brake DODGE SPRINTER 2005 1.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2005, Model line: SPRINTER, Model: DODGE SPRINTER 2005 1.GPages: 288, PDF Size: 27.89 MB

Page 222 of 288

222 MAINTAINING YOUR VEHICLERibbed V-BeltThe ribbed V-belt drives the accessories, such as

generator, coolant pump and hydraulic steering pump.

The ribbed V-belt is automatically kept tensioned.

Check the state of the ribbed V-belt regularly, such as

at every engine oil level check.

The belt must not be damaged, worn, oiled or glazed.

There must be no cracks in the belt running surface.

Replace damaged belts.

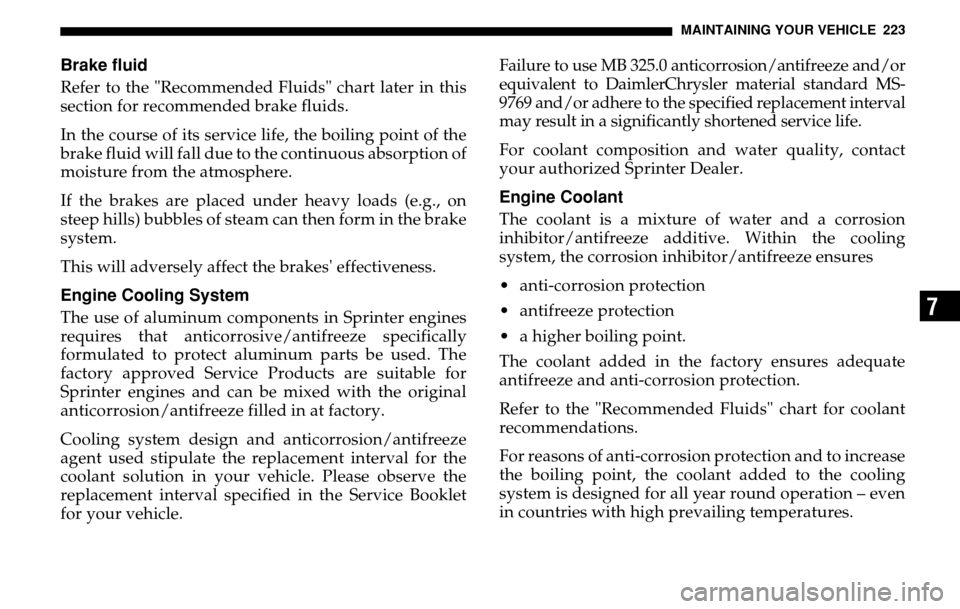

Hydraulic Brake System, Clutch Mechanism Fluid

Level1. Brake fluid reservoir

Brake fluid level must be between the MIN and MAX

marks in the reservoir (1).

If the brake fluid is below the MIN mark, there may be

a fault in the hydraulic system. Have the system

checked as soon as possible by an authorized Sprinter

Dealer.

Page 223 of 288

MAINTAINING YOUR VEHICLE 223

7

Brake fluidRefer to the "Recommended Fluids" chart later in this

section for recommended brake fluids.

In the course of its service life, the boiling point of the

brake fluid will fall due to the continuous absorption of

moisture from the atmosphere.

If the brakes are placed under heavy loads (e.g., on

steep hills) bubbles of steam can then form in the brake

system.

This will adversely affect the brakes' effectiveness.Engine Cooling SystemThe use of aluminum components in Sprinter engines

requires that anticorrosive/antifreeze specifically

formulated to protect aluminum parts be used. The

factory approved Service Products are suitable for

Sprinter engines and can be mixed with the original

anticorrosion/antifreeze filled in at factory.

Cooling system design and anticorrosion/antifreeze

agent used stipulate the replacement interval for the

coolant solution in your vehicle. Please observe the

replacement interval specified in the Service Booklet

for your vehicle.

Failure to use MB 325.0 an ticorrosion/antifreeze and/or

equivalent to DaimlerChrys ler material standard MS-

9769 and/or adhere to the specified replacement interval

may result in a significantly shortened service life.For coolant composition and water quality, contact

your authorized Sprinter Dealer.Engine CoolantThe coolant is a mixture of water and a corrosion

inhibitor/antifreeze additive. Within the cooling

system, the corrosion inhibitor/antifreeze ensures

anti-corrosion protection

antifreeze protection

a higher boiling point.

