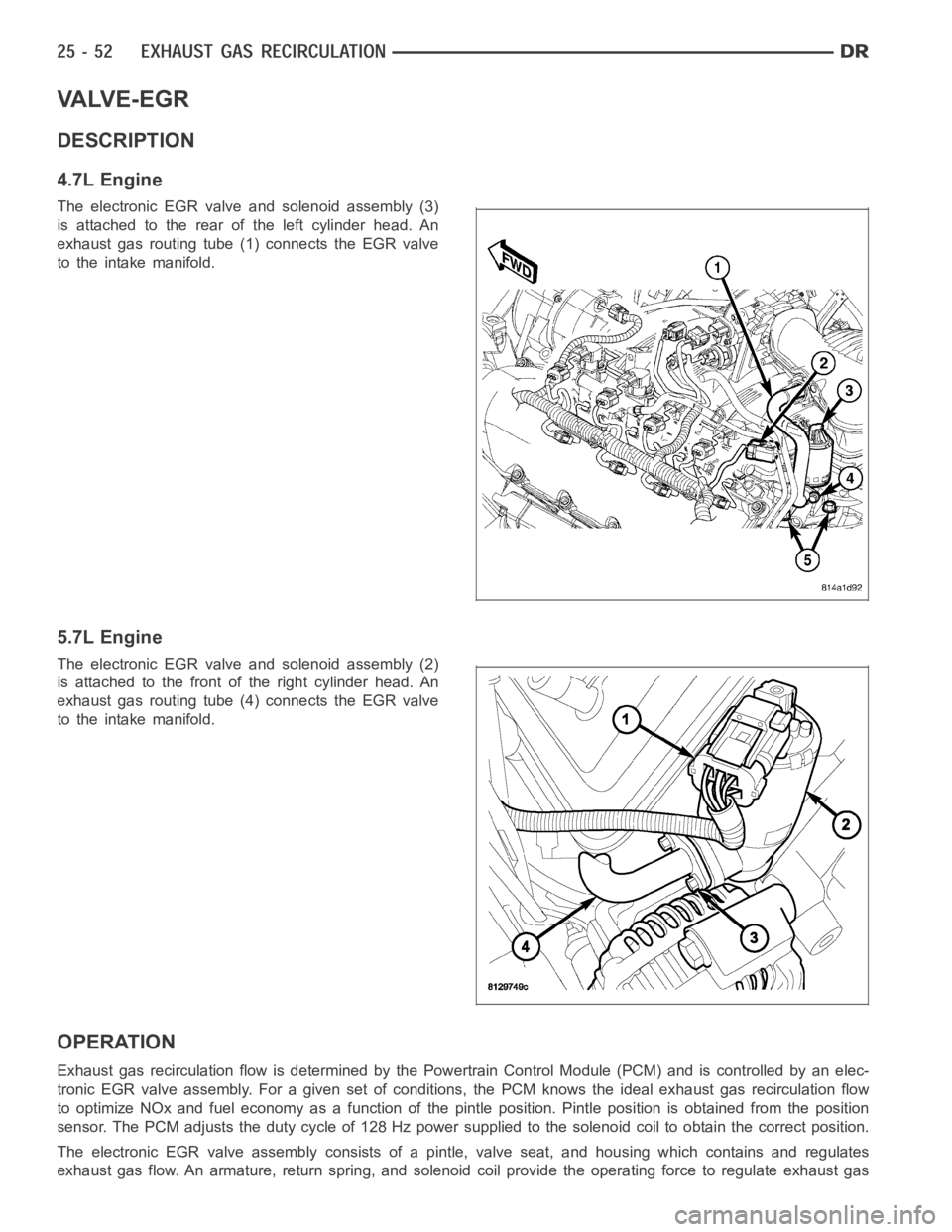

4.7L Engine

The electronic EGR valve and solenoid assembly (3)

is attached to the rear of the left cylinder head. An

exhaust gas routing tube (1) connects the EGR valve

to the intake manifold.

5.7L Engine

The electronic EGR valve and solenoid assembly (2)

is attached to the front of the right cylinder head. An

exhaust gas routing tube (4) connects the EGR valve

to the intake manifold.

OPERATION

Exhaust gas recirculation flow is determined by the Powertrain Control Module (PCM) and is controlled by an elec-

tronic EGR valve assembly. For a given set of conditions, the PCM knows the ideal exhaust gas recirculation flow

to optimize NOx and fuel economy as a function of the pintle position. Pintle position is obtained from the position

sensor. The PCM adjusts the duty cycle of 128 Hz power supplied to the solenoid coil to obtain the correct position.

The electronic EGR valve assembly consists of a pintle, valve seat, and housing which contains and regulates

exhaust gas flow. An armature, return spring, and solenoid coil provide the operating force to regulate exhaust gas

Page 5244 of 5267

flow by changing the pintle position. The solenoid coil assembly is wired in parallel with a diode that connects two

internal connectors.

