lock DODGE SPRINTER 2007 2.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2007, Model line: SPRINTER, Model: DODGE SPRINTER 2007 2.GPages: 393, PDF Size: 7.61 MB

Page 316 of 393

315 Practical hints

Changing the batteries

5

\3 Changing the batteriesIf the remote control batteries (remote

keyless entry) are discharged, you will only

be able to lock and unlock the vehicle man-

ually using the key.

If the batteries in the auxiliary heating re-

mote control are discharged, you will only

be able to switch the auxiliary heating on

or off using the auxiliary heating / heater

booster switch inside the vehicle

(\2page 140).

It is advisable to have the batteries

changed at an authorized Sprinter Dealer.You need two CR 2025 3 V cell batteries or

equivalent.

Do not touch the battery contact surfaces.Warning

G

Keep batteries away from children.

Consult a doctor immediately if a battery is

swallowed.

Dispose of used batteries in an environmen-

tally responsible manner.

Danger of explosion if the battery is not cor-

rectly replaced.

Replacements should always be either of

the same type or one which has been rec-

ommended by the manufacturer.

Environmental note

H

Batteries contain materials that can harm

the environment if disposed of improperly.

Recycling of batteries is the preferred meth-

od of disposal. Many states require sellers

of batteries to accept old batteries for recy-

cling.iAlways replace all the batteries at the

same time. Suitable batteries are avail-

able from an authorized Sprinter Deal-

er. You can also have the batteries

changed there and return used batter-

ies.

Remote control

(remote keyless entry)iWhen inserting the batteries, make

sure that they are clean and lint-free.!

CAUTION

Do not operate the remote control

while the battery is being replaced.

Page 318 of 393

317 Practical hints

Fuel system

5

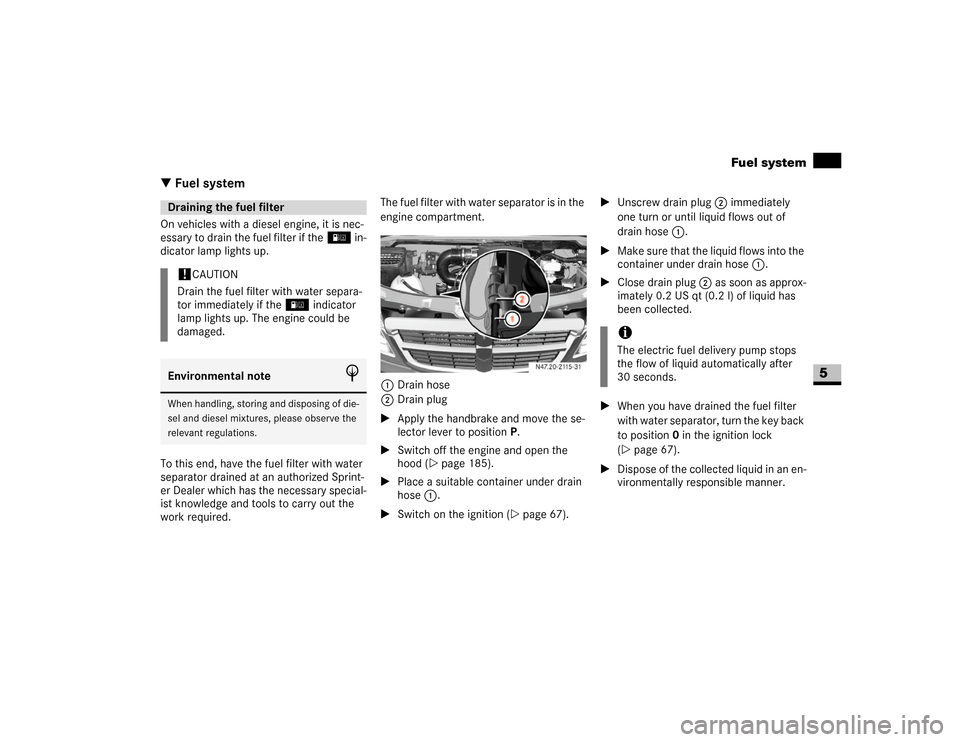

\3 Fuel systemOn vehicles with a diesel engine, it is nec-

essary to drain the fuel filter if the/ in-

dicator lamp lights up.

