ECU DODGE SPRINTER 2008 2.G Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2008, Model line: SPRINTER, Model: DODGE SPRINTER 2008 2.GPages: 666, PDF Size: 14.11 MB

Page 520 of 666

518 Practical hintsWhere will I find...?

5

\1

Open the rear doors (

\2

page 100).

\1

Insert a screwdriver into

recesses

2

and pry off covers

1

.

\1

Using the wheel wrench from the ve-

hicle tool kit (

\2

page 515), now un-

screw the visible bolts approximately

20 turns counterclockwise.

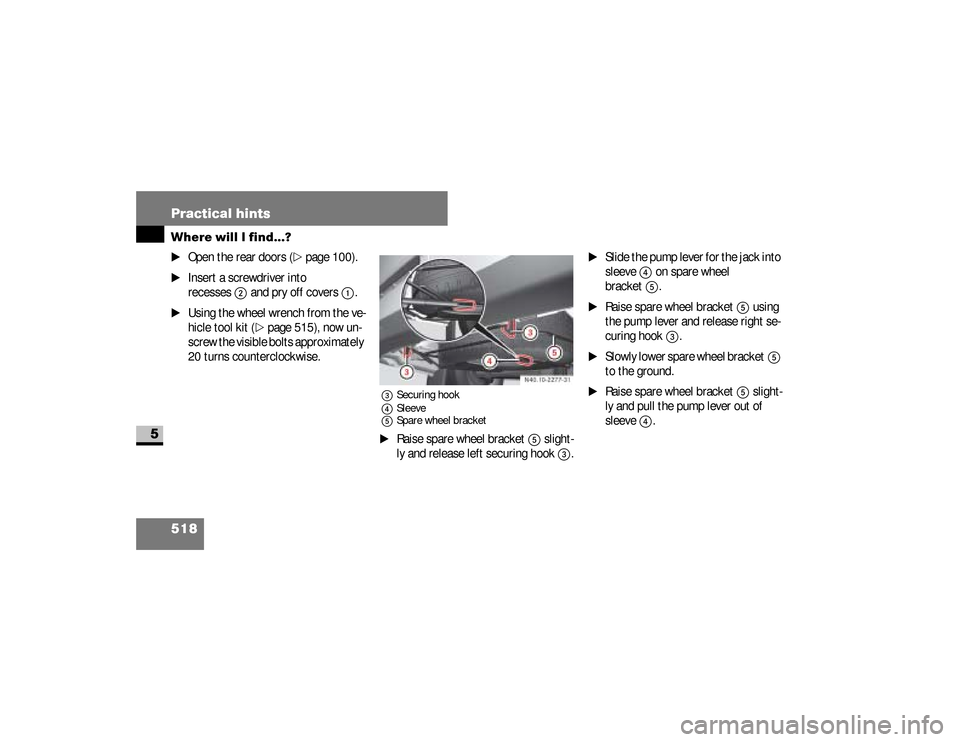

3Securing hook

4Sleeve

5Spare wheel bracket\1

Raise spare wheel bracket

5

slight-

ly and release left securing hook

3

.

\1

Slide the pump lever for the jack into

sleeve

4

on spare wheel

bracket5

.

\1

Raise spare wheel bracket

5

using

the pump lever and release right se-

curing hook

3

.

\1

Slowly lower spare wheel bracket

5

to the ground.

\1

Raise spare wheel bracket

5

slight-

ly and pull the pump lever out of

sleeve

4

.

nf_BA.book Page 518 Friday, January 25, 2008 3:53 PM

Page 521 of 666

519 Practical hints

Where will I find...?

