check engine light DODGE TRUCK 1993 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 135 of 1502

3

- 6

REAR SUSPENSION

AND

AXLE

•

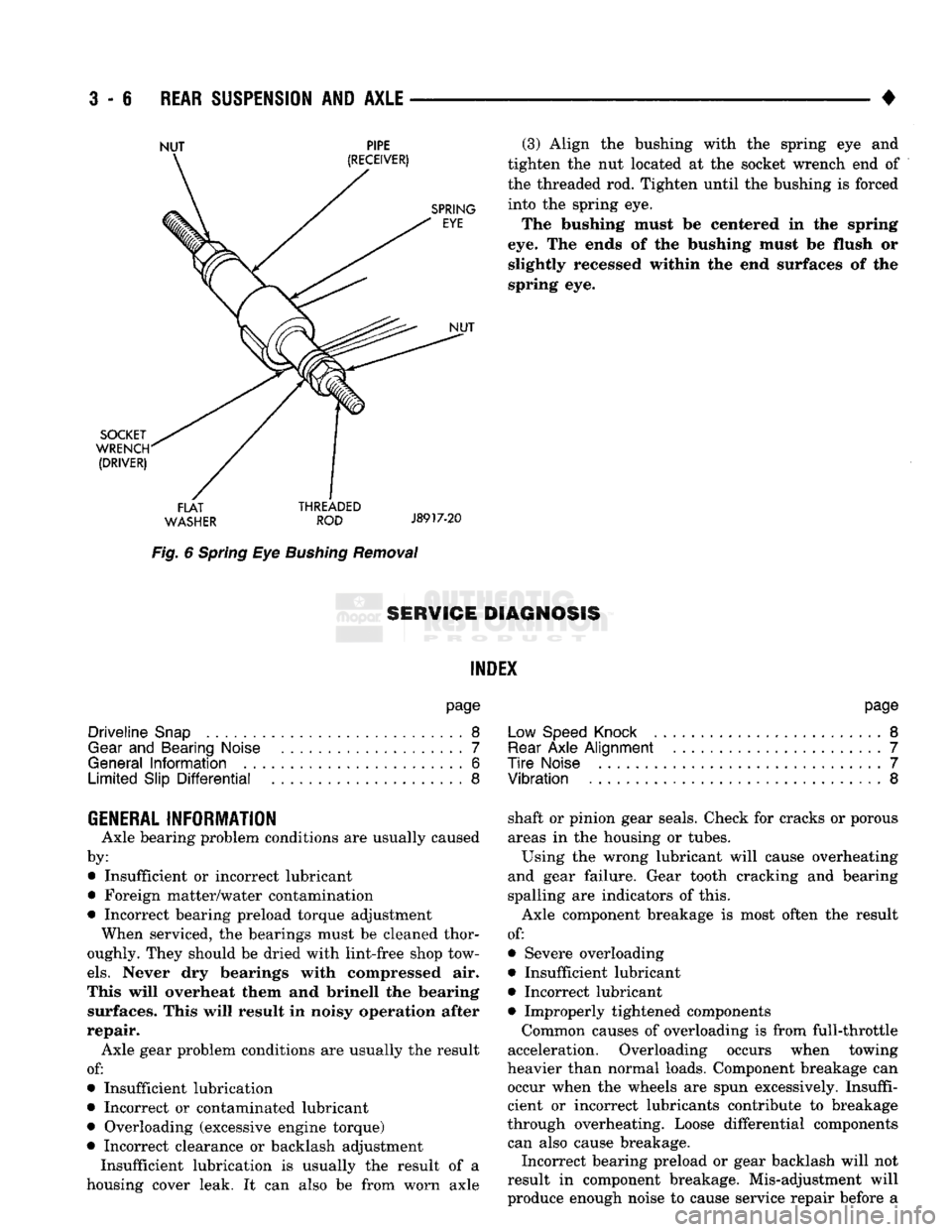

NUT PIPE

SOCKET

WRENCH

(DRIVER)

FLAT

THREADED

WASHER

ROD

J8917-20

Fig.

6

Spring

Eye

Bushing

Removal

(3) Align

the

bushing with

the

spring

eye and

tighten

the nut

located

at the

socket wrench

end of

the threaded

rod.

Tighten until

the

bushing

is

forced into

the

spring

eye.

The bushing must

be

centered

in the

spring

eye.

The

ends

of the

bushing must

be

flush

or

slightly recessed within

the end

surfaces

of the

spring

eye.

8ERW1GE DIAGNOSIS

INDEX

page

Driveline

Snap

8

Gear

and

Bearing Noise

7

General

Information

6

Limited

Slip

Differential

8

page

Low Speed Knock

.........................

8

Rear

Axle

Alignment

.......................

7

Tire

Noise

7

Vibration

8

GENERAL INFORMATION

Axle bearing problem conditions

are

usually caused

by: • Insufficient

or

incorrect lubricant

• Foreign matter/water contamination

• Incorrect bearing preload torque adjustment When serviced,

the

bearings must

be

cleaned thor

oughly. They should

be

dried with lint-free shop tow

els.

Never

dry

bearings with compressed

air.

This will overheat them

and

brinell

the

bearing surfaces. This will result

in

noisy operation after

repair. Axle gear problem conditions

are

usually

the

result

of:

• Insufficient lubrication

• Incorrect

or

contaminated lubricant

• Overloading (excessive engine torque)

• Incorrect clearance

or

backlash adjustment Insufficient lubrication

is

usually

the

result

of a

housing cover leak.

It can

also

be

from worn axle shaft

or

pinion gear seals. Check

for

cracks

or

porous

areas

in the

housing

or

tubes.

Using

the

wrong lubricant will cause overheating

and gear failure. Gear tooth cracking

and

bearing

spalling

are

indicators

of

this.

Axle component breakage

is

most often

the

result

of:

• Severe overloading

• Insufficient lubricant

• Incorrect lubricant • Improperly tightened components

Common causes

of

overloading

is

from full-throttle

acceleration. Overloading occurs when towing

heavier than normal loads. Component breakage

can

occur when

the

wheels

are

spun excessively. Insuffi

cient

or

incorrect lubricants contribute

to

breakage

through overheating. Loose differential components can also cause breakage. Incorrect bearing preload

or

gear backlash will

not

result

in

component breakage. Mis-adjustment will

produce enough noise

to

cause service repair before

a

Page 137 of 1502

3

- 8

REAR SUSPENSION

AND

AXLE

• level. Where axle bearing damage is slight, the noise

is usually not noticeable at speeds above 30 mph.

LOW SPEED KNOCK

Low speed knock is generally caused by a worn

U-joint or by worn side-gear thrust washers. A worn

pinion gear shaft bore will also cause low speed knock.

VIBRATION

Vibration at the rear of the vehicle is usually

caused by a:

• Damaged drive shaft

• Missing drive shaft balance weight

• Worn, out-of-balance wheel and tires

• Loose wheel lug nuts

• Worn U-joint • Loose spring U-bolts

• Loose/broken rear springs or shackles

• Damaged axle shaft bearings

• Loose pinion gear nut

• Excessive pinion yoke run out

• Bent axle shaft Check for loose or damaged front-end components

or engine/transmission mounts. These components

can contribute to what appears to be a rear-end vi

bration. Do not overlook engine accessories, brackets and drive belts. All driveline components should be examined be

fore starting any repair. Refer to Group 22, Wheels and Tires for additional

information.