To this end, have the fuel filter with water

separator drained at an authorized Sprint-

er Dealer which has the necessary special-

ist knowledge and tools to carry out the

work required.The fuel filter with water separator is in the

engine compartment.

1Drain hose

2Drain plug

\1Apply the handbrake and move the se-

lector lever to positionP.

\1Switch off the engine and open the

hood (\2page 185).

\1Place a suitable container under drain

hose1.

\1Switch on the ignition (\2page 67).\1Unscrew drain plug2 immediately

one turn or until liquid flows out of

drain hose1.

\1Make sure that the liquid flows into the

container under drain hose 1.

\1Close drain plug 2 as soon as approx-

imately 0.2 US qt (0.2 l) of liquid has

been collected.

\1When you have drained the fuel filter

with water separator, turn the key back

to position0 in the ignition lock

(\2page 67).

\1Dispose of the collected liquid in an en-

vironmentally responsible manner.Draining the fuel filter!

CAUTION

Drain the fuel filter with water separa-

tor immediately if the/ indicator

lamp lights up. The engine could be

damaged.

Environmental note

H

When handling, storing and disposing of die-

sel and diesel mixtures, please observe the

relevant regulations.

iThe electric fuel delivery pump stops

the flow of liquid automatically after

30 seconds.

Page 320 of 393

319 Practical hints

Replacing the wiper blades

5

\3 Replacing the wiper blades

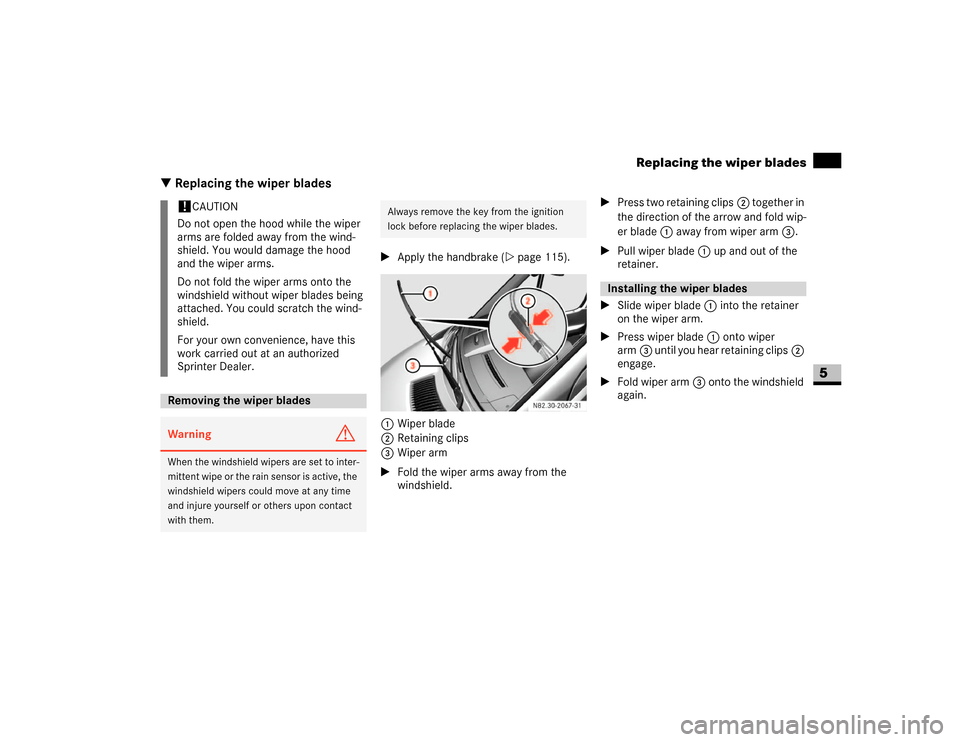

\1Apply the handbrake (\2page 115).

1Wiper blade

2Retaining clips

3Wiper arm

\1Fold the wiper arms away from the

windshield.\1Press two retaining clips2 together in

the direction of the arrow and fold wip-

er blade1 away from wiper arm3.

