DODGE TOWN AND COUNTRY 2001 Service Manual

Manufacturer: DODGE, Model Year: 2001, Model line: TOWN AND COUNTRY, Model: DODGE TOWN AND COUNTRY 2001Pages: 2321, PDF Size: 68.09 MB

Page 271 of 2321

- 124 kPa (14 - 18 psi). This air is replaced with cool-

ant from the coolant bottle.

NOTE: Deaeration does not occur at engine idleÐ

higher engine speeds are required. Normal driving

will deaerate cooling system.

To effectively deaerate the system, multiple ther-

mal cycles of the system may be required.

STANDARD PROCEDURE - COOLING SYSTEM

DRAINING

WARNING: DO NOT REMOVE OR LOOSEN THE

COOLANT PRESSURE CAP, CYLINDER BLOCK

DRAIN PLUGS, OR THE DRAINCOCK WHEN THE

SYSTEM IS HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM THE COOLANT

CAN OCCUR.

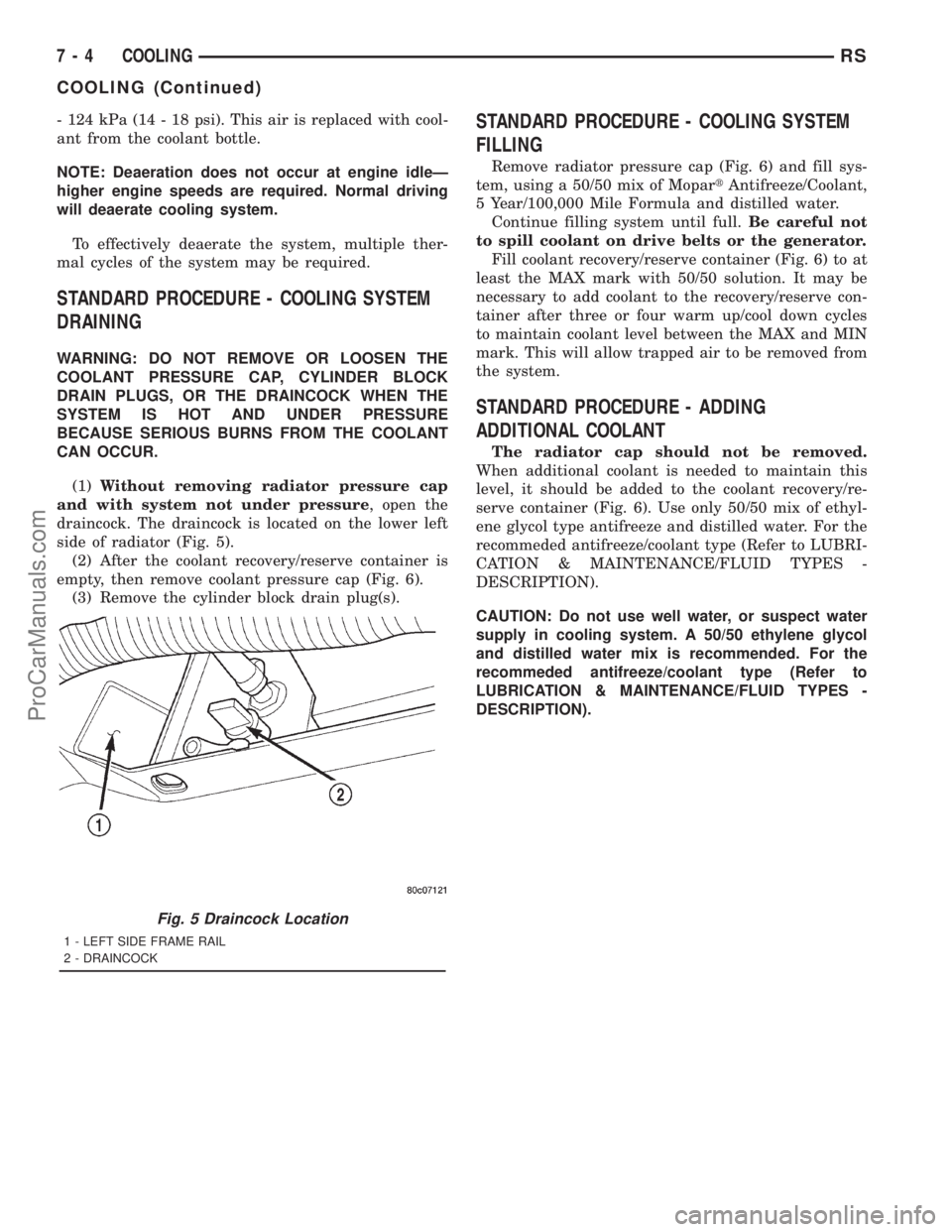

(1)Without removing radiator pressure cap

and with system not under pressure, open the

draincock. The draincock is located on the lower left

side of radiator (Fig. 5).

