ECO mode DODGE TRUCK 1993 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 6 of 1502

INTRODUCTION

INTRODUCTION

DESIGNATIONS,

LABELS/PLATES/DECALS,

CODES

AND DIMENSIONS/WEIGHTS .

CONTENTS

page

MEASUREMENT

AND TORQUE

... 1 SPECIFICATIONS

page

. 11

DESIGNATIONS, LABELS/PLATES/DECALS, CODES

AND

DIMENSIONS/WEIGHTS

INDEX

page

Engine

and

Transmission/Transfer

Case

Identification

2

Engine/Transmission/GVWR

4

Equipment

Identification

Plate

3

International

Vehicle Control

and

Display

Symbols

10

Major Component

Identification 3

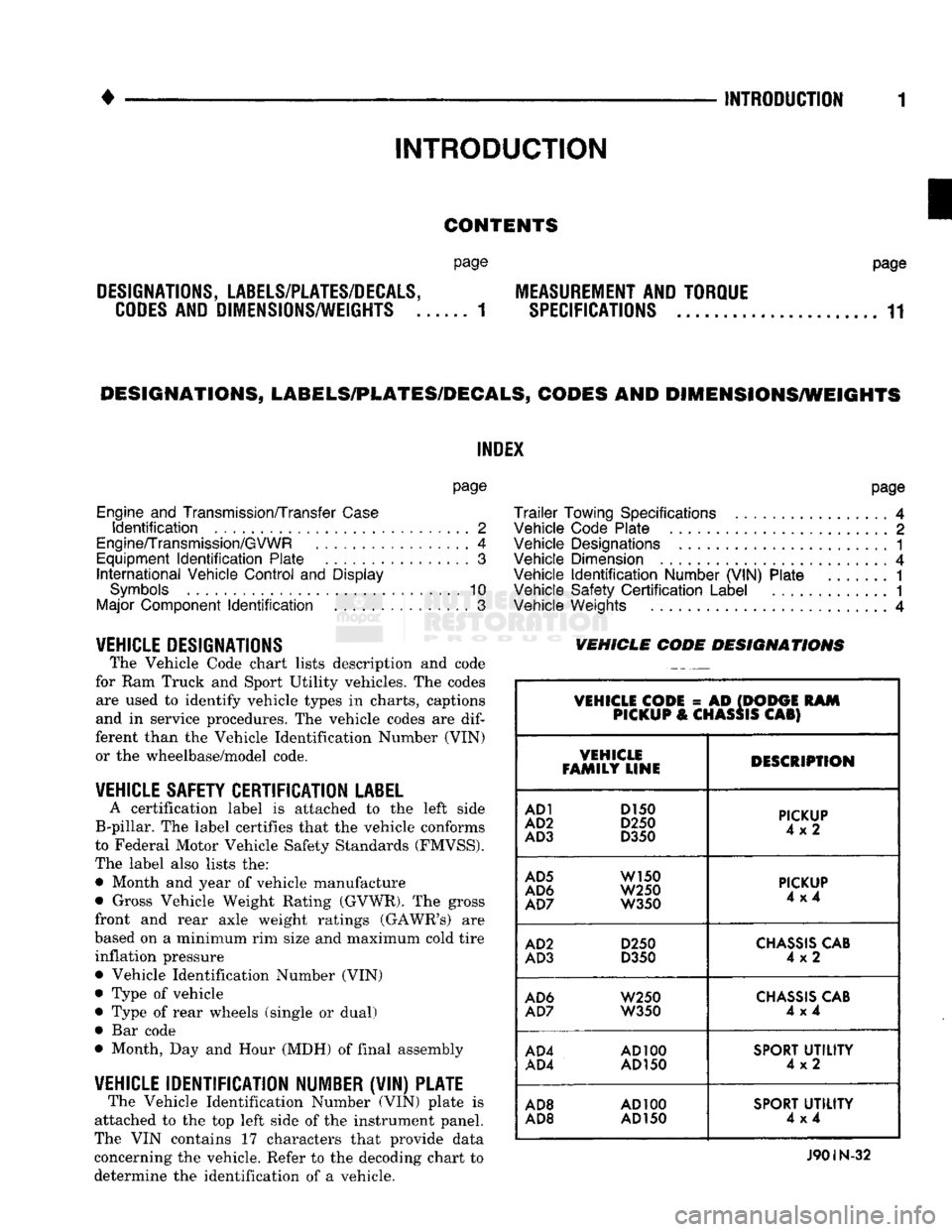

VEHICLE DESIGNATIONS The Vehicle Code chart lists description and code

for Ram Truck and Sport Utility vehicles. The codes are used to identify vehicle types in charts, captions

and in service procedures. The vehicle codes are

dif

ferent than the Vehicle Identification Number (VIN) or the wheelbase/model code.

VEHICLE SAFETY CERTIFICATION

LABEL

A certification label is attached to the left side

B-pillar. The label certifies that the vehicle conforms

to Federal Motor Vehicle Safety Standards (FMVSS).