5

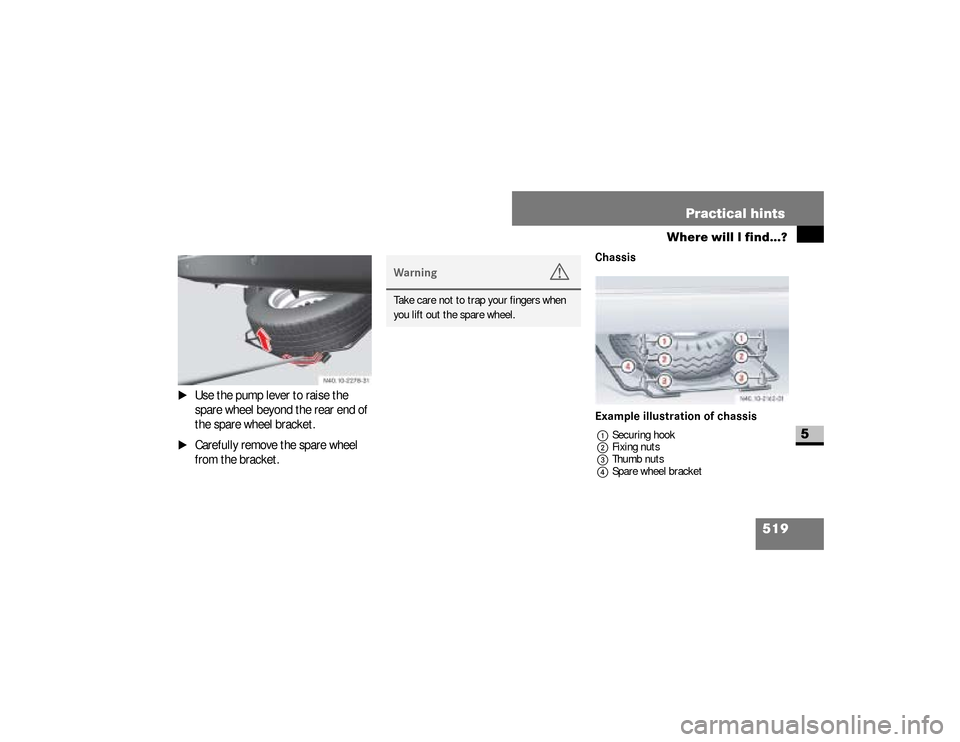

\1

Use the pump lever to raise the

spare wheel beyond the rear end of

the spare wheel bracket.

\1

Carefully remove the spare wheel

from the bracket.

Chassis

Example illustration of chassis1Securing hook

2Fixing nuts

3Thumb nuts

4Spare wheel bracket

Warning

G

Take care not to trap your fingers when

you lift out the spare wheel.

