DODGE TOWN AND COUNTRY 2004 Service Manual

Manufacturer: DODGE, Model Year: 2004, Model line: TOWN AND COUNTRY, Model: DODGE TOWN AND COUNTRY 2004Pages: 2585, PDF Size: 62.54 MB

Page 701 of 2585

WIPER BLADES

REMOVAL

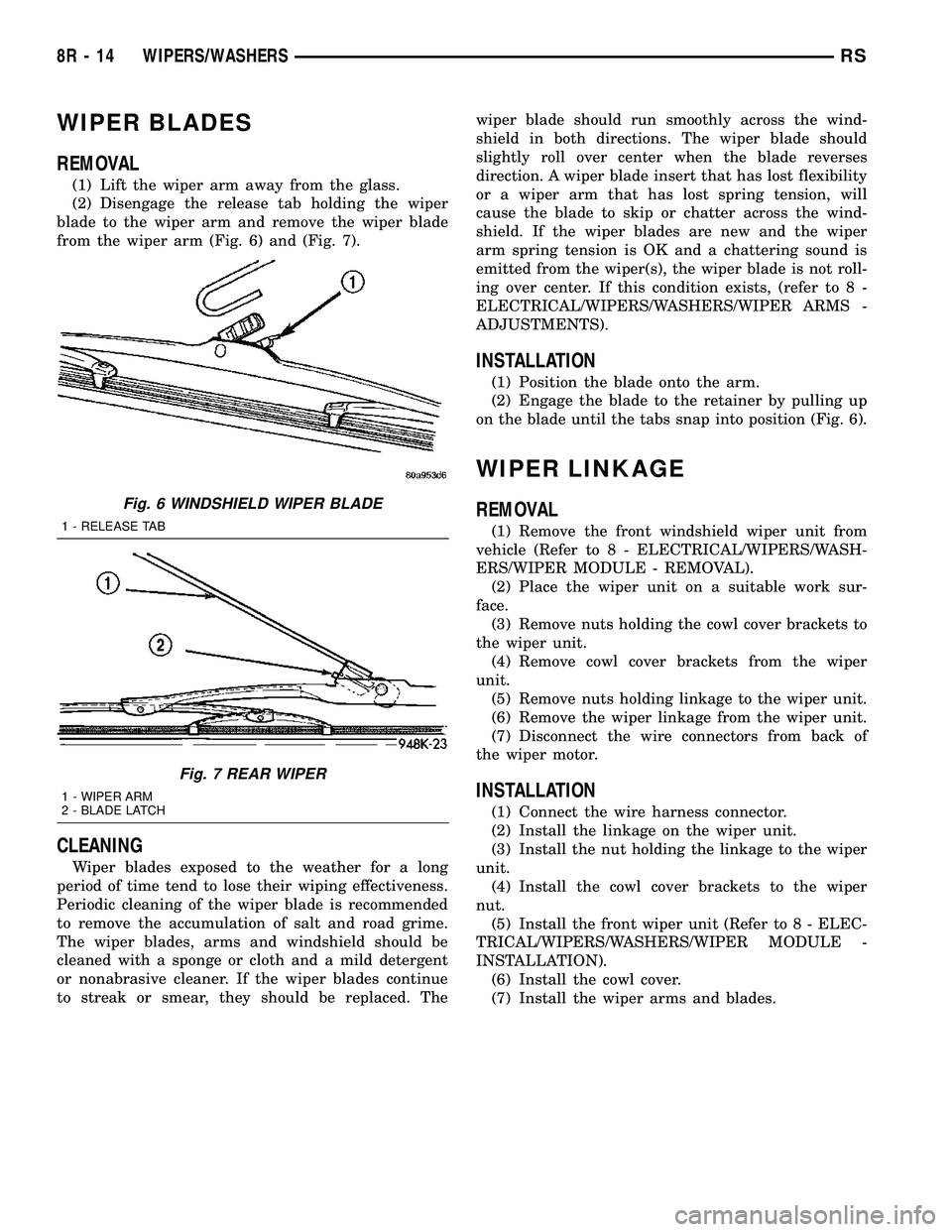

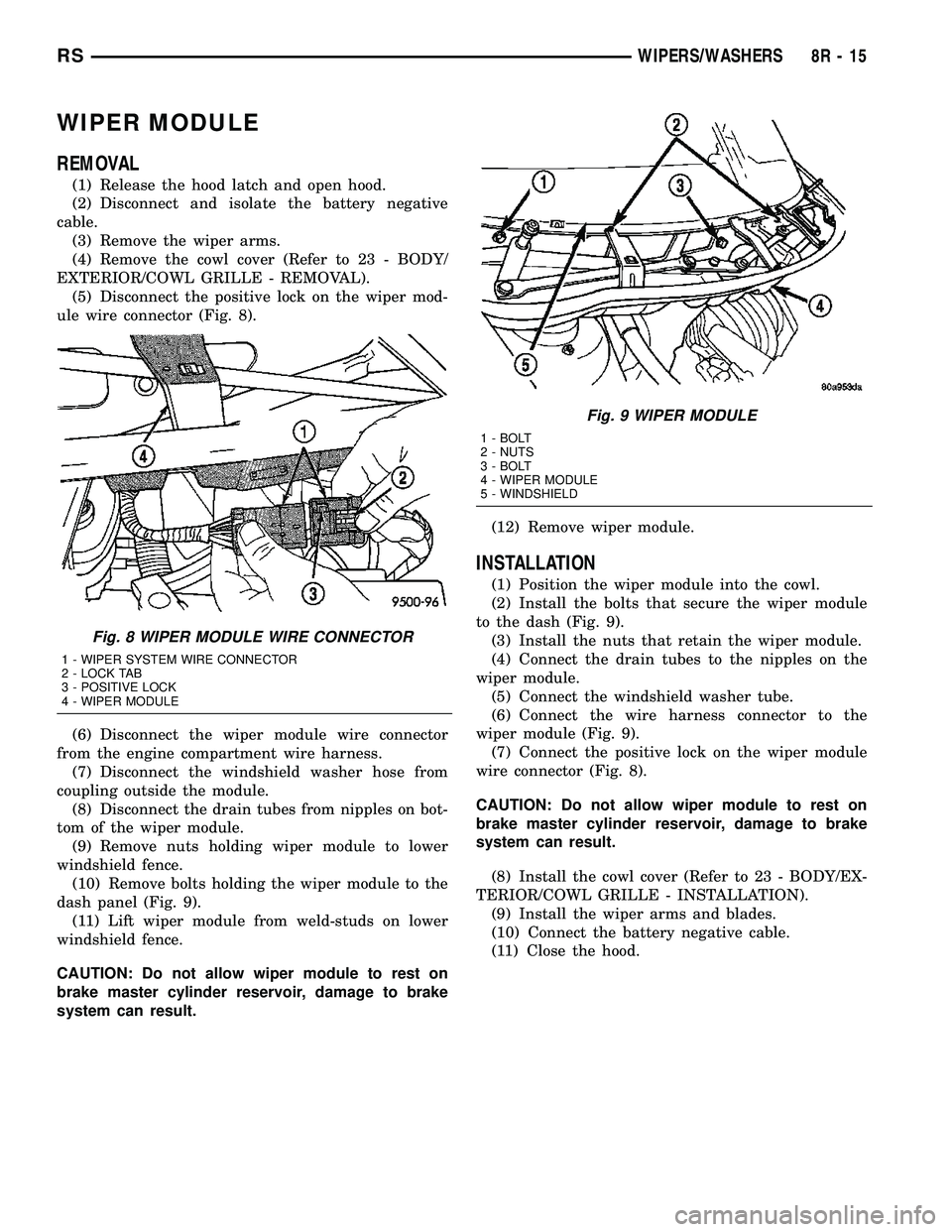

(1) Lift the wiper arm away from the glass.

(2) Disengage the release tab holding the wiper

blade to the wiper arm and remove the wiper blade

from the wiper arm (Fig. 6) and (Fig. 7).

CLEANING

Wiper blades exposed to the weather for a long

period of time tend to lose their wiping effectiveness.

Periodic cleaning of the wiper blade is recommended

to remove the accumulation of salt and road grime.

The wiper blades, arms and windshield should be

cleaned with a sponge or cloth and a mild detergent

or nonabrasive cleaner. If the wiper blades continue

to streak or smear, they should be replaced. Thewiper blade should run smoothly across the wind-

shield in both directions. The wiper blade should

slightly roll over center when the blade reverses

direction. A wiper blade insert that has lost flexibility

or a wiper arm that has lost spring tension, will

cause the blade to skip or chatter across the wind-

shield. If the wiper blades are new and the wiper

arm spring tension is OK and a chattering sound is

emitted from the wiper(s), the wiper blade is not roll-

ing over center. If this condition exists, (refer to 8 -

ELECTRICAL/WIPERS/WASHERS/WIPER ARMS -

ADJUSTMENTS).

INSTALLATION

(1) Position the blade onto the arm.

(2) Engage the blade to the retainer by pulling up

on the blade until the tabs snap into position (Fig. 6).

WIPER LINKAGE

REMOVAL

(1) Remove the front windshield wiper unit from

vehicle (Refer to 8 - ELECTRICAL/WIPERS/WASH-

ERS/WIPER MODULE - REMOVAL).

(2) Place the wiper unit on a suitable work sur-

face.

(3) Remove nuts holding the cowl cover brackets to

the wiper unit.

(4) Remove cowl cover brackets from the wiper

unit.

(5) Remove nuts holding linkage to the wiper unit.

(6) Remove the wiper linkage from the wiper unit.

(7) Disconnect the wire connectors from back of

the wiper motor.