The coolant added in the factory ensures adequate

antifreeze and anti-corrosion protection.

Refer to the "Recommended Fluids" chart for coolant

recommendations.

For reasons of anti-corrosion protection and to increase

the boiling point, the cool ant added to the cooling

system is designed for all year round operation – even

in countries with high prevailing temperatures.

Page 231 of 288

MAINTAINING YOUR VEHICLE 231

7

Appearance Care and Corrosion ProtectionIn operation, your vehicle is subjected to varying

external influences which, if gone unchecked, can

attack the paintwork as well as the underbody and

cause lasting damage.

Such damage is caused not only by extreme and

varying climatic conditions, but also by air pollution,

road salt, tar, gravel and stone chipping. Grease and

oil, fuel, coolant, brake flui d, bird droppings, insects, tree resins etc. should be removed immediately to

avoid paint damage. Frequent washing reduces and/

or eliminates the aggressiveness and potency of the

above adverse influences.

More frequent washings are necessary to deal with

unfavorable conditions; for example operation near the

ocean, in industrial areas (smoke, exhaust emissions),

or during the winter months.

You should check your vehicle from time to time for

stone chipping or other damage. Any damage should

be repaired as soon as possible to prevent the start of

corrosion.

In doing so, do not neglect the underside of the vehicle.

A prerequisite for a thorough check is a washing of the

underbody followed by a thorough inspection.

Damaged areas need to be undercoated again.

Your vehicle has been treated at the factory with a wax-

base rustproofing in the body cavities which will last

for the lifetime of the vehicle. Post-production

treatment is neither necessary nor recommended by

DaimlerChrysler Corporation.

WARNING!

Many cleaning products can be hazardous. Some

are poisonous, others are flammable. Always

keep cleaning products sealed and out of the

reach of children. Always follow the instructions

on the particular container. Always open your ve-

hicle’s doors or windows when cleaning the in-

side.

Never use fluids or solvents that are not designed

for cleaning your vehicle. Do not use fuel as a

cleaning agent. Fuel is flammable and constitutes

a health hazard.

Page 232 of 288

232 MAINTAINING YOUR VEHICLEBecause of the possibility of incompatibility between

materials used in the production process and others

applied later.

Scratches, corrosive deposits, corrosion or damage due

to negligent or incorrect care cannot always be

removed or repaired with car-care products. In such

cases it is best to seek aid by your authorized Sprinter

Dealer.

The following topics deal with the cleaning and care of

your vehicle and give important "how-to" information

as well as references to car-care products.

Power WasherWhen using a power washer for cleaning the vehicle

always observe manufacturers’ operating instructions.

WARNING!

Never use openings in the bodywork as steps.

You could otherwise damage the vehicle and it

could lead to an accident.

CAUTION!

Do not use abrasive or strong cleaning materials

such as steel wool or scouring powder, which will

scratch metal and painted surfaces.

CAUTION!

The intense jet of water of a round nozzle can

result in damage to the tire. Therefore never use a

round nozzle to power wash tires.

Always replace a damaged tire.

Always keep the jet of water moving across the

surface. To avoid damaging the vehicle, do not

aim the water jet directly at electrical components,

end of electrical lines, electrical connectors, intake

or ventilation openings, brake hoses, door joints,

seals, other rubber parts.