REMOVAL

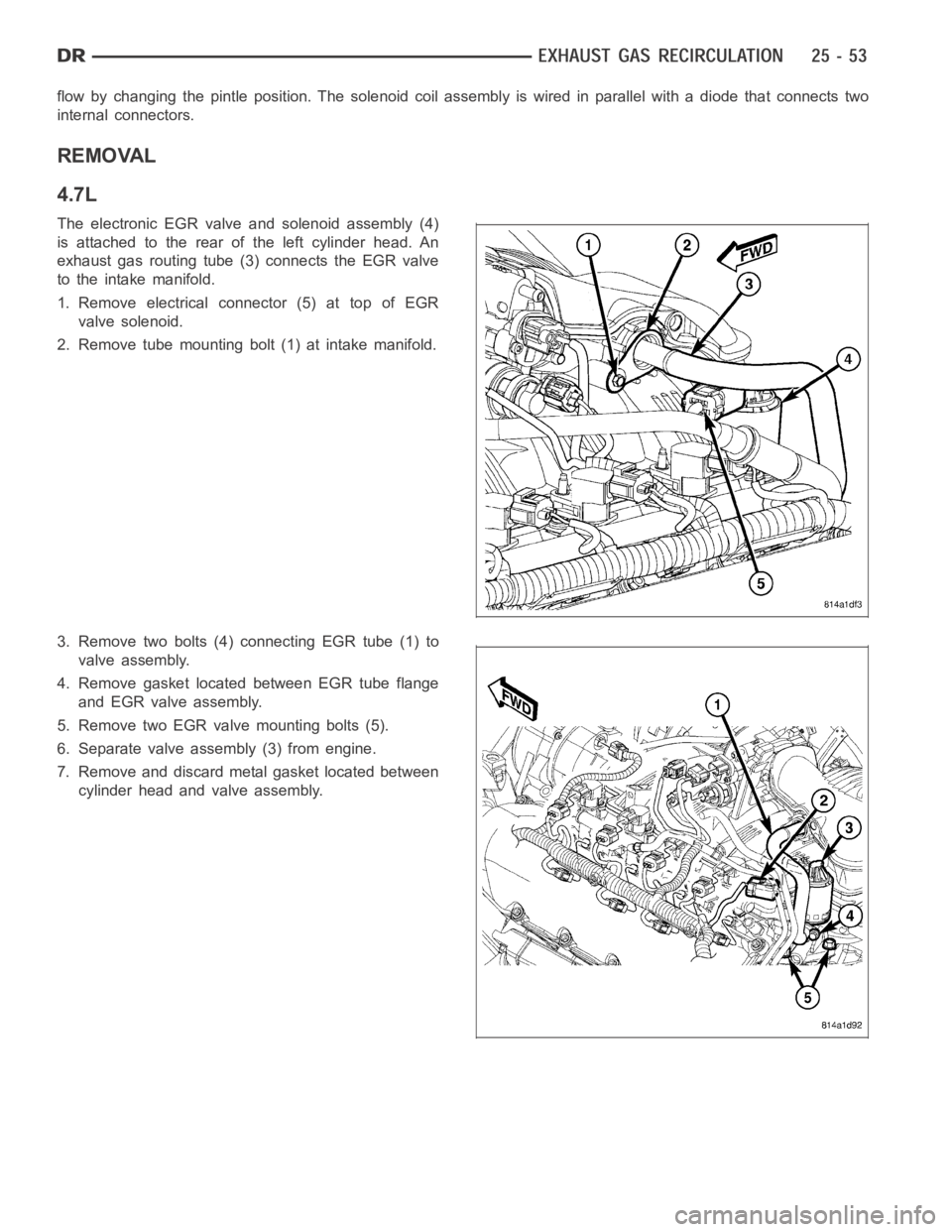

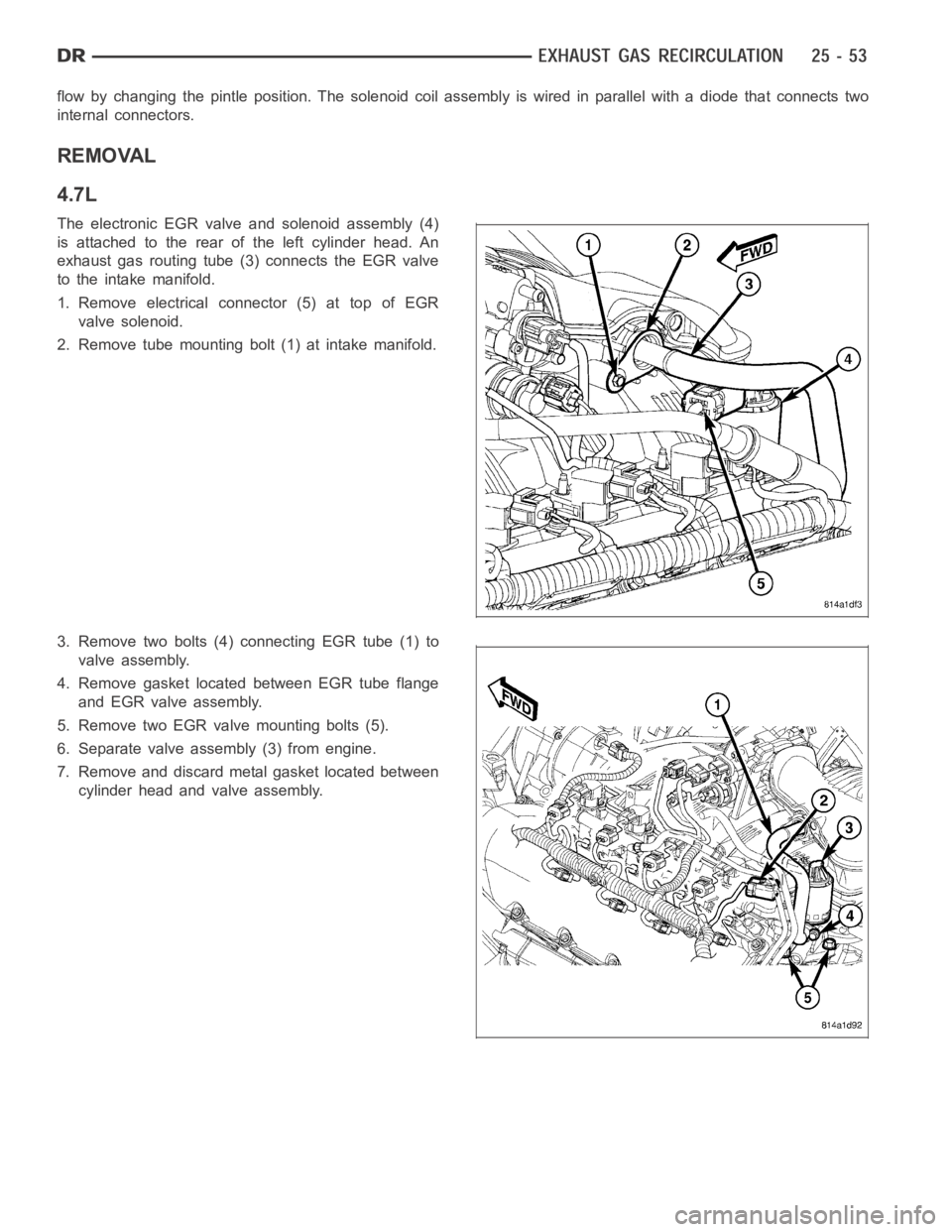

4.7L

The electronic EGR valve and solenoid assembly (4)

is attached to the rear of the left cylinder head. An

exhaust gas routing tube (3) connects the EGR valve

to the intake manifold.

1. Remove electrical connector (5) at top of EGR

valve solenoid.

2. Remove tube mounting bolt (1) at intake manifold.

3. Remove two bolts (4) connecting EGR tube (1) to

valve assembly.

4. Remove gasket located between EGR tube flange

and EGR valve assembly.

5. Remove two EGR valve mounting bolts (5).

6. Separate valve assembly (3) from engine.

7. Remove and discard metal gasket located between

cylinder head and valve assembly.