INSTALLATION

(1) Connect the wire harness connector.

(2) Install the linkage on the wiper unit.

(3) Install the nut holding the linkage to the wiper

unit.

(4) Install the cowl cover brackets to the wiper

nut.

(5) Install the front wiper unit (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

INSTALLATION).

(6) Install the cowl cover.

(7) Install the wiper arms and blades.

Fig. 6 WINDSHIELD WIPER BLADE

1 - RELEASE TAB

Fig. 7 REAR WIPER

1 - WIPER ARM

2 - BLADE LATCH

8R - 14 WIPERS/WASHERSRS

Page 702 of 2585

WIPER MODULE

REMOVAL

(1) Release the hood latch and open hood.

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the wiper arms.

(4) Remove the cowl cover (Refer to 23 - BODY/

EXTERIOR/COWL GRILLE - REMOVAL).

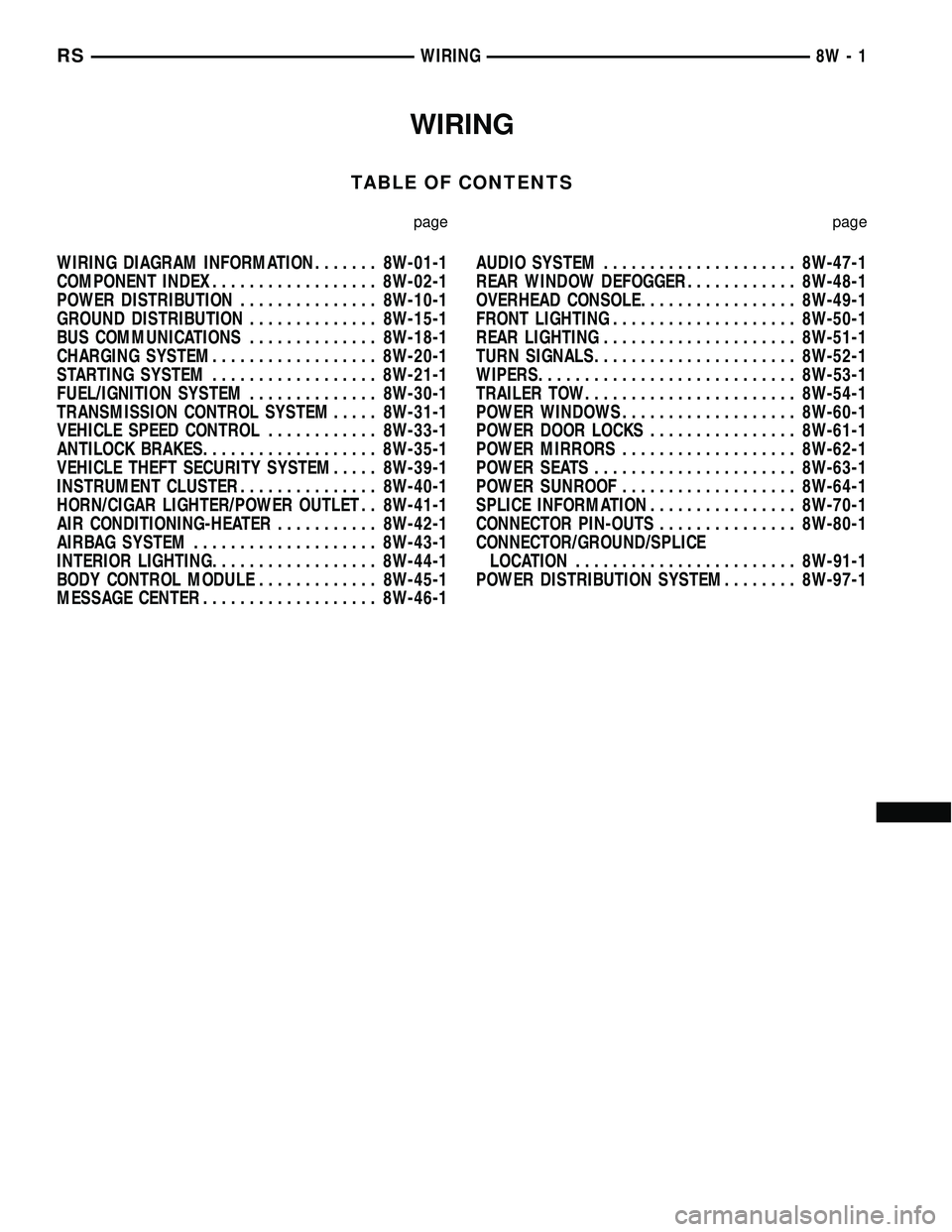

(5) Disconnect the positive lock on the wiper mod-

ule wire connector (Fig. 8).

(6) Disconnect the wiper module wire connector

from the engine compartment wire harness.

(7) Disconnect the windshield washer hose from

coupling outside the module.

(8) Disconnect the drain tubes from nipples on bot-

tom of the wiper module.

