sensor DODGE TRUCK 1993 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 1151 of 1502

21 - 150

AUTOMATIC TRANSMISSION REMOVAL

AND

INSTALLATION

• (3) Remove transmission oil pan, remove gasket,

drain oil and reinstall pan. (4) If overdrive unit had malfunctioned, or if fluid

is contaminated, remove entire transmission. If diag

nosis indicated overdrive clutch or governor problems

only, remove overdrive unit only.

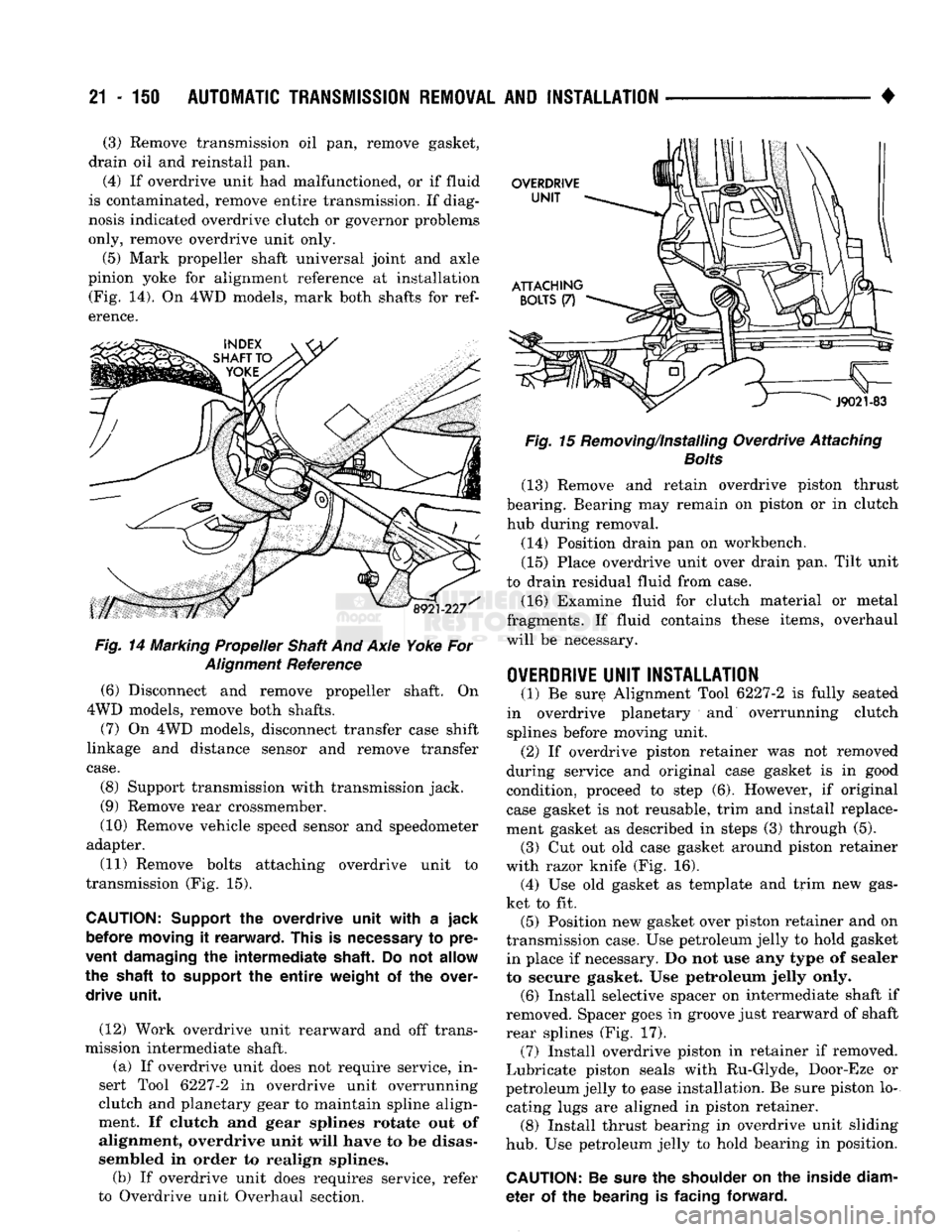

(5) Mark propeller shaft universal joint and axle

pinion yoke for alignment reference at installation (Fig. 14). On 4WD models, mark both shafts for

ref

erence.

Fig.

14 Marking Propeller Shaft And Axle Yoke For

Alignment

Reference

(6) Disconnect and remove propeller shaft. On

4WD models, remove both shafts.

(7) On 4WD models, disconnect transfer case shift

linkage and distance sensor and remove transfer

case.

(8) Support transmission with transmission jack.

(9) Remove rear crossmember.

(10) Remove vehicle speed sensor and speedometer

adapter.

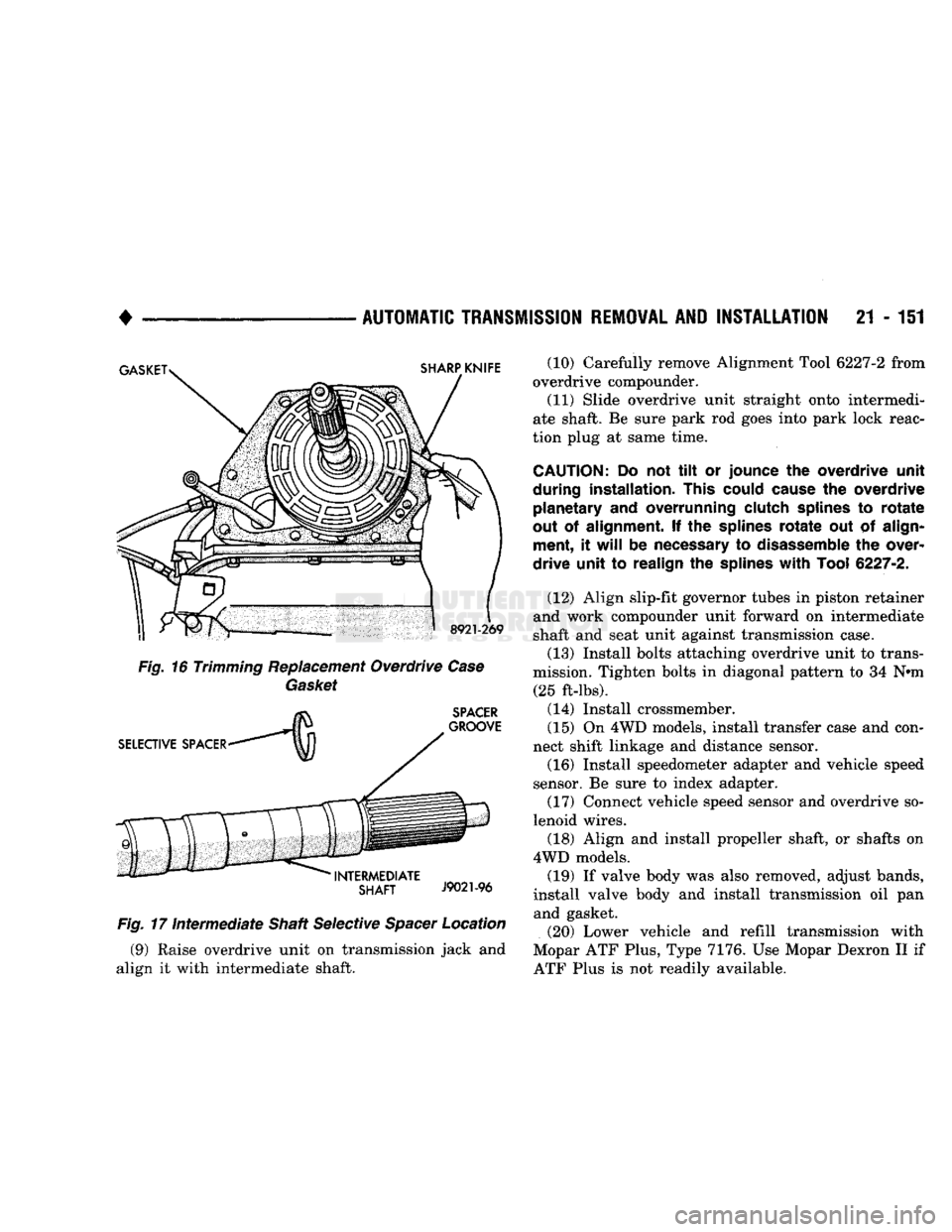

(11) Remove bolts attaching overdrive unit to

transmission (Fig. 15).

CAUTION:

Support

the

overdrive unit with

a

jack before moving

it

rearward. This

is

necessary

to

pre

vent damaging

the

intermediate shaft.

Do not

allow

the shaft

to

support

the

entire

weight

of the

over drive unit.

(12) Work overdrive unit rearward and off trans

mission intermediate shaft.

(a) If overdrive unit does not require service, in

sert Tool 6227-2 in overdrive unit overrunning

clutch and planetary gear to maintain spline align

ment. If clutch and gear splines rotate out of

alignment, overdrive unit will have to be disas

sembled in order to realign splines.