nf_BA.book Page 519 Friday, January 25, 2008 3:53 PM

Page 522 of 666

520 Practical hintsWhere will I find...?

5

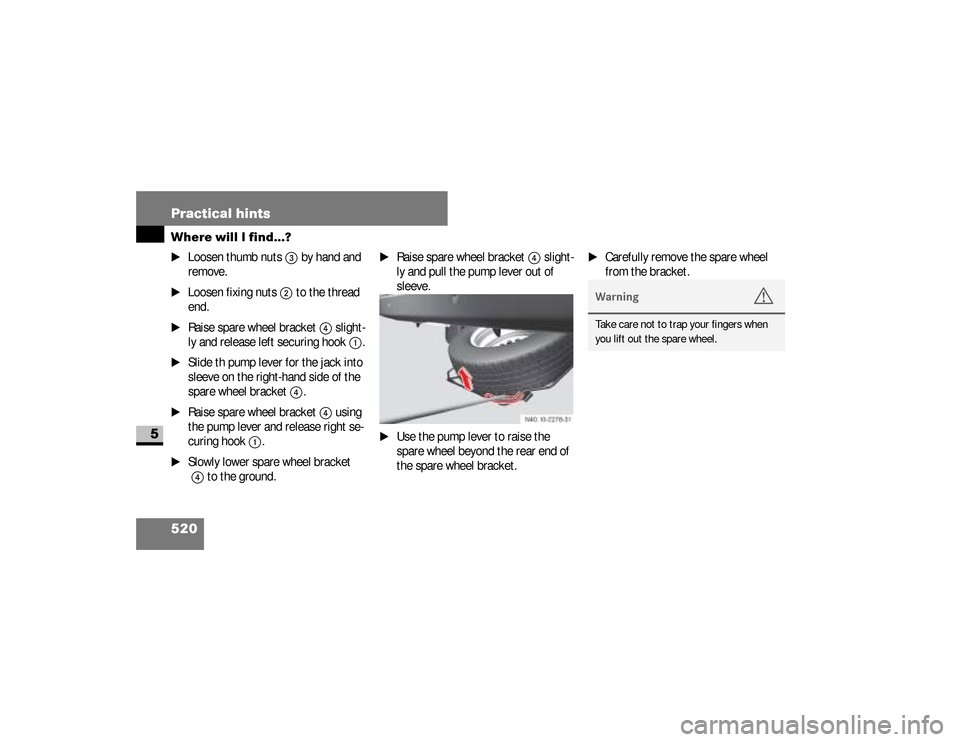

\1

Loosen thumb nuts

3

by hand and

remove.

\1

Loosen fixing nuts

2

to the thread

end.

\1

Raise spare wheel bracket

4

slight-

ly and release left securing hook

1

.

\1

Slide th pump lever for the jack into

sleeve on the right-hand side of the

spare wheel bracket

4

.

\1

Raise spare wheel bracket

4

using

the pump lever and release right se-

curing hook

1

.

\1

Slowly lower spare wheel bracket 4

to the ground.

\1

Raise spare wheel bracket

4

slight-

ly and pull the pump lever out of

sleeve.

\1

Use the pump lever to raise the

spare wheel beyond the rear end of

the spare wheel bracket.

\1

Carefully remove the spare wheel

from the bracket.Warning

G

Take care not to trap your fingers when

you lift out the spare wheel.

nf_BA.book Page 520 Friday, January 25, 2008 3:53 PM

Page 524 of 666

522 Practical hintsWhere will I find...?

5

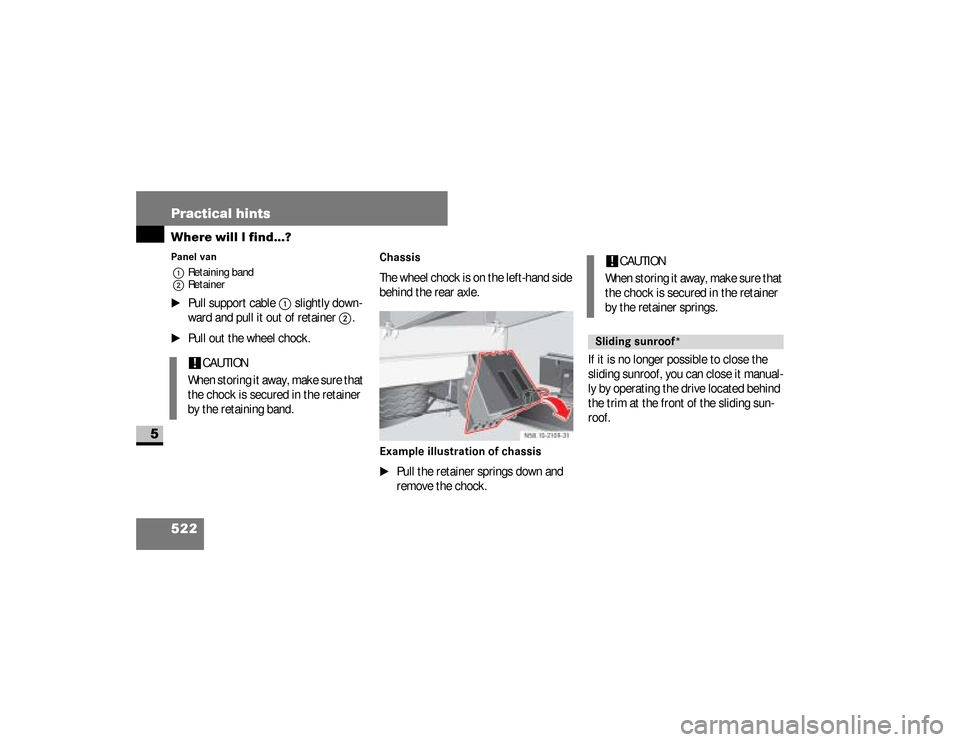

Panel van

1Retaining band

2Retainer\1

Pull support cable

1

slightly down-

ward and pull it out of retainer

2

.

