ECU DODGE SPRINTER 2008 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2008, Model line: SPRINTER, Model: DODGE SPRINTER 2008 2.GPages: 666, PDF Size: 14.11 MB

Page 577 of 666

575 Practical hints

Battery

5

\1

Switch off all electrical consumers.

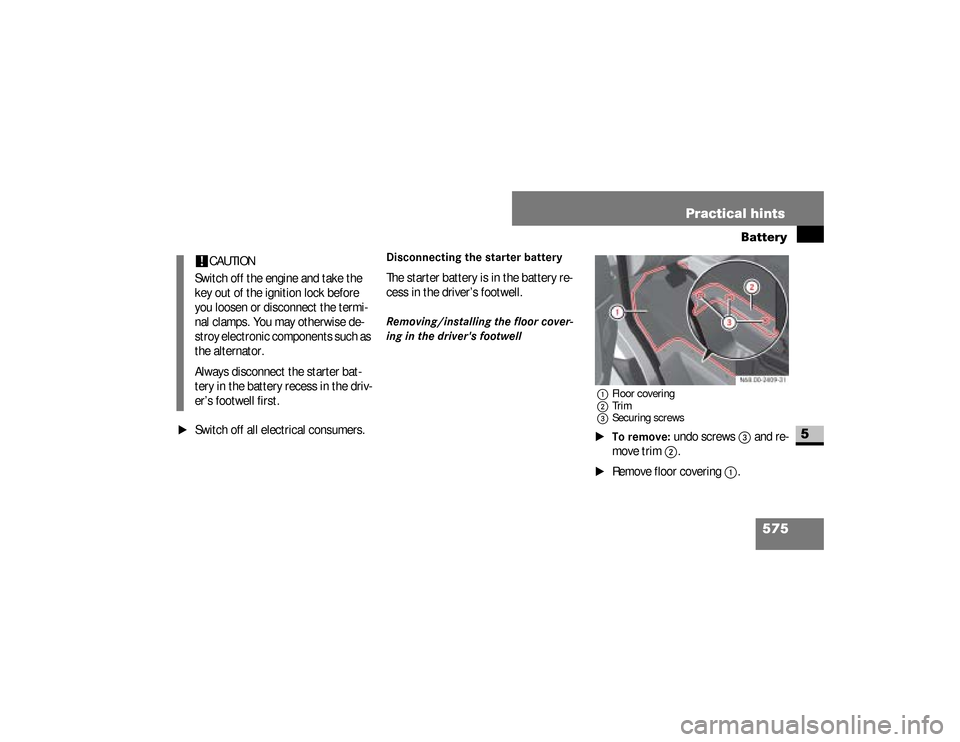

Disconnecting the starter batteryThe starter battery is in the battery re-

cess in the driver’s footwell.Removing/installing the floor cover-

ing in the driver's footwell

1Floor covering

2Trim

3Securing screws\1To remove:

undo screws

3

and re-

move trim

2

.

\1

Remove floor covering

1

.

!

CAUTION

Switch off the engine and take the

key out of the ignition lock before

you loosen or disconnect the termi-

nal clamps. You may otherwise de-

stroy electronic components such as

the alternator.

Always disconnect the starter bat-

tery in the battery recess in the driv-

er’s footwell first.