Page 241 of 288

MAINTAINING YOUR VEHICLE 241

7

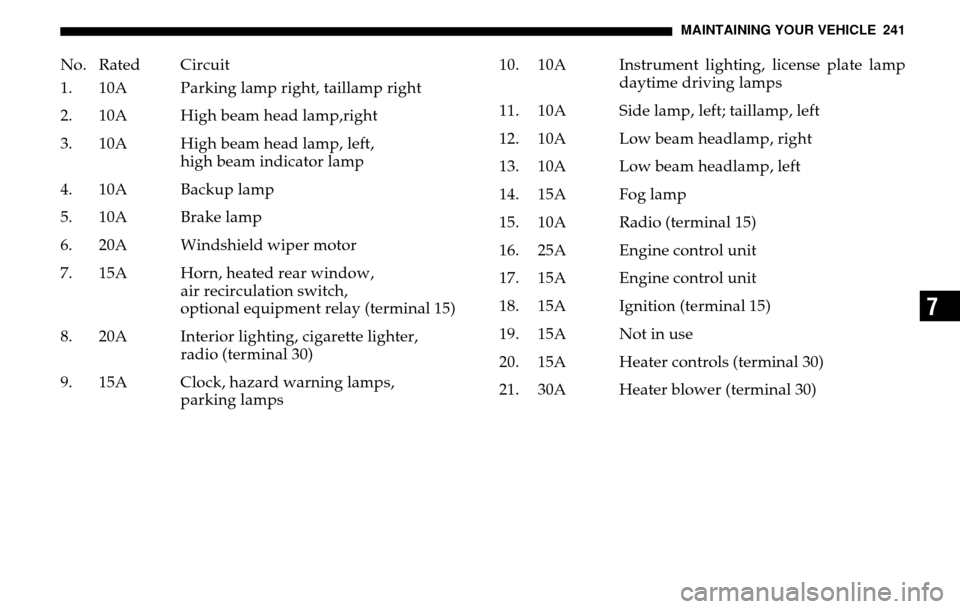

No. Rated Circuit

1. 10A Parking lamp right, taillamp right

2. 10A High beam head lamp,right

3. 10A High beam head lamp, left, high beam indicator lamp

4. 10A Backup lamp

5. 10A Brake lamp

6. 20A Windshield wiper motor

7. 15A Horn, heated rear window, air recirculation switch,

optional equipment relay (terminal 15)

8. 20A Interior lighting, cigarette lighter, radio (terminal 30)

9. 15A Clock, hazard warning lamps, parking lamps 10. 10A Instrument lighting, license plate lamp

daytime driving lamps

11. 10A Side lamp, left; taillamp, left

12. 10A Low beam headlamp, right

13. 10A Low beam headlamp, left

14. 15A Fog lamp

15. 10A Radio (terminal 15)

16. 25A Engine control unit

17. 15A Engine control unit

18. 15A Ignition (terminal 15)

19. 15A Not in use

20. 15A Heater controls (terminal 30)

21. 30A Heater blower (terminal 30)

Page 244 of 288

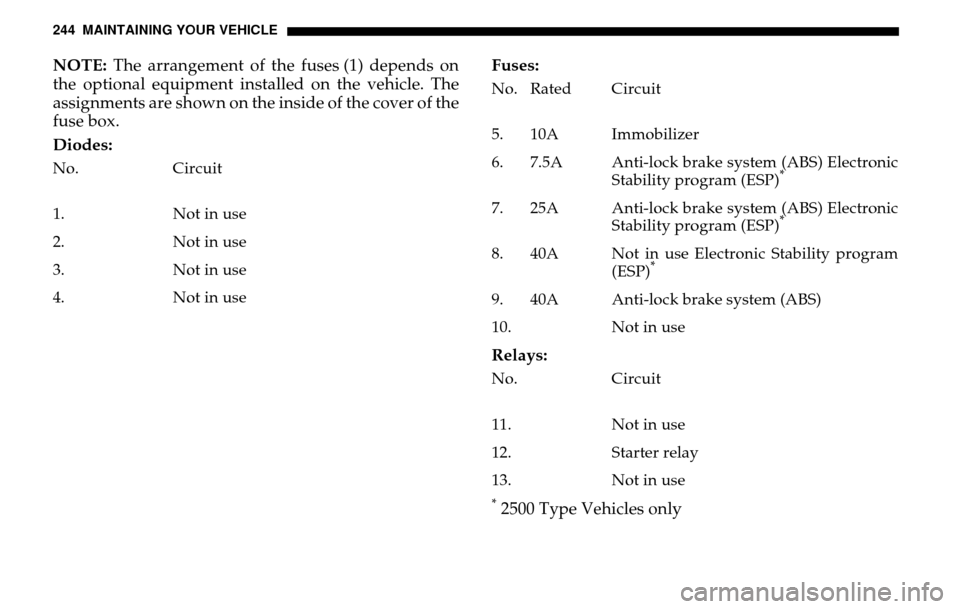

244 MAINTAINING YOUR VEHICLENOTE: The arrangement of the fuses (1) depends on

the optional equipment installed on the vehicle. The

assignments are shown on the inside of the cover of the

fuse box.

