ignition DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1236 of 5267

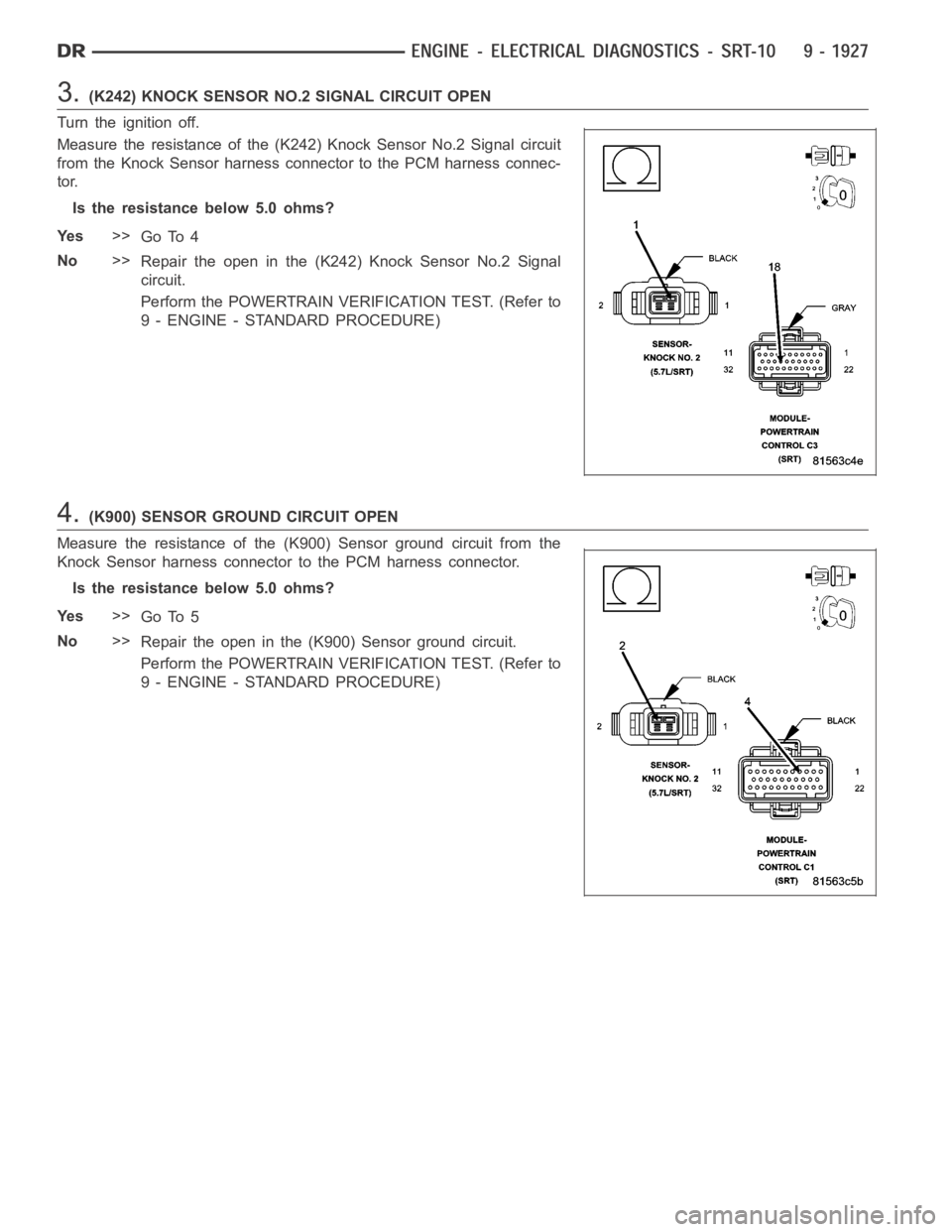

3.(K242) KNOCK SENSOR NO.2 SIGNAL CIRCUIT OPEN

Turn the ignition off.

Measure the resistance of the (K242) Knock Sensor No.2 Signal circuit

from the Knock Sensor harness connector to the PCM harness connec-

tor.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 4

No>>

Repair the open in the (K242) Knock Sensor No.2 Signal

circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

4.(K900) SENSOR GROUND CIRCUIT OPEN

Measure the resistance of the (K900) Sensor ground circuit from the

Knock Sensor harness connector to the PCM harness connector.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 5

No>>

Repair the open in the (K900) Sensor ground circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