The label also lists the: • Month and year of vehicle manufacture

• Gross Vehicle Weight Rating (GVWR). The gross

front and rear axle weight ratings (GAWR's) are

based on a minimum rim size and maximum cold tire inflation pressure Vehicle Identification Number (VIN)

Type of vehicle

Type of rear wheels (single or dual) Bar code

Month, Day and Hour (MDH) of final assembly

VEHICLE IDENTIFICATION NUMBER (VIN) PLATE The Vehicle Identification Number (VIN) plate is

attached to the top left side of the instrument panel.

The VIN contains 17 characters that provide data

concerning the vehicle. Refer to the decoding chart to

determine the identification of a vehicle.

page

Trailer

Towing Specifications

4

Vehicle Code Plate

2

Vehicle Designations

1

Vehicle Dimension

4

Vehicle

Identification

Number (VIN) Plate

1

Vehicle Safety

Certification

Label

............. 1

Vehicle Weights

4

VEHICLE CODE

DESIGNATIONS

VEHICLE CODE

= AD

(DODGE

RAM

PICKUP

&

CHASSIS

CAB)

VEHICLE

FAMILY LINE DESCRIPTION

AD1

D150

AD2

D250

AD3

D350

PICKUP

4x2

AD5

W150

AD6

W250

AD7

W350

PICKUP

4x4

AD2

D250

AD3

D350

CHASSIS

CAB

4x2

AD6

W250

AD7

W350

CHASSIS

CAB

4x4

AD4

AD100

AD4

AD150

SPORT

UTILITY

4x2

AD8

AD100

AD8 AD

150

SPORT

UTILITY

4x4

J90IN-32

Page 8 of 1502

INTRODUCTION

PRIMARY SECONDARY

PAINT PAINT VINYL ROOF

CODE VEHICLE

ORDER-

NUMBER

PAINT- PI

PROCEDURE

(2)

(1)

XXX

)

XXXXX)

