lock DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 3143 of 5267

2.OUTPUT SPEED SENSOR

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install the Transmission Simulator, Miller tool #8333.

Ignition on, engine not running.

With the Transmission Simulator, set the selector switch to 3000/1000 andthe Input/Output switch to ON.

With the scan tool, monitor the Input and Output Speed Sensor RPM

Does the Input Speed read 3000 RPM and the Output Speed read 1000 RPM, ± 50 RPM?

Ye s>>

Replace the Output Speed Sensor per the Service Information.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Go To 3

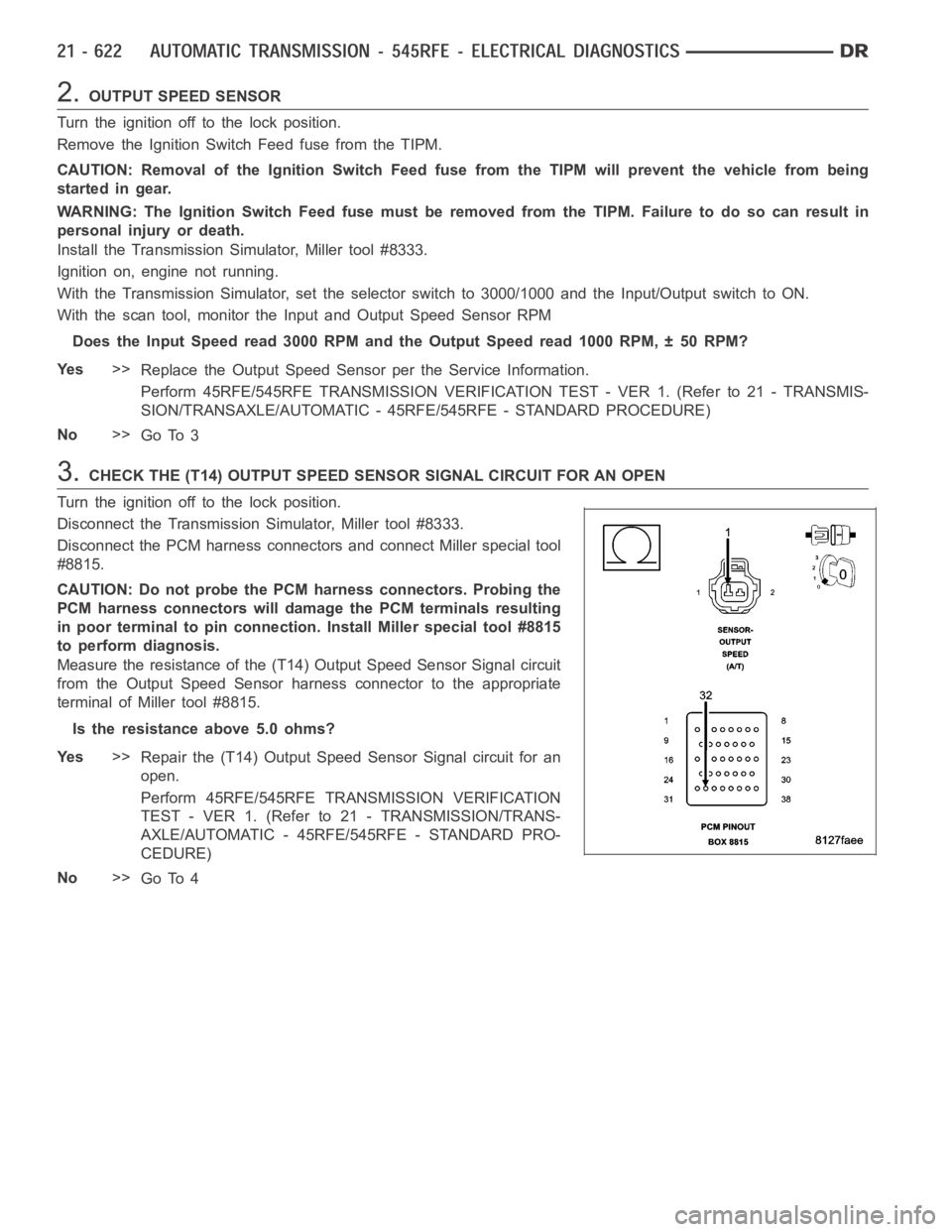

3.CHECK THE (T14) OUTPUT SPEED SENSOR SIGNAL CIRCUIT FOR AN OPEN

Turn the ignition off to the lock position.

Disconnect the Transmission Simulator, Miller tool #8333.

Disconnect the PCM harness connectors and connect Miller special tool

#8815.

CAUTION: Do not probe the PCM harness connectors. Probing the

PCM harness connectors will damage the PCM terminals resulting

in poor terminal to pin connection. Install Miller special tool #8815

to perform diagnosis.

