engine DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 748 of 5267

P0630-VIN NOT ENTERED ERROR

For a complete wiring diagramRefer to Section 8W.

When Monitored:

Whilethekeyison.

Set Condition:

The VIN was not calibrated into the ECM.

Possible Causes

VIN NOT CALIBRATED INTO ECM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.VIN NOT CALIBRATED INTO ECM

Using the scan tool, recalibrate the ECM with the proper VIN.

Did the DTC P0630 reset?

Ye s>>

Replace the ECM.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Te s t C o m p l e t e .

Page 749 of 5267

P0633-SKIM SECRET KEY NOT ENTERED

For a complete wiring diagramRefer to Section 8W.

When Monitored:

Whilethekeyison.

Set Condition:

TheSKIMsecretkeywasnotcalibratedintotheECM.

Possible Causes

IMPROPER IGNITION KEY IS BEING USED

SKIM DTC’S

SKIM NOT CALIBRATED PROPERLY

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.SKIM DTC’S

With the scan tool, read SKIM DTCs.

Are any SKIM DTC’s present?

Ye s>>

Repair all SKIM DTC’s first.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 2

2.IMPROPER IGNITION KEY IS BEING USED

Verify that the proper ignition key is in the ignition lock on the steering column.

Are the proper keys being used?

Ye s>>

Go To 3

No>>

Use the proper key for the vehicle.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

3.SKIM NOT CALIBRATED PROPERLY

Using the scan tool, recalibrate the ECM with the proper SKIM secret key.

With the scan tool, erase DTCs.

Cycle the ignition switch from on to off to on.

With the scan tool, read DTCs.

Did the DTC reset?

No>>

Te s t C o m p l e t e .

Ye s>>

Verify information is correct and replace ECM.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 751 of 5267

When Monitored:

With the key on.

Set Condition:

Voltage detected on the #2 sensor supply circuit is below a calibrated value.

Possible Causes

FAN CLUTCH ASSEMBLY

(K668) 5-VOLT SHORTED TO GROUND

(K668) 5-VOLT SUPPLY SHORTED TO ANOTHER CIRCUIT

FA N D T C

INTERMITTENT CONDITION

ECM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.FAN CLUTCH ASSEMBLY

Disconnect the Fan clutch harness connector.

NOTE: Check connectors - Clean/repair as necessary.

With the scan tool, read DTCs.

Did P0483 set?

Ye s>>

Replace the Fan clutch assembly.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 2