(b) If overdrive unit does requires service, refer

to Overdrive unit Overhaul section.

Fig.

15 Removing/Installing Overdrive Attaching

Bolts

(13) Remove and retain overdrive piston thrust

bearing. Bearing may remain on piston or in clutch hub during removal.

(14) Position drain pan on workbench.

(15) Place overdrive unit over drain pan. Tilt unit

to drain residual fluid from case. (16) Examine fluid for clutch material or metal

fragments. If fluid contains these items, overhaul

will be necessary.

OVERDRIVE

UNIT INSTALLATION

(1) Be sure Alignment Tool 6227-2 is fully seated

in overdrive planetary and overrunning clutch

splines before moving unit.

(2) If overdrive piston retainer was not removed

during service and original case gasket is in good

condition, proceed to step (6). However, if original case gasket is not reusable, trim and install replace

ment gasket as described in steps (3) through (5).

(3) Cut out old case gasket around piston retainer

with razor knife (Fig. 16). (4) Use old gasket as template and trim new gas

ket to fit. (5) Position new gasket over piston retainer and on

transmission case. Use petroleum jelly to hold gasket in place if necessary. Do not use any type of sealer

to secure gasket. Use petroleum jelly only. (6) Install selective spacer on intermediate shaft if

removed. Spacer goes in groove just rearward of shaft

rear splines (Fig. 17). (7) Install overdrive piston in retainer if removed.

Lubricate piston seals with Ru-Glyde, Door-Eze or

petroleum jelly to ease installation. Be sure piston lo

cating lugs are aligned in piston retainer. (8) Install thrust bearing in overdrive unit sliding

hub.

Use petroleum jelly to hold bearing in position.

CAUTION:

Be

sure

the

shoulder

on the

inside diam

eter

of the

bearing

is

facing forward.

Page 1152 of 1502

•

AUTOMATIC

TRANSMISSION

REMOVAL

AND

INSTALLATION

21 - 151

Fig.

17

Intermediate

Shaft Selective

Spacer

Location (9) Raise overdrive unit on transmission jack and

align it with intermediate shaft. (10) Carefully remove Alignment Tool 6227-2 from

overdrive compounder.

(11) Slide overdrive unit straight onto intermedi

ate shaft. Be sure park rod goes into park lock reac

tion plug at same time.

CAUTION:

Do not tilt or

jounce

the

overdrive unit

during installation. This could cause

the

overdrive planetary

and

overrunning clutch splines

to

rotate

out

of

alignment.

If the

splines

rotate

out of

align ment,

it

will

be

necessary

to

disassemble

the

over

drive unit

to

realign

the

splines

with

Tool

6227-2.

(12) Align slip-fit governor tubes in piston retainer

and work compounder unit forward on intermediate

shaft and seat unit against transmission case.

(13) Install bolts attaching overdrive unit to trans

mission. Tighten bolts in diagonal pattern to 34 N»m (25 ft-lbs).

(14) Install crossmember.

(15) On 4WD models, install transfer case and con

nect shift linkage and distance sensor. (16) Install speedometer adapter and vehicle speed

sensor. Be sure to index adapter.

(17) Connect vehicle speed sensor and overdrive so

lenoid wires.

(18) Align and install propeller shaft, or shafts on

4WD models. (19) If valve body was also removed, adjust bands,

install valve body and install transmission oil pan and gasket.

(20) Lower vehicle and refill transmission with

Mopar ATF Plus, Type 7176. Use Mopar Dexron II if

ATF Plus is not readily available.

Page 1346 of 1502

•

NP20I

TRANSFER CASE

21 - 34i (5) Verify that transfer case range lever is in Neu

tral.

(6) Move shift lever bracket forward and retighten

bracket bolts (Fig. 3). Shift rod should not bind in shift lever and range lever. Rod should be slip-fit

both levers. (7) Shift transfer case into 4H range. Shift rod

should now be tension-fit in each lever. Shift lever

should be in 4H detent in gate and range lever should be fully into 4H position.

(8) Shift transfer case into 2H and 4L ranges to

verify correct adjustment.

SPEEDOMETER SERVICE

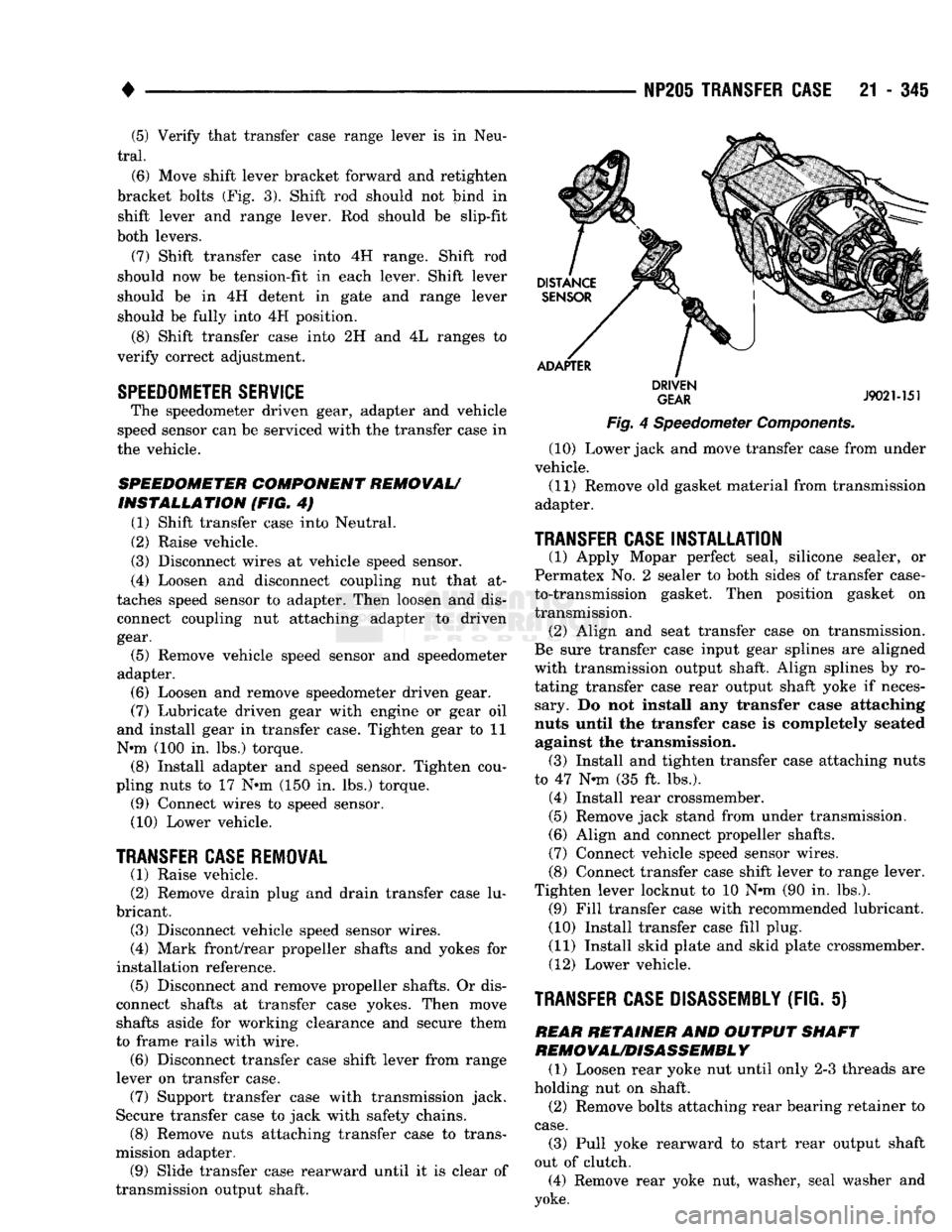

The speedometer driven gear, adapter and vehicle

speed sensor can be serviced with the transfer case in

the vehicle.

SPEEDOMETER COMPONENT REMOVAL/

INSTALLATION (FIG. 4) (1) Shift transfer case into Neutral.

(2) Raise vehicle.

(3) Disconnect wires at vehicle speed sensor.

(4) Loosen and disconnect coupling nut that at

taches speed sensor to adapter. Then loosen and dis connect coupling nut attaching adapter to driven

gear.

(5) Remove vehicle speed sensor and speedometer

adapter. (6) Loosen and remove speedometer driven gear.

(7) Lubricate driven gear with engine or gear oil

and install gear in transfer case. Tighten gear to 11

N*m (100 in. lbs.) torque. (8) Install adapter and speed sensor. Tighten cou

pling nuts to 17 N»m (150 in. lbs.) torque. (9) Connect wires to speed sensor.

(10) Lower vehicle.

TRANSFER CASE

REMOVAL

(1) Raise vehicle.

(2) Remove drain plug and drain transfer case lu

bricant. (3) Disconnect vehicle speed sensor wires.

(4) Mark front/rear propeller shafts and yokes for

installation reference. (5) Disconnect and remove propeller shafts. Or dis

connect shafts at transfer case yokes. Then move shafts aside for working clearance and secure them

to frame rails with wire. (6) Disconnect transfer case shift lever from range

lever on transfer case. (7) Support transfer case with transmission jack.