\1

Pull out the wheel chock.

ChassisThe wheel chock is on the left-hand side

behind the rear axle.Example illustration of chassis

\1

Pull the retainer springs down and

remove the chock.

.If it is no longer possible to close the

sliding sunroof, you can close it manual-

ly by operating the drive located behind

the trim at the front of the sliding sun-

roof.

!

CAUTION

When storing it away, make sure that

the chock is secured in the retainer

by the retaining band.

!

CAUTION

When storing it away, make sure that

the chock is secured in the retainer

by the retainer springs.

Sliding sunroof*

nf_BA.book Page 522 Friday, January 25, 2008 3:53 PM

Page 533 of 666

531 Practical hints

Changing bulbs

5

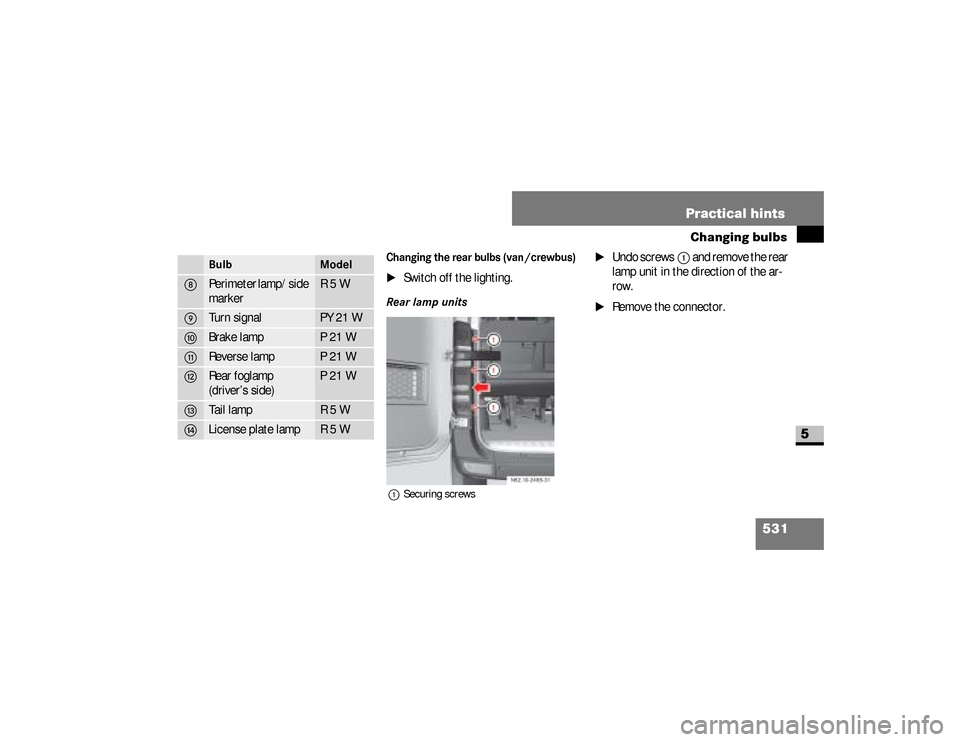

Changing the rear bulbs (van /crewbus)\1

Switch off the lighting.

Rear lamp units1Securing screws

\1

Undo screws

1

and remove the rear

lamp unit in the direction of the ar-

row.

\1

Remove the connector.