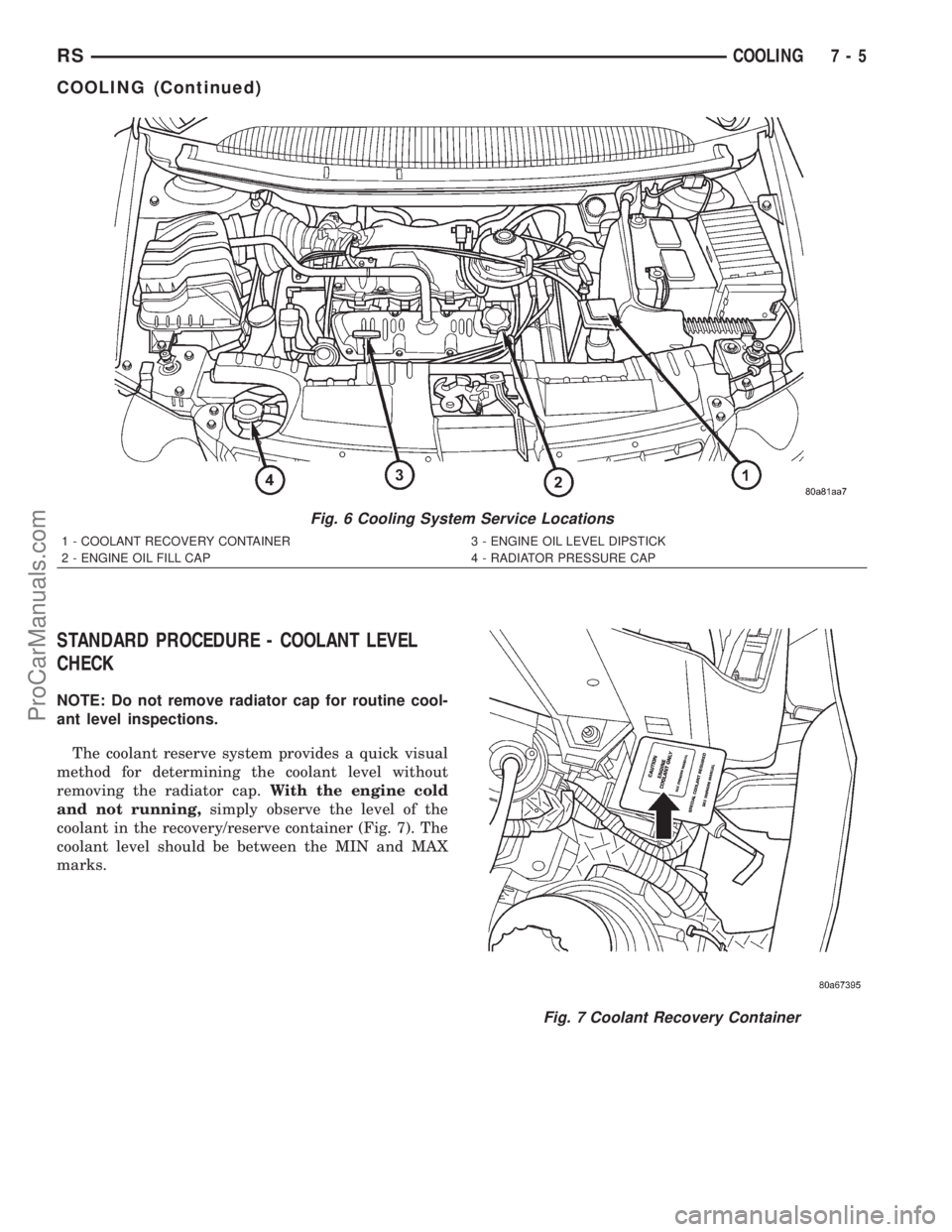

(2) After the coolant recovery/reserve container is

empty, then remove coolant pressure cap (Fig. 6).

(3) Remove the cylinder block drain plug(s).

STANDARD PROCEDURE - COOLING SYSTEM

FILLING

Remove radiator pressure cap (Fig. 6) and fill sys-

tem, using a 50/50 mix of MopartAntifreeze/Coolant,

5 Year/100,000 Mile Formula and distilled water.

Continue filling system until full.Be careful not

to spill coolant on drive belts or the generator.

Fill coolant recovery/reserve container (Fig. 6) to at

least the MAX mark with 50/50 solution. It may be

necessary to add coolant to the recovery/reserve con-

tainer after three or four warm up/cool down cycles

to maintain coolant level between the MAX and MIN

mark. This will allow trapped air to be removed from

the system.

STANDARD PROCEDURE - ADDING

ADDITIONAL COOLANT

The radiator cap should not be removed.

When additional coolant is needed to maintain this

level, it should be added to the coolant recovery/re-

serve container (Fig. 6). Use only 50/50 mix of ethyl-

ene glycol type antifreeze and distilled water. For the

recommeded antifreeze/coolant type (Refer to LUBRI-

CATION & MAINTENANCE/FLUID TYPES -

DESCRIPTION).

CAUTION: Do not use well water, or suspect water

supply in cooling system. A 50/50 ethylene glycol

and distilled water mix is recommended. For the

recommeded antifreeze/coolant type (Refer to

LUBRICATION & MAINTENANCE/FLUID TYPES -

DESCRIPTION).

Fig. 5 Draincock Location

1 - LEFT SIDE FRAME RAIL

2 - DRAINCOCK

7 - 4 COOLINGRS

COOLING (Continued)

ProCarManuals.com

Page 272 of 2321

STANDARD PROCEDURE - COOLANT LEVEL

CHECK

NOTE: Do not remove radiator cap for routine cool-

ant level inspections.

The coolant reserve system provides a quick visual

method for determining the coolant level without

removing the radiator cap.With the engine cold

and not running,simply observe the level of the

coolant in the recovery/reserve container (Fig. 7). The

coolant level should be between the MIN and MAX

marks.

Fig. 6 Cooling System Service Locations

1 - COOLANT RECOVERY CONTAINER 3 - ENGINE OIL LEVEL DIPSTICK

2 - ENGINE OIL FILL CAP 4 - RADIATOR PRESSURE CAP

Fig. 7 Coolant Recovery Container

RSCOOLING7-5

COOLING (Continued)

ProCarManuals.com

Page 273 of 2321

SPECIFICATIONS

TORQUE

DESCRIPTION N´mFt.

Lbs.In.

Lbs.

