DODGE TOWN AND COUNTRY 2001 Service Manual

Manufacturer: DODGE, Model Year: 2001, Model line: TOWN AND COUNTRY, Model: DODGE TOWN AND COUNTRY 2001Pages: 2321, PDF Size: 68.09 MB

Page 1541 of 2321

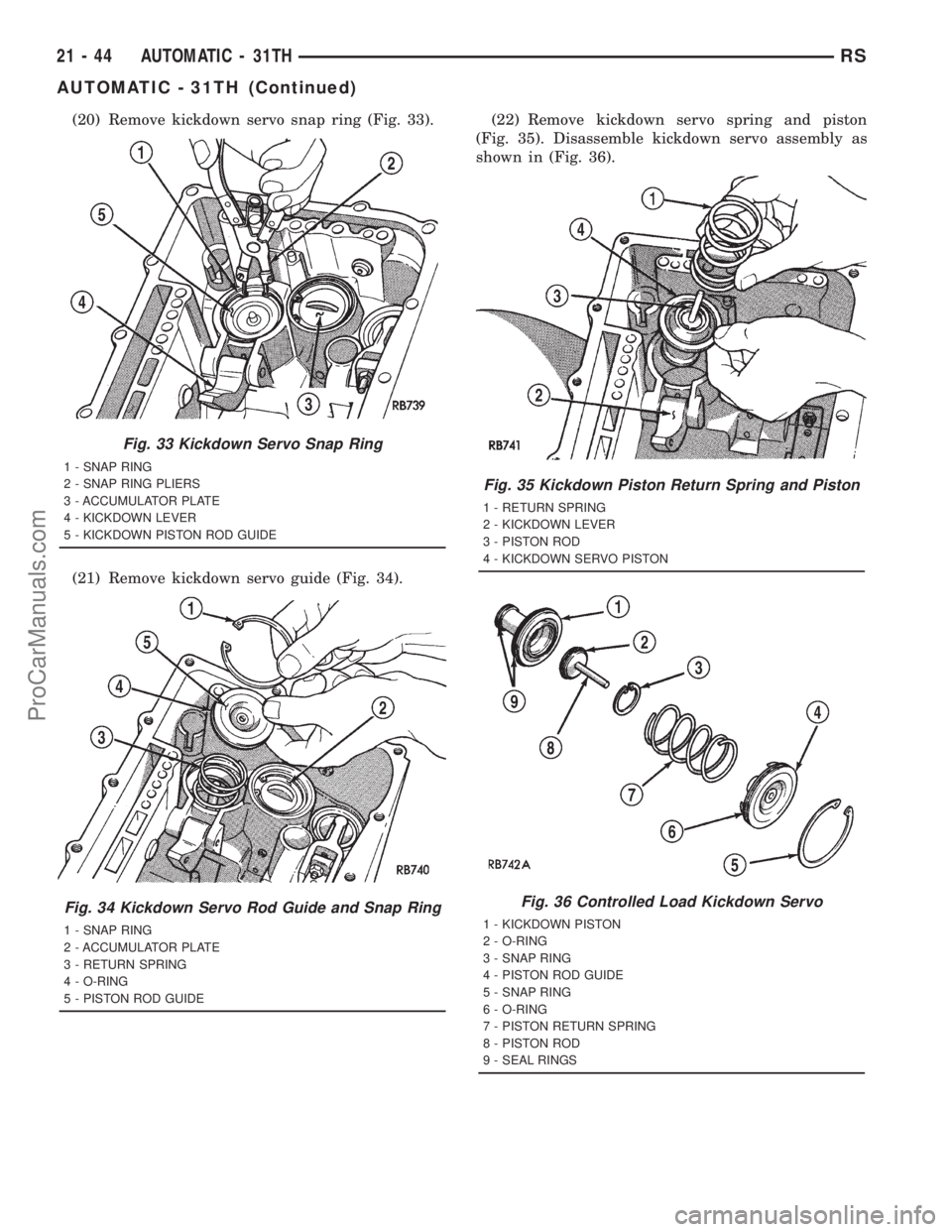

(20) Remove kickdown servo snap ring (Fig. 33).

(21) Remove kickdown servo guide (Fig. 34).(22) Remove kickdown servo spring and piston

(Fig. 35). Disassemble kickdown servo assembly as

shown in (Fig. 36).

