Bearing nut DODGE TRUCK 1993 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 1378 of 1502

•

WHEELS

AND

TIRES

22 - 9

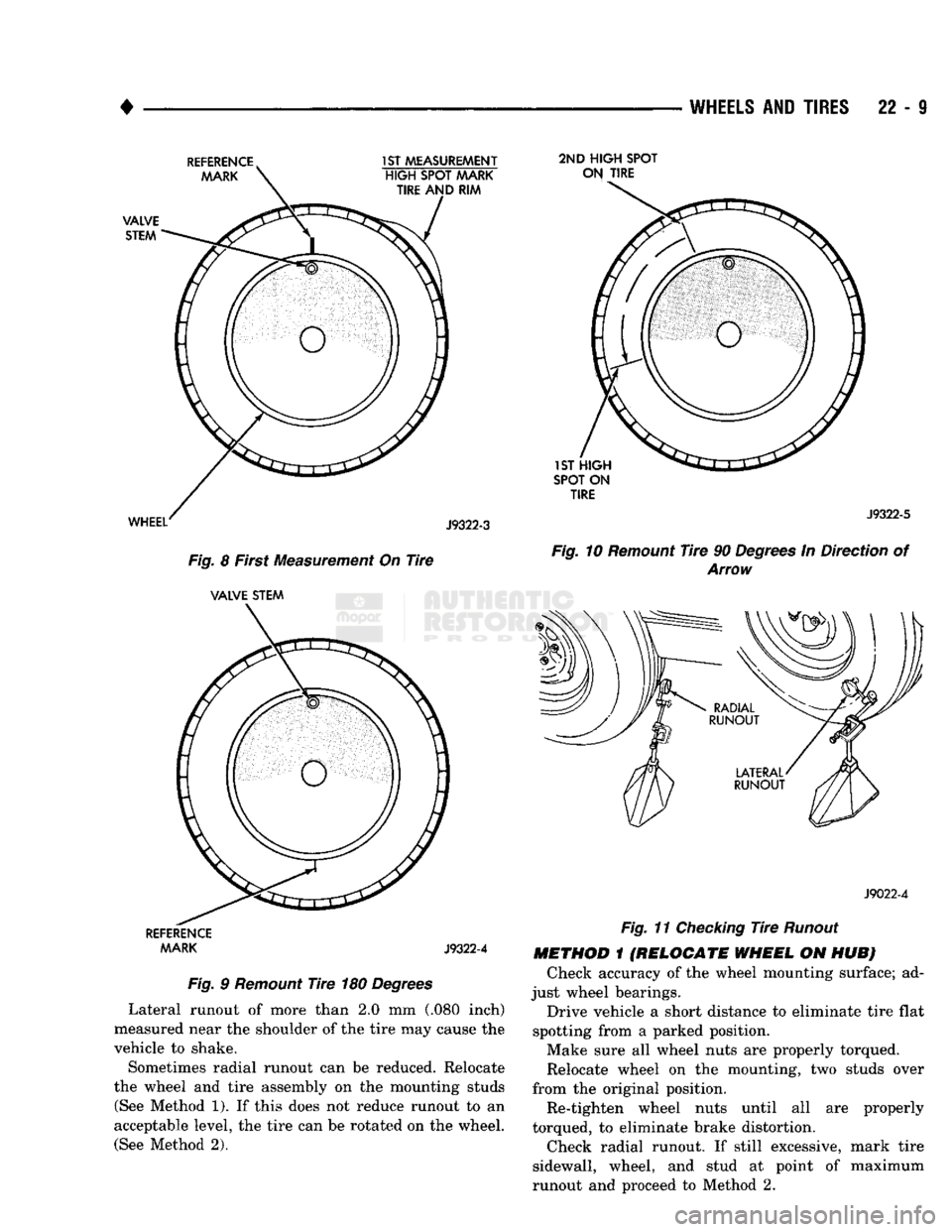

Fig.

8 First Measurement On

Tire

VALVE STEM

REFERENCE

AAARK J9322-4

Fig.

9

Remount

Tire

180

Degrees

Lateral runout of more than 2.0 mm (.080 inch)

measured near the shoulder of the tire may cause the

vehicle to shake.