\1Pull wiper blade1 up and out of the

retainer.

\1Slide wiper blade1 into the retainer

on the wiper arm.

\1Press wiper blade1 onto wiper

arm3 until you hear retaining clips2

engage.

\1Fold wiper arm3 onto the windshield

again.

!

CAUTION

Do not open the hood while the wiper

arms are folded away from the wind-

shield. You would damage the hood

and the wiper arms.

Do not fold the wiper arms onto the

windshield without wiper blades being

attached. You could scratch the wind-

shield.

For your own convenience, have this

work carried out at an authorized

Sprinter Dealer.

Removing the wiper bladesWarning

G

When the windshield wipers are set to inter-

mittent wipe or the rain sensor is active, the

windshield wipers could move at any time

and injure yourself or others upon contact

with them.

Always remove the key from the ignition

lock before replacing the wiper blades.

Installing the wiper blades

Page 323 of 393

322 Practical hintsFlat tire

5

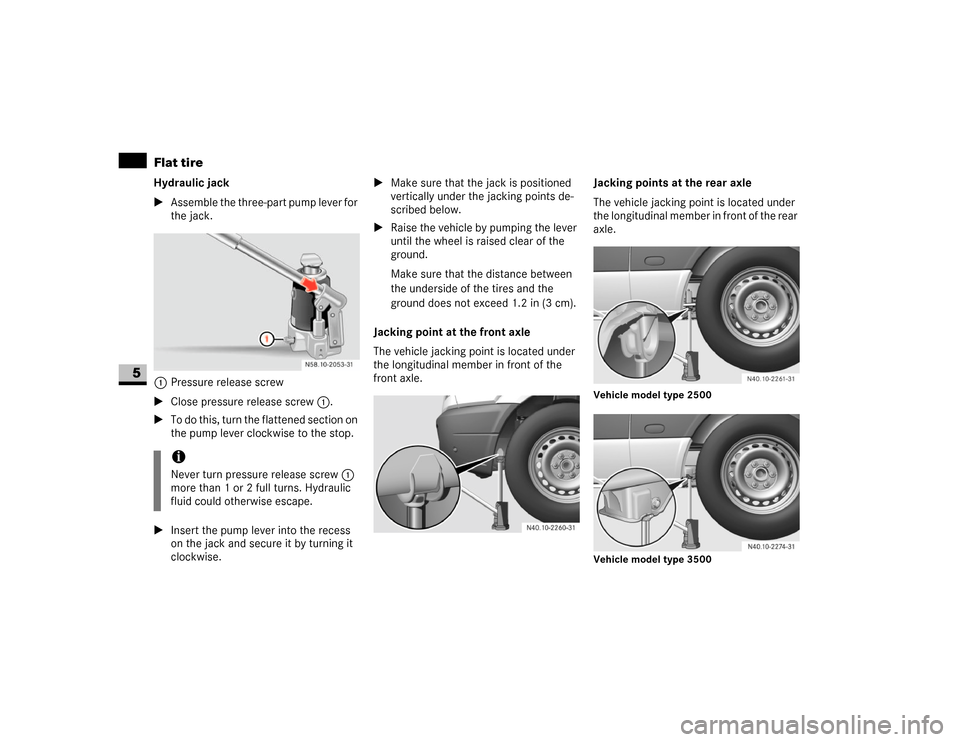

Hydraulic jack

\1Assemble the three-part pump lever for

the jack. 1Pressure release screw

\1Close pressure release screw1.

\1To do this, turn the flattened section on

the pump lever clockwise to the stop.

\1Insert the pump lever into the recess

on the jack and secure it by turning it

clockwise.\1Make sure that the jack is positioned

vertically under the jacking points de-

scribed below.

\1Raise the vehicle by pumping the lever

until the wheel is raised clear of the

ground.

Make sure that the distance between

the underside of the tires and the

ground does not exceed 1.2 in (3 cm).

Jacking point at the front axle

The vehicle jacking point is located under

the longitudinal member in front of the

front axle.

