ECO mode DODGE RAM SRT-10 2006 Service Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2811 of 5267

When Monitored:

Whenever the engine is running.

Set Condition:

The DTC is set if one of the pressure switches are open or closed at the wrong time in a given gear. If the

problem is identified for 3 successive key starts, the transmission will go into Limp-in mode and the MIL will

turn on after 10 seconds of vehicle operation.

Possible Causes

RELATED TIPM TCM POWER CONTROL CIRCUIT DTCS PRESENT

LOSS OF PRIME DTC PRESENT

(T47) 2/4 PRESSURE SWITCH SENSE CIRCUIT OPEN

(T47) 2/4 PRESSURE SWITCH SENSE CIRCUIT SHORT TO GROUND

(T47) 2/4 PRESSURE SWITCH SENSE CIRCUIT SHORT TO VOLTAGE

TRANSMISSION SOLENOID/PRESSURE SWITCH ASSEMBLY

POWERTRAIN CONTROL MODULE

Always perform the 42RLE Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

Theory of Operation

The Transmission system uses three pressure switches to monitor the fluidpressure in the LR, 2/4, and OD ele-

ments. The pressure switches are continuously monitored for the correct states in each gear. The 2/4 pressure

switch monitors the fluid pressure to the 2/4 clutch to confirm proper operation of the 2/4 solenoid. If the 2/4 pres-

sure switch is identified as closed in Por N, the code will immediately be set and normal operation will be allowed

for that given key start. If the problem is identified for 3 successive ignition cycles, the transmission will go into

Limp-in mode.

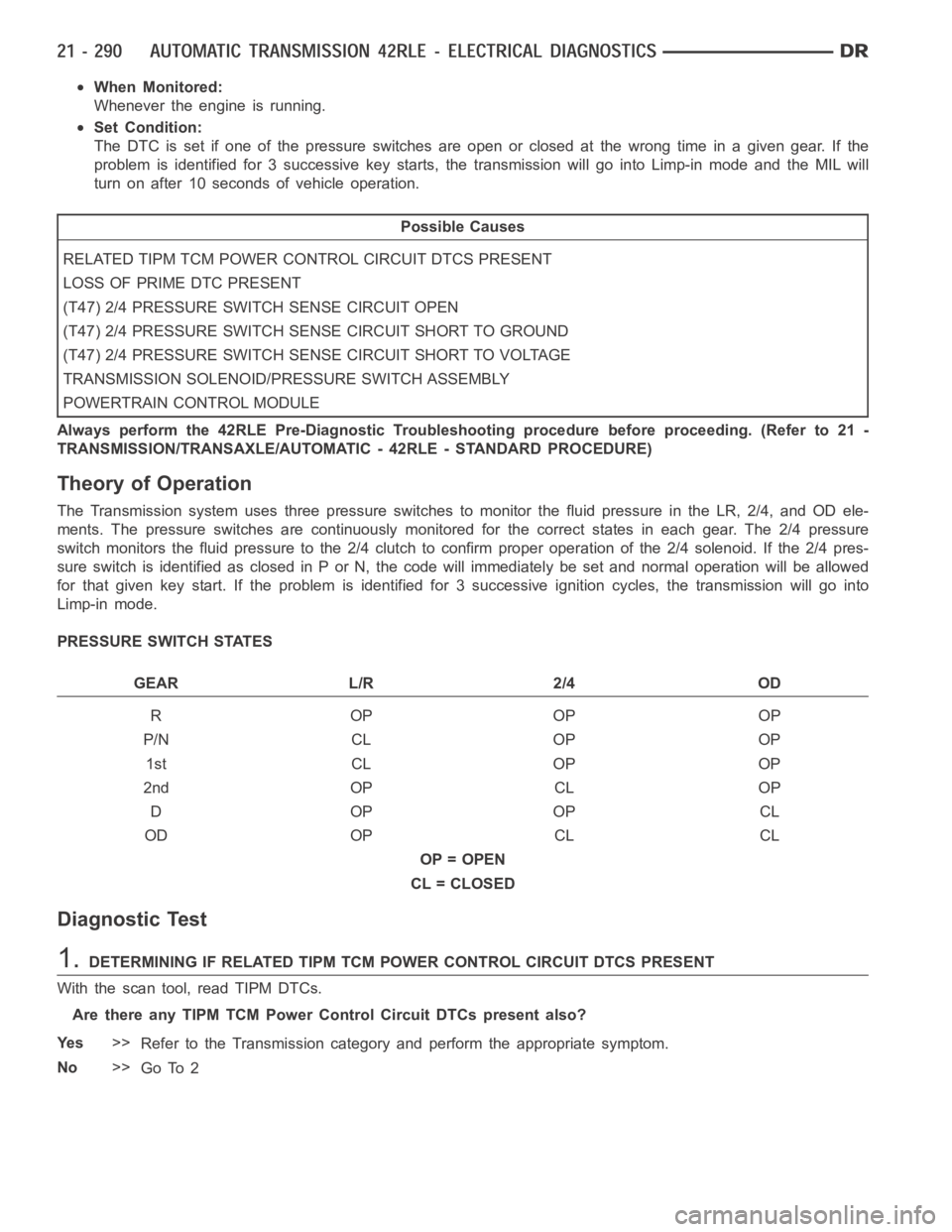

PRESSURE SWITCH STATES

GEAR L/R 2/4 OD

ROPOPOP

P/N CL OP OP

1st CL OP OP

2nd OP CL OP

DOPOPCL

OD OP CL CL

OP = OPEN

CL = CLOSED

Diagnostic Test

1.DETERMINING IF RELATED TIPM TCM POWER CONTROL CIRCUIT DTCS PRESENT

With the scan tool, read TIPM DTCs.

Are there any TIPM TCM Power Control Circuit DTCs present also?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom.