Sometimes radial runout can be reduced. Relocate

the wheel and tire assembly on the mounting studs (See Method 1). If this does not reduce runout to an

acceptable level, the tire can be rotated on the wheel. (See Method 2). 2ND HIGH SPOT

ON TIRE

SPOT ON TIRE J9322-5

Fig.

10

Remount

Tire

90

Degrees

In Direction of

Arrow

J9022-4

Fig.

11

Checking

Tire

Runout

METHOD

1

(RELOCATE WHEEL

ON HUB) Check accuracy of the wheel mounting surface; ad

just wheel bearings.

Drive vehicle a short distance to eliminate tire flat

spotting from a parked position. Make sure all wheel nuts are properly torqued.

Relocate wheel on the mounting, two studs over

from the original position.

Re-tighten wheel nuts until all are properly

torqued, to eliminate brake distortion.

Check radial runout. If still excessive, mark tire

sidewall, wheel, and stud at point of maximum

runout and proceed to Method 2.

Page 1447 of 1502

24 - 10

HEATING

AND AIR

CONDITIONING

•

(3) Add 50 ml (1.7 oz.) of clean refrigerant oil

through the suction port.

(4) Install compressor.

(5) Install the suction and discharge lines to the

compressor. Use new gaskets to prevent leakage.

Tighten the line nuts to 23 N*m (200 in. lbs.) torque.

(6)

Evacuate and charge system.

OVER-ALL

PERFORMANCE

TEST

Humidity has an important bearing on the temper

ature of the air delivered to the vehicle's interior.

This is true of all air conditioning systems It is im

portant to understand the effect humidity has on the

performance of the system. When humidity is high,

the evaporator has to perform a double duty. It must lower the air temperature and the temperature of the

moisture carried in the air. Condensing the moisture

in the air transfers a great deal of heat energy into

the evaporator fins and tubing. This reduces the amount of heat the evaporator can absorb from the

air.

Evaporator capacity used to reduce the amount of

moisture in the air is not wasted. Wringing some of

the moisture out of the air entering the vehicle adds

to the comfort of the passengers. However, an owner may expect too much from their air conditioning sys

tem on humid days. A performance test is the best

way to determine whether or not the system is per

forming up to standard. This test also provides valu able clues to the possible cause of trouble.