Page 5245 of 5267

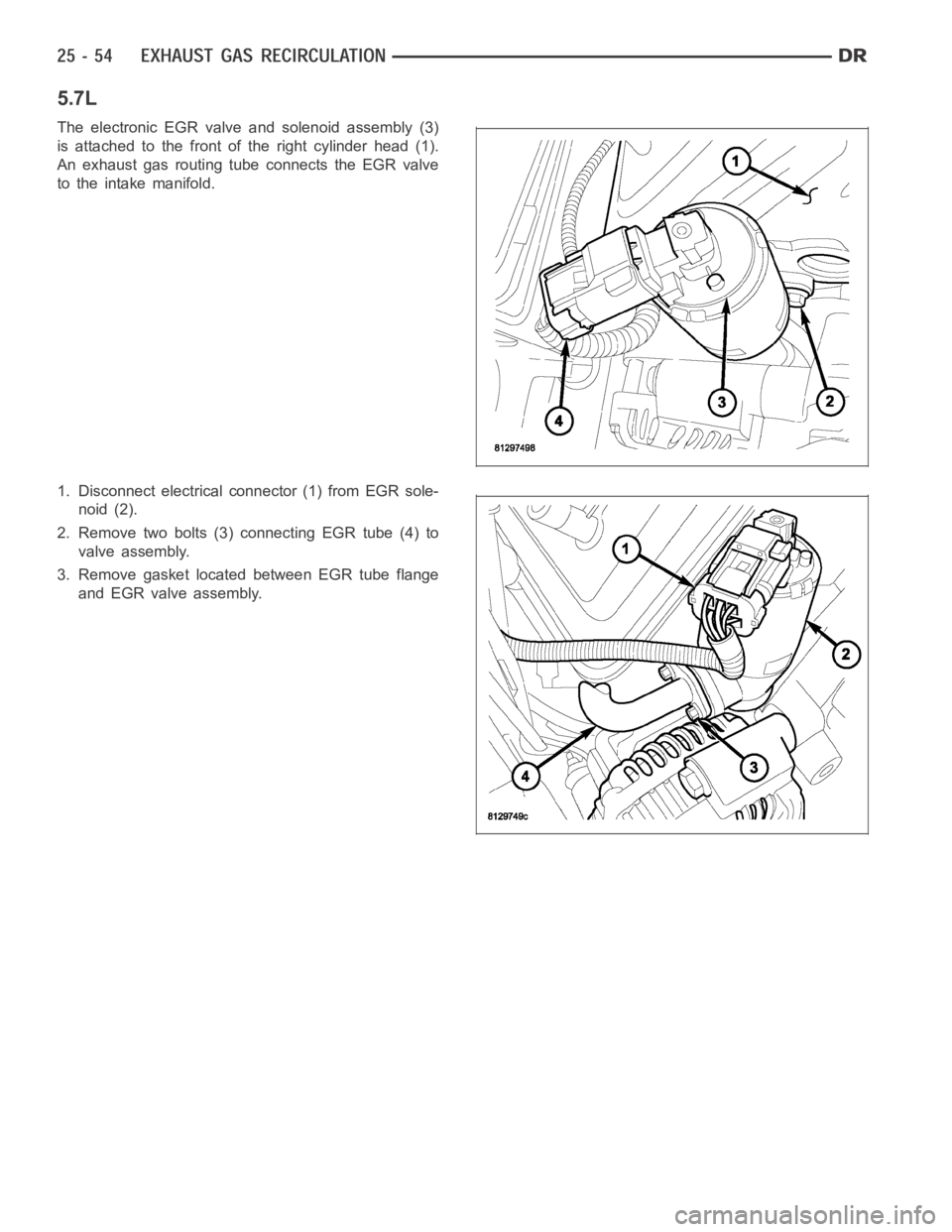

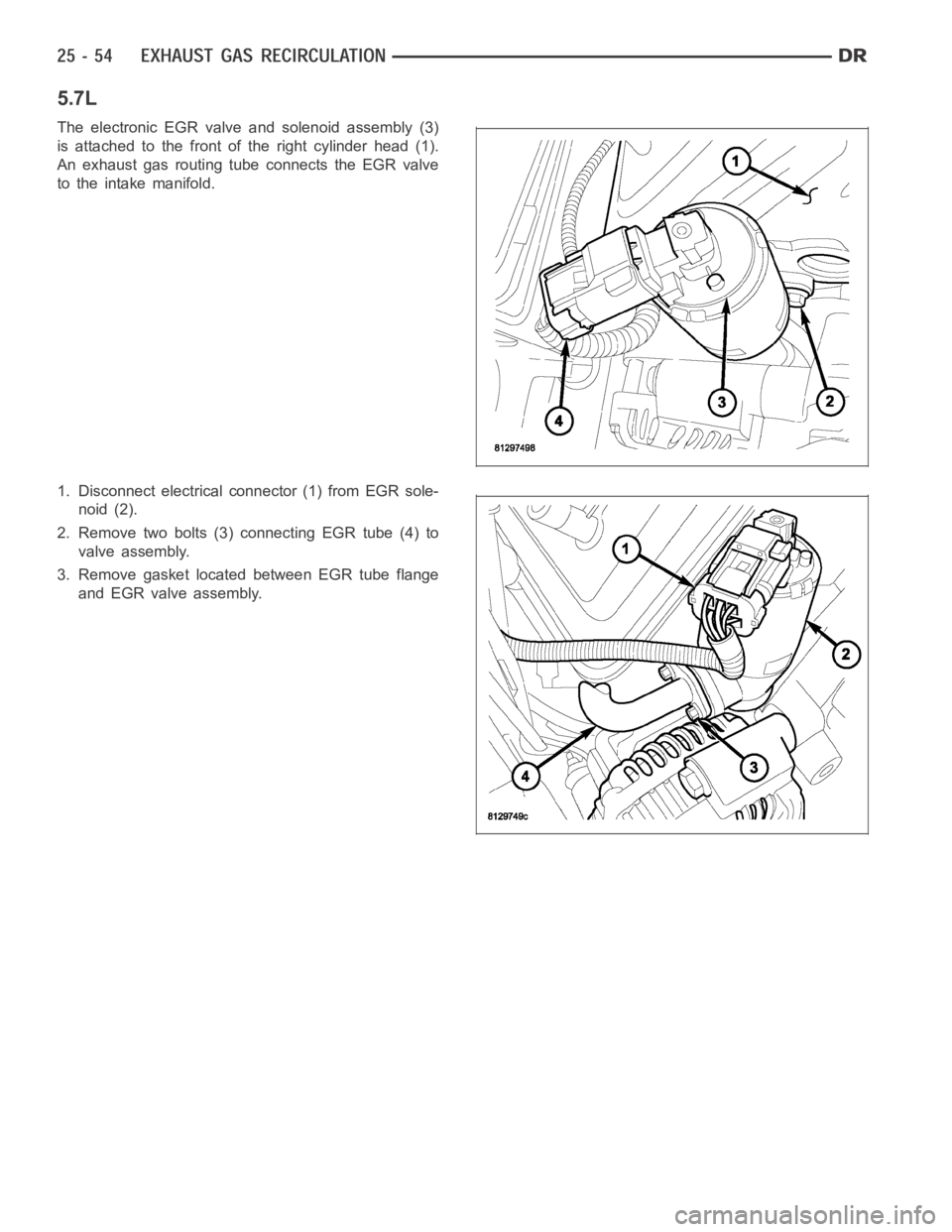

5.7L

The electronic EGR valve and solenoid assembly (3)

is attached to the front of the right cylinder head (1).

An exhaust gas routing tube connects the EGR valve

to the intake manifold.

1. Disconnect electrical connector (1) from EGR sole-

noid (2).

2. Remove two bolts (3) connecting EGR tube (4) to

valve assembly.

3. Remove gasket located between EGR tube flange

and EGR valve assembly.

