sensor DODGE TRUCK 1993 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 1481 of 1502

2i

- 4

EMISSION

CONTROL

SYSTEMS

•

VACUUM

HOSE

ROUTING

SCHEMATICS

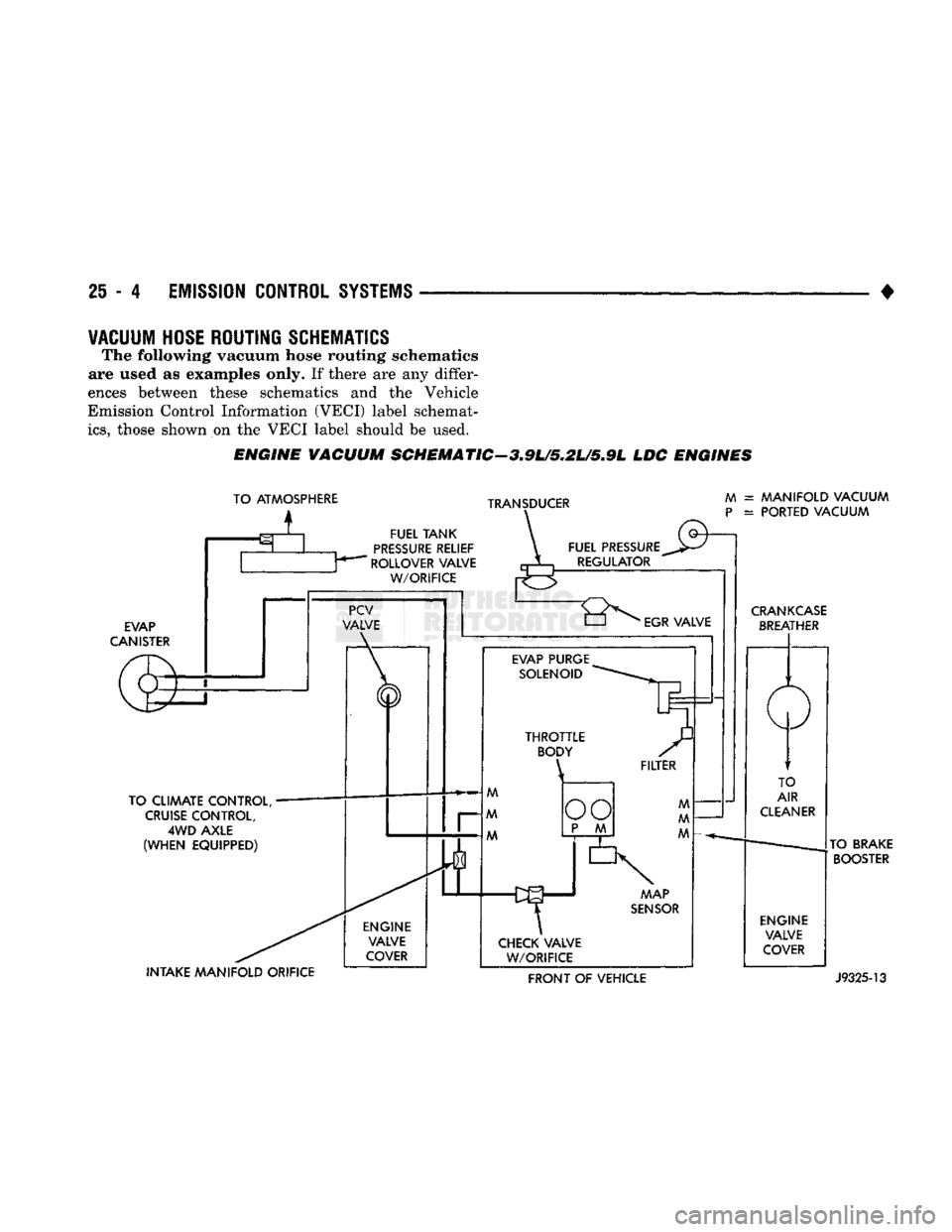

The following vacuum hose routing schematics

are used

as

examples only.

If

there

are any

differ

ences between these schematics

and the

Vehicle

Emission Control Information (VECI) label schemat

ics,

those shown

on the

VECI label should

be

used.