DRIVELINE SNAP

A snap or clunk noise when the vehicle is shifted

into gear (or the clutch engaged), can be caused by: • High engine idle speed

• Loose engine/transmission/transfer case mounts

9

Worn U-joints

• Loose spring shackles or U-bolts

• Loose pinion gear nut and yoke

• Excessive ring gear backlash

• Excessive differential side gear-to-case clearance A worn bushing in the transmission extension

housing can also cause noise. The source of a snap or a clunk noise can be deter

mined with the assistance of a helper. Raise the ve

hicle on a hoist with the wheels free to rotate. Instruct the helper to shift the transmission into gear. Listen for the noise, a mechanics stethoscope is

helpful in isolating the source of a noise.

LIMITED

SLIP DIFFERENTIAL

Under normal traction conditions, engine torque is

divided evenly. With low-traction surfaces, engine

torque is transferred to the wheel with the most tire

traction. When diagnosing a limited-slip differential

problem condition, the wheel with the least traction can continue spinning. The most common problem is a chatter noise when

turning corners. Check for incorrect or contaminated lubricant. Replace the gear lubricant if necessary.

• With Sure-Grip differentials add a container of

MOPAR® Hypoid Gear Additive This will correct the condition in most instances. If

the chatter persists, clutch damage could have oc curred. After changing the lubricant, drive the vehicle and

make 10 to 12 slow, figure-eight turns. This maneu

ver will pump lubricant through the clutches.

Page 190 of 1502

•

BRAKES

i - 3 BRAKE DIAGNOSIS

INDEX

page

Brake

Warning Lights

3

Diagnosing

Brake Problems .................

4

Diagnosis

Procedures

3

Low

Vacuum

Switch—Diesel

Models

3

page

Master

Cylinder/Power Booster Test

5

Power

Booster

Check

Valve Test .............

6

Power

Booster

Vacuum

Test .................

6

Testing Diesel

Engine

Vacuum

Pump

Output

.... 6

DIAGNOSIS

PROCEDURES

Brake diagnosis involves determining

if the

prob

lem

is

related

to a

mechanical, hydraulic

or

vacuum

operated component.

A

preliminary check, road test

ing

and

component inspection

can all be

used

to de

termine

a

problem cause. Road testing will either verify proper brake opera

tion

or

confirm

the

existence

of a

problem. Compo nent inspection will,

in

most cases, identify

the

actual part causing

a

problem. The first diagnosis step

is the

preliminary check. This

involves inspecting fluid level, parking brake action,

wheel

and

tire condition, checking

for

obvious leaks

or

component damage

and

testing brake pedal response. A road test will confirm

the

existence

of a

problem.

Final diagnosis procedure involves road test analysis and

a

visual inspection

of

brake components.

BRAKE

WARNING LIGHTS

The

red

brake warning light

is

connected

to the

parking brake switch

and to the

pressure differential switch

in the

combination valve. The

red

light will illuminate when

the

parking

brakes

are

applied

or

when

a

fluid pressure drop

oc

curs

in the

front

or

rear brake circuit.

The

light will

also illuminate

for

approximately

2-4

seconds

at en

gine start

up.

This

is a

self test feature designed

to

check bulb

and

circuit operation each time

the en

gine

is

started. The amber antilock light

is

connected

to the

anti-

lock rear brake hydraulic valve.

The

light will illu

minate

if a

fault occurs within

the

antilock system.

LOW VACUUM SWITCH-DIESEL MODELS

On diesel models,

the red

brake warning light

is

also

used

to

alert

the

driver

of a low

brake booster vacuum

condition.

The

warning light

is in

circuit with

a

vacuum

warning switch mounted

on the

driver side fender

panel.

The

vacuum side

of the

switch

is

connected

to the

power brake booster.

The

electrical side

of the

switch

is

connected

to the

brake warning light. The

low

vacuum switch monitors booster vacuum

level whenever

the

engine

is

running.

If

booster vac

uum falls below

8.5

inches vacuum

for a

minimum

of

10 seconds,

the

switch completes

the

circuit

to the

warning light causing

it to

illuminate.

The

warning light

is

designed

to

differentiate between

a low

vac

uum condition

and a

hydraulic circuit fault.

PRELIMINARY

BRAKE CHECK

(1) Check condition

of

tires

and

wheels. Damaged

wheels

and

worn, damaged,

or

underinflated tires

can

cause pull, shudder, tramp,

and a

condition similar

to

grab.

(2)

If

complaint

was

based

on

noise when braking,

check suspension components. Jounce front

and

rear

of

vehicle

and

listen

for

noise that might

be

caused

by

loose, worn

or

damaged suspension

or

steering compo

nents.

(3) Inspect brake fluid level

and

condition. Note

that

the

front disc brake reservoir fluid level will drop

in

proportion

to

normal lining wear. Also note

that brake fluid tends

to

darken over time. This

is normal

and

should

not be

mistaken

for

con

tamination.

If the

fluid

is

still clear

and

free

of

foreign material,

it is OK.

(a)

If

fluid level

is

abnormally

low,

look

for

evi

dence

of

leaks

at

calipers, wheel cylinders, brake-

lines

and

master cylinder.

(b)

If

fluid appears contaminated, drain

out a

sample.

If

fluid

is

separated into layers,

or

obvi

ously contains

oil or a

substance other than brake

fluid,

the

system seals

and

cups will have

to be re

placed

and the

hydraulic system flushed.

(4) Check parking brake operation. Verify free

movement

and

full release

of

cables

and

pedal. Also

note

if

vehicle

was

being operated with parking

brake partially applied.

(5) Check brake pedal operation. Verify that pedal

does

not

bind

and has

adequate free play.

If

pedal

lacks free play, check pedal

and

power booster

for be

ing loose

or for

bind condition.

Do not

road test until

condition

is

corrected.

(6)

If

components checked appear

OK,

road test

the

vehicle.

ROAD

TESTING (1)

If

complaint involved

low

brake pedal, pump

the pedal

and

note

if the

pedal comes back

up to

nor mal height.

(2) Check brake pedal response with transmission

in Neutral

and

engine running. Pedal should remain

firm under steady foot pressure.

Page 191 of 1502

5

- 4

BRAKES

• (3) During road test, make normal and firm brake

stops in 25-40 mph (40-64 Km/h) range. Note faulty

brake operation such as pull, grab, drag, noise, low

pedal, etc.

(4) Inspect suspect brake components and refer to

problem diagnosis information for causes of various

brake conditions.

COMPONENT

INSPECTION

Fluid leak points and dragging brake units can usu

ally be located without removing any components. The

area around a leak point will be wet with fluid. The

components at a dragging brake unit (wheel, tire, rotor)

will be quite warm or hot to the touch.

Other brake problem conditions will require compo

nent removal for proper inspection. Raise the vehicle and remove the necessary wheels for better visual ac

cess.

DIAGNOSING BRAKE

PROBLEMS

PEDAL FALLS

AWAY

A

brake pedal that falls away under steady foot

pressure is the result of a system leak. The leak

point could be at a brakeline, fitting, hose, or caliper. Internal leakage in the master cylinder caused by

worn or damaged piston cups, may also be the prob lem cause.

If leakage is severe, fluid will be evident at or around

the leaking component. However, internal leakage in

the master cylinder may not be physically evident. Re fer to the cylinder test procedure in this section.

LOW PEDAL

If a low pedal is experienced, pump the pedal sev

eral times. If the pedal comes back up, worn lining

and worn rotors or drums are the likely causes.