Secure transfer case to jack with safety chains. (8) Remove nuts attaching transfer case to trans

mission adapter. (9) Slide transfer case rearward until it is clear of

transmission output shaft.

DISTANCE

SENSOR

ADAPTER

DRIVEN

GEAR

J9021-151

Fig.

4 Speedometer Components.

(10) Lower jack and move transfer case from under

vehicle.

(11) Remove old gasket material from transmission

adapter.

TRANSFER CASE

INSTALLATION

(1) Apply Mopar perfect seal, silicone sealer, or

Permatex No. 2 sealer to both sides of transfer case-

to-transmission gasket. Then position gasket on

transmission. (2) Align and seat transfer case on transmission.

Be sure transfer case input gear splines are aligned

with transmission output shaft. Align splines by ro

tating transfer case rear output shaft yoke if neces sary. Do not install any transfer case attaching

nuts until the transfer case is completely seated against the transmission. (3) Install and tighten transfer case attaching nuts

to 47 N*m (35 ft. lbs.). (4) Install rear crossmember.

(5) Remove jack stand from under transmission.

(6) Align and connect propeller shafts.

(7) Connect vehicle speed sensor wires.

(8) Connect transfer case shift lever to range lever.

Tighten lever locknut to 10 N»m (90 in. lbs.). (9) Fill transfer case with recommended lubricant.

(10) Install transfer case fill plug.

(11) Install skid plate and skid plate crossmember.

(12) Lower vehicle.

TRANSFER CASE DISASSEMBLY

(FIG.

S) REAR RETAINER AND OUTPUT SHAFT

REMOVAL/DISASSEMBL

Y

(1) Loosen rear yoke nut until only 2-3 threads are

holding nut on shaft. (2) Remove bolts attaching rear bearing retainer to

case.

(3) Pull yoke rearward to start rear output shaft

out of clutch. (4) Remove rear yoke nut, washer, seal washer and

yoke.

Page 1351 of 1502

21 - 350 NP241

TRANSFER CASE

• NP241 TRANSFER CASE

INDEl

page

Checking

Fluid

Level

351

Component Cleaning

and

Inspection

359

Fluid

Drain/Refill

351

General

Information

350

Recommended

Lubricant

.................. 350

Service

Diagnosis

....................... 350

Shift

Linkage

Adjustment

354

Speedometer Adapter/Distance

Sensor

Service

. 352

page

Speedometer Gear, Shaft

Seal,

Bearing

and

Retainer

Service

352

Transfer

Case

Assembly

.................. 361

Transfer

Case

Bearing Replacement

......... 360

Transfer

Case

Disassembly

................ 356

Transfer

Case

Identification ................ 350

Transfer

Case

Installation

................. 356

Transfer

Case

Removal

356

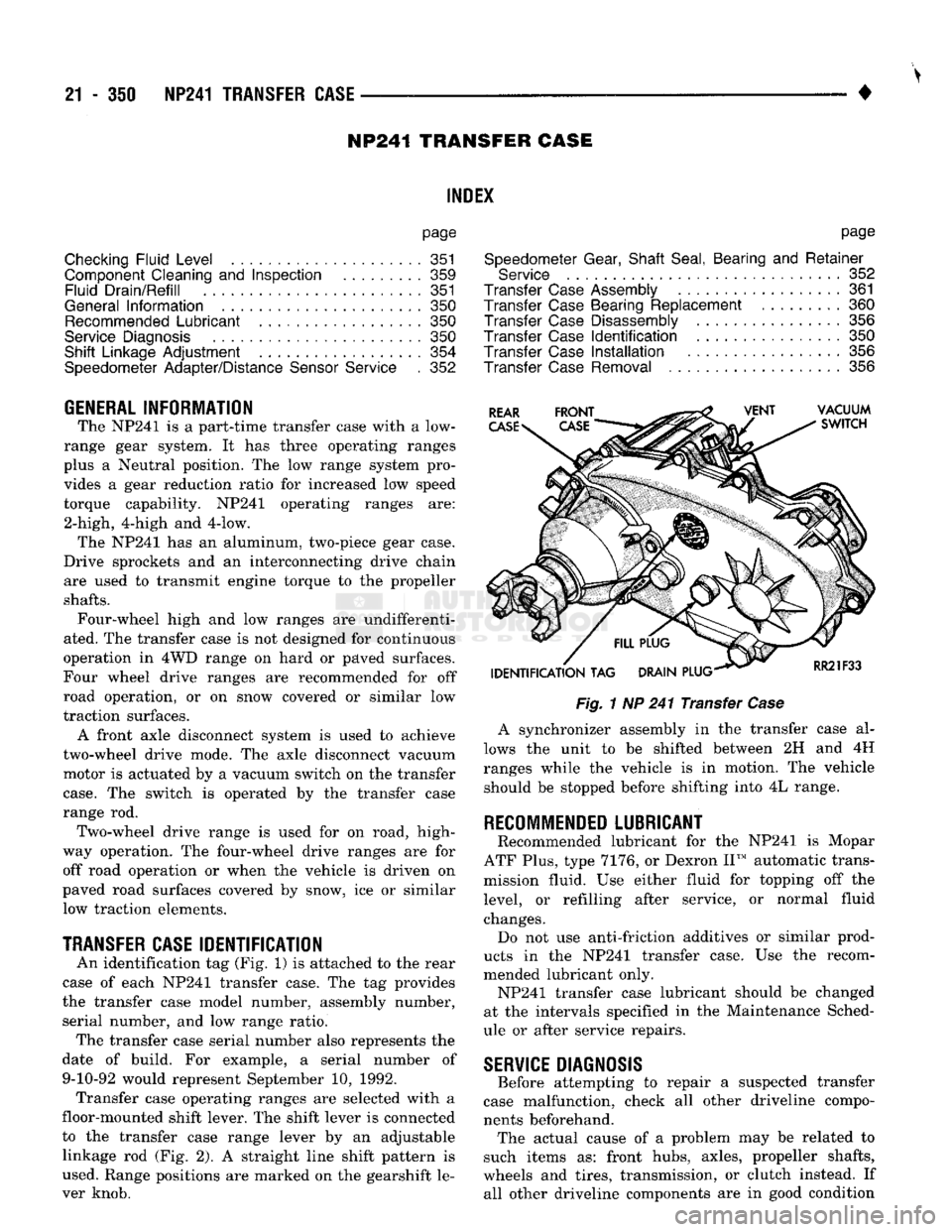

GENERAL

INFORMATION

The NP241 is a part-time transfer case with a low-

range gear system. It has three operating ranges

plus a Neutral position. The low range system pro vides a gear reduction ratio for increased low speed

torque capability. NP241 operating ranges are: 2-high, 4-high and 4-low. The NP241 has an aluminum, two-piece gear case.

Drive sprockets and an interconnecting drive chain are used to transmit engine torque to the propeller

shafts.

Four-wheel high and low ranges are undifferenti

ated. The transfer case is not designed for continuous

operation in 4WD range on hard or paved surfaces.

Four wheel drive ranges are recommended for off

road operation, or on snow covered or similar low

traction surfaces. A front axle disconnect system is used to achieve

two-wheel drive mode. The axle disconnect vacuum motor is actuated by a vacuum switch on the transfer

case.

The switch is operated by the transfer case

range rod. Two-wheel drive range is used for on road, high

way operation. The four-wheel drive ranges are for off road operation or when the vehicle is driven on

paved road surfaces covered by snow, ice or similar low traction elements.

TRANSFER CASE

IDENTIFICATION

An identification tag (Fig, 1) is attached to the rear

case of each NP241 transfer case. The tag provides

the transfer case model number, assembly number, serial number, and low range ratio. The transfer case serial number also represents the

date of build. For example, a serial number of 9-10-92 would represent September 10, 1992. Transfer case operating ranges are selected with a

floor-mounted shift lever. The shift lever is connected

to the transfer case range lever by an adjustable linkage rod (Fig. 2). A straight line shift pattern is

used. Range positions are marked on the gearshift le

ver knob.

Fig.

1 NP 241 Transfer

Case

A synchronizer assembly in the transfer case al

lows the unit to be shifted between 2H and 4H

ranges while the vehicle is in motion. The vehicle should be stopped before shifting into 4L range.

RECOMMENDED

LUBRICANT

Recommended lubricant for the NP241 is Mopar

ATF Plus, type 7176, or Dexron II™ automatic trans

mission fluid. Use either fluid for topping off the

level, or refilling after service, or normal fluid

changes. Do not use anti-friction additives or similar prod

ucts in the NP241 transfer case. Use the recom

mended lubricant only. NP241 transfer case lubricant should be changed

at the intervals specified in the Maintenance Sched

ule or after service repairs.

SERVICE

DIAGNOSIS

Before attempting to repair a suspected transfer

case malfunction, check all other driveline compo

nents beforehand. The actual cause of a problem may be related to

such items as: front hubs, axles, propeller shafts,

wheels and tires, transmission, or clutch instead. If all other driveline components are in good condition

Page 1353 of 1502

21 - 352 NP241

TRANSFER

CASE

—

•

Fig.