Diodes:No. Circuit

1. Not in use

2. Not in use

3. Not in use

4. Not in use

Fuses:No. Rated Circuit

5. 10A Immobilizer

6. 7.5A Anti-lock brake system (ABS) Electronic Stability program (ESP)

*

7. 25A Anti-lock brake system (ABS) ElectronicStability program (ESP)

*

8. 40A Not in use Electronic Stability program(ESP)

*

9. 40A Anti-lock brake system (ABS)

10. Not in useRelays:No. Circuit

11. Not in use

12. Starter relay

13. Not in use* 2500 Type Vehicles only

Page 250 of 288

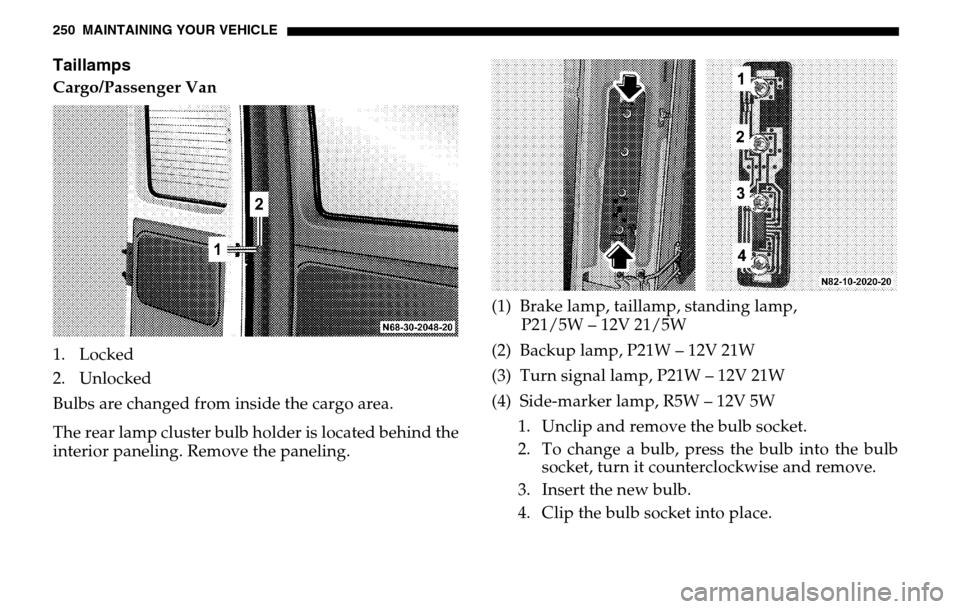

250 MAINTAINING YOUR VEHICLETaillampsCargo/Passenger Van

1. Locked

2. Unlocked

Bulbs are changed from inside the cargo area.

The rear lamp cluster bulb holder is located behind the

interior paneling. Remove the paneling. (1) Brake lamp, taillamp, standing lamp,

P21/5W – 12V 21/5W

(2) Backup lamp, P21W – 12V 21W

(3) Turn signal lamp, P21W – 12V 21W

(4) Side-marker lamp, R5W – 12V 5W 1. Unclip and remove the bulb socket.

2. To change a bulb, press the bulb into the bulb socket, turn it counterclockwise and remove.

3. Insert the new bulb.

4. Clip the bulb socket into place.

Page 252 of 288

252 MAINTAINING YOUR VEHICLELicense Plate Lamps

(Cargo/Passenger Vans Only)1. Press the bulb socket to the left, against the force of the spring, and remove.

2. Replace the bulb, C5W – 12V 5W.

3. Install the cover.

4. Re-install the bulb socket.

Additional Brake Lamp

(Cargo/Passenger Vans Only)(1) Retaining screws

1. Take out the retaining screws (1) and remove the lamp housing.

2. To change a bulb, P21W – 12V 21W Press the bulb into the bulb socket, turn it

counterclockwise and remove.

3. Insert the new bulb.

4. Install the lamp housing.

Page 258 of 288

258 MAINTAINING YOUR VEHICLERecommended Fluids and LubricantsThe manufacturer recommends for your vehicle model

the use of DaimlerChrysler approved fluids and

lubricants, e.g. engine oil, gear oil, automatic

transmission fluid, brake fluid, power steering fluid,

coolant and anti-corrosion/anti-freeze fluid only.