Page 1237 of 5267

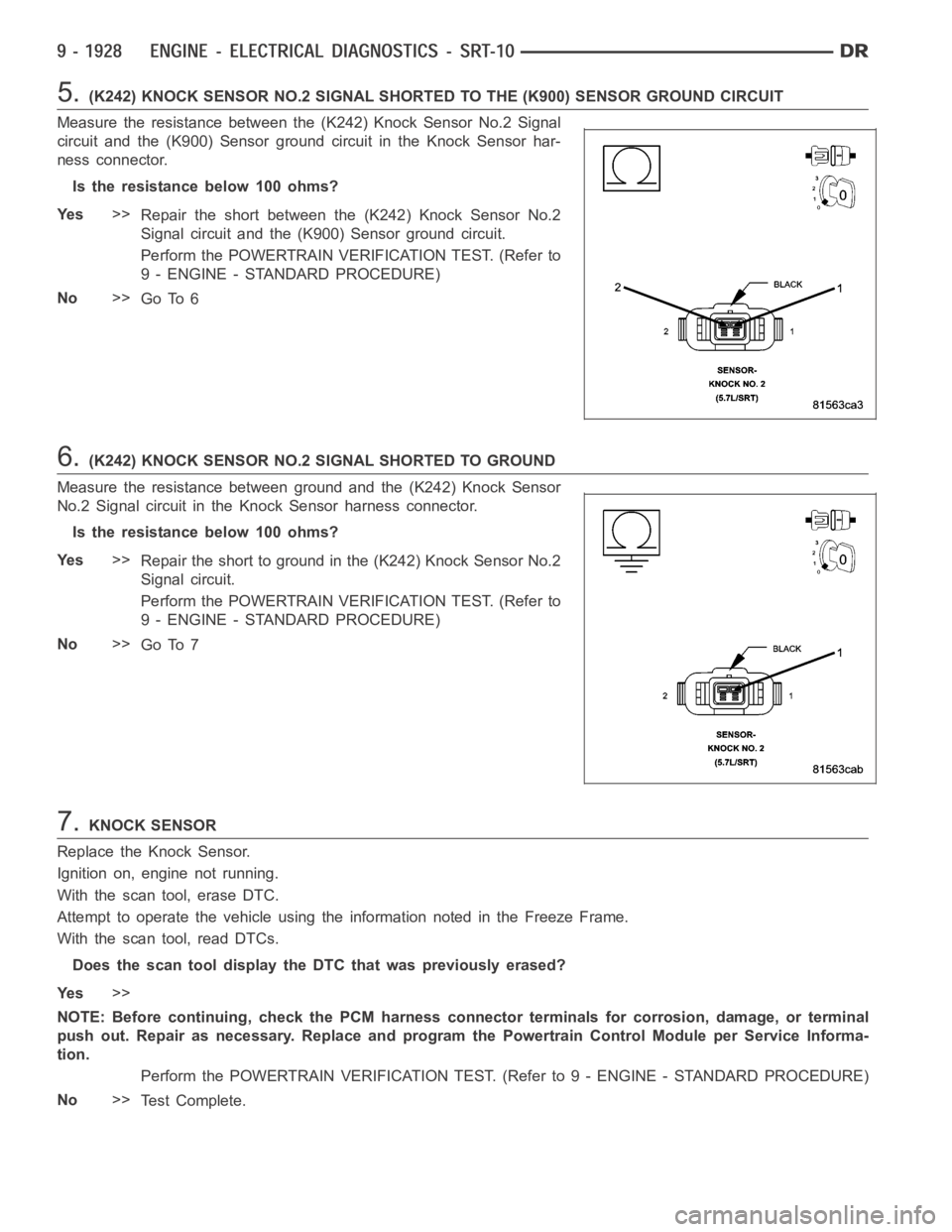

5.(K242) KNOCK SENSOR NO.2 SIGNAL SHORTED TO THE (K900) SENSOR GROUND CIRCUIT

Measure the resistance between the (K242) Knock Sensor No.2 Signal

circuit and the (K900) Sensor ground circuit in the Knock Sensor har-

ness connector.

Istheresistancebelow100ohms?

Ye s>>

Repair the short between the (K242) Knock Sensor No.2

Signal circuit and the (K900) Sensor ground circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 6

6.(K242) KNOCK SENSOR NO.2 SIGNAL SHORTED TO GROUND

Measure the resistance between ground and the (K242) Knock Sensor

No.2 Signal circuit in the Knock Sensor harness connector.

Istheresistancebelow100ohms?

Ye s>>

Repair the short to ground in the (K242) Knock Sensor No.2

Signal circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 7

7.KNOCK SENSOR

Replace the Knock Sensor.

Ignition on, engine not running.

With the scan tool, erase DTC.

Attempt to operate the vehicle using the information noted in the Freeze Frame.

With the scan tool, read DTCs.

Does the scan tool display the DTC that was previously erased?

Ye s>>

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary. Replace and program the Powertrain ControlModule per Service Informa-

tion.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Te s t C o m p l e t e .

Page 1239 of 5267

When Monitored:

During engine cranking and with the engine running. Battery voltage greater than 10 volts.

Set Condition:

At least 5 seconds or 2.5 engine revolutions have elapsed with crankshaft position sensor signals present but

no camshaft position sensor signal. One Trip Fault. Three good trips to turnofftheMIL.

Possible Causes

(F855) 5-VOLT SUPPLY CIRCUIT SHORTED TO BATTERY VOLTAGE

(F855) 5-VOLT SUPPLY CIRCUIT OPEN

(F855) 5-VOLT SUPPLY CIRCUIT SHORTED TO GROUND

(K44) CMP SIGNAL CIRCUIT SHORTED TO BATTERY VOLTAGE

(K44) CMP SIGNAL CIRCUIT OPEN

(K44) CMP SIGNAL CIRCUIT SHORTED GROUND

(K44) CMP SIGNAL SHORTED TO THE (F855) 5-VOLT SUPPLY CIRCUIT

(K900) SENSOR GROUND CIRCUIT OPEN

CAMSHAFT POSITION SENSOR

CRANKSHAFT POSITION SENSOR

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

Crank the engine.

Ignition on, engine not running.

With a scan tool read the DTCs.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Go To 14