To perform the test the air temperature in the test

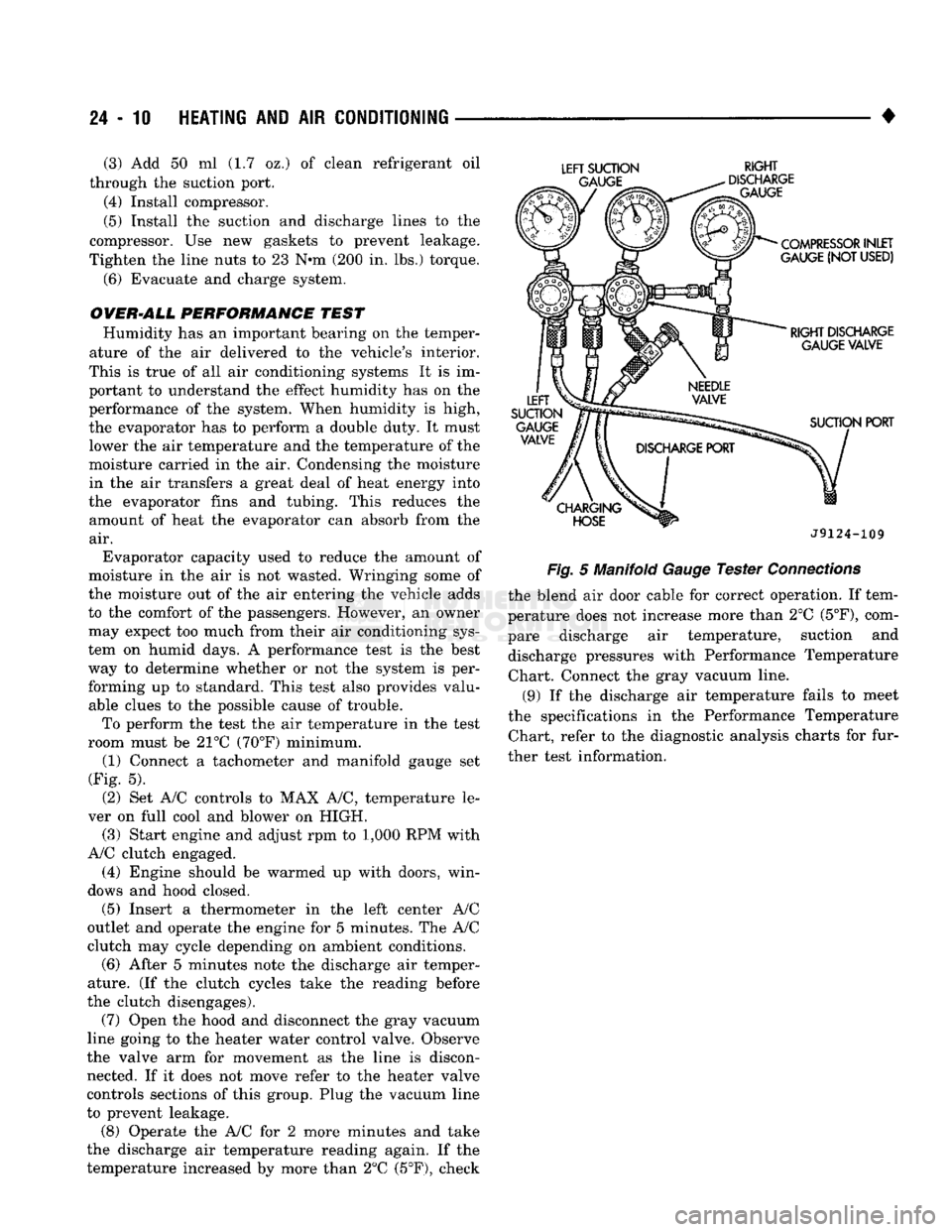

room must be 21°C (70°F) minimum. (1) Connect a tachometer and manifold gauge set

(Fig. 5).

(2) Set A/C controls to MAX A/C, temperature le

ver on full cool and blower on HIGH. (3) Start engine and adjust rpm to 1,000 RPM with

A/C clutch engaged.

(4) Engine should be warmed up with doors, win

dows and hood closed.

(5)

Insert a thermometer in the left center A/C

outlet and operate the engine for 5 minutes. The A/C

clutch may cycle depending on ambient conditions.

(6)

After 5 minutes note the discharge air temper

ature. (If the clutch cycles take the reading before

the clutch disengages).

(7) Open the hood and disconnect the gray vacuum

line going to the heater water control valve. Observe

the valve arm for movement as the line is discon nected. If it does not move refer to the heater valve

controls sections of this group. Plug the vacuum line

to prevent leakage.

(8) Operate the A/C for 2 more minutes and take

the discharge air temperature reading again. If the

temperature increased by more than 2°C (5°F), check

LEFT

SUCTION

RIGHT

J9124-109

Fig.

5 Manifold

Gauge

Tester

Connections

the blend air door cable for correct operation. If tem

perature does not increase more than 2°C

(5°F),

com

pare discharge air temperature, suction and discharge pressures with Performance Temperature Chart. Connect the gray vacuum line.

(9) If the discharge air temperature fails to meet

the specifications in the Performance Temperature Chart, refer to the diagnostic analysis charts for fur

ther test information.