No>>

Go To 2

Page 2833 of 5267

When Monitored:

Whenever the engine is running.

Set Condition:

The DTC is set if one of the pressure switches are open or closed at the wrong time in a given gear. If the

problem is identified for 3 successive key starts, the transmission will go into Limp-in mode and the MIL will

turn on after 10 seconds of vehicle operation.

Possible Causes

RELATED TIPM TCM POWER INPUT DTCS PRESENT

LOSS OF PRIME DTC PRESENT

(T9) OD PRESSURE SWITCH SENSE CIRCUIT OPEN

(T9) OD PRESSURE SWITCH SENSE CIRCUIT SHORT TO GROUND

(T9) OD PRESSURE SWITCH SENSE CIRCUIT SHORT TO VOLTAGE

TRANSMISSION SOLENOID/PRESSURE SWITCH ASSEMBLY

POWERTRAIN CONTROL MODULE

Always perform the 42RLE Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

Theory of Operation

The Transmission system uses three pressure switches to monitor the fluidpressure in the LR, 2/4, and OD ele-

ments. The pressure switches are continuously monitored for the correct states in each gear. Normal operation will

be experienced if no other codes are present. Transmission Control Systemwill ignore the code. Limp-in condition

will only occur if DTC P0871 is present with a DTC P0706.

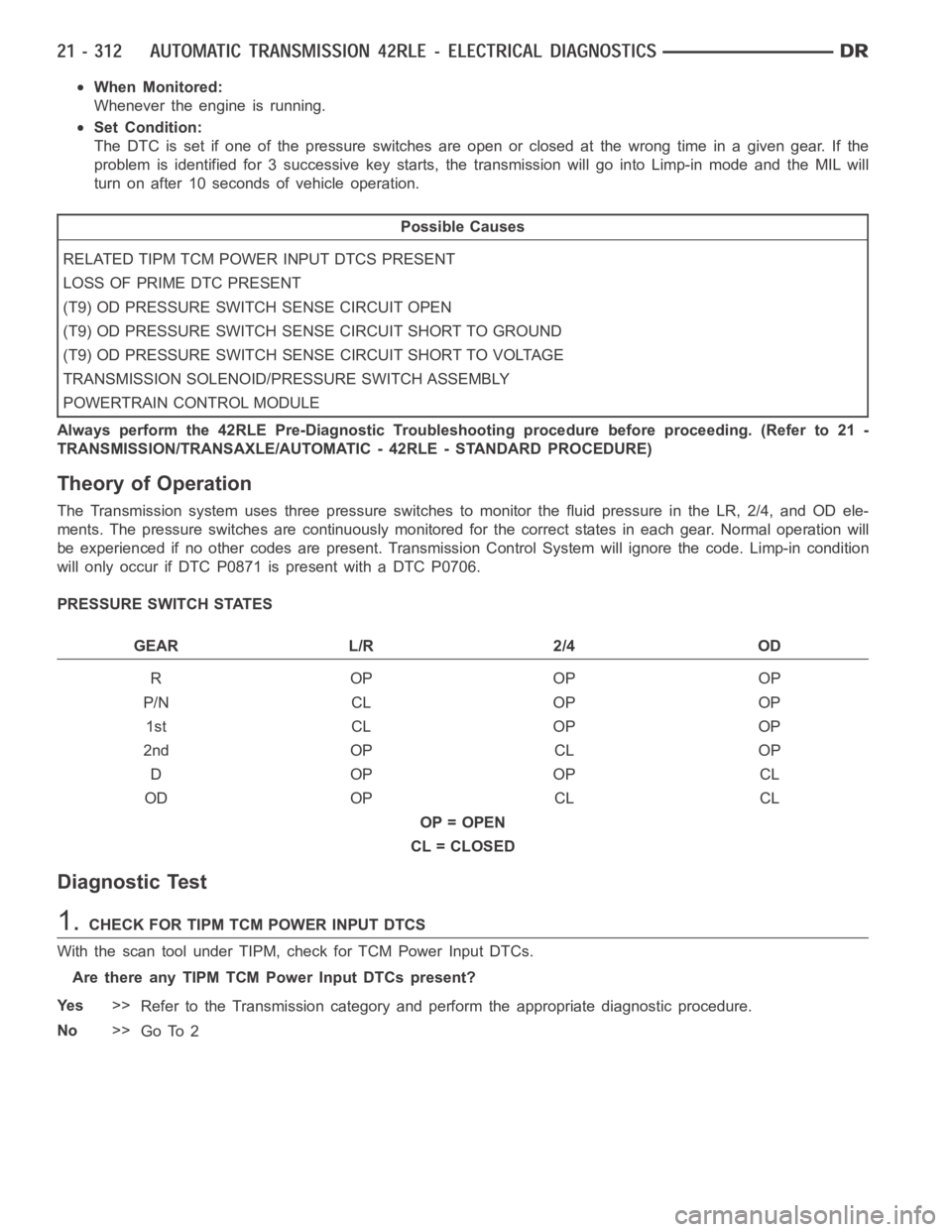

PRESSURE SWITCH STATES

GEAR L/R 2/4 OD

ROPOPOP

P/N CL OP OP

1st CL OP OP

2nd OP CL OP

DOPOPCL

OD OP CL CL

OP = OPEN

CL = CLOSED

Diagnostic Test

1.CHECK FOR TIPM TCM POWER INPUT DTCS

With the scan tool under TIPM, check for TCM Power Input DTCs.

Are there any TIPM TCM Power Input DTCs present?

Ye s>>

Refer to the Transmission category and perform the appropriate diagnostic procedure.

No>>

Go To 2

Page 2847 of 5267

When Monitored:

One time after a reset (ignition key turned to the RUN position or after cranking engine).