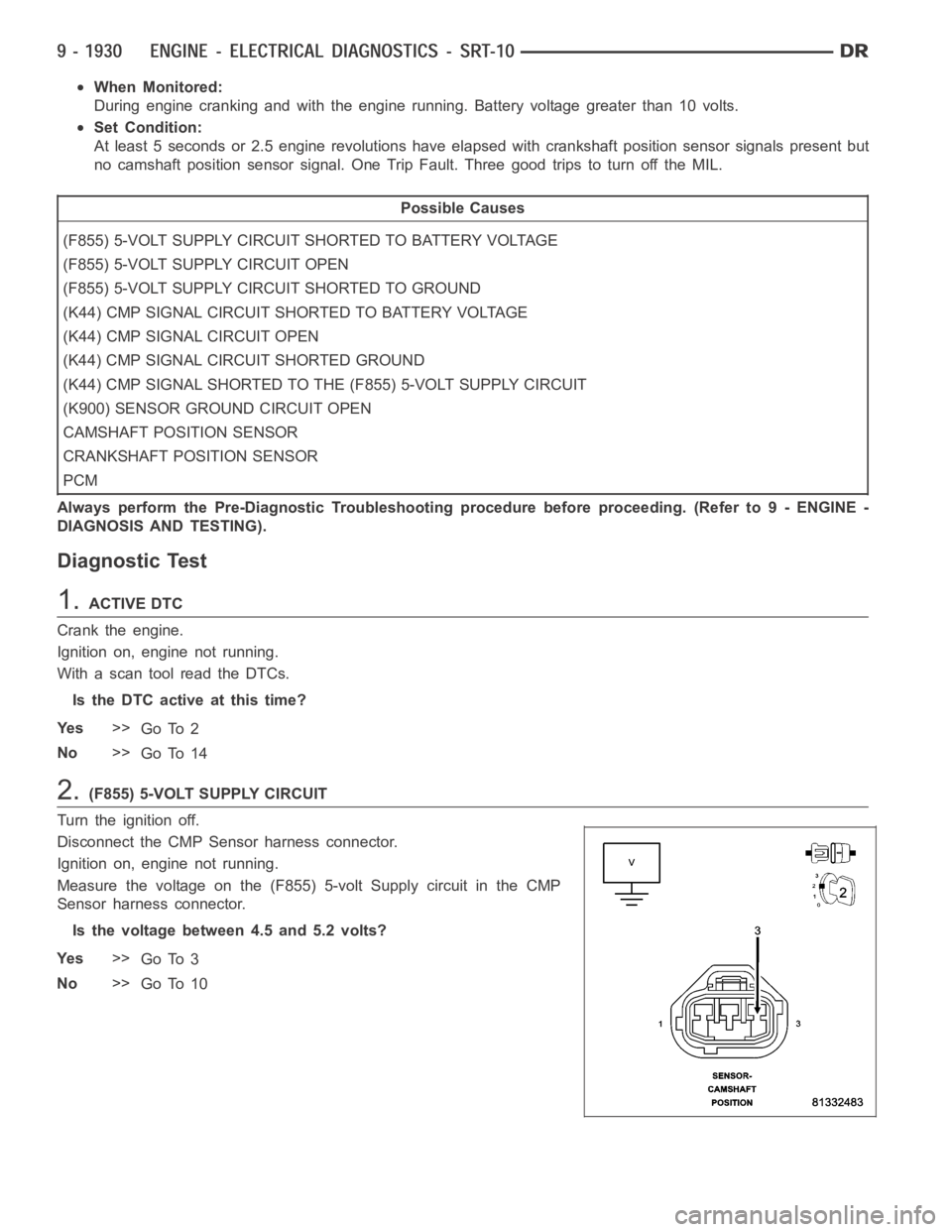

2.(F855) 5-VOLT SUPPLY CIRCUIT

Turn the ignition off.

Disconnect the CMP Sensor harness connector.

Ignition on, engine not running.

Measure the voltage on the (F855) 5-volt Supply circuit in the CMP

Sensor harness connector.

Is the voltage between 4.5 and 5.2 volts?

Ye s>>

Go To 3

No>>

Go To 10

Page 1240 of 5267

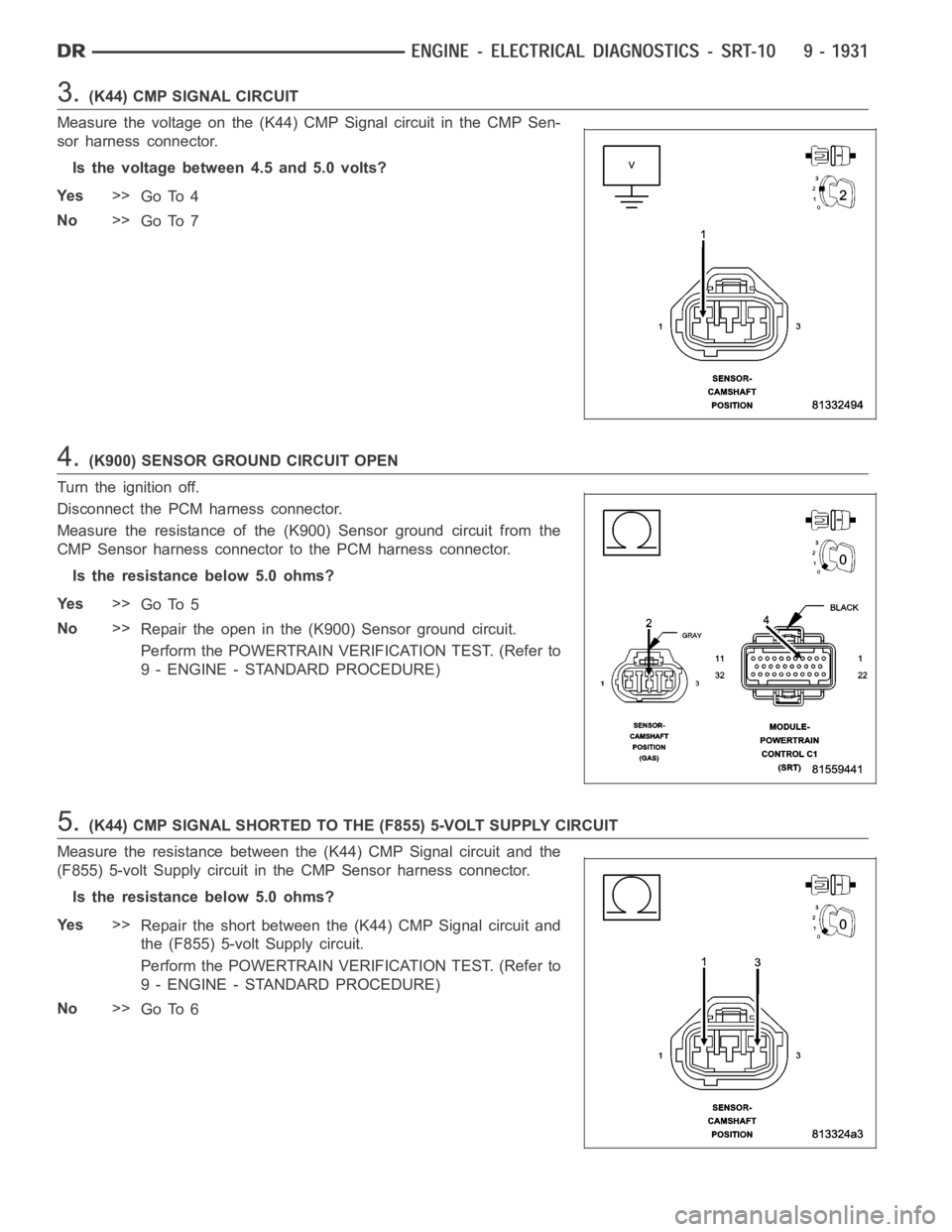

3.(K44) CMP SIGNAL CIRCUIT

Measure the voltage on the (K44) CMP Signal circuit in the CMP Sen-

sor harness connector.