nf_BA.book Page 575 Friday, January 25, 2008 3:53 PM

Page 578 of 666

576 Practical hintsBattery

5

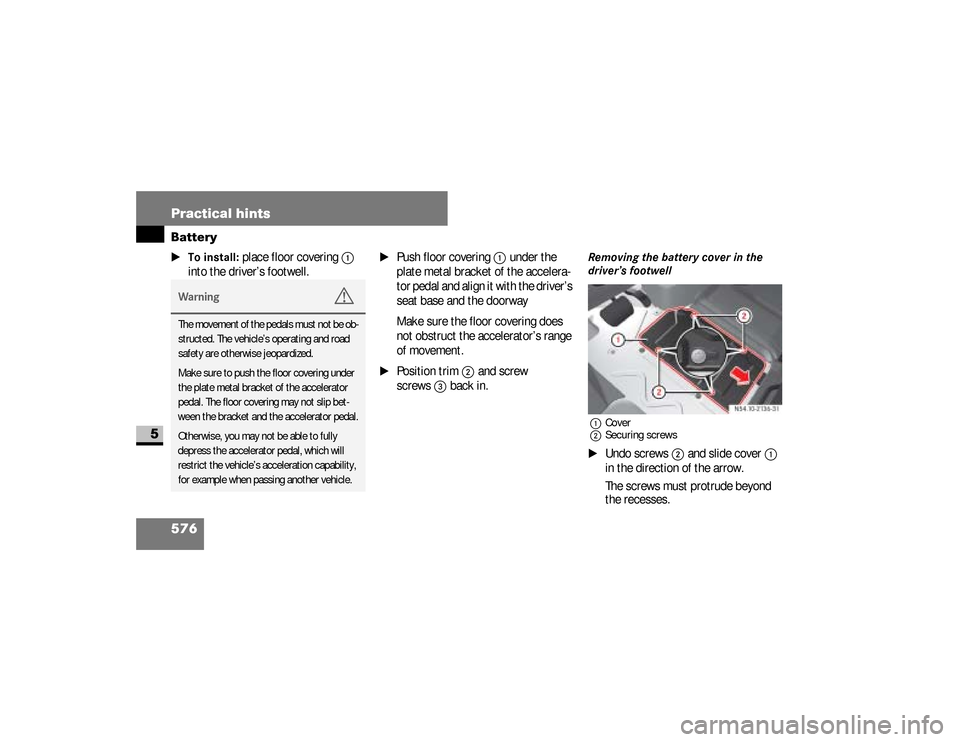

\1To install:

place floor covering

1

into the driver’s footwell.

\1

Push floor covering

1

under the

plate metal bracket of the accelera-

tor pedal and align it with the driver’s

seat base and the doorway

Make sure the floor covering does

not obstruct the accelerator’s range

of movement.

\1

Position trim

2

and screw

screws

3

back in.

Removing the battery cover in the

driver’s footwell1Cover

2Securing screws\1

Undo screws

2

and slide cover

1

in the direction of the arrow.

The screws must protrude beyond

the recesses.

Warning

G

The movement of the pedals must not be ob-

structed. The vehicle’s operating and road

safety are otherwise jeopardized.

Make sure to push the floor covering under

the plate metal bracket of the accelerator

pedal. The floor covering may not slip bet-

ween the bracket and the accelerator pedal.

Otherwise, you may not be able to fully

depress the accelerator pedal, which will

restrict the vehicle’s acceleration capability,

for example when passing another vehicle.

nf_BA.book Page 576 Friday, January 25, 2008 3:53 PM

Page 582 of 666

580 Practical hintsBattery

5

\1

Switch off all electrical consumers.

\1

Connect the positive terminal and

secure the cover.

\1

Connect the negative terminal.

Warning

G

Only charge the battery in well-ventilated

areas. As the battery is being charged,

gases can escape and generate minor ex-

plosions, which can injure you and others

and may cause damage to the paintwork

or permit acid corrosion on the vehicle.

During the charge procedure, there is a

risk of acid burns due to gases escaping

from the battery. Do not, therefore, lean

over the battery while it is being re-

charged.

iIt is also possible to charge the start-

er battery using the jump-starting

connection point in the engine com-

partment (

\2

page 581).

Reconnecting the battery!

CAUTION

Never swap the terminal clamps.

Otherwise, the vehicle’s electronics

system may be damaged. After re-

connecting the battery, you must re-

set the electric sliding door*

(\2

page 92).

nf_BA.book Page 580 Friday, January 25, 2008 3:53 PM

Page 586 of 666

584 Practical hintsJump-starting

5

Use a rigid towing bar and secure this

only to the front towing eye

(\2

page 585).

Tow-starting!

CAUTION

Your vehicle is equipped with an au-

tomatic transmission. Do not tow-

start your vehicle.

Warning

G

When tow-starting another vehicle, its

weight should not be greater than the per-

missible gross weight of your vehicle.

nf_BA.book Page 584 Friday, January 25, 2008 3:53 PM

Page 589 of 666

587 Practical hints

Towing

5

\1

Switch on the ignition (

\2

page 111).

\1

For a distance of up to 30 miles

(50 km), move the selector lever to

position

N.

\1

For a distance greater than 30 miles

(50 km), remove the propeller shafts

to the driven axles.

Take great care when attempting to tow

the vehicle free if its drive wheels have

become embedded in loose earth or

mud, particularly if the vehicle is loaded.

Tow the vehicle smoothly and straight-

ahead. The chassis could otherwise be

damaged.

Do not attempt to tow out the vehicle if

a trailer is coupled up.Where possible, tow the vehicle out

backwards along the track made by the

vehicle previously.

With transmission damage

\1

Always remove the propeller shafts

to the driven axles.

iDeactivate the automatic locking

while driving function when towing .

You could otherwise become locked

out when pushing or towing the vehi-

cle.!

CAUTION

Do not exceed a towing speed of

50 km / h, otherwise the transmis-

sion could be damaged.

Towing out a vehicle that is stuck

Towing the vehicle in the event of

particular malfunctions!

CAUTION

Use new self-securing nuts when in-

stalling the propeller shafts.

nf_BA.book Page 587 Friday, January 25, 2008 3:53 PM

Page 590 of 666

588 Practical hintsTowing

5

With front axle damage

\1

Turn the key to position

1 in the igni-

tion lock(

\2

page 111).

