DODGE TOWN AND COUNTRY 2001 Service Manual

Manufacturer: DODGE, Model Year: 2001, Model line: TOWN AND COUNTRY, Model: DODGE TOWN AND COUNTRY 2001Pages: 2321, PDF Size: 68.09 MB

Page 1271 of 2321

(2) Alternative Method:

²Support the weight of the crankshaft with a jack

under the counterweight adjacent to the bearing

being checked.

(3) Remove oil film from surface to be checked.

Plastigage is soluble in oil.

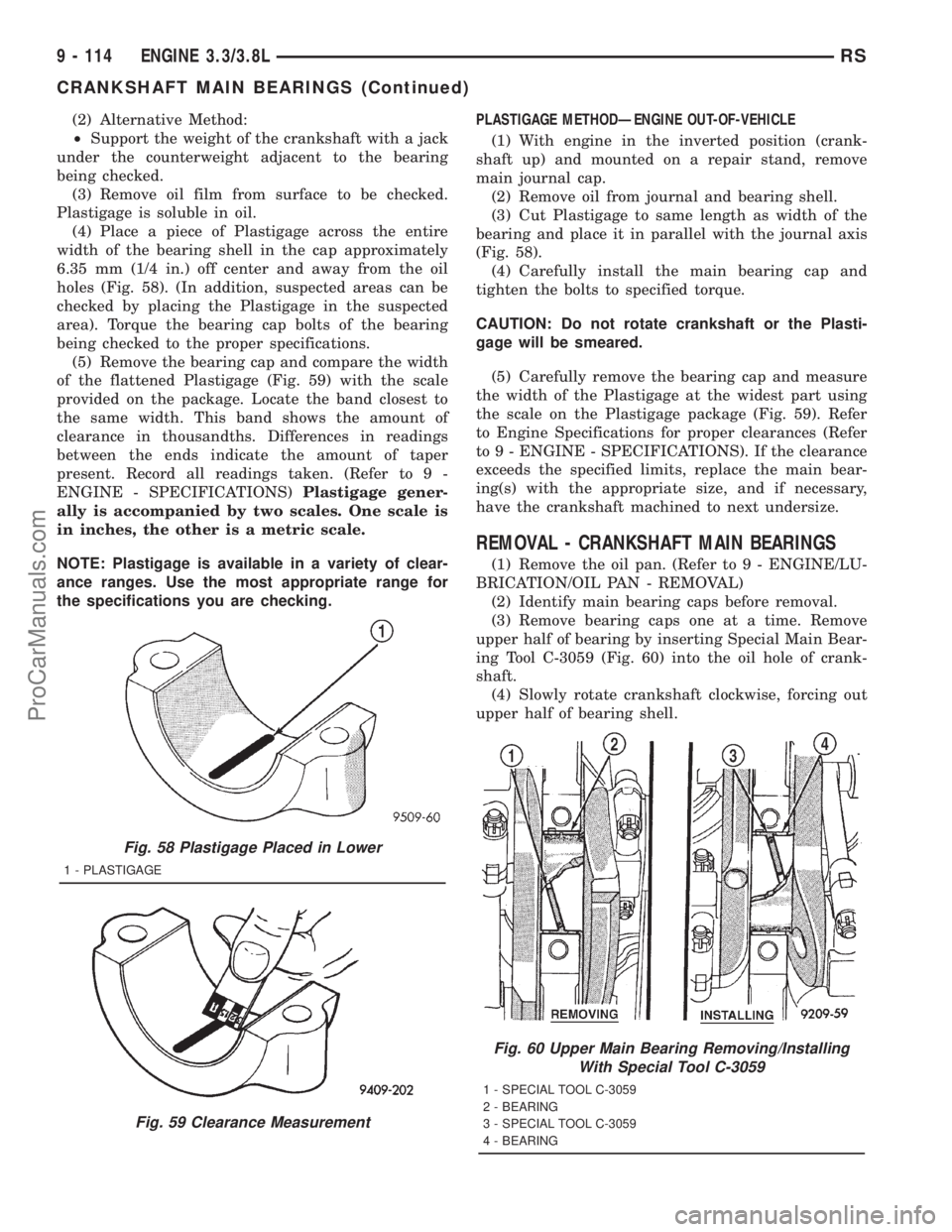

(4) Place a piece of Plastigage across the entire

width of the bearing shell in the cap approximately

6.35 mm (1/4 in.) off center and away from the oil

holes (Fig. 58). (In addition, suspected areas can be

checked by placing the Plastigage in the suspected

area). Torque the bearing cap bolts of the bearing

being checked to the proper specifications.

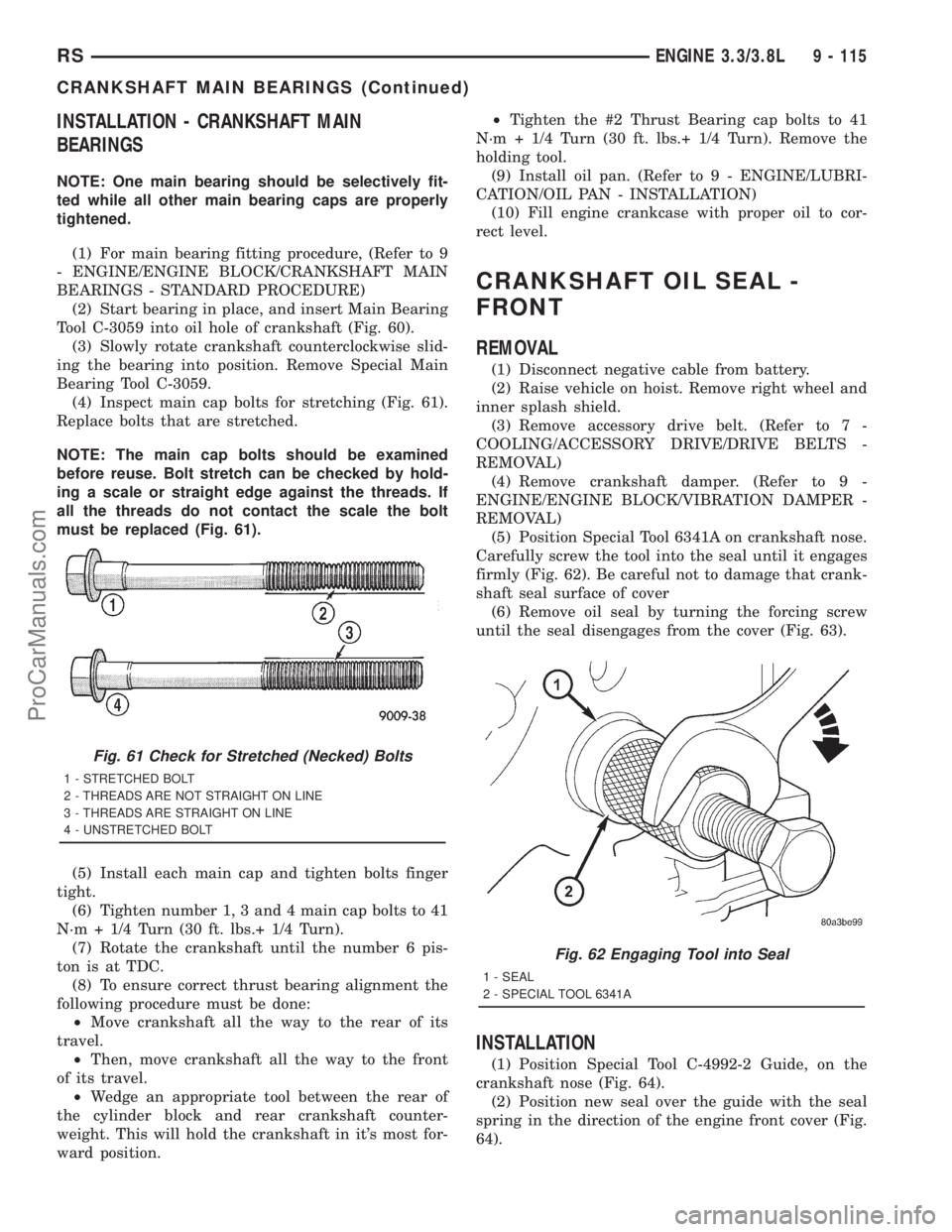

(5) Remove the bearing cap and compare the width

of the flattened Plastigage (Fig. 59) with the scale

provided on the package. Locate the band closest to

the same width. This band shows the amount of

clearance in thousandths. Differences in readings

between the ends indicate the amount of taper

present. Record all readings taken. (Refer to 9 -

ENGINE - SPECIFICATIONS)Plastigage gener-

ally is accompanied by two scales. One scale is

in inches, the other is a metric scale.