ENGINE

VACUUM

SCHEMATIC-3.9U5.2L/5.9L

LDC

ENGINES

TO ATMOSPHERE

i

TRANSDUCER

FUEL

TANK

PRESSURE

RELIEF

ROLLOVER VALVE

W/ORIFICE

EVAP

CANISTER

TO CLIMATE CONTROL,

CRUISE

CONTROL,

4WD

AXLE

(WHEN

EQUIPPED) INTAKE

MANIFOLD

ORIFICE ENGINE

VALVE

COVER FUEL PRESSURE

REGULATOR

M

P

= MANIFOLD VACUUM

= PORTED VACUUM

"8^

EGR

VALVE

EVAP PURGE SOLENOID MAP

SENSOR

CHECK VALVE W/ORIFICE

CRANKCASE

BREATHER

TO

AIR

CLEANER

ENGINE VALVE

COVER TO BRAKE

BOOSTER FRONT

OF

VEHICLE

J9325-13

Page 1487 of 1502

25-10

EMISSION

CONTROL

SYSTEMS

EXHAUST

EMISSION

CONTROLS

INDEX

page

Air Inlet—5.9L Diesel

Engine

13

Exhaust

Gas Recirculation (EGR)

Systems

10

HEATED

INLET

AIR

SYSTEM

The air filter housing mounted-heated inlet air sys

tem is no longer used on any Dodge Truck gas pow ered engine.

EXHAUST

GAS

RECIRCULATION

(EGR)

SYSTEMS

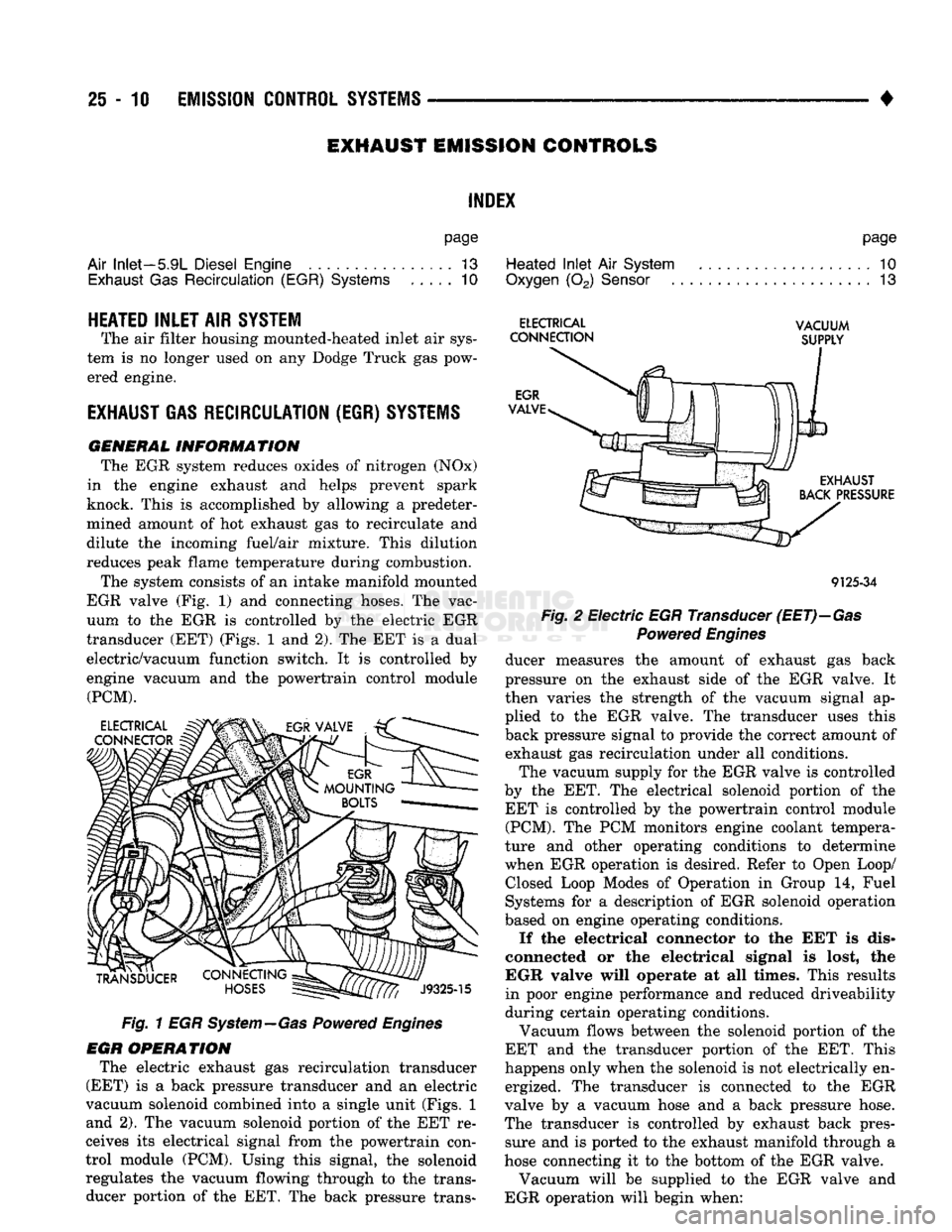

GENERAL INFORMATION The EGR system reduces oxides of nitrogen (NOx)

in the engine exhaust and helps prevent spark

knock. This is accomplished by allowing a predeter

mined amount of hot exhaust gas to recirculate and

dilute the incoming fuel/air mixture. This dilution

reduces peak flame temperature during combustion.

