center console DODGE SPRINTER 2007 2.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2007, Model line: SPRINTER, Model: DODGE SPRINTER 2007 2.GPages: 393, PDF Size: 7.61 MB

Page 327 of 393

326 Practical hintsFlat tire

5

You can use the Premium tire sealant to

seal small punctures, particularly those in

the tire tread. Tire sealants can be used at

outside temperatures down to –22 °F

(–30 °C).

Prepare the vehicle as described

(\2page 320).\1Try to park the vehicle in such a way

that the tire puncture is close to the

ground. If the tire puncture cannot be

seen, park the vehicle in such a way

that the tire valve of the flat tire is in

horizontal alignment with the axle.

\1It is beneficial to the sealing process if

you remove the foreign body that has

pierced the tire, for example the screw

or nail.

\1Remove the Premium tire sealant, the

accompanying "max. 50 mph

(80 km/h)" sticker and the electric air

pump from the storage compartment in

the right-hand doorway (\2page 303).

\1Affix the sticker within the driver’s field

of vision.Using Premium tire sealant*Warning

G

Smoking, fire and naked flames are prohibit-

ed when handling Premium tire sealant.

Avoid creating sparks.

Warning

G

Your safety is at particular risk and the tire

sealant is unable to repair a tire in the fol-

lowing situations:

\4if there are cuts or punctures in the tire

greater than 0.23 in (6 mm)

\4if the rim is damaged

\4if you have driven with very low tire pres-

sures or with flat tires

Do not drive any further. Consult an autho-

rized Sprinter Dealer which has the neces-

sary specialist knowledge and tools to carry

out the work required.

The manufacturer recommends that you use

an authorized Sprinter Dealer for this pur-

pose. In particular, work relevant to safety

or on safety-related systems must be car-

ried out at an authorized Sprinter Dealer.

!

CAUTION

Only connect the electric air pump to

the 12 V socket (\2page 170) on the

center console (12 V, 25 A, 300 watts).

You could otherwise damage the vehi-

cle electrical system.

Page 329 of 393

328 Practical hintsFlat tire

5

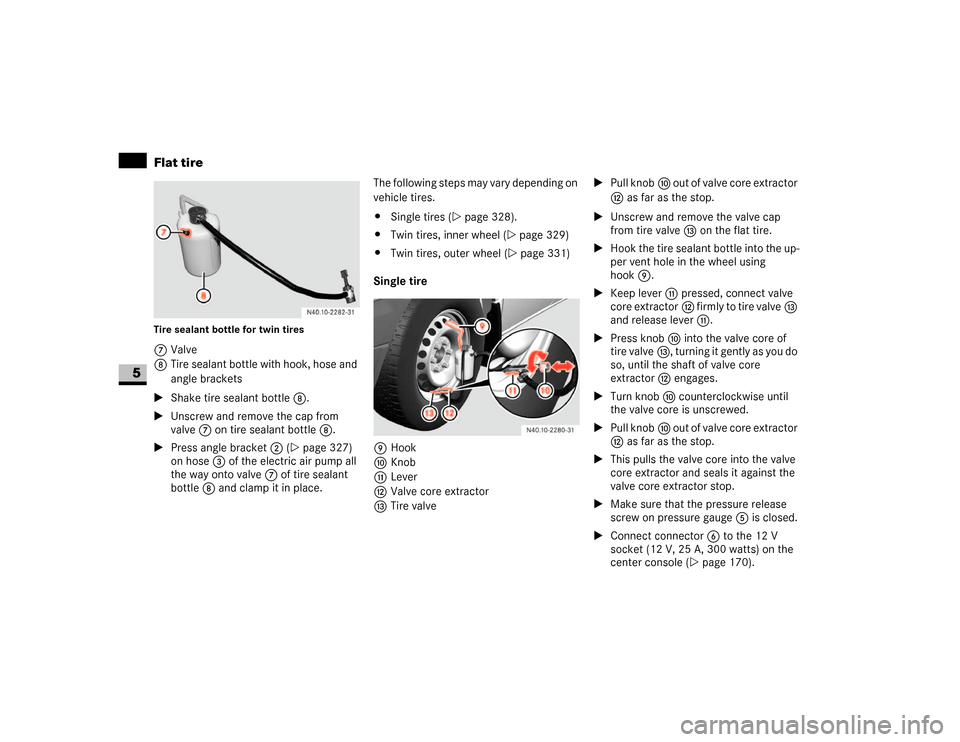

Tire sealant bottle for twin tires7Valve

8Tire sealant bottle with hook, hose and

angle brackets

\1Shake tire sealant bottle8.