Bulb

Model

8

Perimeter lamp/side

marker

R5W

9

Turn signal

PY 21 W

a

Brake lamp

P21W

b

Reverse lamp

P21W

c

Rear foglamp

(driver’s side)

P 21 W

d

Tail lamp

R5W

e

License plate lamp

R5W

nf_BA.book Page 531 Friday, January 25, 2008 3:53 PM

Page 535 of 666

533 Practical hints

Changing bulbs

5

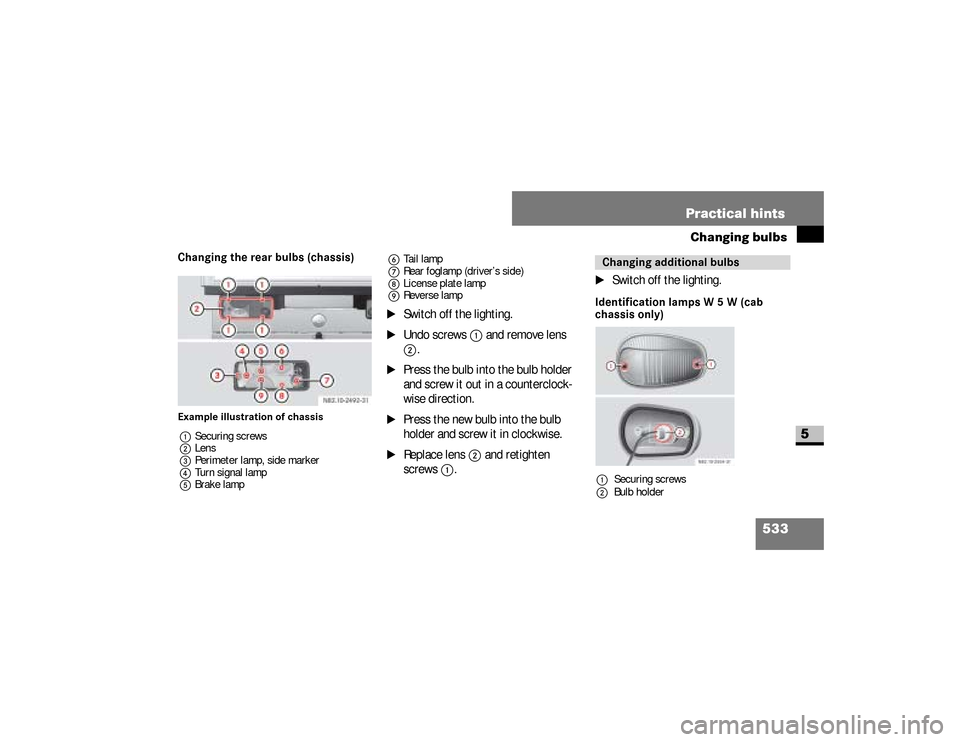

Changing the rear bulbs (chassis)Example illustration of chassis

1Securing screws

2Lens

3Perimeter lamp, side marker

4Turn signal lamp

5Brake lamp6Tail lamp

7Rear foglamp (driver’s side)

8License plate lamp

9Reverse lamp

\1

Switch off the lighting.

\1

Undo screws

1

and remove lens

2

.

\1

Press the bulb into the bulb holder

and screw it out in a counterclock-

wise direction.

\1

Press the new bulb into the bulb

holder and screw it in clockwise.

\1

Replace lens

2

and retighten

screws

1

.

\1

Switch off the lighting.