Accessory Drive Belt Tensioner

Assembly (3.3/3.8L)ÐBolt28 Ð 250

Generator & A/C Compressor Drive

Belt Tensioner Assembly (2.4L)Ð

Bolt28 Ð 250

Coolant Outlet Connector/

Thermostat Housing

(2.4 & 3.3/3.8L)ÐBolts 28 Ð 250

Water Pump

(2.4 & 3.3/3.8L)ÐBolts 12 Ð 105

Water Pump Inlet Tube (2.4L)Ð

Bolts12 Ð 105

Water Pump Inlet Tube (3.3/3.8L)Ð

Bolts28 Ð 250

Water Pump Pulley (3.3/3.8L)Ð

Bolts28 Ð 250

Radiator to A/C CondenserÐ

Screws5Ð45

Radiator FanÐScrews 5 Ð 45

Radiator Mounting (Upper

Bracket)ÐNuts8Ð70

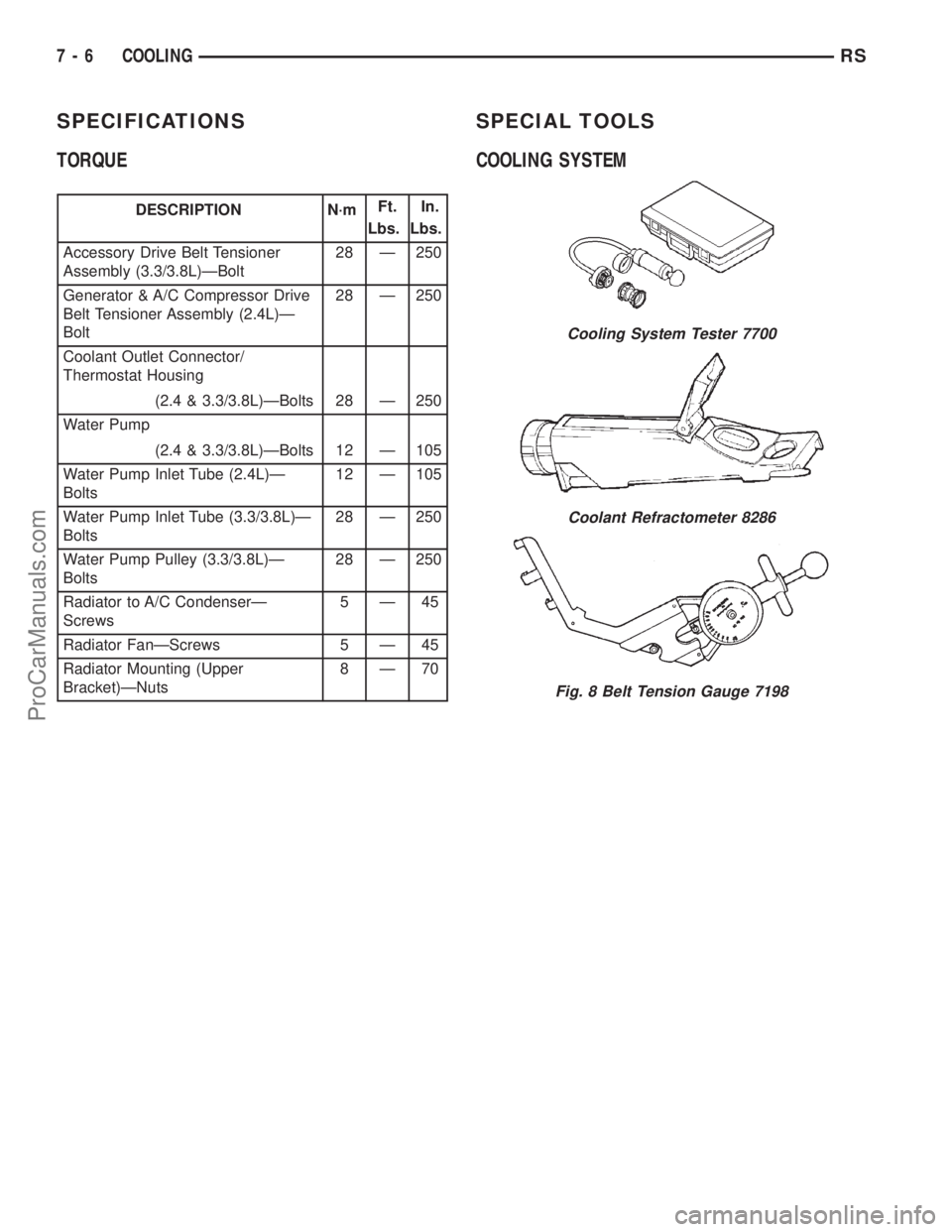

SPECIAL TOOLS

COOLING SYSTEM

Cooling System Tester 7700

Coolant Refractometer 8286

Fig. 8 Belt Tension Gauge 7198

7 - 6 COOLINGRS

ProCarManuals.com

Page 274 of 2321

ACCESSORY DRIVE

TABLE OF CONTENTS

page page

ACCESSORY DRIVE

SPECIFICATIONS.........................7

BELT TENSIONER - 2.4L

REMOVAL...............................7

INSTALLATION............................7

BELT TENSIONER - 3.3/3.8L

REMOVAL...............................8

INSTALLATION............................8

DRIVE BELTS

DESCRIPTION............................8

OPERATION.............................8

DIAGNOSIS AND TESTING..................8ACCESSORY DRIVE BELT.................8

DRIVE BELTS - 2.4L

REMOVAL...............................9

CLEANING..............................10

INSPECTION............................10

INSTALLATION...........................10

ADJUSTMENTS..........................10

DRIVE BELTS - 3.3/3.8L

REMOVAL..............................11

CLEANING..............................11

INSPECTION............................11

INSTALLATION...........................12

ACCESSORY DRIVE

SPECIFICATIONS

SPECIFICATIONS - ACCESSORY BELT TENSION

ACCESSORY DRIVE

BELTGAUGE

2.4L ENGINE

A/C Compressor/

GeneratorDynamic Tensioner

Power SteeringNew Belt: 616 N (140

lbs.)

Used Belt: 396 N (90

lbs.)