WARNING!

Failure to use fluids and lubricants which meet

the standards and specifications described in this

booklet or failure to adhere to the specified re-

placement intervals may result in damage to safe-

ty-related systems of your vehicle, such as the

brake system, which could cause an accident and/

or serious injury to you and others.

Use only fluids and lubricants meeting the

standards and specifications and adhere to

specified replacement intervals.

CAUTION!

Failure to use fluids and lubricants which meet

the standards and specifications described in this

booklet or failure to adhere to the specified

replacement intervals may result in a significantly

shortened service life and/or damage to

components of your vehicle, the repair of which

will not be covered by Warranty.

Use only fluids and lubricants meeting the

standards and specifications and adhere to

specified replacement intervals.

Page 261 of 288

MAINTAINING YOUR VEHICLE 261

7

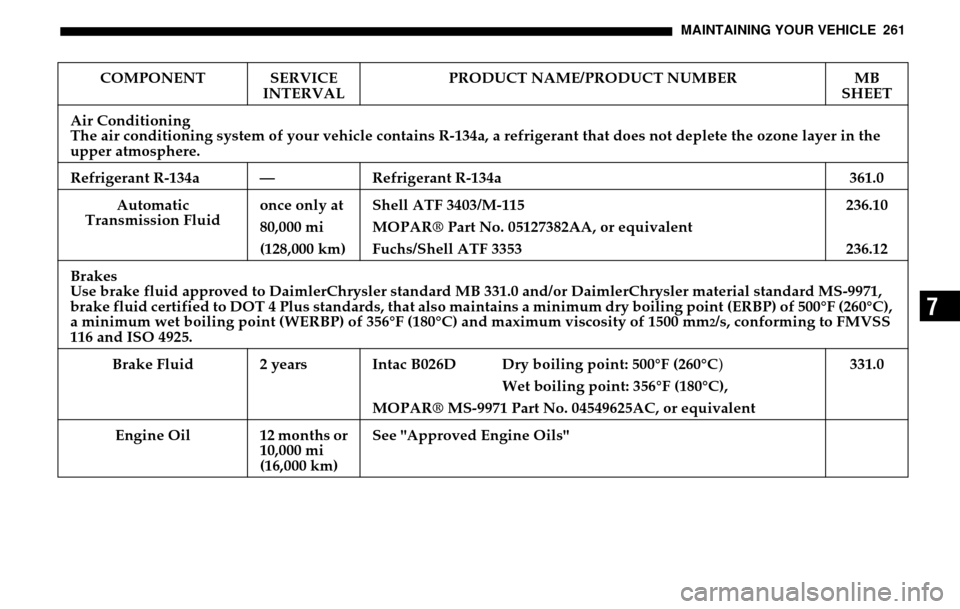

COMPONENT SERVICE INTERVAL PRODUCT NAME/PRODUCT NUMBER MB

SHEET

Air Conditioning

The air conditioning system of your vehicle contains R-134a, a refrigerant that does not deplete the ozone layer in the

upper atmosphere.

Refrigerant R-134a — Refrigerant R-134a 361.0 Automatic

Transmission Fluid once only at

80,000 mi

(128,000 km) Shell ATF 3403/M-115

MOPAR® Part No. 05127382AA, or equivalent

Fuchs/Shell ATF 3353 236.10

236.12

Brakes

Use brake fluid approved to DaimlerChr ysler standard MB 331.0 and/or DaimlerChrysler material standard MS-9971,

brake fluid certified to DOT 4 Plus standards, that also ma intains a minimum dry boiling point (ERBP) of 500°F (260°C),

a minimum wet boiling point (WERBP) of 356°F (180°C) and maximum viscosity of 1500 mm

2/s, conforming to FMVSS

116 and ISO 4925.

Brake Fluid 2 years Intac B026D Dry boiling point: 500°F (260°C )

Wet boiling point: 356°F (180°C),

MOPAR® MS-9971 Part No. 04549625AC, or equivalent 331.0

Engine Oil 12 months or 10,000 mi

(16,000 km) See "Approved Engine Oils"