ignition DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1293 of 5267

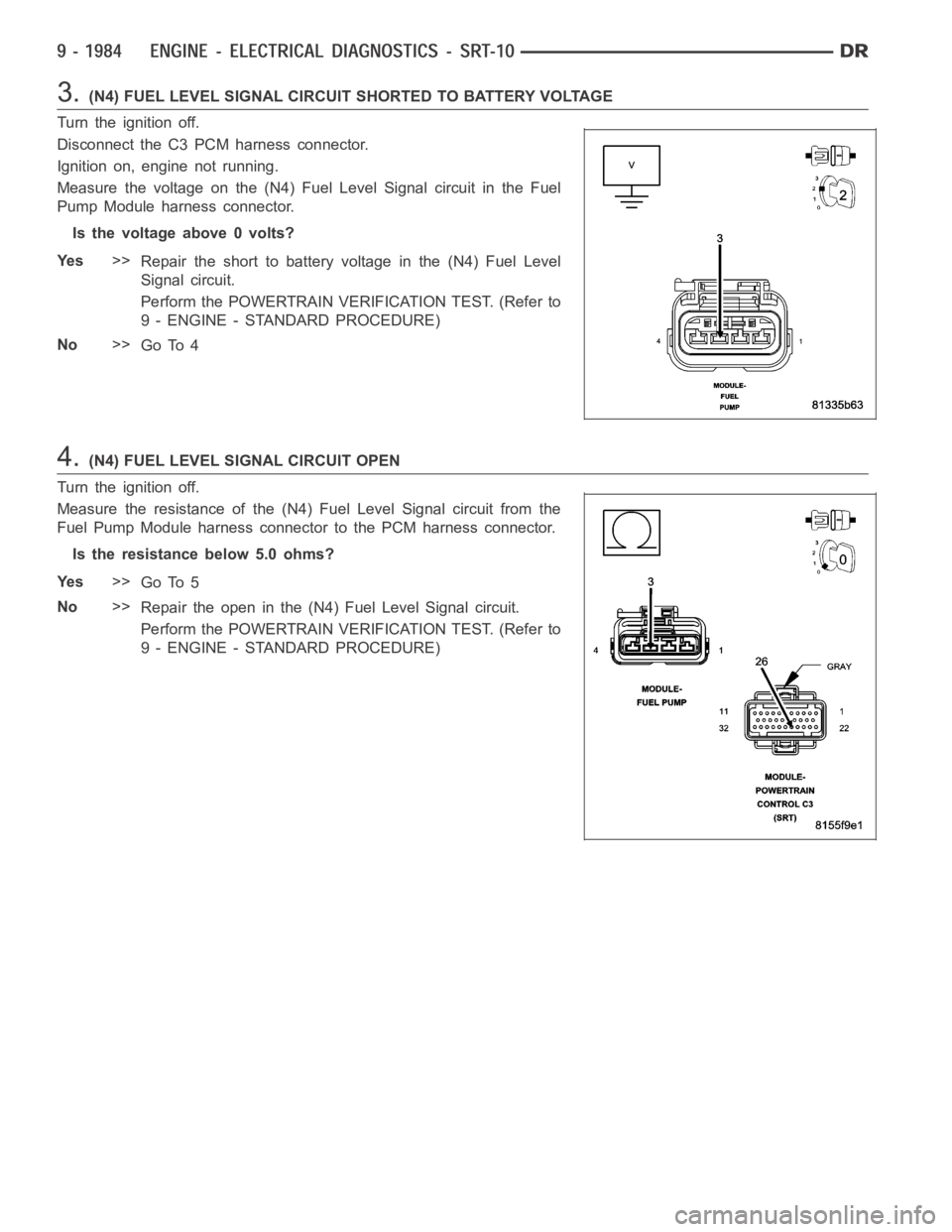

3.(N4) FUEL LEVEL SIGNAL CIRCUIT SHORTED TO BATTERY VOLTAGE

Turn the ignition off.

Disconnect the C3 PCM harness connector.

Ignition on, engine not running.

Measure the voltage on the (N4) Fuel Level Signal circuit in the Fuel

Pump Module harness connector.

Is the voltage above 0 volts?

Ye s>>

Repair the short to battery voltage in the (N4) Fuel Level

Signal circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 4

4.(N4) FUEL LEVEL SIGNAL CIRCUIT OPEN

Turn the ignition off.

Measure the resistance of the (N4) Fuel Level Signal circuit from the

Fuel Pump Module harness connector to the PCM harness connector.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 5

No>>

Repair the open in the (N4) Fuel Level Signal circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

Page 1296 of 5267

When Monitored:

Engine Temperature greater than 104 Deg F, MAP vacuum approximately 15

to 16inches of mercury and

Engine RPM between 1400 and 3000 rpm.

Set Condition:

No Vehicle Speed Signal for more than 15 seconds on two consecutive trips.

Possible Causes

(B22) VEHICLE SPEED SIGNAL CIRCUIT SHORTED TO VOLTAGE

(B22) VEHICLE SPEED SIGNAL CIRCUIT OPEN BETWEEN CAB AND PCM

(B22) VEHICLE SPEED SIGNAL CIRCUIT SHORTED TO GROUND

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

1.GOOD TRIP EQUAL TO ZERO

Ignition on, engine not running.

NOTE: With the scan tool check for any related DTCs that may be present in theABS/RWAL Module or TCM,

diagnose any ABS/RWAL Module DTC’s before continuing.

With the scan tool, read DTCs and record the related Freeze Frame data.