3.3/3.8L ENGINES

A/C Compressor

Dynamic Tensioner

Generator/Water

Pump/Power Steering

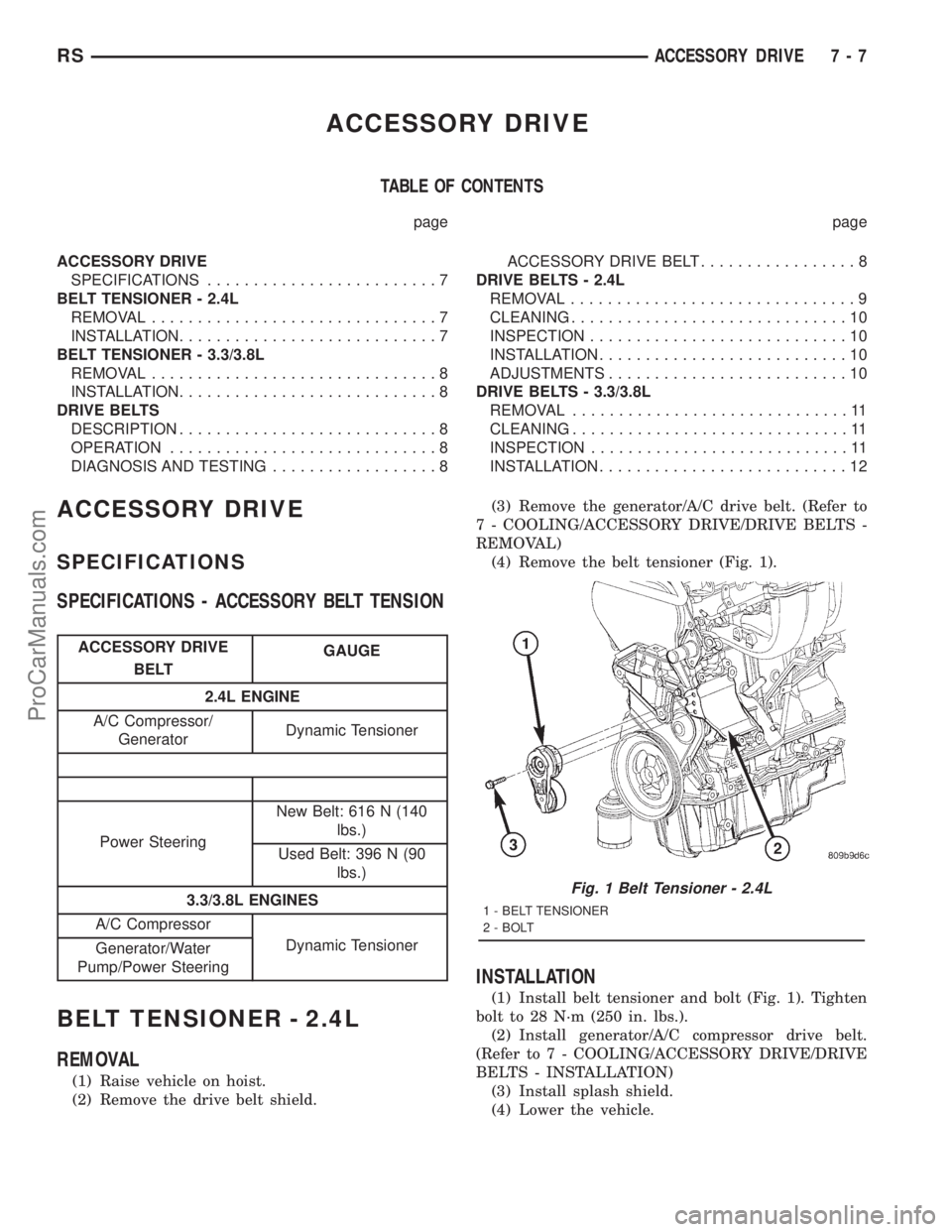

BELT TENSIONER - 2.4L

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove the drive belt shield.(3) Remove the generator/A/C drive belt. (Refer to

7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL)

(4) Remove the belt tensioner (Fig. 1).

INSTALLATION

(1) Install belt tensioner and bolt (Fig. 1). Tighten

bolt to 28 N´m (250 in. lbs.).

(2) Install generator/A/C compressor drive belt.

(Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE

BELTS - INSTALLATION)

(3) Install splash shield.

(4) Lower the vehicle.

Fig. 1 Belt Tensioner - 2.4L

1 - BELT TENSIONER

2 - BOLT

RSACCESSORY DRIVE7-7

ProCarManuals.com

Page 275 of 2321

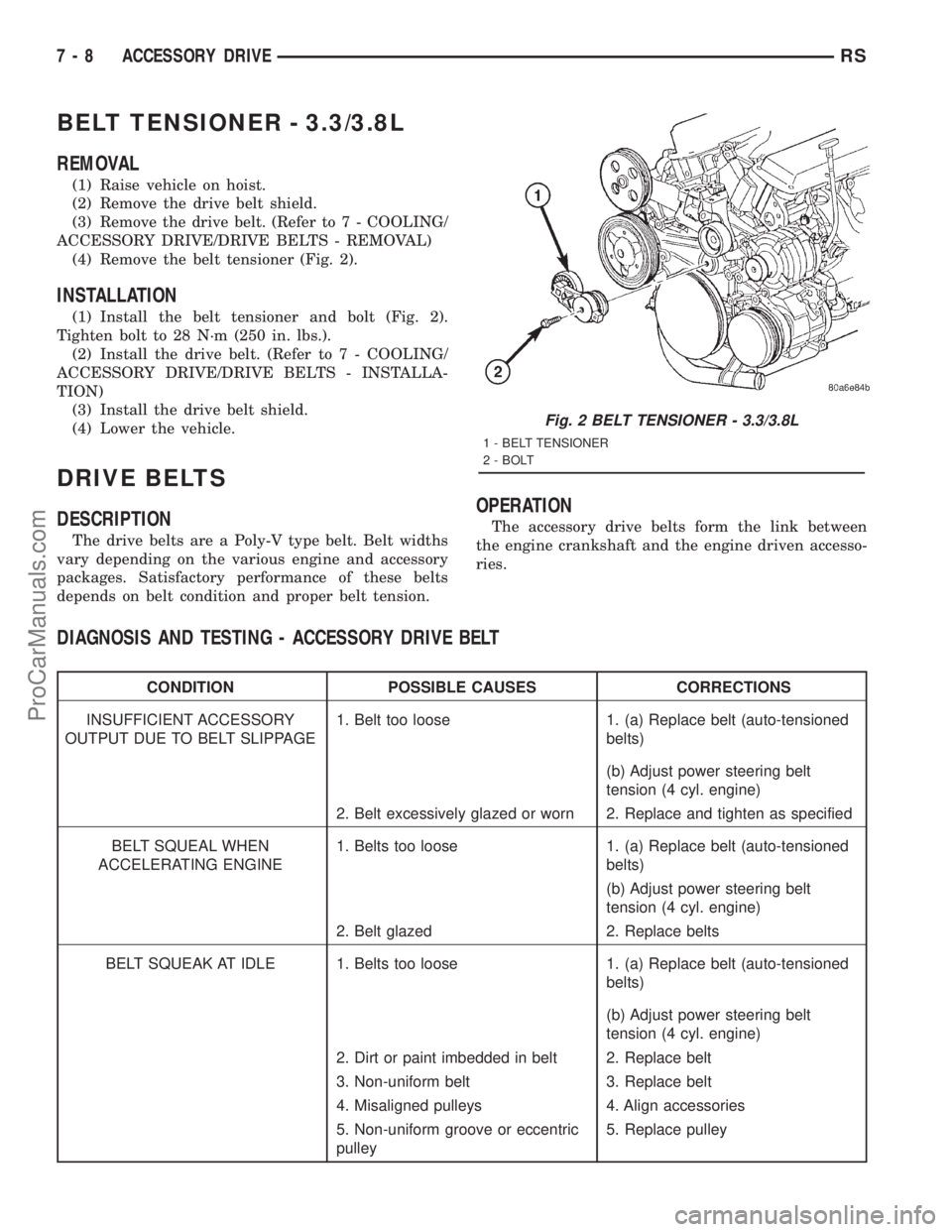

BELT TENSIONER - 3.3/3.8L

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove the drive belt shield.

(3) Remove the drive belt. (Refer to 7 - COOLING/

ACCESSORY DRIVE/DRIVE BELTS - REMOVAL)

(4) Remove the belt tensioner (Fig. 2).

INSTALLATION

(1) Install the belt tensioner and bolt (Fig. 2).

Tighten bolt to 28 N´m (250 in. lbs.).

(2) Install the drive belt. (Refer to 7 - COOLING/

ACCESSORY DRIVE/DRIVE BELTS - INSTALLA-

TION)

(3) Install the drive belt shield.

(4) Lower the vehicle.

DRIVE BELTS

DESCRIPTION

The drive belts are a Poly-V type belt. Belt widths

vary depending on the various engine and accessory

packages. Satisfactory performance of these belts

depends on belt condition and proper belt tension.

OPERATION

The accessory drive belts form the link between

the engine crankshaft and the engine driven accesso-

ries.

