brake DODGE SPRINTER 2006 1.G Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: SPRINTER, Model: DODGE SPRINTER 2006 1.GPages: 330, PDF Size: 10.82 MB

Page 271 of 330

MAINTAINING YOUR VEHICLE 271

7

Power Washer

When using a power washer for cleaning the vehicle

always observe manufacturers’ operating instructions.Automatic Car Wash

If the vehicle is very dirty, prewash it before you drive

into the car wash.

Fold in the exterior mirrors before washing the vehicle

in an automatic car wash and make sure that the

windshield wiper switch is in position 0.

The exterior mirrors and windshield wipers could

otherwise be damaged.

Make sure that mirrors are fully folded out after

leaving the automatic car wash.

CAUTION!

Never use a round nozzle to power wash tires. The

intense jet of water can result in damage to the

tire. Always replace a damaged tire.

Always keep the jet of water moving across the

surface. To avoid damaging the vehicle, do not

aim the water jet directly at electrical components,

end of electrical lines, electrical connectors, intake

or ventilation openings, brake hoses, door joints,

seals, other rubber parts.

WARNING!

Smears impair visibility, which is impaired fur-

ther by unfavourable conditions (e.g. fog, dark-

ness, driving snow).

If a wax preservative is sprayed on after washing

the vehicle, wipe off the wax from the windshield

and the wiper blade rubbers. This will prevent

smears forming on the windshield.

Page 280 of 330

280 MAINTAINING YOUR VEHICLE

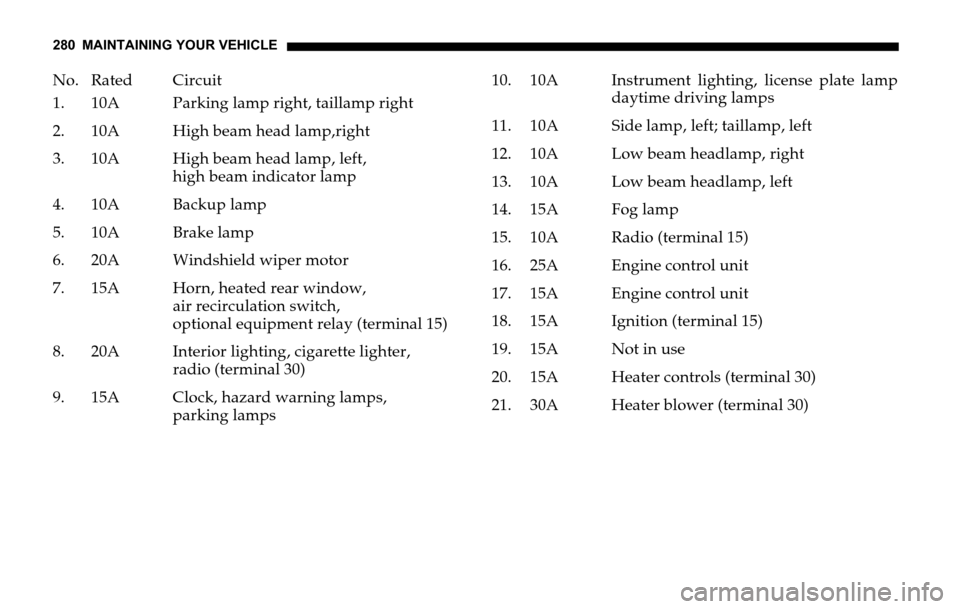

No. Rated Circuit

1. 10A Parking lamp right, taillamp right

2. 10A High beam head lamp,right

3. 10A High beam head lamp, left,

high beam indicator lamp

4. 10A Backup lamp

5. 10A Brake lamp

6. 20A Windshield wiper motor

7. 15A Horn, heated rear window,

air recirculation switch,

optional equipment relay (terminal 15)

8. 20A Interior lighting, cigarette lighter,

radio (terminal 30)

9. 15A Clock, hazard warning lamps,

parking lamps10. 10A Instrument lighting, license plate lamp

daytime driving lamps

11. 10A Side lamp, left; taillamp, left

12. 10A Low beam headlamp, right

13. 10A Low beam headlamp, left

14. 15A Fog lamp

15. 10A Radio (terminal 15)

16. 25A Engine control unit

17. 15A Engine control unit

18. 15A Ignition (terminal 15)

19. 15A Not in use

20. 15A Heater controls (terminal 30)

21. 30A Heater blower (terminal 30)