2

Loosening

Rear Retainer

Fig.

3 Removing/Installing Rear Retainer

(7) Install speedometer driven gear.

(8) Install drain plug. Tighten plug to 54 N-m (40

ft. lbs.). (9) Fill transfer case to edge of fill plug opening

with recommended transmission fluid. (10) Install fill plug. Tighten plug to 54 N-m (40 ft.

lbs.).

(11) Connect propeller shaft. Tighten attaching

bolts to 19 N-m (170 in. lbs.).

(12) Lower vehicle.

SPEEDOMETER

ADAPTER/DISTANCE

SENSOR

SERVICE

ADAPTER/SENSOR

REMOVAL

(1) Raise vehicle.

(2) Remove skid plate and crossmember for access,

if necessary. (3) Remove vehicle speed sensor from pinion gear

adapter (Fig. 4). On models with automatic transmis

sion, remove sensor adapter as well.

(6) Fill transfer case to bottom edge of fill plug

opening with Mopar ATF Plus, or Dexron II auto

matic transmission fluid.

(7) Install fill plug. Tighten plug to 54 N«m (40 ft.

lbs.).

(8) Lower vehicle.

SPEEDOMETER

GEAR, SHAFT

SEAL,

BEARING

AND RETAINER SERVICE

The front and rear yokes, output shaft seals, re

tainers and bearings, and speedometer drive gear can all be serviced with the transfer case in the vehicle.

The following combined procedure outlines removal and installation of these components:

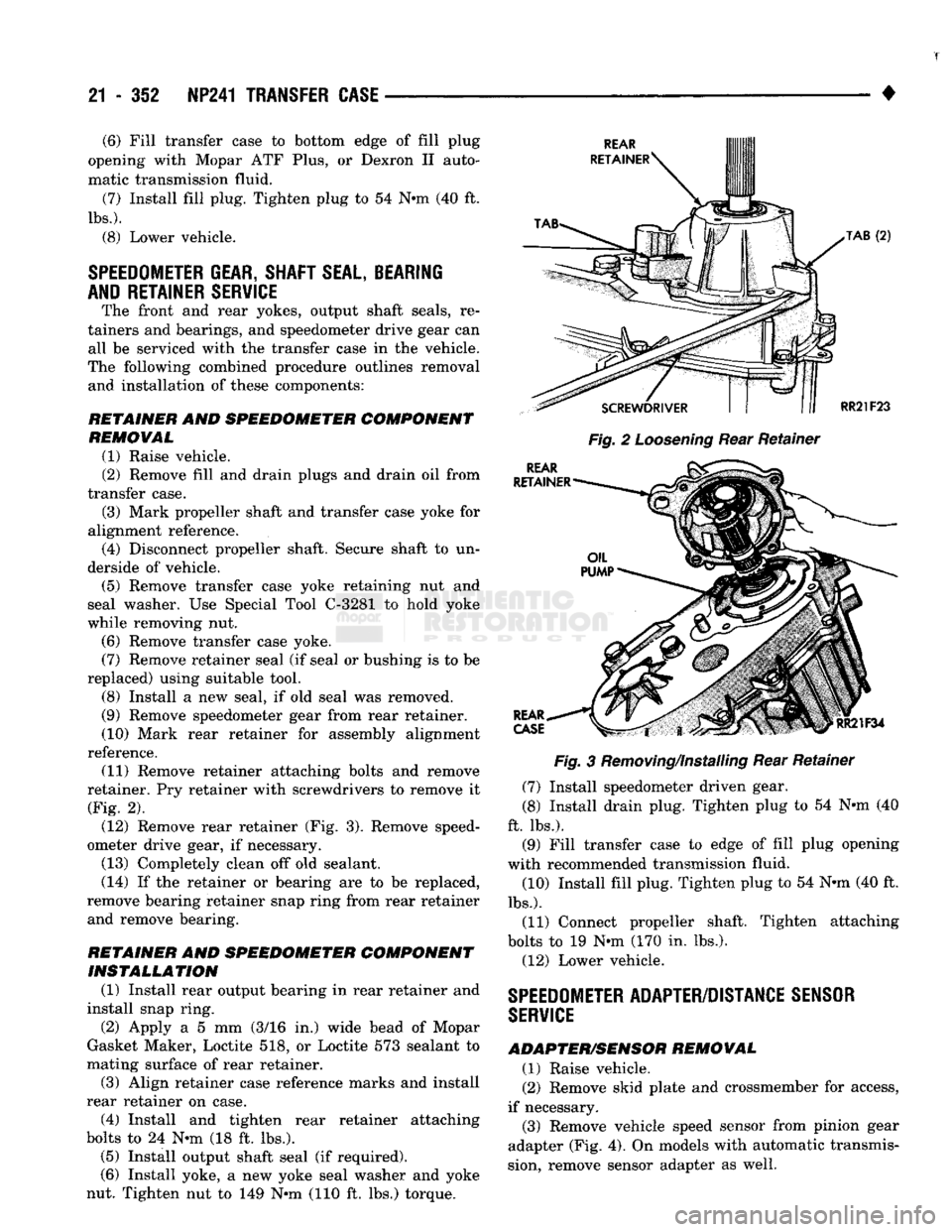

RETAINER

AND

SPEEDOMETER COMPONENT REMOVAL

(1) Raise vehicle.

(2) Remove fill and drain plugs and drain oil from

transfer case. (3) Mark propeller shaft and transfer case yoke for

alignment reference. (4) Disconnect propeller shaft. Secure shaft to un

derside of vehicle. (5) Remove transfer case yoke retaining nut and

seal washer. Use Special Tool C-3281 to hold yoke

while removing nut. (6) Remove transfer case yoke. (7) Remove retainer seal (if seal or bushing is to be

replaced) using suitable tool.

(8) Install a new seal, if old seal was removed.

(9) Remove speedometer gear from rear retainer.

(10) Mark rear retainer for assembly alignment

reference. (11) Remove retainer attaching bolts and remove

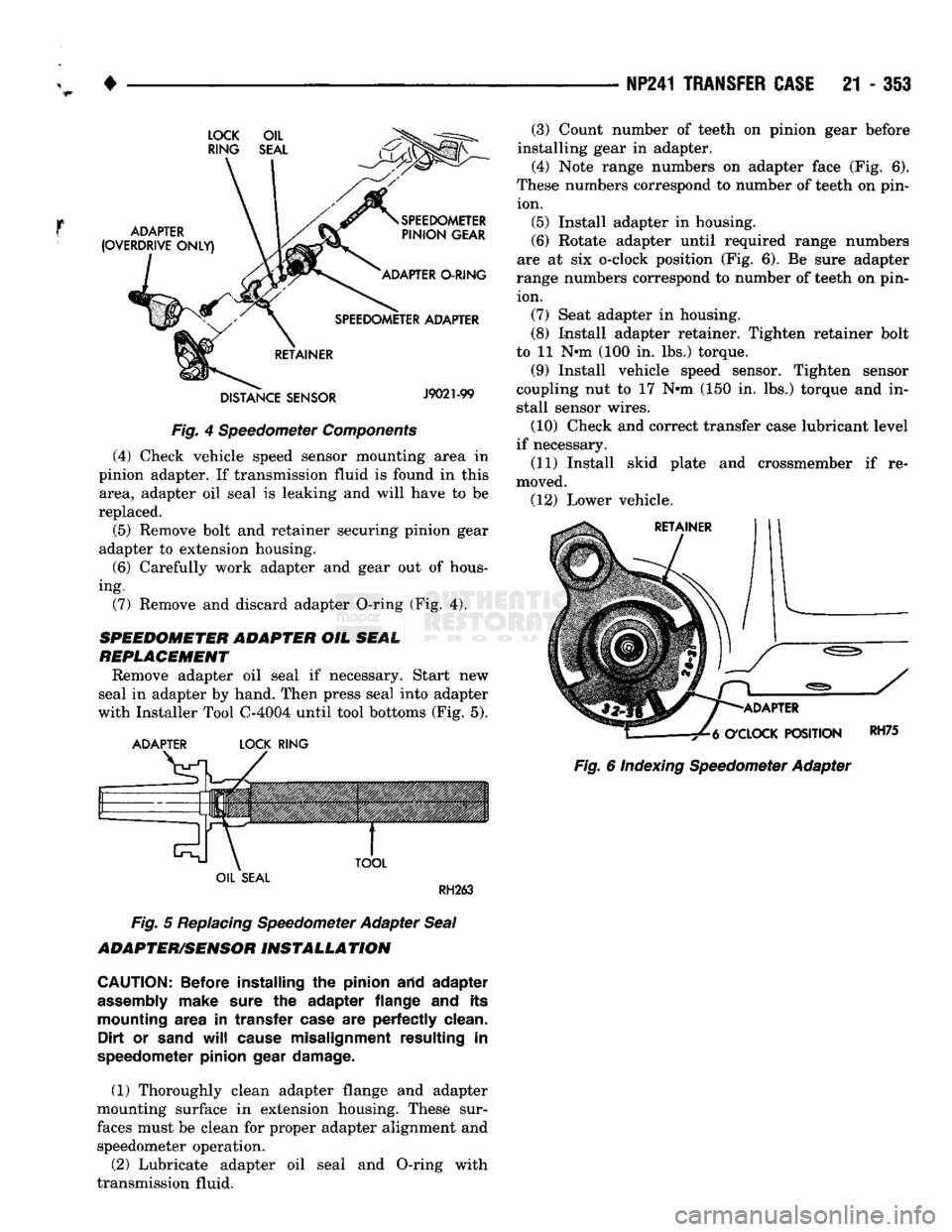

retainer. Pry retainer with screwdrivers to remove it (Fig. 2). (12) Remove rear retainer (Fig. 3). Remove speed

ometer drive gear, if necessary.