Measure the resistance of the (T14) Output Speed Sensor Signal circuit

from the Output Speed Sensor harness connector to the appropriate

terminal of Miller tool #8815.

Is the resistance above 5.0 ohms?

Ye s>>

Repair the (T14) Output Speed Sensor Signal circuit for an

open.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

No>>

Go To 4

Page 3153 of 5267

Diagnostic Test

1.CHECKFORRELATEDDTCS

With the scan tool, check for other transmission DTCs.

Are there any Transmission: solenoid, line pressure, speed sensor, and/or loss of prime DTCs present?

Ye s>>

Refer to appropriate symptom in the Transmission category. Perform the test for P0944-LOSS OF

PRIME first if it is present.

No>>

Go To 2

2.CHECK IF DTC IS CURRENT

With the scan tool, read and record the DTC EVENT DATA.

NOTE: Make sure to record all DTC EVENT DATA stored in the scan tool for future reference in this test

procedure.

Does the DTC EVENT DATA display information for the DTC P0732?

Ye s>>

Go To 4

No>>

Go To 3

3.CHECK DTC EVENT DATA

In the DTC EVENT DATA, identify the DTC that was recorded earlier.

Does the DTC EVENT DATA display information for the DTC P1790, with target gear = 2nd, or with both

2C and UD clutches applying?

Ye s>>

Go To 4

No>>

Go To 7

4.CHECK RPM IN DTC EVENT DATA

Refer to the DTC EVENT DATA recorded earlier.

Does the Input RPM read zero?

Ye s>>

Check the input speed sensor and wiring. Refer to test P0715 and diagnose asif the DTC is current.

No>>

Go To 5

5.CHECK LINE PRESSURE READING

Refer to the DTC EVENT DATA recorded earlier.

Isthelinepressurereadingmorethan10 psi below the desired line pressure?

Ye s>>

Go To 6

No>>

Go To 7

6.CHECK TRANSMISSION OIL FILTER

Turn the ignition off to the lock position.

Remove and inspect the Transmission Oil Pan for excessive debris per the Service Information.

Remove and inspect the Primary Oil Filter per the Service Information.

NOTE: Make sure the Primary Transmission Oil Filter and seal are properly installed and are not cracked or

split.

Does the Oil Pan contain excessive debris and/or is the Primary Oil Filter cracked, plugged or mis-in-

Page 3159 of 5267

Diagnostic Test

1.CHECK IF RELATED DTCS ARE PRESENT

With the scan tool, check for other transmission DTCs

Are there any Transmission; solenoid, line pressure, speed sensor, and/or loss of prime DTCs present?

Ye s>>

Refer to appropriate symptom in the Transmission category. Perform the test for P0944-LOSS OF

PRIME first if it is present.

No>>

Go To 2

2.CHECK DTC EVENT DATA

With the scan tool, read and record the DTC EVENT DATA.

NOTE: Make sure to record all DTC EVENT DATA stored in the scan tool for future reference in this test

procedure.

Does the DTC EVENT DATA display information for the DTC P0733?

Ye s>>

Go To 4

No>>

Go To 3

3.CHECK THE TARGET GEAR IN DTC EVENT DATA

In the DTC EVENT DATA, identify the DTC that was recorded earlier.

Does the DTC EVENT DATA display information for the DTC P1790, with target gear = 3rd, or with both

OD and UD clutches applying?

Ye s>>

Go To 4

No>>

Go To 7

4.CHECK INPUT RPM IN DTC EVENT DATA

Refer to the DTC EVENT DATA recorded earlier.

Does the Input RPM read zero?

Ye s>>

Check the input speed sensor and wiring. Refer to test P0715 and diagnose asif the DTC is current.

No>>

Go To 5

5.CHECK LINE PRESSURE READING

Refer to the DTC EVENT DATA recorded earlier.

Isthelinepressurereadingmorethan10 psi below the desired line pressure?

Ye s>>

Go To 6

No>>

Go To 7

6.CHECK TRANSMISSION OIL FILTER

Turn the ignition off to the lock position.

Remove and inspect the Transmission Oil Pan for excessive debris per the Service Information.

Remove and inspect the Primary Oil Filter per the Service Information.

NOTE: Make sure the Primary Transmission Oil Filter and seal are properly installed and are not cracked or

split.

Does the Oil Pan contain excessive debris and/or is the Primary Oil Filter cracked, plugged or mis-in-

Page 3177 of 5267

When Monitored:

Initially at power-up, then every 10 seconds thereafter. The solenoid circuits will also be tested immediately

after a gear ratio or pressure switch error is detected.

Set Condition:

After three consecutive solenoid continuity test failures, or one failure if test is run in response to a gear ratio

or pressure switch error.Note: This DTC is strictly an electrical fault and does not apply to any internal

transmission failures.