X

XXX xxxxxx

X)0C xxxx xxxx xxxx xxx XXX x xxxxxxxxxxxxxxxxx

TRANSMISSION

I

VEHICLE IDENTIFICATION CODE

J

NUMBER

MARKET

U-C-B-M

CODE 90IN-3

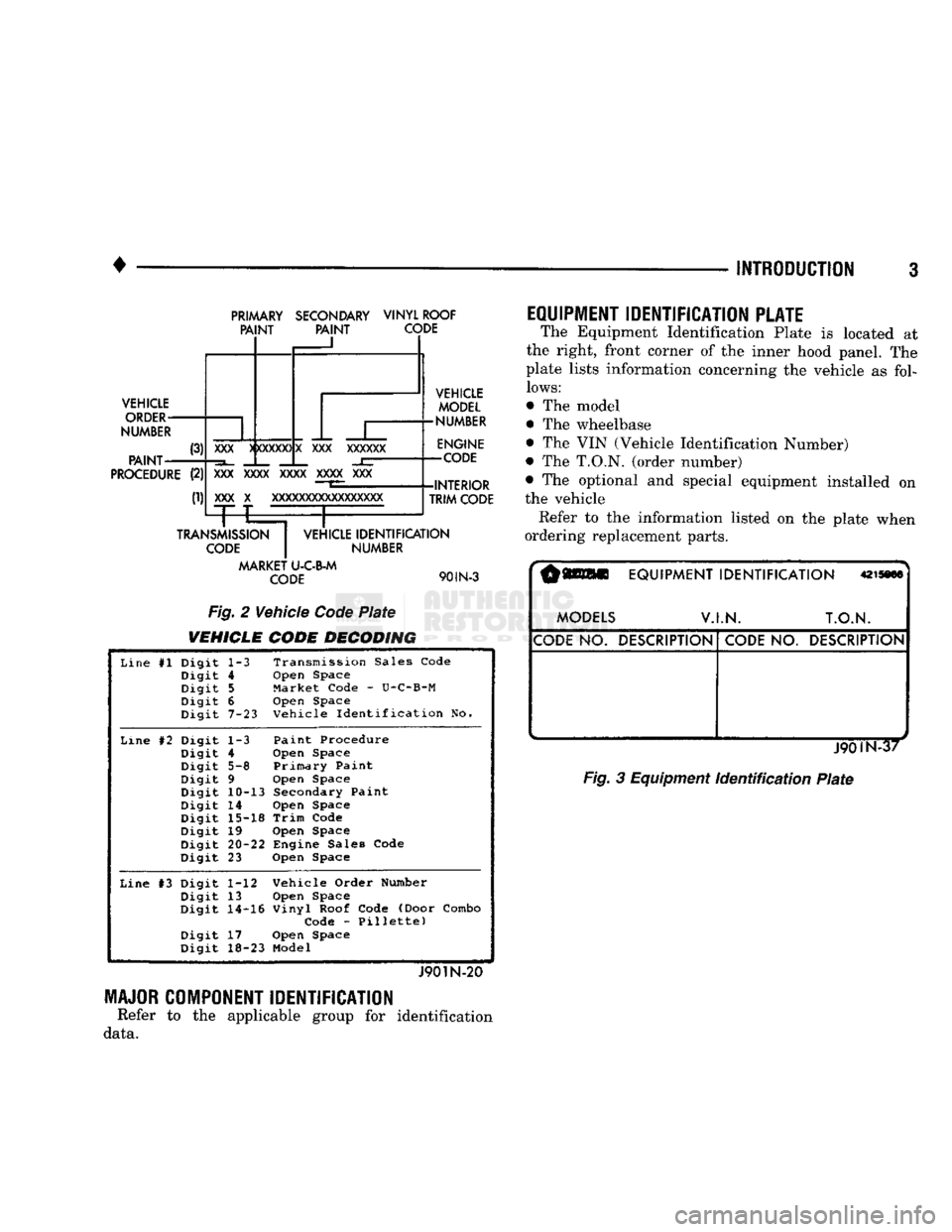

Fig. 2 Vehicle Code Plate

VEHICLE CODE DECODING

VEHICLE

MODEL

•NUMBER

ENGINE

-CODE

-INTERIOR TRIM CODE

Line #1 Digit

1-3 Transmission Sales Code

Digit 4 Open Space

Digit

5

Market Code - U-C-B-M

Digit 6 Open Space

Digit 7-23 Vehicle Identification No.

Line #2 Digit

1-3 Paint Procedure

Digit 4 Open Space

Digit 5-8 Primary Paint

Digit 9 Open Space

Digit 10-13 Secondary Paint

Digit 14 Open Space

Digit 15-18 Trim Code

Digit 19 Open Space

Digit

20-22

Engine Sales Code

Digit 23 Open Space

Line #3 Digit 1-12 Vehicle Order Number

Digit 13 Open Space

Digit 14-16 Vinyl Roof Code (Door Combo

Digit

Code - Pillette)

Digit 17 Open Space

Digit 18-23 Model

J901N-20 MAJOR COMPONENT IDENTIFICATION

Refer to the applicable group for identification

data.

EQUIPMENT IDENTIFICATION PLATE

The Equipment Identification Plate is located at

the right, front corner of the inner hood panel. The

plate lists information concerning the vehicle as fol

lows:

The model

The wheelbase

The VIN (Vehicle Identification Number)

The

T.O.N,

(order number)

The optional and special equipment installed on

the vehicle

Refer to the information listed on the plate when

ordering replacement parts.

r§Wll

EQUIPMENT

IDENTIFICATION

mmm

MODELS

V.I.N. T.O.N.

CODE

NO.

DESCRIPTION

CODE

NO.

DESCRIPTION

. ^

Fig.