(13) Completely clean off old sealant.

(14) If the retainer or bearing are to be replaced,

remove bearing retainer snap ring from rear retainer

and remove bearing.

RETAINER

AND

SPEEDOMETER COMPONENT INSTALLATION

(1) Install rear output bearing in rear retainer and

install snap ring. (2) Apply a 5 mm (3/16 in.) wide bead of Mopar

Gasket Maker, Loctite 518, or Loctite 573 sealant to

mating surface of rear retainer.

(3) Align retainer case reference marks and install

rear retainer on case. (4) Install and tighten rear retainer attaching

bolts to 24 N«m (18 ft. lbs.). (5) Install output shaft seal (if required).

(6) Install yoke, a new yoke seal washer and yoke

nut. Tighten nut to 149 N-m (110 ft. lbs.) torque.

Page 1354 of 1502

•

NP241 TRANSFER

CASE

21 - 313

LOCK OIL RING SEAL

ADAPTER

(OVERDRIVE

ONLY)

SPEEDOMETER

PINION

GEAR

ADAPTER

O-RING

SPEEDOMETER

ADAPTER

RETAINER

DISTANCE

SENSOR

J9021-99

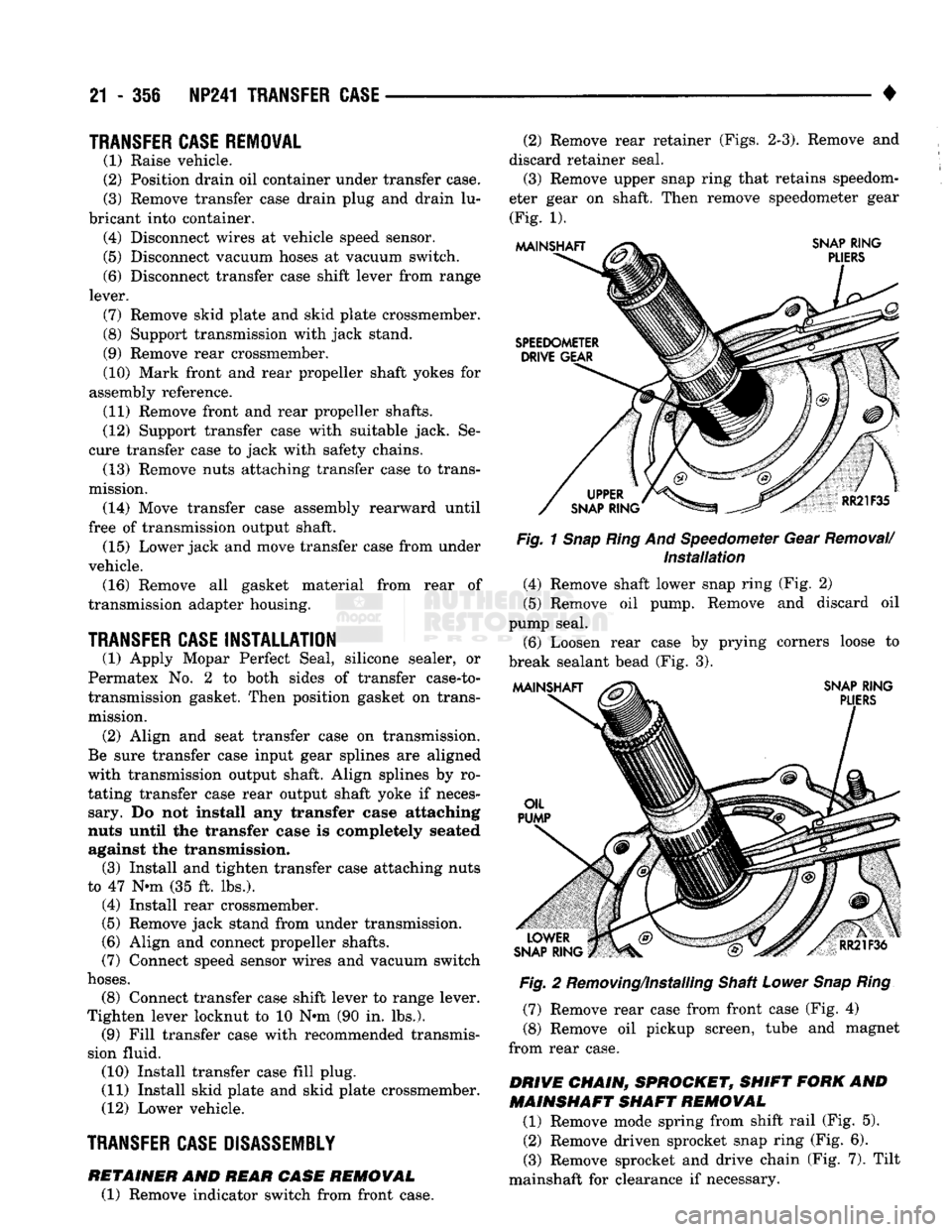

Fig.

4 Speedometer

Components

(4) Check vehicle speed sensor mounting area in

pinion adapter. If transmission fluid is found in this area, adapter oil seal is leaking and will have to be

replaced.

(5) Remove bolt and retainer securing pinion gear

adapter to extension housing.

(6)

Carefully work adapter and gear out of hous

ing. (7) Remove and discard adapter O-ring (Fig. 4).

SPEEDOMETER ADAPTER

OIL

SEAL

REPLACEMENT

Remove adapter oil seal if necessary. Start new

seal in adapter by hand. Then press seal into adapter

with Installer Tool C-4004 until tool bottoms (Fig. 5).

ADAPTER

LOCK

RING

TOOL

(3) Count number of teeth on pinion gear before

installing gear in adapter.

(4) Note range numbers on adapter face (Fig. 6).

These numbers correspond to number of teeth on pin ion. (5) Install adapter in housing.

(6)

Rotate adapter until required range numbers

are at six o-clock position (Fig. 6). Be sure adapter

range numbers correspond to number of teeth on pin ion. (7) Seat adapter in housing.

(8) Install adapter retainer. Tighten retainer bolt

to 11 N-m (100 in. lbs.) torque.

(9) Install vehicle speed sensor. Tighten sensor

coupling nut to 17 N-m (150 in. lbs.) torque and in

stall sensor wires.

(10) Check and correct transfer case lubricant level

if necessary.

(11) Install skid plate and crossmember if re

moved. (12) Lower vehicle.

ADAPTER

O'CLOCK

POSITION

Fig.

6 Indexing Speedometer Adapter

RH75

OIL

SEAL

RH263

Fig.

5

Replacing

Speedometer Adapter

Seal

ADAPTER/SENSOR

INSTALLATION

CAUTION:

Before installing

the

pinion arid adapter

assembly

make sure

the

adapter flange

and its

mounting area

in

transfer case

are

perfectly clean. Dirt

or

sand

will

cause misalignment resulting

in

speedometer pinion gear damage.

(1) Thoroughly clean adapter flange and adapter

mounting surface in extension housing. These sur

faces must be clean for proper adapter alignment and speedometer operation.

(2) Lubricate adapter oil seal and O-ring with

transmission fluid.

Page 1357 of 1502

21 - 356 NP241

TRANSFER

CASE

•

TRANSFER

CASE

REMOVAL

(1) Raise vehicle.

(2) Position drain oil container under transfer case.

(3) Remove transfer case drain plug and drain lu

bricant into container. (4) Disconnect wires at vehicle speed sensor.

(5) Disconnect vacuum hoses at vacuum switch.

(6) Disconnect transfer case shift lever from range

lever. (7) Remove skid plate and skid plate crossmember.

(8) Support transmission with jack stand.

(9) Remove rear crossmember.

(10) Mark front and rear propeller shaft yokes for

assembly reference. (11) Remove front and rear propeller shafts.

(12) Support transfer case with suitable jack. Se

cure transfer case to jack with safety chains. (13) Remove nuts attaching transfer case to trans

mission. (14) Move transfer case assembly rearward until

free of transmission output shaft. (15) Lower jack and move transfer case from under

vehicle. (16) Remove all gasket material from rear of

transmission adapter housing.

TRANSFER CASE

INSTALLATION

(1) Apply Mopar Perfect Seal, silicone sealer, or

Permatex No. 2 to both sides of transfer case-to-

transmission gasket. Then position gasket on trans mission.

(2) Align and seat transfer case on transmission.