A decrease in fluid level in the master cylinder res

ervoirs may only be the result of normal lining wear.

Fluid level can be expected to decrease in proportion to wear. It is a result of the outward movement of

caliper and wheel cylinder pistons to compensate for

normal wear. Top off the reservoir fluid level and

check brake operation to verify proper brake action.

SPONGY PEDAL. A spongy pedal is most often caused by air in the sys

tem. Thin brake drums or substandard brake lines and

hoses can also cause a spongy pedal. The proper course

of action is to bleed the system and replace thin drums and suspect quality brake lines and hoses.

HARD PEDAL

OR

HIGH

PEDAL

EFFORT

A hard pedal or high pedal effort may be due to

lining that is water soaked, contaminated, glazed, or

badly worn. The power booster or check valve could also be faulty. On diesel engine models, high pedal effort may be

the result of a low vacuum condition. If the booster and check valve are OK, the problem may be related

to a vacuum pump hose, hose connection, hose fit

ting, pump diaphragm, or drive gear. Vacuum pump output can be checked with a standard vacuum

gauge. Vacuum output should range from 8.5 to 25 inches vacuum. If vacuum pump output is within

limits,

check the power booster and check valve as

described in this section.

BRAKE DRAG

Brake drag occurs when the lining is in constant

contact with the rotor or drum. Drag can occur at

one wheel, all wheels, fronts only, or rears only. It is a product of incomplete brakeshoe release. Drag can

be minor or severe enough to overheat the linings,

rotors and drums.

Brake drag can also effect fuel economy. If undetec

ted, minor brake drag can be misdiagnosed as an en gine or transmission/torque converter problem.

Minor drag will usually cause slight surface charring

of the lining. It can also generate hard spots in rotors and drums from the overheat-cool down process. In most

cases,

the rotors, drums, wheels and tires are quite

warm to the touch after the vehicle is stopped.

Severe drag can char the brake lining all the way

through. It can also distort and score rotors and drums to the point of replacement. The wheels, tires and brake components will be extremely hot. In se

vere cases, the lining may generate smoke as it chars

from overheating.

Some common causes of brake drag are:

• seized or improperly adjusted parking brake cables

• loose/worn wheel bearing

• seized caliper or wheel cylinder piston

• caliper binding on corroded bushings or rusted

slide surfaces

• loose caliper mounting bracket

• drum brakeshoes binding on worn or damaged sup

port plates

• misassembled components. If brake drag occurs at all wheels, the problem may

be related to a blocked master cylinder return port, or faulty power booster that binds and does not release.

BRAKE FADE

Brake fade is a product of overheating caused by

brake drag. However, brake overheating and subse quent fade can also be caused by riding the brake

pedal, making repeated high deceleration stops in a short time span, or constant braking on steep moun

tain roads. Refer to the Brake Drag information in

this section for additional causes.

PEDAL

PULSA

TION

Pedal pulsation is caused by components that are

loose, out of round, or worn beyond tolerance limits.

Page 192 of 1502

•

BRAKES

5 - 5 Disc brake rotors with excessive lateral runout or

thickness variation, or out of round brake drums are

the primary causes of pulsation. Other causes are loose

wheel bearings or calipers and worn, damaged tires.

PULL A

front pull condition could be the result of con

taminated lining in one caliper, seized caliper piston,

binding caliper, loose caliper, loose or corroded slide

pins,

improper brakeshoes, or a damaged rotor.

A worn, damaged wheel bearing or suspension compo

nent are further causes of pull. A damaged front tire (bruised, ply separation) can also cause pull.

A common and frequently misdiagnosed pull condi

tion is where direction of pull changes after a few

stops.

The cause is a combination of brake drag fol

lowed by fade at one of the brake units.

As the dragging brake overheats, efficiency is so

reduced that fade occurs. Since the opposite brake

unit is still functioning normally, its braking effect is

magnified. This causes pull to switch direction in fa

vor of the normally functioning brake unit.

When diagnosing a change in pull condition, re

member that pull will return to the original direction

if the dragging brake unit is allowed to cool down (and is not seriously damaged).

REAR BRAKE GRAB

OR

PULL

Rear grab or pull is usually caused by an improperly

adjusted or seized parking brake cable, contaminated

lining, bent or binding shoes and support plates, or im

properly assembled components. This is particularly

true when only one rear wheel is involved. However,

when both rear wheels are affected, the master cylinder or proportioning valve could be at fault.

BRAKES

DO NOT

HOLD

AFTER

DRIVING

THROUGH

DEEP

WATER

PUDDLES

This condition is generally caused by water soaked

lining. If the lining is only wet, it can be dried by driv

ing with the brakes very lightly applied for a few min

utes.

However, if the lining is thoroughly wet and dirty,

disassembly and cleaning will be necessary.

BRAKE NOISE

Squeak/Squeal

Brake squeak or squeal may be due to linings that

are wet or contaminated with brake fluid, grease, or oil. Glazed linings and rotors with hard spots can also con

tribute to squeak. Dirt and foreign material embedded in the brake lining can also cause squeak/squeal.

A very loud squeak or squeal is frequently a sign of

severely worn brake lining. If the lining has worn

through to the brakeshoes in spots, metal-to-metal con

tact occurs. If the condition is allowed to continue, ro tors can become so scored that replacement is necessary.

Thump/Clunk

Thumping or clunk noises during braking are fre

quently not caused by brake components. In many

cases,

such noises are caused by loose or damaged steering, suspension, or engine components. How

ever, calipers that bind on the slide pins, or slide sur

faces,

can generate a thump or clunk noise. Worn

out, improperly adjusted, or improperly assembled

rear brakeshoes can also produce a thump noise.

Chatter

Brake chatter is usually caused by loose or worn

components, or glazed/burnt lining. Rotors with hard

spots can also contribute to chatter. Additional

causes of chatter are out of tolerance rotors, brake

lining not securely attached to the shoes, loose wheel

bearings and contaminated brake lining.

Brakelining Contamination Brakelining contamination is usually a product of

leaking calipers or wheel cylinders, driving through

deep water puddles, or lining that has become cov

ered with grease and grit during repair.

Wheel and

Tire

Problems Some conditions attributed to brake components

may actually be caused by a wheel or tire problem.

A damaged wheel can cause shudder, vibration and

pull. A worn or damaged tire can also cause pull.

Severely worn tires with very little tread left can

produce a grab-like condition as the tire loses and re covers traction. Flat-spotted tires can cause vibration and wheel

tramp and generate shudder during brake operation. A tire with internal damage such as a severe

bruise or ply separation can cause pull and vibration.

MASTER

CYLINDER/POWER BOOSTER TEST

(1) Start engine and check booster vacuum hose

connections. Hissing noise indicates a vacuum leak. Correct any leaks before proceeding. (2) Stop engine and shift transmission into Neu

tral (3) Pump brake pedal until all vacuum reserve in

booster is depleted. (4) Press and hold brake pedal under light foot

pressure. (a) If pedal holds firm, proceed to step (5).

(b) If pedal does not hold firm and falls away,

master cylinder is faulty (internal leakage). (5) Start engine and note pedal action. (a) If pedal falls away slightly under light foot

pressure then holds firm, proceed to step (6). (b) If pedal is effort is high, or no pedal action is

discernible, power booster or vacuum check valve is

faulty. Install known good check valve and repeat steps (2) through (5).