3 Equipment

Identification

Plate

Page 45 of 1502

0

- 26

LUBRICATION

AND

MAINTENANCE

•

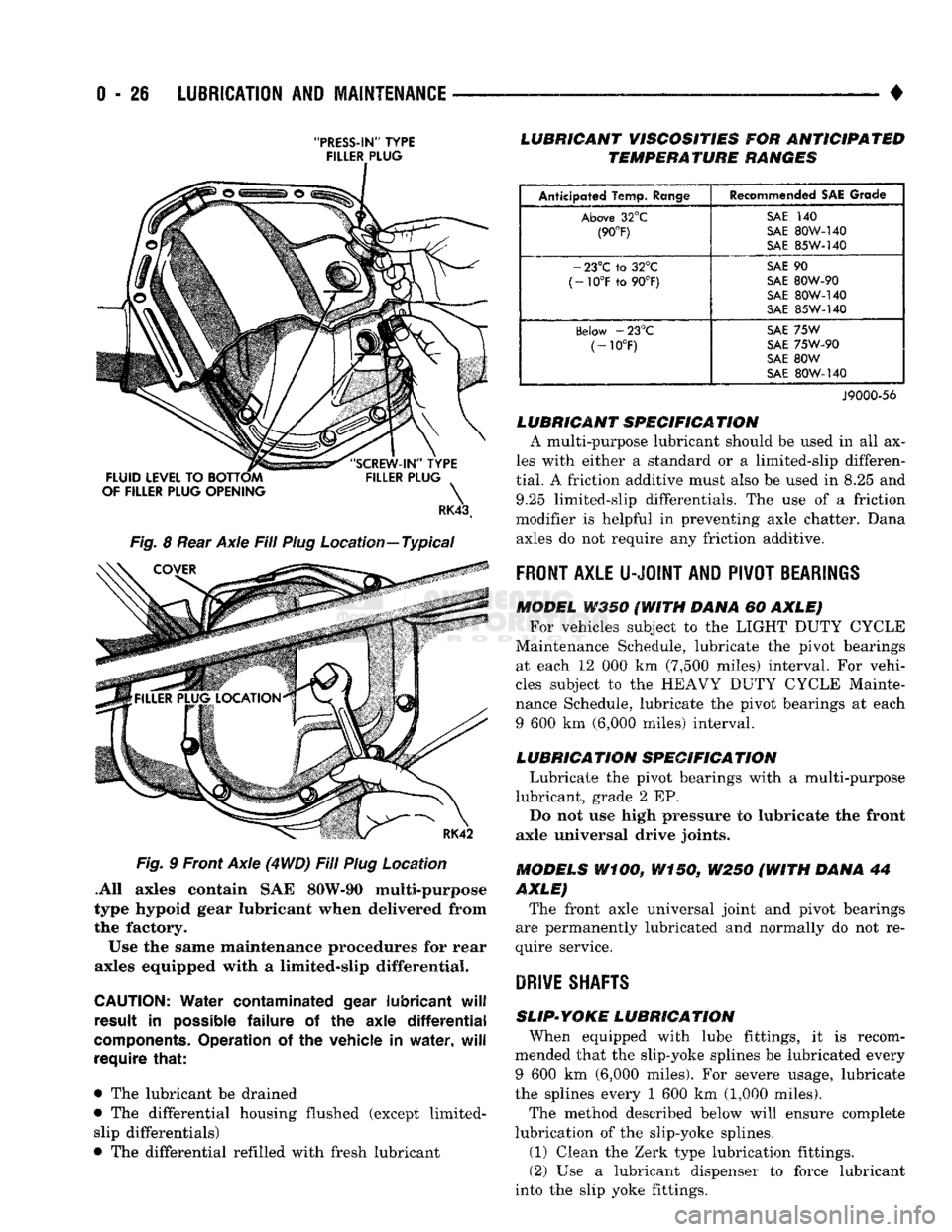

"PRESS-IN"

TYPE FILLER PLUG

RK43t

Fig.

8

Rear Axle Fill Plug Location—Typical Fig.

9

Front Axle (4

WD)

Fill Plug Location

.All axles contain

SAE

80W-90 multi-purpose

type hypoid gear lubricant when delivered from

the factory.

Use

the

same maintenance procedures

for

rear

axles equipped with

a

limited-slip differential.

CAUTION:

Water

contaminated

gear

lubricant

will

result

in

possible

failure

of the

axle

differential

components.

Operation

of the

vehicle

in

water,

will

require

that:

•

The

lubricant

be

drained

•

The

differential housing flushed (except limited- slip differentials)

•

The

differential refilled with fresh lubricant

LUBRICANT

VISCOSITIES

FOR

ANTICIPATED

TEMPERATURE

RANGES

Anticipated Temp.

Range

Recommended

SAE

Grade

Above

32°C

SAi

140

(90°F)

SAE

SOW-140

(90°F)

S\E

85W-140

-

23°C to 32°C

SAE

90

(-10°F

to 90°F)

SAE

80W-90

(-10°F

to 90°F)

SAE

80W-140

oAE

85W-140

(ielow

-23°C

SAE

75W

(-10°F)

SAE

75W-90

(-10°F)

SAE

80W

SAE

80W-I40

J9000-56

LUBRICANT

SPECIFICA

TION

A multi-purpose lubricant should

be

used

in all ax

les with either

a

standard

or a

limited-slip differen

tial.

A

friction additive must also

be

used

in 8.25 and

9.25 limited-slip differentials.

The use of a

friction

modifier

is

helpful

in

preventing axle chatter. Dana axles

do not

require

any

friction additive.

FRONT

AXLE

U-JOINT

AND

PIVOT

BEARINGS

MODEL

W350 (WITH

DANA

60

AXLE) For vehicles subject

to the

LIGHT DUTY CYCLE

Maintenance Schedule, lubricate

the

pivot bearings at each

12 000 km

(7,500 miles) interval.

For

vehi

cles subject

to the

HEAVY DUTY CYCLE Mainte

nance Schedule, lubricate

the

pivot bearings

at

each

9

600 km

(6,000 miles) interval.

LUBRICATION

SPECIFICATION

Lubricate

the

pivot bearings with

a

multi-purpose

lubricant, grade

2 EP.

Do

not use

high pressure

to

lubricate

the

front

axle universal drive joints.

MODELS

WiOO,

W150,

W250 (WITH

DANA

44

AXLE)

The front axle universal joint

and

pivot bearings

are permanently lubricated

and

normally

do not re

quire service.

DRIVE

SHAFTS

SLIP-YOKE

LUBRICATION

When equipped with lube fittings,

it is

recom

mended that

the

slip-yoke splines

be

lubricated every

9

600 km

(6,000 miles).

For

severe usage, lubricate

the splines every

1 600 km

(1,000 miles).

The method described below will ensure complete

lubrication

of the

slip-yoke splines.

(1)

Clean

the

Zerk type lubrication fittings.

(2)

Use a

lubricant dispenser

to

force lubricant

into

the

slip yoke fittings.