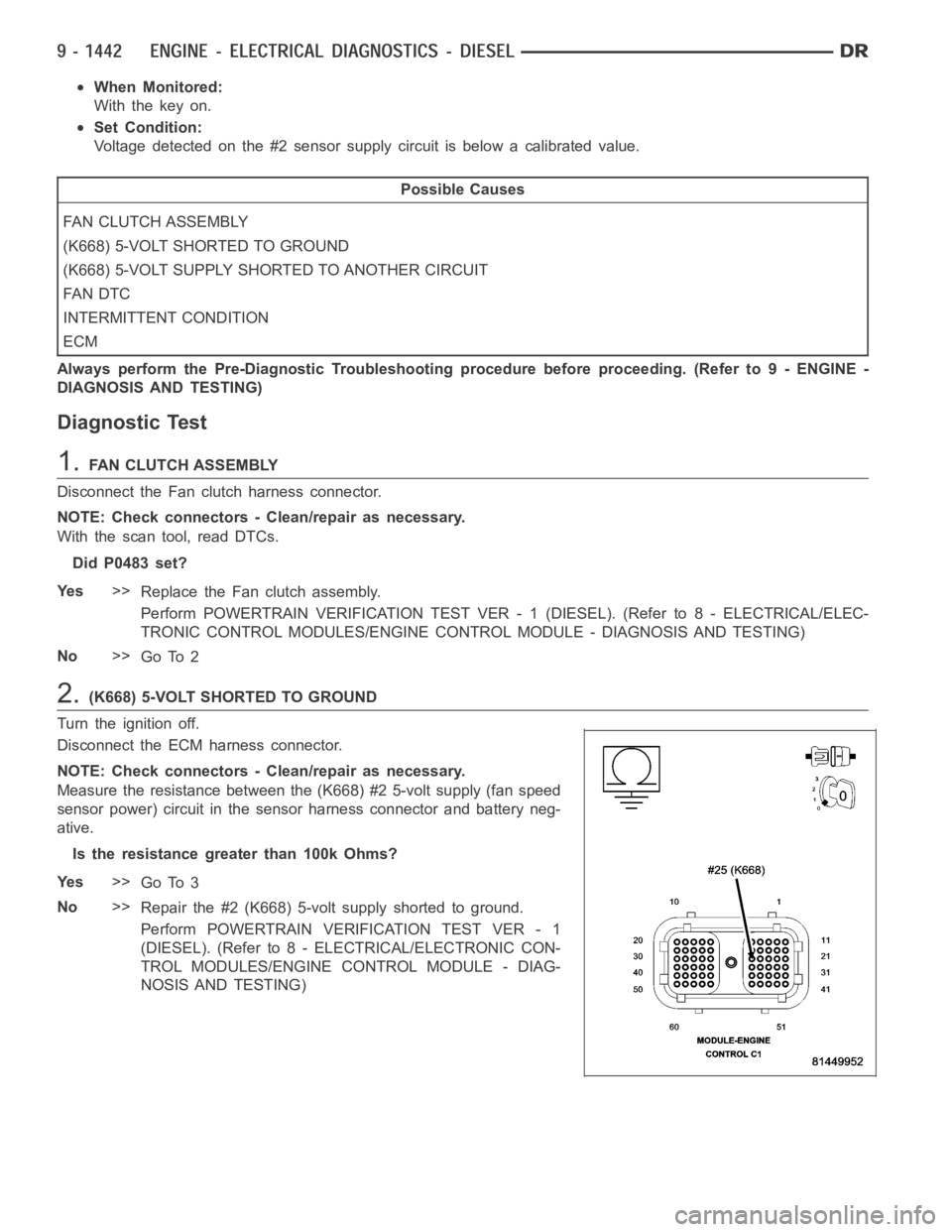

2.(K668) 5-VOLT SHORTED TO GROUND

Turn the ignition off.

Disconnect the ECM harness connector.

NOTE: Check connectors - Clean/repair as necessary.

Measure the resistance between the (K668) #2 5-volt supply (fan speed

sensor power) circuit in the sensor harness connector and battery neg-

ative.

Is the resistance greater than 100k Ohms?

Ye s>>

Go To 3

No>>

Repair the #2 (K668) 5-volt supply shorted to ground.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