(9) Remove nuts holding wiper module to lower

windshield fence.

(10) Remove bolts holding the wiper module to the

dash panel (Fig. 9).

(11) Lift wiper module from weld-studs on lower

windshield fence.

CAUTION: Do not allow wiper module to rest on

brake master cylinder reservoir, damage to brake

system can result.(12) Remove wiper module.

INSTALLATION

(1) Position the wiper module into the cowl.

(2) Install the bolts that secure the wiper module

to the dash (Fig. 9).

(3) Install the nuts that retain the wiper module.

(4) Connect the drain tubes to the nipples on the

wiper module.

(5) Connect the windshield washer tube.

(6) Connect the wire harness connector to the

wiper module (Fig. 9).

(7) Connect the positive lock on the wiper module

wire connector (Fig. 8).

CAUTION: Do not allow wiper module to rest on

brake master cylinder reservoir, damage to brake

system can result.

(8) Install the cowl cover (Refer to 23 - BODY/EX-

TERIOR/COWL GRILLE - INSTALLATION).

(9) Install the wiper arms and blades.

(10) Connect the battery negative cable.

(11) Close the hood.

Fig. 8 WIPER MODULE WIRE CONNECTOR

1 - WIPER SYSTEM WIRE CONNECTOR

2 - LOCK TAB

3 - POSITIVE LOCK

4 - WIPER MODULE

Fig. 9 WIPER MODULE

1 - BOLT

2 - NUTS

3 - BOLT

4 - WIPER MODULE

5 - WINDSHIELD

RSWIPERS/WASHERS8R-15

Page 703 of 2585

Page 704 of 2585

WIRING

TABLE OF CONTENTS

page page

WIRING DIAGRAM INFORMATION....... 8W-01-1

COMPONENT INDEX.................. 8W-02-1

POWER DISTRIBUTION............... 8W-10-1

GROUND DISTRIBUTION.............. 8W-15-1

BUS COMMUNICATIONS.............. 8W-18-1

CHARGING SYSTEM.................. 8W-20-1

STARTING SYSTEM.................. 8W-21-1

FUEL/IGNITION SYSTEM.............. 8W-30-1

TRANSMISSION CONTROL SYSTEM..... 8W-31-1

VEHICLE SPEED CONTROL............ 8W-33-1

ANTILOCK BRAKES................... 8W-35-1

VEHICLE THEFT SECURITY SYSTEM..... 8W-39-1

INSTRUMENT CLUSTER............... 8W-40-1

HORN/CIGAR LIGHTER/POWER OUTLET . . 8W-41-1

AIR CONDITIONING-HEATER........... 8W-42-1

AIRBAG SYSTEM.................... 8W-43-1

INTERIOR LIGHTING.................. 8W-44-1

BODY CONTROL MODULE............. 8W-45-1

MESSAGE CENTER................... 8W-46-1AUDIO SYSTEM..................... 8W-47-1

REAR WINDOW DEFOGGER............ 8W-48-1

OVERHEAD CONSOLE................. 8W-49-1

FRONT LIGHTING.................... 8W-50-1

REAR LIGHTING..................... 8W-51-1

TURN SIGNALS...................... 8W-52-1

WIPERS............................ 8W-53-1

TRAILER TOW....................... 8W-54-1

POWER WINDOWS................... 8W-60-1

POWER DOOR LOCKS................ 8W-61-1

POWER MIRRORS................... 8W-62-1

POWER SEATS...................... 8W-63-1

POWER SUNROOF................... 8W-64-1

SPLICE INFORMATION................ 8W-70-1

CONNECTOR PIN-OUTS............... 8W-80-1

CONNECTOR/GROUND/SPLICE

LOCATION........................ 8W-91-1

POWER DISTRIBUTION SYSTEM........ 8W-97-1 RSWIRING

8W-1

Page 705 of 2585

Page 706 of 2585

8W-01 WIRING DIAGRAM INFORMATION

TABLE OF CONTENTS

page page

WIRING DIAGRAM INFORMATION

DESCRIPTION

DESCRIPTION - HOW TO USE WIRING

DIAGRAMS...........................1

DESCRIPTION - CIRCUIT INFORMATION....5

DESCRIPTION - CIRCUIT FUNCTIONS......6

DESCRIPTION - SECTION IDENTIFICATION

AND INFORMATION....................6

DESCRIPTION - CONNECTOR, GROUND

AND SPLICE INFORMATION..............7

WARNING

WARNINGS - GENERAL.................7

DIAGNOSIS AND TESTING - WIRING

HARNESS............................7

STANDARD PROCEDURE

STANDARD PROCEDURE -

ELECTROSTATIC DISCHARGE (ESD)