Is the Good Trip Counter displayed and equal to zero?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDTION Diagnostic Procedure.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

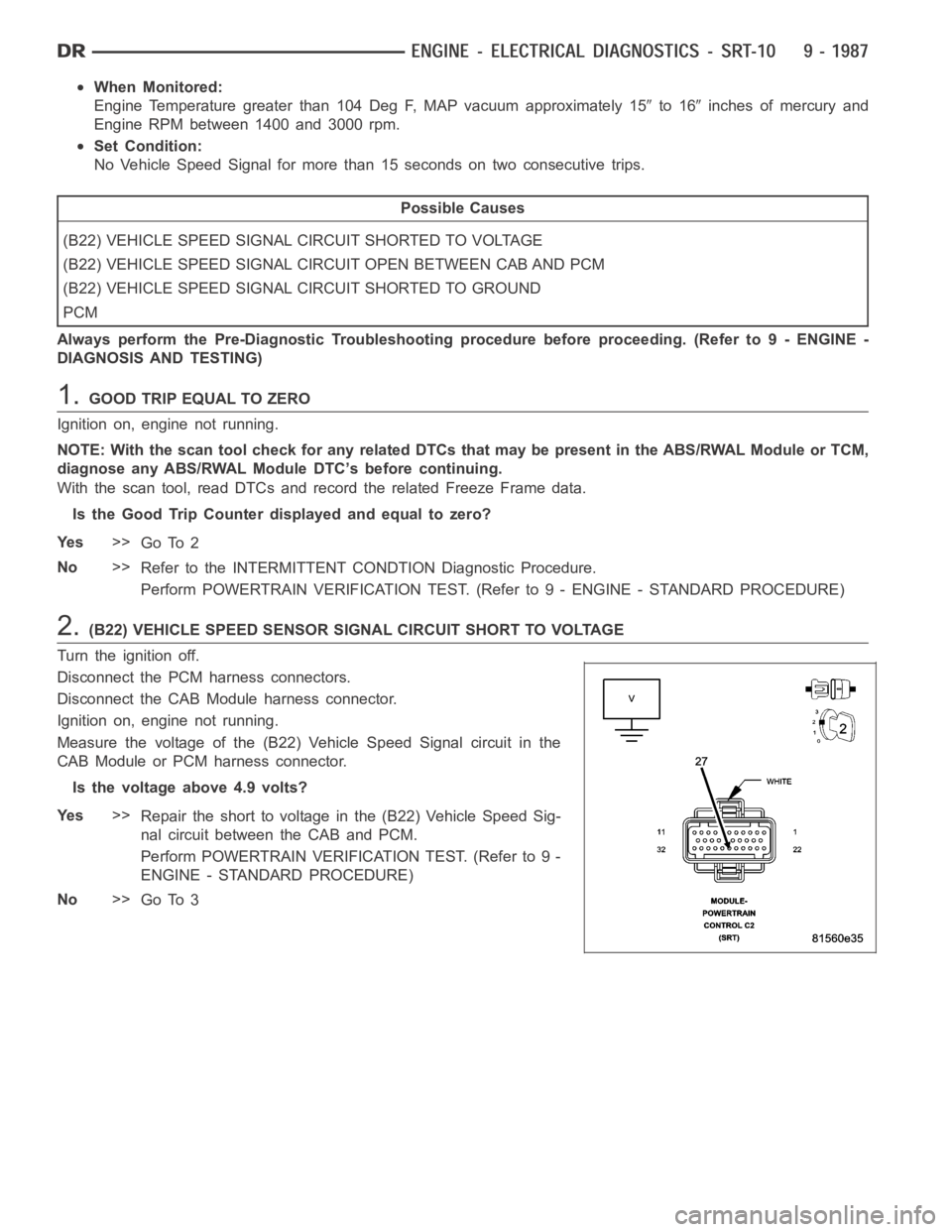

2.(B22) VEHICLE SPEED SENSOR SIGNAL CIRCUIT SHORT TO VOLTAGE

Turn the ignition off.

Disconnect the PCM harness connectors.

Disconnect the CAB Module harness connector.

Ignition on, engine not running.

Measure the voltage of the (B22) Vehicle Speed Signal circuit in the

CAB Module or PCM harness connector.

Is the voltage above 4.9 volts?

Ye s>>

Repair the short to voltage in the (B22) Vehicle Speed Sig-

nal circuit between the CAB and PCM.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 -

ENGINE - STANDARD PROCEDURE)