Page 5246 of 5267

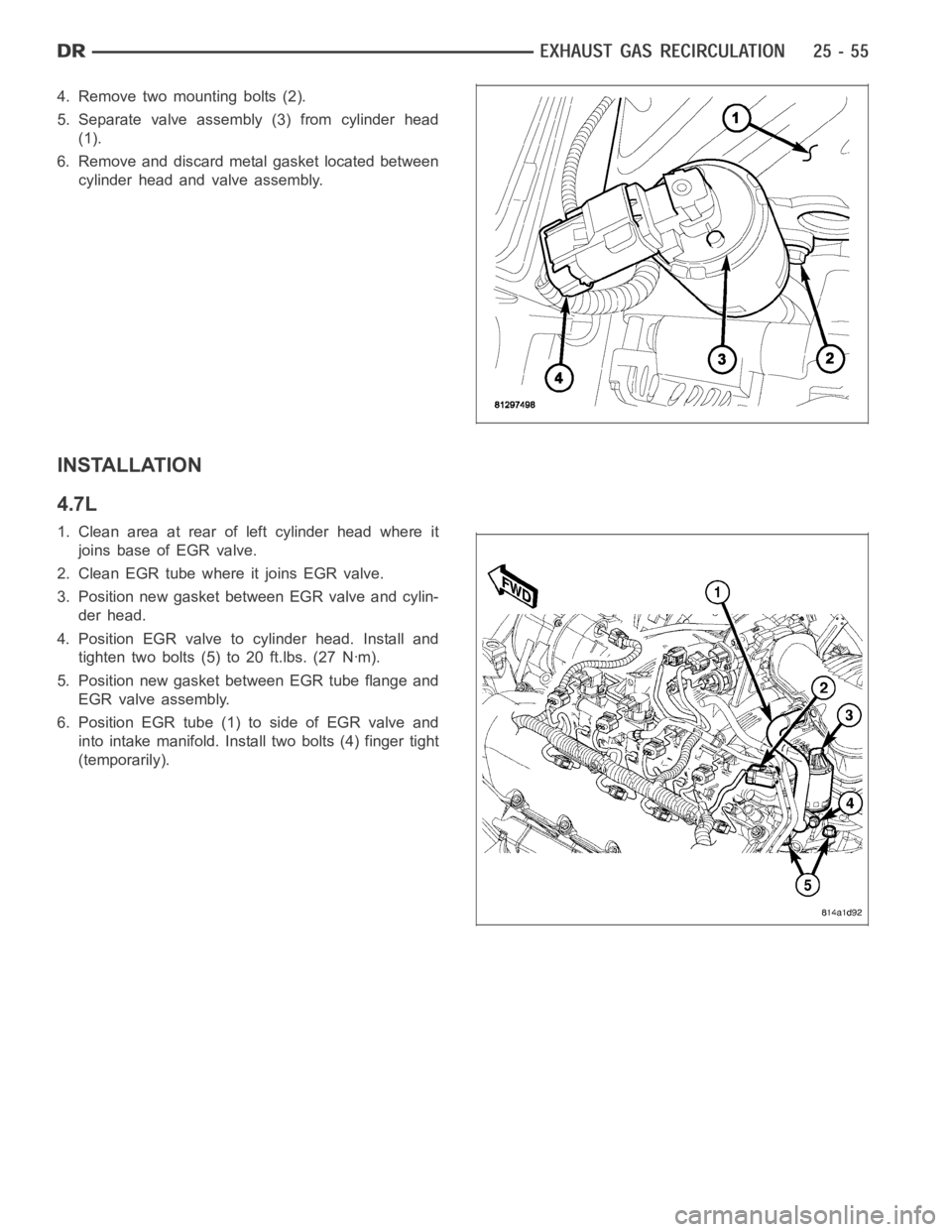

4. Remove two mounting bolts (2).

5. Separate valve assembly (3) from cylinder head

(1).

6. Remove and discard metal gasket located between

cylinder head and valve assembly.

INSTALLATION

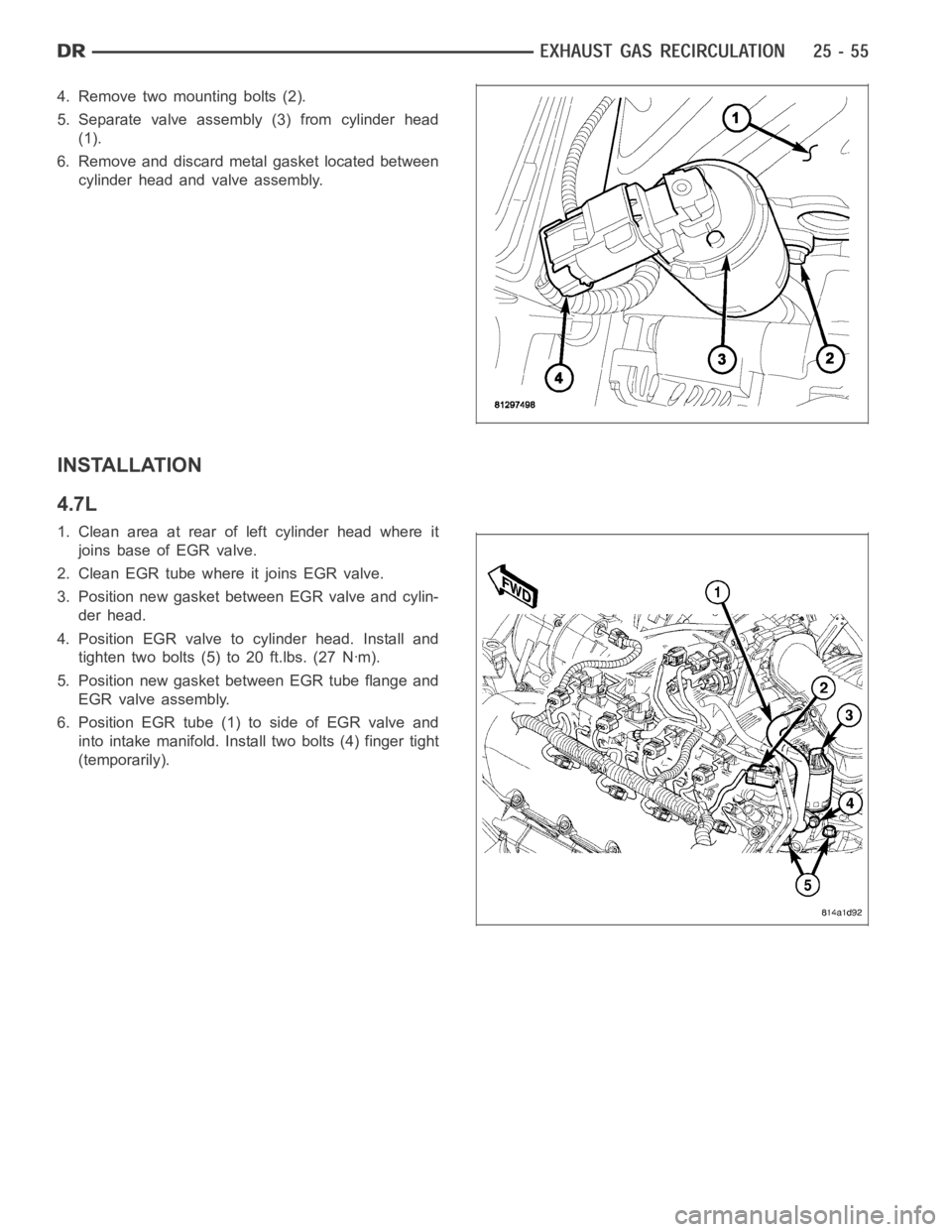

4.7L

1. Clean area at rear of left cylinder head where it

joins base of EGR valve.