\1Unscrew and remove the cap from

valve 7 on tire sealant bottle 8.

\1Press angle bracket 2 (\2page 327)

on hose 3 of the electric air pump all

the way onto valve 7 of tire sealant

bottle 8 and clamp it in place.The following steps may vary depending on

vehicle tires.

\4Single tires (\2page 328).

\4Twin tires, inner wheel (\2page 329)

\4Twin tires, outer wheel (\2page 331)

Single tire

9Hook

aKnob

bLever

cValve core extractor

dTire valve\1Pull knoba out of valve core extractor

c as far as the stop.

\1Unscrew and remove the valve cap

from tire valved on the flat tire.

\1Hook the tire sealant bottle into the up-

per vent hole in the wheel using

hook9.

\1Keep lever b pressed, connect valve

core extractorc firmly to tire valved

and release leverb.

\1Press knob a into the valve core of

tire valved, turning it gently as you do

so, until the shaft of valve core

extractorc engages.

\1Turn knoba counterclockwise until

the valve core is unscrewed.

\1Pull knoba out of valve core extractor

c as far as the stop.

\1This pulls the valve core into the valve

core extractor and seals it against the

valve core extractor stop.

\1Make sure that the pressure release

screw on pressure gauge 5 is closed.

\1Connect connector6 to the 12 V

socket (12 V, 25 A, 300 watts) on the

center console (\2page 170).

Page 331 of 393

330 Practical hintsFlat tire

5

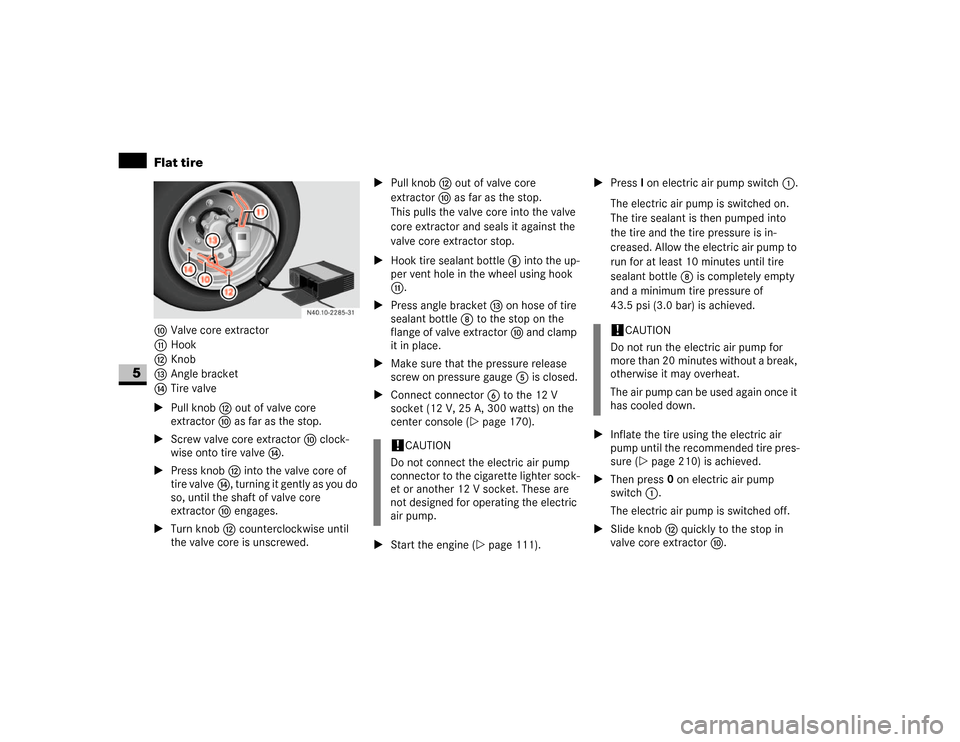

aValve core extractor

bHook

cKnob

dAngle bracket

eTire valve

\1Pull knob c out of valve core

extractora as far as the stop.

\1Screw valve core extractora clock-

wise onto tire valvee.

\1Press knob c into the valve core of

tire valvee, turning it gently as you do

so, until the shaft of valve core

extractora engages.

\1Turn knob c counterclockwise until

the valve core is unscrewed.\1Pull knob c out of valve core

extractora as far as the stop.

This pulls the valve core into the valve

core extractor and seals it against the

valve core extractor stop.

\1Hook tire sealant bottle 8 into the up-

per vent hole in the wheel using hook

b.

\1Press angle bracket d on hose of tire

sealant bottle 8 to the stop on the

flange of valve extractora and clamp

it in place.