Possible Causes

RELATED TIPM TCM DTCS PRESENT

(T20) LR SOLENOID CONTROL CIRCUIT SHORT TO OTHER CIRCUITS

(T20) LR SOLENOID CONTROL CIRCUIT OPEN

(T20) LR SOLENOID CONTROL CIRCUIT SHORT TO GROUND

TRANSMISSION SOLENOID/TRS ASSEMBLY

POWERTRAIN CONTROL MODULE

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

The Transmission Control System uses six electronically controlled solenoids that allow hydraulic fluid to be applied

to various friction elements (clutches), which enables the gear requested. The continuity of each solenoid circuit is

periodically tested. Each inactive solenoid is turned on for a few milliseconds, then off. Each active solenoid is

turned off for a few milliseconds, then on. This pulsing of voltage to the solenoid causes an inductive spike which

can be sensed by the Transmission Control System. If an inductive spike is not sensed by the Transmission Control

System during the continuity check, it is tested again. If the test fails three consecutive times, the appropriate Diag-

nostic Trouble Code (DTC) is set. If the solenoid test is run in response to agear ratio or pressure switch error, one

failure will result in setting the appropriate DTC.Note: This DTC is strictly an electrical fault and does not apply

to any internal transmission failures.

Diagnostic Test

1.CHECK FOR TIPM TCM DTCS

With the scan tool, check for other transmission DTCs.

Are there any TIPM TCM DTCs present?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom.

No>>

Go To 2

2.CHECK TO SEE IF P0750 IS PRESENT

Ignition on, engine not running.

With the scan tool, erase all Transmission DTC’s.

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install the Transmission Simulator, Miller tool #8333.

Ignition on, engine not running.

With the scan tool, actuate the LR Solenoid.

Page 3178 of 5267

Monitor the LR Solenoid LED on the Transmission Simulator.

Did the LR Solenoid LED on the Transmission Simulator blink on and off?

Ye s>>

Go To 3

No>>

Go To 4

3.CHECK THE TRANSMISSION SOLENOID/TRS ASSEMBLY

With the scan tool, continue to actuate the LR Solenoid for the period of 2 minutes with the Transmission Simulator

still connected.

After 2 minutes of actuation, with the scan tool, stop the actuation and check for transmission DTCs.

Did the DTC P0750 reset during the actuation test?

Ye s>>

Go To 4

No>>

Replace the Transmission Solenoid/TRS Assembly per the Service Information. (Refer to 21 - TRANS-

MISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE/TRANS SOLENOID/TRS ASSY -REMOVAL)