Fig. 33 Kickdown Servo Snap Ring

1 - SNAP RING

2 - SNAP RING PLIERS

3 - ACCUMULATOR PLATE

4 - KICKDOWN LEVER

5 - KICKDOWN PISTON ROD GUIDE

Fig. 34 Kickdown Servo Rod Guide and Snap Ring

1 - SNAP RING

2 - ACCUMULATOR PLATE

3 - RETURN SPRING

4 - O-RING

5 - PISTON ROD GUIDE

Fig. 35 Kickdown Piston Return Spring and Piston

1 - RETURN SPRING

2 - KICKDOWN LEVER

3 - PISTON ROD

4 - KICKDOWN SERVO PISTON

Fig. 36 Controlled Load Kickdown Servo

1 - KICKDOWN PISTON

2 - O-RING

3 - SNAP RING

4 - PISTON ROD GUIDE

5 - SNAP RING

6 - O-RING

7 - PISTON RETURN SPRING

8 - PISTON ROD

9 - SEAL RINGS

21 - 44 AUTOMATIC - 31THRS

AUTOMATIC - 31TH (Continued)

ProCarManuals.com

Page 1542 of 2321

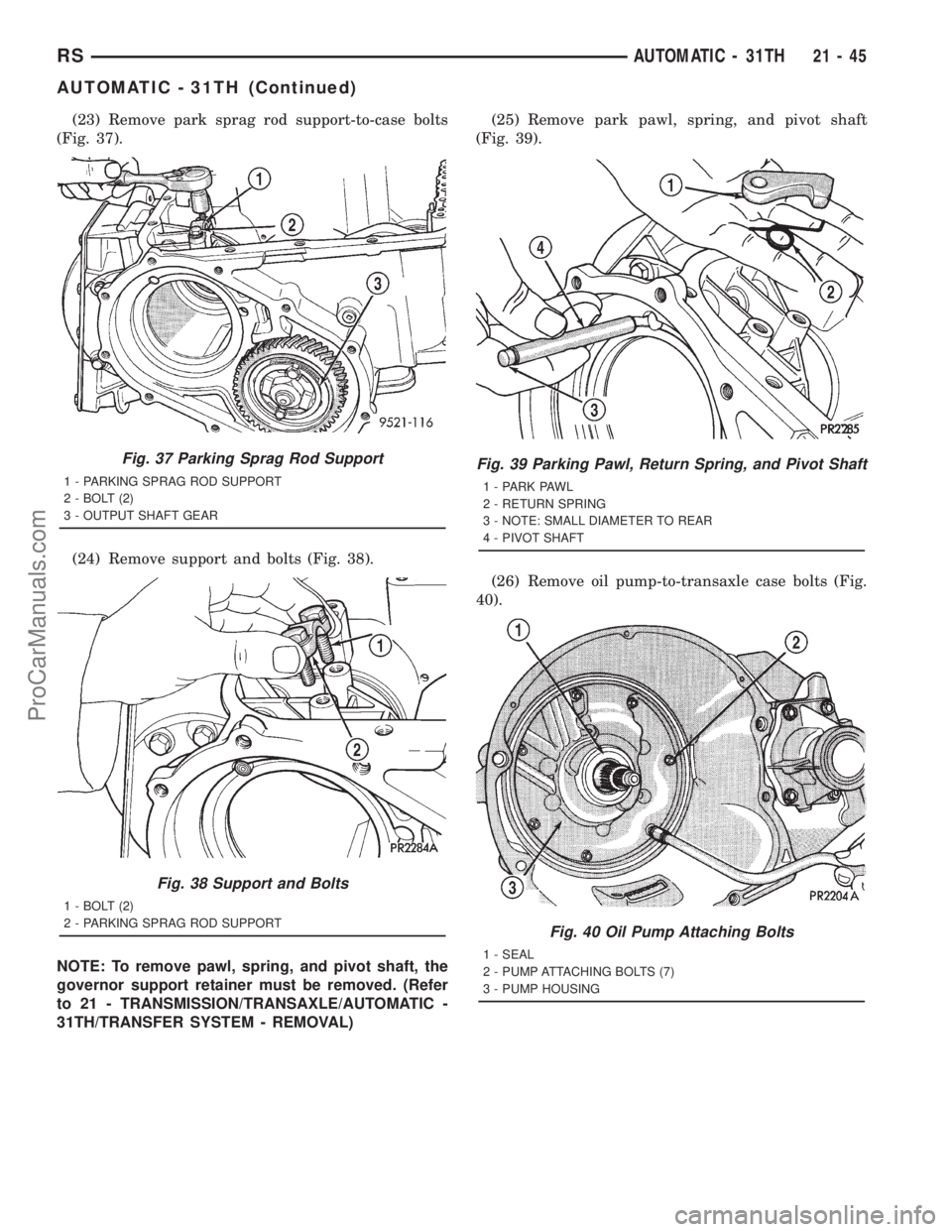

(23) Remove park sprag rod support-to-case bolts

(Fig. 37).

(24) Remove support and bolts (Fig. 38).

NOTE: To remove pawl, spring, and pivot shaft, the

governor support retainer must be removed. (Refer

to 21 - TRANSMISSION/TRANSAXLE/AUTOMATIC -

31TH/TRANSFER SYSTEM - REMOVAL)(25) Remove park pawl, spring, and pivot shaft

(Fig. 39).

(26) Remove oil pump-to-transaxle case bolts (Fig.

40).