Page 283 of 330

MAINTAINING YOUR VEHICLE 283

7

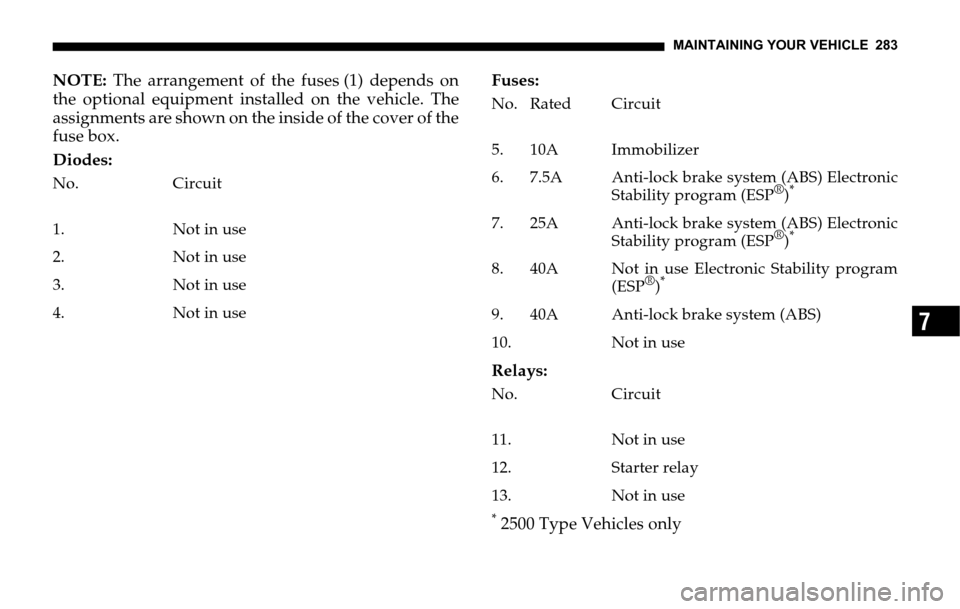

NOTE: The arrangement of the fuses (1) depends on

the optional equipment installed on the vehicle. The

assignments are shown on the inside of the cover of the

fuse box.

Diodes:

No. Circuit

1. Not in use

2. Not in use

3. Not in use

4. Not in use

Fuses:

No. Rated Circuit

5. 10A Immobilizer

6. 7.5A Anti-lock brake system (ABS) Electronic

Stability program (ESP

®)*

7. 25A Anti-lock brake system (ABS) Electronic

Stability program (ESP®)*

8. 40A Not in use Electronic Stability program

(ESP®)*

9. 40A Anti-lock brake system (ABS)

10. Not in use

Relays:

No. Circuit

11. Not in use

12. Starter relay

13. Not in use

* 2500 Type Vehicles only

Page 289 of 330

MAINTAINING YOUR VEHICLE 289

7

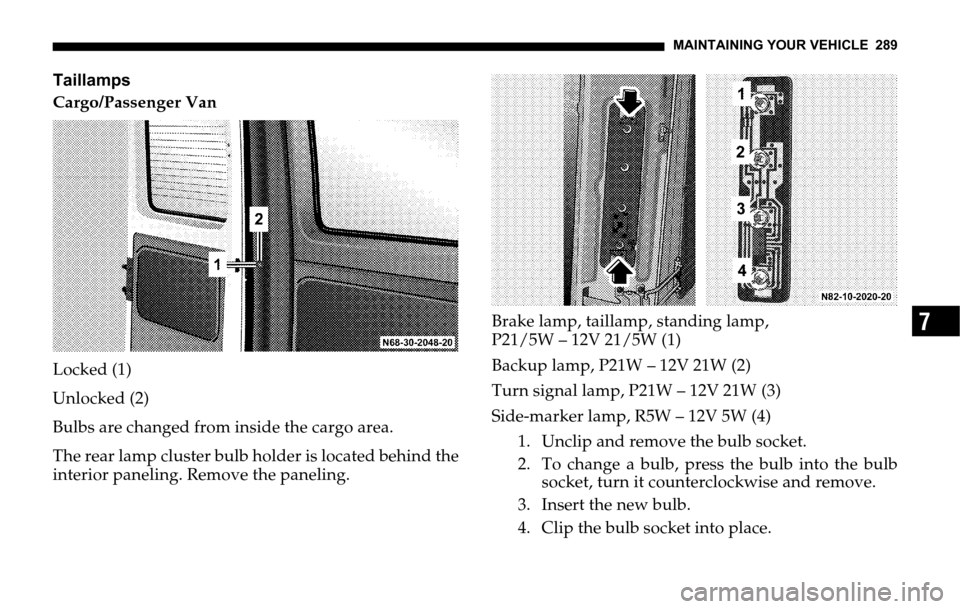

Taillamps

Cargo/Passenger Van

Locked (1)

Unlocked (2)

Bulbs are changed from inside the cargo area.