Jacking points at the rear axle

The vehicle jacking point is located under

the longitudinal member in front of the rear

axle. Vehicle model type 2500

Vehicle model type 3500

iNever turn pressure release screw1

more than 1 or 2 full turns. Hydraulic

fluid could otherwise escape.P58.10-2053-31

N40.10-2260-31

N40.10-2161-31

Page 329 of 393

328 Practical hintsFlat tire

5

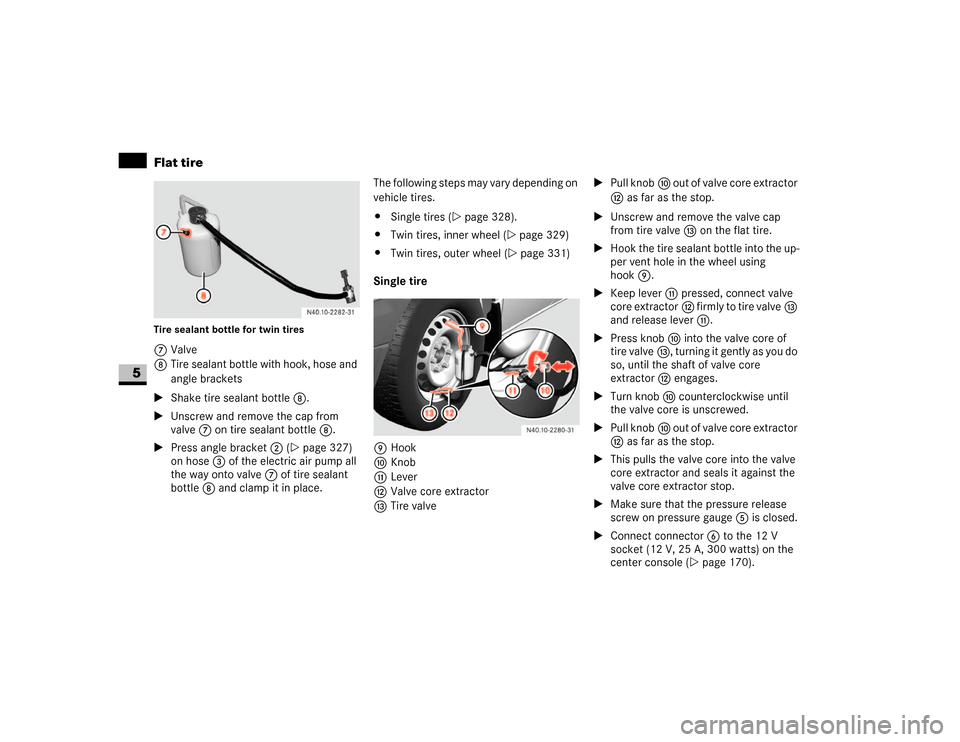

Tire sealant bottle for twin tires7Valve

8Tire sealant bottle with hook, hose and

angle brackets

\1Shake tire sealant bottle8.

\1Unscrew and remove the cap from

valve 7 on tire sealant bottle 8.

\1Press angle bracket 2 (\2page 327)

on hose 3 of the electric air pump all

the way onto valve 7 of tire sealant

bottle 8 and clamp it in place.The following steps may vary depending on

vehicle tires.

\4Single tires (\2page 328).

\4Twin tires, inner wheel (\2page 329)

\4Twin tires, outer wheel (\2page 331)

Single tire

9Hook

aKnob

bLever

cValve core extractor

dTire valve\1Pull knoba out of valve core extractor

c as far as the stop.

\1Unscrew and remove the valve cap

from tire valved on the flat tire.

\1Hook the tire sealant bottle into the up-

per vent hole in the wheel using

hook9.

\1Keep lever b pressed, connect valve

core extractorc firmly to tire valved

and release leverb.

\1Press knob a into the valve core of

tire valved, turning it gently as you do

so, until the shaft of valve core

extractorc engages.

\1Turn knoba counterclockwise until

the valve core is unscrewed.

\1Pull knoba out of valve core extractor

c as far as the stop.

\1This pulls the valve core into the valve

core extractor and seals it against the

valve core extractor stop.