Page 752 of 5267

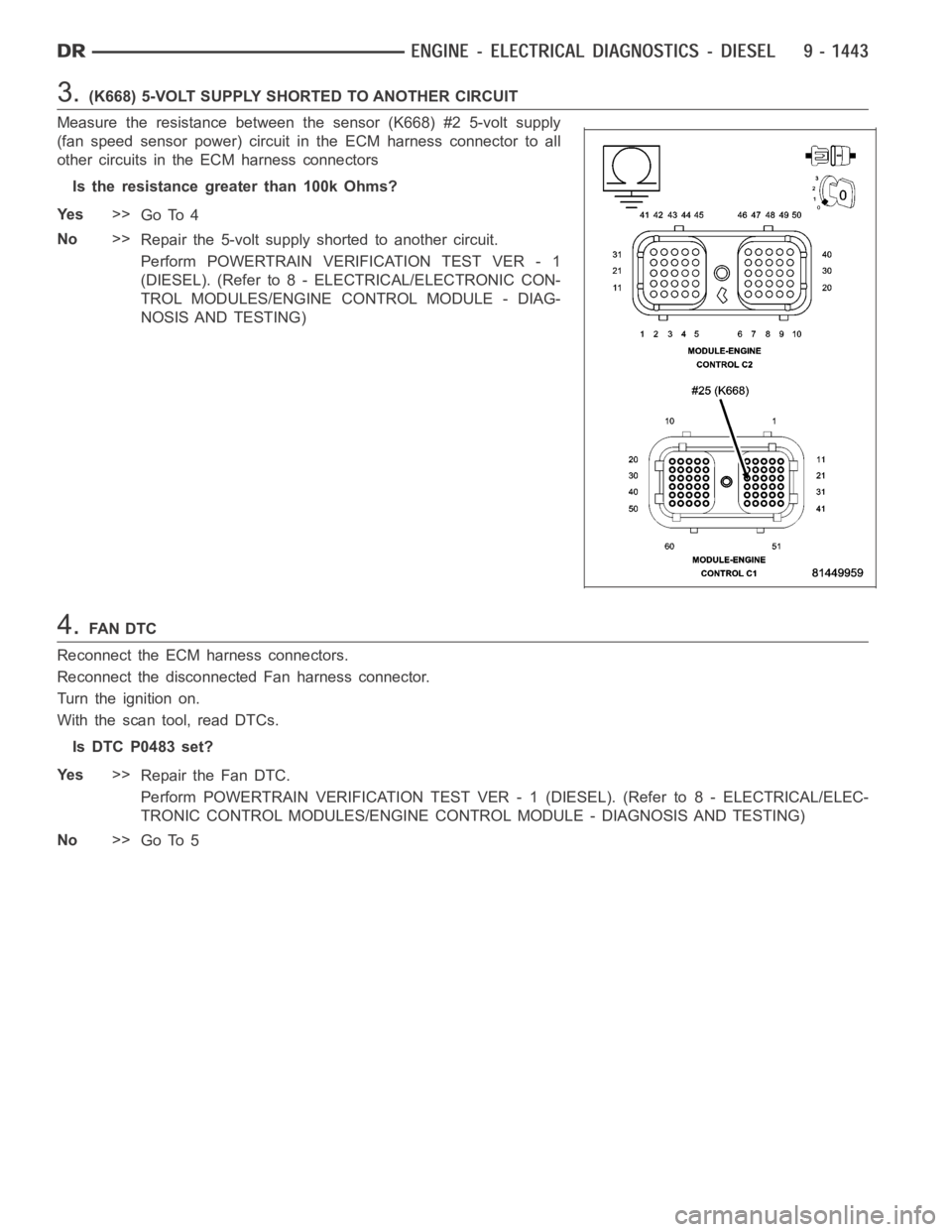

3.(K668) 5-VOLT SUPPLY SHORTED TO ANOTHER CIRCUIT

Measure the resistance between the sensor (K668) #2 5-volt supply

(fan speed sensor power) circuit in the ECM harness connector to all

other circuits in the ECM harness connectors

Is the resistance greater than 100k Ohms?

Ye s>>

Go To 4

No>>

Repair the 5-volt supply shorted to another circuit.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

4.FA N D T C

Reconnect the ECM harness connectors.

Reconnect the disconnected Fan harness connector.

Turn the ignition on.

With the scan tool, read DTCs.

Is DTC P0483 set?