Is the voltage between 4.5 and 5.0 volts?

Ye s>>

Go To 4

No>>

Go To 7

4.(K900) SENSOR GROUND CIRCUIT OPEN

Turn the ignition off.

Disconnect the PCM harness connector.

Measure the resistance of the (K900) Sensor ground circuit from the

CMP Sensor harness connector to the PCM harness connector.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 5

No>>

Repair the open in the (K900) Sensor ground circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

5.(K44) CMP SIGNAL SHORTED TO THE (F855) 5-VOLT SUPPLY CIRCUIT

Measure the resistance between the (K44) CMP Signal circuit and the

(F855) 5-volt Supply circuit in the CMP Sensor harness connector.

Is the resistance below 5.0 ohms?

Ye s>>

Repair the short between the (K44) CMP Signal circuit and

the (F855) 5-volt Supply circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 6

Page 1241 of 5267

6.CAMSHAFT POSITION SENSOR

NOTE: Inspect the Camshaft sprocket for damage per the Service Information. If a problem is found repair

as necessary.

If there are no possible causes remaining, view repair.

Repair

Replace the Camshaft Position Sensor.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

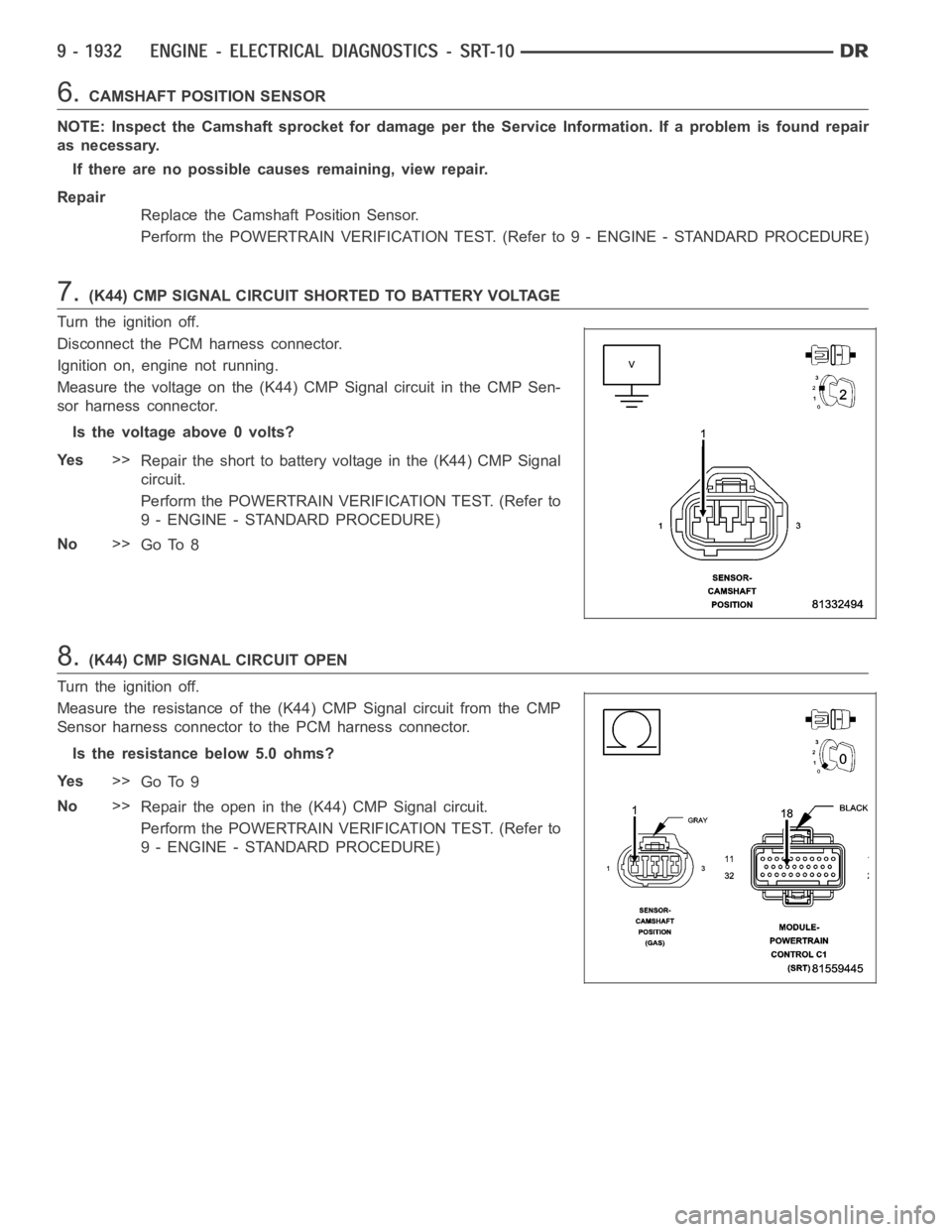

7.(K44) CMP SIGNAL CIRCUIT SHORTED TO BATTERY VOLTAGE

Turn the ignition off.

Disconnect the PCM harness connector.

Ignition on, engine not running.