\1Make sure that the pressure release

screw on pressure gauge 5 is closed.

\1Connect connector6 to the 12 V

socket (12 V, 25 A, 300 watts) on the

center console (\2page 170).

Page 330 of 393

329 Practical hints

Flat tire

5

\1Start the engine (\2page 111).

\1Press I on electric air pump switch1.

The electric air pump is switched on.

The tire sealant is then pumped into

the tire and the tire pressure is in-

creased. Allow the electric air pump to

run for at least 10 minutes until tire

sealant bottle 8 is completely empty

and a minimum tire pressure of

43.5 psi (3.0 bar) is achieved.

\1Inflate the tire using the electric air

pump until the recommended tire pres-

sure (\2page 210) is achieved.

\1Then press0 on electric air pump

switch1.

The electric air pump is switched off.

\1Slide knoba quickly to the stop in

valve core extractorc.

\1Turn knob a clockwise until the valve

core is firmly screwed into tire

valved.

\1Press leverb and remove valve core

extractorc from tire valved.

\1Screw the valve cap onto tire valved.

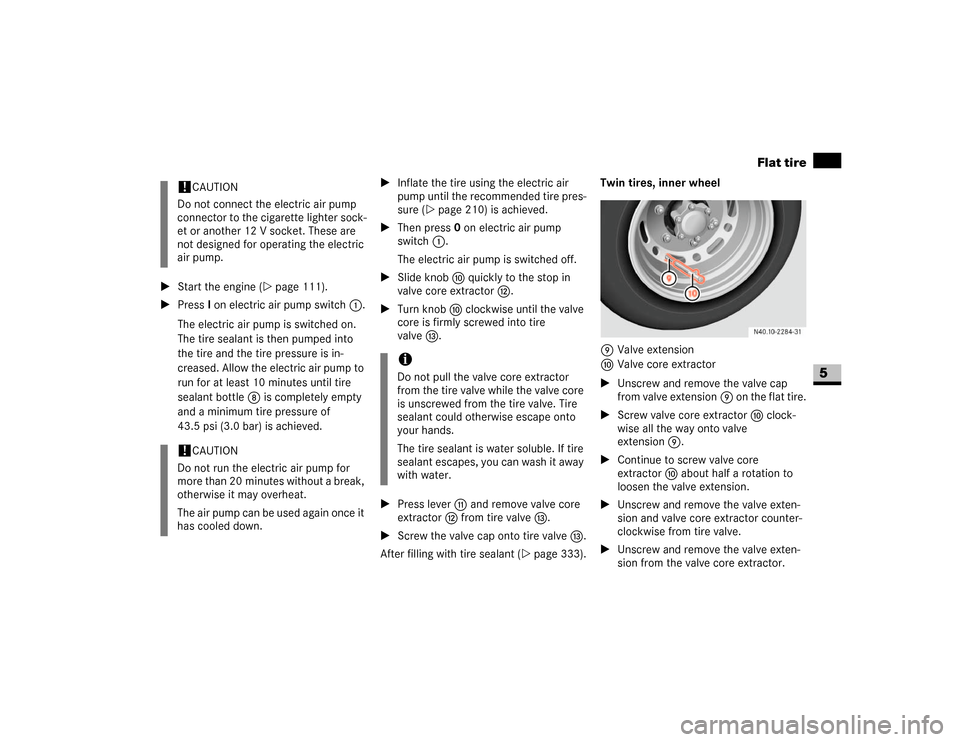

After filling with tire sealant (\2page 333).Twin tires, inner wheel

9Valve extension

aValve core extractor

\1Unscrew and remove the valve cap

from valve extension9 on the flat tire.

\1Screw valve core extractora clock-

wise all the way onto valve

extension9.

\1Continue to screw valve core

extractora about half a rotation to

loosen the valve extension.

\1Unscrew and remove the valve exten-

sion and valve core extractor counter-

clockwise from tire valve.

\1Unscrew and remove the valve exten-

sion from the valve core extractor.

!

CAUTION

Do not connect the electric air pump

connector to the cigarette lighter sock-

et or another 12 V socket. These are

not designed for operating the electric

air pump.