Fig. 37 Parking Sprag Rod Support

1 - PARKING SPRAG ROD SUPPORT

2 - BOLT (2)

3 - OUTPUT SHAFT GEAR

Fig. 38 Support and Bolts

1 - BOLT (2)

2 - PARKING SPRAG ROD SUPPORT

Fig. 39 Parking Pawl, Return Spring, and Pivot Shaft

1 - PARK PAWL

2 - RETURN SPRING

3 - NOTE: SMALL DIAMETER TO REAR

4 - PIVOT SHAFT

Fig. 40 Oil Pump Attaching Bolts

1 - SEAL

2 - PUMP ATTACHING BOLTS (7)

3 - PUMP HOUSING

RSAUTOMATIC - 31TH21-45

AUTOMATIC - 31TH (Continued)

ProCarManuals.com

Page 1543 of 2321

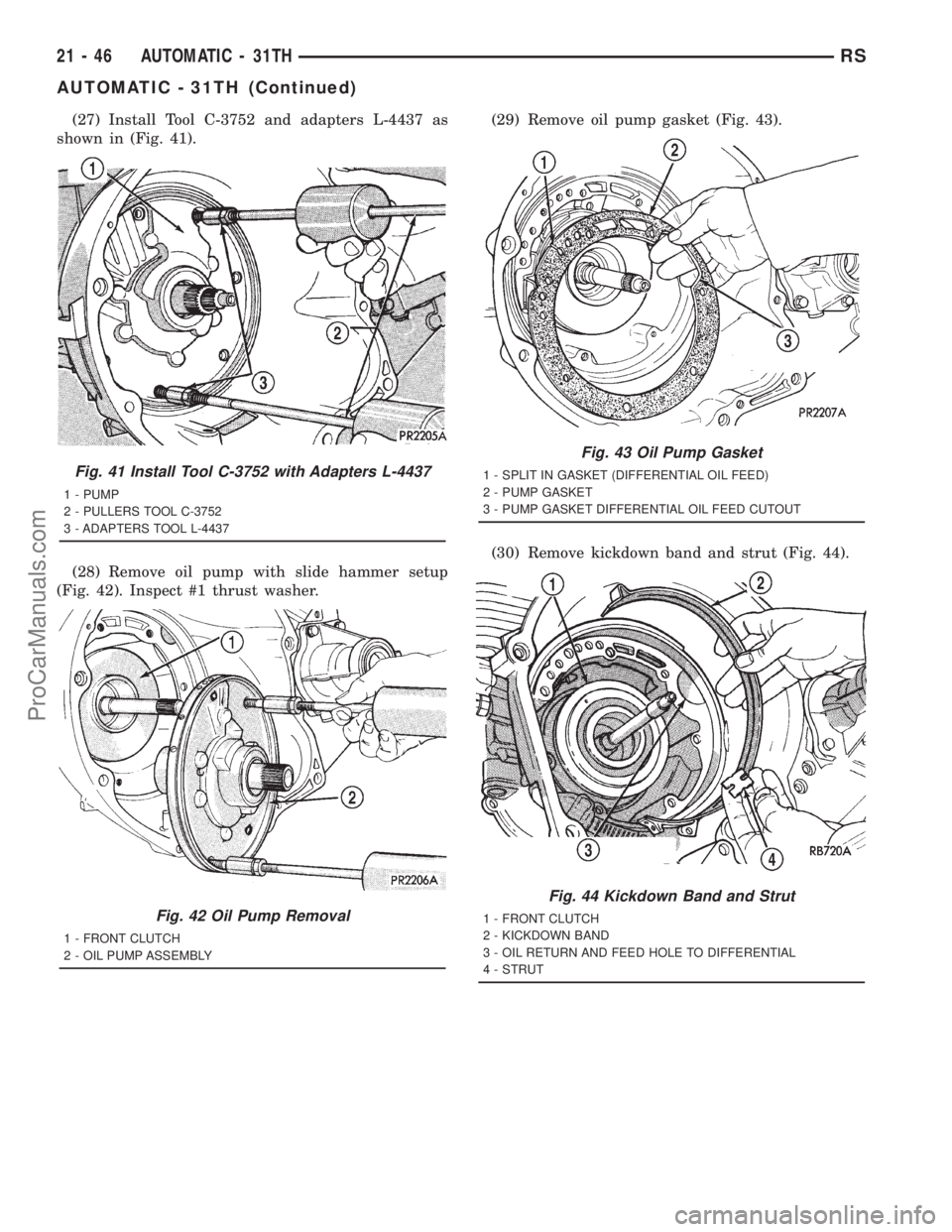

(27) Install Tool C-3752 and adapters L-4437 as

shown in (Fig. 41).

(28) Remove oil pump with slide hammer setup

(Fig. 42). Inspect #1 thrust washer.(29) Remove oil pump gasket (Fig. 43).

(30) Remove kickdown band and strut (Fig. 44).

