check engine DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 3108 of 5267

3.CHECK THROTTLE POSITION SENSOR OPERATION

Ignition On, Engine Not Running.

With the scan tool, under Transmission Sensors, monitor the TPS voltage inthe following step.

Slowly open and close the throttle while checking for erratic voltage changes.

IfequippedwithETC,usetheETCThrottleFollowertestinthescantooltocheck for erratic voltage changes.

Was the TPS voltage change smooth and consistent?

Ye s>>

Using the schematics as a guide, check the Powertrain Control Module (PCM)terminals for corrosion,

damage, or terminal push out. Pay particular attention to all power and ground circuits. If no problems

are found, replace the PCM per the Service Information. With the scan tool,perform QUICK LEARN.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Replace the Throttle Position Sensor per the Service Information.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

4.INTERMITTENT WIRING AND CONNECTORS

The conditions necessary to set the DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specifictothiscircuit.

Wiggle the wiring and connectors while checking for shorted and open circuits.

With the scan tool, check the DTC EVENT DATA to help identify the conditionsin which the DTC was set.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Te s t C o m p l e t e .

Page 3109 of 5267

P0218-HIGH TEMPERATURE OPERATION ACTIVATED

For a complete wiring diagramRefer to Section 8W.

Theory of Operation

The DTC is intended as an informational DTC to aid the technician in determining the root cause of a customer

dirveability issue. The DTC is also intended to alert the technician to determine if a cooling system malfunction has

occurred or if an additional transmission air to oil cooler is needed to support the customers driving behavior.

When Monitored:

Whenever the engine is running.

Set Condition:

Immediately after a Overheat shift schedule is activated when the Transmission temperature exceeds 127° C

or 260° F.

Possible Causes

H I G H T E M P E R AT U R E O P E R AT I O N A C T I VAT E D

TORQUE CONVERTER CLUTCH SLIPPING / NOT ACTIVATING

EXCESSIVE TIME IDLING IN GEAR

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Diagnostic Test

1.HIGH TEMPERATURE OPERATION

This DTC is an informational DTC designed to aid the Technician in diagnosing shift quality complaints.

This DTC indicates that the transmission has been operating in the

Overheatshift schedule which may generate

a customer complaint.

The customer driving patterns may indicate the need for an additional transmission oil cooler.

Verify proper Engine cooling system operation which would affect proper transmission operation.

Verify proper torque converter clutch operation.

With the scan tool, check the DTC EVENT DATA to help identify the conditionsin which the DTC was set.

If there are no possible causes remaining, view repair.

Repair

Repair the cause of transmission overheating. Refer to the Service Information for the proper repair

procedure. Make sure to check for any Service Bulletins pertaining to thisproblem.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Page 3111 of 5267

When Monitored:

With the engine running and the PCM has closed the Transmission Control Relay.

Set Condition:

If the battery voltage of the Transmission Output circuit(s) to the PCM is less than 10.0 volts for the period of

15 seconds. Note: P0562 generally indicates a gradually falling battery voltage or a resistive connection(s) to

the PCM. The DTC will also set if the battery voltage sensed at the PCM is lessthan 6.5-volts for 200ms or

where the Transmission Output circuits are less than 7.2-volts for 200ms.

Possible Causes

RELATED CHARGING SYSTEM DTC’S

(Z904, Z908, Z977) GROUND CIRCUITS OPEN OR HIGH RESISTANCE

(T16) TIPM OUTPUT CIRCUIT OPEN OR HIGH RESISTANCE

TOTALLY INTEGRATED POWER MODULE (TIPM)

POWERTRAIN CONTROL MODULE

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

Friction element distress could result from an insufficient supply voltage to properly control the solenoids. To prevent

this possibility, the battery voltage is monitored and the system is placed in logical limp-in if the battery voltage

drops below the limit.

Diagnostic Test

1.RELATED CHARGING SYSTEM DTCS

With the scan tool, read the Engine DTCs.

Are there any related Charging System DTCs also present?

Ye s>>

Refer to the Charging System category and repair any Engine Charging System DTCs, before testing

DTC P0562. NOTE: After repairing the Engine Charging System DTC’s, perform the Transmission Ver-

ification test to verify the transmission control systemwas not damaged.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Go To 2

2.CHECK FOR TIPM DTCS

NOTE: Generator, battery, and charging system must be fully functional before performing this test.

