check engine DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 3142 of 5267

When Monitored:

The transmission gear ratio is monitored continuously while the transmission is in gear.

Set Condition:

If there is an excessive change in output RPM in any gear. This DTC can take upto five minutes of problem

identification beforeilluminating the MIL.

Possible Causes

(T14) OUTPUT SPEED SENSOR SIGNAL CIRCUIT OPEN

(T13) SPEED SENSOR GROUND CIRCUIT OPEN

(T14) OUTPUT SPEED SENSOR SIGNAL CIRCUIT SHORT TO GROUND

(T13) SPEED SENSOR GROUND CIRCUIT SHORT TO GROUND

(T14) OUTPUT SPEED SENSOR SIGNAL CIRCUIT SHORT TO VOLTAGE

(T13) SPEED SENSOR GROUND CIRCUIT SHORT TO VOLTAGE

OUTPUT SPEED SENSOR

POWERTRAIN CONTROL MODULE

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

The transmission system uses two speed sensors, one to measure input RPM and one to measure output RPM.

These inputs are essential for proper transmission operation. Therefore, the integrity of this data is verified through

the following checks:

1) When in gear, if the gear ratio does not compare to a known gear ratio, the corresponding in-gear trouble code

is set (codes P0731 through P0736).

2) An excessive change in input or output speeds indicating signal intermittent will result in codes P0715 and/or

P0720 being set.

3) If the common speed sensor ground circuit is lost, both sensor inputs will read the signal from the input speed

sensor at idle in neutral. Since the input speed sensor has 60 teeth and the output speed sensor has 30 teeth, this

results in a an apparent speed ratio of 1:2 and may cause the DTC P1794 to set.

Diagnostic Test

1.CHECK TO SEE IF DTC P0720 IS CURRENT

Turn the ignition off to the lock position.

CAUTION: Properly support the vehicle and raise all drive wheels off the ground.

Release the parking brake.

Start the engine in park.

Place the transmission gear selector in drive, release foot from brake.

WARNING: Be sure to keep hands and feet clear of rotation wheels.

With the scan tool, monitor the Output Speed Sensor RPM.

Is the Output Speed Sensor RPM below 100 RPM?

Ye s>>

Go To 2

No>>

Go To 9

Page 3143 of 5267

2.OUTPUT SPEED SENSOR

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install the Transmission Simulator, Miller tool #8333.

Ignition on, engine not running.

With the Transmission Simulator, set the selector switch to 3000/1000 andthe Input/Output switch to ON.

With the scan tool, monitor the Input and Output Speed Sensor RPM

Does the Input Speed read 3000 RPM and the Output Speed read 1000 RPM, ± 50 RPM?

Ye s>>

Replace the Output Speed Sensor per the Service Information.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Go To 3