NOTE: Plastigage is available in a variety of clear-

ance ranges. Use the most appropriate range for

the specifications you are checking.PLASTIGAGE METHODÐENGINE OUT-OF-VEHICLE

(1) With engine in the inverted position (crank-

shaft up) and mounted on a repair stand, remove

main journal cap.

(2) Remove oil from journal and bearing shell.

(3) Cut Plastigage to same length as width of the

bearing and place it in parallel with the journal axis

(Fig. 58).

(4) Carefully install the main bearing cap and

tighten the bolts to specified torque.

CAUTION: Do not rotate crankshaft or the Plasti-

gage will be smeared.

(5) Carefully remove the bearing cap and measure

the width of the Plastigage at the widest part using

the scale on the Plastigage package (Fig. 59). Refer

to Engine Specifications for proper clearances (Refer

to 9 - ENGINE - SPECIFICATIONS). If the clearance

exceeds the specified limits, replace the main bear-

ing(s) with the appropriate size, and if necessary,

have the crankshaft machined to next undersize.

REMOVAL - CRANKSHAFT MAIN BEARINGS

(1) Remove the oil pan. (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL)

(2) Identify main bearing caps before removal.

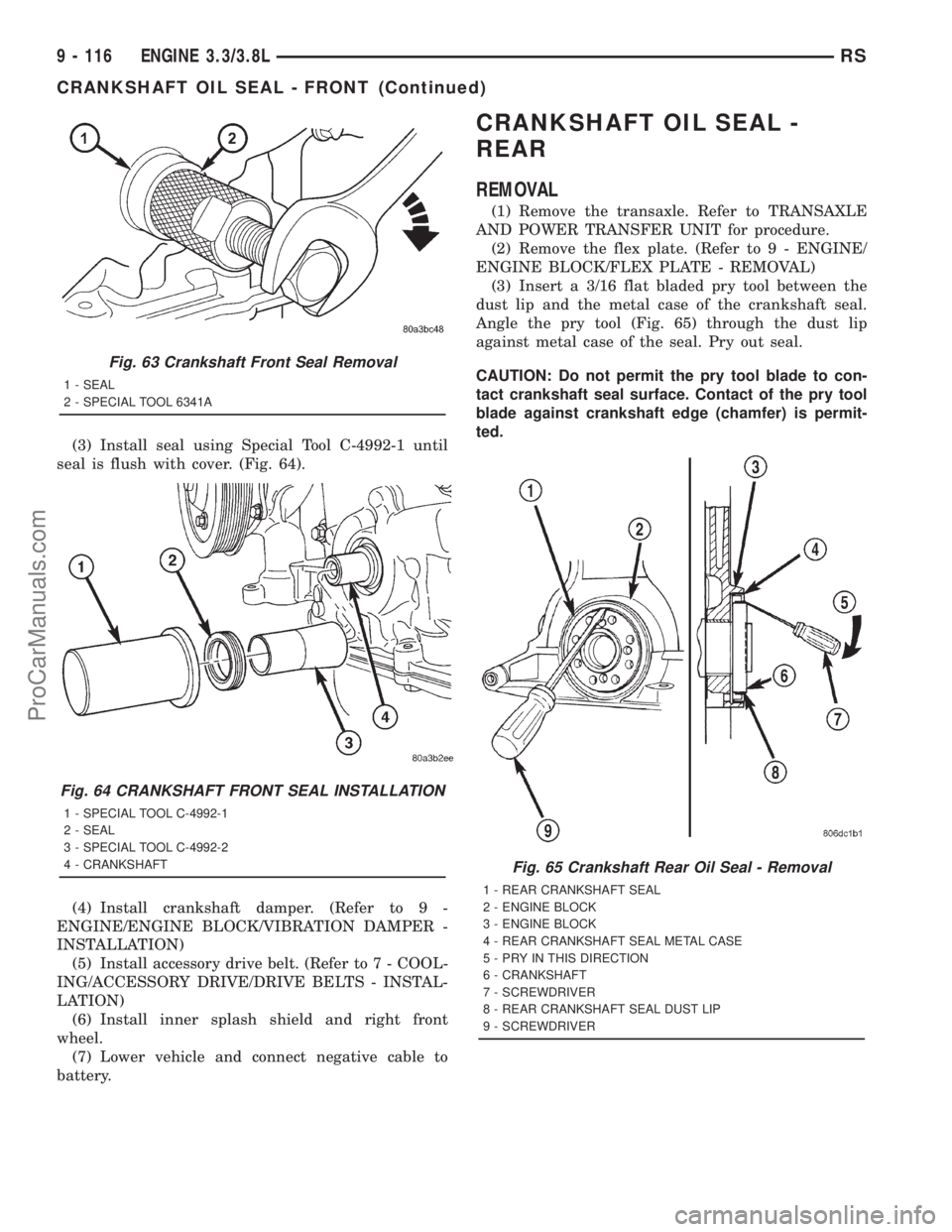

(3) Remove bearing caps one at a time. Remove

upper half of bearing by inserting Special Main Bear-

ing Tool C-3059 (Fig. 60) into the oil hole of crank-

shaft.

(4) Slowly rotate crankshaft clockwise, forcing out

upper half of bearing shell.

Fig. 58 Plastigage Placed in Lower

1 - PLASTIGAGE

Fig. 59 Clearance Measurement

Fig. 60 Upper Main Bearing Removing/Installing

With Special Tool C-3059

1 - SPECIAL TOOL C-3059

2 - BEARING

3 - SPECIAL TOOL C-3059

4 - BEARING

9 - 114 ENGINE 3.3/3.8LRS

CRANKSHAFT MAIN BEARINGS (Continued)

ProCarManuals.com

Page 1272 of 2321

INSTALLATION - CRANKSHAFT MAIN

BEARINGS

NOTE: One main bearing should be selectively fit-

ted while all other main bearing caps are properly

tightened.

(1) For main bearing fitting procedure, (Refer to 9

- ENGINE/ENGINE BLOCK/CRANKSHAFT MAIN

BEARINGS - STANDARD PROCEDURE)

(2) Start bearing in place, and insert Main Bearing

Tool C-3059 into oil hole of crankshaft (Fig. 60).

(3) Slowly rotate crankshaft counterclockwise slid-

ing the bearing into position. Remove Special Main

Bearing Tool C-3059.