Identification lamps W 5 W (cab

chassis only) Changing additional bulbs1Securing screws

2Bulb holder

nf_BA.book Page 533 Friday, January 25, 2008 3:53 PM

Page 537 of 666

535 Practical hints

Changing bulbs

5

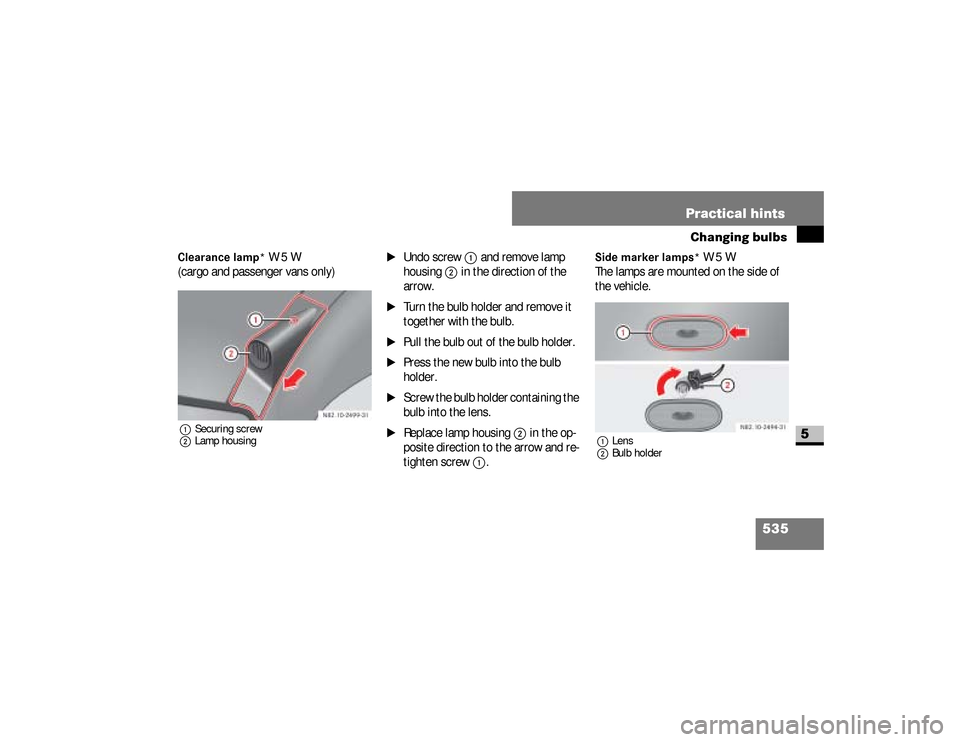

Clearance lamp*

W5W

(cargo and passenger vans only)

1Securing screw

2Lamp housing

\1

Undo screw

1

and remove lamp

housing

2

in the direction of the

arrow.

\1

Turn the bulb holder and remove it

together with the bulb.

\1

Pull the bulb out of the bulb holder.

\1

Press the new bulb into the bulb

holder.

\1

Screw the bulb holder containing the

bulb into the lens.

\1

Replace lamp housing

2

in the op-

posite direction to the arrow and re-

tighten screw

1

.

Side marker lamps*

W5W

The lamps are mounted on the side of

the vehicle.