Be sure transfer case input gear splines are aligned

with transmission output shaft. Align splines by ro

tating transfer case rear output shaft yoke if neces sary. Do not install any transfer case attaching

nuts until the transfer case is completely seated against the transmission.

(3) Install and tighten transfer case attaching nuts

to 47 N*m (35 ft. lbs.). (4) Install rear crossmember.

(5) Remove jack stand from under transmission.

(6) Align and connect propeller shafts.

(7) Connect speed sensor wires and vacuum switch

hoses.

(8) Connect transfer case shift lever to range lever.

Tighten lever locknut to 10 N*m (90 in. lbs.). (9) Fill transfer case with recommended transmis

sion fluid. (10) Install transfer case fill plug.

(11) Install skid plate and skid plate crossmember.

(12) Lower vehicle.

TRANSFER CASE DISASSEMBLY

(2) Remove rear retainer (Figs. 2-3). Remove and

discard retainer seal. (3) Remove upper snap ring that retains speedom

eter gear on shaft. Then remove speedometer gear (Fig. 1).

Fig.

1

Snap Ring

And Speedometer Gear

Removal/

Installation

(4) Remove shaft lower snap ring (Fig. 2)

(5) Remove oil pump. Remove and discard oil

pump seal. (6) Loosen rear case by prying corners loose to

break sealant bead (Fig. 3).

Fig.

2 Removing/Installing Shaft

Lower

Snap Ring

(7) Remove rear case from front case (Fig. 4)

(8) Remove oil pickup screen, tube and magnet

from rear case.

DRIVE CHAIN, SPROCKET, SHIFT FORK

AND

MAINSHAFT SHAFT REMOVAL

(1) Remove mode spring from shift rail (Fig. 5).

(2) Remove driven sprocket snap ring (Fig. 6).

(3) Remove sprocket and drive chain (Fig. 7). Tilt

mainshaft for clearance if necessary.

RETAINER

AND

REAR CASE

REMOVAL

(1) Remove indicator switch from front case.

Page 1368 of 1502

•

TRANSMISSION/TRANSFER

CASE

SPECIFICATIONS

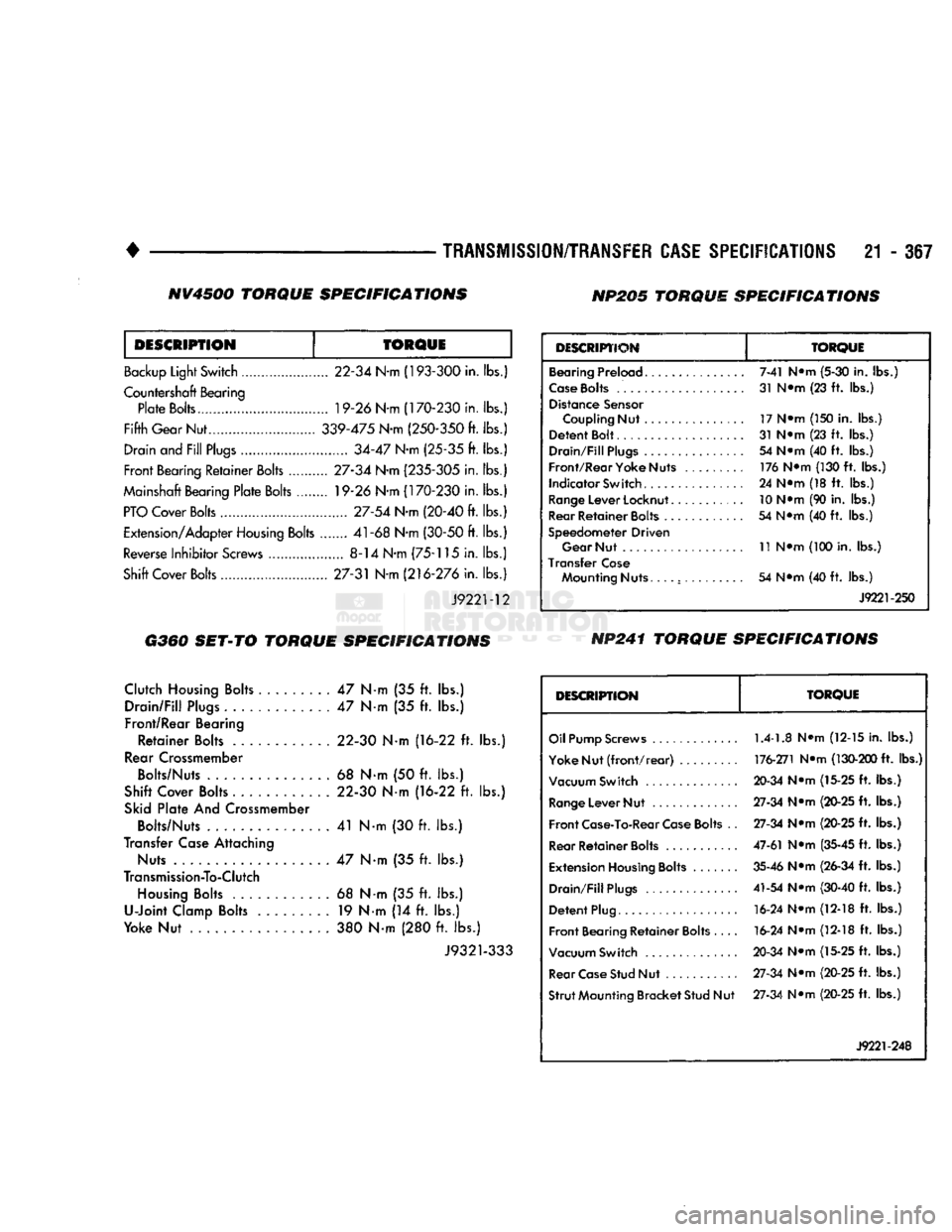

21 - 367

DESCRIPTION

TORQUE

Backup Light Switch 22-34 N-m (193-300 in.

lbs.)

Countershaft Bearing Plate Bolts 19-26 N-m (170-230 in.

lbs.)

Fifth Gear Nut 339-475 N-m (250-350

ft. lbs.)

Drain

and

Fill Plugs 34-47 N-m (25-35

ft. lbs.)

Front Bearing Retainer Bolts 27-34 N-m (235-305 in.

lbs.)

Mainshaft Bearing Plate Bolts 19-26 N-m (170-230 in.

lbs.)

PTO

Cover Bolts 27-54 N-rn (20-40

ft.

lbs.)

Extension/Adapter Housing Bolts 41-68 N-m (30-50

ft.

lbs.)

Reverse Inhibitor Screws

8-14

N-m (75-115 in.

lbs.)

Shift Cover Bolts 27-31 N-m (216-276 in.

lbs.)

J9221-12

DESCRIPTION

TORQUE

Bearing Preload

Case

Bolts

Distance

Sensor

Coupling

Nut

Detent

Bolt

Drain/Fill

Plugs

Front/Rear Yoke Nuts Indicator Switch

Range

Lever

Locknut..

Rear

Retainer

Bolts

...

Speedometer Driven Gear

Nut

Transfer

Case

Mounting

Nuts.

. . . . 7-41

N»m

(5-30

in.

lbs.)

31

mm (23 ft. lbs.)

17

N»m

(150

in.

lbs.)

31

N»m (23 ft. lbs.) 54

N«m

(40 ft. lbs.) 176

N®m

(130 ft. lbs.)

24

N«m

(18 ft. lbs.)

10 N*m (90 in. lbs.)

54

N«m

(40 ft. lbs.)

11

N»m (100

in.

lbs.)

54

N«m

(40 ft. lbs.) J9221-250

G360

SET-TO

TORQUE

SPECIFICATIONS

NP241

TORQUE SPECIFICATIONS

Clutch Housing Bolts

47 N-m (35 ft. lbs.)

Drain/Fill Plugs

47 Nm (35 ft. lbs.)

Front/Rear Bearing

Retainer Bolts

.

22-30

N-m

(16-22

ft. lbs.)

Rear Crossmember Bolts/Nuts

. 68 N-m (50 ft. lbs.)

Shift Cover Bolts 22-30

N-m

(16-22

ft. lbs.)

Skid Plate

And

Crossmember Bolts/Nuts

41 N-m (30 ft. lbs.)

Transfer Case Attaching Nuts

47 Nm (35 ft. lbs.)

Transmission-To-Clutch Housing Bolts

68 N-m (35 ft. lbs.)

U-Joint Clamp Bolts

19 Nm (14 ft. lbs.)

Yoke

Nut 380 N-m (280 ft. lbs.)

J9321-333

DESCRIPTION

TORQUE

Oil Pump

Screws

1.4-1.8

N«m (12-15 in. lbs.)

Yoke

Nut (front/rear) 176-271 N»m (130-200 ft. lbs.)

Vacuum Switch

20-34 N«m (15-25 ft. lbs.)

Range

Lever

Nut

27-34 N»m (20-25 ft. lbs.)

Front

Case-To-Rear

Case

Bolts

.. 27-34 N»m (20-25 ft. lbs.)