DIAGNOSIS AND TESTING - ACCESSORY DRIVE BELT

CONDITION POSSIBLE CAUSES CORRECTIONS

INSUFFICIENT ACCESSORY

OUTPUT DUE TO BELT SLIPPAGE1. Belt too loose 1. (a) Replace belt (auto-tensioned

belts)

(b) Adjust power steering belt

tension (4 cyl. engine)

2. Belt excessively glazed or worn 2. Replace and tighten as specified

BELT SQUEAL WHEN

ACCELERATING ENGINE1. Belts too loose 1. (a) Replace belt (auto-tensioned

belts)

(b) Adjust power steering belt

tension (4 cyl. engine)

2. Belt glazed 2. Replace belts

BELT SQUEAK AT IDLE 1. Belts too loose 1. (a) Replace belt (auto-tensioned

belts)

(b) Adjust power steering belt

tension (4 cyl. engine)

2. Dirt or paint imbedded in belt 2. Replace belt

3. Non-uniform belt 3. Replace belt

4. Misaligned pulleys 4. Align accessories

5. Non-uniform groove or eccentric

pulley5. Replace pulley

Fig. 2 BELT TENSIONER - 3.3/3.8L

1 - BELT TENSIONER

2 - BOLT

7 - 8 ACCESSORY DRIVERS

ProCarManuals.com

Page 276 of 2321

CONDITION POSSIBLE CAUSES CORRECTIONS

BELT ROLLED OVER IN GROOVE

OR BELT JUMPS OFF1. Broken cord in belt 1. Replace belt

2. Belt too loose, or too tight 2. (a) Replace belt (auto-tensioned

belts.)

(b) Adjust power steering belt

tension (4 cyl. engine)

3. Misaligned pulleys 3. Align accessories

4. Non-uniform groove or eccentric

pulley4. Replace pulley

DRIVE BELTS - 2.4L

REMOVAL

GENERATOR AND AIR CONDITIONING BELT

(1) Raise vehicle on hoist.

(2) Remove the drive belt shield (Fig. 7).

WARNING: DO NOT ALLOW DRIVE BELT TEN-

SIONER TO SNAP BACK, AS DAMAGE TO TEN-

SIONER AND/OR PERSONAL INJURY COULD

RESULT.

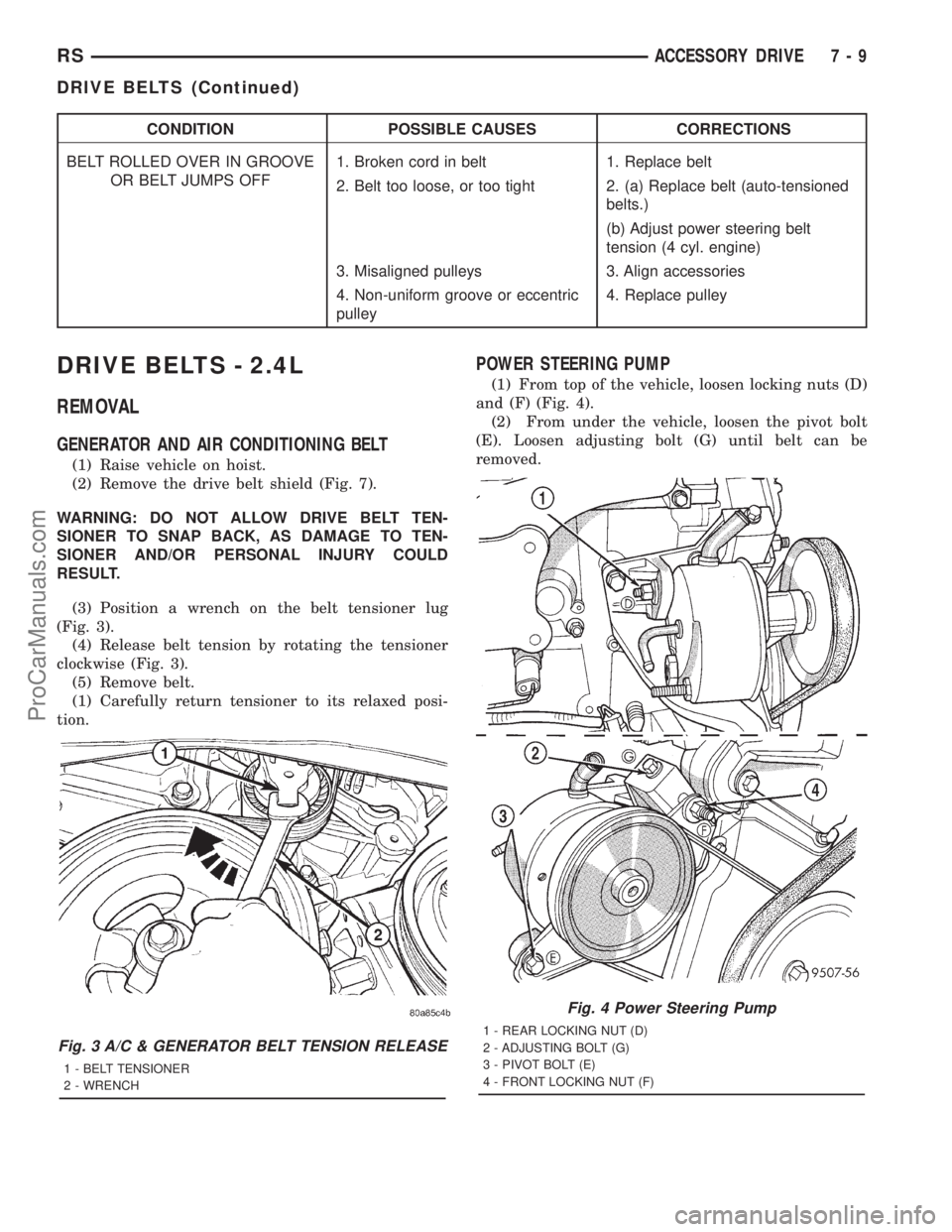

(3) Position a wrench on the belt tensioner lug

(Fig. 3).

(4) Release belt tension by rotating the tensioner

clockwise (Fig. 3).

(5) Remove belt.

(1) Carefully return tensioner to its relaxed posi-

tion.

POWER STEERING PUMP

(1) From top of the vehicle, loosen locking nuts (D)

and (F) (Fig. 4).

(2) From under the vehicle, loosen the pivot bolt

(E). Loosen adjusting bolt (G) until belt can be

removed.

Fig. 3 A/C & GENERATOR BELT TENSION RELEASE

1 - BELT TENSIONER

2 - WRENCH

Fig. 4 Power Steering Pump

1 - REAR LOCKING NUT (D)

2 - ADJUSTING BOLT (G)

3 - PIVOT BOLT (E)

4 - FRONT LOCKING NUT (F)

RSACCESSORY DRIVE7-9

DRIVE BELTS (Continued)

ProCarManuals.com

Page 277 of 2321

CLEANING

Clean all foreign debris from belt pulley grooves.