The system consists of an intake manifold mounted

EGR valve (Fig. 1) and connecting hoses. The vac

uum to the EGR is controlled by the electric EGR

transducer (EET) (Figs. 1 and 2). The EET is a dual

electric/vacuum function switch. It is controlled by

engine vacuum and the powertrain control module (PCM).

Fig. 1 EGR System—Gas Powered Engines

EGR OPERATION The electric exhaust gas recirculation transducer

(EET) is a back pressure transducer and an electric

vacuum solenoid combined into a single unit (Figs. 1 and 2). The vacuum solenoid portion of the EET re

ceives its electrical signal from the powertrain con

trol module (PCM). Using this signal, the solenoid regulates the vacuum flowing through to the trans ducer portion of the EET. The back pressure trans-

page

Heated

Inlet

Air

System

. 10

Oxygen

(02)

Sensor

13

ELECTRICAL

VACUUM

CONNECTION

SUPPLY

9125-34

Fig.

2 Electric EGR Transducer

(EET)—Gas

Powered

Engines

ducer measures the amount of exhaust gas back

pressure on the exhaust side of the EGR valve. It

then varies the strength of the vacuum signal ap

plied to the EGR valve. The transducer uses this

back pressure signal to provide the correct amount of exhaust gas recirculation under all conditions.

The vacuum supply for the EGR valve is controlled

by the EET. The electrical solenoid portion of the EET is controlled by the powertrain control module (PCM). The PCM monitors engine coolant tempera

ture and other operating conditions to determine

when EGR operation is desired. Refer to Open Loop/ Closed Loop Modes of Operation in Group 14, Fuel

Systems for a description of EGR solenoid operation

based on engine operating conditions.

If the electrical connector to the EET is dis

connected or the electrical signal is lost, the

EGR valve will operate at all times. This results

in poor engine performance and reduced driveability

during certain operating conditions.

Vacuum flows between the solenoid portion of the

EET and the transducer portion of the EET. This

happens only when the solenoid is not electrically en ergized. The transducer is connected to the EGR

valve by a vacuum hose and a back pressure hose.

The transducer is controlled by exhaust back pres sure and is ported to the exhaust manifold through a

hose connecting it to the bottom of the EGR valve.

Vacuum will be supplied to the EGR valve and

EGR operation will begin when:

Page 1488 of 1502

•

EMISSION

CONTROL

SYSTEMS

25 - 11 • The electrical solenoid portion of the EET is not

energized.

• The engine back pressure entering the EGR valve

inlet is strong enough to close the transducer bleed

valve.

If back pressure is not strong enough to close the

transducer bleed valve, the transducer will bleed off the vacuum preventing EGR operation.

When the electrical solenoid portion of the EET is

de-energized by the powertrain control module (PCM), vacuum flows to the transducer. The trans

ducer is connected to the engine exhaust system by a small hose that connects to the base of the EGR

valve.

The vacuum section of the transducer is controlled

by exhaust system back pressure. When back pres sure is high enough it will close a bleed valve in the

transducer allowing vacuum to actuate the EGR

valve. If back pressure does not close the bleed valve,

vacuum will be bled off.

For more information, refer to Group 14, Fuel Sys

tems.

Refer to the Component Removal/Installation sec

tion of this group for EGR valve replacement proce

dures.

EGR SYSTEM ON-BOARD DIAGNOSTICS

(CALIFORNIA VEHICLES

ONLY)

The powertrain control module (PCM) performs an

On-Board Diagnostic (OBD) check of the EGR system

on all California vehicles. The diagnostic system uses

the electric EGR transducer (EET) for the system

tests.

The OBD check activates only during selected en

gine/driving conditions. When the conditions are met,

the PCM energizes the EET solenoid to disable the EGR. The PCM checks for a change in the oxygen sensor signal. If the air-fuel mixture goes lean, the

PCM will attempt to enrichen the mixture. The PCM

registers a diagnostic trouble code (DTC) if the EGR system has failed or degraded. After registering a

DTC,

the PCM turns the malfunction indicator

lamp (MIL) on. (The malfunction indicator lamp was formerly referred to as the check engine lamp). The

malfunction indicator lamp indicates the need for im

mediate service.