No>>

Go To 3

Page 1297 of 5267

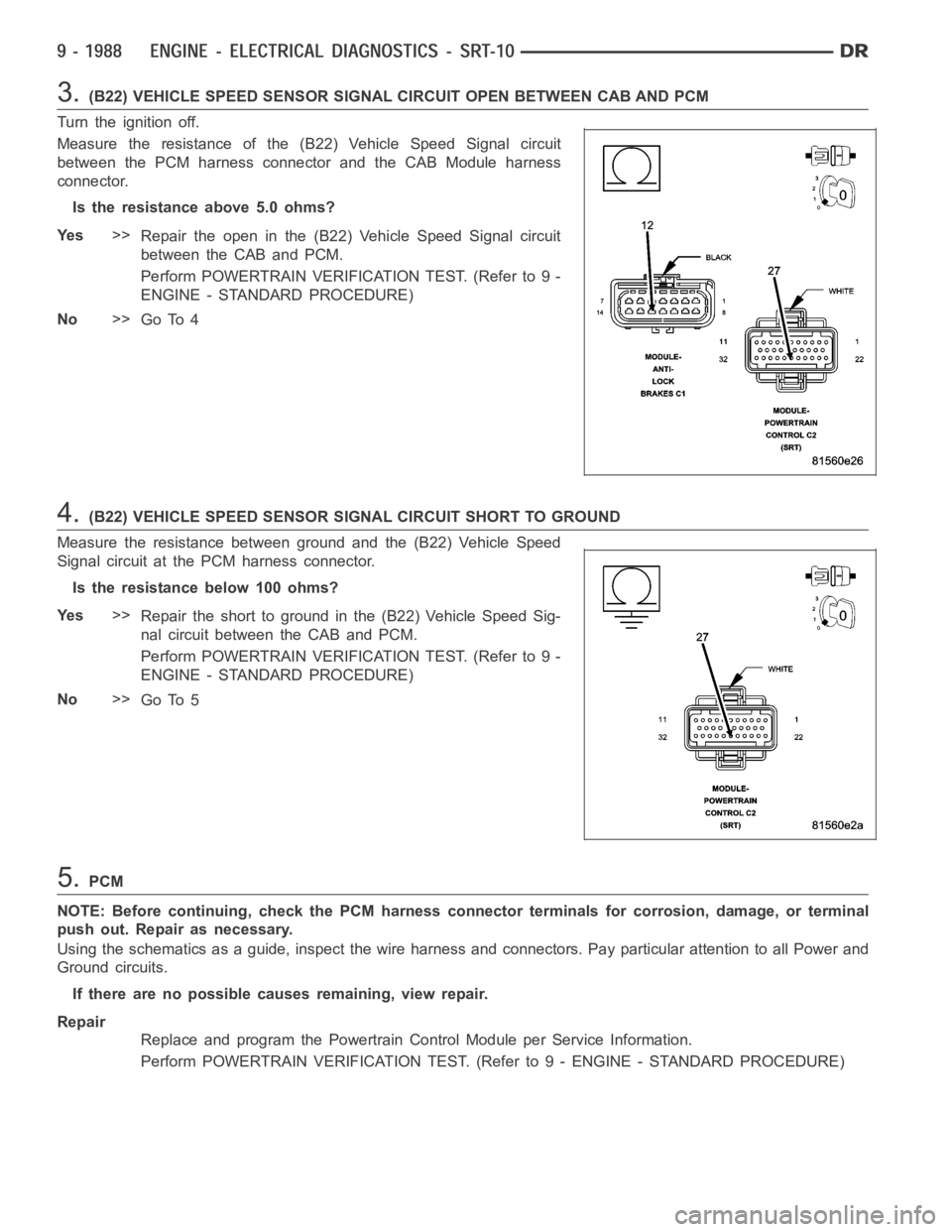

3.(B22) VEHICLE SPEED SENSOR SIGNAL CIRCUIT OPEN BETWEEN CAB AND PCM

Turn the ignition off.

Measure the resistance of the (B22) Vehicle Speed Signal circuit

between the PCM harness connector and the CAB Module harness

connector.

Is the resistance above 5.0 ohms?

Ye s>>

Repair the open in the (B22) Vehicle Speed Signal circuit

between the CAB and PCM.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 -

ENGINE - STANDARD PROCEDURE)

No>>

Go To 4

4.(B22) VEHICLE SPEED SENSOR SIGNAL CIRCUIT SHORT TO GROUND

Measure the resistance between ground and the (B22) Vehicle Speed

Signal circuit at the PCM harness connector.

Istheresistancebelow100ohms?

Ye s>>

Repair the short to ground in the (B22) Vehicle Speed Sig-

nal circuit between the CAB and PCM.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 -

ENGINE - STANDARD PROCEDURE)

No>>

Go To 5

5.PCM

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

If there are no possible causes remaining, view repair.

Repair

Replace and program the Powertrain Control Module per Service Information.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 1299 of 5267

When Monitored:

At power-up and battery voltage greater than 11.5 volts.

Set Condition:

The PCM senses a short to ground or battery voltage on any of the four Idle AirControl (IAC) driver circuits

for 100 ms while the IAC motor is active.

Possible Causes

(K40) IAC #1 DRIVER CIRCUIT SHORTED TO (K60) #2, (K39) #3, OR (K59) #4 IAC DRIVER CIRCUITS

(K60) IAC #2 DRIVER CIRCUIT SHORTED TO (K39) IAC #3 OR (K59) IAC #4

(K39) IAC #3 DRIVER CIRCUIT SHORTED TO (K59) IAC #4 DRIVER CIRCUIT

IAC DRIVER CIRCUIT SHORTED TO VOLTAGE

IAC DRIVER CIRCUIT SHORTED TO GROUND

IAC MOTOR

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

1.GOOD TRIP EQUAL TO ZERO

Ignition on, engine not running.

With the scan tool, read DTCs and record the related Freeze Frame data.

Is the Good Trip Counter displayed and equal to zero?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITIONSymptom (Diagnostic Procedure).