Fig. 41 Install Tool C-3752 with Adapters L-4437

1 - PUMP

2 - PULLERS TOOL C-3752

3 - ADAPTERS TOOL L-4437

Fig. 42 Oil Pump Removal

1 - FRONT CLUTCH

2 - OIL PUMP ASSEMBLY

Fig. 43 Oil Pump Gasket

1 - SPLIT IN GASKET (DIFFERENTIAL OIL FEED)

2 - PUMP GASKET

3 - PUMP GASKET DIFFERENTIAL OIL FEED CUTOUT

Fig. 44 Kickdown Band and Strut

1 - FRONT CLUTCH

2 - KICKDOWN BAND

3 - OIL RETURN AND FEED HOLE TO DIFFERENTIAL

4 - STRUT

21 - 46 AUTOMATIC - 31THRS

AUTOMATIC - 31TH (Continued)

ProCarManuals.com

Page 1544 of 2321

(31) Remove front clutch assembly (Fig. 45).

(32) Remove rear clutch assembly (Fig. 46).

Inspect #2 thrust washer.(33) Remove #3 thrust washer (Fig. 47).

(34) Remove front planetary gear-to-output shaft

snap ring (Fig. 48).

Fig. 45 Front Clutch Assembly

1 - REAR CLUTCH ASSEMBLY

2 - FRONT CLUTCH ASSEMBLY

Fig. 46 No. 2 Thrust Washer and Rear Clutch

1 - REAR CLUTCH ASSEMBLY

2 - #2 THRUST WASHER

Fig. 47 No. 3 Thrust Washer

1 - OUTPUT SHAFT

2 - SUN GEAR DRIVING SHELL

3 - #3 THRUST WASHER (SELECT FIT)

Fig. 48 Front Planetary Gear Snap Ring

1 - FRONT PLANETARY GEAR SNAP RING

2 - SNAP RING PLIERS

3 - FRONT PLANETARY GEAR ASSEMBLY

RSAUTOMATIC - 31TH21-47

AUTOMATIC - 31TH (Continued)

ProCarManuals.com

Page 1545 of 2321

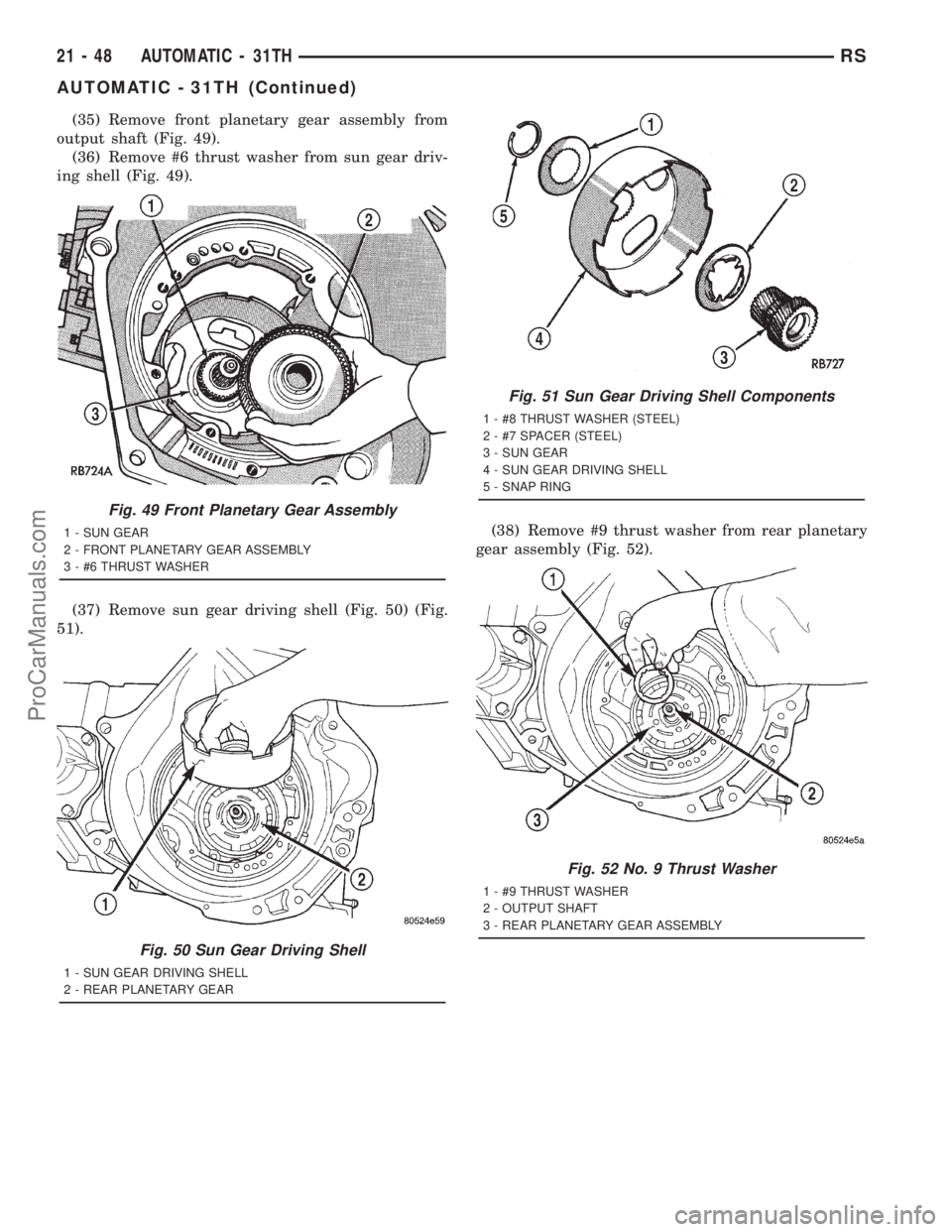

(35) Remove front planetary gear assembly from

output shaft (Fig. 49).