If a malfunction is indicated by the malfunction in

dicator lamp and a DTC for the EGR system was set,

check for proper operation of EGR system. Use the

following: System Test, EGR Gas Flow Test and EGR

Diagnosis Chart.

If the EGR system tests properly, check the system

using the DRB II scan tool. For use of the DRB II,

refer to the appropriate Powertrain Diagnostics Pro cedure service manual. EGR SYSTEM SERVICE

A malfunctioning EGR system can cause engine

spark knock, sags or hesitation, rough idle, engine

stalling and poor driveability. To be sure of proper

operation of the EGR system, inspect all passages for

blockage. Check moving parts for binding. Inspect

the complete system for leaks. Replace system com ponents or hoses that are leaking.

Inspect all hose connections between throttle body,

intake manifold, EGR valve and EGR purge solenoid.

Replace any vacuum harness components that are

leaking or damaged. Refer to EGR Control System Test and EGR Gas

Flow Test to check EGR System operation.

EGR GAS FLOW TEST (1) Disconnect hose from EGR valve and connect a

hand vacuum pump to EGR valve nipple. Apply a

minimum of 12 inches vacuum the valve.

(2) The engine should now idle roughly or stall. If

this occurs, the valve is performing correctly. Proceed

to Electric EGR Transducer Test.

(3) If the engine idle speed did not change, remove

the EGR valve and inspect the valve and the exhaust passage in the manifold for blockage. Repair as nec

essary. If blockage is not present, replace the EGR

valve.

ELECTRIC EGR TRANSDUCER (EET)

TESTING ELECTRIC SOLENOID PORTION OF TRANSDUCER

(1) Bring the engine to normal operating tempera

ture.

Operate at idle speed. Test the EET as follows: (2) Check vacuum at EET vacuum source. Discon

nect the hose and attach a vacuum gauge to it.

(3) Vacuum should be a minimum of 15 inches:

• If vacuum is low, check the line for kinks, twists

or a loose connection at vacuum connector or intake

manifold.

• If vacuum is correct, remove gauge. Connect the

vacuum line and proceed to next step. (4) Check EET operation using the appropriate

Powertrain Diagnostic Procedures service manual.

Refer to this manual for use of the DRB II scan tool and repair EET as necessary.

TESTING VACUUM PORTION

OF

TRANSDUCER

(1) Disconnect the EET vacuum lines, back pres

sure line and electrical connector. Remove trans

ducer.

(2) Plug the EET EGR valve port.

(3) Apply 1-2 pounds air pressure to exhaust back

pressure port. Air pressure can be supplied with a

hand operated air pump or compressed air (regulated

to correct psi).

(4) Apply a minimum of 12 inches of vacuum to

vacuum supply port.

Replace the EET if it will not hold vacuum.

Page 1490 of 1502

EMISSION

CONTROL

SYSTEMS

25 - 13

For electrical tests

of the EET and its

circuitry,

re

fer

to the

appropriate Powertrain Diagnostic Proce dures service manual

for use of the DRB II

scan tool.

Refer

to the

Component Removal/Installation sec

tion

of

this group

for EET

replacement procedures.

OXYGEN

(02)

SENSOR

For description, operation, diagnosis

and

removal/

installation procedures

of the 02

sensor, refer

to

Group

14,

Fuel Systems.

AIR

INLET—5.9L

DIESEL

ENGINE

The diesel engine

air

inlet system consists

of the:

•

Air

filter housing

• Filter element •

Air

filter housing-to-turbocharger inlet tube

•

Air

crossover tube •

Air

intake heaters Ambient

air

enters

the air

filter housing through

an opening

at the

bottom

of the

housing

(Fig. 3). Air

in

the

housing

is

filtered

by the air

filter element (Fig.

4)

before

it is

drawn into

the

turbocharger.

Fig.

4 Air Filter

Element—Diesel The turbocharger increases

the

amount

of air

flow

to

the

engine.

The

turbocharger allows

the

engine

to

use

a

higher air-to-fuel ratio. This results

in im

proved emissions.