Measure the voltage on the (K44) CMP Signal circuit in the CMP Sen-

sor harness connector.

Is the voltage above 0 volts?

Ye s>>

Repair the short to battery voltage in the (K44) CMP Signal

circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 8

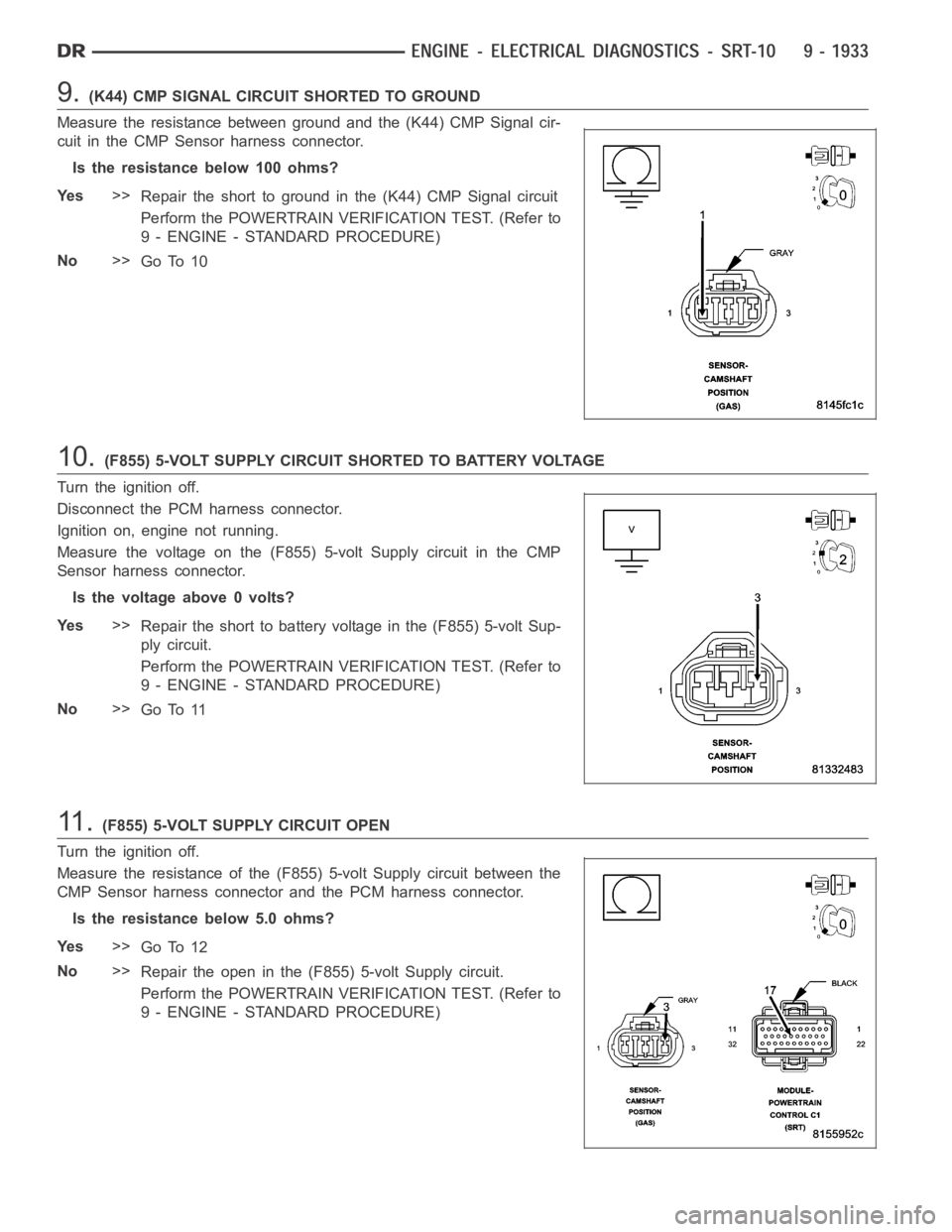

8.(K44) CMP SIGNAL CIRCUIT OPEN

Turn the ignition off.

Measure the resistance of the (K44) CMP Signal circuit from the CMP

Sensor harness connector to the PCM harness connector.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 9

No>>

Repair the open in the (K44) CMP Signal circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