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

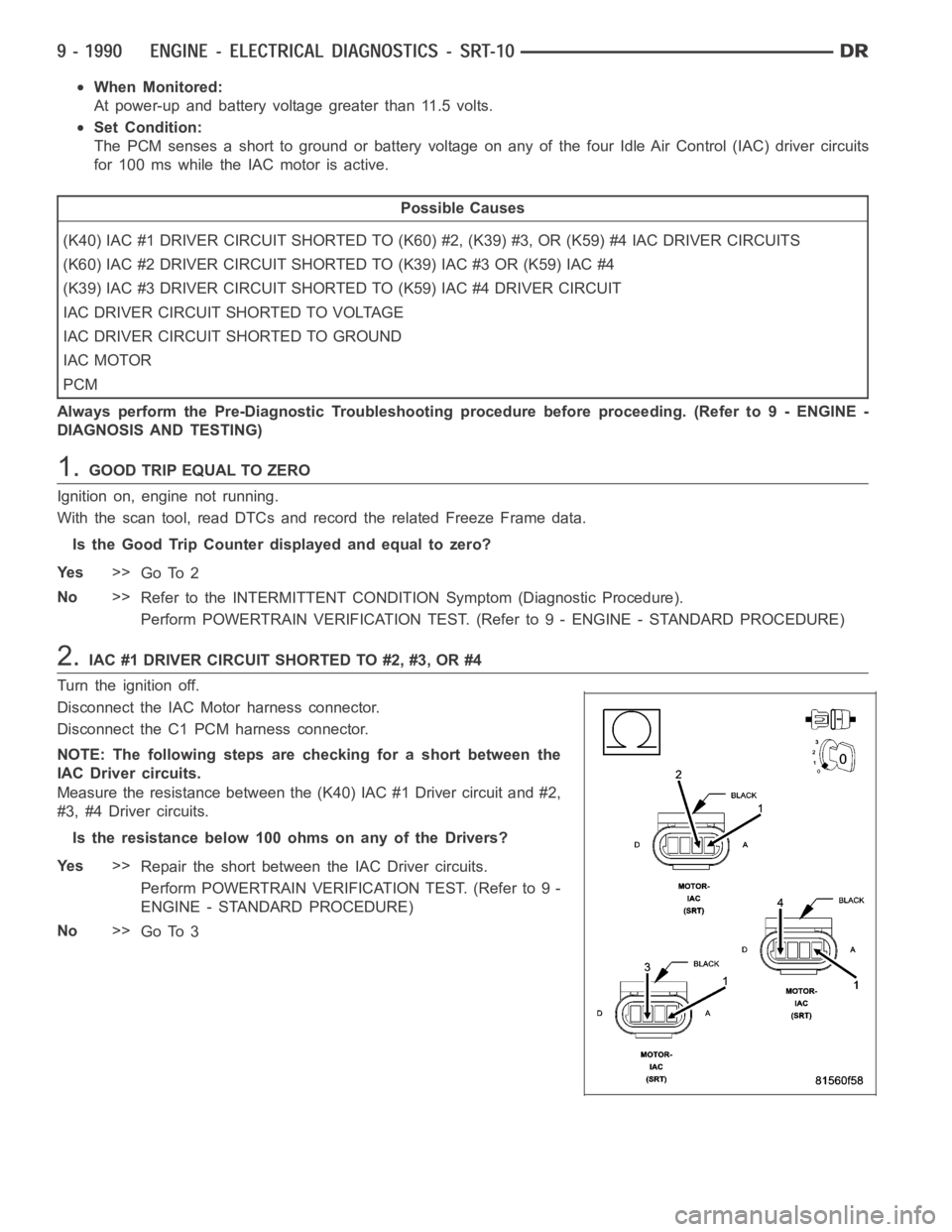

2.IAC #1 DRIVER CIRCUIT SHORTED TO #2, #3, OR #4

Turn the ignition off.

Disconnect the IAC Motor harness connector.

Disconnect the C1 PCM harness connector.

NOTE: The following steps are checking for a short between the

IAC Driver circuits.

Measure the resistance between the (K40) IAC #1 Driver circuit and #2,

#3, #4 Driver circuits.

Istheresistancebelow100ohmsonanyoftheDrivers?

Ye s>>

Repair the short between the IAC Driver circuits.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 -

ENGINE - STANDARD PROCEDURE)