Set Condition:

A fault is set if voltage greater than 4.5 volts is detected for 7 msec on any of the pressure switch circuits

before the relay is energized. The transmission is placed in Limp-In. The MIL is on after 10 seconds. of vehicle

operation.

Possible Causes

(T47) 2/4 PRESSURE SWITCH SENSE CIRCUIT SHORT TO VOLTAGE

(T50) L/R PRESSURE SWITCH SENSE CIRCUIT SHORT TO VOLTAGE

(T9) OD PRESSURE SWITCH SENSE CIRCUIT SHORT TO VOLTAGE

POWERTRAIN CONTROL MODULE

Always perform the 42RLE Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

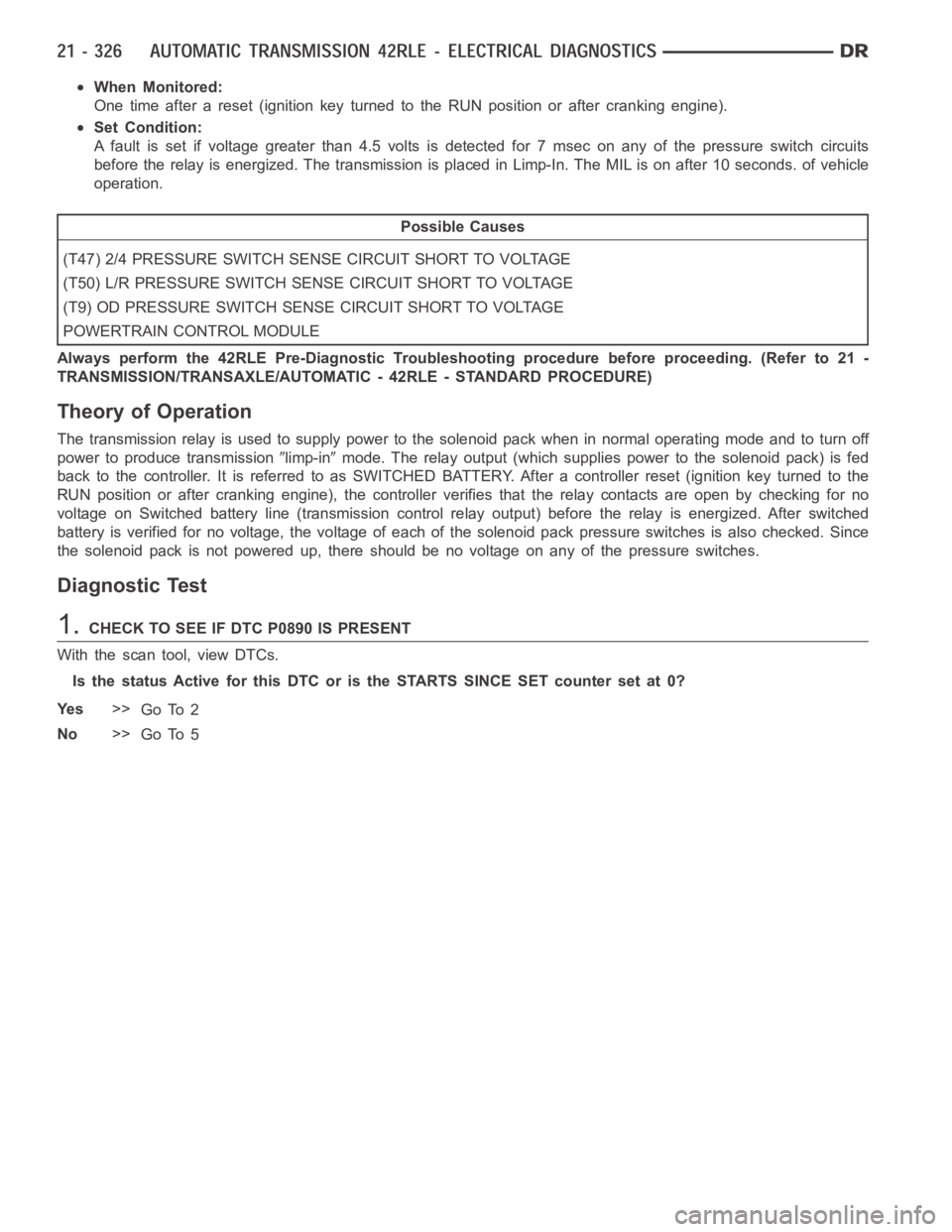

Theory of Operation

The transmission relay is used to supply power to the solenoid pack when in normal operating mode and to turn off

power to produce transmission

limp-inmode. The relay output (which supplies power to the solenoid pack) is fed

back to the controller. It is referred to as SWITCHED BATTERY. After a controller reset (ignition key turned to the

RUN position or after cranking engine), the controller verifies that the relay contacts are open by checking for no

voltage on Switched battery line (transmission control relay output) before the relay is energized. After switched

battery is verified for no voltage, the voltage of each of the solenoid packpressure switches is also checked. Since

the solenoid pack is not powered up, there should be no voltage on any of the pressure switches.

Diagnostic Test

1.CHECK TO SEE IF DTC P0890 IS PRESENT

With the scan tool, view DTCs.

Is the status Active for this DTC or is the STARTS SINCE SET counter set at 0?