Page 193 of 1502

5

- 6

BRAKES

• (c) On diesel models, vacuum pump hose or

pump component may have malfunctioned. Check

pump output with vacuum gauge and repair as necessary. Refer to service procedures in Power

Booster/Vacuum Pump section.

(6) Rebuild booster vacuum reserve as follows: Re

lease brake pedal. Increase engine speed to 1500

rpm, close throttle and immediately turn off ignition. (7) Wait a minimum of 90 seconds and try brake ac

tion again. Booster should provide two or more vacuum assisted pedal applications. If vacuum assist is not pro

vided, perform booster and check valve vacuum tests.

Also check vacuum output on diesel models.

POWER

BOOSTER

CHECK

VALVE

TEST

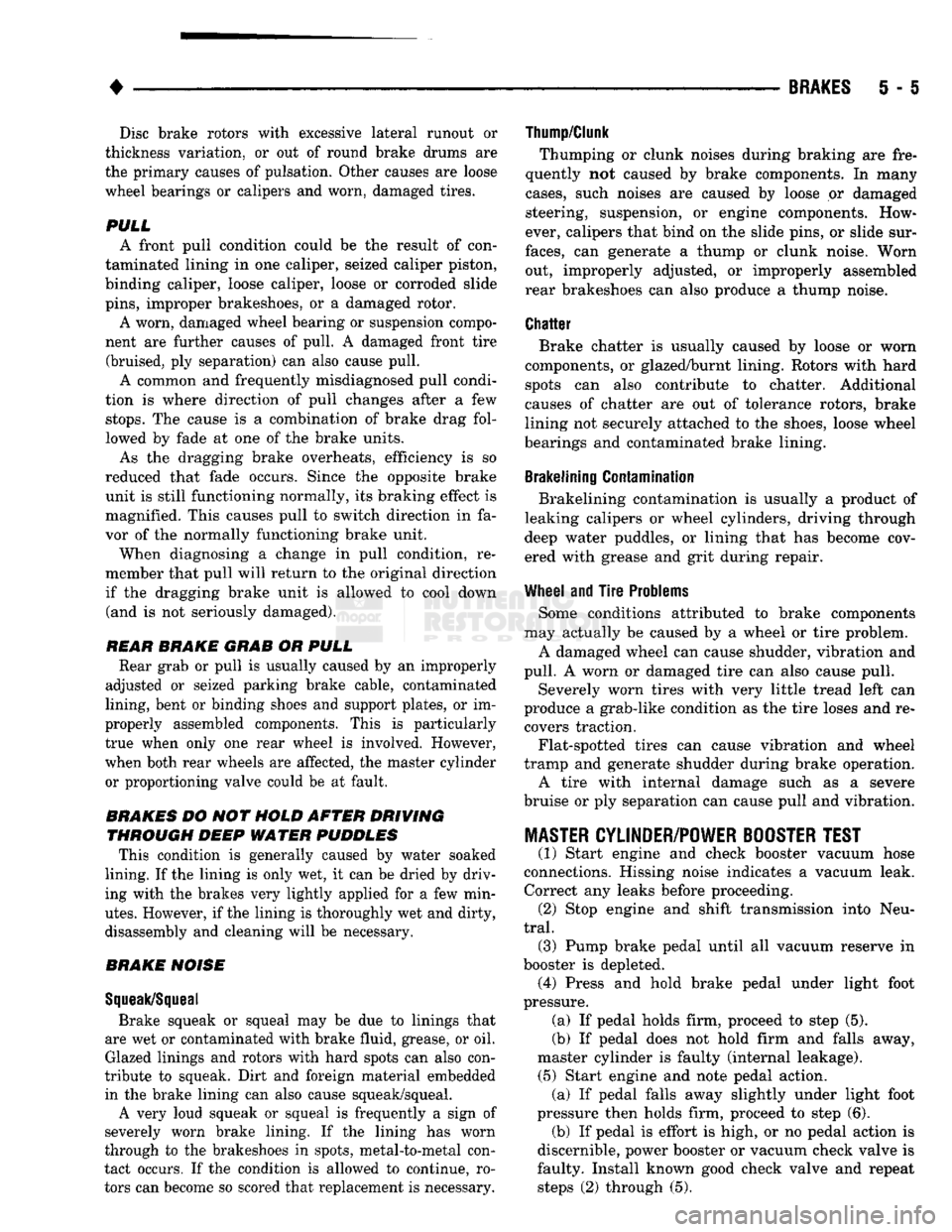

(1) Disconnect vacuum hose from check valve.

(2) Remove check valve and valve seal from

booster (Fig. 1). (3) Hand operated vacuum pump can be used for

test (Fig. 2). (4) Apply 15-20 inches (50-67 kPa) vacuum at

large end of check valve (Fig. 1). (5) Vacuum should hold steady. If gauge on pump

indicates any vacuum loss, valve is faulty and must

be replaced.

BOOSTER

CHECK

VALVE

APPLY

TEST

\

VACUUM

HERE

Fig.

1

Vacuum

Check

Vaive

And

Seal

J9005-80

Fig.