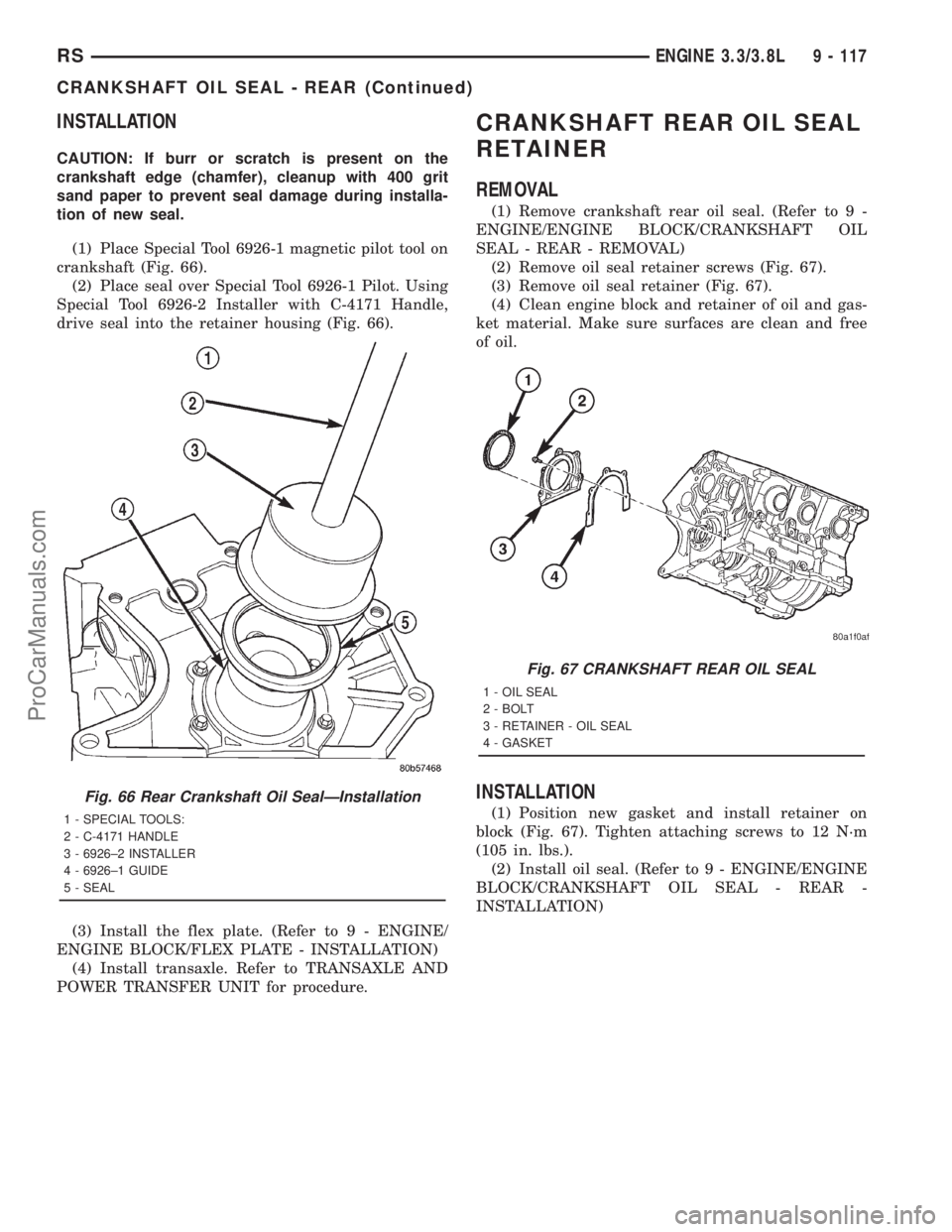

(4) Inspect main cap bolts for stretching (Fig. 61).

Replace bolts that are stretched.

NOTE: The main cap bolts should be examined

before reuse. Bolt stretch can be checked by hold-

ing a scale or straight edge against the threads. If

all the threads do not contact the scale the bolt

must be replaced (Fig. 61).

(5) Install each main cap and tighten bolts finger

tight.

(6) Tighten number 1, 3 and 4 main cap bolts to 41

N´m + 1/4 Turn (30 ft. lbs.+ 1/4 Turn).

(7) Rotate the crankshaft until the number 6 pis-

ton is at TDC.

(8) To ensure correct thrust bearing alignment the

following procedure must be done:

²Move crankshaft all the way to the rear of its

travel.

²Then, move crankshaft all the way to the front

of its travel.

²Wedge an appropriate tool between the rear of

the cylinder block and rear crankshaft counter-

weight. This will hold the crankshaft in it's most for-

ward position.²Tighten the #2 Thrust Bearing cap bolts to 41

N´m + 1/4 Turn (30 ft. lbs.+ 1/4 Turn). Remove the

holding tool.

(9) Install oil pan. (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - INSTALLATION)

(10) Fill engine crankcase with proper oil to cor-

rect level.

CRANKSHAFT OIL SEAL -

FRONT

REMOVAL

(1) Disconnect negative cable from battery.

(2) Raise vehicle on hoist. Remove right wheel and

inner splash shield.

(3) Remove accessory drive belt. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL)

(4) Remove crankshaft damper. (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL)

(5) Position Special Tool 6341A on crankshaft nose.

Carefully screw the tool into the seal until it engages

firmly (Fig. 62). Be careful not to damage that crank-

shaft seal surface of cover

(6) Remove oil seal by turning the forcing screw

until the seal disengages from the cover (Fig. 63).

INSTALLATION

(1) Position Special Tool C-4992-2 Guide, on the

crankshaft nose (Fig. 64).

(2) Position new seal over the guide with the seal

spring in the direction of the engine front cover (Fig.

64).

Fig. 61 Check for Stretched (Necked) Bolts

1 - STRETCHED BOLT

2 - THREADS ARE NOT STRAIGHT ON LINE

3 - THREADS ARE STRAIGHT ON LINE

4 - UNSTRETCHED BOLT

Fig. 62 Engaging Tool into Seal

1 - SEAL

2 - SPECIAL TOOL 6341A

RSENGINE 3.3/3.8L9 - 115

CRANKSHAFT MAIN BEARINGS (Continued)

ProCarManuals.com

Page 1273 of 2321

(3) Install seal using Special Tool C-4992-1 until

seal is flush with cover. (Fig. 64).

(4) Install crankshaft damper. (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

INSTALLATION)

(5) Install accessory drive belt. (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION)

(6) Install inner splash shield and right front

wheel.

(7) Lower vehicle and connect negative cable to

battery.

CRANKSHAFT OIL SEAL -

REAR

REMOVAL

(1) Remove the transaxle. Refer to TRANSAXLE

AND POWER TRANSFER UNIT for procedure.

(2) Remove the flex plate. (Refer to 9 - ENGINE/

ENGINE BLOCK/FLEX PLATE - REMOVAL)

(3) Insert a 3/16 flat bladed pry tool between the

dust lip and the metal case of the crankshaft seal.

Angle the pry tool (Fig. 65) through the dust lip

against metal case of the seal. Pry out seal.

CAUTION: Do not permit the pry tool blade to con-

tact crankshaft seal surface. Contact of the pry tool

blade against crankshaft edge (chamfer) is permit-

ted.