2. Clean EGR tube where it joins EGR valve.

3. Position new gasket between EGR valve and cylin-

der head.

4. Position EGR valve to cylinder head. Install and

tighten two bolts (5) to 20 ft.lbs. (27 Nꞏm).

5. Position new gasket between EGR tube flange and

EGR valve assembly.

6. Position EGR tube (1) to side of EGR valve and

into intake manifold. Install two bolts (4) finger tight

(temporarily).

Page 5247 of 5267

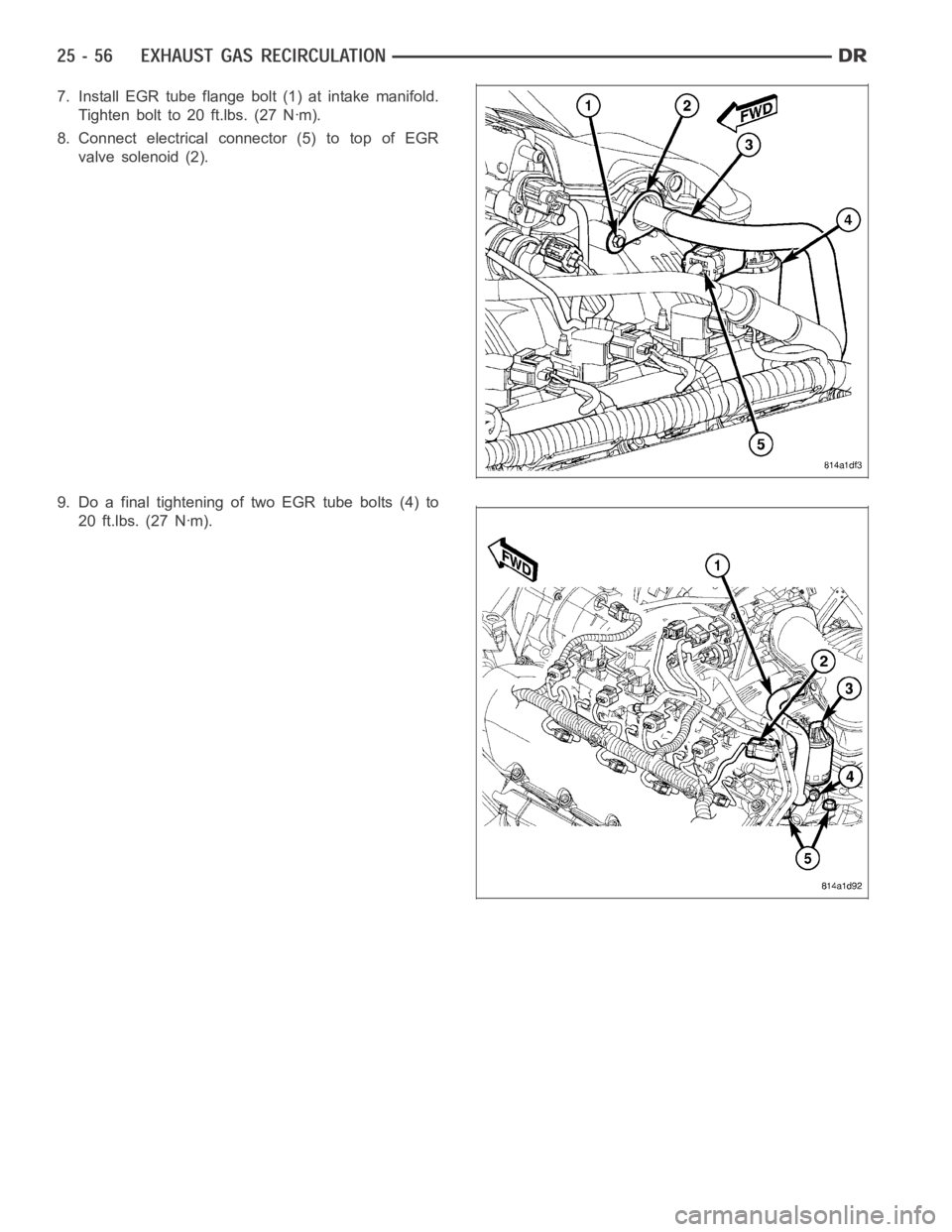

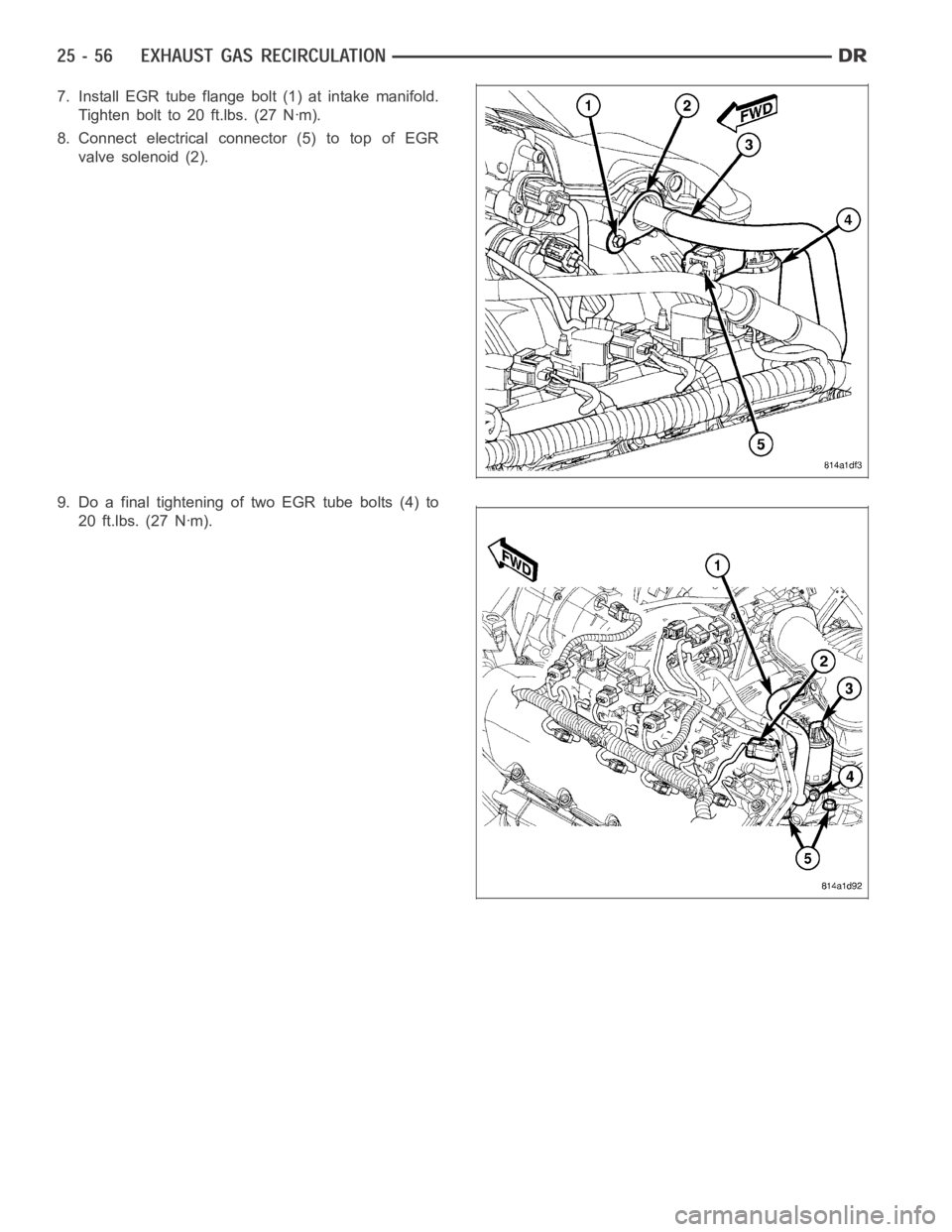

7. Install EGR tube flange bolt (1) at intake manifold.

Tighten bolt to 20 ft.lbs. (27 Nꞏm).

8. Connect electrical connector (5) to top of EGR

valve solenoid (2).

9. Do a final tightening of two EGR tube bolts (4) to

20 ft.lbs. (27 Nꞏm).