The belt pulleys must be free of oil, grease, and cool-

ants before installing the drive belt.

INSPECTION

Belt replacement under any or all of the following

conditions is required:

²Excessive wear

²Frayed cords

²Severe glazing

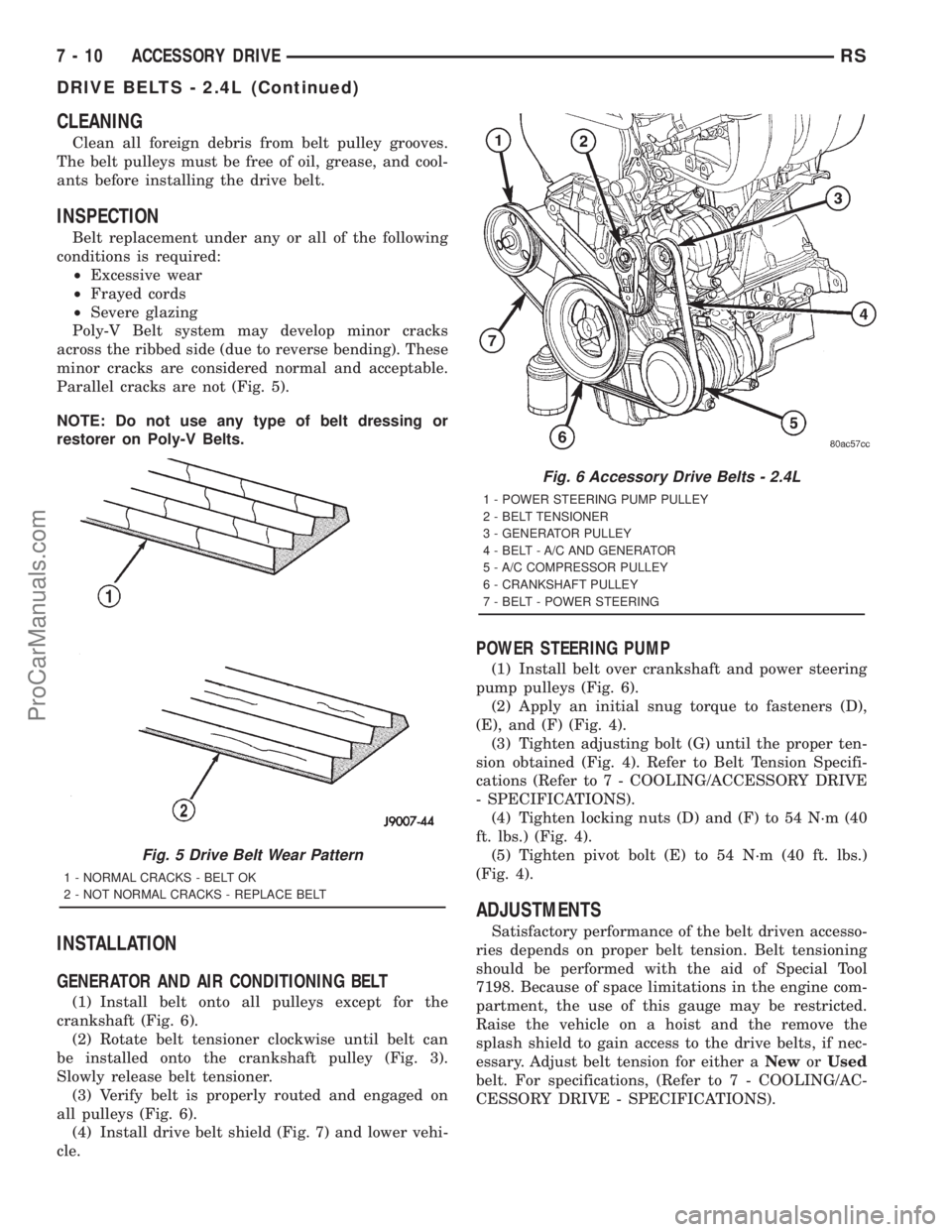

Poly-V Belt system may develop minor cracks

across the ribbed side (due to reverse bending). These

minor cracks are considered normal and acceptable.

Parallel cracks are not (Fig. 5).

NOTE: Do not use any type of belt dressing or

restorer on Poly-V Belts.

INSTALLATION

GENERATOR AND AIR CONDITIONING BELT

(1) Install belt onto all pulleys except for the

crankshaft (Fig. 6).

(2) Rotate belt tensioner clockwise until belt can

be installed onto the crankshaft pulley (Fig. 3).

Slowly release belt tensioner.

(3) Verify belt is properly routed and engaged on

all pulleys (Fig. 6).

(4) Install drive belt shield (Fig. 7) and lower vehi-

cle.

POWER STEERING PUMP

(1) Install belt over crankshaft and power steering

pump pulleys (Fig. 6).

(2) Apply an initial snug torque to fasteners (D),

(E), and (F) (Fig. 4).

(3) Tighten adjusting bolt (G) until the proper ten-

sion obtained (Fig. 4). Refer to Belt Tension Specifi-

cations (Refer to 7 - COOLING/ACCESSORY DRIVE

- SPECIFICATIONS).

(4) Tighten locking nuts (D) and (F) to 54 N´m (40

ft. lbs.) (Fig. 4).

(5) Tighten pivot bolt (E) to 54 N´m (40 ft. lbs.)

(Fig. 4).

ADJUSTMENTS

Satisfactory performance of the belt driven accesso-

ries depends on proper belt tension. Belt tensioning

should be performed with the aid of Special Tool

7198. Because of space limitations in the engine com-

partment, the use of this gauge may be restricted.

Raise the vehicle on a hoist and the remove the

splash shield to gain access to the drive belts, if nec-

essary. Adjust belt tension for either aNeworUsed

belt. For specifications, (Refer to 7 - COOLING/AC-

CESSORY DRIVE - SPECIFICATIONS).