SENSITIVE DEVICES...................8

STANDARD PROCEDURE - TESTING OF

VOLTAGE POTENTIAL...................9

STANDARD PROCEDURE - TESTING FOR

CONTINUITY..........................9STANDARD PROCEDURE - TESTING FOR A

SHORT TO GROUND...................9

STANDARD PROCEDURE - TESTING FOR A

SHORT TO GROUND ON FUSES

POWERING SEVERAL LOADS...........10

STANDARD PROCEDURE - TESTING FOR A

VOLTAGE DROP......................10

SPECIAL TOOLS

WIRING/TERMINAL....................10

CONNECTOR

REMOVAL.............................11

INSTALLATION.........................11

DIODE

REMOVAL.............................14

INSTALLATION.........................14

TERMINAL

REMOVAL.............................14

INSTALLATION.........................14

WIRE

STANDARD PROCEDURE - WIRE SPLICING . . 15

WIRING DIAGRAM

INFORMATION

DESCRIPTION

DESCRIPTION - HOW TO USE WIRING

DIAGRAMS

DaimlerChrysler Corporation wiring diagrams are

designed to provide information regarding the vehi-

cles wiring content. In order to effectively use the

wiring diagrams to diagnose and repair

DaimlerChrysler Corporation vehicles, it is important

to understand all of their features and characteris-

tics.

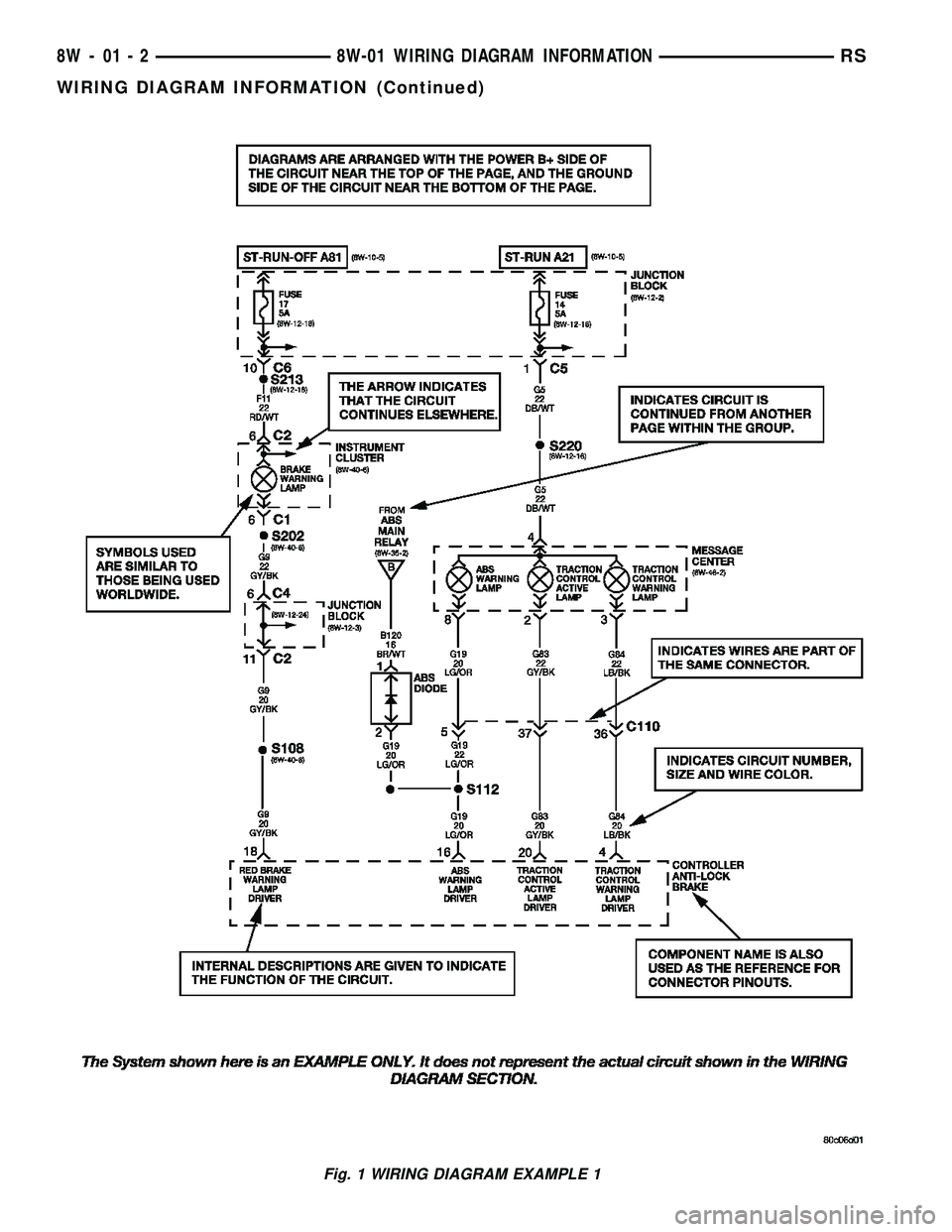

Diagrams are arranged such that the power (B+)

side of the circuit is placed near the top of the page,

and the ground (B-) side of the circuit is placed near

the bottom of the page (Fig. 1).