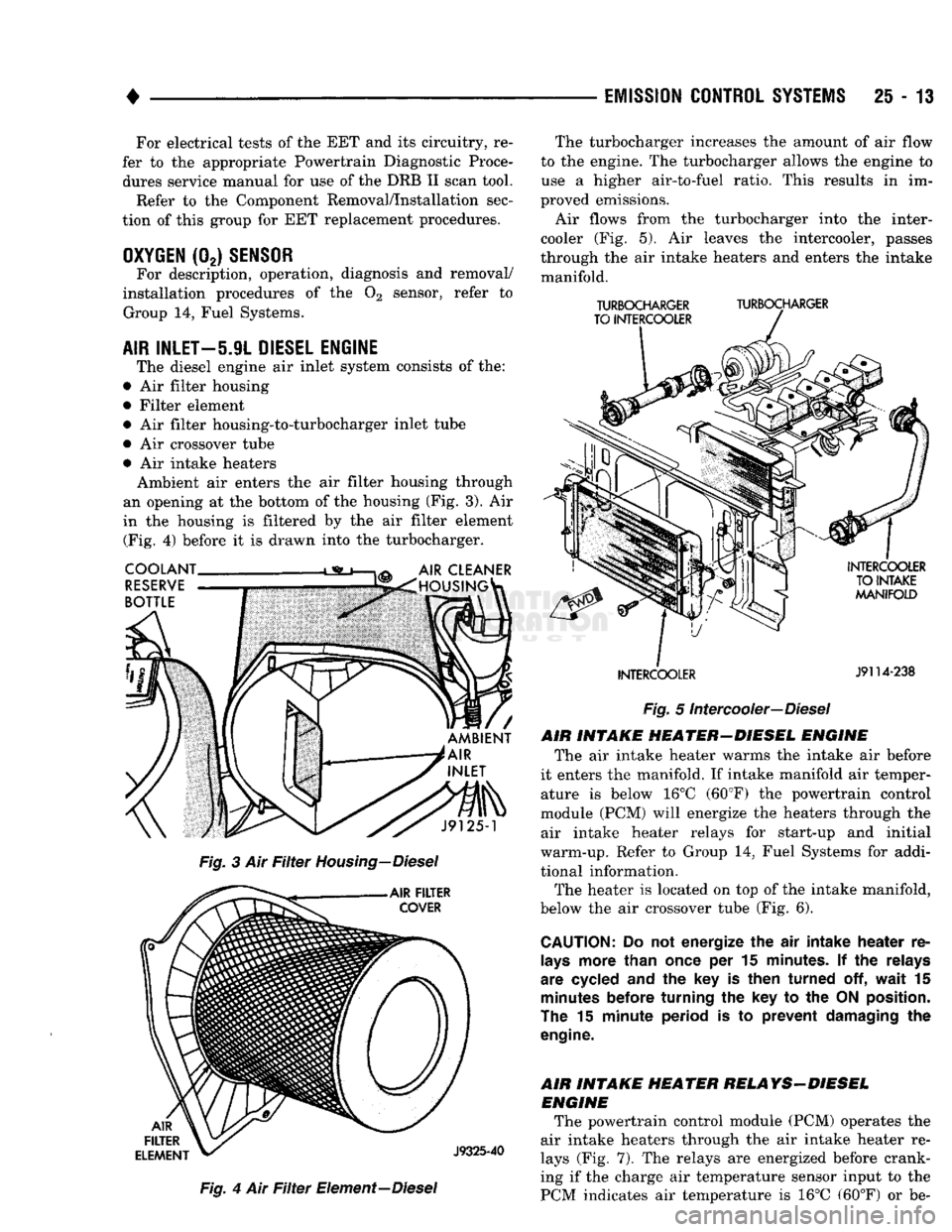

Air flows from

the

turbocharger into

the

inter-

cooler

(Fig. 5). Air

leaves

the

intercooler, passes

through

the air

intake heaters

and

enters

the

intake manifold.

TURBOCHARGER

TURBOCHARGER

TO INTERCOOLER

INTERCOOLER

J9114-238

Fig.

5

Intercooler—Diesel

AIR INTAKE HEATER-DIESEL ENGINE The

air

intake heater warms

the

intake

air

before

it enters

the

manifold.

If

intake manifold

air

temper ature

is

below

16°C

(60°F)

the

powertrain control

module

(PCM)

will energize

the

heaters through

the

air intake heater relays

for

start-up

and

initial

warm-up. Refer

to

Group

14,

Fuel Systems

for

addi

tional information. The heater

is

located

on top of the

intake manifold,

below

the air

crossover tube

(Fig. 6).

CAUTION:

Do not

energize

the air

intake heater

re

lays

more than once

per 15

minutes.

If the

relays

are cycled

and the key is

then turned

off,

wait

15

minutes

before turning

the key to the

ON

position.

The

15

minute period

is to

prevent damaging

the

engine.