Ye s>>

Go To 2

No>>

Go To 5

Page 2922 of 5267

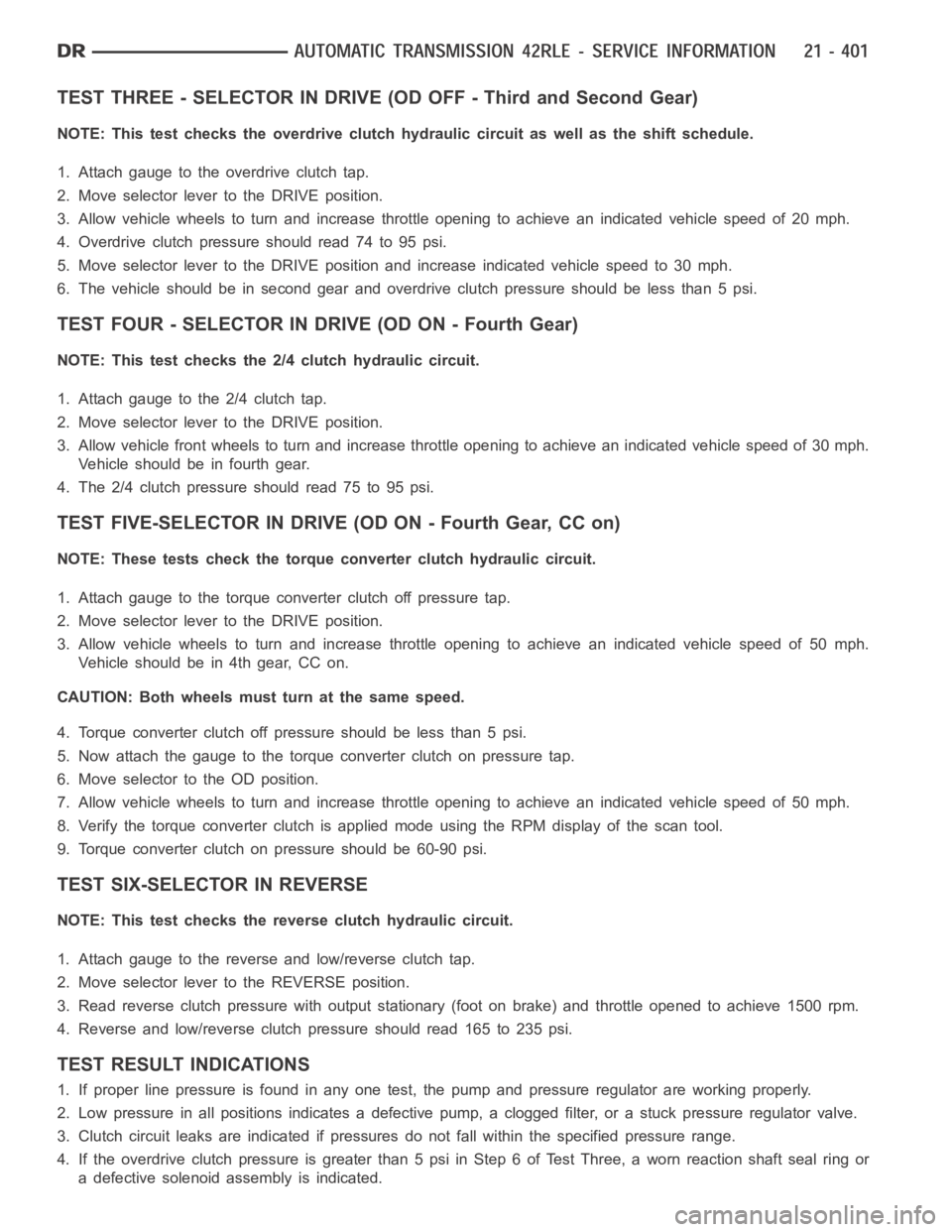

TEST THREE - SELECTOR IN DRIVE (OD OFF - Third and Second Gear)

NOTE: This test checks the overdrive clutch hydraulic circuit as well as the shift schedule.

1. Attach gauge to the overdrive clutch tap.

2. Move selector lever to the DRIVE position.

3. Allow vehicle wheels to turn and increase throttle opening to achieve anindicated vehicle speed of 20 mph.

4. Overdrive clutch pressure should read 74 to 95 psi.

5. Move selector lever to the DRIVE position and increase indicated vehicle speed to 30 mph.

6. The vehicle should be in second gearand overdrive clutch pressure shouldbelessthan5psi.

TEST FOUR - SELECTOR IN DRIVE (OD ON - Fourth Gear)

NOTE: This test checks the 2/4 clutch hydraulic circuit.

1. Attach gauge to the 2/4 clutch tap.

2. Move selector lever to the DRIVE position.

3. Allow vehicle front wheels to turn and increase throttle opening to achieve an indicated vehicle speed of 30 mph.

Vehicleshouldbeinfourthgear.

4. The 2/4 clutch pressure should read 75 to 95 psi.

TEST FIVE-SELECTOR IN DRIVE (OD ON - Fourth Gear, CC on)

NOTE: These tests check the torque converter clutch hydraulic circuit.

1. Attach gauge to the torque converter clutch off pressure tap.

2. Move selector lever to the DRIVE position.

3. Allow vehicle wheels to turn and increase throttle opening to achieve anindicated vehicle speed of 50 mph.

Vehicle should be in 4th gear, CC on.

CAUTION: Both wheels must turn at the same speed.

4. Torque converter clutch off pressure should be less than 5 psi.

5. Now attach the gauge to the torque converter clutch on pressure tap.

6. Move selector to the OD position.

7. Allow vehicle wheels to turn and increase throttle opening to achieve anindicated vehicle speed of 50 mph.

8. Verify the torque converter clutch is applied mode using the RPM displayof the scan tool.

9. Torque converter clutch on pressure should be 60-90 psi.

TEST SIX-SELECTOR IN REVERSE

NOTE: This test checks the reverse clutch hydraulic circuit.