With the scan tool, read TIPM DTCs.

Are there any TCM TIPM DTCs present.

Ye s>>

Refer to the Transmission category and perform the appropriate symptom. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - DIAGNOSIS AND TESTING)

No>>

Go To 3

Page 3113 of 5267

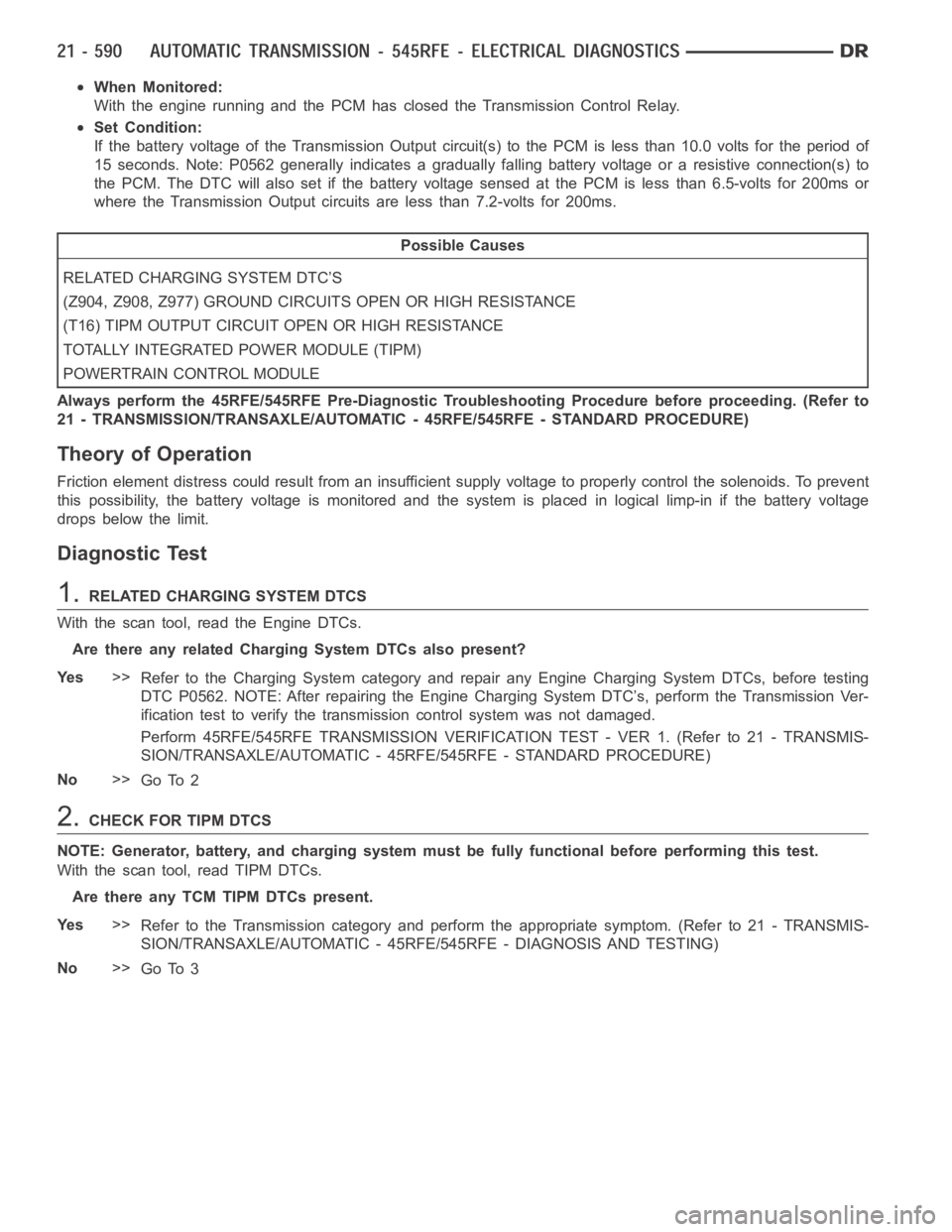

5.CHECK THE (T16) TRANSMISSION CONTROL OUTPUT CIRCUIT

Turn the ignition off to the lock position.