Page 1451 of 1502

24 - 14

HEATING

AND AIR

CONDITIONING

•

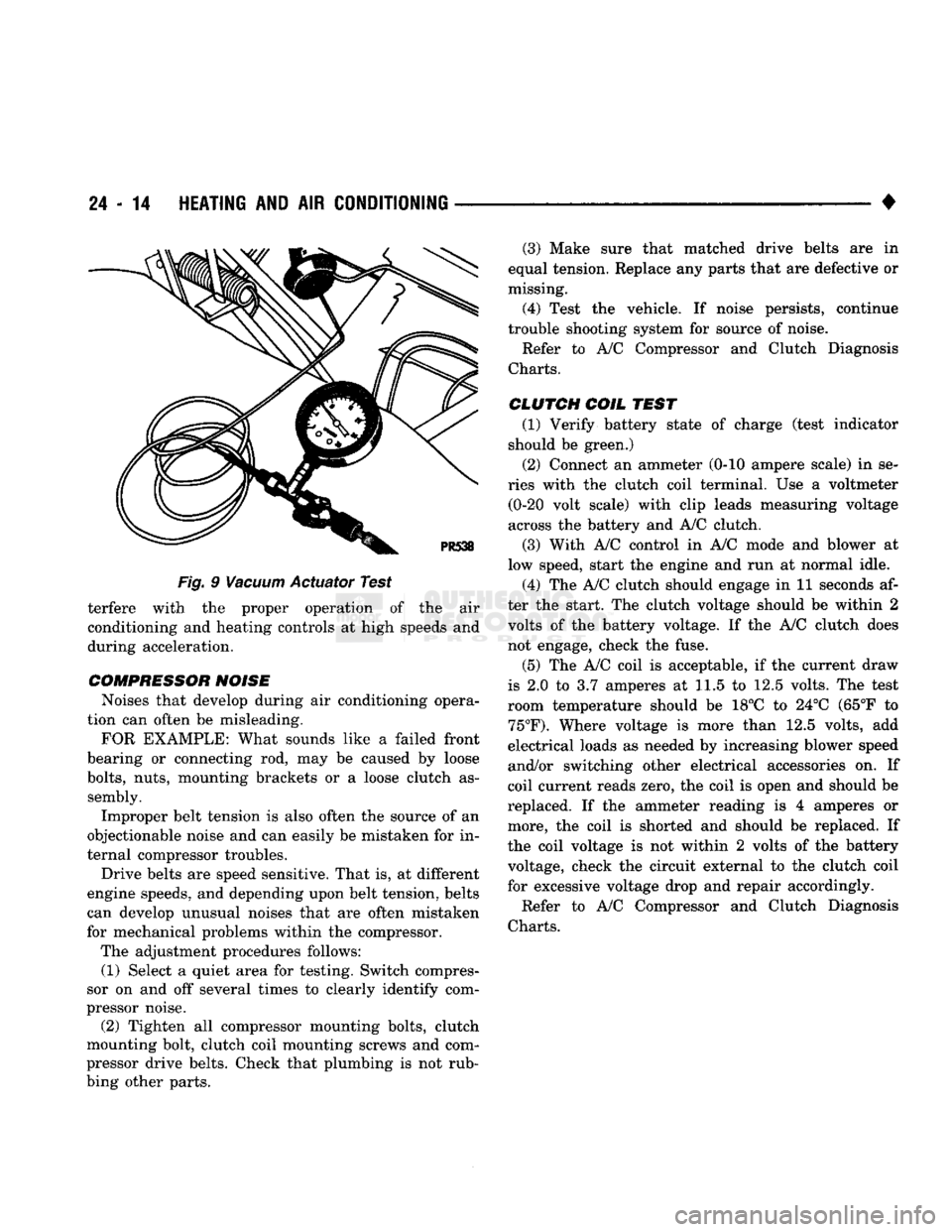

Fig.

9

Vacuum

Actuator Test terfere with the proper operation of the air

conditioning and heating controls at high speeds and

during acceleration.

COMPRESSOR NOISE Noises that develop during air conditioning opera

tion can often be misleading.

FOR EXAMPLE: What sounds like a failed front

bearing or connecting rod, may be caused by loose

bolts,

nuts, mounting brackets or a loose clutch as sembly.

Improper belt tension is also often the source of an

objectionable noise and can easily be mistaken for in

ternal compressor troubles.

Drive belts are speed sensitive. That is, at different

engine speeds, and depending upon belt tension, belts

can develop unusual noises that are often mistaken

for mechanical problems within the compressor.

The adjustment procedures follows: (1) Select a quiet area for testing. Switch compres

sor on and off several times to clearly identify com

pressor noise. (2) Tighten all compressor mounting bolts, clutch

mounting bolt, clutch coil mounting screws and com

pressor drive belts. Check that plumbing is not rub

bing other parts. (3) Make sure that matched drive belts are in

equal tension. Replace any parts that are defective or

missing.