Page 70 of 1502

•

FRONT

SUSPENSION

AND

AXLE

2 - 17

MODEL

44

FRONT

AXLE

INDEX

page

Axle Shaft

and

U-Joint

Service

23

Complete Axle Removal/Installation

31

Differential

Assembly

35

Differential

Disassembly

. 32

Drain

and Refill

19

General

Information

17

Hub,

Spindle

and

Axle Shaft

20

Intermediate

Axle Shaft

30

Lubricant

17

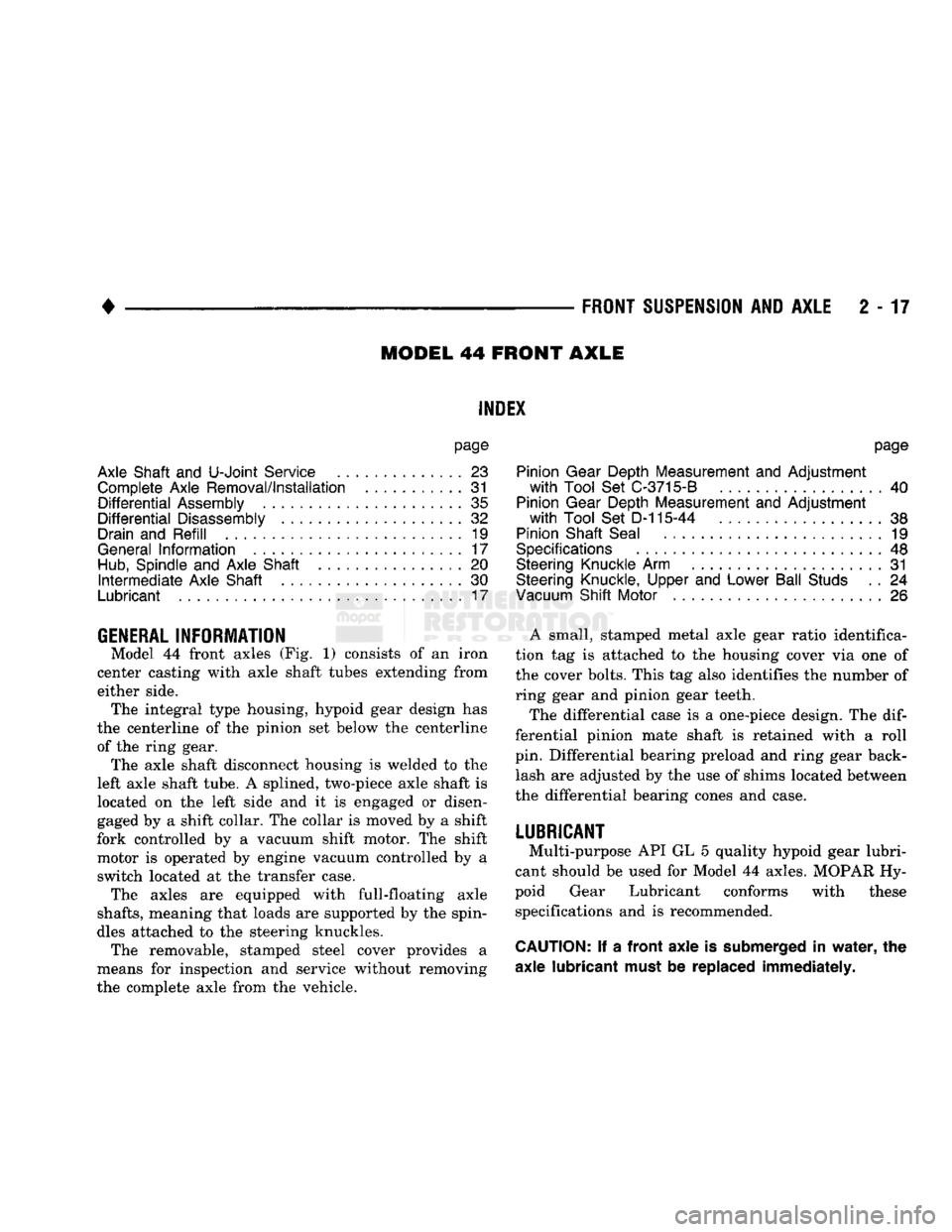

GENERAL

INFORMATION

Model

44

front axles

(Fig. 1)

consists

of an

iron

center casting with axle shaft tubes extending from

either side. The integral type housing, hypoid gear design

has

the centerline

of the

pinion

set

below

the

centerline of

the

ring gear. The axle shaft disconnect housing

is

welded

to the

left axle shaft tube.

A

splined, two-piece axle shaft

is

located

on the

left side

and it is

engaged

or

disen

gaged

by a

shift collar.

The

collar

is

moved

by a

shift

fork controlled

by a

vacuum shift motor.

The

shift motor

is

operated

by

engine vacuum controlled

by a

switch located

at the

transfer case. The axles

are

equipped with full-floating axle

shafts,

meaning that loads

are

supported

by the

spin

dles attached

to the

steering knuckles. The removable, stamped steel cover provides

a

means

for

inspection

and

service without removing

the complete axle from

the

vehicle.

page

Pinion Gear Depth Measurement

and

Adjustment

with

Tool

Set

C-3715-B

40

Pinion Gear Depth Measurement

and

Adjustment

with

Tool

Set

D-115-44

... 38

Pinion Shaft Seal

19

Specifications

48

Steering Knuckle

Arm

31

Steering Knuckle, Upper

and

Lower Ball Studs

. . 24

Vacuum

Shift Motor

26

A small, stamped metal axle gear ratio identifica

tion

tag is

attached

to the

housing cover

via one of

the cover bolts. This

tag

also identifies

the

number

of

ring gear

and

pinion gear teeth.

The differential case

is a

one-piece design.

The dif

ferential pinion mate shaft

is

retained with

a

roll

pin. Differential bearing preload

and

ring gear back lash

are

adjusted

by the use of

shims located between

the differential bearing cones

and

case.

LUBRICANT

Multi-purpose

API GL 5

quality hypoid gear lubri

cant should

be

used

for

Model

44

axles. MOPAR

Hy

poid Gear Lubricant conforms with these specifications

and is

recommended.

CAUTION:

If a

front axle

is

submerged

in

water,

the

axle lubricant must

be

replaced immediately.