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

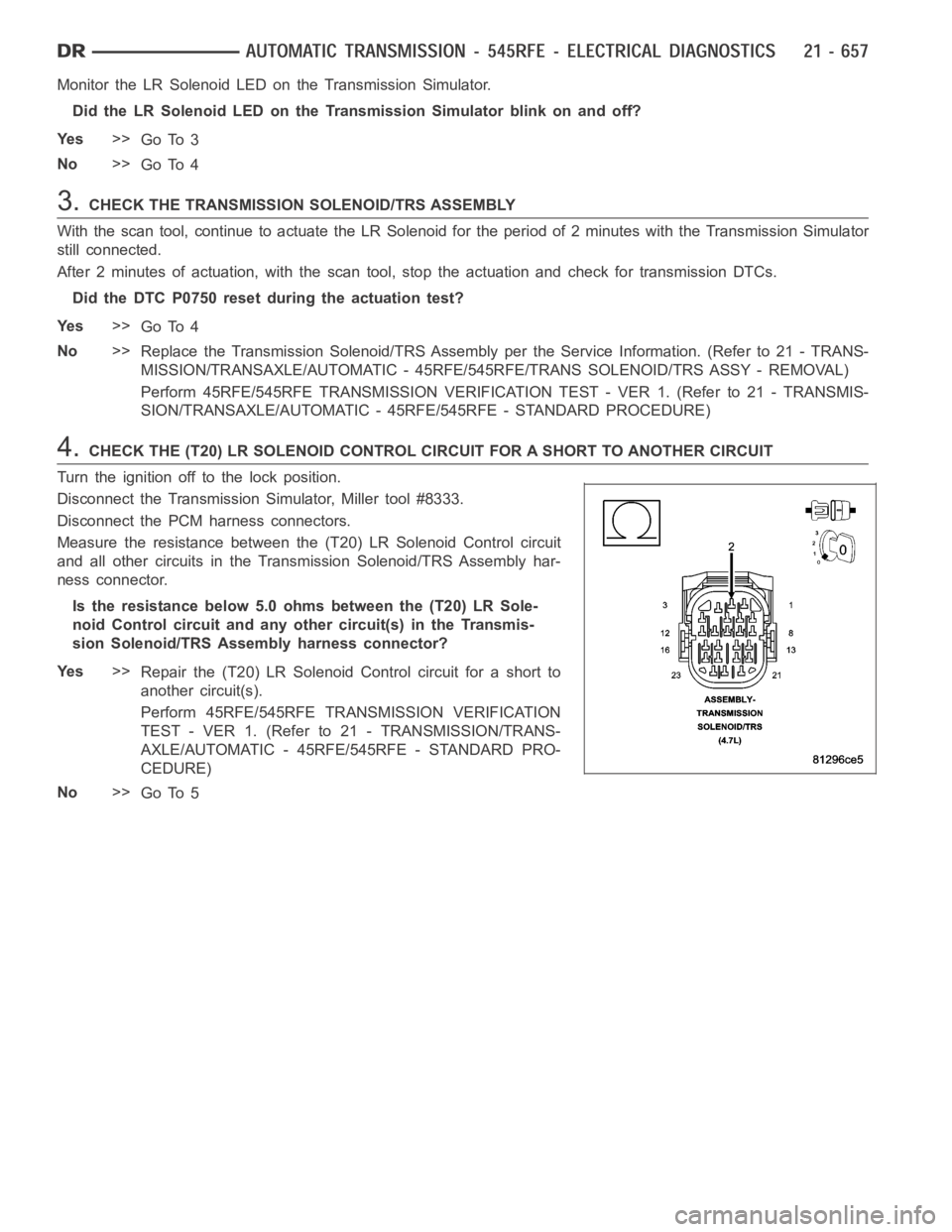

4.CHECK THE (T20) LR SOLENOID CONTROL CIRCUIT FOR A SHORT TO ANOTHER CIRCUIT

Turn the ignition off to the lock position.

Disconnect the Transmission Simulator, Miller tool #8333.

Disconnect the PCM harness connectors.

Measure the resistance between the (T20) LR Solenoid Control circuit

and all other circuits in the Transmission Solenoid/TRS Assembly har-

ness connector.

Is the resistance below 5.0 ohms between the (T20) LR Sole-

noid Control circuit and any other circuit(s) in the Transmis-

sion Solenoid/TRS Assembly harness connector?

Ye s>>

Repair the (T20) LR Solenoid Control circuit for a short to

another circuit(s).

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

No>>

Go To 5

Page 3181 of 5267

When Monitored:

Initially at power-up, then every 10 seconds thereafter. The solenoid circuits will also be tested immediately

after a gear ratio or pressure switch error is detected.

Set Condition:

After three consecutive solenoid continuity test failures, or one failure if test is run in response to a gear ratio

or pressure switch error.Note: This DTC is strictly an electrical fault and does not apply to any internal

transmission failures.

Possible Causes

RELATED TIPM TCM DTCS PRESENT

(T219) 2C SOLENOID CONTROL CIRCUIT SHORT TO OTHER CIRCUITS

(T219) 2C SOLENOID CONTROL CIRCUIT OPEN

(T219) 2C SOLENOID CONTROL CIRCUIT SHORT TO GROUND

TRANSMISSION SOLENOID/TRS ASSEMBLY

POWERTRAIN CONTROL MODULE

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

The Transmission Control System uses six electronically controlled solenoids that allow hydraulic fluid to be applied

to various friction elements (clutches), which enables the gear requested. The continuity of each solenoid circuit is

periodically tested. Each inactive solenoid is turned on for a few milliseconds, then off. Each active solenoid is

turned off for a few milliseconds, then on. This pulsing of voltage to the solenoid causes an inductive spike which

can be sensed by the Transmission Control System. If an inductive spike is not sensed by the Transmission Control

System during the continuity check, it is tested again. If the test fails three consecutive times, the appropriate Diag-

nostic Trouble Code (DTC) is set. If the solenoid test is run in response to agear ratio or pressure switch error, one

failure will result in setting the appropriate DTC.Note: This DTC is strictly an electrical fault and does not apply

to any internal transmission failures.

Diagnostic Test

1.CHECK FOR TCM TIPM DTCS

With the scan tool under TIPM, check for TCM Power Input DTCs.

Are there any TIPM TCM Power Input DTCs present?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom.

No>>

Go To 2

2.CHECK TO SEE IF P0755 IS PRESENT

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install the Transmission Simulator, Miller tool #8333.

Ignition on, engine not running.

With the scan tool, actuate the 2C Solenoid.

Did the 2C Solenoid LED blink on and off on the Transmission Simulator?

Ye s>>

Go To 3

No>>

Go To 4

Page 3182 of 5267

3.CHECK THE TRANSMISSION SOLENOID/TRS ASSEMBLY

With the scan tool, continue to actuate the 2C Solenoid for the period of 2 minutes with the Transmission Simulator

still connected.