\1Make sure that the pressure release

screw on pressure gauge 5 is closed.

\1Connect connector6 to the 12 V

socket (12 V, 25 A, 300 watts) on the

center console (\2page 170).

\1Start the engine (\2page 111).\1Press I on electric air pump switch1.

The electric air pump is switched on.

The tire sealant is then pumped into

the tire and the tire pressure is in-

creased. Allow the electric air pump to

run for at least 10 minutes until tire

sealant bottle 8 is completely empty

and a minimum tire pressure of

43.5 psi (3.0 bar) is achieved.

\1Inflate the tire using the electric air

pump until the recommended tire pres-

sure (\2page 210) is achieved.

\1Then press0 on electric air pump

switch1.

The electric air pump is switched off.

\1Slide knob c quickly to the stop in

valve core extractora.

!

CAUTION

Do not connect the electric air pump

connector to the cigarette lighter sock-

et or another 12 V socket. These are

not designed for operating the electric

air pump.

!

CAUTION

Do not run the electric air pump for

more than 20 minutes without a break,

otherwise it may overheat.

The air pump can be used again once it

has cooled down.

Page 333 of 393

332 Practical hintsFlat tire

5

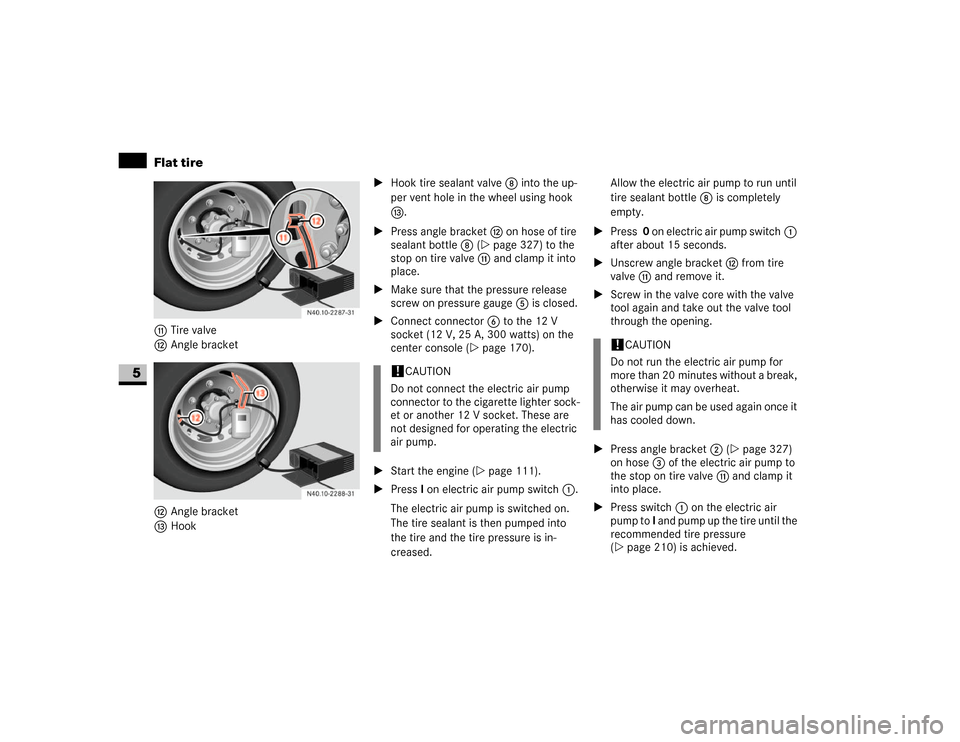

bTire valve

cAngle bracket

cAngle bracket

dHook\1Hook tire sealant valve 8 into the up-

per vent hole in the wheel using hook

d.

\1Press angle bracket c on hose of tire

sealant bottle 8 (\2page 327) to the

stop on tire valveb and clamp it into

place.

\1Make sure that the pressure release

screw on pressure gauge 5 is closed.

\1Connect connector6 to the 12 V

socket (12 V, 25 A, 300 watts) on the

center console (\2page 170).

\1Start the engine (\2page 111).

\1Press I on electric air pump switch1.

The electric air pump is switched on.

The tire sealant is then pumped into

the tire and the tire pressure is in-

creased.Allow the electric air pump to run until

tire sealant bottle 8 is completely

empty.

\1Press 0 on electric air pump switch1

after about 15 seconds.

\1Unscrew angle bracket c from tire

valveb and remove it.

\1Screw in the valve core with the valve

tool again and take out the valve tool

through the opening.

\1Press angle bracket 2 (\2page 327)

on hose 3 of the electric air pump to

the stop on tire valveb and clamp it

into place.