Disconnect the Transmission Solenoid/TRS Assembly harness connec-

tor.

Ignition on, engine not running.

With the scan tool in TIPM, actuate the TCM output.

Using a 12-volt test light connected to ground, check all (T16) Trans-

mission Control Output circuits at the Transmission Solenoid/TRS

Assembly harness connector and the appropriate terminals of Miller tool

#8815.

NOTE: The (T16) Transmission Control Output circuit branches off

to both Transmission Solenoid/TRS Assembly and the PCM.

Does the test light illuminate brightly while cycling on and off

on all (T16) Transmission Control Output circuits?

Ye s>>

Go To 6

No>>

Repair the (T16) Transmission Control Output circuit for an

open or high resistance.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

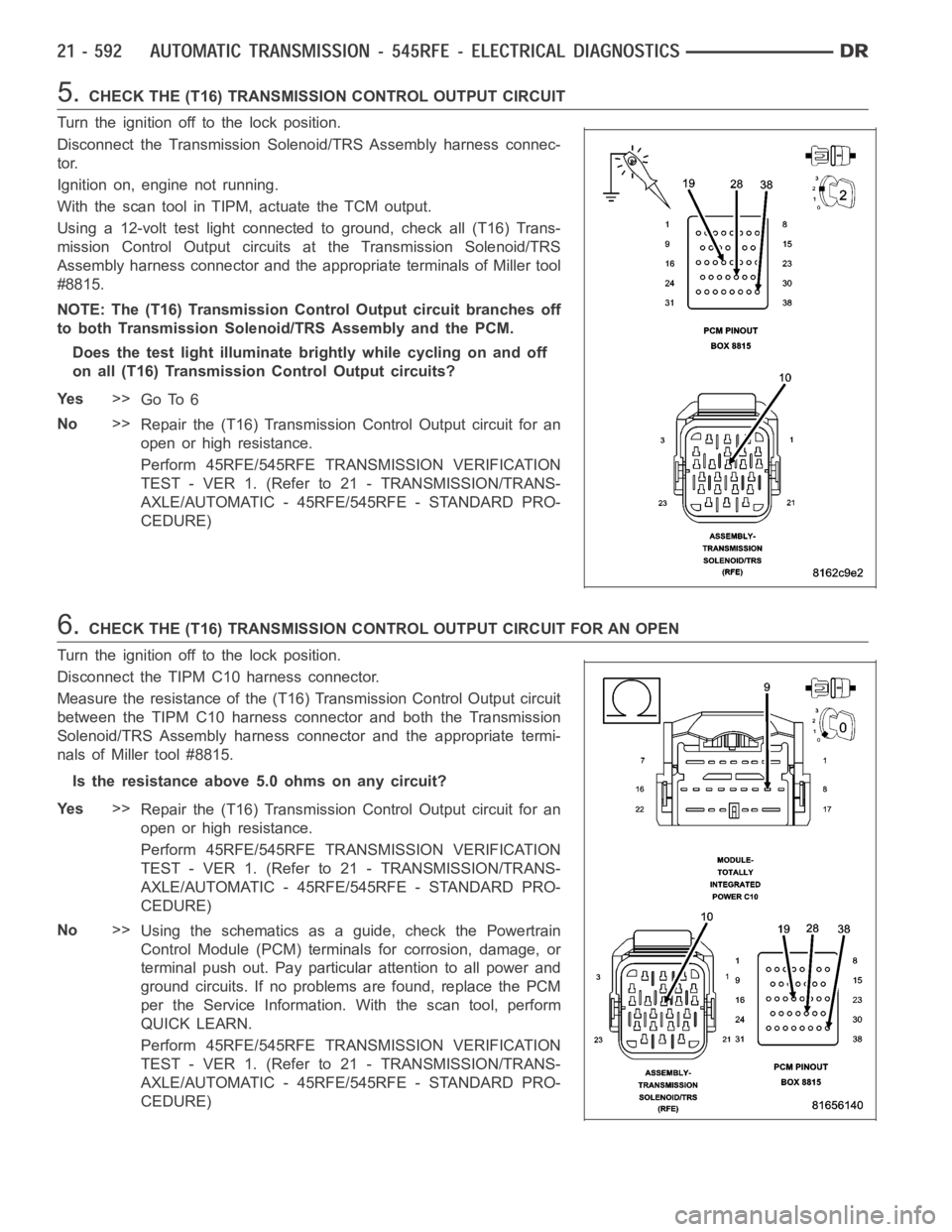

6.CHECK THE (T16) TRANSMISSION CONTROL OUTPUT CIRCUIT FOR AN OPEN

Turn the ignition off to the lock position.