!

CAUTION

Do not run the electric air pump for

more than 20 minutes without a break,

otherwise it may overheat.

The air pump can be used again once it

has cooled down.

iDo not pull the valve core extractor

from the tire valve while the valve core

is unscrewed from the tire valve. Tire

sealant could otherwise escape onto

your hands.

The tire sealant is water soluble. If tire

sealant escapes, you can wash it away

with water.

Page 331 of 393

330 Practical hintsFlat tire

5

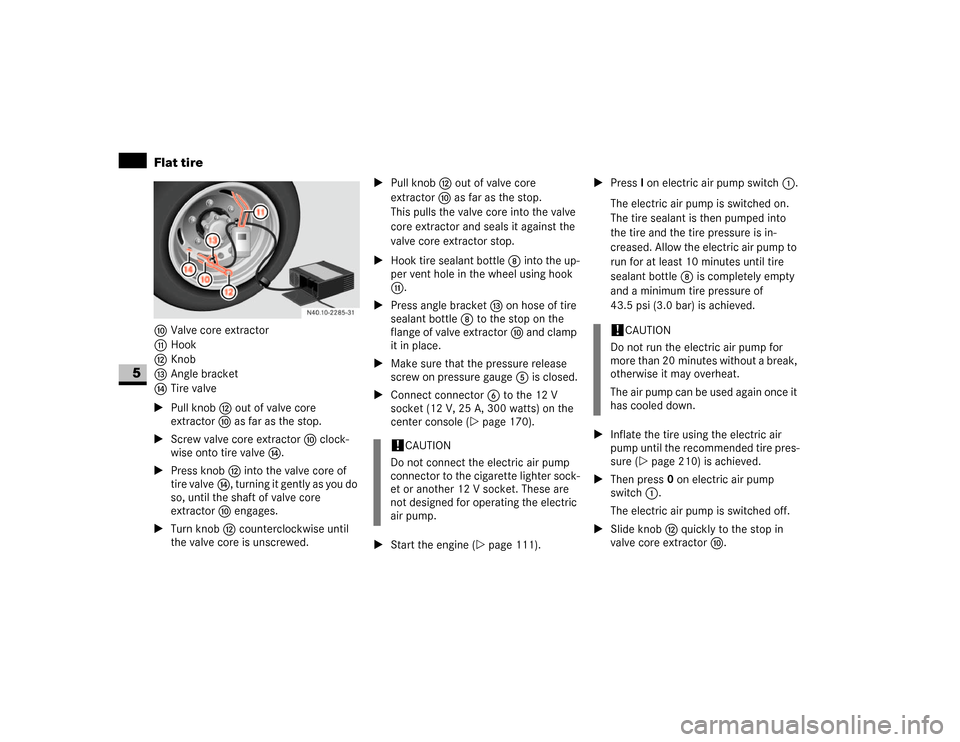

aValve core extractor

bHook

cKnob

dAngle bracket

eTire valve

\1Pull knob c out of valve core

extractora as far as the stop.

\1Screw valve core extractora clock-

wise onto tire valvee.

\1Press knob c into the valve core of

tire valvee, turning it gently as you do

so, until the shaft of valve core

extractora engages.

\1Turn knob c counterclockwise until

the valve core is unscrewed.\1Pull knob c out of valve core

extractora as far as the stop.

This pulls the valve core into the valve

core extractor and seals it against the

valve core extractor stop.

\1Hook tire sealant bottle 8 into the up-

per vent hole in the wheel using hook

b.

\1Press angle bracket d on hose of tire

sealant bottle 8 to the stop on the

flange of valve extractora and clamp

it in place.

\1Make sure that the pressure release

screw on pressure gauge 5 is closed.

\1Connect connector6 to the 12 V

socket (12 V, 25 A, 300 watts) on the

center console (\2page 170).

\1Start the engine (\2page 111).\1Press I on electric air pump switch1.

The electric air pump is switched on.

The tire sealant is then pumped into

the tire and the tire pressure is in-

creased. Allow the electric air pump to

run for at least 10 minutes until tire

sealant bottle 8 is completely empty

and a minimum tire pressure of

43.5 psi (3.0 bar) is achieved.