Page 104 of 1502

FRONT

SUSPENSION

AND

AXLE

2 - 51

LUBRICANT

Multi-purpose API GL 5 quality hypoid gear lubri

cant should be used for Model 60 axles. MOPAR Hy

poid Gear Lubricant conforms to these specifications and is recommended.

CAUTION:

If a front axle is

submerged

in

water,

the

axle lubricant

must

be replaced immediately.

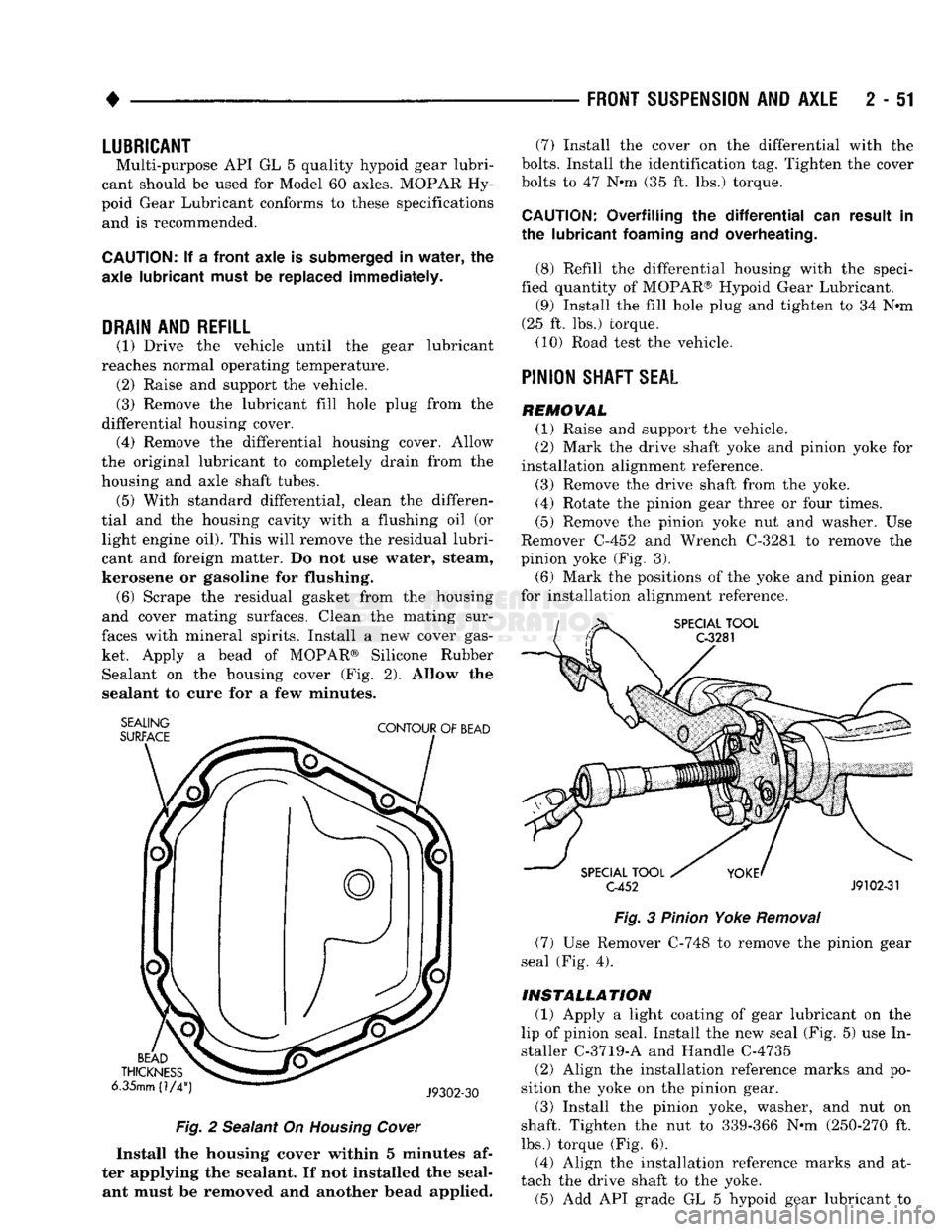

DRAIN AND REFILL

(1) Drive the vehicle until the gear lubricant

reaches normal operating temperature. (2) Raise and support the vehicle.

(3) Remove the lubricant fill hole plug from the

differential housing cover. (4) Remove the differential housing cover. Allow

the original lubricant to completely drain from the

housing and axle shaft tubes. (5) With standard differential, clean the differen

tial and the housing cavity with a flushing oil (or light engine oil). This will remove the residual lubricant and foreign matter. Do not use water, steam,

kerosene or gasoline for flushing. (6) Scrape the residual gasket from the housing

and cover mating surfaces. Clean the mating sur

faces with mineral spirits. Install a new cover gas

ket. Apply a bead of MOPAR® Silicone Rubber Sealant on the housing cover (Fig. 2). Allow the

sealant to cure for a few minutes.

SEALING

SURFACE

CONTOUR

OF

BEAD

BEAD

THICKNESS

6.35mm (1/4

J9302-30

Fig.

2 Sealant On

Housing

Cover

Install the housing cover within 5 minutes af

ter applying the sealant. If not installed the seal ant must be removed and another bead applied. (7) Install the cover on the differential with the

bolts.