In the event of a malfunction in the

electrical systemIf the battery is malfunctioning, the auto-

matic transmission will be locked in

position

P. To shift the automatic trans-

mission to position

N, you must provide

power to the vehicle’s electrical system

in the same way as jump-starting

(

\2

page 581).

Have the vehicle transported on a trans-

porter or trailer.The towing eye can be used to pull the

vehicle onto a special transporter or

trailer for transportation.

\1

Shift the transmission to neutral or

move the selector lever to

position

N.

!

CAUTION

The vehicle must not be towed with

its front wheels raised and with the

key in position

2 in the ignition lock.

Active brake intervention by ESP

® or

ASR could otherwise lock the wheels

and damage the brake system.

Transporting the vehicle!

CAUTION

Only secure the vehicle at the

wheels / rims. Your vehicle could oth-

erwise be damaged.

nf_BA.book Page 588 Friday, January 25, 2008 3:53 PM

Page 632 of 666

630 *Technical dataLashing points and carrier systems

6

The specified values only apply to loads

on the load compartment floor if:\4

the load is secured to 2 lashing

points on the rail and

\4

the distance to the next lashing point

used on the same rail is about 3 ft

(1 m).Maximum roof load and minimum num-

ber of pairs of roof rack supports on ve-

hicles with:The data is valid when the load is distrib-

uted evenly over the entire roof area.

When using a shorter roof rack, reduce

the load proportionately.

The maximum load is 110 lbs (50 kg) per

pair of roof rack supports.

Roof carrier systems

Maxi-

mum

roof load

Minimum

number

of pairs of

supports

Standard

roof

660 lbs

(300 kg)

6

Raised roof

330 lbs

(150 kg)

3

nf_BA.book Page 630 Friday, January 25, 2008 3:53 PM

Page 634 of 666

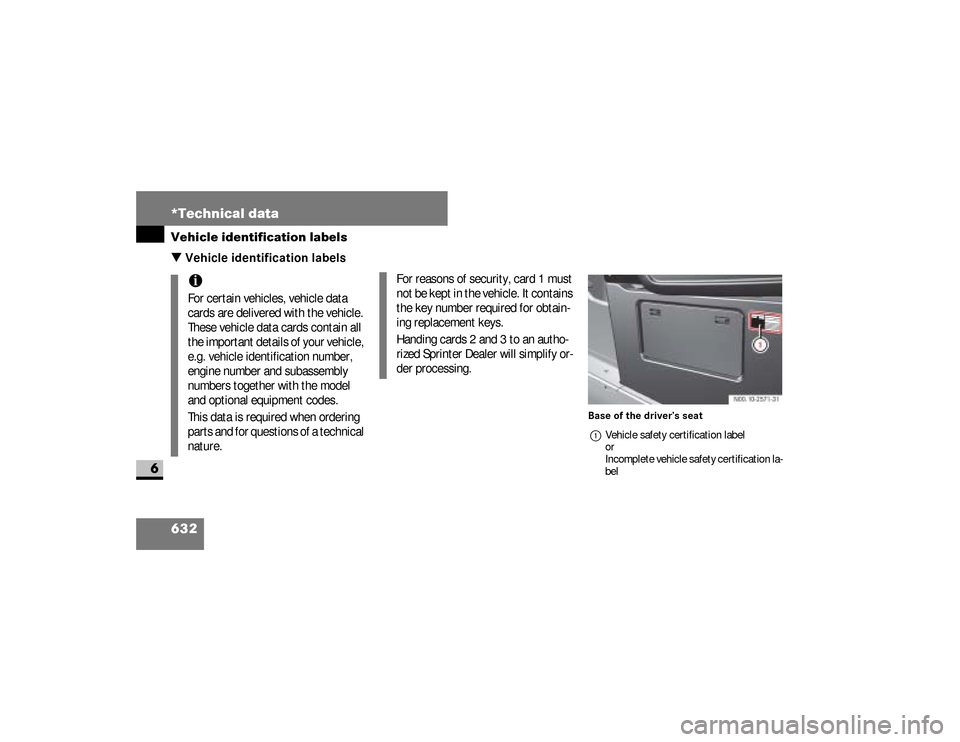

632 *Technical dataVehicle identification labels

6

\3 Vehicle identification labels

Base of the driver’s seat

1Vehicle safety certification label

or

Incomplete vehicle safety certification la-

bel

iFor certain vehicles, vehicle data

cards are delivered with the vehicle.

These vehicle data cards contain all

the important details of your vehicle,

e.g. vehicle identification number,

engine number and subassembly

numbers together with the model

and optional equipment codes.

This data is required when ordering

parts and for questions of a technical

nature.