No>>

Go To 3

Page 1301 of 5267

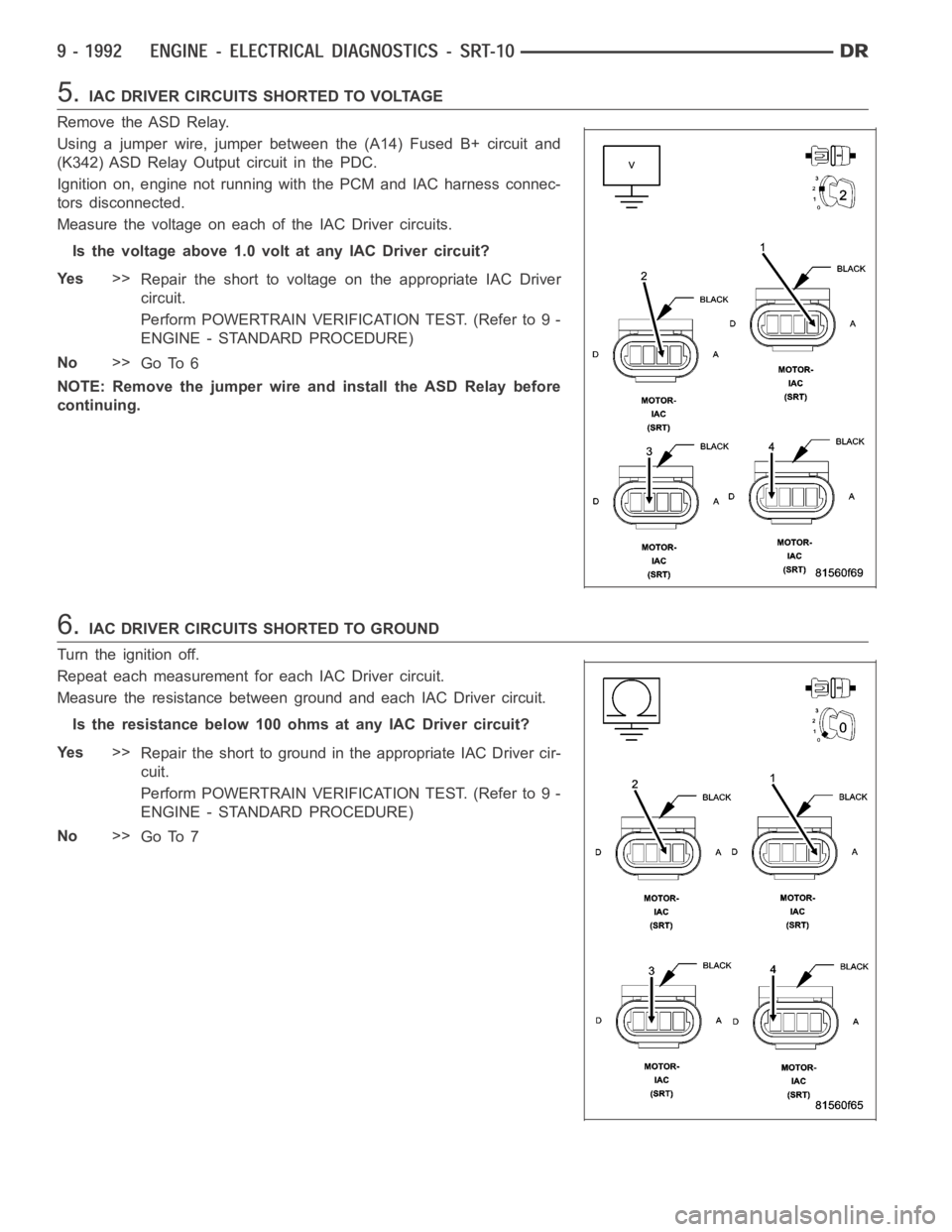

5.IAC DRIVER CIRCUITS SHORTED TO VOLTAGE

Remove the ASD Relay.

Using a jumper wire, jumper between the (A14) Fused B+ circuit and

(K342) ASD Relay Output circuit in the PDC.

Ignition on, engine not running with the PCM and IAC harness connec-

tors disconnected.

Measure the voltage on each of the IAC Driver circuits.

Is the voltage above 1.0 volt at any IAC Driver circuit?

Ye s>>

Repair the short to voltage onthe appropriate IAC Driver

circuit.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 -

ENGINE - STANDARD PROCEDURE)

No>>

Go To 6

NOTE: Remove the jumper wire and install the ASD Relay before

continuing.

6.IAC DRIVER CIRCUITS SHORTED TO GROUND

Turn the ignition off.

Repeat each measurement for each IAC Driver circuit.

Measure the resistance between ground and each IAC Driver circuit.

Is the resistance below 100 ohms at any IAC Driver circuit?

Ye s>>

Repair the short to ground in the appropriate IAC Driver cir-

cuit.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 -

ENGINE - STANDARD PROCEDURE)

No>>

Go To 7

Page 1302 of 5267

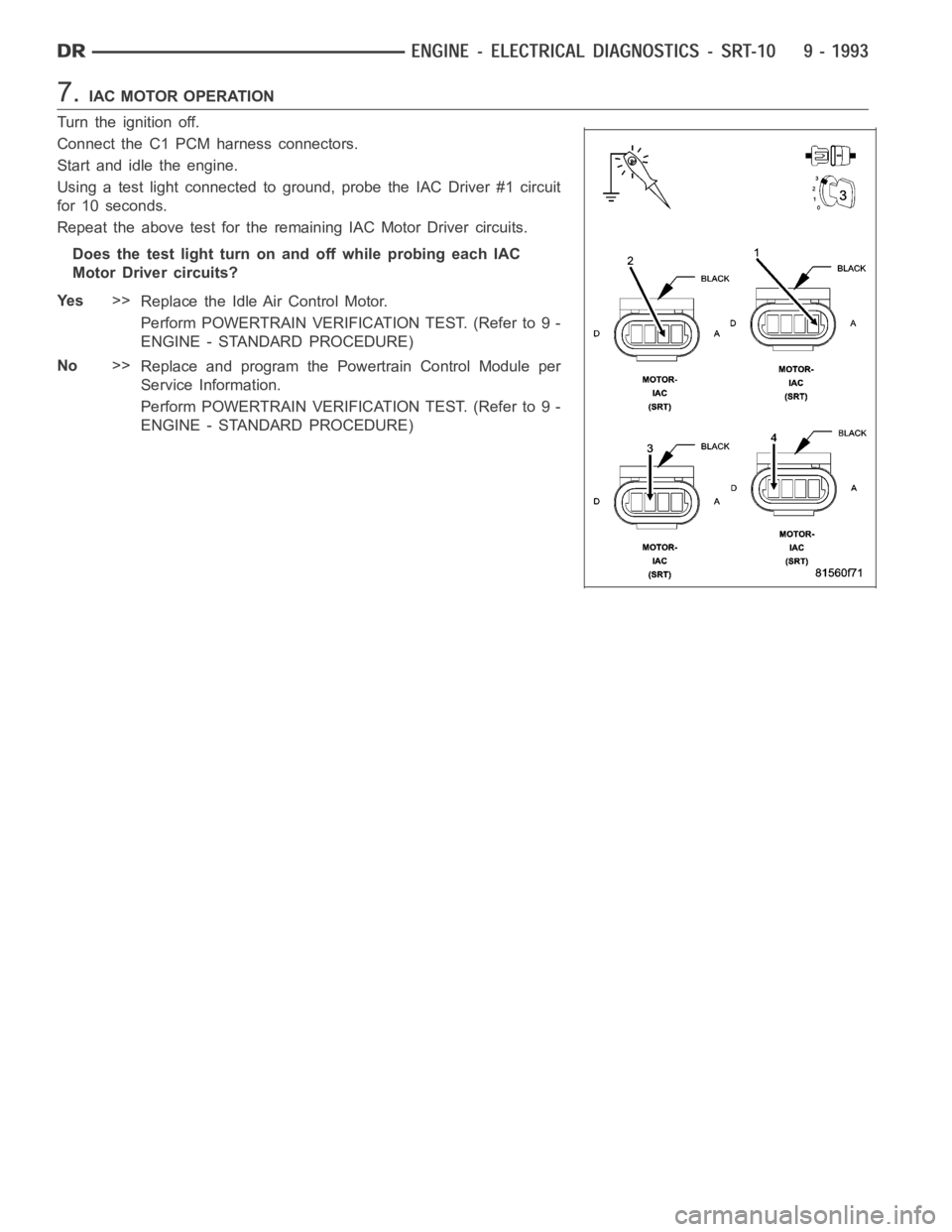

7.IAC MOTOR OPERATION

Turn the ignition off.