1Lens

2Bulb holder

nf_BA.book Page 535 Friday, January 25, 2008 3:53 PM

Page 538 of 666

536 Practical hintsChanging bulbs

5

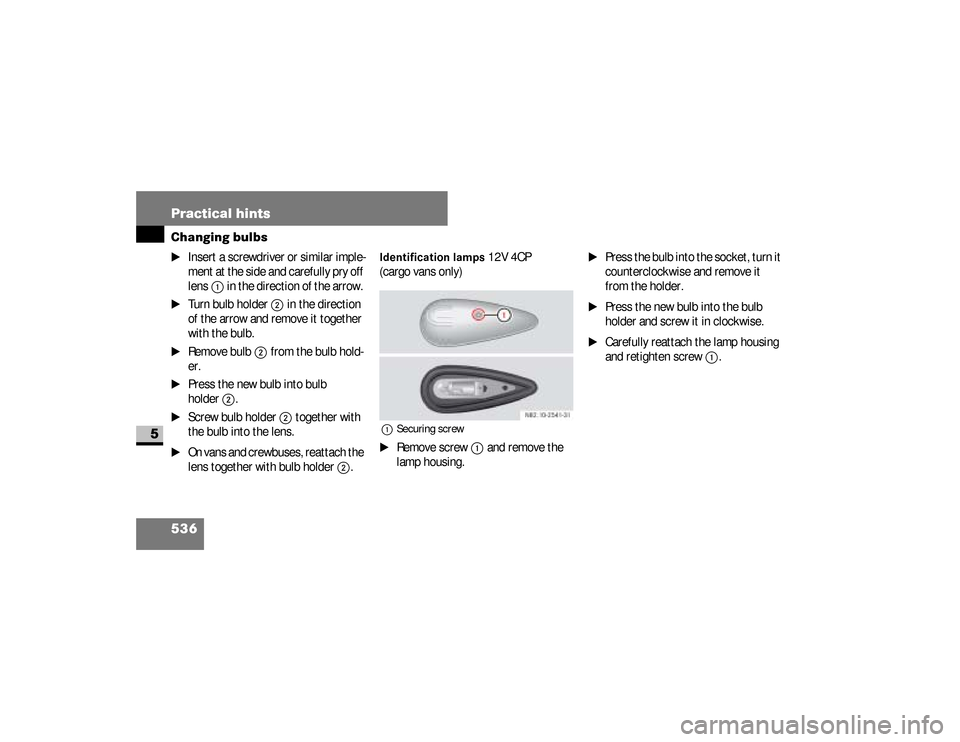

\1

Insert a screwdriver or similar imple-

ment at the side and carefully pry off

lens

1

in the direction of the arrow.

\1

Turn bulb holder

2

in the direction

of the arrow and remove it together

with the bulb.

\1

Remove bulb

2

from the bulb hold-

er.

\1

Press the new bulb into bulb

holder

2

.

\1

Screw bulb holder

2

together with

the bulb into the lens.

\1

On vans and crewbuses, reattach the

lens together with bulb holder

2

.

Identification lamps

12V 4CP

(cargo vans only)

1Securing screw\1

Remove screw

1

and remove the

lamp housing.

\1

Press the bulb into the socket, turn it

counterclockwise and remove it

from the holder.

\1

Press the new bulb into the bulb

holder and screw it in clockwise.

\1

Carefully reattach the lamp housing

and retighten screw

1

.

nf_BA.book Page 536 Friday, January 25, 2008 3:53 PM

Page 550 of 666

548 Practical hintsFlat tire

5

\1

Park the vehicle as far away as pos-

sible from traffic and on a level, firm,

and non-slip surface.

\1

Switch on the hazard warning lamps.

\1

Apply the handbrake.

\1

Engage first gear or reverse gear or

move the selector lever to

position

P.

\1

Any passengers should leave the ve-

hicle, ensuring that they are not en-

dangered as they do so.

\1

Place the warning triangle or hazard

warning lamps at a suitable distance.

Observe legal requirements.Preparing the vehicle

Changing a wheelWarning

G

To avoid the risk of causing serious or fa-

tal injury, or damage to the vehicle, please

bear the following points in mind:The jack is only designed to raise the ve-

hicle for a short time when changing a

wheel.Position the jack under the appropriate

jacking point only (\2page 551). Check

that the jack is correctly seated under the

jacking point before raising the vehicle.The jack must be placed on a firm, flat sur-

face only.

Continued

Warning (Continued)

G

Before raising the vehicle, also secure it

against rolling away, for example using

chocks or similar. Never release the hand-

brake while the vehicle is raised. Make

sure that the distance between the under-

side of the tires and the ground does not

exceed 1.2 in (3 cm). The vehicle could

slip or topple off the jack.Do not reach under the raised vehicle with

your hands or feet.Do not start the engine and avoid creating

other vibrations while the vehicle is

jacked up. The vehicle could slip off the

jack.

nf_BA.book Page 548 Friday, January 25, 2008 3:53 PM

Page 552 of 666

550 Practical hintsFlat tire

5

Hydraulic jack

\1

Assemble the three-part pump lever

for the jack.

1Pressure release screw\1

Close pressure release screw

1

.

\1

To do this, turn the flattened section

on the pump lever clockwise to the

stop.

\1

Insert the pump lever into the recess

on the jack and secure it by turning it

clockwise.

\1

Make sure that the jack is positioned

vertically under the jacking points

described below.

\1

Raise the vehicle by pumping the le-

ver until the wheel is raised clear of

the ground.

Make sure that the distance between

the underside of the tires and the

ground does not exceed 1.2 in

(3 cm).

P58.10-2053-31

iNever turn pressure release

screw

1

mor e than 1 or 2 fu ll turns .

Hydraulic fluid could otherwise es-

cape.

nf_BA.book Page 550 Friday, January 25, 2008 3:53 PM