1. Attach gauge to the reverse and low/reverse clutch tap.

2. Move selector lever to the REVERSE position.

3. Read reverse clutch pressure with output stationary (foot on brake) andthrottle opened to achieve 1500 rpm.

4. Reverse and low/reverse clutch pressure should read 165 to 235 psi.

TEST RESULT INDICATIONS

1. If proper line pressure is found in any one test, the pump and pressure regulator are working properly.

2. Low pressure in all positions indicates a defective pump, a clogged filter, or a stuck pressure regulator valve.

3. Clutch circuit leaks are indicated if pressures do not fall within the specified pressure range.

4. If the overdrive clutch pressure is greater than 5 psi in Step 6 of Test Three, a worn reaction shaft seal ring or

a defective solenoid assembly is indicated.

Page 3037 of 5267

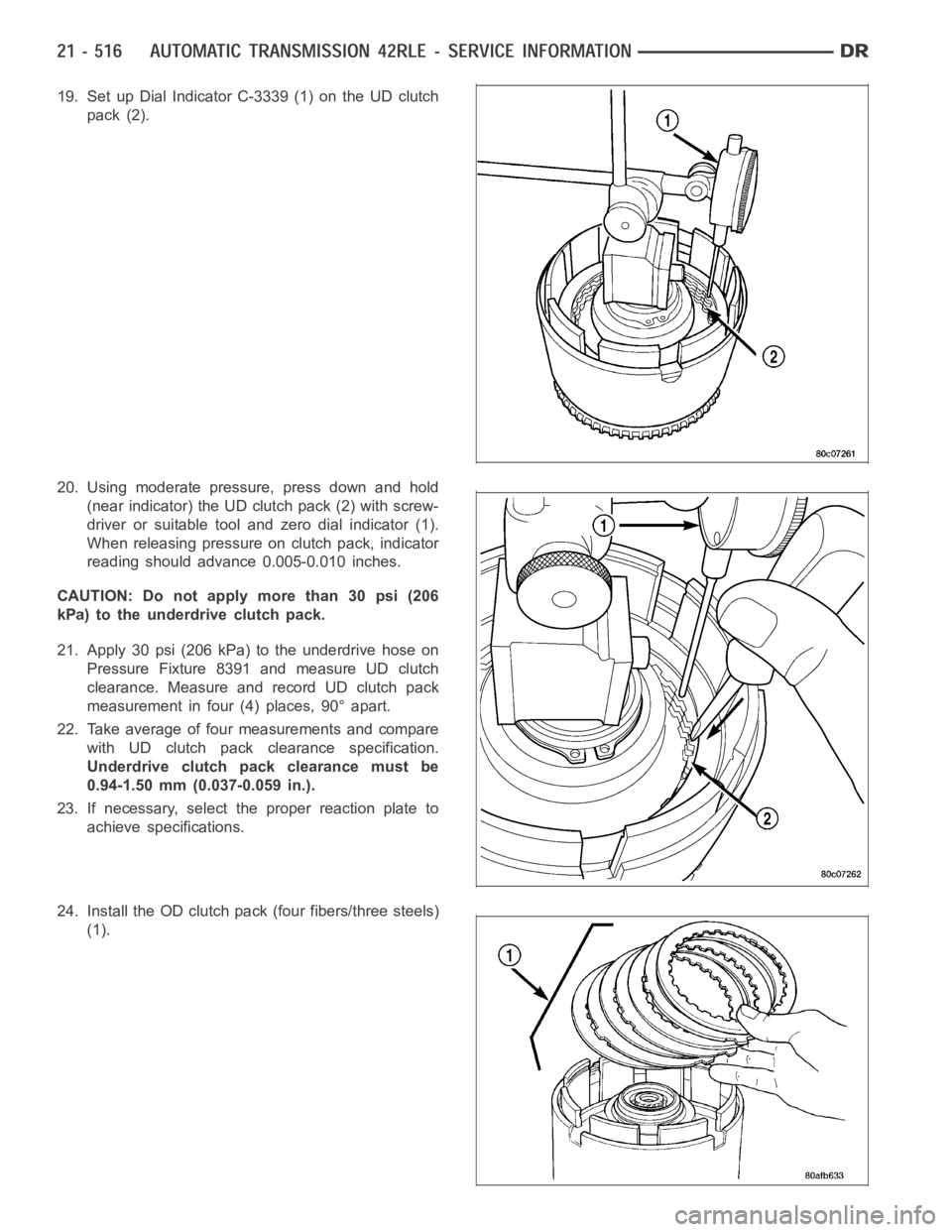

19. Set up Dial Indicator C-3339 (1) on the UD clutch

pack (2).

20. Using moderate pressure, press down and hold

(near indicator) the UD clutch pack (2) with screw-

driver or suitable tool and zero dial indicator (1).

When releasing pressure on clutch pack, indicator

reading should advance 0.005-0.010 inches.

CAUTION: Do not apply more than 30 psi (206

kPa) to the underdrive clutch pack.

21. Apply 30 psi (206 kPa) to the underdrive hose on

Pressure Fixture 8391 and measure UD clutch

clearance. Measure and record UD clutch pack

measurement in four (4) places, 90° apart.

22. Take average of four measurements and compare

with UD clutch pack clearance specification.

Underdrive clutch pack clearance must be

0.94-1.50 mm (0.037-0.059 in.).

23. If necessary, select the proper reaction plate to

achieve specifications.

24. Install the OD clutch pack(four fibers/three steels)

(1).