Fig. 63 Crankshaft Front Seal Removal

1 - SEAL

2 - SPECIAL TOOL 6341A

Fig. 64 CRANKSHAFT FRONT SEAL INSTALLATION

1 - SPECIAL TOOL C-4992-1

2 - SEAL

3 - SPECIAL TOOL C-4992-2

4 - CRANKSHAFT

Fig. 65 Crankshaft Rear Oil Seal - Removal

1 - REAR CRANKSHAFT SEAL

2 - ENGINE BLOCK

3 - ENGINE BLOCK

4 - REAR CRANKSHAFT SEAL METAL CASE

5 - PRY IN THIS DIRECTION

6 - CRANKSHAFT

7 - SCREWDRIVER

8 - REAR CRANKSHAFT SEAL DUST LIP

9 - SCREWDRIVER

9 - 116 ENGINE 3.3/3.8LRS

CRANKSHAFT OIL SEAL - FRONT (Continued)

ProCarManuals.com

Page 1274 of 2321

INSTALLATION

CAUTION: If burr or scratch is present on the

crankshaft edge (chamfer), cleanup with 400 grit

sand paper to prevent seal damage during installa-

tion of new seal.

(1) Place Special Tool 6926-1 magnetic pilot tool on

crankshaft (Fig. 66).

(2) Place seal over Special Tool 6926-1 Pilot. Using

Special Tool 6926-2 Installer with C-4171 Handle,

drive seal into the retainer housing (Fig. 66).

(3) Install the flex plate. (Refer to 9 - ENGINE/

ENGINE BLOCK/FLEX PLATE - INSTALLATION)

(4) Install transaxle. Refer to TRANSAXLE AND

POWER TRANSFER UNIT for procedure.

CRANKSHAFT REAR OIL SEAL

RETAINER

REMOVAL

(1) Remove crankshaft rear oil seal. (Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT OIL

SEAL - REAR - REMOVAL)

(2) Remove oil seal retainer screws (Fig. 67).

(3) Remove oil seal retainer (Fig. 67).

(4) Clean engine block and retainer of oil and gas-

ket material. Make sure surfaces are clean and free

of oil.

INSTALLATION

(1) Position new gasket and install retainer on

block (Fig. 67). Tighten attaching screws to 12 N´m

(105 in. lbs.).

(2) Install oil seal. (Refer to 9 - ENGINE/ENGINE

BLOCK/CRANKSHAFT OIL SEAL - REAR -

INSTALLATION)

Fig. 66 Rear Crankshaft Oil SealÐInstallation

1 - SPECIAL TOOLS:

2 - C-4171 HANDLE

3 - 6926±2 INSTALLER

4 - 6926±1 GUIDE

5 - SEAL

Fig. 67 CRANKSHAFT REAR OIL SEAL

1 - OIL SEAL

2 - BOLT

3 - RETAINER - OIL SEAL

4 - GASKET

RSENGINE 3.3/3.8L9 - 117

CRANKSHAFT OIL SEAL - REAR (Continued)

ProCarManuals.com

Page 1275 of 2321

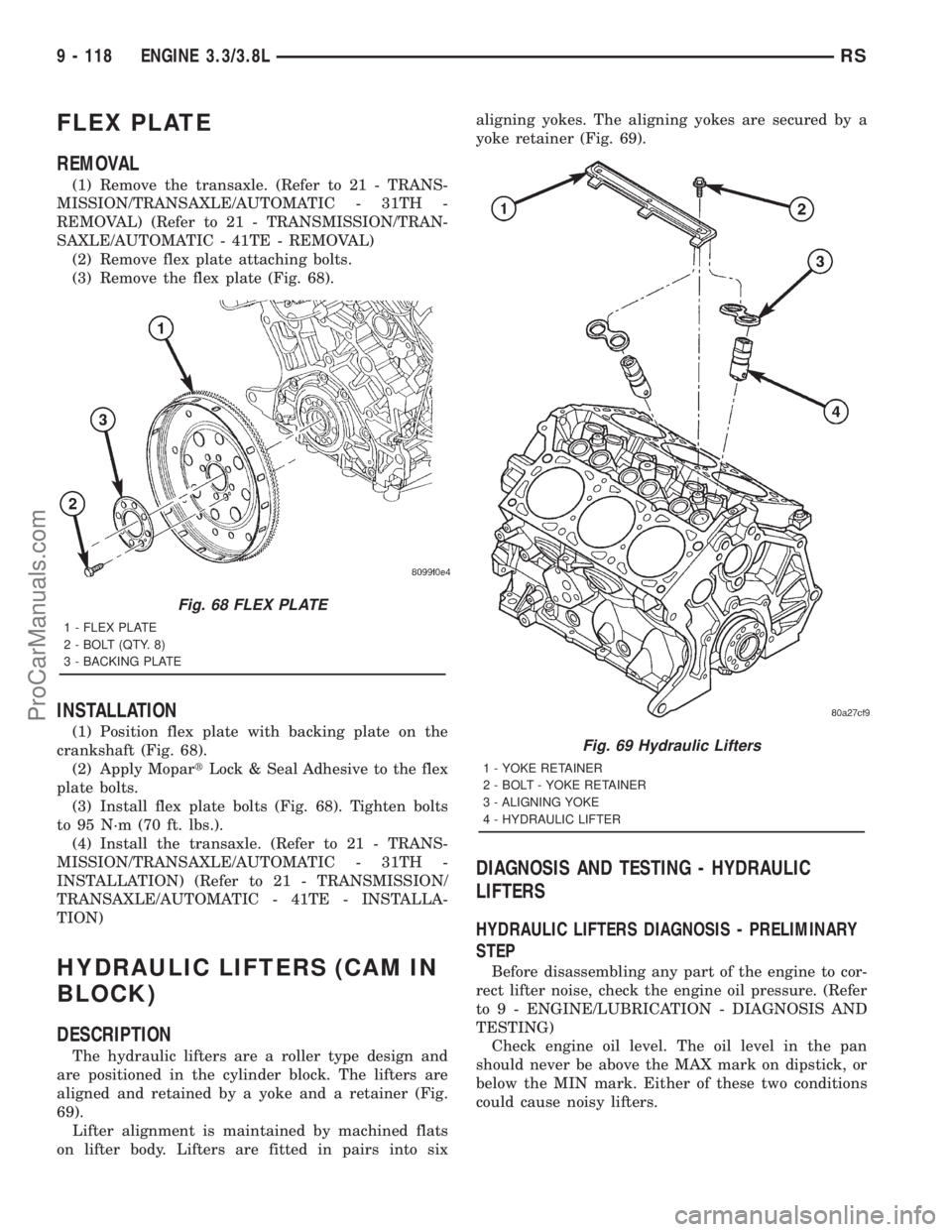

FLEX PLATE

REMOVAL

(1) Remove the transaxle. (Refer to 21 - TRANS-

MISSION/TRANSAXLE/AUTOMATIC - 31TH -

REMOVAL) (Refer to 21 - TRANSMISSION/TRAN-

SAXLE/AUTOMATIC - 41TE - REMOVAL)

(2) Remove flex plate attaching bolts.

(3) Remove the flex plate (Fig. 68).

INSTALLATION

(1) Position flex plate with backing plate on the

crankshaft (Fig. 68).

(2) Apply MopartLock & Seal Adhesive to the flex

plate bolts.

(3) Install flex plate bolts (Fig. 68). Tighten bolts

to 95 N´m (70 ft. lbs.).