The rear lamp cluster bulb holder is located behind the

interior paneling. Remove the paneling.Brake lamp, taillamp, standing lamp,

P21/5W – 12V 21/5W (1)

Backup lamp, P21W – 12V 21W (2)

Turn signal lamp, P21W – 12V 21W (3)

Side-marker lamp, R5W – 12V 5W (4)

1. Unclip and remove the bulb socket.

2. To change a bulb, press the bulb into the bulb

socket, turn it counterclockwise and remove.

3. Insert the new bulb.

4. Clip the bulb socket into place.

Page 291 of 330

MAINTAINING YOUR VEHICLE 291

7

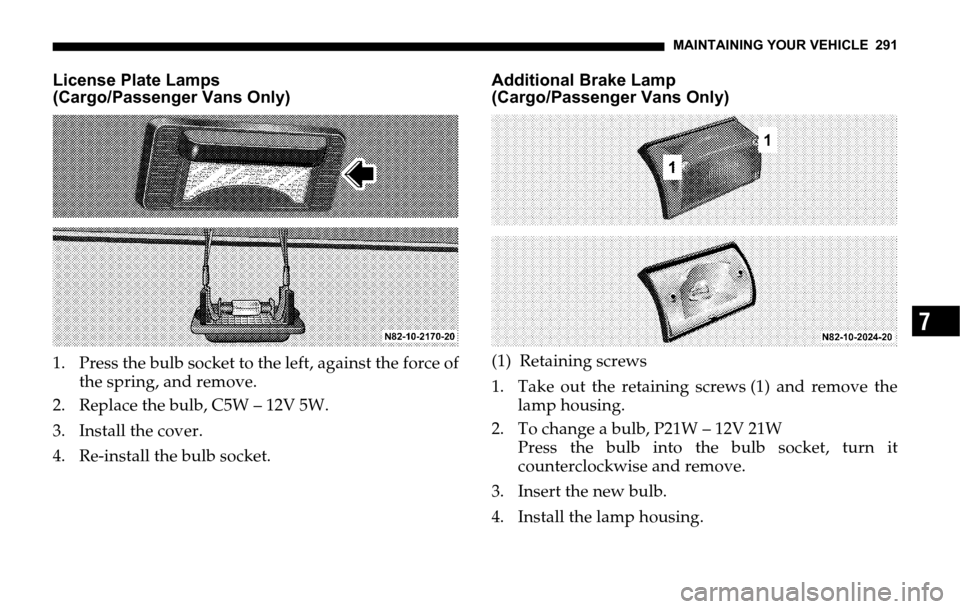

License Plate Lamps

(Cargo/Passenger Vans Only)

1. Press the bulb socket to the left, against the force of

the spring, and remove.

2. Replace the bulb, C5W – 12V 5W.

3. Install the cover.

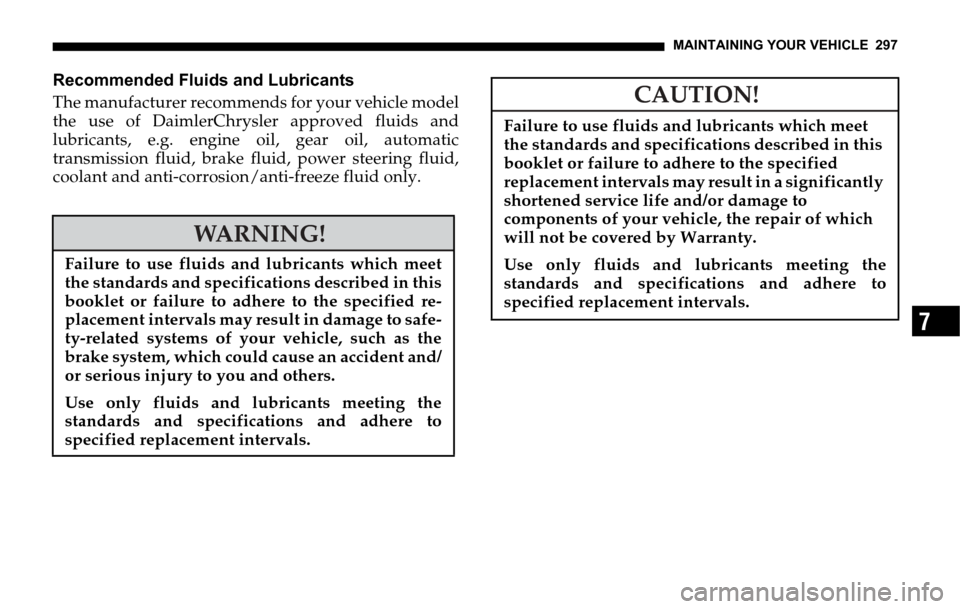

4. Re-install the bulb socket.Additional Brake Lamp

(Cargo/Passenger Vans Only)

(1) Retaining screws

1. Take out the retaining screws (1) and remove the

lamp housing.