Page 3041 of 5267

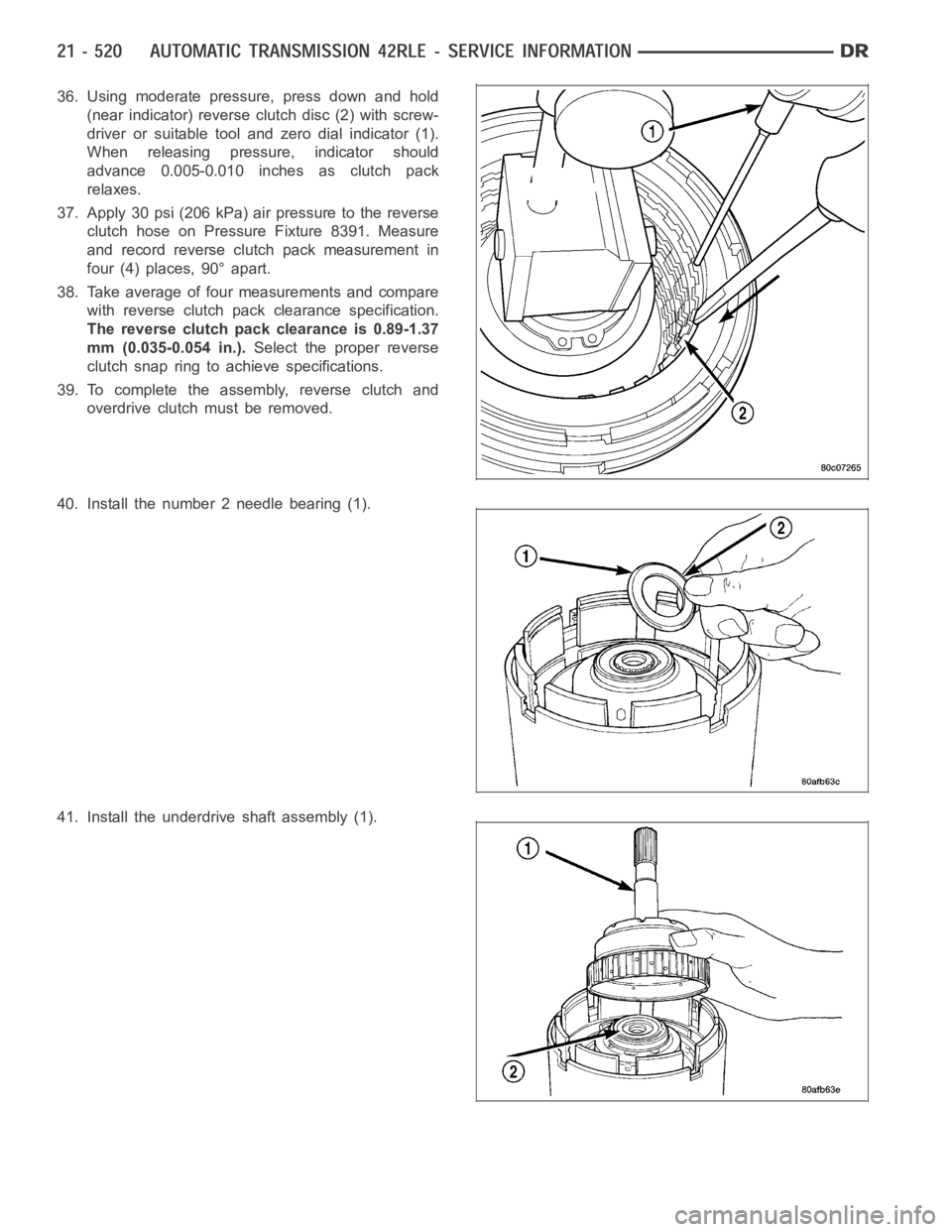

36. Using moderate pressure, press down and hold

(near indicator) reverse clutch disc (2) with screw-

driver or suitable tool and zero dial indicator (1).

When releasing pressure, indicator should

advance 0.005-0.010 inches as clutch pack

relaxes.

37. Apply 30 psi (206 kPa) air pressure to the reverse

clutch hose on Pressure Fixture 8391. Measure

and record reverse clutch pack measurement in

four (4) places, 90° apart.

38. Take average of four measurements and compare

with reverse clutch pack clearance specification.

The reverse clutch pack clearance is 0.89-1.37

mm (0.035-0.054 in.).Select the proper reverse

clutch snap ring to achieve specifications.

39. To complete the assembly, reverse clutch and

overdrive clutch must be removed.