(4) Install the transaxle. (Refer to 21 - TRANS-

MISSION/TRANSAXLE/AUTOMATIC - 31TH -

INSTALLATION) (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 41TE - INSTALLA-

TION)

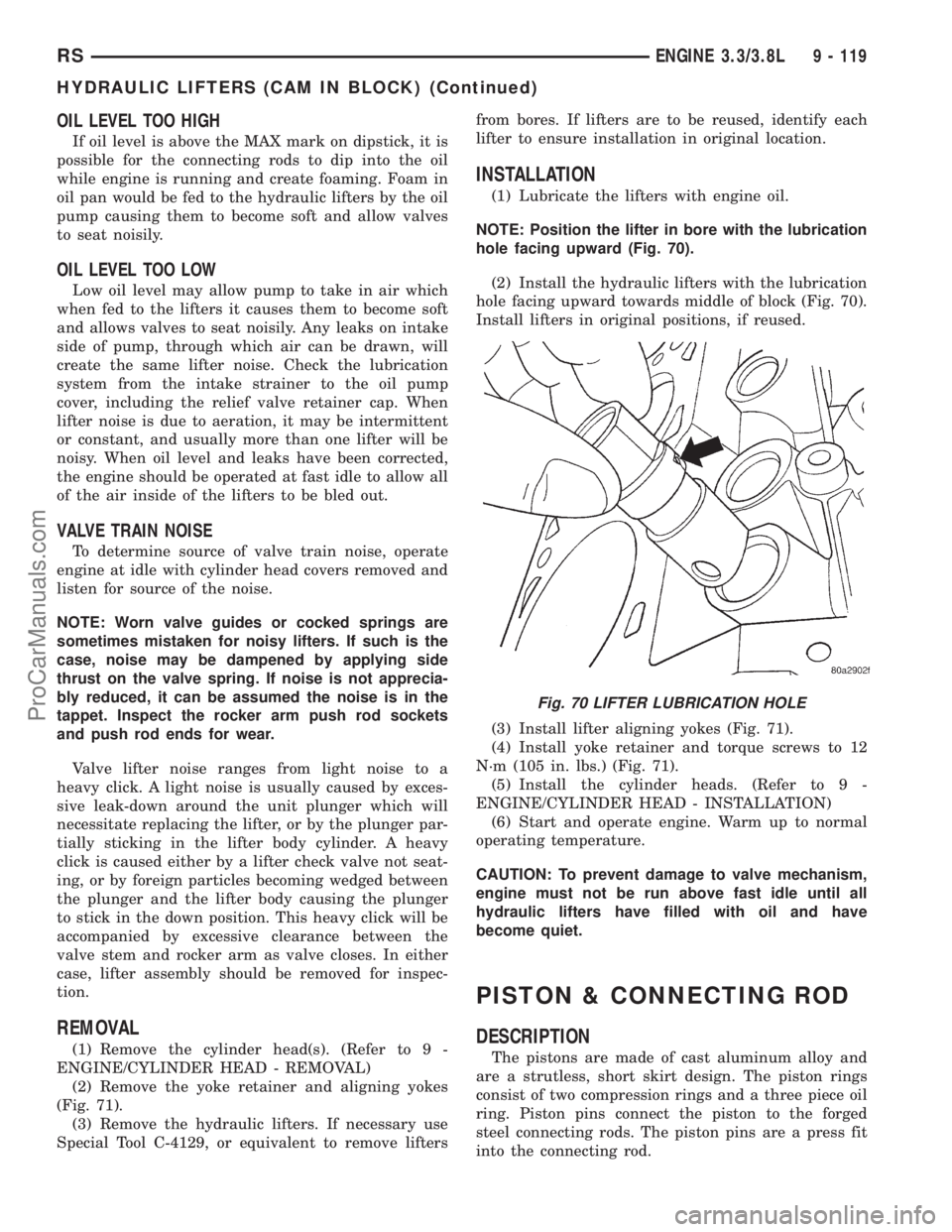

HYDRAULIC LIFTERS (CAM IN

BLOCK)

DESCRIPTION

The hydraulic lifters are a roller type design and

are positioned in the cylinder block. The lifters are

aligned and retained by a yoke and a retainer (Fig.

69).

Lifter alignment is maintained by machined flats

on lifter body. Lifters are fitted in pairs into sixaligning yokes. The aligning yokes are secured by a

yoke retainer (Fig. 69).

DIAGNOSIS AND TESTING - HYDRAULIC

LIFTERS

HYDRAULIC LIFTERS DIAGNOSIS - PRELIMINARY

STEP

Before disassembling any part of the engine to cor-

rect lifter noise, check the engine oil pressure. (Refer

to 9 - ENGINE/LUBRICATION - DIAGNOSIS AND

TESTING)

Check engine oil level. The oil level in the pan

should never be above the MAX mark on dipstick, or

below the MIN mark. Either of these two conditions

could cause noisy lifters.

Fig. 68 FLEX PLATE

1 - FLEX PLATE

2 - BOLT (QTY. 8)

3 - BACKING PLATE

Fig. 69 Hydraulic Lifters

1 - YOKE RETAINER

2 - BOLT - YOKE RETAINER

3 - ALIGNING YOKE

4 - HYDRAULIC LIFTER

9 - 118 ENGINE 3.3/3.8LRS

ProCarManuals.com

Page 1276 of 2321

OIL LEVEL TOO HIGH

If oil level is above the MAX mark on dipstick, it is

possible for the connecting rods to dip into the oil

while engine is running and create foaming. Foam in

oil pan would be fed to the hydraulic lifters by the oil

pump causing them to become soft and allow valves

to seat noisily.

OIL LEVEL TOO LOW

Low oil level may allow pump to take in air which

when fed to the lifters it causes them to become soft

and allows valves to seat noisily. Any leaks on intake

side of pump, through which air can be drawn, will

create the same lifter noise. Check the lubrication

system from the intake strainer to the oil pump

cover, including the relief valve retainer cap. When

lifter noise is due to aeration, it may be intermittent

or constant, and usually more than one lifter will be

noisy. When oil level and leaks have been corrected,

the engine should be operated at fast idle to allow all

of the air inside of the lifters to be bled out.

VALVE TRAIN NOISE

To determine source of valve train noise, operate

engine at idle with cylinder head covers removed and

listen for source of the noise.

NOTE: Worn valve guides or cocked springs are

sometimes mistaken for noisy lifters. If such is the

case, noise may be dampened by applying side

thrust on the valve spring. If noise is not apprecia-

bly reduced, it can be assumed the noise is in the

tappet. Inspect the rocker arm push rod sockets

and push rod ends for wear.

Valve lifter noise ranges from light noise to a

heavy click. A light noise is usually caused by exces-

sive leak-down around the unit plunger which will

necessitate replacing the lifter, or by the plunger par-

tially sticking in the lifter body cylinder. A heavy

click is caused either by a lifter check valve not seat-

ing, or by foreign particles becoming wedged between

the plunger and the lifter body causing the plunger

to stick in the down position. This heavy click will be

accompanied by excessive clearance between the

valve stem and rocker arm as valve closes. In either

case, lifter assembly should be removed for inspec-

tion.