2 Typical

Hand

Operated

Vacuum

Pump

POWER

BOOSTER

VACUUM

TEST

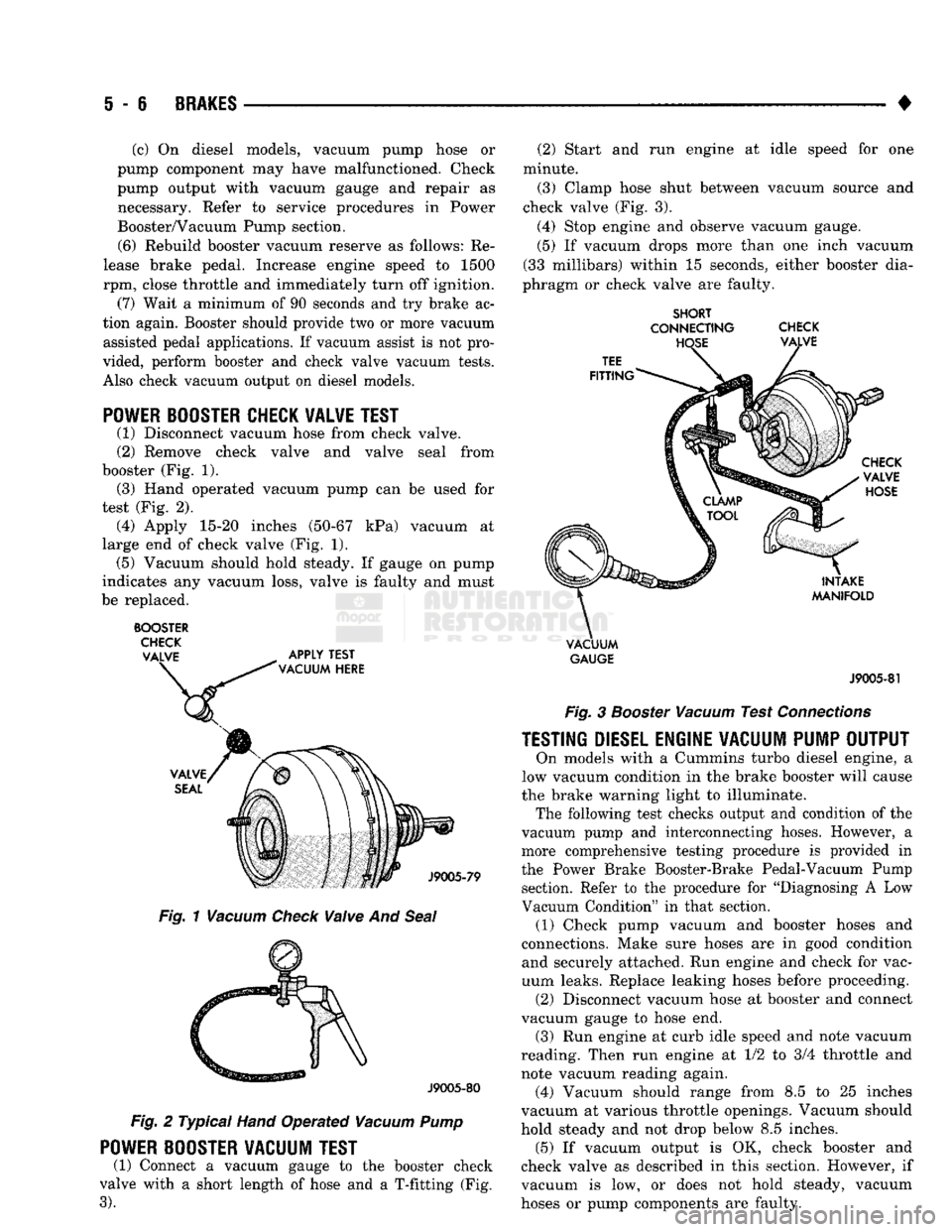

(1) Connect a vacuum gauge to the booster check

valve with a short length of hose and a T-fitting (Fig.

3).

(2) Start and run engine at idle speed for one

minute.

(3) Clamp hose shut between vacuum source and

check valve (Fig. 3).

(4) Stop engine and observe vacuum gauge.

(5) If vacuum drops more than one inch vacuum

(33 millibars) within 15 seconds, either booster dia

phragm or check valve are faulty.

SHORT

CONNECTING

CHECK

VACUUM

GAUGE

J9005-81

Fig.

3

Booster

Vacuum

Test

Connections

TESTING

DIESEL

ENGINE

VACUUM

PUMP

OUTPUT

On models with a Cummins turbo diesel engine, a

low vacuum condition in the brake booster will cause

the brake warning light to illuminate. The following test checks output and condition of the

vacuum pump and interconnecting hoses. However, a

more comprehensive testing procedure is provided in

the Power Brake Booster-Brake Pedal-Vacuum Pump section. Refer to the procedure for "Diagnosing A Low

Vacuum Condition" in that section. (1) Check pump vacuum and booster hoses and

connections. Make sure hoses are in good condition and securely attached. Run engine and check for vac

uum leaks. Replace leaking hoses before proceeding. (2) Disconnect vacuum hose at booster and connect

vacuum gauge to hose end. (3) Run engine at curb idle speed and note vacuum

reading. Then run engine at 1/2 to 3/4 throttle and

note vacuum reading again. (4) Vacuum should range from 8.5 to 25 inches

vacuum at various throttle openings. Vacuum should

hold steady and not drop below 8.5 inches. (5) If vacuum output is OK, check booster and

check valve as described in this section. However, if

vacuum is low, or does not hold steady, vacuum

hoses or pump components are faulty.

Page 210 of 1502

•

BRAKES

5 - 23

VACUUM PUMP OPERATION

Vacuum pump output is transmitted to the power

brake booster through a supply hose. The hose is con nected to an outlet port on the pump housing and to

the check valve in the power brake booster.

Pump output ranges from a minimum of 8.5 to 25

inches vacuum. The pump rotor and vanes are rotated by the pump

drive gear. The drive gear is operated by the cam

shaft gear. Booster vacuum level is monitored by a warning

switch (Fig. 2). The switch consists of a vacuum

chamber that measures vacuum level and a sensor in

circuit with the brake warning light. The vacuum chamber is connected to the booster

check valve by a vacuum supply hose. A wire har

ness connects the switch sensor to the brake warning

light. If booster vacuum falls below 8.5 inches for 8-10 seconds or more, the switch sensor completes

the circuit to the warning light causing it to illumi

nate.

VACUUM PUMP DIAGNOSIS

Vacuum pump diagnosis involves checking pump

output with a vacuum gauge. The low vacuum warn

ing switch can also be checked with a vacuum gauge.

Refer to the diagnosis procedure in this section. A standard vacuum gauge can be used to check

pump output when necessary. Simply disconnect the

pump supply hose and connect a vacuum gauge to

the outlet port for testing purposes. Vacuum should

hold steady in a range of approximately 8.5 to 25 inches at various engine speeds.

DIAGNOSING LOW VACUUM OUTPUT CONDITION A low booster vacuum condition or a faulty low

vacuum warning switch will cause the brake warn ing light to illuminate. If the light does go on and in

dicates the existence of a low vacuum condition,

check the vacuum pump, booster and warning switch

as follows:

(1) Check vacuum pump oil feed line. Verify that

line connections are secure and not leaking. If leak age is noted and pump is noisy, replace pump.

(2) Disconnect supply hose to booster. Connect vac

uum gauge to this hose and run engine at various

throttle openings. Output should range from 8.5 to 25 inches vacuum. If vacuum is consistently below

8.5 inches, problem is with vacuum hoses or pump

component. If output is within specified limits, con

tinue testing.

(3) Check booster operation as described in diagno

sis section. Replace check valve, vacuum hoses, or

booster if necessary. However, if booster operation is correct but warning light is still on, continue testing. (4) Disconnect vacuum hose at warning switch.

Plug hose and connect hand vacuum pump to switch. (5) Start and run engine.

(6) Apply 8.5 to 9 inches of vacuum to warning

switch and observe warning light. If light goes out,

switch vacuum hose is either loose or leaking. If

light remains on, leave engine running and continue

testing.

(7) Apply 20-25 inches vacuum to switch and ob

serve warning light operation. If light now goes out,

switch is at fault and should be replaced. If light re

mains on, continue testing.

(8) Reconnect vacuum hoses and replace original

warning switch with known good switch. Run engine and observe warning light operation. If light is now

off, old switch is faulty. If light remains on, problem

is in wiring between switch and warning light.

VACUUM-STEERING PUMP

ASSEMBLY

REMOVAL

(1) Disconnect battery negative cable.

(2) Position drain pan under power steering pump.