Ye s>>

Repair the Fan DTC.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 5

Page 753 of 5267

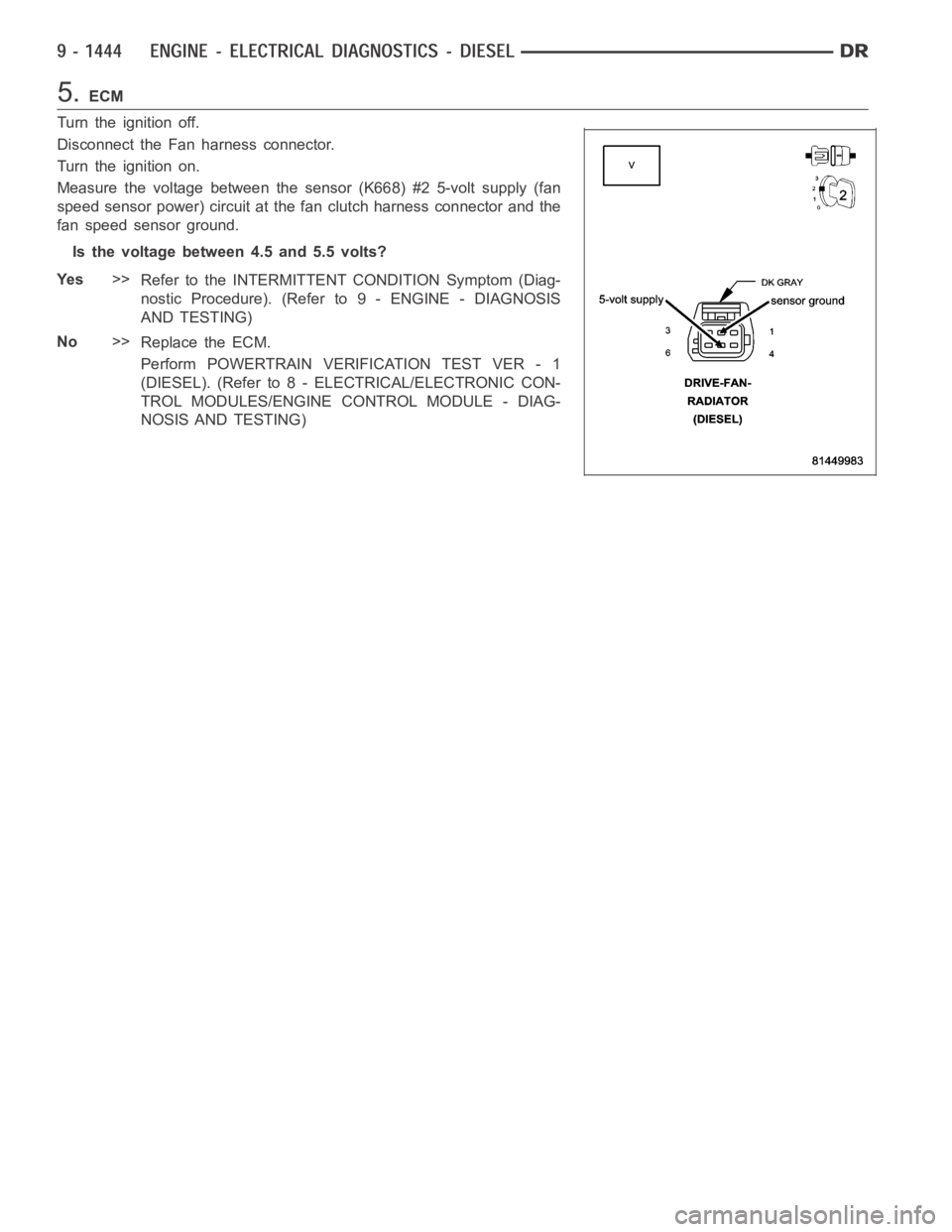

5.ECM

Turn the ignition off.

Disconnect the Fan harness connector.

Turn the ignition on.

Measure the voltage between the sensor (K668) #2 5-volt supply (fan

speed sensor power) circuit at the fan clutch harness connector and the

fan speed sensor ground.

Is the voltage between 4.5 and 5.5 volts?

Ye s>>

Refer to the INTERMITTENT CONDITION Symptom (Diag-

nostic Procedure). (Refer to 9 - ENGINE - DIAGNOSIS

AND TESTING)

No>>

Replace the ECM.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

Page 755 of 5267

When Monitored:

With the key on.

Set Condition:

Voltage detected on the #2 sensor supply circuit was above a calibrated value.

Possible Causes

FAN CLUTCH ASSEMBLY

(K668) 5-VOLT SHORTED TO VOLTAGE

INTERMITTENT CONDITION

ECM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.FAN CLUTCH ASSEMBLY

Disconnect the Fan clutch harness connector.

NOTE: Check connectors - Clean/repair as necessary.

With the scan tool, read DTCs.

Did P0483 set?