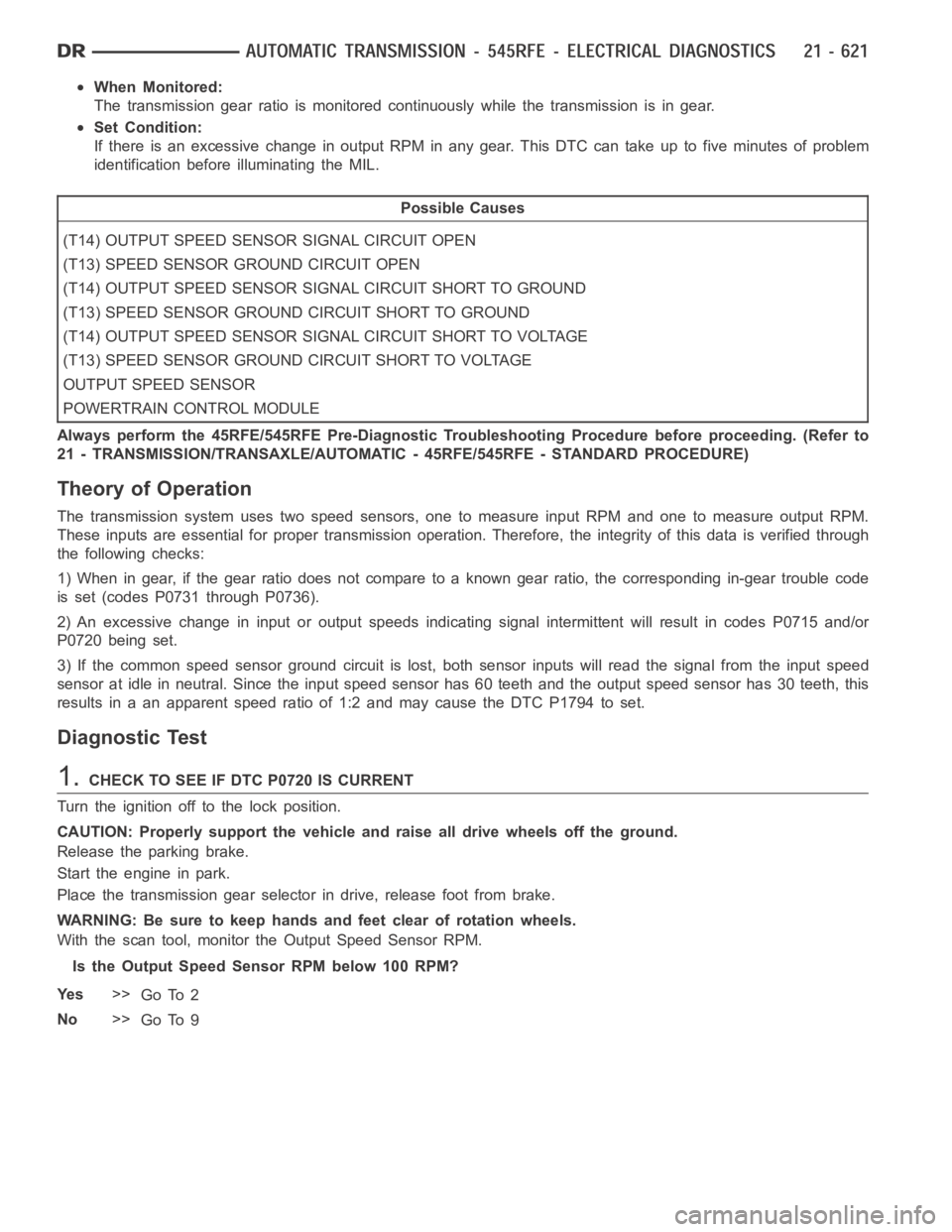

3.CHECK THE (T14) OUTPUT SPEED SENSOR SIGNAL CIRCUIT FOR AN OPEN

Turn the ignition off to the lock position.

Disconnect the Transmission Simulator, Miller tool #8333.

Disconnect the PCM harness connectors and connect Miller special tool

#8815.

CAUTION: Do not probe the PCM harness connectors. Probing the

PCM harness connectors will damage the PCM terminals resulting

in poor terminal to pin connection. Install Miller special tool #8815

to perform diagnosis.

Measure the resistance of the (T14) Output Speed Sensor Signal circuit

from the Output Speed Sensor harness connector to the appropriate

terminal of Miller tool #8815.

Is the resistance above 5.0 ohms?