Connect the C1 PCM harness connectors.

Start and idle the engine.

Using a test light connected to ground, probe the IAC Driver #1 circuit

for 10 seconds.

Repeat the above test for the remaining IAC Motor Driver circuits.

Does the test light turn on and off while probing each IAC

MotorDrivercircuits?

Ye s>>

Replace the Idle Air Control Motor.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 -

ENGINE - STANDARD PROCEDURE)

No>>

Replace and program the Powertrain Control Module per

Service Information.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 -

ENGINE - STANDARD PROCEDURE)

Page 1303 of 5267

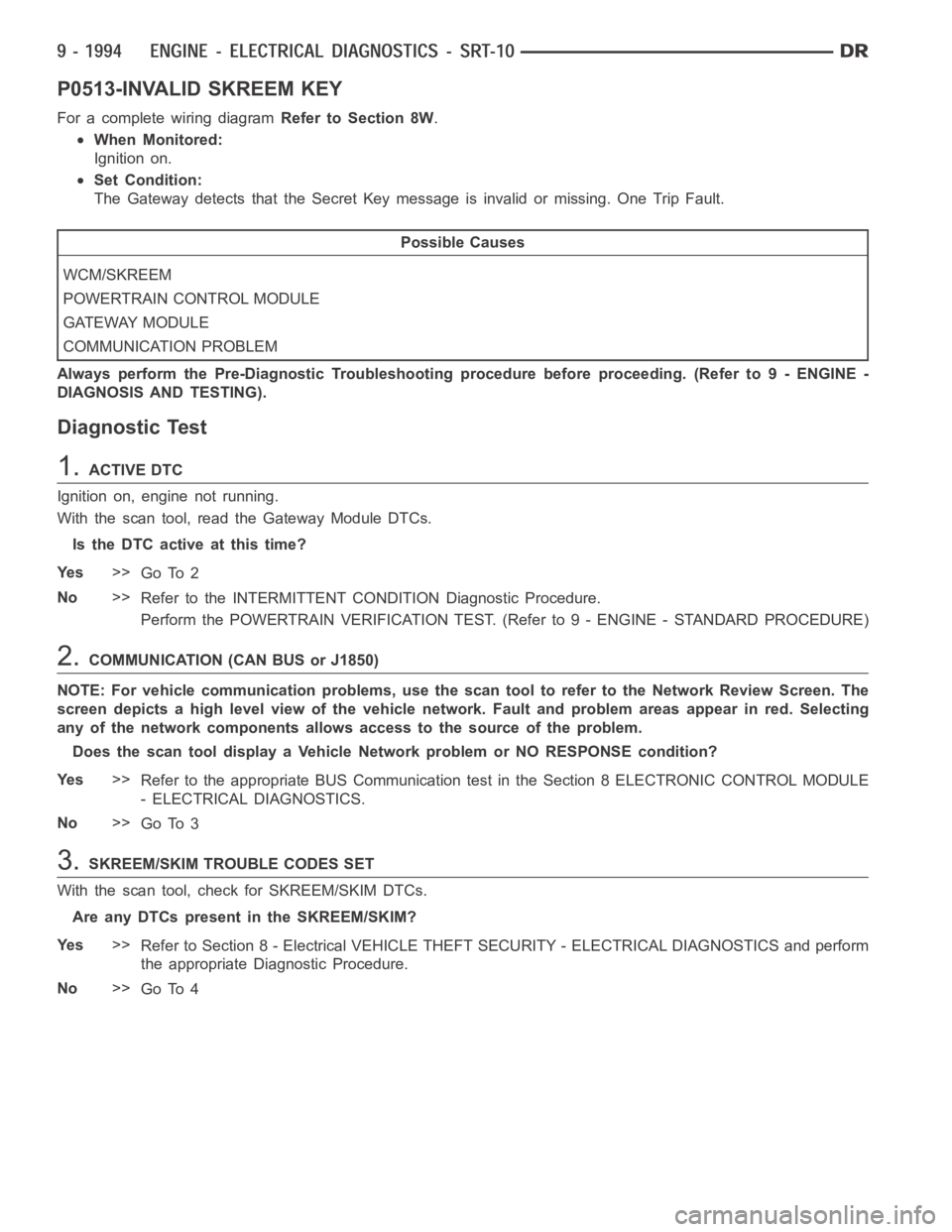

P0513-INVALID SKREEM KEY

For a complete wiring diagramRefer to Section 8W.

When Monitored:

Ignition on.

Set Condition:

The Gateway detects that the Secret Key message is invalid or missing. One Trip Fault.

Possible Causes

WCM/SKREEM

POWERTRAIN CONTROL MODULE

GATEWAY MODULE

COMMUNICATION PROBLEM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

Ignition on, engine not running.

With the scan tool, read the Gateway Module DTCs.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.COMMUNICATION (CAN BUS or J1850)

NOTE: For vehicle communication problems, use the scan tool to refer to theNetwork Review Screen. The

screen depicts a high level view of the vehicle network. Fault and problem areas appear in red. Selecting

any of the network components allows access to the source of the problem.