For reasons of security, card 1 must

not be kept in the vehicle. It contains

the key number required for obtain-

ing replacement keys.

Handing cards 2 and 3 to an autho-

rized Sprinter Dealer will simplify or-

der processing.

nf_BA.book Page 632 Friday, January 25, 2008 3:53 PM

Page 643 of 666

641 Index

Checking tire pressure electronically

with the Advanced Tire Pressure

Monitoring System

(Advanced TPMS)

. . . . . . . . . . . . 373

Checking tire pressure electronically

with the Tire Pressure Monitoring

System (TPMS)

. . . . . . . . . . . . . . 367

Checks, regular

. . . . . . . . . . . . . . 312

Childrenin the vehicle . . . . . . . . . . . . . . . . 55

ISOFIX seat securing system . . . . 61

LATCH type child restraint

system . . . . . . . . . . . . . . . . . . . . . 61

restraint systems . . . . . . . . . . . . . 56Chock

. . . . . . . . . . . . . . . . . . . . . . 521

Cigarette lighter

. . . . . . . . . . . . . 295

Cleaning

. . . . . . . . . . . . . . . . 416

,424

after driving off-road or

on construction sites . . . . . . . . . 425

air cleaner element . . . . . . . . . . 415

cockpit . . . . . . . . . . . . . . . . . . . . 424

headlamps . . . . . . . . . . . . . . . . . 421

padded boss of the steering

wheel . . . . . . . . . . . . . . . . . . . . . 424

radio display . . . . . . . . . . . . . . . 424

rear view camera lens . . . . . . . . 422

rear view camera monitor . . . . . 424

rear window . . . . . . . . . . . . . . . . 421

side windows . . . . . . . . . . . . . . . 421

vehicle . . . . . . . . . . . . . . . . . . . . 418

windshield . . . . . . . . . . . . . . . . . 420

windshield wipers . . . . . . . . . . . 420

Clearance lampchanging bulbs . . . . . . . . . . . . . 535

see identification lamp . . . . . . . 533Clocksetting

vehicles with steering wheel

buttons . . . . . . . . . . . . . . . . . . 168

vehicles without steering

wheel buttons . . . . . . . . . . . . 150Cockpit

. . . . . . . . . . . . . . . . . . . . . .18

Cold tire inflation pressure

. . . . 394

COMANDsee the separate Operating

InstructionsComfort seat

. . . . . . . . . . . . . . . . 114

Constant headlamp mode

. . . . . 171

nf_BA.book Page 641 Friday, January 25, 2008 3:53 PM

Page 650 of 666

648 Indexbrake pad/lining wear . . . . . . . . 470

coolant . . . . . . . . . . . . . . . . . . . . 474

engine diagnostic . . . . . . . . . . . . 477

ESP

®

. . . . . . . . . . . . . . . . . 462

,468

handbrake . . . . . . . . . . . . . . . . . 189

operating speed governor (ADR) . . 274poly-V-belt . . . . . . . . . . . . . . . . . 469

preglow . . . . . . . . . . . . . . . 186

,476

reserve warning

indicator (fuel) . . . . . . . . . . 475,476

windshield washer/headlamp

cleaning system washer fluid

level . . . . . . . . . . . . . . . . . . . . . . 482

Inflation pressuresee Tires, Inflation pressuresInformation regarding electronic

recording devices

. . . . . . . . . . . . . 16

Instrument cluster

. . . . . . . . 20

,142

lighting . . . . . . . . . . . . . . . . . . . . 144

speedometer . . . . . . . . . . . . . . . 145

tachometer . . . . . . . . . . . . . . . . 145

vehicles with steering wheel buttons

selecting the language . . . . . . 166

setting the status line . . . . . . . 167

Instrument lighting

. . . . . . . . . . . 144

Interior lightingchanging bulbs . . . . . . . . . . . . . . 537

front . . . . . . . . . . . . . . . . . . . . . . 137

rear . . . . . . . . . . . . . . . . . . . . . . 138Interior lighting, rear

. . . . . . . . . 138

Interior motion sensor

. . . . . . . . . 80

Intermittent wipe

. . . . . . . . . . . . 210

ISOFIX child seat securing

system

. . . . . . . . . . . . . . . . . . . . . . 61

TopTether . . . . . . . . . . . . . . . . . . 64

J

Jackjacking points . . . . . . . . . . . . . . 551

preparing . . . . . . . . . . . . . . . . . . 550

storage location . . . . . . . . . . . . . 515Jump-starting

. . . . . . . . . . . . . . . 581

connection point . . . . . . . . . . . . 582

Jump-starting connection

point

. . . . . . . . . . . . . . . . . . . . . . . 582

J

nf_BA.book Page 648 Friday, January 25, 2008 3:53 PM