After 2 minutes of actuation, with the scan tool, stop the actuation and check for transmission DTCs.

Did the DTC P0755 reset during the actuation test?

Ye s>>

Go To 4

No>>

Replace the Transmission Solenoid/TRS Assembly per the Service Information. (Refer to 21 - TRANS-

MISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE/TRANS SOLENOID/TRS ASSY -REMOVAL)

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

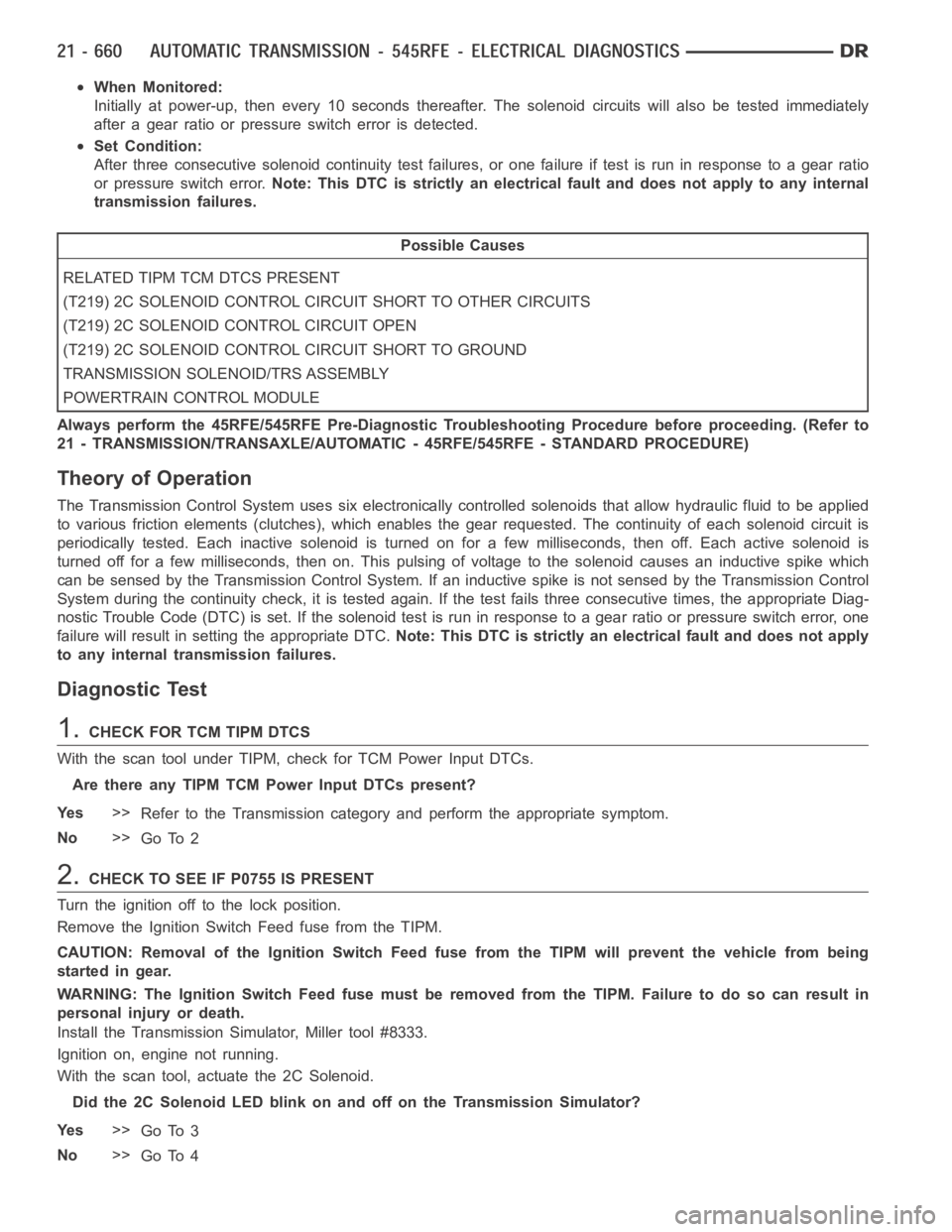

4.CHECK THE (T219) 2C SOLENOID CONTROL CIRCUIT FOR A SHORT TO ANOTHER CIRCUIT

Turn the ignition off to the lock position.

Disconnect the Transmission Simulator, Miller tool #8333.

Disconnect the PCM harness connectors.

Measure the resistance between the (T219) 2C Solenoid Control circuit

and all other circuits in the Transmission Solenoid/TRS Assembly har-

ness connector.