Rear

Retainer

Bolts

47-61 N»m (35-45 ft. lbs.)

Extension

Housing

Bolts

35-46 N»m (26-34 ft. lbs.)

Drain/Fill

Plugs

41-54 N*m (30-40 ft. lbs.)

Detent

Plug

16-24

N@m

(12-18 ft. lbs.)

Front

Bearing

Retainer

Bolts

16-24 N»m (12-18 ft. lbs.)

Vacuum Switch

20-34 N*m (15-25 ft. lbs.)

Rear

Case

Stud

Nut 27-34 N*m (20-25 ft. lbs.)

Strut

Mounting Bracket Stud

Nut 27-34 N»m (20-25 ft. lbs.)

J9221-248

NV4500

TORQUE

SPECIFICATIONS

NP205

TORQUE

SPECIFICATIONS

Page 1478 of 1502

•

EMISSION

CONTROL

SYSTEMS

25

- 1

CONTENTS

page page

AIR INJECTION

SYSTEM-o

9L

HDC-GAS EVAPORATIVE EMISSION CONTROLS

6

ENGINE

15

EXHAUST EMISSION CONTROLS

10

COMPONENT

REMOVAL/INSTALLATION

17

GENERAL INFORMATION

1

GENERAL

INFORMATION

Throughout this group, references are made

to

par

ticular vehicle models

by

alphabetical designation

or

by the particular vehicle nameplate.

A

chart showing a breakdown

of

alphabetical designations

is

included

in

the

Introduction section

at

the

beginning

of

this

manual.

The 5.9L (V-8) gas powered engine will

be

referred

to

in

this group

as

either the: LDC (Light Duty Cy cle)

or

HDC (Heavy Duty Cycle) engine.

The

HDC

engine can

be

easily identified

by

the

use

of

an en

gine mounted

air

injection pump. The 3.9L/5.2L/5.9L

LDC engine will not use

an

air

injection pump.

Maintenance requirements for LDC and HDC emis

sion systems differ because

of

different load

and

op

erating conditions. This section will cover emission control systems

for

the 3.9L (V-6), 5.2L (V-8), 5.9L LDC (V-8), 5.9L HDC (V-8) and 5.9L (in-line six cylinder) diesel engines.

SERVICE

REMINDER INDICATOR

(SRI)

LIGHT

The instrument panel mounted SRI light was for

merly referred

to as the

emission maintenance

re

minder (EMR) light.

It is

used with 5.9L HDC-gas

powered engines only.

It is

not

used with diesel

en

gines.

The SRI system

is

incorporated into the powertrain

control module (PCM)

(the

PCM

was

formerly

re

ferred

to as the

engine controller

or

SBEC).

The

PCM records

the

vehicles mileage and stores

it

into

memory every

8

miles. At that time, the PCM checks

for the 60,000 and 82,500 mileage trip points. When

the current mileage matches one

of

the above men

tioned trip points,

the

SRI light

is

activated.

The following parts are

to

be replaced

at

either the

indicated mileage

or

when the SRI light remains

on

when the key

is in

the ON position. After performing

the required maintenance,

the

SRI light must

be

re set

to

turn the light

off.

96,000

km

(60,000 miles):

• Replace EGR Valve

• Clean EGR passage • Replace PCV Valve

132,000

km

(82,500 miles):

• Replace Oxygen Sensor

Refer

to

Group

0,

Lubrication and Maintenance

for

all required maintenance schedules.

Failure

to

perform

the

required maintenance

and

only reset the SRI light may be

a

violation of federal

law. Only after performing

the

required mainte

nance, should the SRI light

be

reset.

RESETTING

SRI

LIGHT

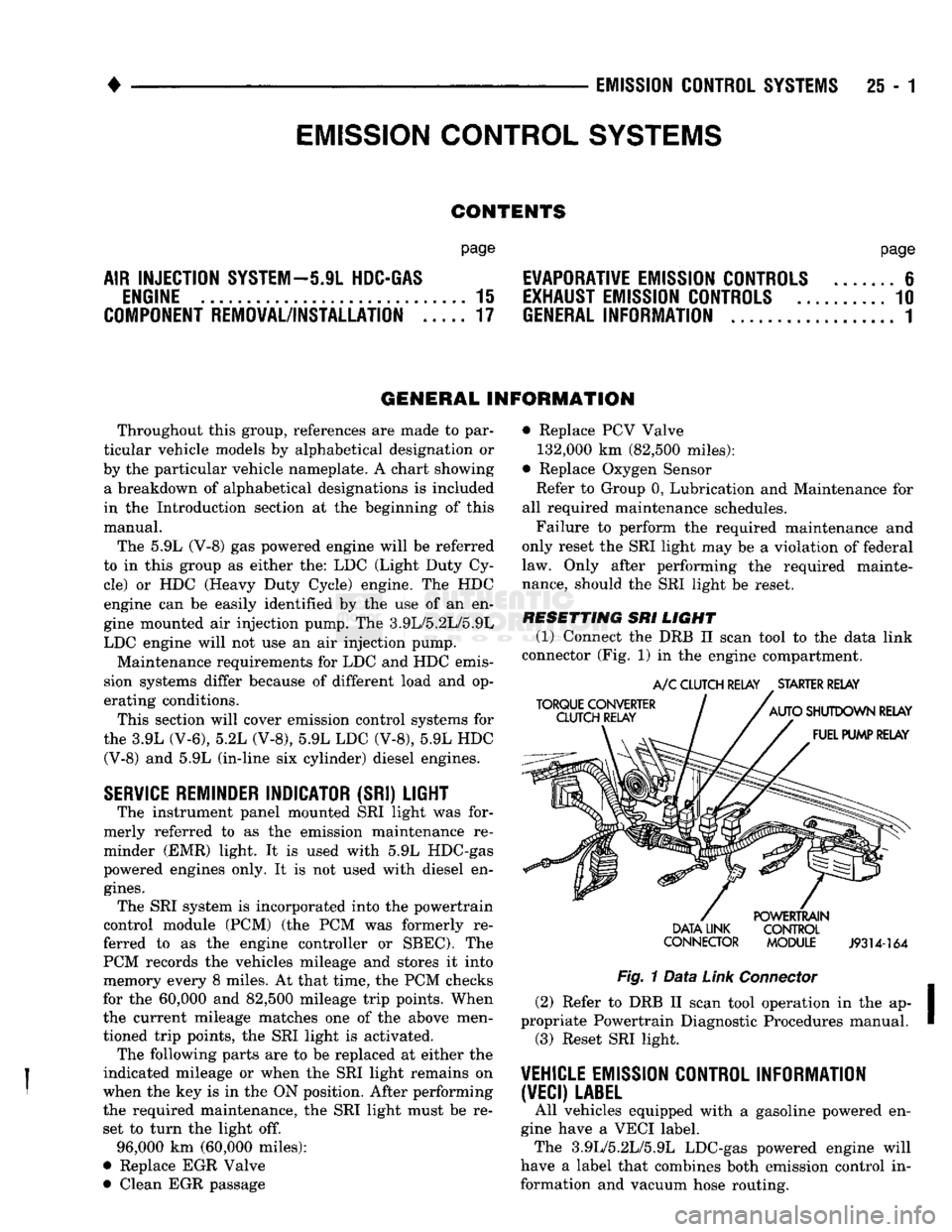

(1) Connect

the

DRB

II

scan tool

to

the

data link

connector (Fig.

1)

in

the engine compartment.

TORQUE CONVERTER

CLUTCH RELAY

A/C

CLUTCH RELAY

.

STARTER RELAY

AUTO

SHUTDOWN RELAY FUEL PUMP RELAY DATA LINK

CONNECTOR POWERTRAIN

CONTROL

MODULE

J9314-164

Fig.

1

Data

Link

Connector

(2) Refer

to

DRB

II

scan tool operation

in

the ap

propriate Powertrain Diagnostic Procedures manual. (3) Reset SRI light.