Does the scan tool display a Vehicle Network problem or NO RESPONSE condition?

Ye s>>

Refer to the appropriate BUS Communication test in the Section 8 ELECTRONIC CONTROL MODULE

- ELECTRICAL DIAGNOSTICS.

No>>

Go To 3

3.SKREEM/SKIM TROUBLE CODES SET

With the scan tool, check for SKREEM/SKIM DTCs.

Are any DTCs present in the SKREEM/SKIM?

Ye s>>

Refer to Section 8 - Electrical VEHICLE THEFT SECURITY - ELECTRICAL DIAGNOSTICS and perform

the appropriate Diagnostic Procedure.

No>>

Go To 4

Page 1304 of 5267

4.GATEWAY MODULE

Turn the ignition off.

Replace and program the Gateway Module in accordance with Service Information.

Ignition on, engine not running.

With the scan tool, erase all SKREEM and PCM DTCs.

Attempt to start and idle the engine.

With the scan tool, read the Gateway Module DTCs.

Does the scan tool display this code?

Ye s>>

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or termi-

nal push out. Repair as necessary. Replace and program the Powertrain Control Module per Service

Information.

Perform SKREEM VERIFICATION. (Refer to 8 - ELECTRICAL/VEHICLE THEFT SECURITY - STAN-

DARD PROCEDURE)

No>>

Te s t C o m p l e t e .

Page 1306 of 5267

When Monitored:

Ignition on.

Set Condition:

When the PCM recognizes the Oil Pressure signal voltage lower than 0.3 of a volt.

Possible Causes

(F855) 5-VOLT SUPPLY CIRCUIT OPEN

(F855) 5-VOLT SUPPLY CIRCUIT SHORTED TO GROUND

OIL PRESSURE SENSOR

(G6) OIL PRESSURE SIGNAL CIRCUIT SHORTED TO GROUND

(G6) OIL PRESSURE SIGNAL CIRCUIT SHORTED TO THE (K900) SENSOR GROUND

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

1.OIL PRESSURE SENSOR VOLTAGE BELOW 0.1 VOLT

Start the engine.

With the scan tool in Sensors, read the Oil Pressure Sensor voltage.

Is the Oil Pressure Sensor voltage below 0.1 of a volt?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

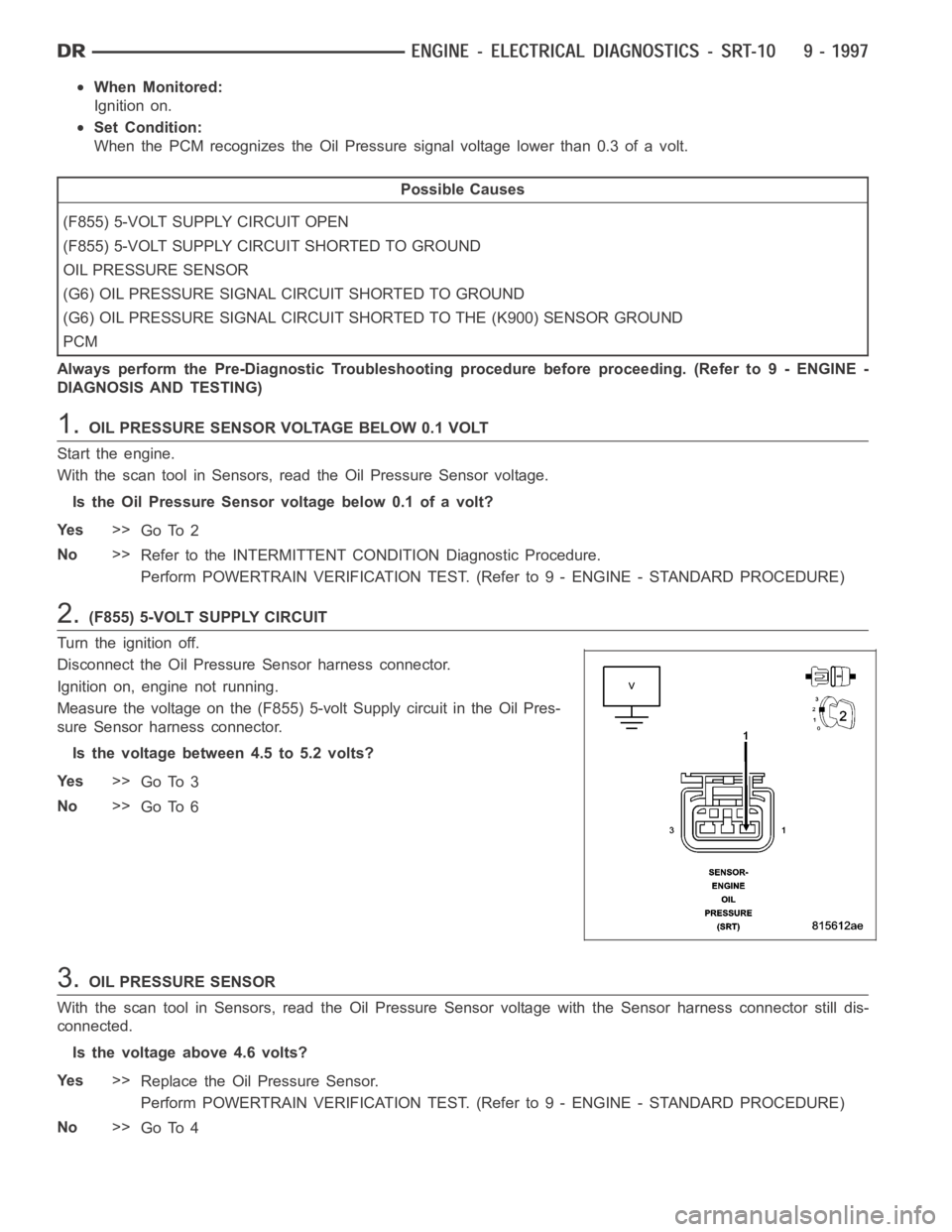

2.(F855) 5-VOLT SUPPLY CIRCUIT

Turn the ignition off.