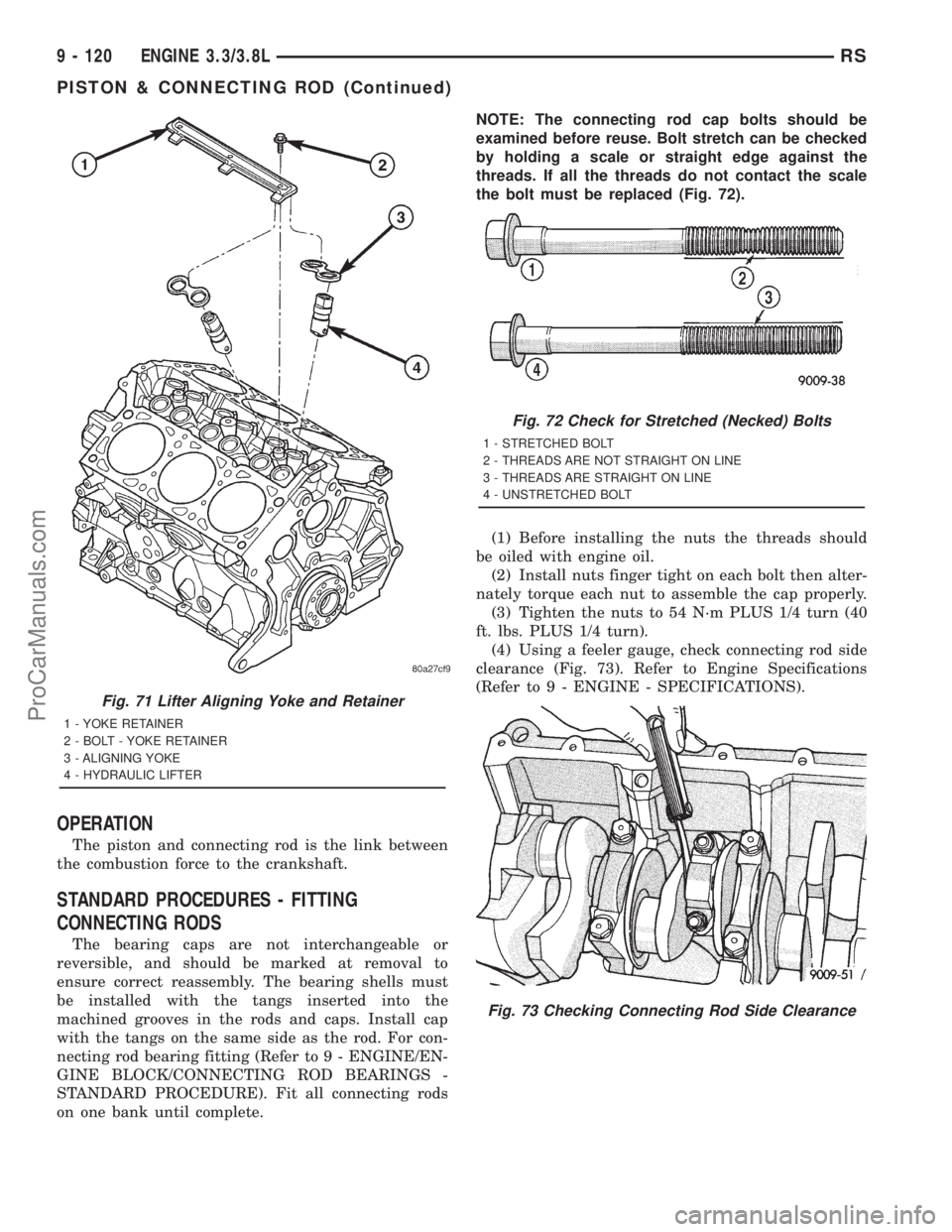

REMOVAL

(1) Remove the cylinder head(s). (Refer to 9 -

ENGINE/CYLINDER HEAD - REMOVAL)

(2) Remove the yoke retainer and aligning yokes

(Fig. 71).

(3) Remove the hydraulic lifters. If necessary use

Special Tool C-4129, or equivalent to remove liftersfrom bores. If lifters are to be reused, identify each

lifter to ensure installation in original location.

INSTALLATION

(1) Lubricate the lifters with engine oil.

NOTE: Position the lifter in bore with the lubrication

hole facing upward (Fig. 70).

(2) Install the hydraulic lifters with the lubrication

hole facing upward towards middle of block (Fig. 70).

Install lifters in original positions, if reused.

(3) Install lifter aligning yokes (Fig. 71).

(4) Install yoke retainer and torque screws to 12

N´m (105 in. lbs.) (Fig. 71).

(5) Install the cylinder heads. (Refer to 9 -

ENGINE/CYLINDER HEAD - INSTALLATION)

(6) Start and operate engine. Warm up to normal

operating temperature.

CAUTION: To prevent damage to valve mechanism,

engine must not be run above fast idle until all

hydraulic lifters have filled with oil and have

become quiet.

PISTON & CONNECTING ROD

DESCRIPTION

The pistons are made of cast aluminum alloy and

are a strutless, short skirt design. The piston rings

consist of two compression rings and a three piece oil

ring. Piston pins connect the piston to the forged

steel connecting rods. The piston pins are a press fit

into the connecting rod.

Fig. 70 LIFTER LUBRICATION HOLE

RSENGINE 3.3/3.8L9 - 119

HYDRAULIC LIFTERS (CAM IN BLOCK) (Continued)

ProCarManuals.com

Page 1277 of 2321

OPERATION

The piston and connecting rod is the link between

the combustion force to the crankshaft.