Ye s>>

Replace the Fan clutch assembly.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 2

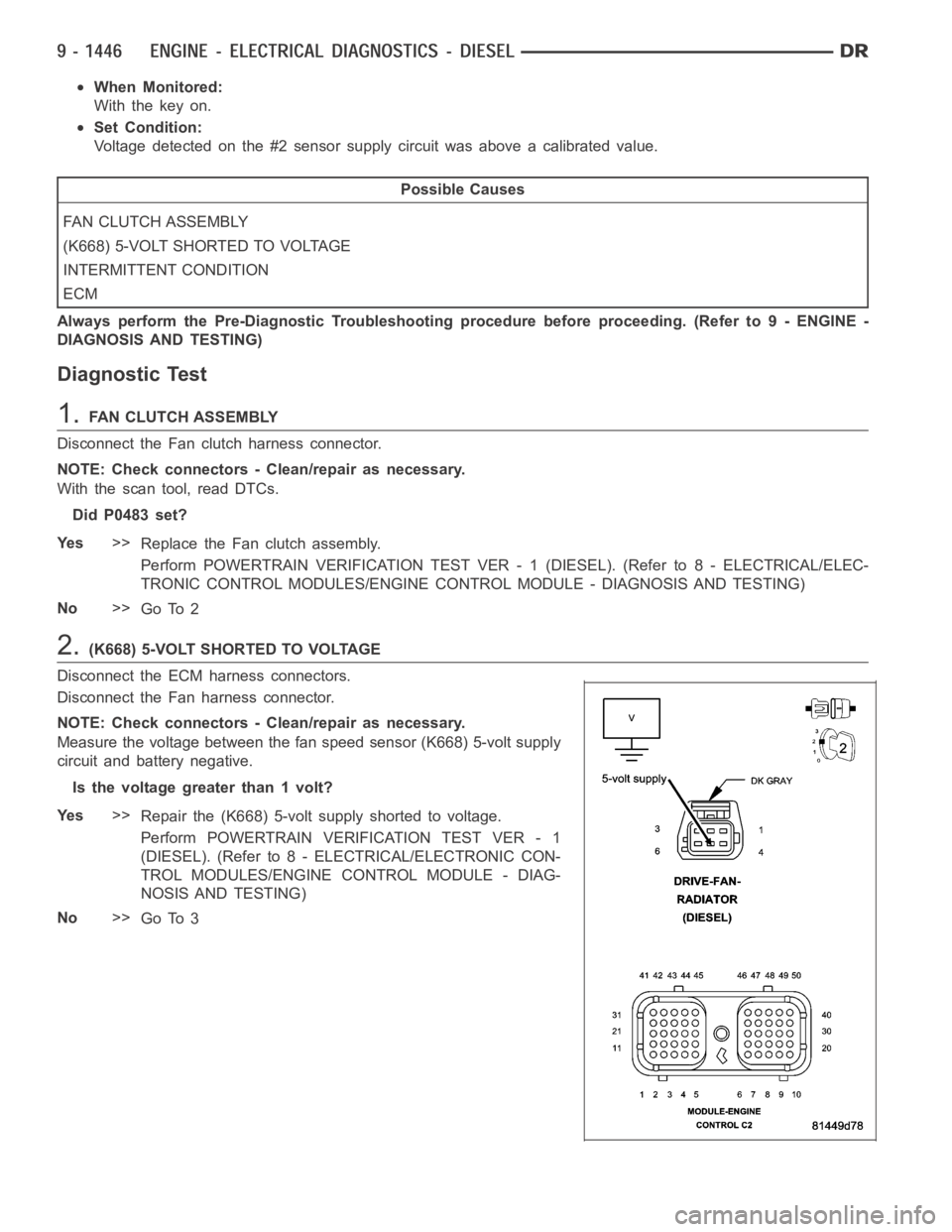

2.(K668) 5-VOLT SHORTED TO VOLTAGE

Disconnect the ECM harness connectors.

Disconnect the Fan harness connector.

NOTE: Check connectors - Clean/repair as necessary.

Measure the voltage between the fan speed sensor (K668) 5-volt supply

circuit and battery negative.

Is the voltage greater than 1 volt?