AIR INTAKE HEATER RELAYS-DIESEL ENGINE The powertrain control module

(PCM)

operates

the

air intake heaters through

the air

intake heater

re

lays

(Fig. 7). The

relays

are

energized before crank

ing

if the

charge

air

temperature sensor input

to the

PCM indicates

air

temperature

is 16°C

(60°F)

or be-

Page 1494 of 1502

•

EMISSION

CONTROL SYSTEMS

25 - 17

COMPONENT REMOVAL/INSTALLATION

INDEI

page

Air

Filter/Filter

Housing—Diesel Engines

17

Air

Filter/Filter

Housing—Gas Engines

17

Air

Injection

Pump

17

Air

Injection

Pump Relief Valve

18

Check

Valve—Air

Injection

Tube

18

Coolant Temperature

Sensor

. 18

EGR

Tube—Gas Powered Engines

19

EGR

Valve

19

AIR FILTER/FILTER HOUSING-GAS ENGINES

REMOVAL/INSTALLATION Remove crankcase breather/filter hose at side of air

filter housing. Remove wingnut (Fig. 1) and remove

housing from engine. Check condition of gasket at

throttle body and replace as necessary. To replace air filter element only: Remove wingnut

and air filter housing cover (Fig. 1). Clean inside of

housing before replacing filter. Housing removal is not necessary for filter replacement.

^

WING NUT

COVER

:

GASKET

| I

MOUNTING

STUD

Fig.

1 Air

Filter

Housing—Gas

Powered

Engines—Typical

page

Electric

EGR Transducer (EET)

20

EVAP

Canister

20

EVAP

Canister Purge Solenoid

20

Fuel Tank

Filler

Tube

Cap . 21

Oxygen

(02)

Sensor

21

Powertrain Control Module (PCM)

21

Pressure

Relief/Rollover Valve

21

If housing-to-throttle body mounting stud is being

installed, tighten to 10 N»m (90 in. lbs.) torque. In stall housing to engine and tighten wingnut to 1.5

N»m (15 in. lbs.) torque.