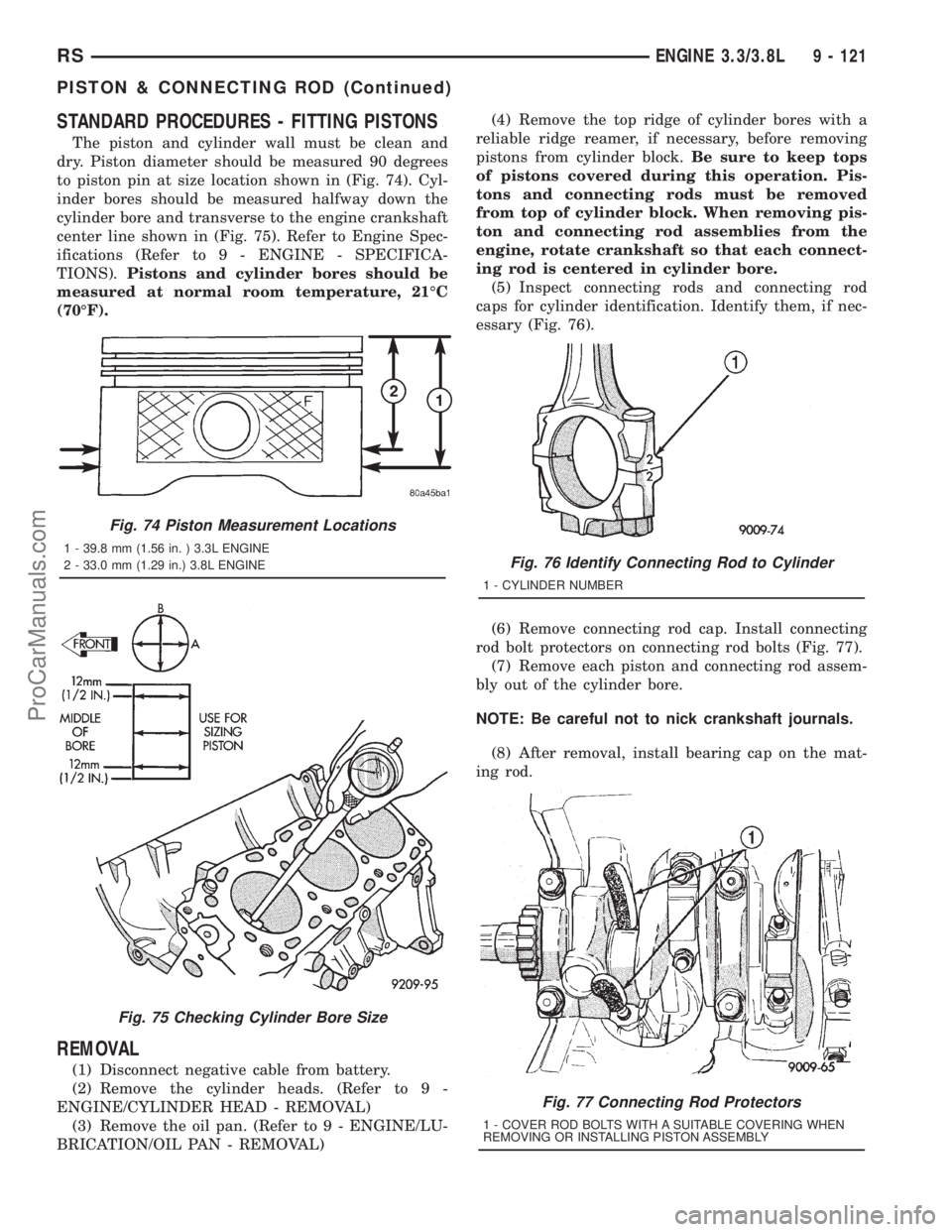

STANDARD PROCEDURES - FITTING

CONNECTING RODS

The bearing caps are not interchangeable or

reversible, and should be marked at removal to

ensure correct reassembly. The bearing shells must

be installed with the tangs inserted into the

machined grooves in the rods and caps. Install cap

with the tangs on the same side as the rod. For con-

necting rod bearing fitting (Refer to 9 - ENGINE/EN-

GINE BLOCK/CONNECTING ROD BEARINGS -

STANDARD PROCEDURE). Fit all connecting rods

on one bank until complete.NOTE: The connecting rod cap bolts should be

examined before reuse. Bolt stretch can be checked

by holding a scale or straight edge against the

threads. If all the threads do not contact the scale

the bolt must be replaced (Fig. 72).

(1) Before installing the nuts the threads should

be oiled with engine oil.

(2) Install nuts finger tight on each bolt then alter-

nately torque each nut to assemble the cap properly.

(3) Tighten the nuts to 54 N´m PLUS 1/4 turn (40

ft. lbs. PLUS 1/4 turn).

(4) Using a feeler gauge, check connecting rod side

clearance (Fig. 73). Refer to Engine Specifications

(Refer to 9 - ENGINE - SPECIFICATIONS).

Fig. 71 Lifter Aligning Yoke and Retainer

1 - YOKE RETAINER

2 - BOLT - YOKE RETAINER

3 - ALIGNING YOKE

4 - HYDRAULIC LIFTER

Fig. 72 Check for Stretched (Necked) Bolts

1 - STRETCHED BOLT

2 - THREADS ARE NOT STRAIGHT ON LINE

3 - THREADS ARE STRAIGHT ON LINE

4 - UNSTRETCHED BOLT

Fig. 73 Checking Connecting Rod Side Clearance

9 - 120 ENGINE 3.3/3.8LRS

PISTON & CONNECTING ROD (Continued)

ProCarManuals.com

Page 1278 of 2321

STANDARD PROCEDURES - FITTING PISTONS

The piston and cylinder wall must be clean and

dry. Piston diameter should be measured 90 degrees

to piston pin at size location shown in (Fig. 74). Cyl-

inder bores should be measured halfway down the

cylinder bore and transverse to the engine crankshaft

center line shown in (Fig. 75). Refer to Engine Spec-

ifications (Refer to 9 - ENGINE - SPECIFICA-

TIONS).Pistons and cylinder bores should be

measured at normal room temperature, 21ÉC

(70ÉF).

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the cylinder heads. (Refer to 9 -

ENGINE/CYLINDER HEAD - REMOVAL)

(3) Remove the oil pan. (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL)(4) Remove the top ridge of cylinder bores with a

reliable ridge reamer, if necessary, before removing

pistons from cylinder block.Be sure to keep tops

of pistons covered during this operation. Pis-

tons and connecting rods must be removed

from top of cylinder block. When removing pis-

ton and connecting rod assemblies from the

engine, rotate crankshaft so that each connect-

ing rod is centered in cylinder bore.

(5) Inspect connecting rods and connecting rod

caps for cylinder identification. Identify them, if nec-

essary (Fig. 76).

(6) Remove connecting rod cap. Install connecting

rod bolt protectors on connecting rod bolts (Fig. 77).

(7) Remove each piston and connecting rod assem-

bly out of the cylinder bore.

NOTE: Be careful not to nick crankshaft journals.

(8) After removal, install bearing cap on the mat-

ing rod.

Fig. 74 Piston Measurement Locations

1 - 39.8 mm (1.56 in. ) 3.3L ENGINE

2 - 33.0 mm (1.29 in.) 3.8L ENGINE

Fig. 75 Checking Cylinder Bore Size

Fig. 76 Identify Connecting Rod to Cylinder

1 - CYLINDER NUMBER

Fig. 77 Connecting Rod Protectors

1 - COVER ROD BOLTS WITH A SUITABLE COVERING WHEN

REMOVING OR INSTALLING PISTON ASSEMBLY

RSENGINE 3.3/3.8L9 - 121

PISTON & CONNECTING ROD (Continued)

ProCarManuals.com

Page 1279 of 2321

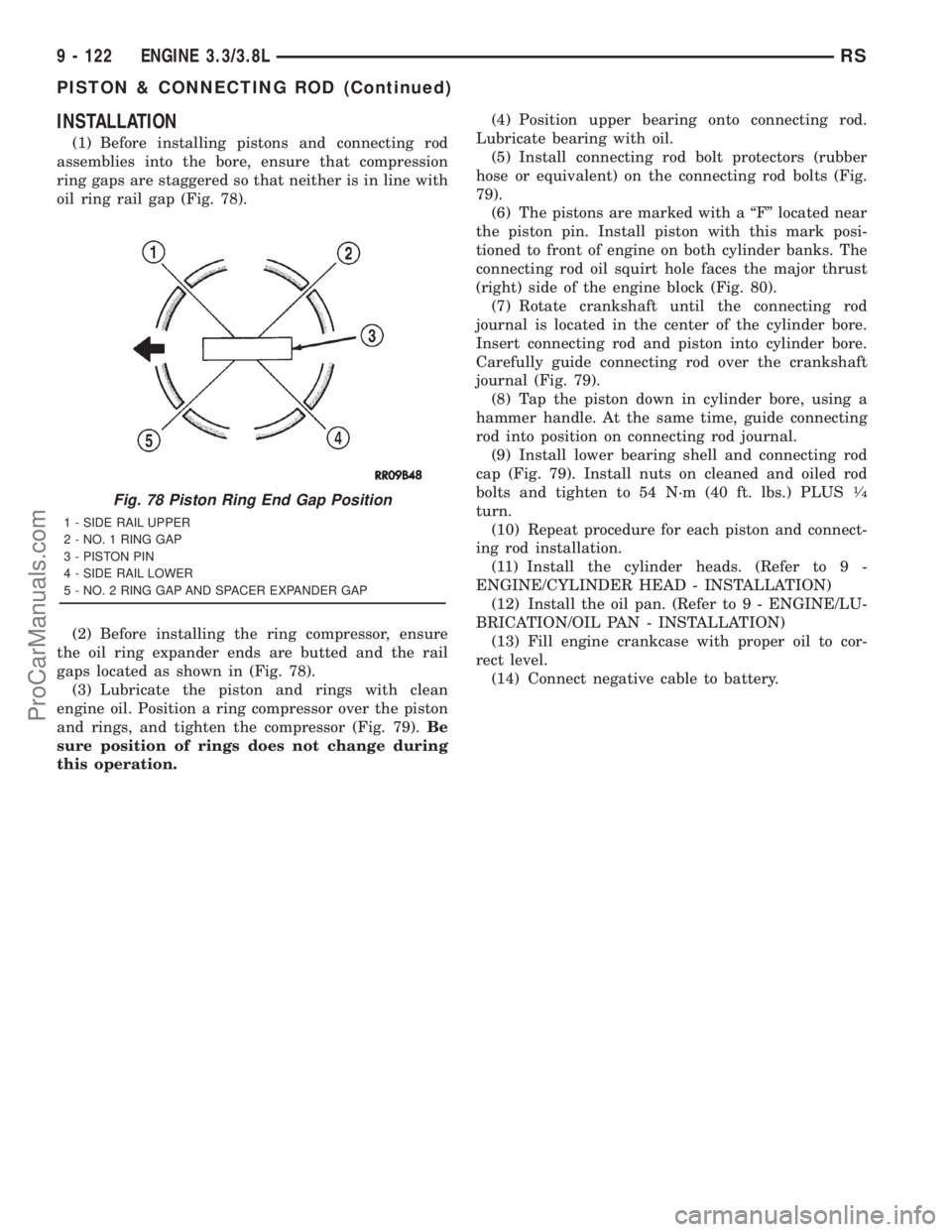

INSTALLATION

(1) Before installing pistons and connecting rod

assemblies into the bore, ensure that compression

ring gaps are staggered so that neither is in line with

oil ring rail gap (Fig. 78).