Ye s>>

Repair the (T14) Output Speed Sensor Signal circuit for an

open.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

No>>

Go To 4

Page 3145 of 5267

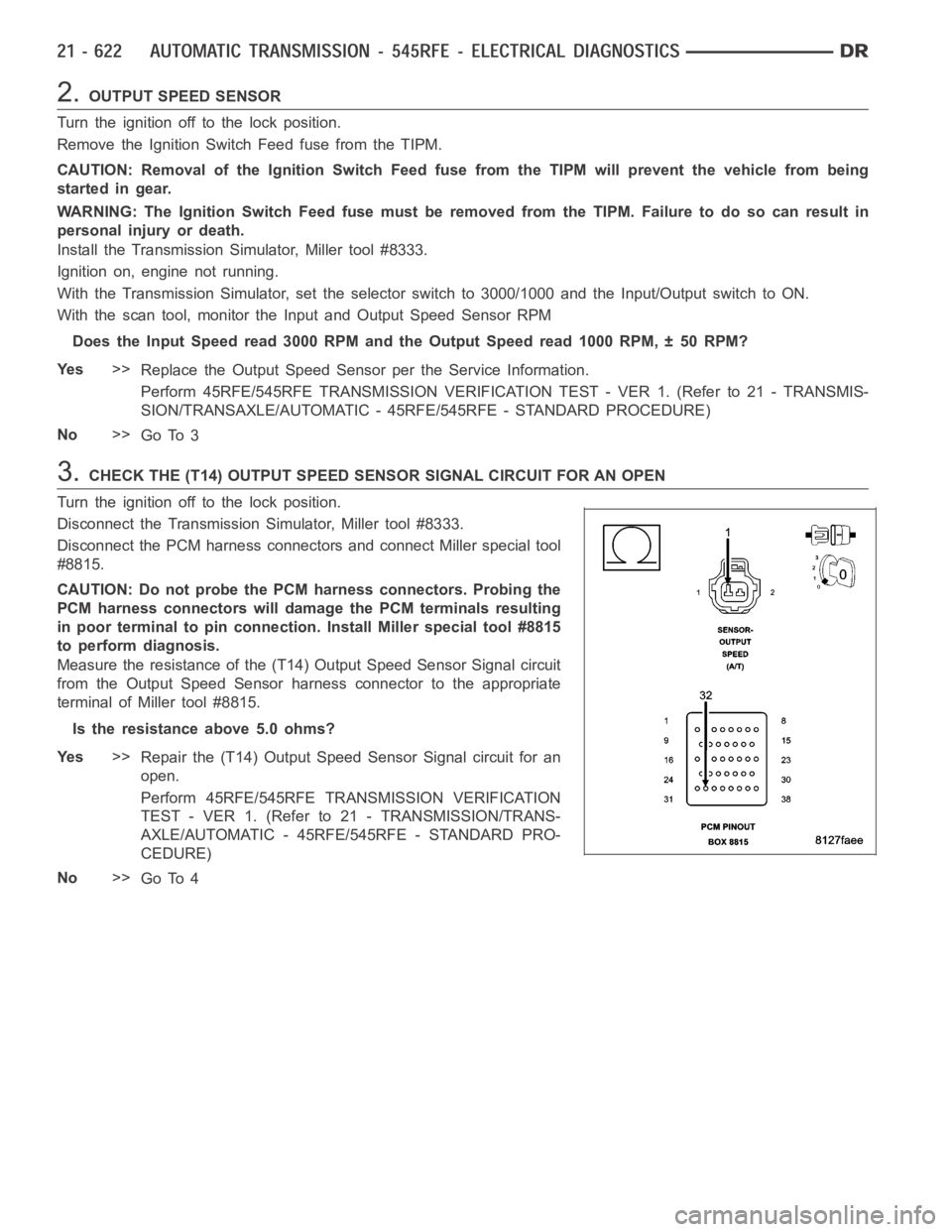

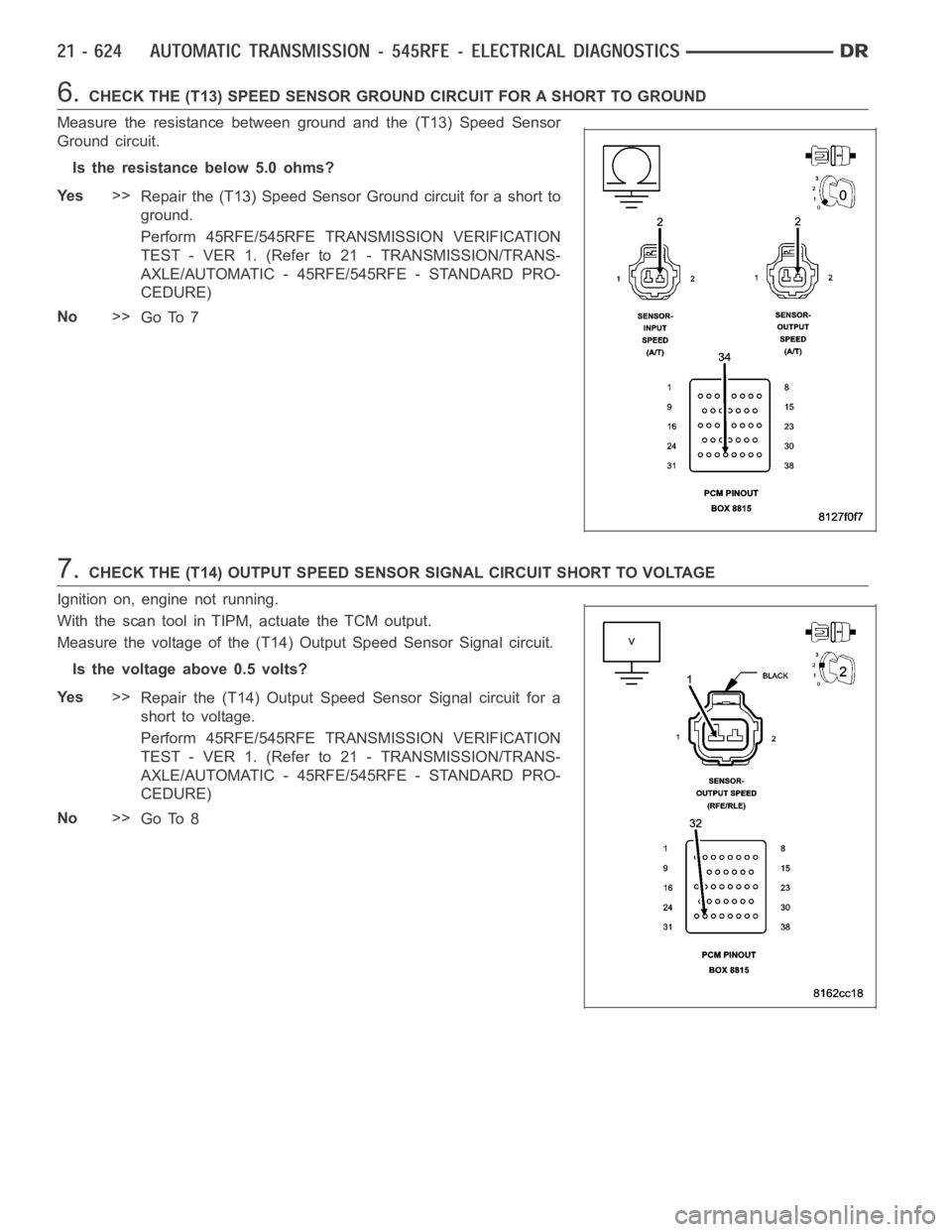

6.CHECK THE (T13) SPEED SENSOR GROUND CIRCUIT FOR A SHORT TO GROUND

Measure the resistance between ground and the (T13) Speed Sensor

Ground circuit.

Is the resistance below 5.0 ohms?

Ye s>>

Repair the (T13) Speed Sensor Ground circuit for a short to

ground.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

No>>

Go To 7

7.CHECK THE (T14) OUTPUT SPEED SENSOR SIGNAL CIRCUIT SHORT TO VOLTAGE

Ignition on, engine not running.

With the scan tool in TIPM, actuate the TCM output.

Measure the voltage of the (T14) Output Speed Sensor Signal circuit.

Is the voltage above 0.5 volts?

Ye s>>

Repair the (T14) Output Speed Sensor Signal circuit for a

short to voltage.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

No>>

Go To 8

Page 3147 of 5267

P0725-ENGINE SPEED SENSOR CIRCUIT

For a complete wiring diagramRefer to Section 8W.

When Monitored:

Continuously every 7 msec with the ignition on and engine running.

Set Condition:

This DTC will set when the calculated engine speed is less than 390 RPM with the engine running, or greater

than 8000 RPM, for the period of 2.0 seconds. The PCM will place the Transmission in Limp-in when this DTC

is set.Note: This is not a Transmission Input Speed Sensor DTC.

Possible Causes

RELATED ENGINE DTC’S PRESENT

CRANK POSITION SENSOR OR WIRING

POWERTRAIN CONTROL MODULE

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

The Transmission Control System calculates the engine RPM by directly reading the engine crank position sensor.

It compares the calculated value to the engine speed sensor signal transmitted from the Engine Control System

over the controllers internal BUS. The calculated engine RPM is also comparedtoaminimumandamaximum

value.Note: Due to the integration of the Powertrain Control Module (PCM) and Transmission Control Mod-

ule (TCM), BUS communication between the modules is internal and unserviceable.

Diagnostic Test

1.CHECKFORRELATEDENGINEDTCS

NOTE: This is not a Transmission Input Speed Sensor DTC.

Ignition on, engine not running.

With the scan tool, read all Engine DTCs. This includes any active or storedor one trip DTCs.

Are there any engine RPM related DTCs present?

Ye s>>

Refer to the Powertrain category and perform the appropriate symptom.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Go To 2

2.CHECK IF DTC IS CURRENT

Ignition on, engine not running.