\1Inflate the tire using the electric air

pump until the recommended tire pres-

sure (\2page 210) is achieved.

\1Then press0 on electric air pump

switch1.

The electric air pump is switched off.

\1Slide knob c quickly to the stop in

valve core extractora.

!

CAUTION

Do not connect the electric air pump

connector to the cigarette lighter sock-

et or another 12 V socket. These are

not designed for operating the electric

air pump.

!

CAUTION

Do not run the electric air pump for

more than 20 minutes without a break,

otherwise it may overheat.

The air pump can be used again once it

has cooled down.

Page 332 of 393

331 Practical hints

Flat tire

5

\1Turn knob c clockwise until the valve

core is firmly screwed into tire

valvee.

\1Pull knob c out of valve core

extractora as far as the stop.

\1Unscrew valve core extractora coun-

terclockwise and remove it from tire

valvee .

\1Screw valve extension9 onto tire

valvee and tighten.

\1Screw the valve cap onto valve

extension9.

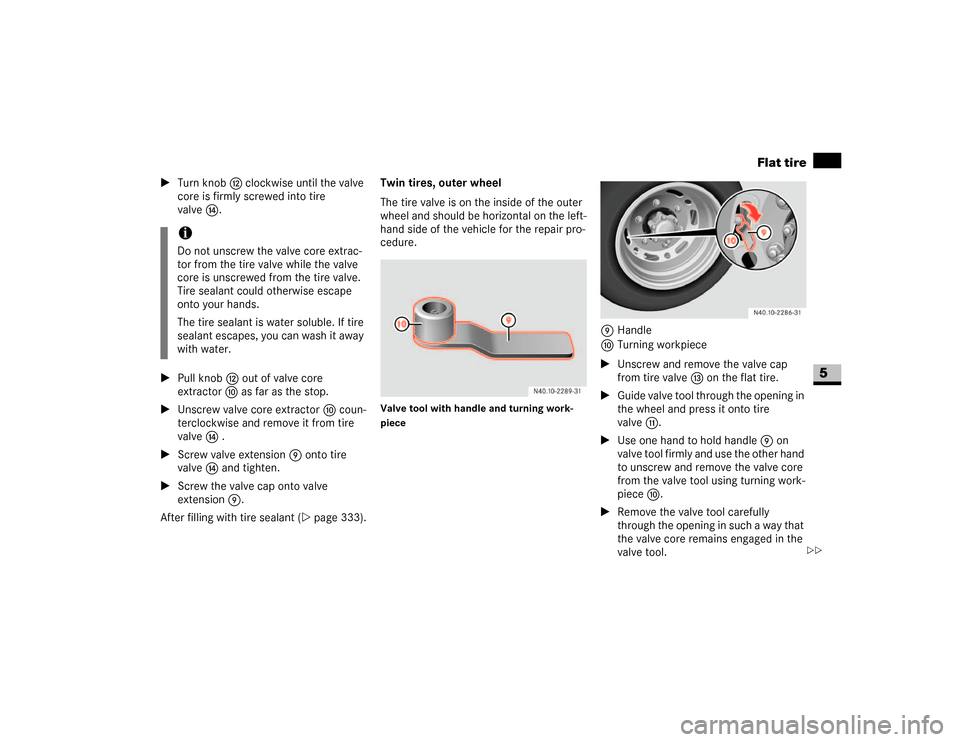

After filling with tire sealant (\2page 333).Twin tires, outer wheel

The tire valve is on the inside of the outer

wheel and should be horizontal on the left-

hand side of the vehicle for the repair pro-

cedure.

Valve tool with handle and turning work-

piece

9Handle

aTurning workpiece

\1Unscrew and remove the valve cap

from tire valved on the flat tire.

\1Guide valve tool through the opening in

the wheel and press it onto tire

valveb.

\1Use one hand to hold handle9 on

valve tool firmly and use the other hand

to unscrew and remove the valve core

from the valve tool using turning work-

piece a.