(36) Remove #6 thrust washer from sun gear driv-

ing shell (Fig. 49).

(37) Remove sun gear driving shell (Fig. 50) (Fig.

51).(38) Remove #9 thrust washer from rear planetary

gear assembly (Fig. 52).

Fig. 49 Front Planetary Gear Assembly

1 - SUN GEAR

2 - FRONT PLANETARY GEAR ASSEMBLY

3 - #6 THRUST WASHER

Fig. 50 Sun Gear Driving Shell

1 - SUN GEAR DRIVING SHELL

2 - REAR PLANETARY GEAR

Fig. 51 Sun Gear Driving Shell Components

1 - #8 THRUST WASHER (STEEL)

2 - #7 SPACER (STEEL)

3 - SUN GEAR

4 - SUN GEAR DRIVING SHELL

5 - SNAP RING

Fig. 52 No. 9 Thrust Washer

1 - #9 THRUST WASHER

2 - OUTPUT SHAFT

3 - REAR PLANETARY GEAR ASSEMBLY

21 - 48 AUTOMATIC - 31THRS

AUTOMATIC - 31TH (Continued)

ProCarManuals.com

Page 1546 of 2321

(39) Remove rear planetary gear assembly (Fig.

53).

(40) Remove #10 thrust washer (Fig. 54).(41) Remove overrunning clutch cam assembly

(Fig. 55). Collect eight rollers and eight springs from

rear of case (Fig. 56).

Fig. 53 Rear Planetary Gear Assembly

1 - REAR PLANETARY GEAR ASSEMBLY

Fig. 54 No. 10 Thrust Washer

1 - OVERRUNNING CLUTCH CAM ASSEMBLY

2 - #10 THRUST WASHER

Fig. 55 Overrunning Clutch Cam Assembly

1 - OUTPUT SHAFT

2 - OVERRUNNING CLUTCH CAM ASSEMBLY

Fig. 56 Overrunning Clutch Rollers and Spring

1 - LOW-REVERSE BAND

2 - OVERRUNNING CLUTCH ROLLERS (8)

3 - OVERRUNNING CLUTCH SPRINGS (8)

RSAUTOMATIC - 31TH21-49

AUTOMATIC - 31TH (Continued)