Page 1242 of 5267

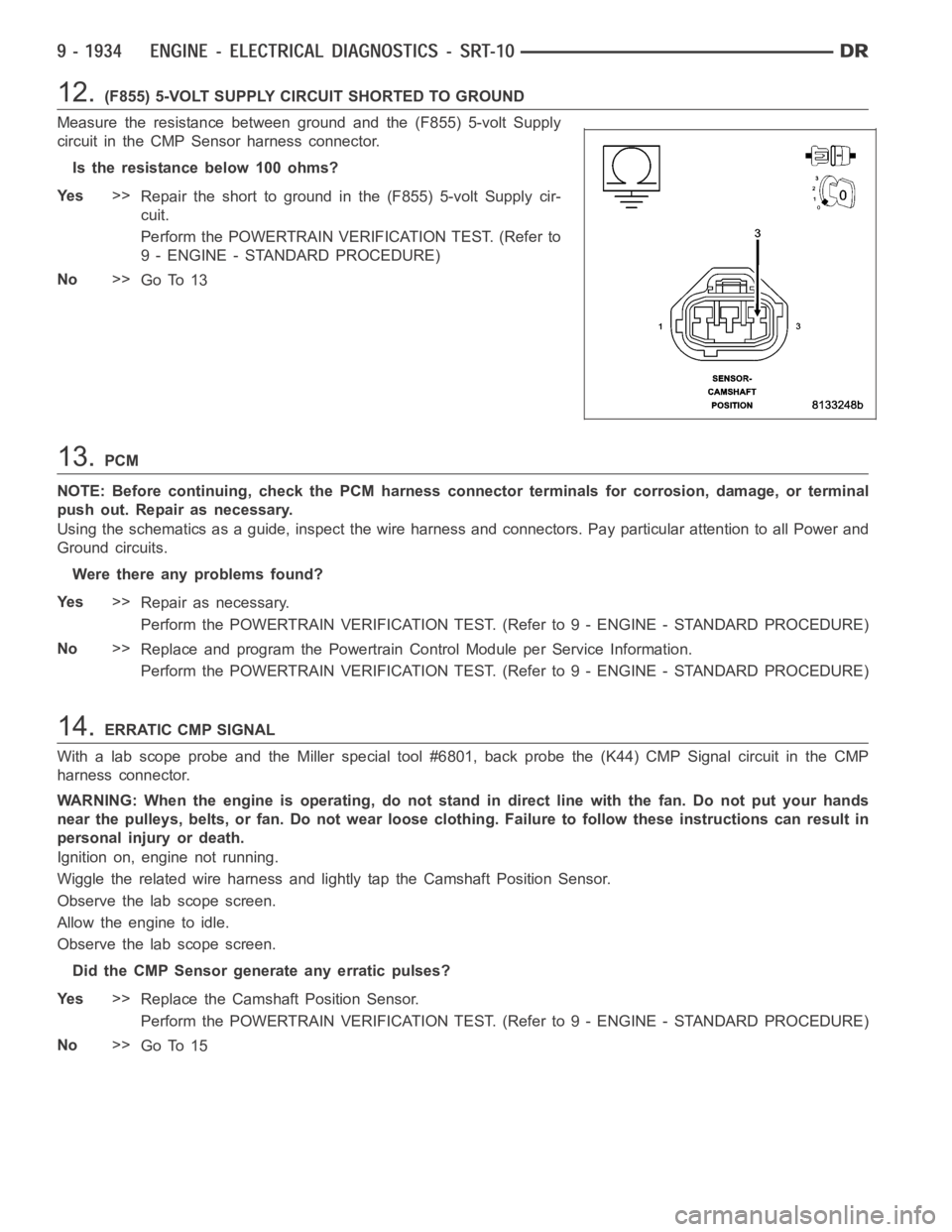

9.(K44) CMP SIGNAL CIRCUIT SHORTED TO GROUND

Measure the resistance between ground and the (K44) CMP Signal cir-

cuit in the CMP Sensor harness connector.

Istheresistancebelow100ohms?

Ye s>>

Repair the short to ground in the (K44) CMP Signal circuit

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 10

10.(F855) 5-VOLT SUPPLY CIRCUIT SHORTED TO BATTERY VOLTAGE

Turn the ignition off.

Disconnect the PCM harness connector.

Ignition on, engine not running.

Measure the voltage on the (F855) 5-volt Supply circuit in the CMP

Sensor harness connector.

Is the voltage above 0 volts?

Ye s>>

Repair the short to battery voltage in the (F855) 5-volt Sup-

ply circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 11

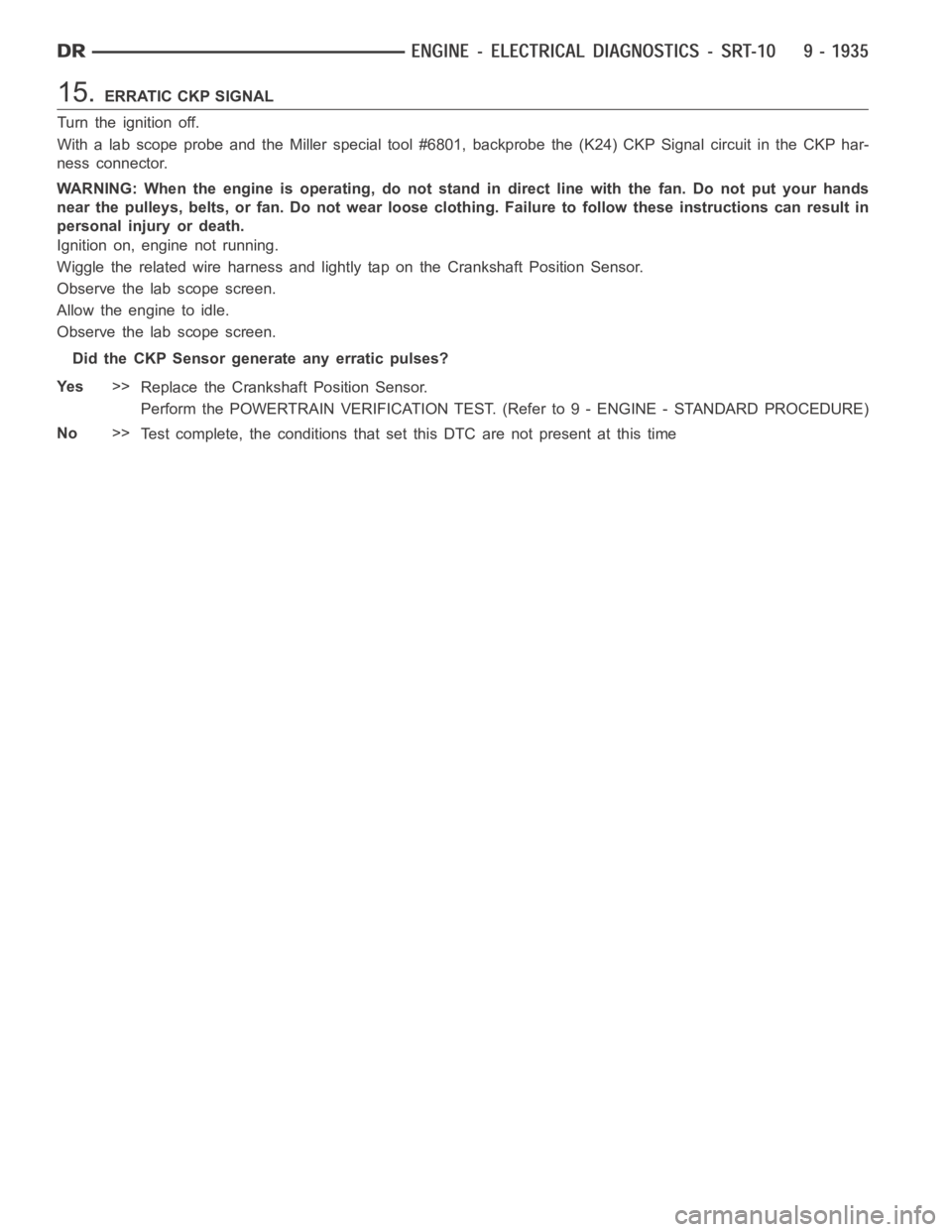

11 .(F855) 5-VOLT SUPPLY CIRCUIT OPEN

Turn the ignition off.