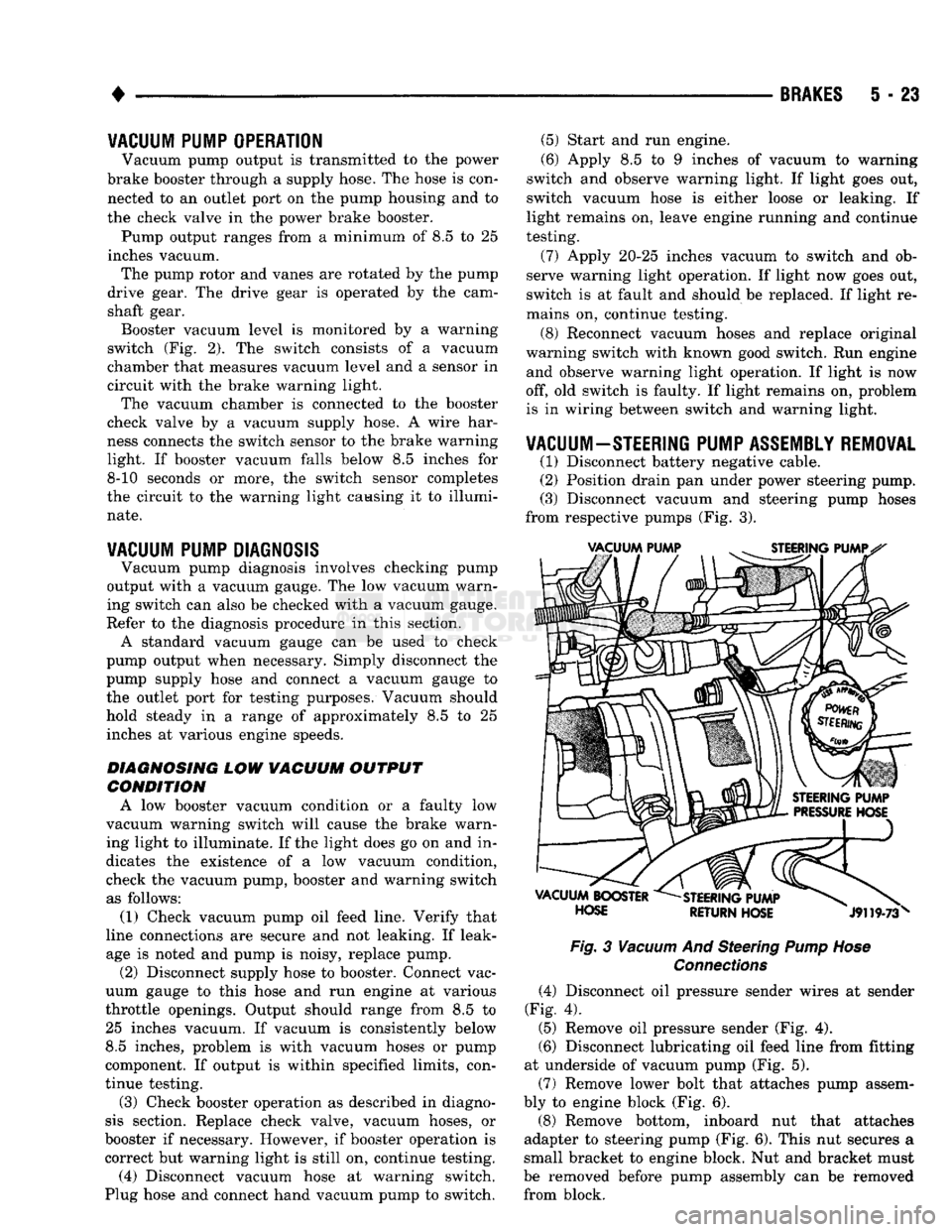

(3) Disconnect vacuum and steering pump hoses

from respective pumps (Fig. 3).

Fig.

3

Vacuum

And Steering

Pump Hose

Connections

(4) Disconnect oil pressure sender wires at sender

(Fig. 4).

(5) Remove oil pressure sender (Fig. 4).

(6) Disconnect lubricating oil feed line from fitting

at underside of vacuum pump (Fig. 5).

(7) Remove lower bolt that attaches pump assem

bly to engine block (Fig. 6).

(8) Remove bottom, inboard nut that attaches

adapter to steering pump (Fig. 6). This nut secures a

small bracket to engine block. Nut and bracket must

be removed before pump assembly can be removed from block.

Page 259 of 1502

6 - 6

CLUTCH

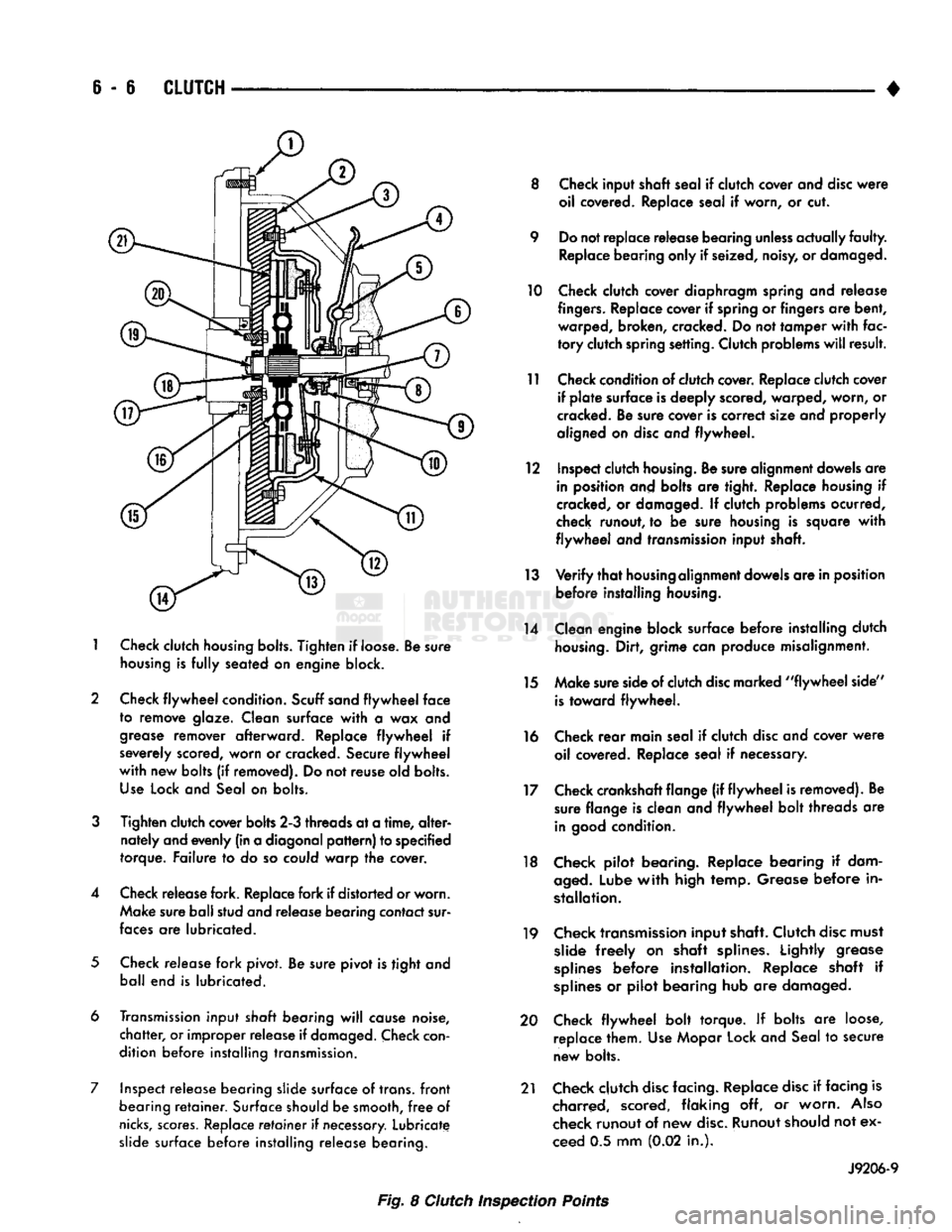

1

Check

clutch

housing bolts.

Tighten

if loose. Be sure

housing

is

fully

seated on engine block.

2 Check

flywheel

condition.

Scuff sand

flywheel

face

to remove glaze. Clean surface

with

a wax and

grease

remover afterward. Replace

flywheel

if

severely scored, worn or cracked. Secure

flywheel

with

new bolts (if removed). Do not reuse old bolts.

Use

Lock and Seal on bolts.

3

Tighten clutch cover bolts 2-3 threads at a

time,

alter

nately and evenly (in a diagonal

pattern)

to specified

torque. Failure to do so could warp the cover.