Page 5248 of 5267

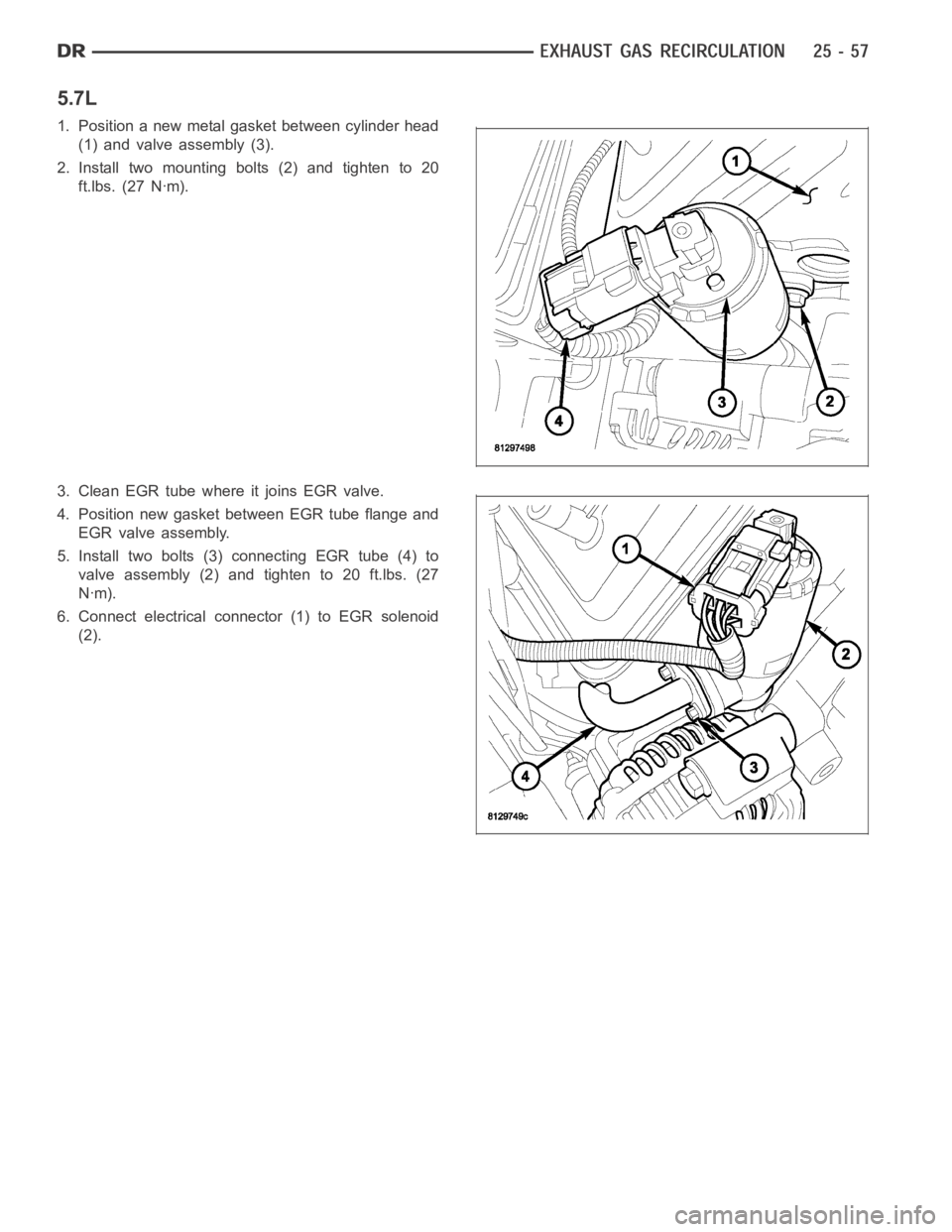

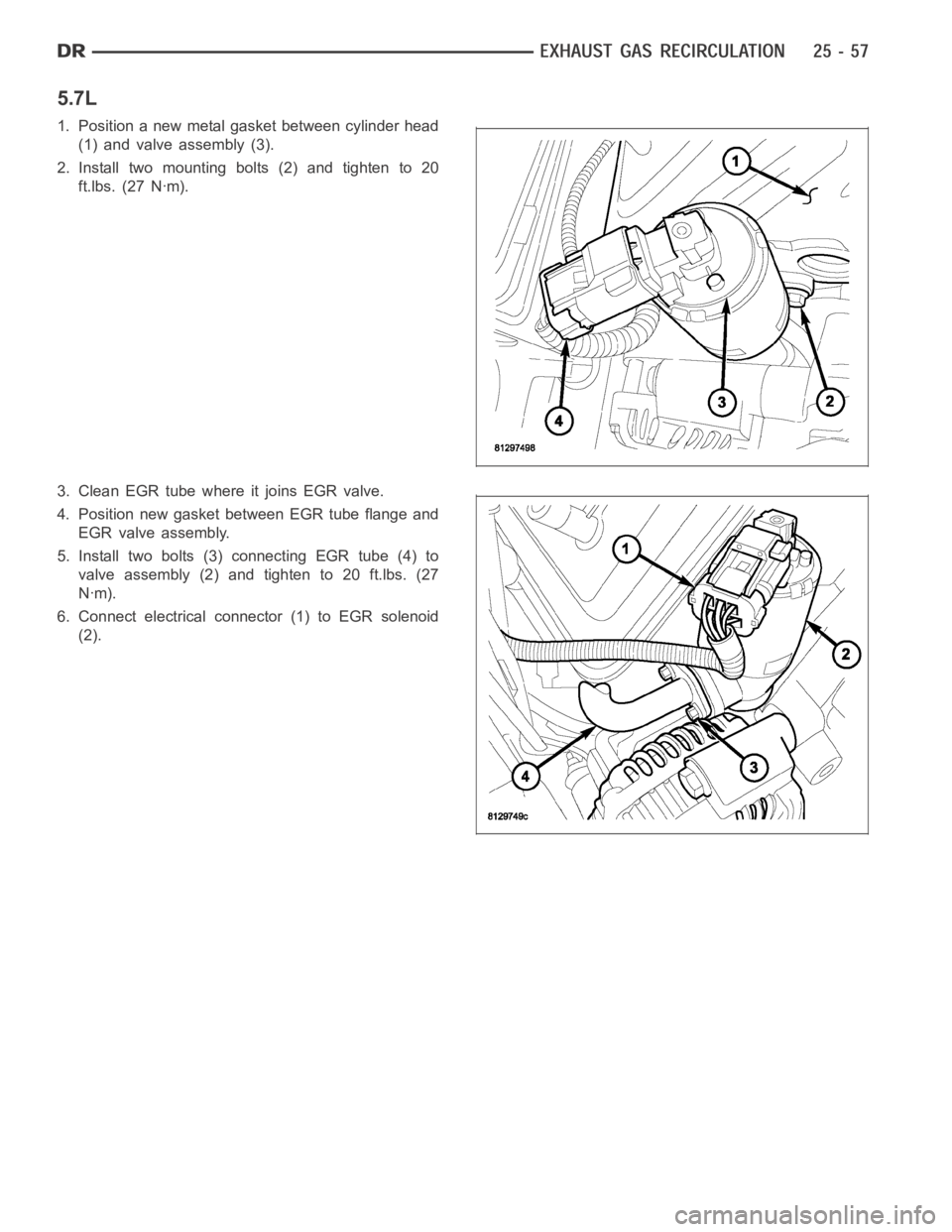

5.7L

1. Position a new metal gasket between cylinder head

(1) and valve assembly (3).

2. Install two mounting bolts (2) and tighten to 20

ft.lbs. (27 Nꞏm).

3. Clean EGR tube where it joins EGR valve.

4. Position new gasket between EGR tube flange and

EGR valve assembly.

5. Install two bolts (3) connecting EGR tube (4) to

valve assembly (2) and tighten to 20 ft.lbs. (27

Nꞏm).

6. Connect electrical connector (1) to EGR solenoid

(2).

Page 5249 of 5267

Page 5250 of 5267

INDEXDescription Group-Page Description Group-Page Description Group-Page

Trending: tire size, warning light, relay, phone, fuel cap, tire pressure, oil capacities