Measure the resistance of the (F855) 5-volt Supply circuit between the

CMP Sensor harness connector and the PCM harness connector.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 12

No>>

Repair the open in the (F855) 5-volt Supply circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

Page 1243 of 5267

12.(F855) 5-VOLT SUPPLY CIRCUIT SHORTED TO GROUND

Measure the resistance between ground and the (F855) 5-volt Supply

circuit in the CMP Sensor harness connector.

Istheresistancebelow100ohms?

Ye s>>

Repair the short to ground in the (F855) 5-volt Supply cir-

cuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 13

13.PCM

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

14.ERRATIC CMP SIGNAL

With a lab scope probe and the Miller special tool #6801, back probe the (K44) CMP Signal circuit in the CMP

harness connector.

WARNING: When the engine is operating, do not stand in direct line with the fan. Do not put your hands

near the pulleys, belts, or fan. Do notwear loose clothing. Failure to follow these instructions can result in

personal injury or death.

Ignition on, engine not running.

Wiggle the related wire harness and lightly tap the Camshaft Position Sensor.

Observe the lab scope screen.

Allow the engine to idle.

Observe the lab scope screen.

Did the CMP Sensor generate any erratic pulses?

Ye s>>

Replace the Camshaft Position Sensor.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 15

Page 1244 of 5267

15.ERRATIC CKP SIGNAL

Turn the ignition off.

With a lab scope probe and the Miller special tool #6801, backprobe the (K24) CKP Signal circuit in the CKP har-

ness connector.

WARNING: When the engine is operating, do not stand in direct line with the fan. Do not put your hands

near the pulleys, belts, or fan. Do notwear loose clothing. Failure to follow these instructions can result in

personal injury or death.

Ignition on, engine not running.

Wiggle the related wire harness and lightly tap on the Crankshaft PositionSensor.

Observe the lab scope screen.

Allow the engine to idle.

Observe the lab scope screen.

Did the CKP Sensor generate any erratic pulses?

Ye s>>

Replace the Crankshaft Position Sensor.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Test complete, the conditions that set this DTC are not present at this time

Page 1245 of 5267

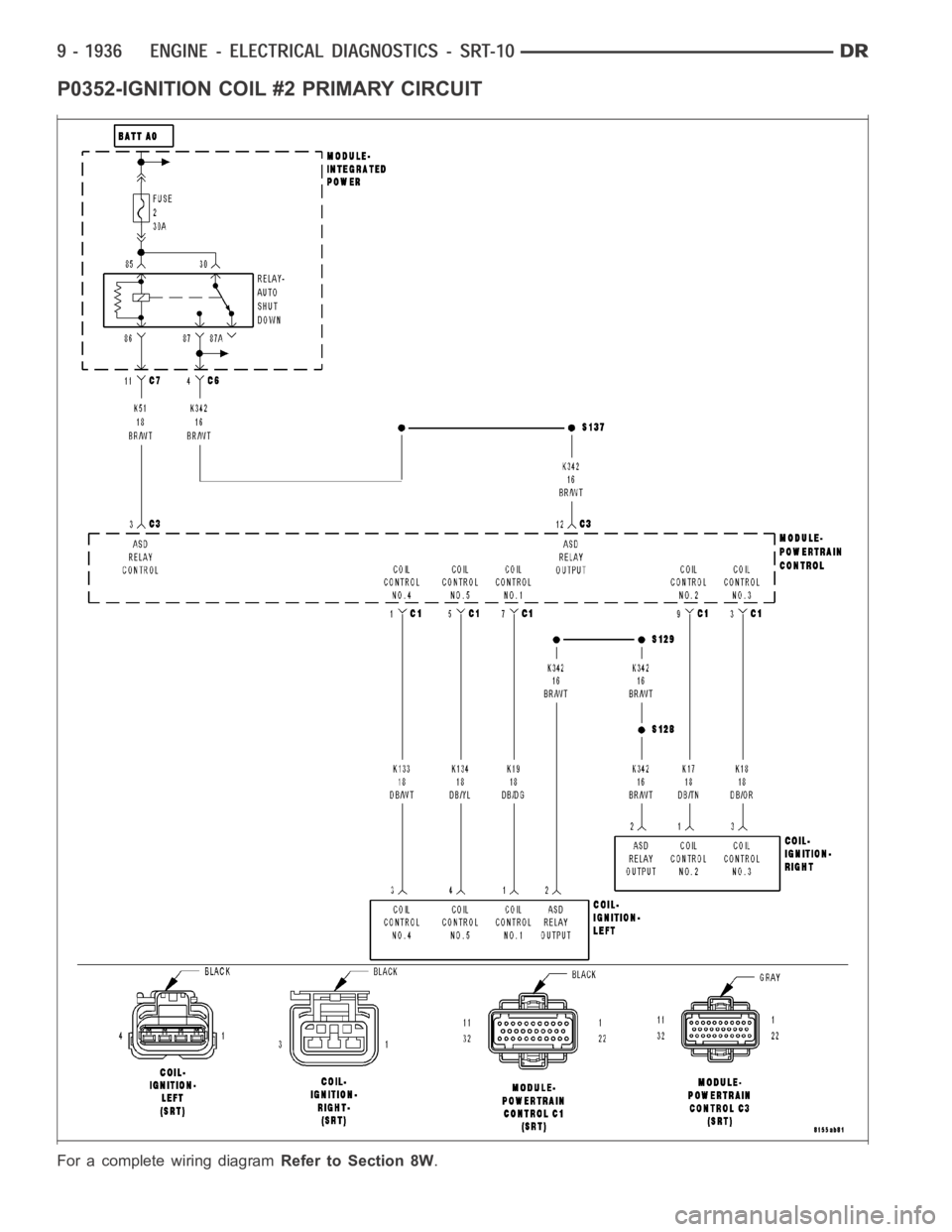

P0352-IGNITION COIL #2 PRIMARY CIRCUIT

For a complete wiring diagramRefer to Section 8W.