Disconnect the TIPM C10 harness connector.

Measure the resistance of the (T16) Transmission Control Output circuit

between the TIPM C10 harness connector and both the Transmission

Solenoid/TRS Assembly harness connector and the appropriate termi-

nals of Miller tool #8815.

Is the resistance above 5.0 ohms on any circuit?

Ye s>>

Repair the (T16) Transmission Control Output circuit for an

open or high resistance.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

No>>

Using the schematics as a guide, check the Powertrain

Control Module (PCM) terminals for corrosion, damage, or

terminal push out. Pay particular attention to all power and

ground circuits. If no problems are found, replace the PCM

per the Service Information.With the scan tool, perform

QUICK LEARN.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

Page 3120 of 5267

When Monitored:

Continuously with the ignition on.

Set Condition:

The DTC will set if the controller detects an invalid PRNDL code which lastsfor more than 0.042 seconds.

Possible Causes

SHIFTER OUT OF ADJUSTMENT

TRS SENSE CIRCUIT OPEN

TRS SENSE CIRCUIT SHORT TO GROUND

TRS SENSE CIRCUIT SHORT TO VOLTAGE

METAL DEBRIS IN OIL PAN

TRANSMISSION RANGE SENSOR

POWERTRAIN CONTROL MODULE

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

The T1, T2, T3, T41, or T42 (C1 - C5) Sense circuits communicate the shift lever position to the Transmission

Control System. Each circuit is terminated at the transmission by a switch(TRS). Each switch can be either open

or closed, depending on the shift lever position. The PCM can decode this information and determine the shift lever

position.

Each shift lever position has it own unique combination of closed and open switches. This is called a PRNDL code.

There are 5 switches, therefore: there are many possible combinations of open and closed switches (codes). There

are 12 valid codes: two for neutral, one for each other gear position (5), and five temporary (transition zone) codes.

The remainder of the codes should never occur, these are called invalid codes.

Diagnostic Test

1.CHECK TO SEE IF P0706 DTC IS CURRENT

With the scan tool, perform the Shift Lever Position Test.

Select the test outcome from the following:

Test passes:

Go To 6

Test fails with Error Code:

Go To 2

Test fails without Error Code:

Perform the Gearshift Adjustment Procedure per the Service Information.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

2.CHECK THE TRANSMISSION SOLENOID/TRS ASSEMBLY

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install Transmission Simulator, Miller tool #8333.

Ignition on, engine not running.

With the scan tool, perform the Shift Lever Position Test.

Page 3124 of 5267

When Monitored:

Continuously with the ignition on and engine running.

Set Condition:

This DTC will set when the desired transmission temperature does not reacha normal operating temperature

within a given time frame. Time is variable due to ambient temperature. Approximate times are starting tem-

perature to warm up time: (-40° F / -40° C - 35 min) (-20° F / -28° C - 25 min) (20°F / -6.6° C - 20 min) (60°

F/15.5°C-10min)

Possible Causes

RELATED DTC’S PRESENT

TRANSMISSION TEMPERATURE SENSOR

POWERTRAIN CONTROL MODULE

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

The Transmission Temperature Sensor is a variable resistor that changes with temperature, or otherwise known as

a thermister. The temperature of the transmission fluid can affect a variety of electronically controlled transmission

operations such as shift quality, torque converter lock-up, and when and/or if certain OBDII or system self-diagnostic

test are performed. The Powertrain Control Module (PCM) substitutes a calculated transmission temperature value

if a fault is detected in the Transmission Temperature Sensor circuit.

Diagnostic Test

1.DETERMINE IF RELATED DTC’S ARE PRESENT

With the scan tool, check Transmission DTC’s.