Ye s>>

Repair the (K668) 5-volt supply shorted to voltage.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

No>>

Go To 3

Page 756 of 5267

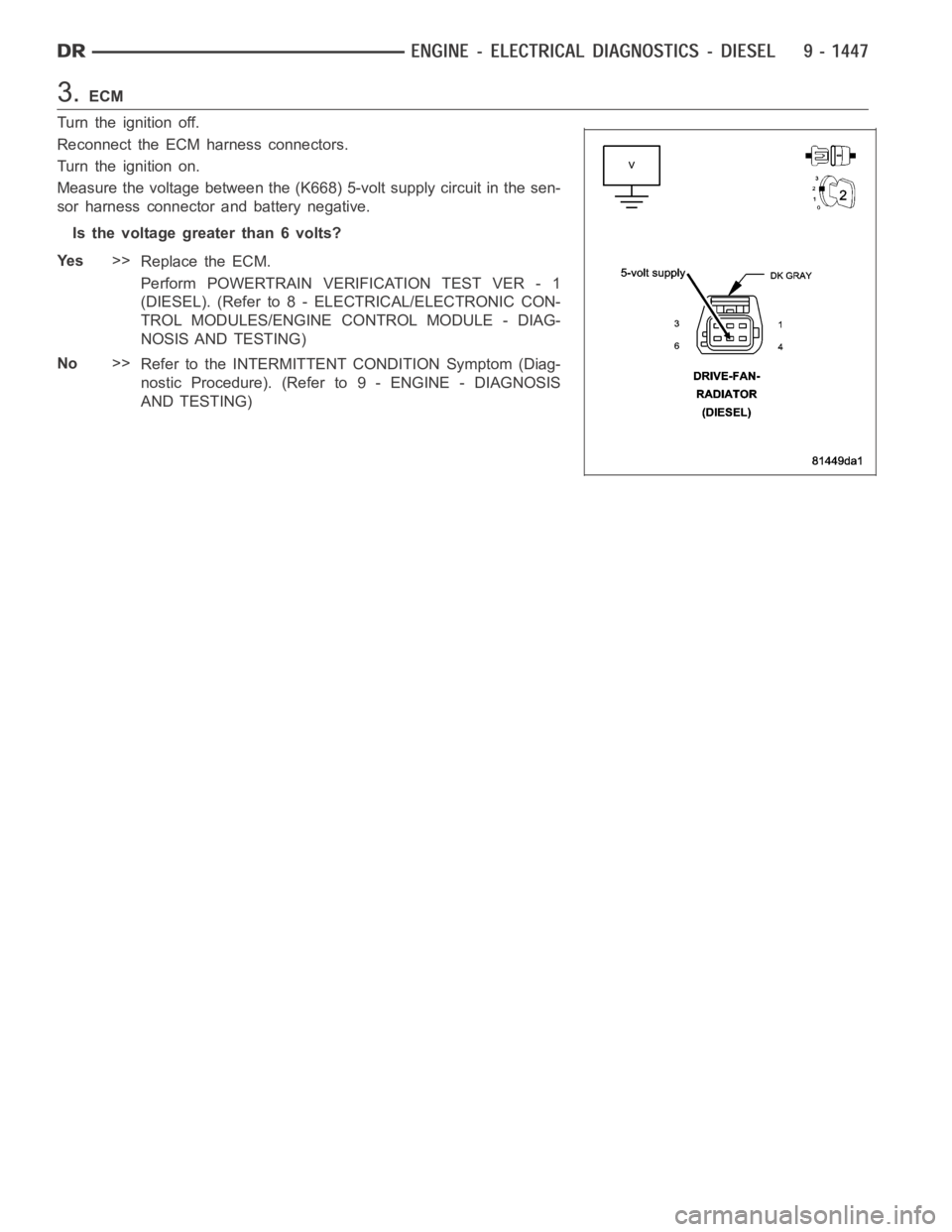

3.ECM

Turn the ignition off.

Reconnect the ECM harness connectors.

Turn the ignition on.

Measure the voltage between the (K668) 5-volt supply circuit in the sen-

sor harness connector and battery negative.