2. To change a bulb, P21W – 12V 21W

Press the bulb into the bulb socket, turn it

counterclockwise and remove.

3. Insert the new bulb.

4. Install the lamp housing.

Page 297 of 330

MAINTAINING YOUR VEHICLE 297

7

Recommended Fluids and Lubricants

The manufacturer recommends for your vehicle model

the use of DaimlerChrysler approved fluids and

lubricants, e.g. engine oil, gear oil, automatic

transmission fluid, brake fluid, power steering fluid,

coolant and anti-corrosion/anti-freeze fluid only.

WARNING!

Failure to use fluids and lubricants which meet

the standards and specifications described in this

booklet or failure to adhere to the specified re-

placement intervals may result in damage to safe-

ty-related systems of your vehicle, such as the

brake system, which could cause an accident and/

or serious injury to you and others.

Use only fluids and lubricants meeting the

standards and specifications and adhere to

specified replacement intervals.

CAUTION!

Failure to use fluids and lubricants which meet

the standards and specifications described in this

booklet or failure to adhere to the specified

replacement intervals may result in a significantly

shortened service life and/or damage to

components of your vehicle, the repair of which

will not be covered by Warranty.

Use only fluids and lubricants meeting the

standards and specifications and adhere to

specified replacement intervals.

Page 300 of 330

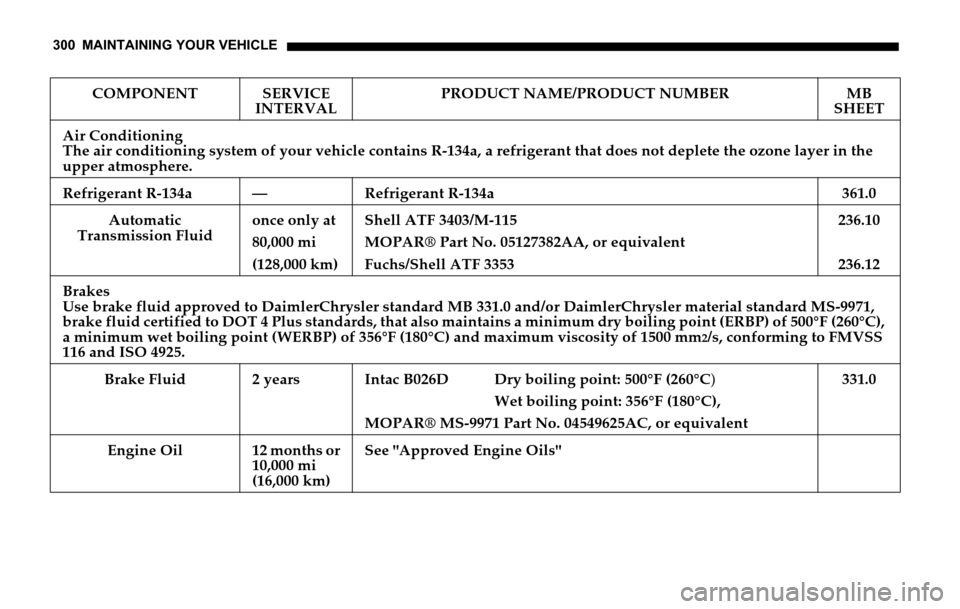

300 MAINTAINING YOUR VEHICLE

COMPONENT SERVICE

INTERVALPRODUCT NAME/PRODUCT NUMBER MB

SHEET

Air Conditioning

The air conditioning system of your vehicle contains R-134a, a refrigerant that does not deplete the ozone layer in the

upper atmosphere.