Is the resistance below 5.0 ohms between the (T219) 2C Sole-

noid Control circuit and any other circuit(s) in the Transmis-

sion Solenoid/TRS Assembly harness connector?

Ye s>>

Repair the (T219) 2C Solenoid Control circuit for a short to

another circuit(s).

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

No>>

Go To 5

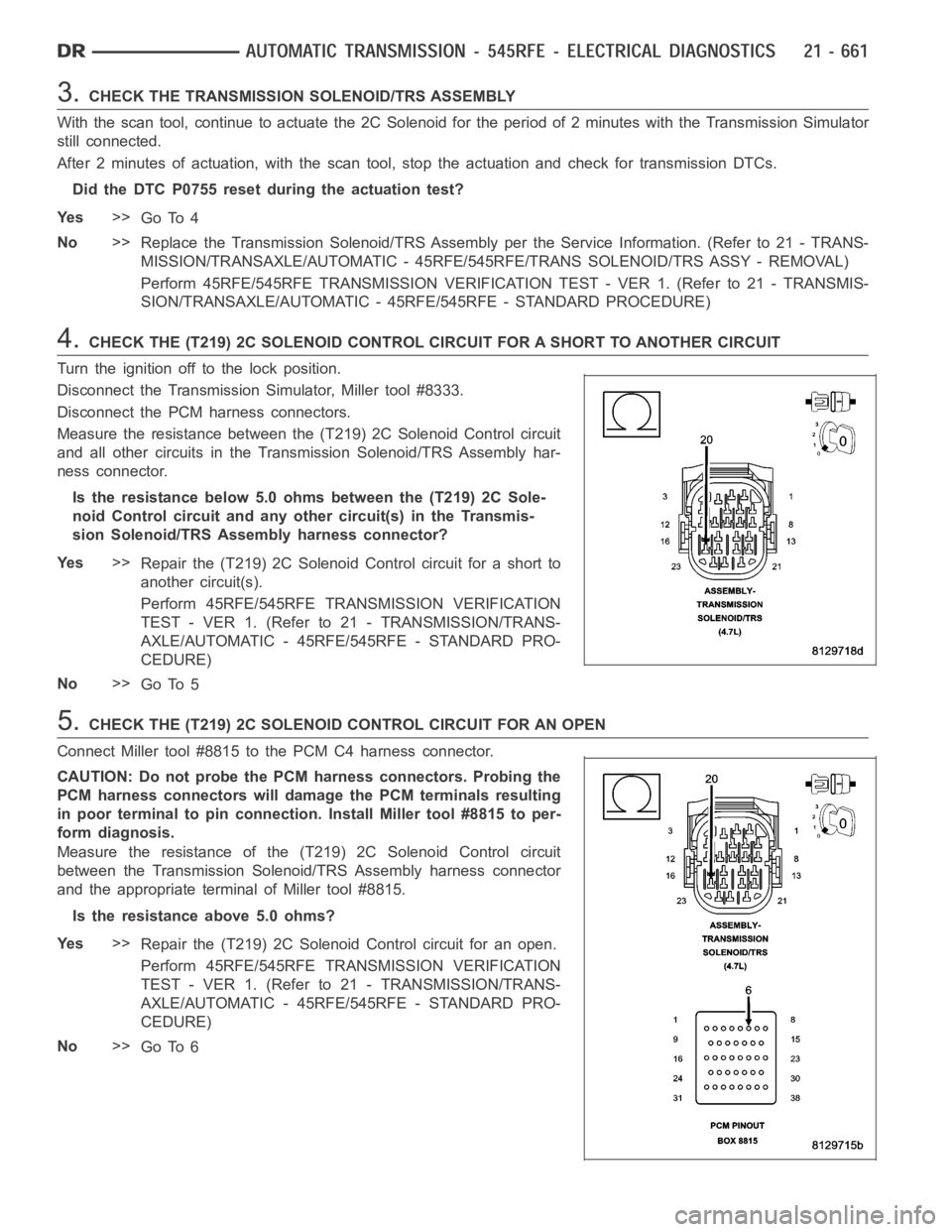

5.CHECK THE (T219) 2C SOLENOID CONTROL CIRCUIT FOR AN OPEN

Connect Miller tool #8815 to the PCM C4 harness connector.

CAUTION: Do not probe the PCM harness connectors. Probing the

PCM harness connectors will damage the PCM terminals resulting

in poor terminal to pin connection. Install Miller tool #8815 to per-

form diagnosis.

Measure the resistance of the (T219) 2C Solenoid Control circuit

between the Transmission Solenoid/TRS Assembly harness connector

and the appropriate terminal of Miller tool #8815.

Is the resistance above 5.0 ohms?