Is the voltage greater than 6 volts?

Ye s>>

Replace the ECM.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

No>>

Refer to the INTERMITTENT CONDITION Symptom (Diag-

nostic Procedure). (Refer to 9 - ENGINE - DIAGNOSIS

AND TESTING)

Page 758 of 5267

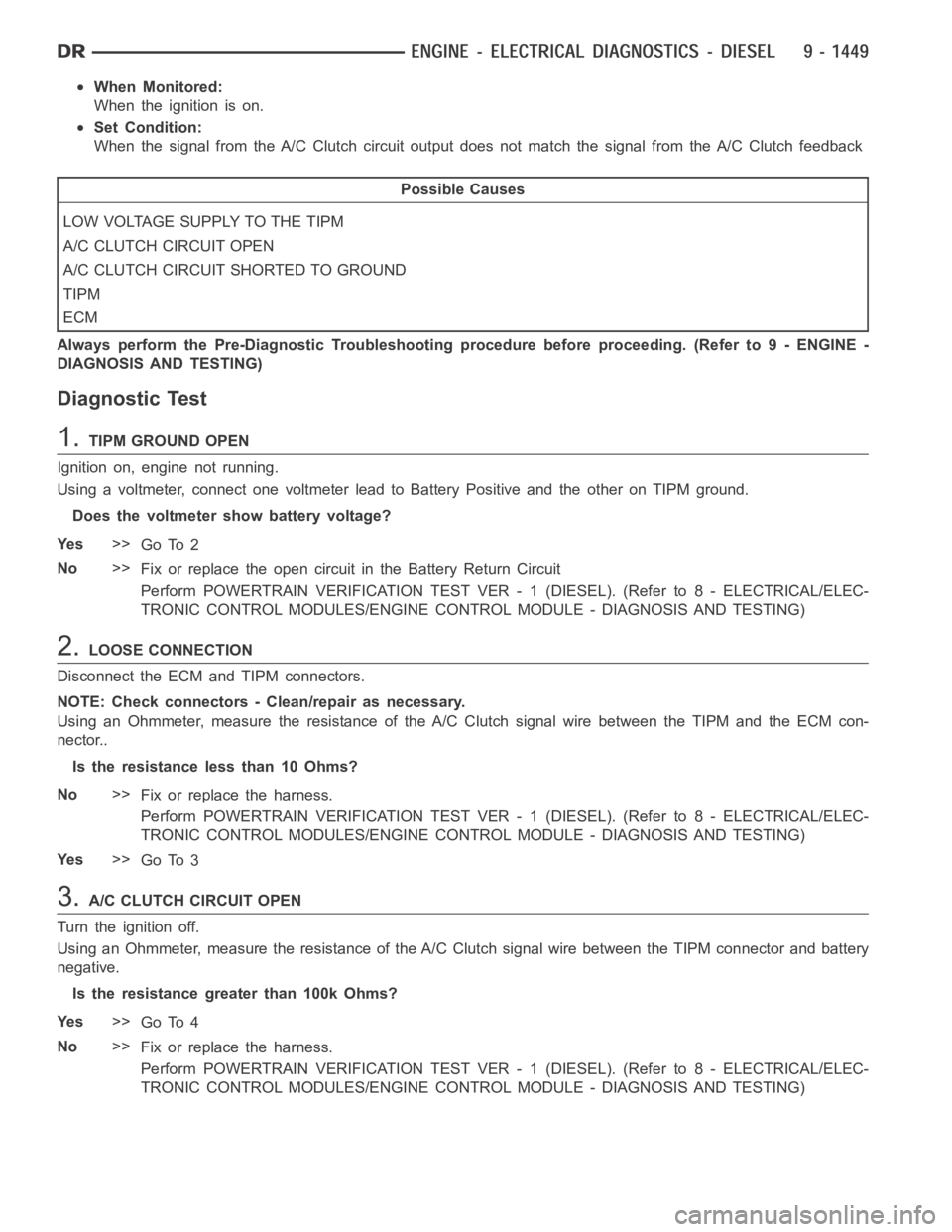

When Monitored:

When the ignition is on.