ProCarManuals.com

Page 1547 of 2321

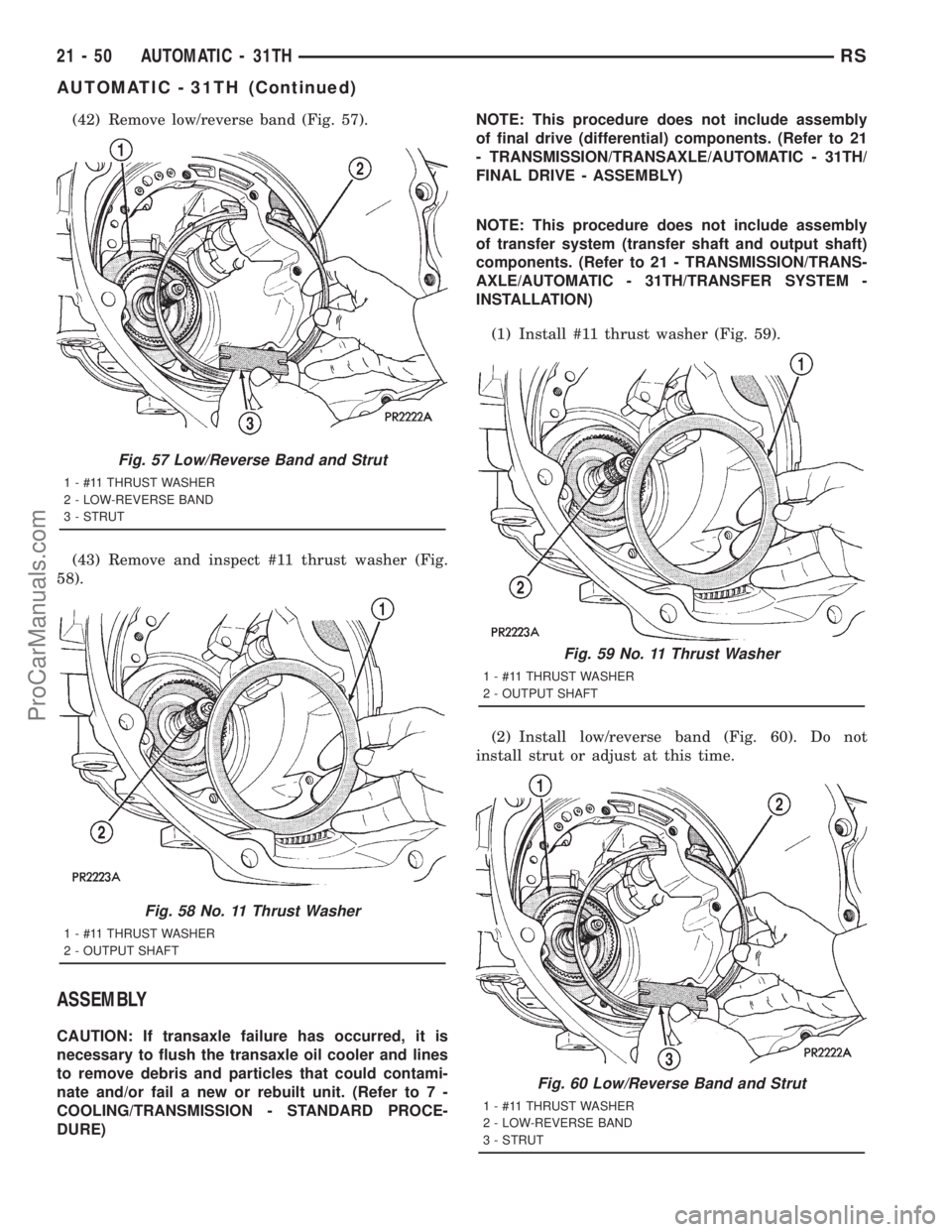

(42) Remove low/reverse band (Fig. 57).

(43) Remove and inspect #11 thrust washer (Fig.

58).

ASSEMBLY

CAUTION: If transaxle failure has occurred, it is

necessary to flush the transaxle oil cooler and lines

to remove debris and particles that could contami-

nate and/or fail a new or rebuilt unit. (Refer to 7 -

COOLING/TRANSMISSION - STANDARD PROCE-

DURE)NOTE: This procedure does not include assembly

of final drive (differential) components. (Refer to 21

- TRANSMISSION/TRANSAXLE/AUTOMATIC - 31TH/

FINAL DRIVE - ASSEMBLY)

NOTE: This procedure does not include assembly

of transfer system (transfer shaft and output shaft)

components. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 31TH/TRANSFER SYSTEM -

INSTALLATION)

(1) Install #11 thrust washer (Fig. 59).

(2) Install low/reverse band (Fig. 60). Do not

install strut or adjust at this time.

Fig. 57 Low/Reverse Band and Strut

1 - #11 THRUST WASHER

2 - LOW-REVERSE BAND

3 - STRUT

Fig. 58 No. 11 Thrust Washer

1 - #11 THRUST WASHER

2 - OUTPUT SHAFT

Fig. 59 No. 11 Thrust Washer

1 - #11 THRUST WASHER

2 - OUTPUT SHAFT

Fig. 60 Low/Reverse Band and Strut

1 - #11 THRUST WASHER

2 - LOW-REVERSE BAND

3 - STRUT

21 - 50 AUTOMATIC - 31THRS

AUTOMATIC - 31TH (Continued)