Are there any other related Transmission Temperature Sensor DTCs present?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom.

No>>

Go To 2

2.CHECK IF DTC IS CURRENT

With the scan tool, Check the STARTS SINCE SET counter for P0711.

NOTE: This counter only applies to the last DTC set.

Is the STARTS SINCE SET counter 2 or less?

Ye s>>

Go To 3

No>>

Go To 4

3.TRANSMISSION TEMPERATURE SENSOR

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install the Transmission Simulator, Miller tool #8333.

Ignition on, engine not running.

With the Transmission Simulator, turn the Input/Output switch to OFF.

With the scan tool, monitor the TRANS TEMP VOLTS while turning the ThermistorVoltageswitchtoallthreeposi-

tions on the Transmission Simulator.

Page 3127 of 5267

When Monitored:

Continuously with the ignition on and engine running.

Set Condition:

The DTC will set when the monitored Temperature Sensor voltage drops below0.078 volts for the period of

0.45 seconds.

Possible Causes

RELATED DTC’S PRESENT

(T54) TRANSMISSION TEMPERATURE SENSOR SIGNAL CIRCUIT SHORT TO GROUND

TRANSMISSION TEMPERATURE SENSOR

POWERTRAIN CONTROL MODULE

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

The Transmission Temperature Sensor is a variable resistor that changes with temperature, or otherwise known as

a thermister. The temperature of the transmission fluid can affect a variety of electronically controlled transmission

operations such as shift quality, torque converter lock-up, and when and/or if certain OBDII or system self-diagnostic

test are performed. The Powertrain Control Module (PCM) substitutes a calculated transmission temperature value

if a fault is detected in the Transmission Temperature Sensor circuit.

Diagnostic Test

1.DETERMINE IF RELATED DTC’S ARE PRESENT

With the scan tool, check Transmission DTC’s.

Are there any line pressure sensor or throttle position sensor DTCs present?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom.

No>>

Go To 2

2.CHECK TO SEE IF DTC IS CURRENT

With the scan tool, Check the STARTS SINCE SET counter for P0712.

NOTE: This counter only applies to the last DTC set.

Is the STARTS SINCE SET counter 2 or less?

Ye s>>

Go To 3

No>>

Go To 5

3.TRANSMISSION TEMPERATURE SENSOR

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install the Transmission Simulator, Miller tool #8333.

Ignition on, engine not running.

With the Transmission Simulator, turn the Input/Output switch to OFF.

With the scan tool, monitor the TRANS TEMP VOLTS while turning the ThermistorVoltageswitchtoallthreeposi-

tions on the Transmission Simulator.

Page 3130 of 5267

When Monitored:

Continuously with the ignition on and engine running.

Set Condition:

The DTC will set when the monitored Temperature Sensor voltage rises above4.94 volts for the period of 0.45

seconds.

Possible Causes

RELATED DTC’S PRESENT

(T54) TRANSMISSION TEMPERATURE SENSOR SIGNAL CIRCUIT SHORT TO OTHER CIRCUITS

TRANSMISSION TEMPERATURE SENSOR

POWERTRAIN CONTROL MODULE

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

The Transmission Temperature Sensor is a variable resistor that changes with temperature, or otherwise known as

a thermister. The temperature of the transmission fluid can affect a variety of electronically controlled transmission

operations such as shift quality, torque converter lock-up, and when and/or if certain OBDII or system self-diagnostic

test are performed. The Powertrain Control Module (PCM) substitutes a calculated transmission temperature value

if a fault is detected in the Transmission Temperature Sensor circuit.

Diagnostic Test

1.DETERMINE IF RELATED DTC’S ARE PRESENT

With the scan tool, check Transmission DTC’s.

Are there any line pressure sensor or throttle position sensor DTCs present?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom.

No>>

Go To 2

2.CHECK IF DTC IS CURRENT

With the scan tool, check the STARTS SINCE SET counter for P0713.

NOTE: This counter only applies to the last DTC set.

Is the STARTS SINCE SET counter 2 or less?

Ye s>>

Go To 3

No>>

Go To 5

3.TRANSMISSION TEMPERATURE SENSOR

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install the Transmission Simulator, Miller tool #8333.