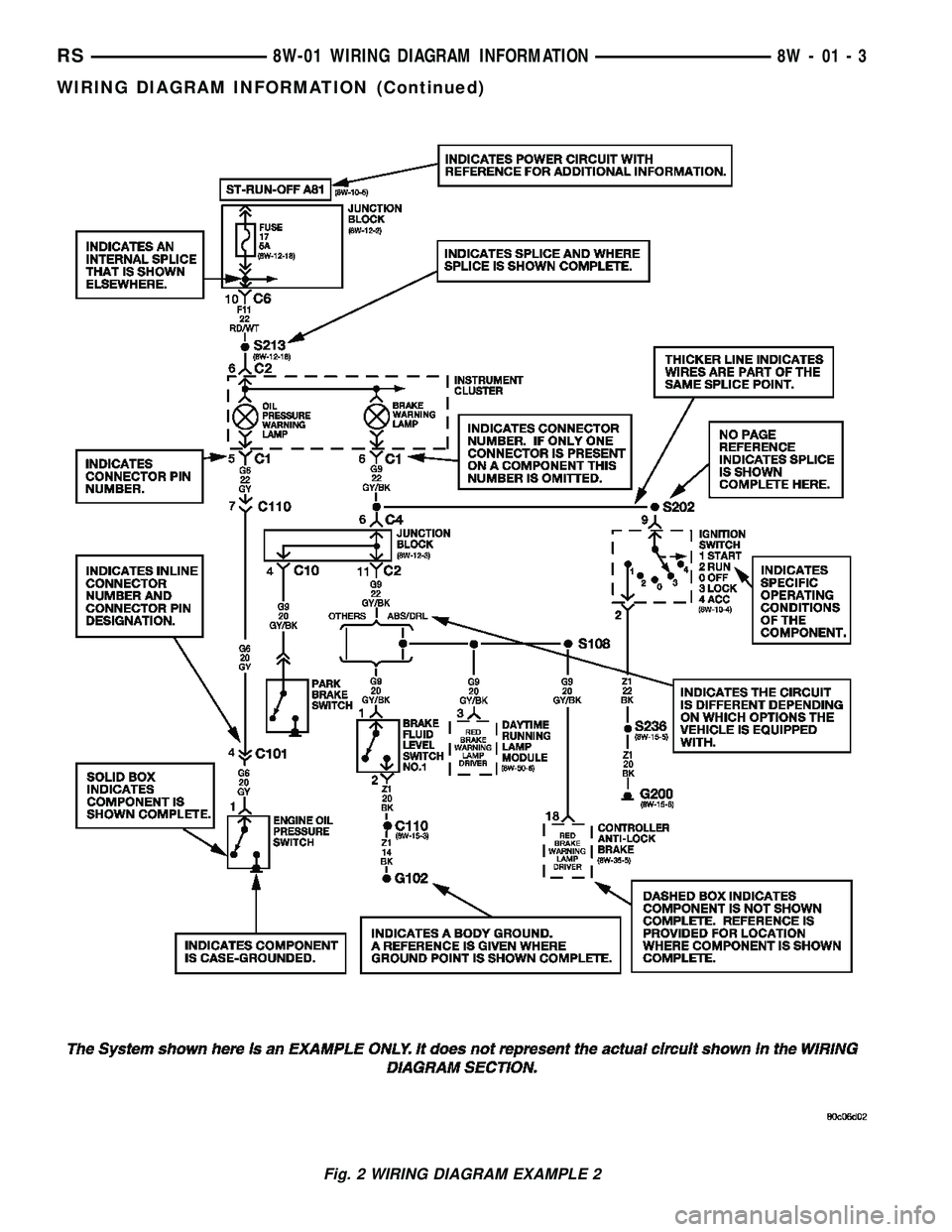

All switches, components, and modules are shown

in the at rest position with the doors closed and the

key removed from the ignition (Fig. 2).Components are shown two ways. A solid line

around a component indicates that the component is

complete. A dashed line around the component indi-

cates that the component is being shown is not com-

plete. Incomplete components have a reference

number to indicate the page where the component is

shown complete.

It is important to realize that no attempt is made

on the diagrams to represent components and wiring

as they appear on the vehicle. For example, a short

piece of wire is treated the same as a long one. In

addition, switches and other components are shown

as simply as possible, with regard to function only.