ProCarManuals.com

Page 1548 of 2321

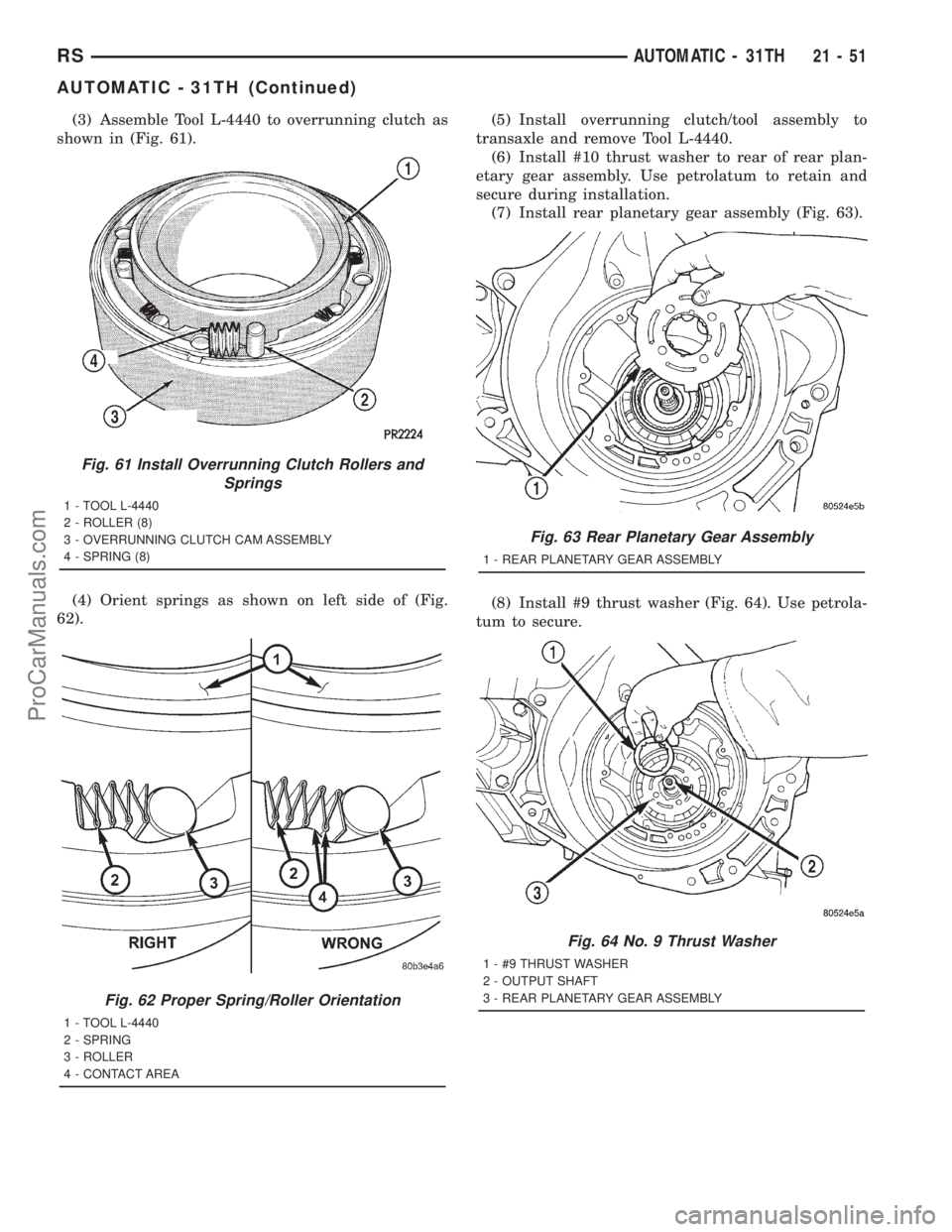

(3) Assemble Tool L-4440 to overrunning clutch as

shown in (Fig. 61).

(4) Orient springs as shown on left side of (Fig.

62).(5) Install overrunning clutch/tool assembly to

transaxle and remove Tool L-4440.

(6) Install #10 thrust washer to rear of rear plan-

etary gear assembly. Use petrolatum to retain and

secure during installation.

(7) Install rear planetary gear assembly (Fig. 63).

(8) Install #9 thrust washer (Fig. 64). Use petrola-

tum to secure.

Fig. 61 Install Overrunning Clutch Rollers and

Springs

1 - TOOL L-4440

2 - ROLLER (8)

3 - OVERRUNNING CLUTCH CAM ASSEMBLY

4 - SPRING (8)

Fig. 62 Proper Spring/Roller Orientation

1 - TOOL L-4440

2 - SPRING

3 - ROLLER

4 - CONTACT AREA

Fig. 63 Rear Planetary Gear Assembly

1 - REAR PLANETARY GEAR ASSEMBLY

Fig. 64 No. 9 Thrust Washer

1 - #9 THRUST WASHER

2 - OUTPUT SHAFT

3 - REAR PLANETARY GEAR ASSEMBLY

RSAUTOMATIC - 31TH21-51

AUTOMATIC - 31TH (Continued)

ProCarManuals.com

Page 1549 of 2321

(9) Install sun gear driving shell (Fig. 65).

(10) Install front planetary gear assembly (Fig.

66).(11) Install front planetary gear snap ring (Fig.

67).

(12) Install #3 thrust washer (Fig. 68). Refer to

end play specification recorded during transaxle dis-

assembly to determine whether or not replacement is

necessary.

Fig. 65 Sun Gear Driving Shell

1 - SUN GEAR DRIVING SHELL

2 - REAR PLANETARY GEAR

Fig. 66 Front Planetary Gear Assembly

1 - SUN GEAR

2 - FRONT PLANETARY GEAR ASSEMBLY

3 - #6 THRUST WASHER

Fig. 67 Front Planetary Gear Snap Ring

1 - FRONT PLANETARY GEAR SNAP RING

2 - SNAP RING PLIERS

3 - FRONT PLANETARY GEAR ASSEMBLY

Fig. 68 No. 3 Thrust Washer

1 - OUTPUT SHAFT

2 - SUN GEAR DRIVING SHELL

3 - #3 THRUST WASHER (SELECT FIT)

21 - 52 AUTOMATIC - 31THRS

AUTOMATIC - 31TH (Continued)