Refrigerant R-134a — Refrigerant R-134a 361.0

Automatic

Transmission Fluidonce only at

80,000 mi

(128,000 km)Shell ATF 3403/M-115

MOPAR® Part No. 05127382AA, or equivalent

Fuchs/Shell ATF 3353236.10

236.12

Brakes

Use brake fluid approved to DaimlerChrysler standard MB 331.0 and/or DaimlerChrysler material standard MS-9971,

brake fluid certified to DOT 4 Plus standards, that also maintains a minimum dry boiling point (ERBP) of 500°F (260°C),

a minimum wet boiling point (WERBP) of 356°F (180°C) and maximum viscosity of 1500 mm

2/s, conforming to FMVSS

116 and ISO 4925.

Brake Fluid 2 years Intac B026D Dry boiling point: 500°F (260°C)

Wet boiling point: 356°F (180°C),

MOPAR® MS-9971 Part No. 04549625AC, or equivalent331.0

Engine Oil 12 months or

10,000 mi

(16,000 km)See "Approved Engine Oils"

Page 303 of 330

MAINTENANCE SCHEDULES

CONTENTS

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S

�Q Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

�Q Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

�Q Maintenance - Without ASSYST

Maintenance Computer . . . . . . . . . . . . . . . . . . . . . 305

�…Maintenance Intervals . . . . . . . . . . . . . . . . . . . . 305

�Q Maintenance - With ASSYST

Maintenance Computer . . . . . . . . . . . . . . . . . . . . . 306

�Q Regular Check-Ups. . . . . . . . . . . . . . . . . . . . . . . . . 306

�Q Special Maintenance Requirements . . . . . . . . . . . 307

�…Brake Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

�…Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

�…Dust Filter for Heating/Ventilation

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

�Q Engine Oil Change and Filter Replacement . . . . 307

�…Once a Year . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

�Q Scope of Work for Maintenance service . . . . . . . 308

�…Oil Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

�…Additional Maintenance Work . . . . . . . . . . . . . 310

�…Additional Maintenance Work After ... Years 310

Page 306 of 330

306 MAINTENANCE SCHEDULESM

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S

8

MAINTENANCE - WITH ASSYST MAINTENANCE

COMPUTER

ASSYST provides you with information on the best

possible timing for maintenance work.

When the next maintenance service is due, this will be

indicated in the multi-function display with the

symbol

9 Oil service and fuel filter replacement

9 Maintenance service - displayed in km/miles

or days.

9

If the display shows the number of days, the symbol

È will also appear in the multi-function display.

You should have the maintenance performed within

the stated period/distance.

The service indicator will be reset by your Sprinter

Dealer after an oil service and/or maintenance service

has been performed.REGULAR CHECK-UPS

To maintain the safe operation of your vehicle, it is

recommended that you perform the following tasks on

a regular basis (i.e., weekly or whenever the vehicle is

refueled). Check:

Engine oil level

Brake system, clutch mechanism – fluid level

Battery – acid level

Windshield washer system and headlamp cleaning

system – fluid level

Mechanical assemblies (e. g. ,engine, transmission,

etc.) – check for leaks

Condition of tires and tire pressures

All exterior lights

Page 307 of 330

MAINTENANCE SCHEDULES 307

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S

SPECIAL MAINTENANCE REQUIREMENTS

If bodies built by manufacturers other than

DaimlerChrysler Corporation are fitted to the vehicle, the

maintenance requirements and lubrication intervals

specified by the body manufacturer must be adhered to,

in addition to all standard maintenance requirements.

Brake Fluid

Only use brake fluids approved by the manufacturer

(DOT 4 plus). Information about brake fluids is

available from your Sprinter Dealer.

Coolant

Have the corrosion inhibitor/antifreeze concentration

in the coolant checked before the onset of winter (once

a year in countries with high prevailing temperatures).

Have the coolant renewed every fifteen years or

100,000 miles.

Dust Filter for Heating/Ventilation Replacement

The dust filter and the tailgate interior filter are

renewed during routine maintenance service.

However, if operating conditions are dusty, these

filters should be renewed more frequently.ENGINE OIL CHANGE AND FILTER

REPLACEMENT

In a minimum, change the engine oil and oil filter once

a year - even if the vehicle mileage per year is extremly

low. For standard oil service schedules, please see the

chapter oil service and maintenance service.

Once a Year

Select the viscosity of the engine oil (SAE classes)

according to the outside air temperature.

Only use engine oil approved by DaimlerChrysler

Corporation if following the ASSYST system

guidelines.

Information is available from your Sprinter Dealer.

If the fuel used has a sulphur content exceeding 0.05 %

by weight, the service intervals should be split in half.

If the sulphur content of the fuel used is between 0.3%

and 0.8% by weight, the service intervals should be

split in half (i.e. every 5,000 miles instead of every

10,000 miles).