Set Condition:

When the signal from the A/C Clutch circuit output does not match the signalfrom the A/C Clutch feedback

Possible Causes

LOW VOLTAGE SUPPLY TO THE TIPM

A/C CLUTCH CIRCUIT OPEN

A/C CLUTCH CIRCUIT SHORTED TO GROUND

TIPM

ECM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.TIPM GROUND OPEN

Ignition on, engine not running.

Using a voltmeter, connect one voltmeter lead to Battery Positive and the other on TIPM ground.

Does the voltmeter show battery voltage?

Ye s>>

Go To 2

No>>

Fix or replace the open circuit in the Battery Return Circuit

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

2.LOOSE CONNECTION

Disconnect the ECM and TIPM connectors.

NOTE: Check connectors - Clean/repair as necessary.

Using an Ohmmeter, measure the resistance of the A/C Clutch signal wire between the TIPM and the ECM con-

nector..

Is the resistance less than 10 Ohms?

No>>

Fix or replace the harness.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

Ye s>>

Go To 3

3.A/C CLUTCH CIRCUIT OPEN

Turn the ignition off.

Using an Ohmmeter, measure the resistance of the A/C Clutch signal wire between the TIPM connector and battery

negative.

Is the resistance greater than 100k Ohms?

Ye s>>

Go To 4

No>>

Fix or replace the harness.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 759 of 5267

4.FUSED BATTERY SUPPLY

Connect the ECM and TIPM connectors.

Ignition on, engine not running.

Using a back probing tool 6801, back probe the A/C clutch logic pin in the TIPM logic connector.

Usinga12volttestlightconnectedtobatterypositive,checkthetransmission logic circuit at the TIPM connector

while actuating the A/C clutch circuit with the Electronic Service Tool.

NOTE: The test light must illuminate brightly.

Compare the brightness to that of a direct connection to the battery.

Does the test light illuminate brightly?

Ye s>>

Go To 5

No>>

Replace the ECM.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

5.TIPM

Using a back probing tool, back probe the A/C clutch power pin from the TIPM power connector.

Using a 12 volt test light connected to battery positive, check the transmission power circuit at the TIPM connector

while actuating the A/C clutch circuit with the Electronic Service Tool.

NOTE: The test light must illuminate brightly.

Compare the brightness to that of a direct connection to the battery.

Does the test light illuminate brightly?

Ye s>>

Te s t c o m p l e t e .

Perform Intermittent Condition test. (Refer to 9 - ENGINE - DIAGNOSIS AND TESTING)

No>>

Replace the TIPM.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 761 of 5267

When Monitored:

When the ignition is on.

Set Condition:

When the signal from the A/C Clutch output does not match the signal from theA/C Clutch feedback.

Possible Causes

WIRING HARNESS OR CONNECTIONS

A/C CLUTCH CIRCUIT SHORTED TO EXTERNAL VOLTAGE

TIPM

ECM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.A/C CLUTCH CIRCUIT SHORTED TO EXTERNAL VOLTAGE

Ignition off.

Disconnect the ECM and TIPM connectors.

NOTE: Check connectors - Clean/repair as necessary.

Ignition on, engine not running.

Using a Voltmeter, measure the voltage of the A/C Clutch Control Circuit between the TIPM connector and battery

negative..

Is the voltage less than 1 volt?

Ye s>>

Go To 2

Ye s>>

Repair or Replace the wiring harness.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

2.ECM

Ignition off.

Connect the ECM and TIPM connectors.

Ignition on, engine not running.

Using a back probing tool 6801, back probe the A/C clutch control circuit inthe TIPM connector.

Using a 12 volt test light connected to battery positive, check the transmission control circuit at the TIPM connector

while actuating the A/C clutch circuit with the Electronic Service Tool.

NOTE: The test light must illuminate brightly.

Compare the brightness to that of a direct connection to the battery.

Does the test light illuminate brightly?

Ye s>>

Go To 3

No>>

Replace the ECM.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)