ProCarManuals.com

Page 1550 of 2321

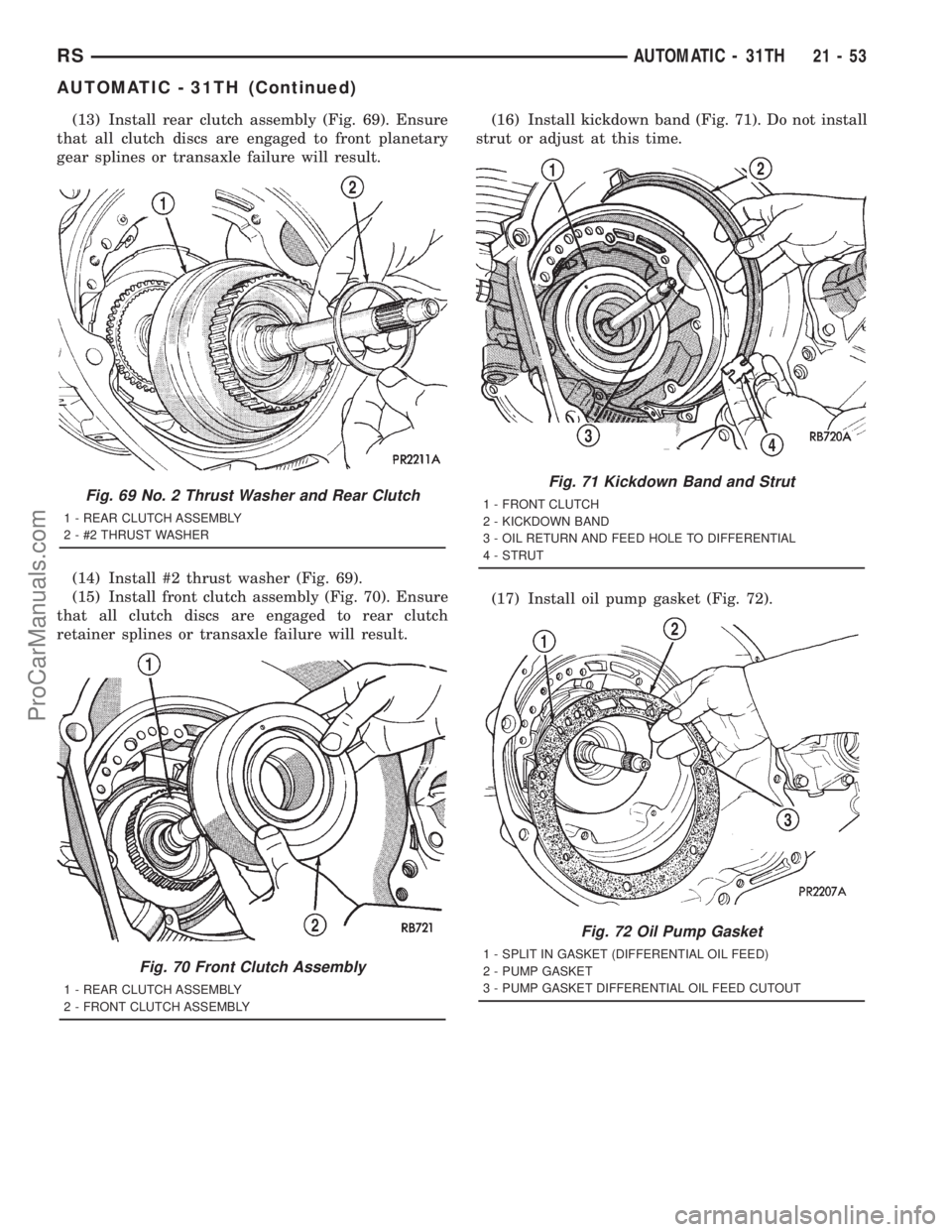

(13) Install rear clutch assembly (Fig. 69). Ensure

that all clutch discs are engaged to front planetary

gear splines or transaxle failure will result.

(14) Install #2 thrust washer (Fig. 69).

(15) Install front clutch assembly (Fig. 70). Ensure

that all clutch discs are engaged to rear clutch

retainer splines or transaxle failure will result.(16) Install kickdown band (Fig. 71). Do not install

strut or adjust at this time.

(17) Install oil pump gasket (Fig. 72).

Fig. 69 No. 2 Thrust Washer and Rear Clutch

1 - REAR CLUTCH ASSEMBLY

2 - #2 THRUST WASHER

Fig. 70 Front Clutch Assembly

1 - REAR CLUTCH ASSEMBLY

2 - FRONT CLUTCH ASSEMBLY

Fig. 71 Kickdown Band and Strut

1 - FRONT CLUTCH

2 - KICKDOWN BAND

3 - OIL RETURN AND FEED HOLE TO DIFFERENTIAL

4 - STRUT

Fig. 72 Oil Pump Gasket

1 - SPLIT IN GASKET (DIFFERENTIAL OIL FEED)

2 - PUMP GASKET

3 - PUMP GASKET DIFFERENTIAL OIL FEED CUTOUT

RSAUTOMATIC - 31TH21-53

AUTOMATIC - 31TH (Continued)

ProCarManuals.com