4 Check release fork. Replace fork if distorted or worn. Make sure ball stud and release bearing contact sur

faces

are lubricated.

5

Check release fork pivot. Be sure pivot is tight and ball end is lubricated.

6 Transmission input

shaft

bearing

will

cause noise,

chatter,

or improper release if

damaged.

Check

con

dition before installing transmission.

7 Inspect release bearing slide surface of trans,

front

bearing

retainer.

Surface should be smooth,

free

of

nicks,

scores.

Replace

retainer

if

necessary.

Lubricate slide surface before installing release bearing. 8 Check input shaft seal if clutch cover and

disc

were

oil covered. Replace seal if worn, or cut.

9 Do not replace release bearing

unless

actually

faulty.

Replace bearing only if seized, noisy, or damaged.

10 Check clutch cover diaphragm spring and release

fingers.

Replace cover if spring or fingers are bent, warped, broken, cracked. Do not tamper

with

fac

tory

clutch spring setting. Clutch problems

will

result.

11 Check condition of clutch cover. Replace clutch cover if

plate

surface is deeply scored, warped, worn, or

cracked. Be sure cover is correct size and properly

aligned on

disc

and flywheel.

12 Inspect clutch

housing.

Be sure alignment dowels are in position and bolts are tight. Replace housing if

cracked, or damaged. If clutch problems ocurred,

check runout, to be sure housing is square

with

flywheel

and transmission input shaft.

13

Verify

that

housing

alignment dowels are in position before installing

housing.

14 Clean engine block surface before installing clutch

housing.

Dirt, grime can produce misalignment.

15 Make sure side of clutch

disc

marked

"flywheel

side"

is

toward flywheel.

16 Check

rear

main seal if clutch

disc

and cover

were

oil covered. Replace seal if necessary.

17 Check crankshaft flange (if

flywheel

is removed). Be sure flange is clean and

flywheel

bolt threads are

in

good

condition.

18 Check pilot bearing. Replace bearing if dam

aged.

Lube

with

high temp. Grease before in

stallation.

19 Check transmission input shaft. Clutch

disc

must slide

freely

on shaft splines. Lightly grease

splines

before installation. Replace shaft if

splines

or pilot bearing hub are damaged.

20 Check

flywheel

bolt torque. If bolts are loose, replace them. Use Mopar Lock and Seal to secure

new bolts.

21 Check clutch

disc

facing. Replace

disc

if facing is charred, scored, flaking off, or worn.

Also

check runout of new

disc.

Runout should not ex

ceed 0.5 mm (0.02 in.).

J9206-9

Fig. 8 Clutch Inspection Points

Page 262 of 1502

•

CLUTCH

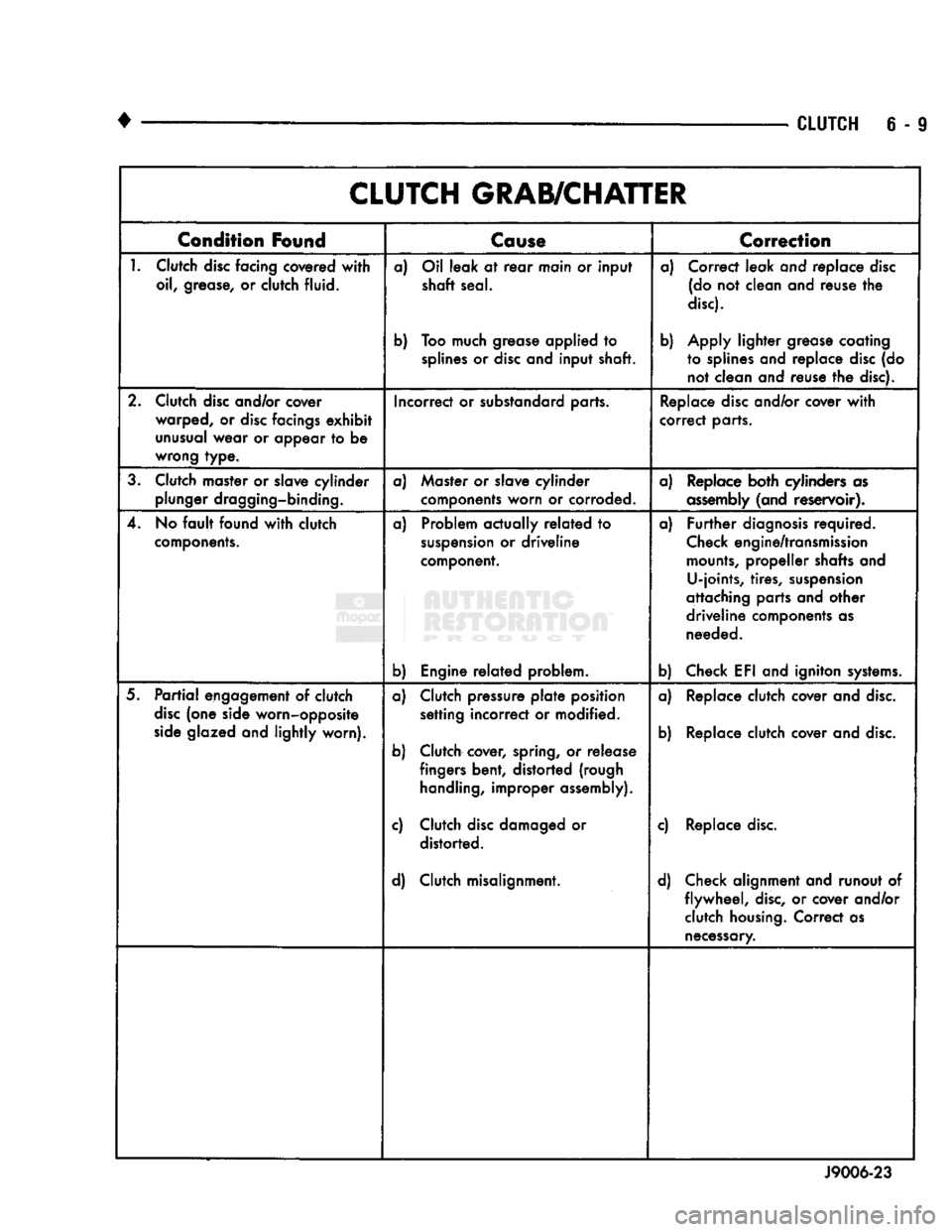

6 - 9 CLUTCH GRAB/CHATTER

Condition

Found

Cause

T

Correction

1.

Clutch

disc

facing covered

with

oil, grease, or clutch fluid. a) Oil leak at

rear

main or input

shaft seal.

b) Too much grease applied to

splines

or

disc

and input shaft. a) Correct leak and replace

disc

(do not clean and reuse the

disc).

b) Apply lighter grease coating to splines and replace

disc

(do not clean and reuse the disc).

2. Clutch

disc

and/or cover warped, or

disc

facings

exhibit

unusual

wear or appear to be

wrong type. Incorrect or substandard parts.

Replace

disc

and/or cover

with

correct parts.

3. Clutch master or slave cylinder plunger dragging-binding. a) Master or slave cylinder

components worn or corroded. a) Replace both cylinders as

assembly

(and reservoir).

4. No

fault

found

with

clutch

components.

a) Problem actually

related

to

suspension

or driveline

component.

b) Engine

related

problem. a)

Further

diagnosis

required.