(4) Test the vehicle. If noise persists, continue

trouble shooting system for source of noise. Refer to A/C Compressor and Clutch Diagnosis

Charts.

CLUTCH COIL

TEST

(1) Verify battery state of charge (test indicator

should be green.)

(2) Connect an ammeter (0-10 ampere scale) in se

ries with the clutch coil terminal. Use a voltmeter (0-20 volt scale) with clip leads measuring voltage

across the battery and A/C clutch.

(3) With A/C control in A/C mode and blower at

low speed, start the engine and run at normal idle.

(4) The A/C clutch should engage in 11 seconds af

ter the start. The clutch voltage should be within 2

volts of the battery voltage. If the A/C clutch does not engage, check the fuse.

(5) The A/C coil is acceptable, if the current draw

is 2.0 to 3.7 amperes at 11.5 to 12.5 volts. The test

room temperature should be 18°C to 24°C (65°F to

75°F).

Where voltage is more than 12.5 volts, add

electrical loads as needed by increasing blower speed

and/or switching other electrical accessories on. If

coil current reads zero, the coil is open and should be

replaced. If the ammeter reading is 4 amperes or more, the coil is shorted and should be replaced. If

the coil voltage is not within 2 volts of the battery

voltage, check the circuit external to the clutch coil for excessive voltage drop and repair accordingly.

Refer to A/C Compressor and Clutch Diagnosis

Charts.

Page 1459 of 1502

24 - 22

HEATING

AND AIR

CONDITIONING

•

(4)

Remove the tape or plastic plugs from all the

suction and discharge openings and install the ser

vice valves on the compressor.

(5)

Connect the clutch lead wire.

(6) Connect the negative cable to the battery.

(7)

Evacuate, charge and test the system for leaks.