AIR FILTER/FILTER HOUSING-DIESEL ENGINES

REMO

VAL/INSTALLA

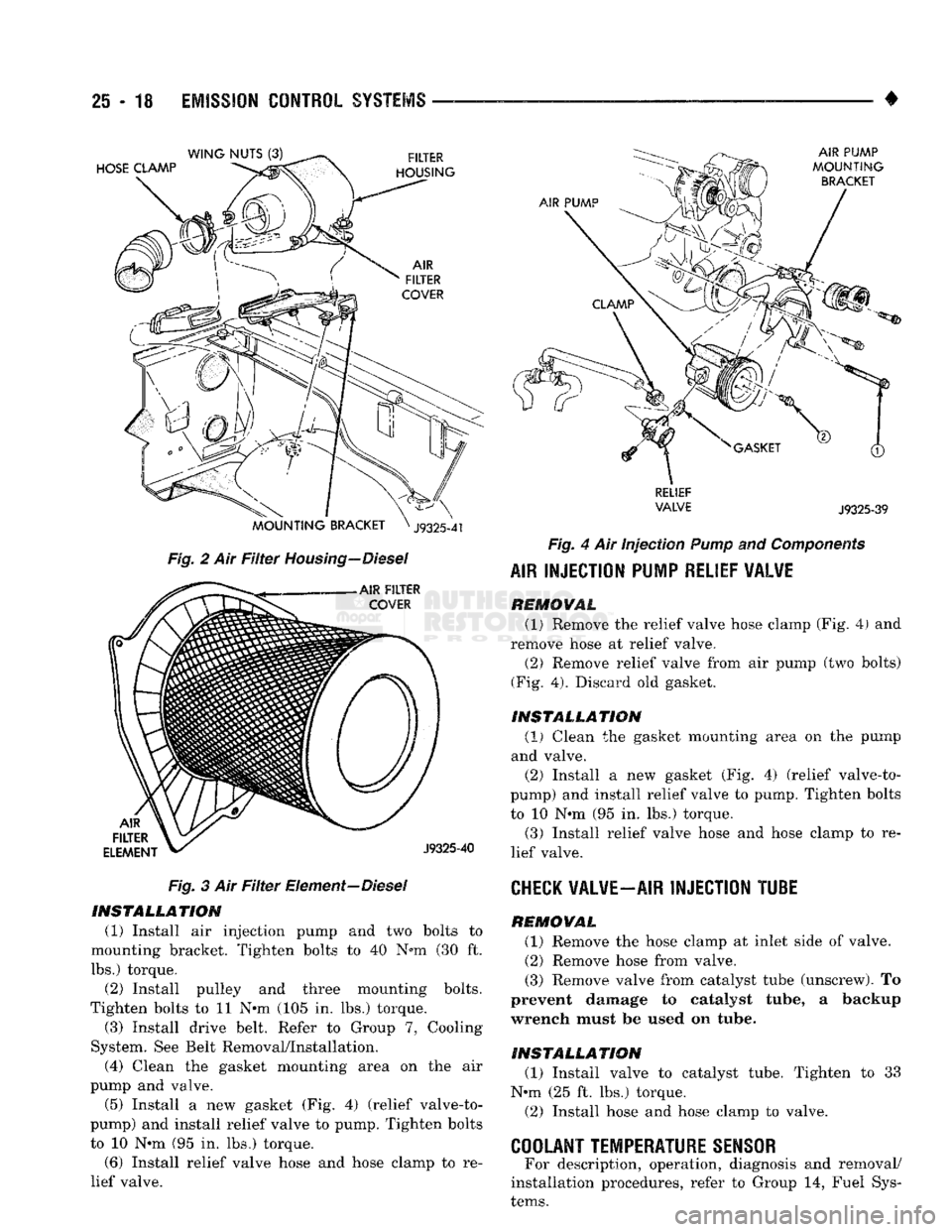

TION Remove the hose clamp at air filter housing (Fig.

2).

Remove mounting nuts and remove air filter

housing from vehicle.

To replace air filter element only: Remove hose clamp

and hose at air filter housing inlet tube. Remove three

wingnuts and air filter housing cover (Figs. 2 and 3). Clean inside of housing before replacing filter. Housing

removal is not necessary for filter replacement.

When installing a new air filter element, push el

ement into cover. Be sure it is pushed into tabs in

back of filter housing. Install wing nuts.

If housing had been removed, install mounting

nuts and tighten to 10 N»m (95 in. lbs.) torque.

AIR INJECTION PUMP

REMOVAL (1) Remove the relief valve hose clamp (Fig. 4) and

remove hose at relief valve.

(2) Remove relief valve from air pump (two bolts)

(Fig. 4). (3) Loosen (but do not remove at this time) the

three air pump pulley mounting bolts (number 2—figure 4).

(4) Relax the automatic belt tensioner and remove

the engine accessory drive belt. Refer to Group 7, Cooling System. See Belt Removal/Installation.

(5) Remove the three air pump pulley bolts and re

move pulley from pump.

(6) Remove the two air pump mounting bolts

(number

1—figure

4) and remove pump from mount

ing bracket.

Page 1495 of 1502

25

- 18

EMISSION

CONTROL

SYSTEMS

Fig. 2 Air Filter Housing—Diesel Fig. 3 Air Filter Element—Diesel INSTALLATION

(1) Install air injection pump and two bolts to

mounting bracket. Tighten bolts to 40 N*m (30 ft.

lbs.) torque. (2) Install pulley and three mounting bolts.

Tighten bolts to 11 N*m (105 in. lbs.) torque.

(3) Install drive belt. Refer to Group 7, Cooling

System. See Belt Removal/Installation.

(4) Clean the gasket mounting area on the air

pump and valve. (5) Install a new gasket (Fig. 4) (relief valve-to-

pump) and install relief valve to pump. Tighten bolts to 10 N*m (95 in. lbs.) torque.

(6) Install relief valve hose and hose clamp to re

lief valve. •

RELIEF

VALVE

J9325-39

Fig. 4 Air Injection

Pump

and

Components

AIR

INJECTION PUMP RELIEF VALVE REMOVAL

(1) Remove the relief valve hose clamp (Fig. 4) and

remove hose at relief valve.

(2) Remove relief valve from air pump (two bolts)

(Fig. 4). Discard old gasket.

INSTALLATION (1)

Clean the gasket mounting area on the pump

and valve. (2) Install a new gasket (Fig. 4) (relief valve-to-

pump) and install relief valve to pump. Tighten bolts

to 10 N*m (95 in. lbs.) torque. (3) Install relief valve hose and hose clamp to re

lief valve.

CHECK

VALVE—AIR INJECTION TUBE REMOVAL

(1) Remove the hose clamp at inlet side of valve.

(2) Remove hose from valve.

(3) Remove valve from catalyst tube (unscrew). To

prevent damage to catalyst tube, a backup

wrench must be used on tube.

INSTALLATION

(1) Install valve to catalyst tube. Tighten to 33

N«m (25 ft. lbs.) torque.

(2) Install hose and hose clamp to valve.

COOLANT TEMPERATURE SENSOR

For description, operation, diagnosis and removal/

installation procedures, refer to Group 14, Fuel Sys

tems.

Page 1498 of 1502

•

EMISSION CONTROL SYSTEMS 25 - 21 (4) Remove solenoid and its support bracket from

intake manifold (one bolt—5.2L/5.9L engine, one

nut—3.9L engine). (5) Remove EVAP canister purge solenoid from en

gine.

INSTALLATION

(1) Install EVAP canister purge solenoid and its

mounting bracket to intake manifold.

(2) Connect vacuum harness and wiring connector.

(3) Install air filter housing.