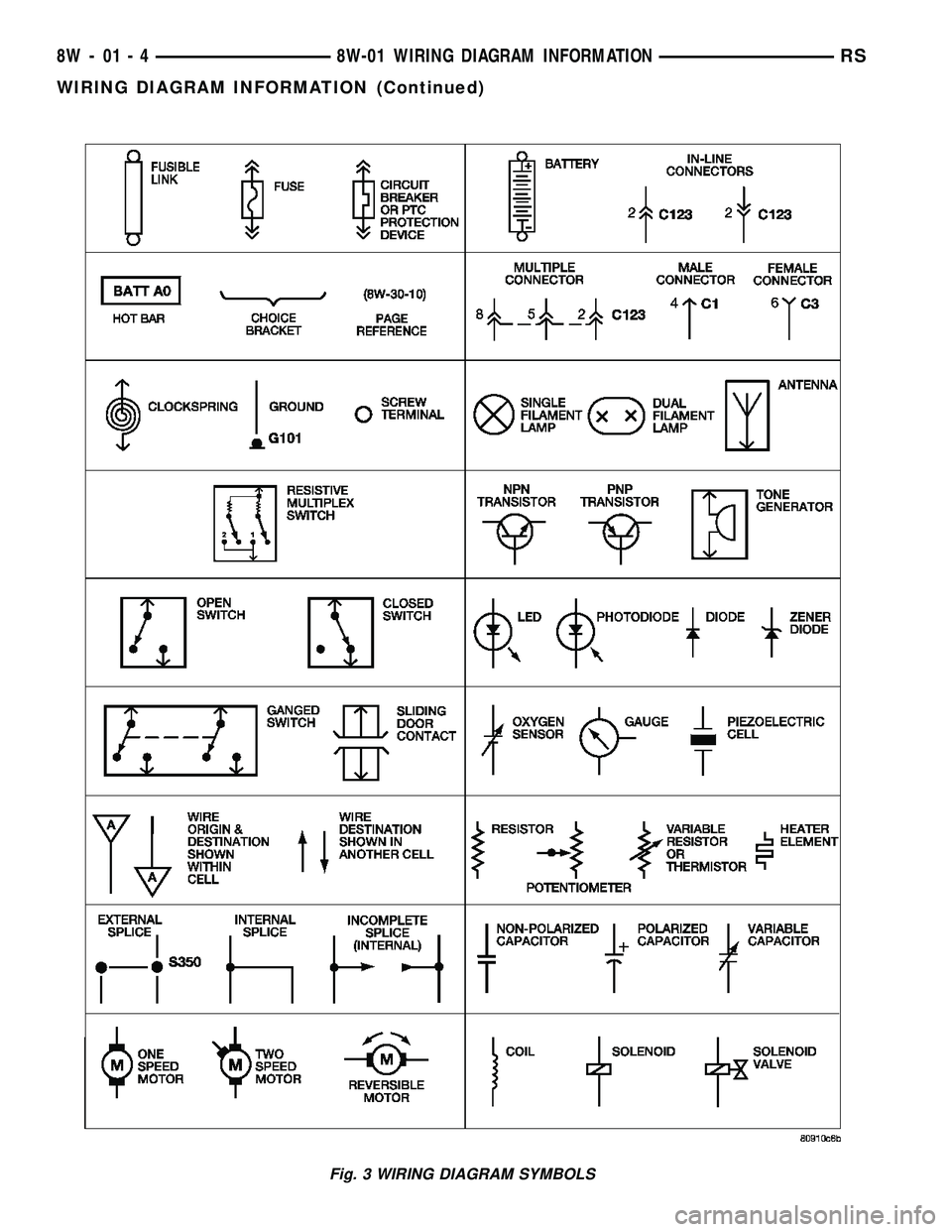

SYMBOLS

International symbols are used throughout the wir-

ing diagrams. These symbols are consistent with

those being used around the world (Fig. 3).

RS8W-01 WIRING DIAGRAM INFORMATION8W-01-1

Page 707 of 2585

Fig. 1 WIRING DIAGRAM EXAMPLE 1

8W - 01 - 2 8W-01 WIRING DIAGRAM INFORMATIONRS

WIRING DIAGRAM INFORMATION (Continued)

Page 708 of 2585

Fig. 2 WIRING DIAGRAM EXAMPLE 2

RS8W-01 WIRING DIAGRAM INFORMATION8W-01-3

WIRING DIAGRAM INFORMATION (Continued)

Page 709 of 2585

Fig. 3 WIRING DIAGRAM SYMBOLS

8W - 01 - 4 8W-01 WIRING DIAGRAM INFORMATIONRS

WIRING DIAGRAM INFORMATION (Continued)

Page 710 of 2585

TERMINOLOGY

This is a list of terms and definitions used in the

wiring diagrams.