With a scan tool, read and record all DTC EVENT DATA.

Withthescantool,eraseallactiveandstoredtransmissionDTCs.(Note:it may be necessary to perform a battery

disconnect with the scan tool to clear DTC EVENT DATA.)

Using the DTC EVENT DATA, duplicate theconditions in which the original DTCset.

With the scan tool, read transmission and engine DTCs.

NOTE: Refer to all engine DTCs first in the following question.

Pick the answer below that best describes your findings, (this includes one trip failures).

Transmission DTC P0725 set

Using the schematics as a guide, check the Powertrain Control Module (PCM)terminals for corrosion,

damage, or terminal push out. Also check the Crank Position sensor and wiring. Pay particular attention

Page 3148 of 5267

to all power and ground circuits. If no problems are found, replace the PCM per the Service Information.

With the scan tool, perform QUICK LEARN.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Engine DTC set

Refer to the Driveability category and perform the appropriate symptom.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No DTC set at all

Go To 3

3.CHECK WIRING AND CONNECTORS

The conditions necessary to set this DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specifictothiscircuit.

Wiggle the wires while checking for shorted and open circuits.

With the scan tool, check the DTC EVENT DATA to help identify the conditionsin which the DTC was set.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Te s t C o m p l e t e .

Page 3149 of 5267

P0731-GEAR RATIO ERROR IN 1ST

For a complete wiring diagramRefer to Section 8W

When Monitored:

Continuously with the ignition on, engine running, with the transmissionin gear.

Set Condition:

If the ratio of the Input RPM to the Output RPM does not match the current gearratio. This DTC can take up

to five minutes of problem identification before illuminating the MIL

Possible Causes

CUT UD PISTON SEAL

LOW FLUID LEVEL

CRACKED OR MIS-INSTALLED PRIMARY OIL FILTER OR SEAL

STUCK OR STICKING MAIN REGULATOR VALVE

FAILED OVERRUNNING CLUTCH

CUT UD ACCUMULATOR SEAL RING

BROKEN UD ACCUMULATOR PISTON

BROKEN REACTION SHAFT SUPPORT SEAL RING

LOW LINE PRESSURE

BROKEN / MISSING MAIN VALVE BODY BLEED ORIFICE

BROKEN / MISSING DRIBBLER ORIFICE ASSEMBLY IN REACTION SHAFT SUPPORT

POOR MACHINING ON PUMP VALVE BODY FACE

INPUT SPEED SENSOR AND RELATED WIRING

TRANSMISSION SOLENOID/TRS ASSEMBLY

POWERTRAIN CONTROL MODULE

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

The transmission system uses two speed sensors, one to measure input RPM and one to measure output RPM.

These inputs are essential for proper transmission operation. Therefore, the integrity of this data is verified through

the following checks:

1) Once in a particular gear, if the gear ratio varies from the correct gear ratio, the corresponding in-gear trouble

code is set (DTCs P0731–36).

2) An excessive change in input or output speeds indicating signal intermittent may result in the DTCs P0715 and/or

P0720 being set.

3) If the common speed sensor ground circuit is lost, both sensor inputs will read the pulses from the input speed

sensor when at a stop in neutral. Since the input speed sensor reads 60 teethfrom the input clutch hub and the

output speed sensor reads 30 teeth from the park gear, the result is an apparent speed ratio of 1:2 and may cause

the DTC P1794 to set.

Page 3152 of 5267

P0732-GEAR RATIO ERROR IN 2ND

For a complete wiring diagramRefer to Section 8W

When Monitored:

Continuously with the ignition on, engine running, with the transmissionin gear.

Set Condition:

If the ratio of the Input RPM to the Output RPM does not match the current gearratio. This DTC can take up

to five minutes of problem identification before illuminating the MIL

Possible Causes

RELATED DTC’S PRESENT

INPUT SPEED SENSOR OR WIRING

LOW FLUID LEVEL

CRACKED OR MIS-INSTALLED PRIMARY OIL FILTER OR SEAL

WORN SOLENOID SWITCH VALVE OR PLUGS

STUCK OR STICKING MAIN REGULATOR VALVE

BURNED UD OR 2C CLUTCH

CUT 2C OR UD PISTON SEAL

BROKEN 2C PISTON CASTING

BROKEN OR MISSING 2C BLEED ORIFICE

BROKEN OR MISSING UD BLEED ORIFICE

CUT 2C OR UD ACCUMULATOR PISTON SEAL

CRACKED 2C OR UD ACCUMULATOR PISTON

CUT OR MISSING #5 OR #7 CHECK BALL

TRANSMISSION SOLENOID/TRS ASSEMBLY

BROKEN WELD - REACTION CARRIER TO REVERSE SUN GEAR

MISSING TEETH ON INPUT CLUTCH HUB TONE WHEEL

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

The transmission system uses two speed sensors, one to measure input RPM and one to measure output RPM.