\1Remove the valve tool carefully

through the opening in such a way that

the valve core remains engaged in the

valve tool.

iDo not unscrew the valve core extrac-

tor from the tire valve while the valve

core is unscrewed from the tire valve.

Tire sealant could otherwise escape

onto your hands.

The tire sealant is water soluble. If tire

sealant escapes, you can wash it away

with water.

\2\2

Page 334 of 393

333 Practical hints

Flat tire

5

\1Then press0 on electric air pump

switch1.

The electric air pump is switched off.

\1Screw the valve cap onto tire valveb.

\1After filling with tire sealant

(\2page 333).

After filling with tire sealant

\1Turn the pressure release screw on

pressure gauge5 counterclockwise

and bleed the system.

\1Turn the key to position0 in the igni-

tion lock (\2page 67).

\1Pull the electric air pump connector out

of the 12 V socket.

\1Store the electric air pump, tire sealant

bottle 8 with valve core extractorc

and, if used, the warning triangle and

hazard warning lamps inside the vehi-

cle.\1Unscrew and remove angle bracket 2

from valve7 on tire sealant bottle 8

and screw the valve cap onto the valve.

\1Pull away immediately.

This enables the tire sealant to distrib-

ute inside the tire and create a more ef-

fective seal.

\1Stop after about 3 minutes and check

the tire pressure using the electric air

pump, for example.\1Correct the tire pressure accordingly if

it does not correspond to the recom-

mended tire pressure (\2page 210).

Increasing the tire pressure

\1Switch on the electric air pump.

Reducing the tire pressure

\1Open the pressure release screw

on pressure gauge 5.

\1Drive to the nearest workshop and

have the tire repaired or replaced.

\1Clean the valve core extractor using

clean water.

\1Have tire sealant bottle8 replaced as

soon as possible at an authorized

Sprinter Dealer.

iThe tire sealant is water soluble. If tire

sealant escapes, you can wash it away

with water.

Warning

G

Do not exceed the maximum speed of

50 mph (80 km/h).

The "max. 50 mph (80 km/h)" sticker must

be affixed within the driver's field of vision.

The vehicle’s handling characteristics may

be affected.iYou must connect the angle bracket on

hose 3 of the electric air pump direct-

ly to the tire valve on the tire.

Page 336 of 393

335 Practical hints

Battery

5

\3 BatteryYour vehicle may be equipped with two

batteries, depending on the equipment

version:

\4Starter battery in the battery recess in

the driver’s footwell

\4Auxiliary battery* in the engine com-

partmentHave the batteries removed at an autho-

rized Sprinter Dealer which has the neces-

sary specialist knowledge and tools to

carry out the work required.

The manufacturer recommends that you

use an authorized Sprinter Dealer for this

purpose.

\1Switch off all electrical consumers.

iThe auxiliary battery* in the engine

compartment is not suitable for jump-

starting operations. Only use the jump-

starting connection in the engine com-

partment if you require jump-starting

assistance or wish to provide jump-

starting assistance (\2page 340).Warning

G

Observe the safety notes in the “Operation”

section (\2page 195).

Do not place any metal objects on the bat-

tery. Doing so can cause a short circuit.

Use only impact-resistant batteries with a

central gas release cover to prevent corro-

sion damage and to protect occupants from

caustic burns in the event of an accident.Disconnecting the batteryWarning

G

There is a risk of a short circuit if the positive

terminal of the connected battery comes

into contact with vehicle parts. The highly

explosive gas mixture could ignite as a re-

sult. You and others could be seriously in-

jured as a result.

\4Do not place any metal objects or tools

on the batteries.

\4When disconnecting the batteries, al-

ways disconnect the negative terminals

first and then the positive terminals.

\4When reconnecting the batteries, al-

ways reconnect the positive terminals

first and then the negative terminals.

\4Do not loosen or disconnect the termi-

nal clamps on the batteries while the en-

gine is running.!

CAUTION

Switch off the engine and take the key

out of the ignition lock before you loos-

en or disconnect the terminal clamps.

You may otherwise destroy electronic

components such as the alternator.

Always disconnect the starter battery

in the battery recess in the driver’s

footwell first.