Page 1246 of 5267

When Monitored:

With battery voltage greater than 8 volts during engine cranking or greater than 12 volts with engine running,

engine rpm less than 2016, and none of the coils in dwell when checked.

Set Condition:

Peak current is not achieved with battery based dwell plus 1.5 ms of diagnostic offset. It takes less than 3

seconds during cranking or up to 6 seconds while running to set.

Possible Causes

(K343) ASD RELAY OUTPUT CIRCUIT

IGNITION COIL

(K17) IGNITION COIL NO.2 CONTROL CIRCUIT OPEN

(K17) IGNITION COIL NO.2 CONTROL CIRCUIT SHORTED TO GROUND

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

1.GOOD TRIP EQUAL TO ZERO

Ignition on, engine not running.

With the scan tool, read DTCs and record the related Freeze Frame data.

Is the Good Trip Counter displayed and equal to zero?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDTION Diagnostic Procedure.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

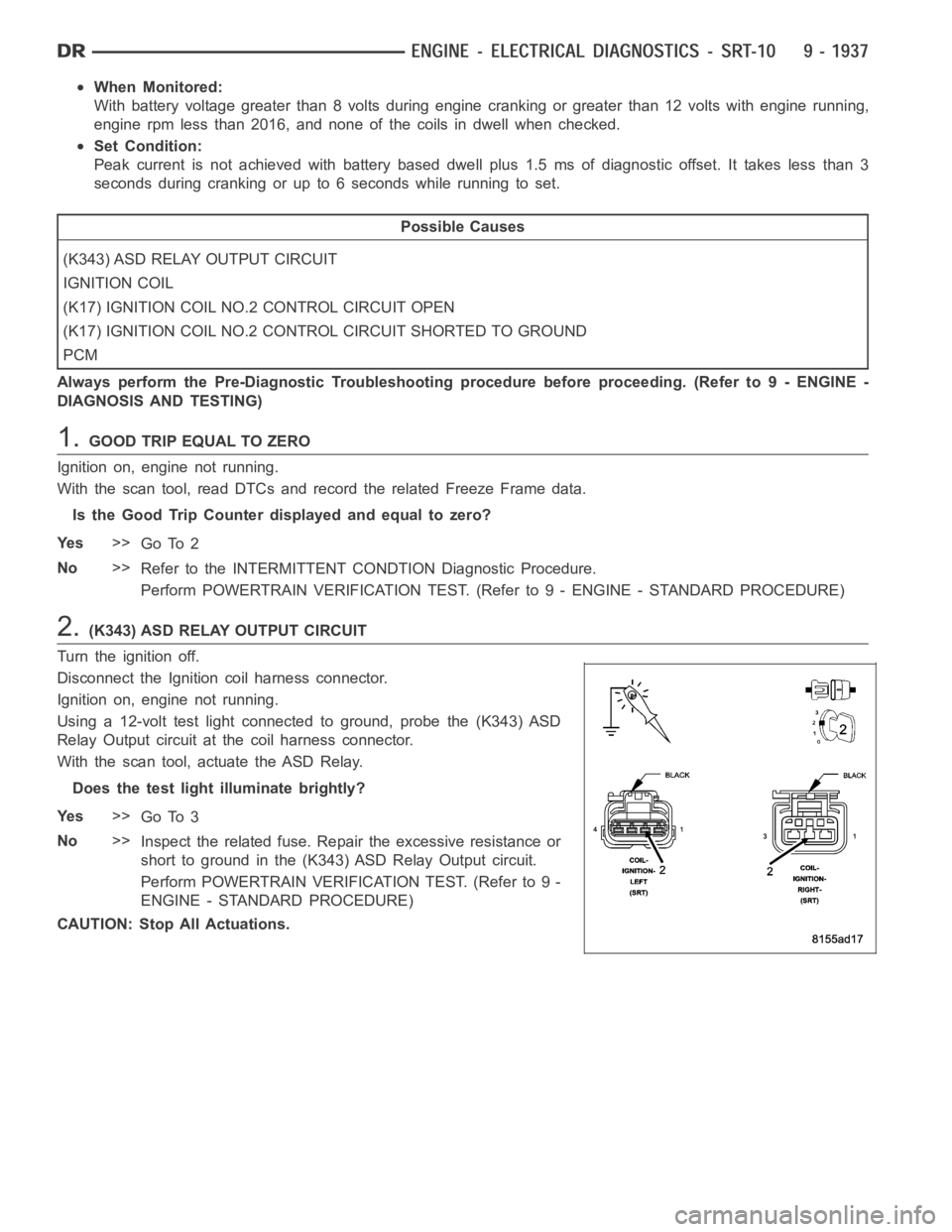

2.(K343) ASD RELAY OUTPUT CIRCUIT

Turn the ignition off.

Disconnect the Ignition coil harness connector.

Ignition on, engine not running.

Using a 12-volt test light connected to ground, probe the (K343) ASD

Relay Output circuit at the coil harness connector.

With the scan tool, actuate the ASD Relay.

Does the test light illuminate brightly?

Ye s>>

Go To 3

No>>

Inspect the related fuse. Repair the excessive resistance or

short to ground in the (K343) ASD Relay Output circuit.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 -

ENGINE - STANDARD PROCEDURE)

CAUTION: Stop All Actuations.