Ye s>>

Repair the (T219) 2C Solenoid Control circuit for an open.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

No>>

Go To 6

Page 3185 of 5267

When Monitored:

Initially at power-up, then every 10 seconds thereafter. The solenoid circuits will also be tested immediately

after a gear ratio or pressure switch error is detected.

Set Condition:

After three consecutive solenoid continuity test failures, or one failure if test is run in response to a gear ratio

or pressure switch error.Note: This DTC is strictly an electrical fault and does not apply to any internal

transmission failures.

Possible Causes

RELATED TIPM TCM DTCS PRESENT

(T60) OD SOLENOID CONTROL CIRCUIT SHORT TO OTHER CIRCUITS

(T60) OD SOLENOID CONTROL CIRCUIT OPEN

(T60) OD SOLENOID CONTROL CIRCUIT SHORT TO GROUND

TRANSMISSION SOLENOID/TRS ASSEMBLY

POWERTRAIN CONTROL MODULE

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

The Transmission Control System uses six electronically controlled solenoids that allow hydraulic fluid to be applied

to various friction elements (clutches), which enables the gear requested. The continuity of each solenoid circuit is

periodically tested. Each inactive solenoid is turned on for a few milliseconds, then off. Each active solenoid is

turned off for a few milliseconds, then on. This pulsing of voltage to the solenoid causes an inductive spike which

can be sensed by the Transmission Control System. If an inductive spike is not sensed by the Transmission Control

System during the continuity check, it is tested again. If the test fails three consecutive times, the appropriate Diag-

nostic Trouble Code (DTC) is set. If the solenoid test is run in response to agear ratio or pressure switch error, one

failure will result in setting the appropriate DTC.Note: This DTC is strictly an electrical fault and does not apply

to any internal transmission failures.

Diagnostic Test

1.RELATED TIPM TCM DTCS PRESENT

With the scan tool, check for TIPM DTCs.

Are there any TIPM TCM DTCs present?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom.

No>>

Go To 2

2.CHECK TO SEE IF P0760 IS PRESENT

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install Transmission Simulator, Miller tool #8333.

Ignition on, engine not running.

With the scan tool, actuate the OD Solenoid.

Page 3186 of 5267

Monitor the OD Solenoid LED on the Transmission Simulator.

Did the OD Solenoid LED on the Transmission Simulator blink on and off?

Ye s>>

Go To 3

No>>

Go To 4

3.CHECK THE TRANSMISSION SOLENOID/TRS ASSEMBLY

With the scan tool, continue to actuate the OD Solenoid for the period of 2 minutes with the Transmission Simulator

still connected.

After 2 minutes of actuation, with the scan tool, stop the actuation and check for transmission DTCs.

Did the DTC P0760 reset during the actuation test?

Ye s>>

Go To 4

No>>

Replace the Transmission Solenoid/TRS Assembly per the Service Information. (Refer to 21 - TRANS-

MISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE/TRANS SOLENOID/TRS ASSY -REMOVAL)