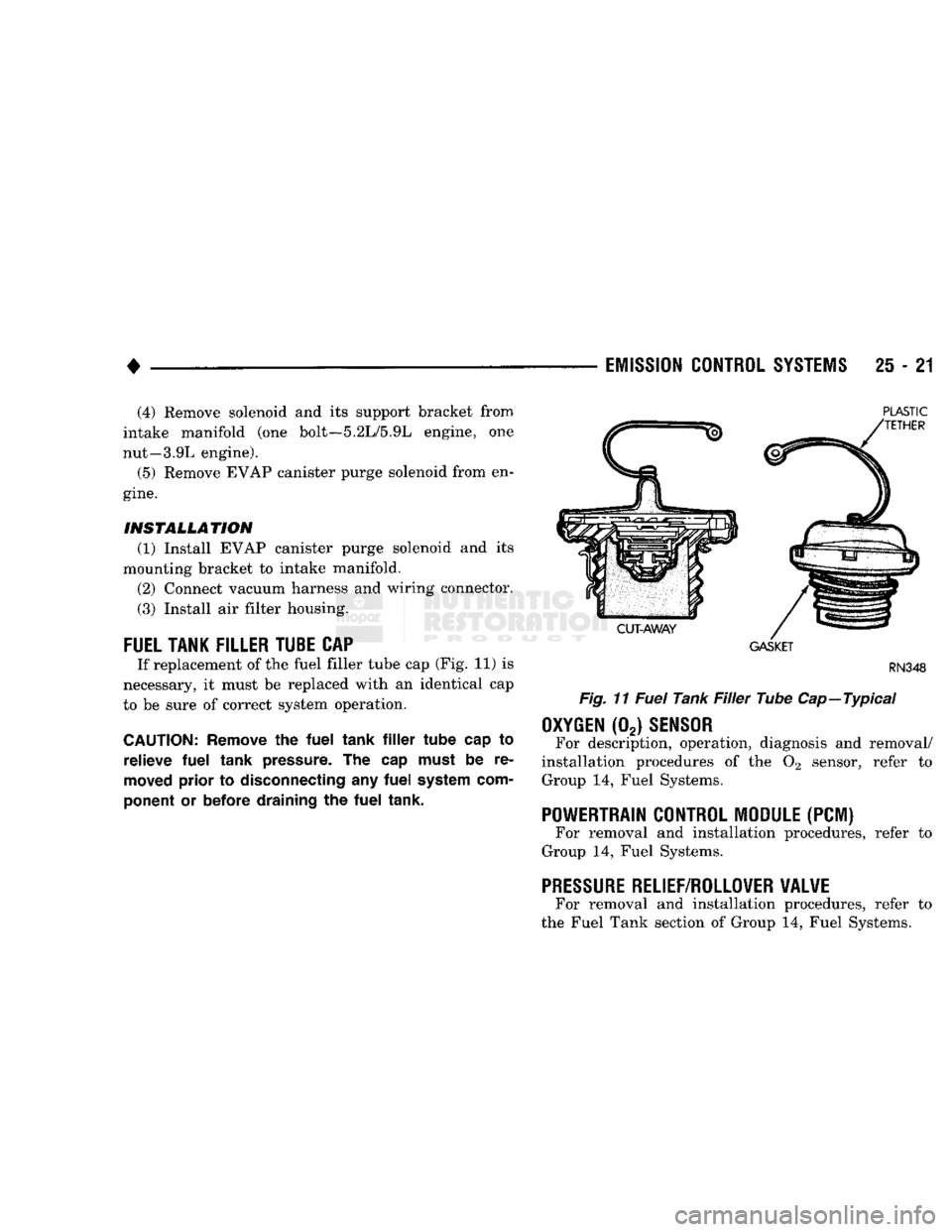

FUEL TANK FILLER TUBE CAP If replacement of the fuel filler tube cap (Fig. 11) is

necessary, it must be replaced with an identical cap

to be sure of correct system operation.

CAUTION:

Remove

the

fuel

tank

filler

tube

cap to

relieve

fuel

tank

pressure.

The cap

must

be re

moved

prior

to

disconnecting

any

fuel

system

com

ponent

or

before

draining

the

fuel

tank.

PLASTIC

GASKET

RN348

Fig.

11

Fuel

Tank

Filler

Tube Cap—Typical

OXYGEN (02) SENSOR For description, operation, diagnosis and removal/

installation procedures of the 02 sensor, refer to Group 14, Fuel Systems. POWERTRAIN CONTROL MODULE (PCM)

For removal and installation procedures, refer to

Group 14, Fuel Systems.

PRESSURE RELIEF/ROLLOWER WALWE For removal and installation procedures, refer to

the Fuel Tank section of Group 14, Fuel Systems.