Fig. 5 Drive Belt Wear Pattern

1 - NORMAL CRACKS - BELT OK

2 - NOT NORMAL CRACKS - REPLACE BELT

Fig. 6 Accessory Drive Belts - 2.4L

1 - POWER STEERING PUMP PULLEY

2 - BELT TENSIONER

3 - GENERATOR PULLEY

4 - BELT - A/C AND GENERATOR

5 - A/C COMPRESSOR PULLEY

6 - CRANKSHAFT PULLEY

7 - BELT - POWER STEERING

7 - 10 ACCESSORY DRIVERS

DRIVE BELTS - 2.4L (Continued)

ProCarManuals.com

Page 278 of 2321

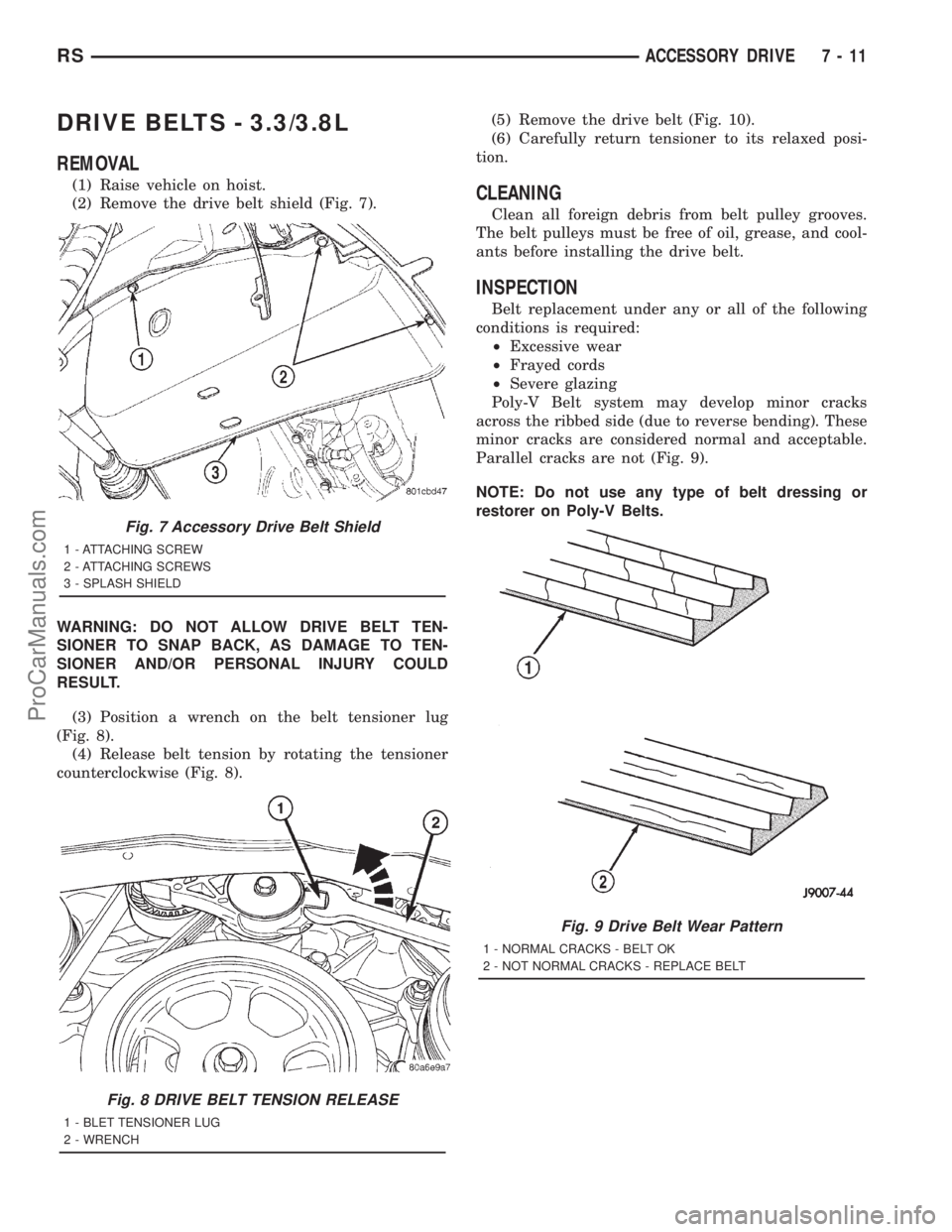

DRIVE BELTS - 3.3/3.8L

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove the drive belt shield (Fig. 7).

WARNING: DO NOT ALLOW DRIVE BELT TEN-

SIONER TO SNAP BACK, AS DAMAGE TO TEN-

SIONER AND/OR PERSONAL INJURY COULD

RESULT.

(3) Position a wrench on the belt tensioner lug

(Fig. 8).

(4) Release belt tension by rotating the tensioner

counterclockwise (Fig. 8).(5) Remove the drive belt (Fig. 10).

(6) Carefully return tensioner to its relaxed posi-

tion.CLEANING

Clean all foreign debris from belt pulley grooves.

The belt pulleys must be free of oil, grease, and cool-

ants before installing the drive belt.

INSPECTION

Belt replacement under any or all of the following

conditions is required:

²Excessive wear

²Frayed cords

²Severe glazing

Poly-V Belt system may develop minor cracks

across the ribbed side (due to reverse bending). These

minor cracks are considered normal and acceptable.

Parallel cracks are not (Fig. 9).

NOTE: Do not use any type of belt dressing or

restorer on Poly-V Belts.