(2) Before installing the ring compressor, ensure

the oil ring expander ends are butted and the rail

gaps located as shown in (Fig. 78).

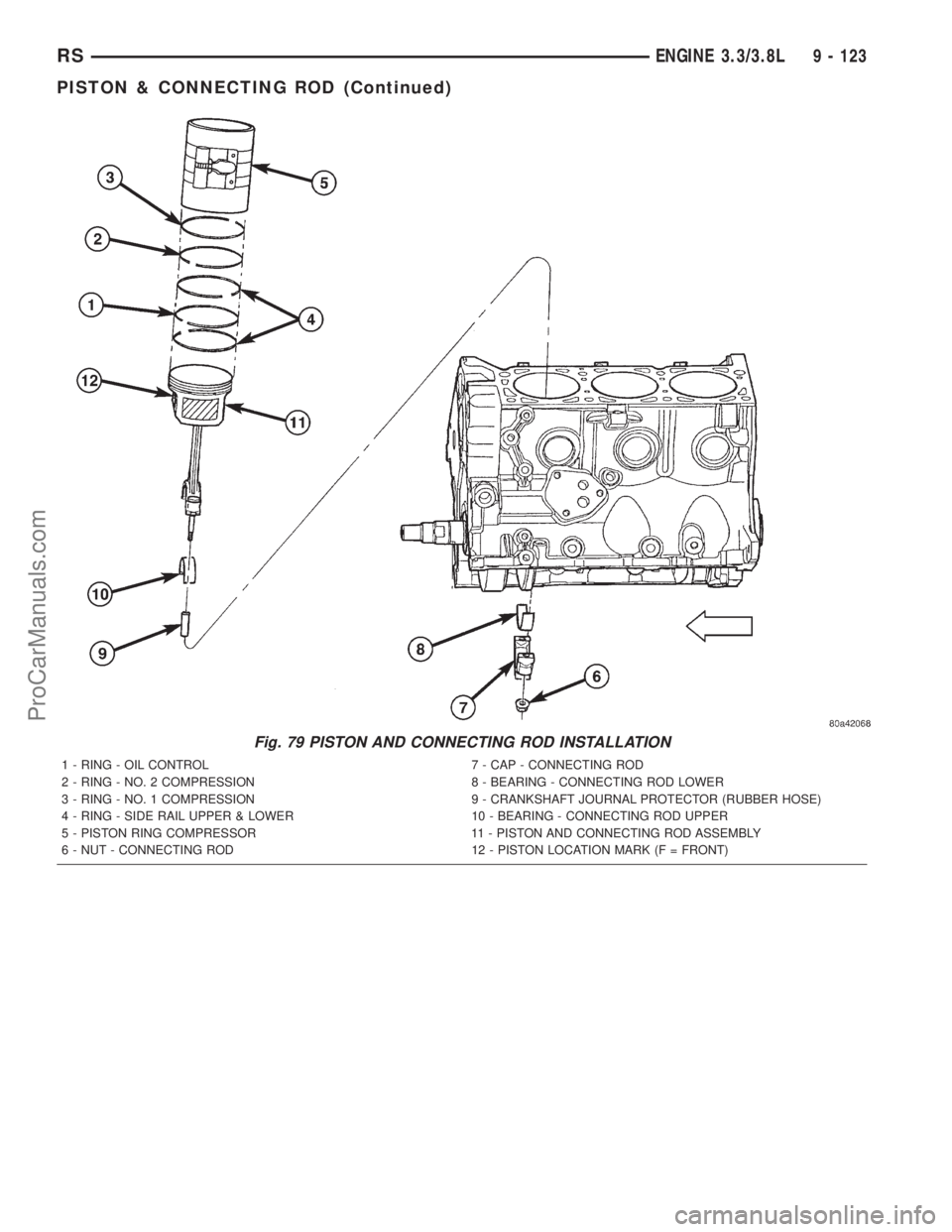

(3) Lubricate the piston and rings with clean

engine oil. Position a ring compressor over the piston

and rings, and tighten the compressor (Fig. 79).Be

sure position of rings does not change during

this operation.(4) Position upper bearing onto connecting rod.

Lubricate bearing with oil.

(5) Install connecting rod bolt protectors (rubber

hose or equivalent) on the connecting rod bolts (Fig.

79).

(6) The pistons are marked with a ªFº located near

the piston pin. Install piston with this mark posi-

tioned to front of engine on both cylinder banks. The

connecting rod oil squirt hole faces the major thrust

(right) side of the engine block (Fig. 80).

(7) Rotate crankshaft until the connecting rod

journal is located in the center of the cylinder bore.

Insert connecting rod and piston into cylinder bore.

Carefully guide connecting rod over the crankshaft

journal (Fig. 79).

(8) Tap the piston down in cylinder bore, using a

hammer handle. At the same time, guide connecting

rod into position on connecting rod journal.

(9) Install lower bearing shell and connecting rod

cap (Fig. 79). Install nuts on cleaned and oiled rod

bolts and tighten to 54 N´m (40 ft. lbs.) PLUS

1¤4

turn.

(10) Repeat procedure for each piston and connect-

ing rod installation.

(11) Install the cylinder heads. (Refer to 9 -

ENGINE/CYLINDER HEAD - INSTALLATION)

(12) Install the oil pan. (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - INSTALLATION)

(13) Fill engine crankcase with proper oil to cor-

rect level.

(14) Connect negative cable to battery.Fig. 78 Piston Ring End Gap Position

1 - SIDE RAIL UPPER

2 - NO. 1 RING GAP

3 - PISTON PIN

4 - SIDE RAIL LOWER

5 - NO. 2 RING GAP AND SPACER EXPANDER GAP

9 - 122 ENGINE 3.3/3.8LRS

PISTON & CONNECTING ROD (Continued)

ProCarManuals.com

Page 1280 of 2321

Fig. 79 PISTON AND CONNECTING ROD INSTALLATION

1 - RING - OIL CONTROL 7 - CAP - CONNECTING ROD

2 - RING - NO. 2 COMPRESSION 8 - BEARING - CONNECTING ROD LOWER

3 - RING - NO. 1 COMPRESSION 9 - CRANKSHAFT JOURNAL PROTECTOR (RUBBER HOSE)

4 - RING - SIDE RAIL UPPER & LOWER 10 - BEARING - CONNECTING ROD UPPER

5 - PISTON RING COMPRESSOR 11 - PISTON AND CONNECTING ROD ASSEMBLY

6 - NUT - CONNECTING ROD 12 - PISTON LOCATION MARK (F = FRONT)

RSENGINE 3.3/3.8L9 - 123

PISTON & CONNECTING ROD (Continued)

ProCarManuals.com