40. Install the number 2 needle bearing (1).

41. Install the underdrive shaft assembly (1).

Page 3071 of 5267

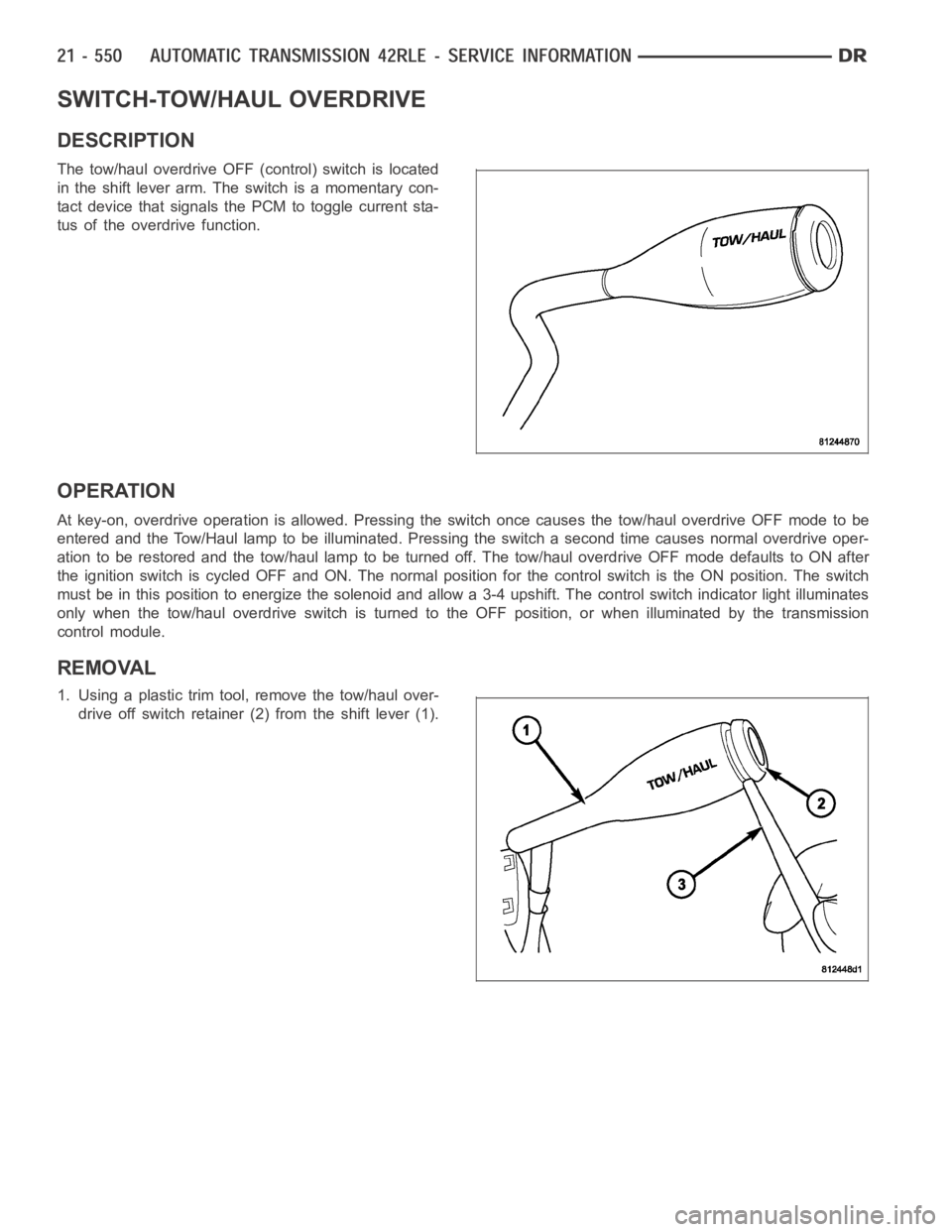

SWITCH-TOW/HAUL OVERDRIVE

DESCRIPTION

The tow/haul overdrive OFF (control) switch is located

in the shift lever arm. The switch is a momentary con-

tact device that signals the PCM to toggle current sta-

tus of the overdrive function.

OPERATION

At key-on, overdrive operation is allowed. Pressing the switch once causes the tow/haul overdrive OFF mode to be

entered and the Tow/Haul lamp to be illuminated. Pressing the switch a second time causes normal overdrive oper-

ationtoberestoredandthetow/haullamptobeturnedoff.Thetow/hauloverdrive OFF mode defaults to ON after

the ignition switch is cycled OFF and ON. The normal position for the control switch is the ON position. The switch

must be in this position to energize the solenoid and allow a 3-4 upshift. The control switch indicator light illuminates

only when the tow/haul overdrive switch is turned to the OFF position, or when illuminated by the transmission

control module.

REMOVAL

1. Using a plastic trim tool, remove the tow/haul over-

drive off switch retainer (2) from the shift lever (1).

Page 3115 of 5267

P0602-CONTROL MODULE PROGRAMMING ERROR/NOT PROGRAMMED

For a complete wiring diagramRefer to Section 8W

Theory of Operation

The controller is programmed during manufacturing with generic softwareto facilitate testing. However, generic soft-

ware does not have the proper calibrations to control a transmission in a vehicle. The check for generic software is

made at power-up. If generic software is found , the MIL will light immediately and the MIL will stay on even if the

fault is cleared, until the proper software is installed. Note: Transmission will be placed in limp-in mode.

When Monitored:

Check for generic software is made at power-up

Set Condition:

If generic software is found, the MIL will light immediately. This DTC is designed to inform the technician that

the controller still has generic software installed.

Possible Causes

PCM - PROGRAMMING ERROR

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Diagnostic Test

1.CONTROL MODULE PROGRAMMING ERROR

NOTE: Controller is programmed with generic software and will not allow the correct vehicle Powertrain

management.

With the scan tool.

Record the vehicles controller part number.

Select Use Controller Part Number under the Flash Tab.

Flash the controller with the correct software.

Verify the controller flashed successfully.

Te s t C o m p l e t e

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Page 3366 of 5267

GEAR RATIOS

The 545RFE gear ratios are:

OPERATION

The 45RFE/545RFE offers full electronic control of all automatic up and downshifts, and features real-time adaptive

closed-loop shift and pressure control. Electronic shift and torque converter clutch controls help protect the trans-

mission from damage due to high temperatures, which can occur under severeoperating conditions. By altering shift

schedules, line pressure, and converter clutch control, these controls reduce heat generation and increase trans-

mission cooling.

To help reduce efficiency-robbing parasitic losses, the transmissions includes a dual-stage transmission fluid pump

with electronic output pressure control. Under most driving conditions,pump output capacity greatly exceeds that

which is needed to keep the clutches applied. The 45RFE/545RFE pump-pressure control system monitors input

torque and adjusts the pump pressure accordingly. The primary stage of thepump works continuously; the second

stage is bypassed when demand is low. The control system also monitors input and output speed and, if incipient

clutch slip is observed, the pressure control solenoid duty cycle is varied, increasing pressure in proportion to

demand.

A high-travel torque converter damper assembly allows earlier torque converter clutch engagement to reduce slip-

page. Needle-type thrust bearings reduce internal friction. The 45RFE/545RFE is packaged in a one-piece die-cast

aluminum case. To reduce NVH, the case has high lateral, vertical and torsional stiffness. It is also designed to

maximize the benefit of the structural dust cover that connects the bottomof the bell housing to the engine bed-

plate, enhancing overall power train stiffness. Dual filters protect thepump and other components. A cooler return

filter is added to the customary main sump filter. Independent lubrication and cooler circuits assure ample pressure

for normal transmission operation even if the cooler is obstructed or the fluid cannot flow due to extremely low

temperatures.