These inputs are essential for proper transmission operation. Therefore, the integrity of this data is verified through

the following checks:

1) Once in a particular gear, if the gear ratio varies from the correct gear ratio, the corresponding in-gear trouble

code is set (DTCs P0731-36).

2) An excessive change in input or output speeds indicating signal intermittent may result in the DTCs P0715 and/or

P0720 being set.

3) If the common speed sensor ground circuit is lost, both sensor inputs will read the pulses from the input speed

sensor when at a stop in neutral. Since the input speed sensor reads 60 teethfrom the input clutch hub and the

output speed sensor reads 30 teeth from the park gear, the result is an apparent speed ratio of 1:2 and may cause

the DTC P1794 to set.

Page 3158 of 5267

P0733-GEAR RATIO ERROR IN 3RD

For a complete wiring diagramRefer to Section 8W

When Monitored:

Continuously with the ignition on, engine running, with the transmissionin gear.

Set Condition:

If the ratio of the Input RPM to the Output RPM does not match the current gearratio. This DTC can take up

to five minutes of problem identification before illuminating the MIL

Possible Causes

RELATED DTCS PRESENT

INPUT SPEED SENSOR OR WIRING

LOW FLUID LEVEL

CRACKED OR MIS-INSTALLED PRIMARY OIL FILTER OR SEAL

BENT OR BROKEN ACCUMULATOR COVER ON MAIN VALVE BODY

WORN SOLENOID SWITCH VALVE OR PLUGS

STUCK OR STICKING MAIN REGULATOR VALVE

BURNED UD OR OD CLUTCH

CUT OD OR UD PISTON SEAL

BROKEN OR MISSING UD OR OD BLEED ORIFICE IN MAIN VALVE BODY

BROKEN OR MISSING BLEED ORIFICE IN UD OR OD CLUTCH PISTON

CUT OD OR UD ACCUMULATOR PISTON SEAL

CRACKED OD OR UD ACCUMULATOR PISTON

CUT OR MISSING #6 CHECK BALL

TRANSMISSION SOLENOID/TRS ASSEMBLY

BROKEN WELD - REVERSE CARRIER HUB TO CARRIER

BROKEN REACTION SHAFT SUPPORT SEAL RING

POOR MACHINING ON PUMP VALVE BODY FACE

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

The transmission system uses two speed sensors, one to measure input RPM and one to measure output RPM.

These inputs are essential for proper transmission operation. Therefore, the integrity of this data is verified through

the following checks:

1) Once in a particular gear, if the gear ratio varies from the correct gear ratio, the corresponding in-gear trouble

code is set (DTCs P0731-36).

2) An excessive change in input or output speeds indicating signal intermittent may result in the DTCs P0715 and/or

P0720 being set.

3) If the common speed sensor ground circuit is lost, both sensor inputs will read the pulses from the input speed

sensor when at a stop in neutral. Since the input speed sensor reads 60 teethfrom the input clutch hub and the

output speed sensor reads 30 teeth from the park gear, the result is an apparent speed ratio of 1:2 and may cause

the DTC P1794 to set.

Page 3164 of 5267

P0734-GEAR RATIO ERROR IN 4TH

For a complete wiring diagramRefer to Section 8W

When Monitored:

Continuously with the ignition on, engine running, with the transmissionin gear.

Set Condition:

If the ratio of the Input RPM to the Output RPM does not match the current gearratio. This DTC can take up

to five minutes of problem identification before illuminating the MIL.