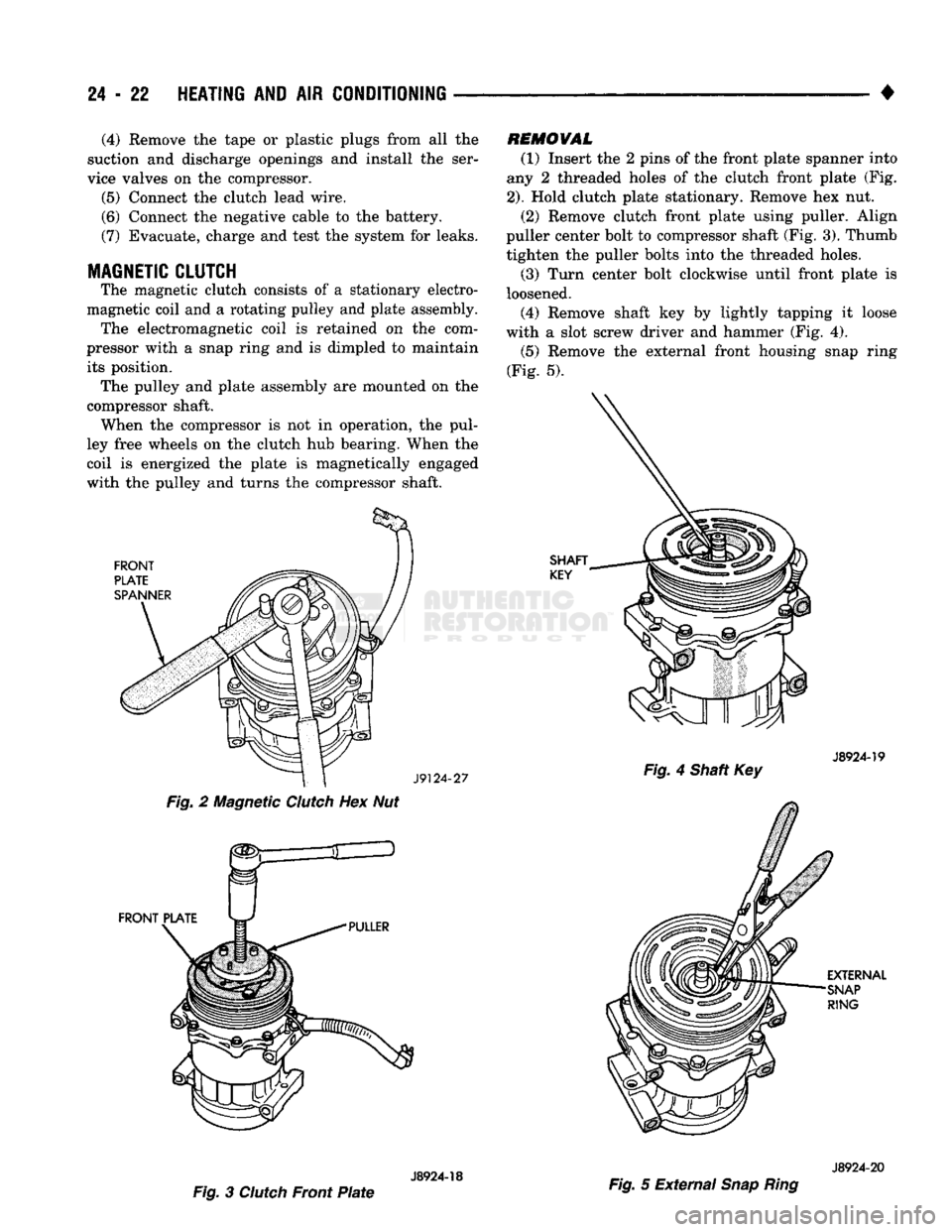

MAGNETIC

CLUTCH

The magnetic clutch consists of a stationary electro

magnetic coil and a rotating pulley and plate assembly. The electromagnetic coil is retained on the com

pressor with a snap ring and is dimpled to maintain its position. The pulley and plate assembly are mounted on the

compressor shaft. When the compressor is not in operation, the pul

ley free wheels on the clutch hub bearing. When the

coil is energized the plate is magnetically engaged

with the pulley and turns the compressor shaft.

J8924-18

Fig.

3

Clutch

Front

Plate

REMOVAL

(1) Insert the 2 pins of the front plate spanner into

any 2 threaded holes of the clutch front plate (Fig.

2).

Hold clutch plate stationary. Remove hex nut. (2) Remove clutch front plate using puller. Align

puller center bolt to compressor shaft (Fig. 3). Thumb tighten the puller bolts into the threaded holes. (3) Turn center bolt clockwise until front plate is

loosened. (4) Remove shaft key by lightly tapping it loose

with a slot screw driver and hammer (Fig. 4).

(5)

Remove the external front housing snap ring

(Fig. 5).

J8924-19

Fig.

4 Shaft Key

J8924-20

Fig.