Check

engine/transmission

mounts,

propeller shafts and U-joints, tires,

suspension

attaching parts and other

driveline components as needed.

b) Check EFI and igniton

systems.

5.

Partial

engagement of clutch

disc

(one side worn-opposite

side

glazed and lightly worn). a) Clutch pressure

plate

position

setting incorrect or modified.

b) Clutch cover, spring, or release fingers bent, distorted (rough

handling,

improper assembly).

c) Clutch

disc

damaged or distorted.

d) Clutch misalignment. a) Replace clutch cover and

disc.

b) Replace clutch cover and

disc.

c) Replace

disc.

d) Check alignment and runout of flywheel,

disc,

or cover and/or clutch

housing.

Correct as

necessary.

J9006-23

Page 265 of 1502

6-12

CLUTCH

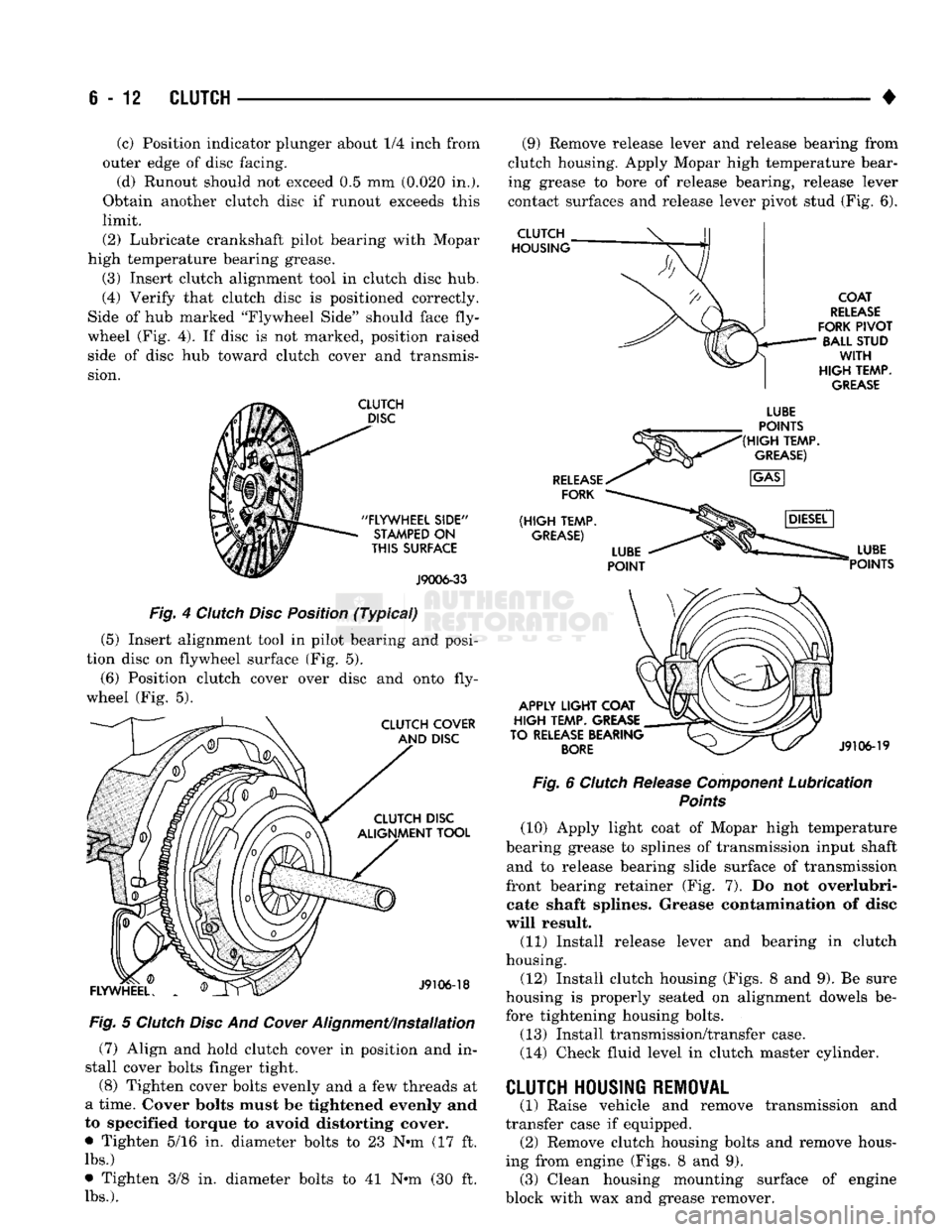

(c) Position indicator plunger about 1/4 inch from

outer edge of disc facing.

(d) Runout should not exceed 0.5 mm (0.020 in.).

Obtain another clutch disc if runout exceeds this

limit.

(2) Lubricate crankshaft pilot bearing with Mopar

high temperature bearing grease.

(3) Insert clutch alignment tool in clutch disc hub,

(4) Verify that clutch disc is positioned correctly.

Side of hub marked "Flywheel Side" should face fly

wheel (Fig. 4). If disc is not marked, position raised side of disc hub toward clutch cover and transmis

sion.

CLUTCH

DISC

"FLYWHEEL

SIDE"

STAMPED

ON

THIS

SURFACE

J9006-33

Fig. 4 Clutch Disc Position (Typical)

(5) Insert alignment tool in pilot bearing and posi

tion disc on flywheel surface (Fig. 5).

(6) Position clutch cover over disc and onto fly

wheel (Fig. 5).

CLUTCH COVER AND DISC CLUTCH DISC

ALIGNMENT TOOL

FLYWHEEL.

J9106-18

Fig. 5 Clutch Disc And

Cower

Alignment/installation (7) Align and hold clutch cover in position and in

stall cover bolts finger tight.

(8) Tighten cover bolts evenly and a few threads at

a time. Cover bolts must be tightened evenly and

to specified torque to avoid distorting cover.

• Tighten 5/16 in. diameter bolts to 23 N-m (17 ft.

lbs.)

• Tighten 3/8 in. diameter bolts to 41 N-m (30 ft.

lbs.).

(9) Remove release lever and release bearing from

clutch housing. Apply Mopar high temperature bear

ing grease to bore of release bearing, release lever

contact surfaces and release lever pivot stud (Fig. 6).

CLUTCH

HOUSING

COAT

RELEASE

FORK

PIVOT

BALL STUD

WITH

HIGH

TEMP.

GREASE

RELEASE

FORK

(HIGH

TEMP.

GREASE)

LUBE

POINTS

(HIGH

TEMP.

GREASE)

APPLY

LIGHT

COAT

HIGH

TEMP. GREASE

TO RELEASE BEARING

BORE

LUBE

POINTS

J9106-19

Fig. 6 Clutch Release Component Lubrication

Points

(10) Apply light coat of Mopar high temperature

bearing grease to splines of transmission input shaft and to release bearing slide surface of transmission

front bearing retainer (Fig. 7). Do not overlubri- cate shaft splines. Grease contamination of disc

will result. (11) Install release lever and bearing in clutch

housing.

(12) Install clutch housing (Figs. 8 and 9). Be sure

housing is properly seated on alignment dowels be fore tightening housing bolts.

(13) Install transmission/transfer case.

(14) Check fluid level in clutch master cylinder. transmission and

CLUTCH HOUSING REMOVAL

(1) Raise vehicle and remove

transfer case if equipped. (2) Remove clutch housing bolts and remove hous

ing from engine (Figs. 8 and 9). (3) Clean housing mounting surface of engine

block with wax and grease remover.