Disconnect the Oil Pressure Sensor harness connector.

Ignition on, engine not running.

Measure the voltage on the (F855) 5-volt Supply circuit in the Oil Pres-

sure Sensor harness connector.

Is the voltage between 4.5 to 5.2 volts?

Ye s>>

Go To 3

No>>

Go To 6

3.OIL PRESSURE SENSOR

WiththescantoolinSensors,readtheOilPressureSensorvoltagewiththeSensor harness connector still dis-

connected.

Is the voltage above 4.6 volts?

Ye s>>

Replace the Oil Pressure Sensor.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 4

Page 1307 of 5267

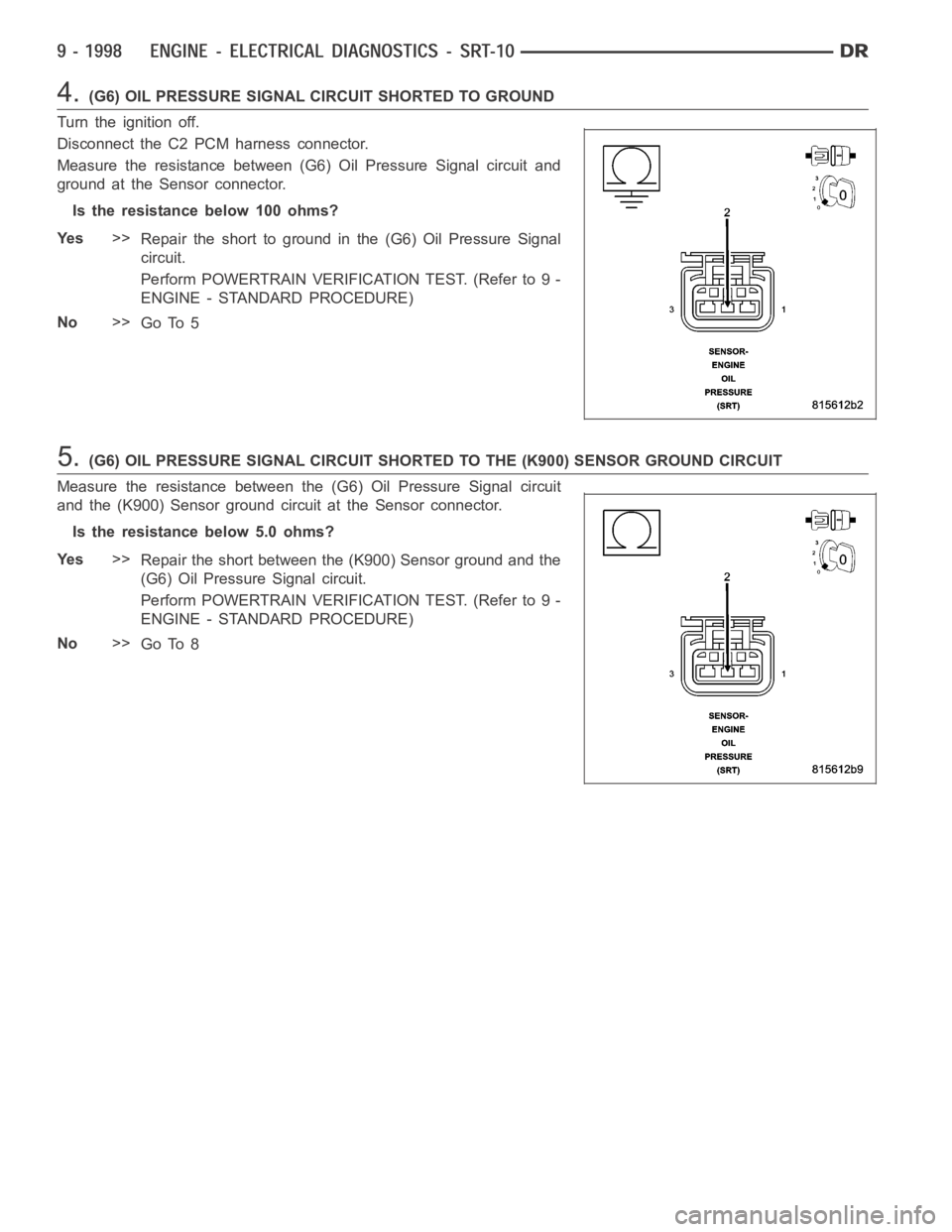

4.(G6) OIL PRESSURE SIGNAL CIRCUIT SHORTED TO GROUND

Turn the ignition off.

Disconnect the C2 PCM harness connector.

Measure the resistance between (G6) Oil Pressure Signal circuit and

ground at the Sensor connector.

Istheresistancebelow100ohms?

Ye s>>

Repair the short to ground in the (G6) Oil Pressure Signal

circuit.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 -

ENGINE - STANDARD PROCEDURE)

No>>

Go To 5

5.(G6) OIL PRESSURE SIGNAL CIRCUIT SHORTED TO THE (K900) SENSOR GROUND CIRCUIT

Measure the resistance between the (G6) Oil Pressure Signal circuit

and the (K900) Sensor ground circuit at the Sensor connector.

Is the resistance below 5.0 ohms?

Ye s>>

Repair the short between the (K900) Sensor ground and the

(G6) Oil Pressure Signal circuit.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 -

ENGINE - STANDARD PROCEDURE)

No>>

Go To 8