VEHICLE

EMISSION CONTROL INFORMATION

(VECI)

LABEL

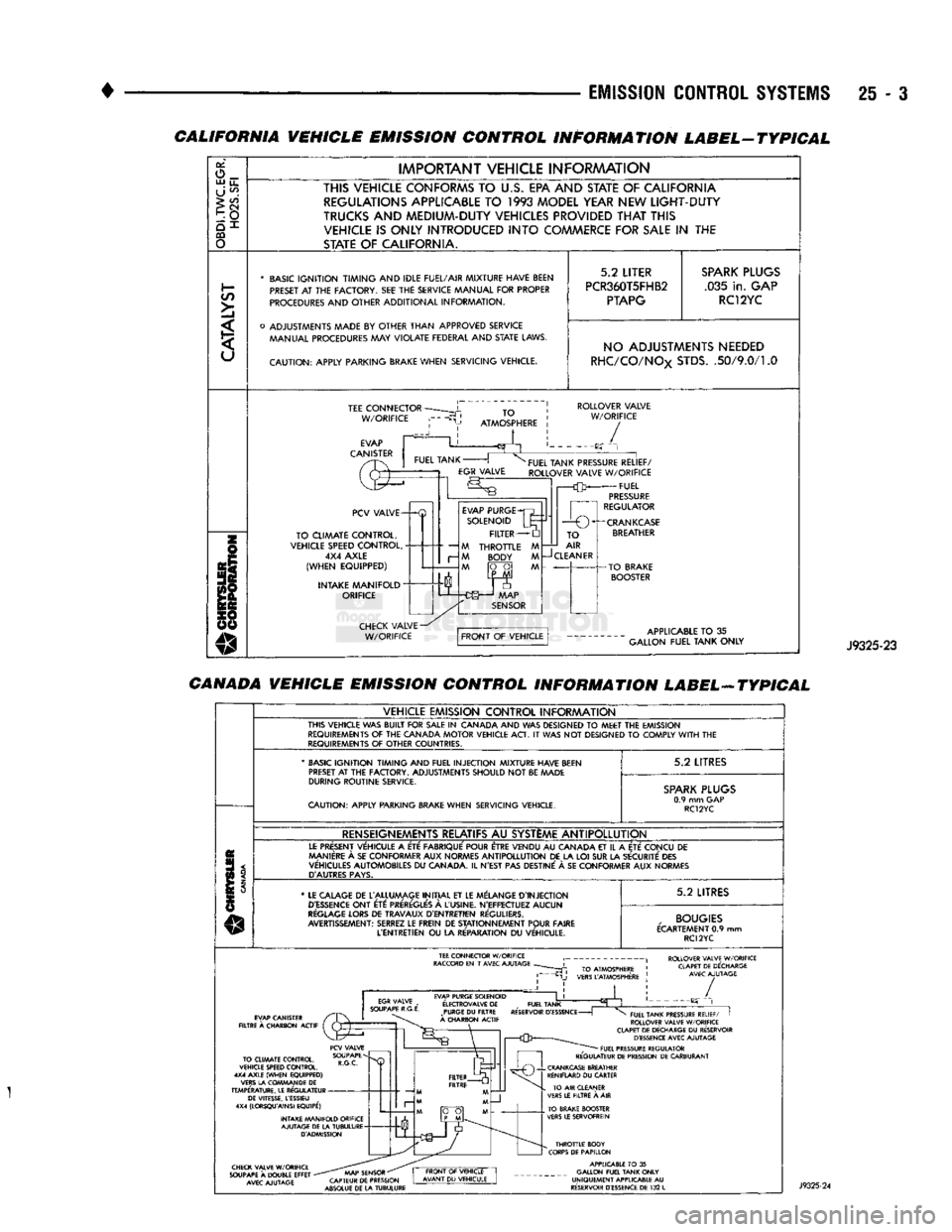

All vehicles equipped with

a

gasoline powered

en

gine have

a

VECI label. The 3.9L/5.2L/5.9L LDC-gas powered engine will

have

a

label that combines both emission control

in

formation and vacuum hose routing.

EMISSION CONTROL

SYSTEMS

Page 1480 of 1502

EMISSION

CONTROL SYSTEMS

25 - :

CALIFORNIA VEHICLE EMISSION CONTROL INFORMATION LABEL-TYPICAL

or,

o_ UJ

u_

U

^

>

CO

CQ

o

IMPORTANT

VEHICLE

INFORAAATION

THIS VEHICLE CONFORMS

TO

U.S.

EPA AND STATE

OF

CALIFORNIA REGULATIONS APPLICABLE

TO 1993

MODEL YEAR NEW

LIGHT-DUTY

TRUCKS

AND

MEDIUM-DUTY VEHICLES PROVIDED

THAT

THIS VEHICLE

IS

ONLY INTRODUCED

INTO

COMMERCE FOR

SALE

IN THE

STATE

OF

CALIFORNIA.

*

BASIC

IGNITION TIMING

AND

IDLE FUEL/AIR

MIXTURE HAVE BEEN

PRESET

AT THE

FACTORY.

SEE THE

SERVICE MANUAL

FOR

PROPER

PROCEDURES

AND

OTHER

ADDITIONAL

INFORMATION.

o

ADJUSTMENTS MADE

BY

OTHER

THAN

APPROVED

SERVICE MANUAL PROCEDURES

MAY

VIOLATE

FEDERAL

AND

STATE

LAWS.

CAUTION:

APPLY

PARKING BRAKE

WHEN

SERVICING

VEHICLE.

5.2

LITER

PCR360T5FHB2

PTAPG

SPARK

PLUGS

.035

in.

GAP RC12YC NO ADJUSTMENTS NEEDED

RHC/CO/NOx

STDS.

.50/9.0/1.0

TEE

CONNECTOR

W/ORIFICE

TO

ATMOSPHERE

ROLLOVER

VALVE

W/ORIFICE

/

PCV

VALVE-

TO

CLIMATE

CONTROL,

VEHICLE SPEED

CONTROL,

4X4

AXLE

(WHEN

EQUIPPED)

INTAKE

MANIFOLD"

ORIFICE

—

M

r-

M

EVAP

PURGE

SOLENOID

FILTER

THROTTLE

BODY

FUEL

TANK PRESSURE

RELIEF/

ROLLOVER

VALVE

W/ORIFICE

FUEL

PRESSURE

REGULATOR

1

r—O

O^-CRANKCASE

TO

AIR

CLEANER

APPLICABLE

TO

35

GALLON

FUEL

TANK

ONLY

J9325-23

CANADA VEHICLE EMISSION CONTROL INFORMATION LABEL-ATYPICAL

VEHICLE

EMISSION

CONTROL

INFORAAATION

THIS

VEHICLE

WAS

BUILT

FOR

SALE

IN

CANADA

AND WAS

DESIGNED

TO

MEET

THE

EMISSION

REQUIREMENTS

OF THE

CANADA

MOTOR

VEHICLE

ACT.

IT

WAS NOT

DESIGNED

TO

COMPLY

WITH

THE

REQUIREMENTS

OF

OTHER

COUNTRIES.

'

BASIC

IGNITION TIMING

AND

FUEL

INJECTION

MIXTURE HAVE BEEN

PRESET

AT

THE

FACTORY.

ADJUSTMENTS

SHOULD

NOT

BE

MADE

DURING

ROUTINE

SERVICE.

CAUTION:

APPLY

PARKING BRAKE

WHEN

SERVICING

VEHICLE.

5.2

LITRES

SPARK

PLUGS

0.9

mm GAP

RC12YC

RENSEIGNEMENTS RELATIFS

AU

SYSTEME

ANTIPOLLUTION

LE

PRESENT

VEHICULE

A

ETE

FABRIQUE'

POUR ETRE

VENDU

AU

CANADA

ET

IL

A

ETE

CONCU

DE

MANIERE

A

SE

CON

FORMER

AUX

NORMES

ANTIPOLLUTION

DE LA LOI SUR LA

SECURITE

DES

VEHICULES

AUTOMOBILES

DU

CANADA.

IL

N'EST

PAS

DESTINE'

A SE

CON

FORMER

AUX

NORMES

D'AUTRES

PAYS.

*

LE

CALAGE

DE

L'ALLUMAGE

INITIAL

ET LE

MELANGE

D'INJECTION

D'ESSENCE

ONT

ETC:

PREREGLE'S

A

L'USINE.

N'EFFECTUEZ

AUCUN

REGLAGE

LORS

DE

TRAVAUX

D'ENTRETIEN

REGULIERS.

AVERTISSEMENT:

SERREZ

LE

FREIN

DE

STATIONNEMENT

POUR

FAIRE

L'ENTRETIEN

OU

LA

RE'PARATION

DU

VEHICULE.

5.2

LITRES

,

BOUGIES

ECARTEMENT

0.9 mm

RC12YC

ROLLOVER VALVE W/ORIFICE CLAPET DE DECHARGE AVEC AJUTAGE EVAP PURGE SOLENOID

E'LECTROVALVE

DE

_

FUEL TANK PURGE

DU

FILTRE RESERVOIR

D'ESSENCE

-

A CHARBON ACTIF /

TO CLIMATE CONTROL,

VEHICLE SPEED CONTROL.

4X4 AXLE (WHEN EQUIPPED)

VERS LA COWMAN DE

DE

TEMPERATURE. LE REGULATEUR DE VITESSE, LESSIEU

4X4 (LORSQU'AINSI EQUIPE')

INTAKE MANIFOLD ORIFICE AJUTAGE DE LA TUBULURE D'ADMISSION FUEL TANK PRESSURE RELIEF/

I

ROLLOVER VALVE W/ORIFICE

CLAPET DE DECHARGE

DU

RESERVOIR D'ESSENCE AVEC AJUTAGE FUEL PRESSURE REGULATOR

REGULATEUR DE PRESSION DE CARBURANT CHECK VALVE W/ORIFICE

SOUPAPE

A

DOUBLE EFFET

-

AVEC AJUTAGE AAAP SENSOR

"

CAPTEUR DE PRESSION

ABSOLUE DE LA TUBULURE THROTTLE BODY

CORPS DE PAPILLON APPLICABLE

TO

35

GALLON FUEL TANK ONLY

UNIQUEMENT APPLICABLE

AU

RESERVOIR D'ESSENCE DE

132

L