The hydraulic control system design (without electronic assist) provides the transmission with PARK, REVERSE,

NEUTRAL, SECOND, and THIRD gears, based solely on driver shift lever selection. This design allows the vehicle

to be driven (in “limp-in” mode) in the event of a electronic control systemfailure, or a situation that the Transmis-

sion Control Module (TCM) recognizes as potentially damaging to the transmission.

The TCM also performs certain self-diagnostic functions and provides comprehensive information (sensor data,

DTC’s, etc.) which is helpful in proper diagnosis and repair. This information can be viewed with the DRB

scan

tool.

DIAGNOSIS AND TESTING

AUTOMATIC TRANSMISSION

CAUTION: Before attempting any repair on a RFE automatic transmission, check for Diagnostic Trouble

Codes with the scan tool.

Transmission malfunctions may be caused by these general conditions:

Poor engine performance

Page 3474 of 5267

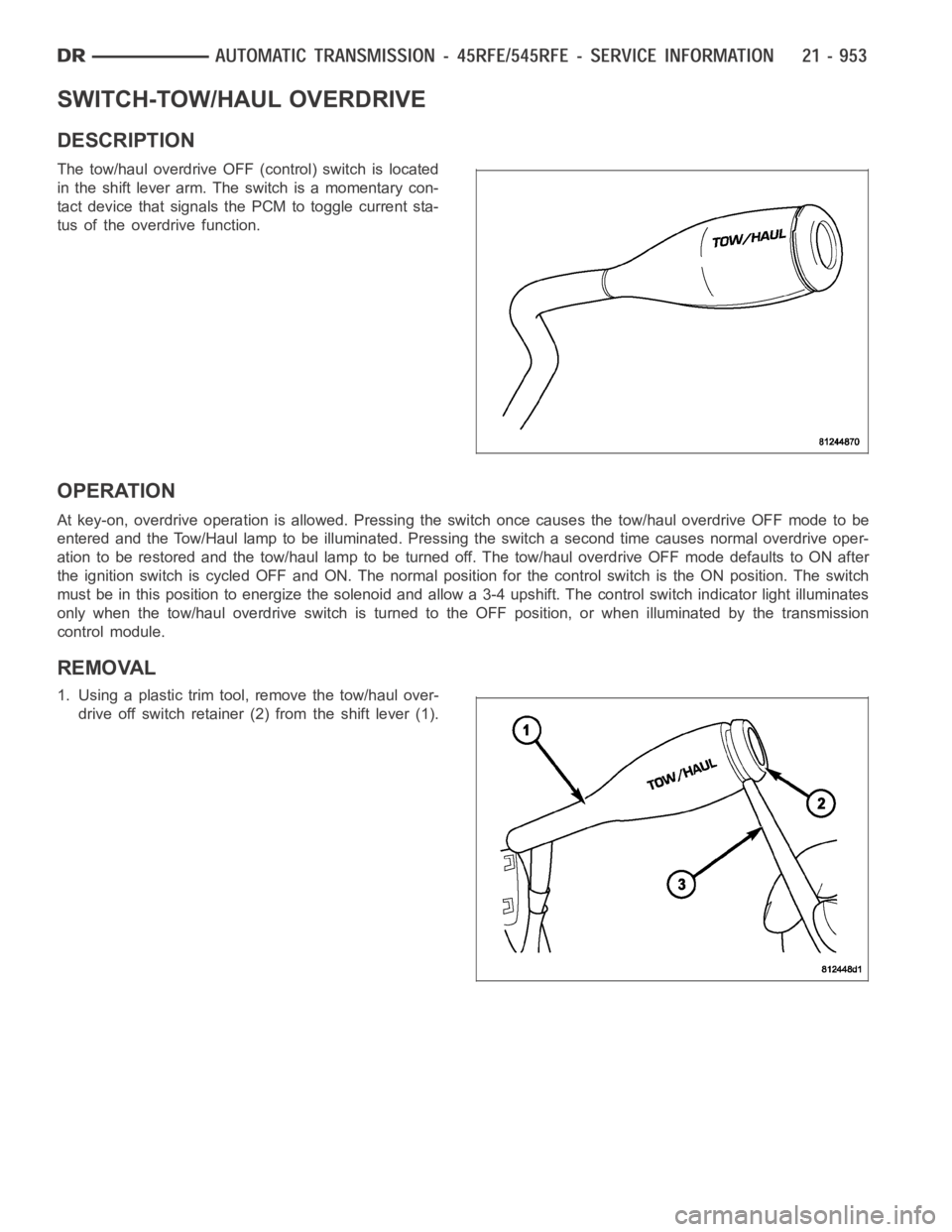

SWITCH-TOW/HAUL OVERDRIVE

DESCRIPTION

The tow/haul overdrive OFF (control) switch is located

in the shift lever arm. The switch is a momentary con-

tact device that signals the PCM to toggle current sta-

tus of the overdrive function.

OPERATION

At key-on, overdrive operation is allowed. Pressing the switch once causes the tow/haul overdrive OFF mode to be

entered and the Tow/Haul lamp to be illuminated. Pressing the switch a second time causes normal overdrive oper-

ationtoberestoredandthetow/haullamptobeturnedoff.Thetow/hauloverdrive OFF mode defaults to ON after

the ignition switch is cycled OFF and ON. The normal position for the control switch is the ON position. The switch

must be in this position to energize the solenoid and allow a 3-4 upshift. The control switch indicator light illuminates

only when the tow/haul overdrive switch is turned to the OFF position, or when illuminated by the transmission

control module.

REMOVAL

1. Using a plastic trim tool, remove the tow/haul over-

drive off switch retainer (2) from the shift lever (1).