\1Press switch 1 on the electric air

pump to I and pump up the tire until the

recommended tire pressure

(\2page 210) is achieved.

!

CAUTION

Do not connect the electric air pump

connector to the cigarette lighter sock-

et or another 12 V socket. These are

not designed for operating the electric

air pump.

!

CAUTION

Do not run the electric air pump for

more than 20 minutes without a break,

otherwise it may overheat.

The air pump can be used again once it

has cooled down.

Page 348 of 393

347 Practical hintsFuses

5

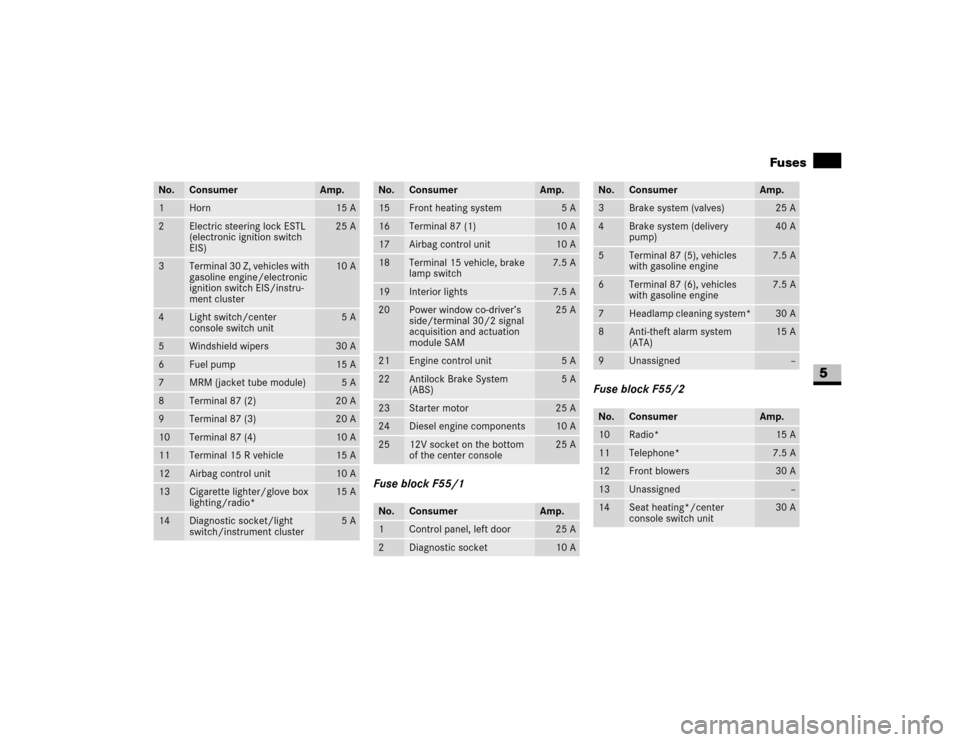

Fuse block F55/1Fuse block F55/2

No.

Consumer

Amp.

1

Horn

15 A

2

Electric steering lock ESTL

(electronic ignition switch

EIS)

25 A

3

Te rm ina l 30 Z , ve hi cle s wit h

gasoline engine/electronic

ignition switch EIS/instru-

ment cluster

10 A

4

Light switch/center

console switch unit

5A

5

Windshield wipers

30 A

6

Fuel pump

15 A

7

MRM (jacket tube module)

5A

8

Terminal 87 (2)

20 A

9

Terminal 87 (3)

20 A

10

Terminal 87 (4)

10 A

11

Terminal 15 R vehicle

15 A

12

Airbag control unit

10 A

13

Cigarette lighter/glove box

lighting/radio*

15 A

14

Diagnostic socket/light

switch/instrument cluster

5A

No.

Consumer

Amp.

15

Front heating system

5A

16

Terminal 87 (1)

10 A

17

Airbag control unit

10 A

18

Terminal 15 vehicle, brake

lamp switch

7.5 A

19

Interior lights

7.5 A

20

Power window co-driver’s

side/terminal 30/2 signal

acquisition and actuation

module SAM

25 A

21

Engine control unit

5A

22

Antilock Brake System

(ABS)

5A

23

Starter motor

25 A

24

Diesel engine components

10 A

25

12V socket on the bottom

of the center console

25 A

No.

Consumer

Amp.

1

Control panel, left door

25 A

2

Diagnostic socket

10 A

No.

Consumer

Amp.