Ignition on, engine not running.

With the Transmission Simulator, turn the Input/Output switch to OFF.

With the scan tool, monitor the TRANS TEMP VOLTS while turning the ThermistorVoltageswitchtoallthreeposi-

tions on the Transmission Simulator.

Page 3133 of 5267

When Monitored:

Continuously with the ignition on and engine running.

Set Condition:

The DTC will set when the monitored Temperature Sensor voltage fluctuatesor changes abruptly within a pre-

determined period of time.

Possible Causes

RELATED DTC’S PRESENT

TRANSMISSION TEMPERATURE SENSOR

POWERTRAIN CONTROL MODULE

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

The Transmission Temperature Sensor is a variable resistor that changes with temperature, or otherwise known as

a thermister. The temperature of the transmission fluid can affect a variety of electronically controlled transmission

operations such as shift quality, torque converter lock-up, and when and/or if certain OBDII or system self-diagnostic

test are performed. The Powertrain Control Module (PCM) substitutes a calculated transmission temperature value

if a fault is detected in the Transmission Temperature Sensor circuit.

Diagnostic Test

1.DETERMINE IF RELATED DTC’S ARE PRESENT

With the scan tool, check Transmission DTC’s.

Are there any line pressure sensor or throttle position sensor DTCs present?

Ye s>> Refer to the Transmission category and perform the appropriate symptom.(Referto21-TRANS-

MISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - DIAGNOSIS AND TESTING)

No>>

Go To 2

2.CHECK TO SEE IF DTC IS CURRENT

With the scan tool, Check the STARTS SINCE SET counter for P0714.

NOTE: This counter only applies to the last DTC set.

Is the STARTS SINCE SET counter 2 or less?

Ye s>>

Go To 3

No>>

Go To 4

3.TRANSMISSION TEMPERATURE SENSOR

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install the Transmission Simulator, Miller tool #8333.

Ignition on, engine not running.

With the Transmission Simulator, turn the Input/Output switch to OFF.

With the scan tool, monitor the TRANS TEMP VOLTS while turning the ThermistorVoltageswitchtoallthreeposi-

tions on the Transmission Simulator.

Page 3136 of 5267

When Monitored:

The transmission gear ratio is monitored continuously while the transmission is in gear.

Set Condition:

IfthereisanexcessivechangeininputRPMinanygear.ThisDTCcantakeupto five minutes of problem

identification beforeilluminating the MIL.

Possible Causes

(T52) INPUT SPEED SENSOR SIGNAL CIRCUIT OPEN

(T13) SPEED SENSOR GROUND CIRCUIT OPEN

(T52) INPUT SPEED SENSOR SIGNAL CIRCUIT SHORT TO GROUND

(T13) SPEED SENSOR GROUND CIRCUIT SHORT TO GROUND

(T52) INPUT SPEED SENSOR SIGNAL CIRCUIT SHORT TO VOLTAGE

(T13) SPEED SENSOR GROUND CIRCUIT SHORT TO VOLTAGE

INPUT SPEED SENSOR

POWERTRAIN CONTROL MODULE

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

The transmission system uses two speed sensors, one to measure input RPM and one to measure output RPM.

These inputs are essential for proper transmission operation. Therefore, the integrity of this data is verified through

the following checks:

1) When in gear, if the gear ratio does not compare to a known gear ratio, the corresponding in-gear trouble code

is set (DTCs P0731–36).

2) An excessive change in input or output speeds indicating signal intermittent which may result in the DTCs P0715

and/or P0720 to set.

3) If the common speed sensor ground circuit is lost, both sensor inputs will read the signal from the input speed

sensor at idle in neutral. Since the input speed sensor reads 60 teeth from the input clutch hub and the output

speed sensor reads 30 teeth from the park gear, the result is an apparent speed ratio of 1:2 and may cause the

DTC P1794 to set when at a stop.

Diagnostic Test

1.CHECK TO SEE IF DTC P0715 IS CURRENT

Start the engine in park.

With the scan tool, monitor the Input Speed Sensor RPM.

Is the Input Speed Sensor RPM below 400 RPM?

Ye s>>

Go To 2

No>>

Go To 9