5 External

Snap Ring

Page 1461 of 1502

24 - 24

HEATING

AND AIR

CONDITIONING

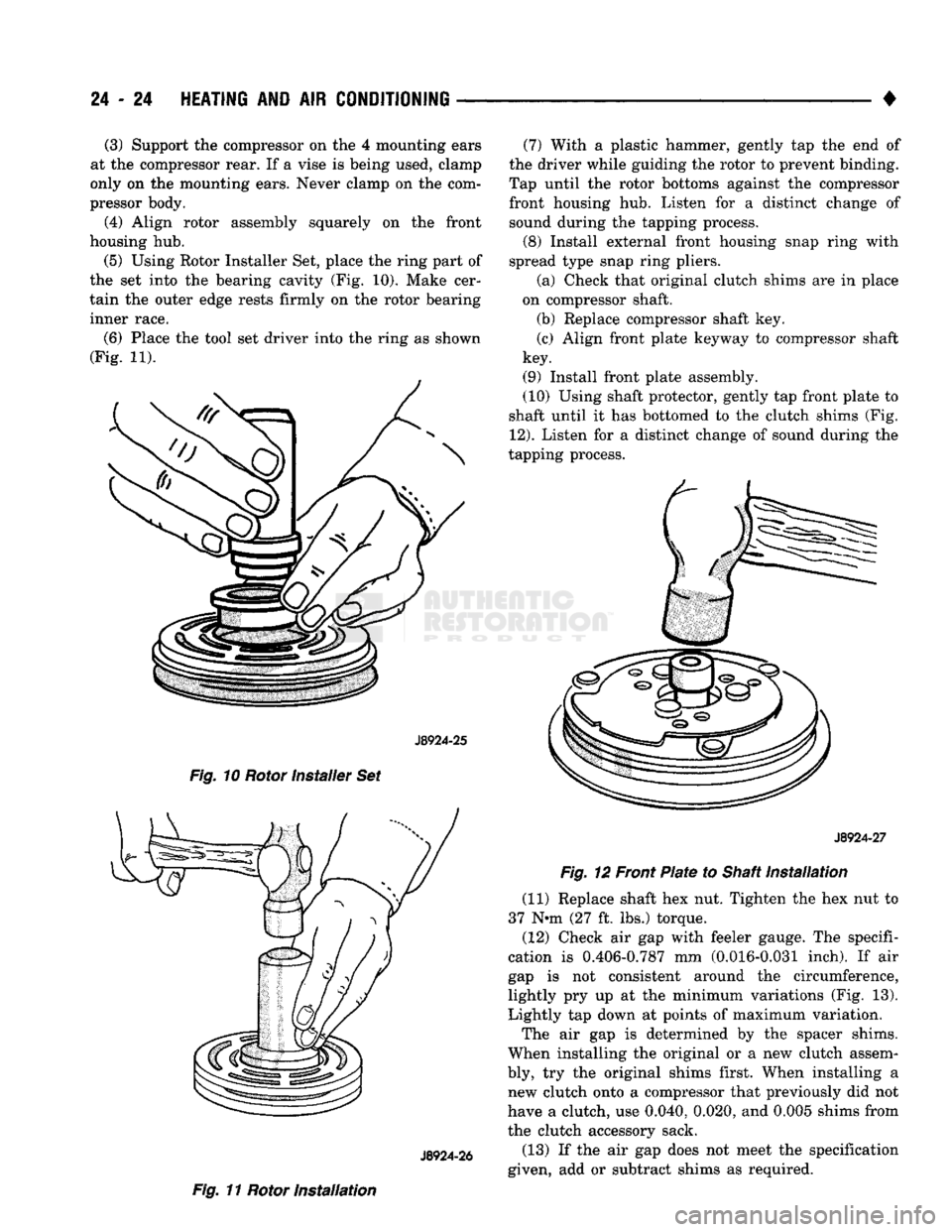

(3) Support the compressor on the 4 mounting ears

at the compressor rear. If a vise is being used, clamp

only on the mounting ears. Never clamp on the com

pressor body.

(4) Align rotor assembly squarely on the front

housing hub.

(5)

Using Rotor Installer Set, place the ring part of

the set into the bearing cavity (Fig. 10). Make cer

tain the outer edge rests firmly on the rotor bearing

inner race.

(6) Place the tool set driver into the ring as shown

(Fig. 11).

J8924-25

Fig. 10 Rotor installer Set

J8924-26

Fig. 11 Rotor Installation (7) With a plastic hammer, gently tap the end of

the driver while guiding the rotor to prevent binding.

Tap until the rotor bottoms against the compressor front housing hub. Listen for a distinct change of sound during the tapping process.

(8) Install external front housing snap ring with

spread type snap ring pliers.

(a) Check that original clutch shims are in place

on compressor shaft.

(b) Replace compressor shaft key.

(c) Align front plate keyway to compressor shaft

key.

(9) Install front plate assembly.

(10) Using shaft protector, gently tap front plate to

shaft until it has bottomed to the clutch shims (Fig.

12).

Listen for a distinct change of sound during the

tapping process.

J8924-27

Fig. 12 Front Plate to Shaft Installation

(11) Replace shaft hex nut. Tighten the hex nut to

37 N*m (27 ft, lbs.) torque.

(12) Check air gap with feeler gauge. The specifi

cation is 0.406-0.787 mm (0.016-0.031 inch). If air

gap is not consistent around the circumference,

lightly pry up at the minimum variations (Fig. 13).

Lightly tap down at points of maximum variation.

The air gap is determined by the spacer shims.

When installing the original or a new clutch assem

bly, try the original shims first. When installing a new clutch onto a compressor that previously did not

have a clutch, use 0.040, 0.020, and 0.005 shims from

the clutch accessory sack.

(13) If the air gap does not meet the specification

given, add or subtract shims as required.