LHD.................Left Hand Drive Vehicles

RHD ...............Right Hand Drive Vehicles

ATX . . Automatic Transmissions-Front Wheel Drive

MTX . . . Manual Transmissions-Front Wheel Drive

AT....Automatic Transmissions-Rear Wheel Drive

MT .....Manual Transmissions-Rear Wheel Drive

SOHC...........Single Over Head Cam Engine

DOHC..........Double Over Head Cam Engine

Built-Up-Export....... Vehicles Built For Sale In

Markets Other Than North America

Except Built-Up-Export . Vehicles Built For Sale In

North America

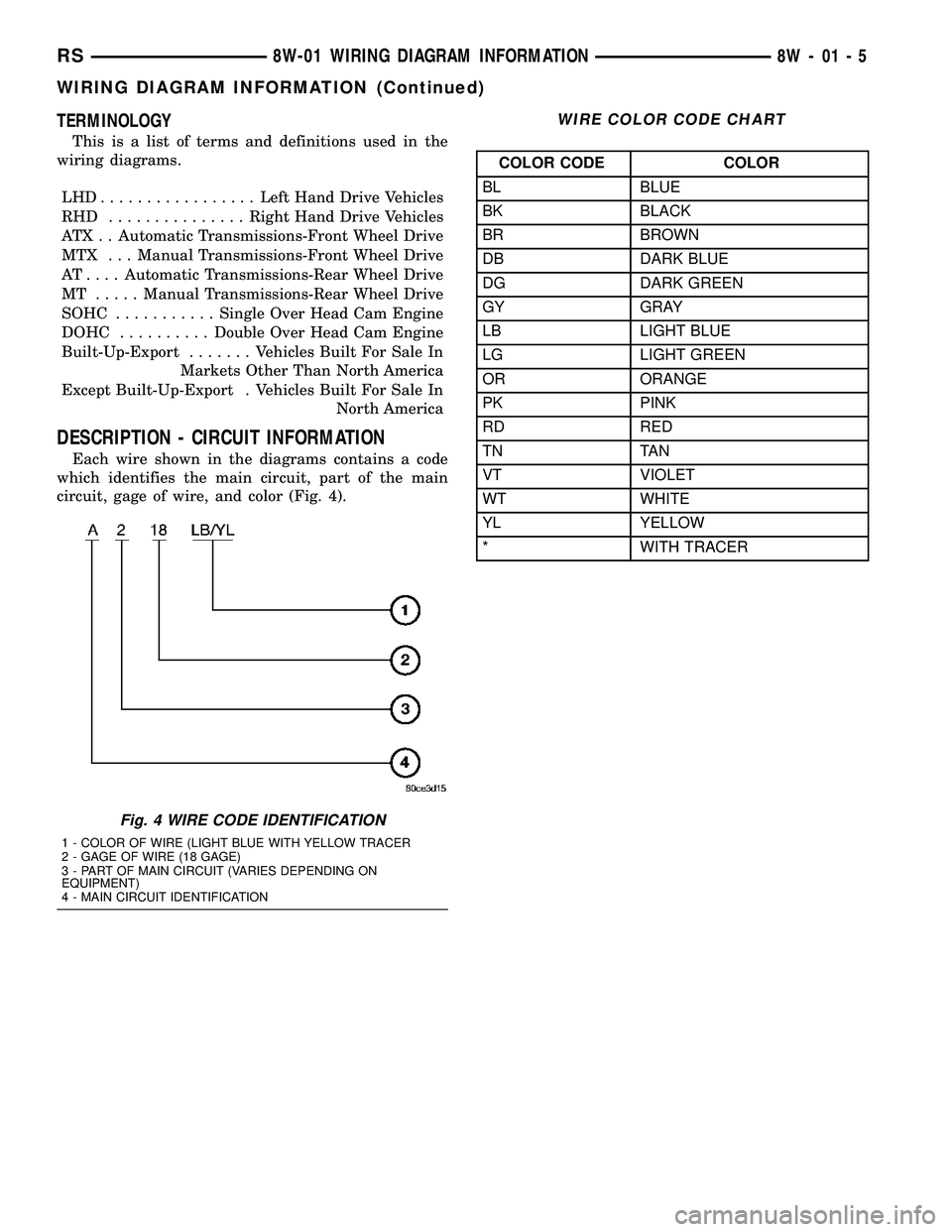

DESCRIPTION - CIRCUIT INFORMATION

Each wire shown in the diagrams contains a code

which identifies the main circuit, part of the main

circuit, gage of wire, and color (Fig. 4).

WIRE COLOR CODE CHART

COLOR CODE COLOR

BL BLUE

BK BLACK

BR BROWN

DB DARK BLUE

DG DARK GREEN

GY GRAY

LB LIGHT BLUE

LG LIGHT GREEN

OR ORANGE

PK PINK

RD RED

TN TAN

VT VIOLET

WT WHITE

YL YELLOW

* WITH TRACER

Fig. 4 WIRE CODE IDENTIFICATION

1 - COLOR OF WIRE (LIGHT BLUE WITH YELLOW TRACER

2 - GAGE OF WIRE (18 GAGE)

3 - PART OF MAIN CIRCUIT (VARIES DEPENDING ON

EQUIPMENT)

4 - MAIN CIRCUIT IDENTIFICATION

RS8W-01 WIRING DIAGRAM INFORMATION8W-01-5

WIRING DIAGRAM INFORMATION (Continued)