3

Brake system (valves)

25 A

4

Brake system (delivery

pump)

40 A

5

Terminal 87 (5), vehicles

with gasoline engine

7.5 A

6

Terminal 87 (6), vehicles

with gasoline engine

7.5 A

7

Headlamp cleaning system*

30 A

8

Anti-theft alarm system

(ATA)

15 A

9

Unassigned

–

No.

Consumer

Amp.

10

Radio*

15 A

11

Telephone*

7.5 A

12

Front blowers

30 A

13

Unassigned

–

14

Seat heating*/center

console switch unit

30 A

Page 380 of 393

379 Index

Care of batteries

. . . . . . . . . . . . . . . 196

Care of the vehicle . . . . . . . . . . . . . 241

after driving off-road or on

construction sites . . . . . . . . . . . . . 246

Carrier systems

. . . . . . . . . . . 162

, 372

Catalytic converter

. . . . . . . . . . . . . 181

CD player/CD changer

. . . . . . . . . . . 94

Cell phone

. . . . . . . . . . . . . . . . . . . . 171

Center console

. . . . . . . . . . . . . . . . . 18

switch unit

. . . . . . . . . . . . . . . . . . . . 20

Central locking

locking/unlocking

. . . . . . . . . . . . . . 52

(from the inside)

. . . . . . . . . . . . . . . 63

Central locking system

malfunctions

. . . . . . . . . . . . . . . . . 259

Certification label

. . . . . . . . . . . . . . 209

Changing bulbs

. . . . . . . . . . . . . . . . 306

clearance lamp . . . . . . . . . . . . . . . 312

headlamps

. . . . . . . . . . . . . . . . . . . 308

identification lamps

. . . . . . . . 311

, 313

interior lamp

. . . . . . . . . . . . . . . . . 314

license plate lamp

. . . . . . . . . . . . . 312

rear lamp units

chassis

. . . . . . . . . . . . . . . . . . . . 310

panel van/crewbus

. . . . . . . . . . 310

side marker lamps

. . . . . . . . . . . . . 312Checking tire pressure electronically

with the Advanced Tire Pressure

Monitoring System

(Advanced TPMS)

. . . . . . . . . . . . . . 217

Checking tire pressure electronically

with the Tire Pressure Monitoring

System (TPMS)

. . . . . . . . . . . . . . . . 214

Checks, regular . . . . . . . . . . . . . . . . 181

Children

in the vehicle

. . . . . . . . . . . . . . . . . . 36

ISOFIX seat securing system

. . . . . . 39

LATCH type child restraint system

. 39

restraint systems

. . . . . . . . . . . . . . . 37

Chock

. . . . . . . . . . . . . . . . . . . . . . . . 303

Cigarette lighter

. . . . . . . . . . . . . . . 169

Cleaning

. . . . . . . . . . . . . . . . . . . . . . 241

after driving off-road or

on construction sites

. . . . . . . . . . . 246

air cleaner element

. . . . . . . . . . . . 240

cockpit

. . . . . . . . . . . . . . . . . . . . . . 245

headlamps

. . . . . . . . . . . . . . . . . . . 244

padded boss of the steering wheel

245

rear view camera lens

. . . . . . . . . . 244

rear window

. . . . . . . . . . . . . . . . . . 244

side windows . . . . . . . . . . . . . . . . . 244

vehicle

. . . . . . . . . . . . . . . . . . . . . . 242

windshield . . . . . . . . . . . . . . . . . . . 243

windshield wipers

. . . . . . . . . . . . . 243Clearance lamp

changing bulbs

. . . . . . . . . . . . . . . . 312

see identification lamp

. . . . . . . . . . 311

Clock

setting

vehicles with steering wheel

buttons

. . . . . . . . . . . . . . . . . . . . 101

vehicles without steering wheel

buttons . . . . . . . . . . . . . . . . . . . . . 88

Cockpit

. . . . . . . . . . . . . . . . . . . . . . . . 12

Co-driver's seat

foldable . . . . . . . . . . . . . . . . . . . . . . 74

Cold tire inflation pressure

. . . . . . 228

COMAND

see the separate Operating Instructions

Comfort seat

. . . . . . . . . . . . . . . . . . . 69

Constant headlamp mode

. . . . . . . 102

Consumption statistics

(vehicles with steering wheel

buttons)

. . . . . . . . . . . . . . . . . . . . . . 106

Coolant . . . . . . . . . . . . . . . . . . . . . . . 363

adding . . . . . . . . . . . . . . . . . . . . . . 191

anticorrosion/antifreeze fluid

. . . . 363

display message

. . . . . . . . . . . . . . 292

temperature

. . . . . . . . . . . . . . . . . . 120

temperature display

(vehicle with steering wheel

buttons)

. . . . . . . . . . . . . . . . . . . . . . 93