Install the identification tag. Tighten the cover

bolts to 47 Nnn (35 ft. lbs.) torque.

CAUTION:

Overfilling the

differential

can result in

the lubricant

foaming

and overheating.

(8) Refill the differential housing with the speci

fied quantity of MOPAR® Hypoid Gear Lubricant. (9) Install the fill hole plug and tighten to 34 N«m

(25 ft. lbs.) torque. (10) Road test the vehicle.

PINION

SHAFT

SEAL

REMOVAL (1) Raise and support the vehicle.

(2) Mark the drive shaft yoke and pinion yoke for

installation alignment reference.

(3) Remove the drive shaft from the yoke.

(4) Rotate the pinion gear three or four times.

(5) Remove the pinion yoke nut and washer. Use

Remover C-452 and Wrench C-3281 to remove the

pinion yoke (Fig. 3).

(6) Mark the positions of the yoke and pinion gear

for installation alignment reference.

SPECIAL

TOOL

C-3281

SPECIAL

TOOL

C-452

J9102-31

Fig.

3

Pinion

Yoke

Removal

(7) Use Remover C-748 to remove the pinion gear

seal (Fig. 4).

INSTALLATION

(1) Apply a light coating of gear lubricant on the

lip of pinion seal. Install the new seal (Fig. 5) use In

staller C-3719-A and Handle C-4735

(2) Align the installation reference marks and po

sition the yoke on the pinion gear.

(3) Install the pinion yoke, washer, and nut on

shaft. Tighten the nut to 339-366 N-m (250-270 ft.

lbs.) torque (Fig. 6).

(4) Align the installation reference marks and at

tach the drive shaft to the yoke. (5) Add API grade GL 5 hypoid gear lubricant to

Page 113 of 1502

2

- 60

FRONT

SUSPENSION

AND

AXLE

•

Fig.

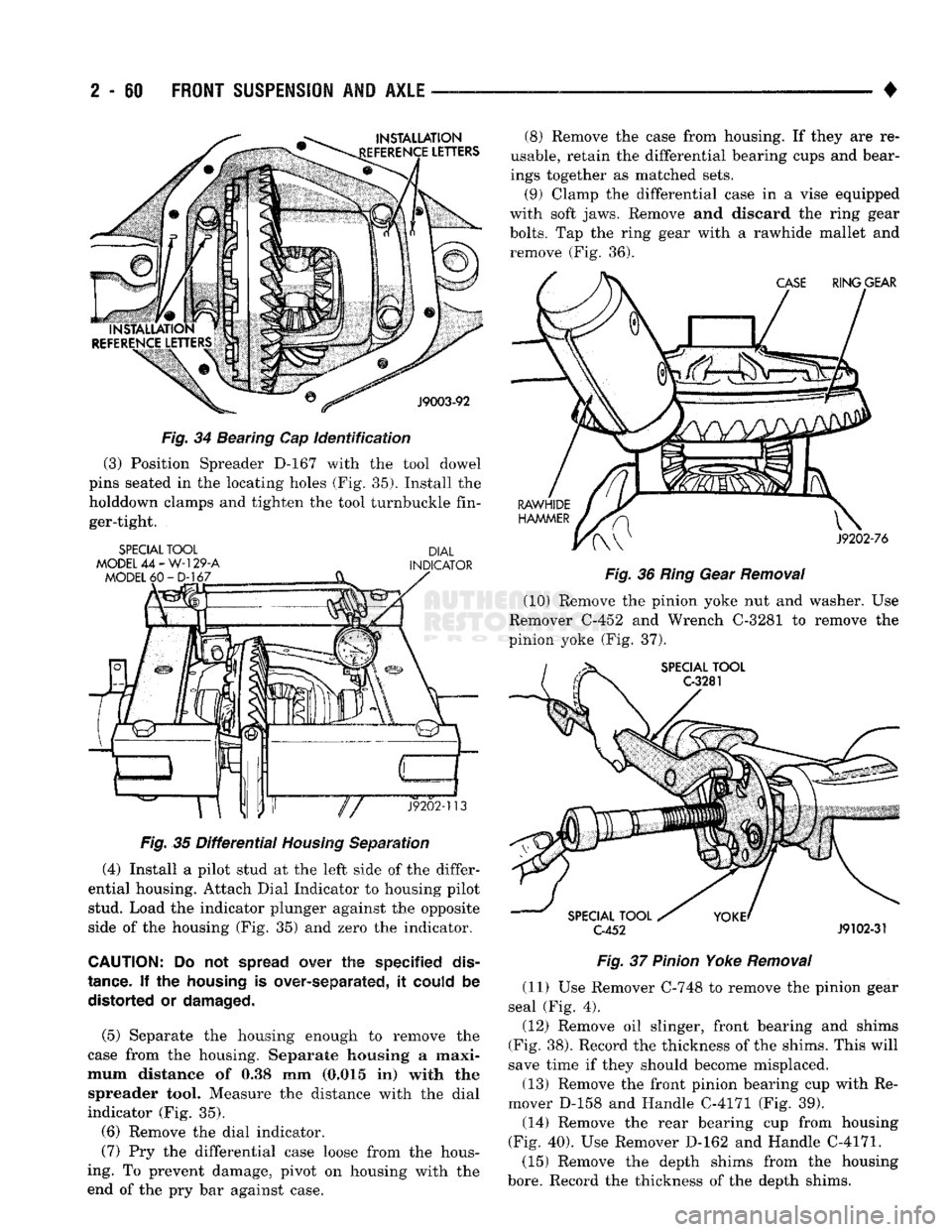

34 Bearing Cap identification (3) Position Spreader D-167 with the tool dowel

pins seated in the locating holes (Fig. 35). Install the

holddown clamps and tighten the tool turnbuckle fin ger-tight.