Fig. 7 Accessory Drive Belt Shield

1 - ATTACHING SCREW

2 - ATTACHING SCREWS

3 - SPLASH SHIELD

Fig. 8 DRIVE BELT TENSION RELEASE

1 - BLET TENSIONER LUG

2 - WRENCH

Fig. 9 Drive Belt Wear Pattern

1 - NORMAL CRACKS - BELT OK

2 - NOT NORMAL CRACKS - REPLACE BELT

RSACCESSORY DRIVE7-11

ProCarManuals.com

Page 279 of 2321

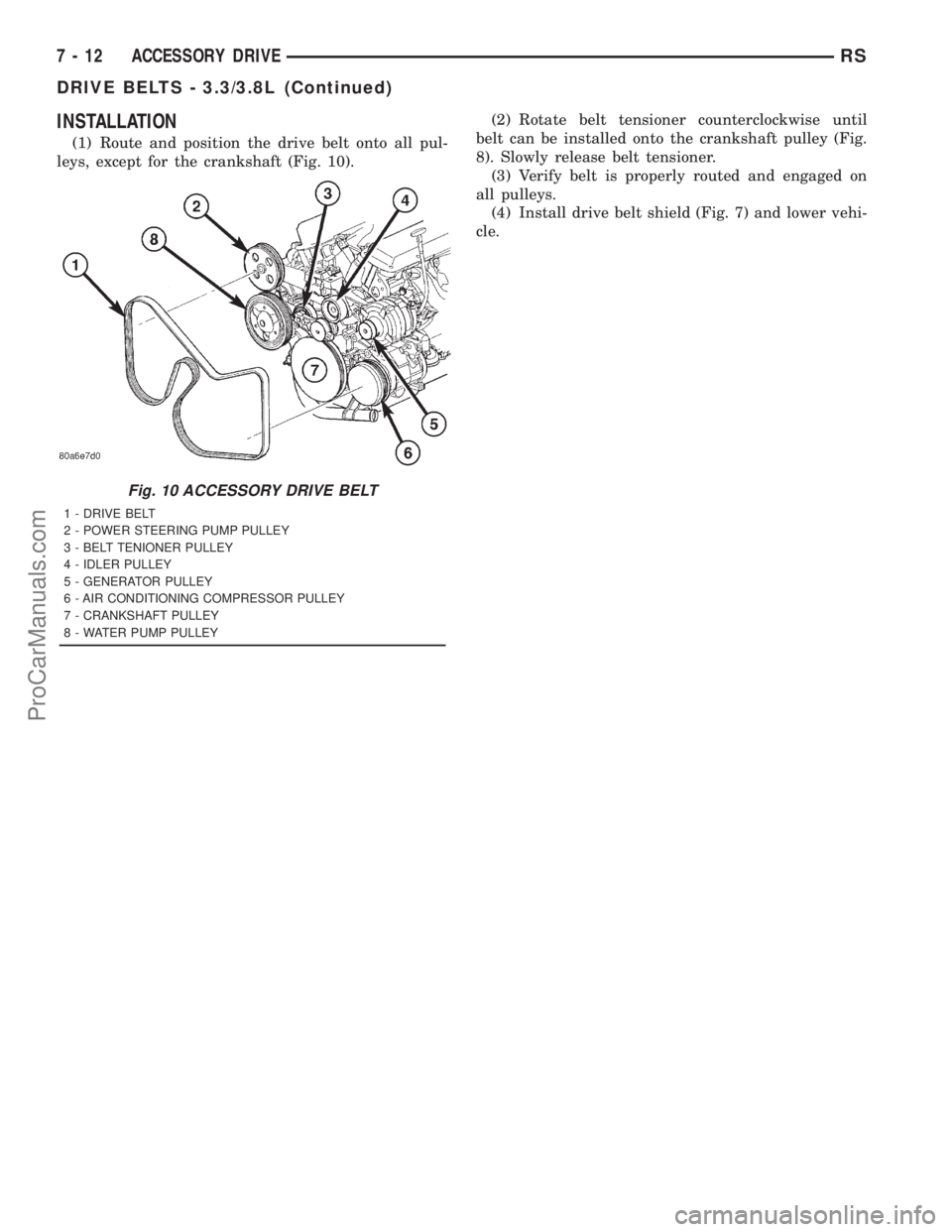

INSTALLATION

(1) Route and position the drive belt onto all pul-

leys, except for the crankshaft (Fig. 10).(2) Rotate belt tensioner counterclockwise until

belt can be installed onto the crankshaft pulley (Fig.

8). Slowly release belt tensioner.

(3) Verify belt is properly routed and engaged on

all pulleys.

(4) Install drive belt shield (Fig. 7) and lower vehi-

cle.

Fig. 10 ACCESSORY DRIVE BELT

1 - DRIVE BELT

2 - POWER STEERING PUMP PULLEY

3 - BELT TENIONER PULLEY

4 - IDLER PULLEY

5 - GENERATOR PULLEY

6 - AIR CONDITIONING COMPRESSOR PULLEY

7 - CRANKSHAFT PULLEY

8 - WATER PUMP PULLEY

7 - 12 ACCESSORY DRIVERS

DRIVE BELTS - 3.3/3.8L (Continued)

ProCarManuals.com

Page 280 of 2321

ENGINE

TABLE OF CONTENTS

page page

ENGINE

DIAGNOSIS AND TESTING.................14

COOLING SYSTEM DIAGNOSIS...........14

CLEANING..............................17

INSPECTION............................17

COOLANT

DIAGNOSIS AND TESTING.................17

COOLANT CONCENTRATION TESTING......17

STANDARD PROCEDURE..................18

COOLANT SERVICE.....................18

COOLANT RECOVERY CONTAINER

DESCRIPTION...........................18

OPERATION.............................18

DIAGNOSIS AND TESTING.................19

COOLANT RECOVERY SYSTEM CHECK.....19

REMOVAL..............................19

INSTALLATION...........................19

ENGINE BLOCK HEATER

DESCRIPTION...........................19

OPERATION.............................19

DIAGNOSIS AND TESTING.................19

ENGINE BLOCK HEATER TESTING.........19

REMOVAL..............................19

INSTALLATION...........................19

ENGINE COOLANT TEMP SENSOR - 2.4L

DESCRIPTION...........................20

REMOVAL..............................20

INSTALLATION...........................20

ENGINE COOLANT TEMP SENSOR - 3.3/3.8L

DESCRIPTION...........................20

REMOVAL..............................20

INSTALLATION...........................21

ENGINE COOLANT THERMOSTAT

DESCRIPTION...........................21

OPERATION.............................21

DIAGNOSIS AND TESTING.................22

THERMOSTAT.........................22

ENGINE COOLANT THERMOSTAT - 2.4L

REMOVAL..............................22

INSTALLATION...........................22

ENGINE COOLANT THERMOSTAT - 3.3/3.8L

REMOVAL..............................23

INSTALLATION...........................23

RADIATOR

DESCRIPTION...........................24

OPERATION.............................24

REMOVAL..............................24INSTALLATION...........................25

RADIATOR DRAINCOCK

REMOVAL..............................25

INSTALLATION...........................25

RADIATOR PRESSURE CAP

DESCRIPTION...........................26

OPERATION.............................26

DIAGNOSIS AND TESTING.................26

COOLING SYSTEM PRESSURE CAP

TESTING.............................26

RADIATOR CAP TO FILLER NECK SEAL.....26

CLEANING..............................27

INSPECTION............................27

RADIATOR FAN

DESCRIPTION...........................27

OPERATION.............................28

DIAGNOSIS AND TESTING.................28

RADIATOR FAN MOTOR TEST.............28

REMOVAL..............................29

INSTALLATION...........................29

RADIATOR FAN RELAY

DESCRIPTION...........................29

OPERATION.............................29

REMOVAL..............................29

INSTALLATION...........................29

WATER PUMP - 2.4L

DESCRIPTION...........................30

OPERATION.............................30

REMOVAL..............................30

CLEANING..............................31

INSPECTION............................31

INSTALLATION...........................31

WATER PUMP - 3.3/3.8L

DESCRIPTION...........................32

OPERATION.............................32

REMOVAL..............................32

CLEANING..............................33

INSPECTION............................33

INSTALLATION...........................33

WATER PUMP INLET TUBE - 2.4L

DESCRIPTION...........................34

REMOVAL..............................34

INSTALLATION...........................34

WATER PUMP INLET TUBE - 3.3/3.8L

REMOVAL..............................35

INSTALLATION...........................35

RSENGINE7-13

ProCarManuals.com