Possible Causes

LOW FLUID LEVEL

INPUT SPEED SENSOR OR WIRING

VALVE BODY ACCUMULATOR COVER FAILED

CUT OD OR 4C ACCUMULATOR SEAL

CRACKED OD OR 4C ACCUMULATOR PISTON

BROKEN OR MISSING OD BLEED ORIFICE IN MAIN VALVE BODY

CUT 4C TOWER SEAL

TRANSMISSION SOLENOID/TRS ASSEMBLY

CUT OR MISSING #5 OR #6 CHECK BALL

WORN SOLENOID SWITCH VALVE OR PLUGS

CUT OD OR 4C PISTON SEAL

STUCK MAIN REGULATOR VALVE

BURNED OD OR 4C CLUTCH

BROKEN OR MISSING 4C BLEED ORIFICE IN 2C/4C RETAINER

BROKEN REACTION SHAFT SUPPORT SEAL RING

POOR MACHINING ON PUMP VALVE BODY FACE

LOOSE / MISSING DRIBBLER ORIFICE ASSEMBLY IN REACTION SHAFT SUPPORT

CRACKED / LOOSE / MISSING OD/REVERSE PISTON BLEED ORIFICE

BROKEN REVERSE CARRIER HUB WELD

BROKEN REVERSE SUN GEAR WELD TO REACTION CARRIER

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

The transmission system uses two speed sensors, one to measure input RPM and one to measure output RPM.

These inputs are essential for proper transmission operation. Therefore, the integrity of this data is verified through

the following checks:

1) Once in a particular gear, if the gear ratio varies from the correct gear ratio, the corresponding in-gear trouble

code is set (DTCs P0731–36).

2) An excessive change in input or output speeds indicating signal intermittent may result in the DTCs P0715 and/or

P0720 being set.

3) If the common speed sensor ground circuit is lost, both sensor inputs will read the pulses from the input speed

sensor when at a stop in neutral. Since the input speed sensor reads 60 teethfrom the input clutch hub and the

output speed sensor reads 30 teeth from the park gear, the result is an apparent speed ratio of 1:2 and may cause

the DTC P1794 to set.

Page 3168 of 5267

P0735-GEAR RATIO ERROR IN 5TH

For a complete wiring diagramRefer to Section 8W

When Monitored:

Continuously with the ignition on, engine running, with the transmissionin gear.

Set Condition:

If the ratio of the Input RPM to the Output RPM does not match the current gearratio. This DTC can take up

to five minutes of problem identification before illuminating the MIL.

Possible Causes

LOW FLUID LEVEL

INPUT SPEED SENSOR OR WIRING

VALVE BODY ACCUMULATOR COVER FAILED

CUT OD OR 2C ACCUMULATOR SEAL

CRACKED OD OR 2C ACCUMULATOR PISTON

BROKEN OR MISSING OD BLEED ORIFICE IN MAIN VALVE BODY

CUT 2C TOWER SEAL

TRANSMISSION SOLENOID/TRS ASSEMBLY

CUT OR MISSING #5, #6, OR #7 CHECK BALL

WORN SOLENOID SWITCH VALVE OR PLUGS

CUT OD OR 2C PISTON SEAL

STUCK MAIN REGULATOR VALVE

BURNED OD OR 2C CLUTCH

BROKEN OR MISSING 2C BLEED ORIFICE IN 2C/4C RETAINER

BROKEN REACTION SHAFT SUPPORT SEAL RING

POOR MACHINING ON PUMP VALVE BODY FACE

LOOSE / MISSING DRIBBLER ORIFICE ASSEMBLY IN REACTION SHAFT SUPPORT

CRACKED / LOOSE / MISSING OD/REVERSE PISTON BLEED ORIFICE

BROKEN REVERSE CARRIER HUB WELD

BROKEN REVERSE SUN GEAR WELD TO REACTION CARRIER

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

The transmission system uses two speed sensors, one to measure input RPM and one to measure output RPM.

These inputs are essential for proper transmission operation. Therefore, the integrity of this data is verified through

the following checks:

1) Once in a particular gear, if the gear ratio varies from the correct gear ratio, the corresponding in-gear trouble

code is set (DTCs P0731-36).

2) An excessive change in input or output speeds indicating signal intermittent may result in the DTCs P0715 and/or

P0720 being set.

3) If the common speed sensor ground circuit is lost, both sensor inputs will read the pulses from the input speed

sensor when at a stop in neutral. Since the input speed sensor reads 60 teethfrom the input clutch hub and the

output speed sensor reads 30 teeth from the park gear, the result is an apparent speed ratio of 1:2 and may cause

the DTC P1794 to set.