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

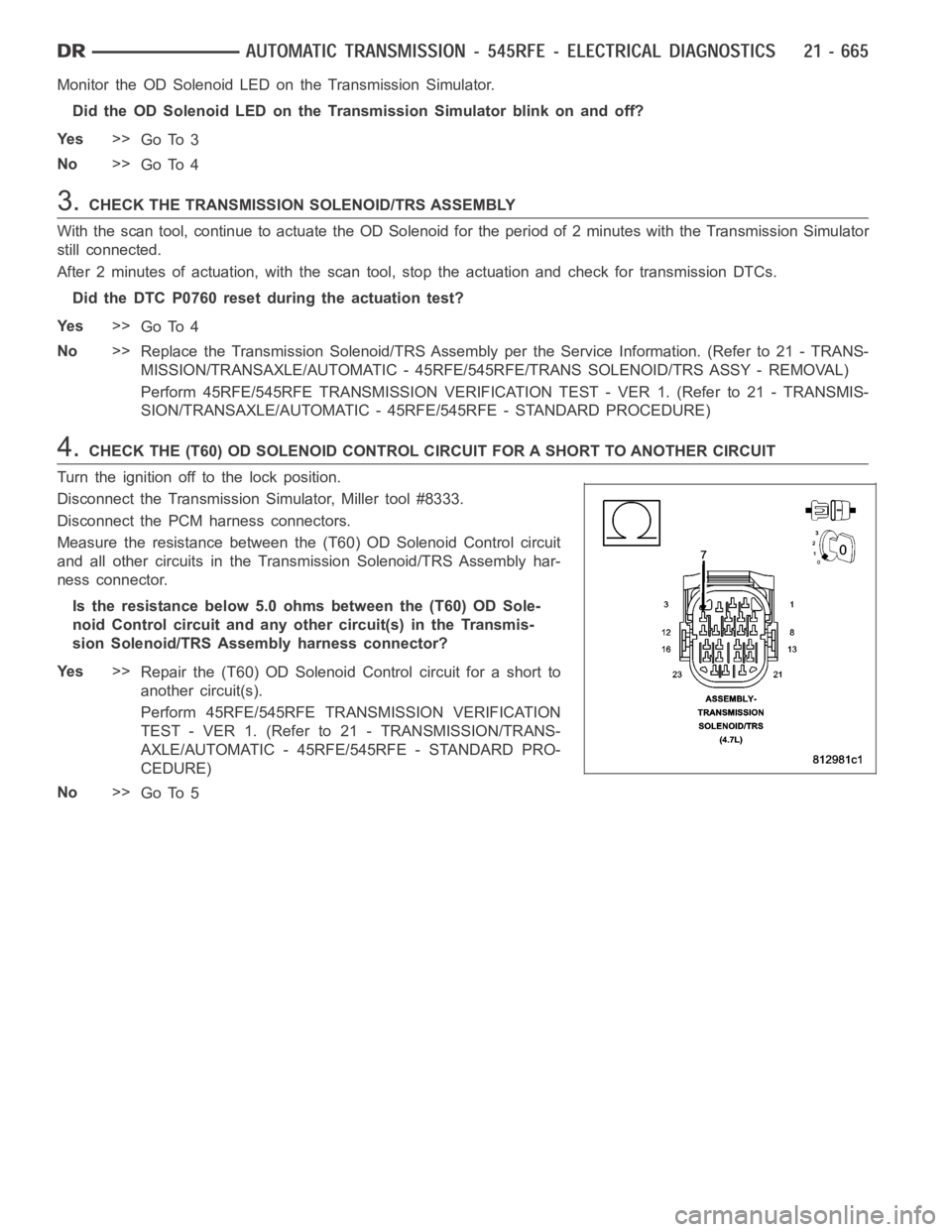

4.CHECK THE (T60) OD SOLENOID CONTROL CIRCUIT FOR A SHORT TO ANOTHER CIRCUIT

Turn the ignition off to the lock position.

Disconnect the Transmission Simulator, Miller tool #8333.

Disconnect the PCM harness connectors.

Measure the resistance between the (T60) OD Solenoid Control circuit

and all other circuits in the Transmission Solenoid/TRS Assembly har-

ness connector.

Is the resistance below 5.0 ohms between the (T60) OD Sole-

noid Control circuit and any other circuit(s) in the Transmis-

sion Solenoid/TRS Assembly harness connector?

Ye s>>

Repair the (T60) OD Solenoid Control circuit for a short to

another circuit(s).

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

No>>

Go To 5

Page 3189 of 5267

When Monitored:

Initially at power-up, then every 10 seconds thereafter. The solenoid circuits will also be tested immediately

after a gear ratio or pressure switch error is detected.

Set Condition:

After three consecutive solenoid continuity test failures, or one failure if test is run in response to a gear ratio

or pressure switch error.Note: This DTC is strictly an electrical fault and does not apply to any internal

transmission failures.

Possible Causes

RELATED TIPM TCM DTCS PRESENT

(T59) UD SOLENOID CONTROL CIRCUIT SHORT TO OTHER CIRCUITS

(T59) UD SOLENOID CONTROL CIRCUIT OPEN

(T59) UD SOLENOID CONTROL CIRCUIT SHORT TO GROUND

TRANSMISSION SOLENOID/TRS ASSEMBLY

POWERTRAIN CONTROL MODULE

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

The Transmission Control System uses six electronically controlled solenoids that allow hydraulic fluid to be applied

to various friction elements (clutches), which enables the gear requested. The continuity of each solenoid circuit is

periodically tested. Each inactive solenoid is turned on for a few milliseconds, then off. Each active solenoid is

turned off for a few milliseconds, then on. This pulsing of voltage to the solenoid causes an inductive spike which

can be sensed by the Transmission Control System. If an inductive spike is not sensed by the Transmission Control

System during the continuity check, it is tested again. If the test fails three consecutive times, the appropriate Diag-

nostic Trouble Code (DTC) is set. If the solenoid test is run in response to agear ratio or pressure switch error, one

failure will result in setting the appropriate DTC.Note: This DTC is strictly an electrical fault and does not apply

to any internal transmission failures.

Diagnostic Test

1.CHECK FOR TCM TIPM DTCS

With the scan tool under TIPM, check for TCM Power Input DTCs.

Are there any TIPM TCM Power Input DTCs present?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom.

No>>

Go To 2

2.CHECK IF P0765 IS PRESENT

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install Transmission Simulator, Miller tool #8333.

Ignition on, engine not running.

With the scan tool, actuate the UD Solenoid.