SPECIAL

TOOL

DIAL

MODEL

44 -

W-129-A

INDICATOR

Fig.

35

Differential

Housing

Separation (4) Install a pilot stud at the left side of the differ

ential housing. Attach Dial Indicator to housing pilot stud. Load the indicator plunger against the opposite

side of the housing (Fig. 35) and zero the indicator.

CAUTION:

Do not

spread

over the specified

dis

tance.

If the

housing

is over-separated, it

could

be distorted or

damaged.

(5) Separate the housing enough to remove the

case from the housing. Separate housing a maxi

mum distance of 0.38 mm (0.015 in) with the spreader tool. Measure the distance with the dial

indicator (Fig. 35).

(6) Remove the dial indicator.

(7) Pry the differential case loose from the hous

ing. To prevent damage, pivot on housing with the

end of the pry bar against case. (8) Remove the case from housing. If they are re

usable, retain the differential bearing cups and bear

ings together as matched sets. (9) Clamp the differential case in a vise equipped

with soft jaws. Remove and discard the ring gear

bolts.

Tap the ring gear with a rawhide mallet and remove (Fig. 36).

Fig.

36

Ring

Gear

Removal

(10) Remove the pinion yoke nut and washer. Use

Remover C-452 and Wrench C-3281 to remove the

pinion yoke (Fig. 37). C-452

J9102-31

Fig.

37

Pinion

Yoke

Removal

(11) Use Remover C-748 to remove the pinion gear

seal (Fig. 4).

(12) Remove oil slinger, front bearing and shims

(Fig. 38). Record the thickness of the shims. This will

save time if they should become misplaced.

(13) Remove the front pinion bearing cup with Re

mover D-158 and Handle C-4171 (Fig. 39). (14) Remove the rear bearing cup from housing

(Fig. 40). Use Remover D-162 and Handle C-4171.

(15) Remove the depth shims from the housing

bore.

Record the thickness of the depth shims.

Page 156 of 1502

•

REAR

SUSPENSION

AND

AXLE

3-29

WARNING: WHEN SERVICING VEHICLES

WITH

SURE-GRIP,

DO NOT

USE THE ENGINE

TO

ROTATE

THE AXLE

AND

WHEELS. BOTH REAR WHEELS MUST BE RAISED AND

THE

VEHICLE SUPPORTED.

A

SURE-GRIP AXLE

CAN

EXERT ENOUGH FORCE

(IF ONE

WHEEL

IS IN

CONTACT

WITH

THE

SUR FACE)

TO

CAUSE

THE

VEHICLE

TO

MOVE.

LUBRICATION

Multi-Purpose Gear Lubricant, as defined by MIL-

L-2105-B (API GL-5) should be used in all axles.

MOPAR Hypoid Lubricant is recommended or equiv alent. In Sure-Grip differentials 4 ounces of MOPAR Hy

poid Gear Lubricant Additive must be added with each re-fill.

It is recommended the vehicle be driven through 10

to 12 slow, figure-eight turns. This ensures the lubri cant is thoroughly pumped through the Sure-Grip

differential clutches.

MODEL 60 and 70 AXLES

INDEX

page

Axle Shaft Removal/Installation

32

Complete Axle Removal/Installation

........... 33

Differential

Assembly

38

Differential

Disassembly

34

Drain

and Refill 31

General

Information

29

Lubricant

31

GENERAL

INFORMATION

The housing (Fig. 1) consists of an iron center cast

ing with axle shaft tubes extending from either side.

The tubes are pressed in to form a one-piece axle housing. The integral type housing, hypoid gear design has

the centerline of the pinion set below the centerline of the ring gear. The axles are equipped with full-floating axle

shafts,

meaning that loads are supported by the axle

housing tubes. The full-float axle shafts are retained

by bolts attached to the hub. The hub rides on two

bearings at the outboard end of the axle tube. The axle shafts can be removed without disturbing or re

moving the wheel bearings. The wheel bearings are

opposed tapered roller bearings that are part of the

hub/drum assembly.

page

Pinion Gear Depth Measurement

and

Adjustment

with Tool Set C-758-D6 43

Pinion Gear Depth Measurement

and

Adjustment

with

Tool

Set

D-116

. 40

Pinion Shaft Seal

31

Specifications

50

Wheel Bearing Service

33

The removable, stamped steel cover provides a

means for inspection and service without removing

the complete axle from the vehicle.

A small, stamped metal axle gear ratio identifica

tion tag is attached to the housing cover via one of

the cover bolts. This tag also identifies the number of

ring and pinion teeth.

The differential case is a one-piece design. The

dif

ferential pinion mate shaft is retained with a roll

pin. Model 70 axles with the optional Powr-Lok use a

two piece differential case. Differential bearing pre load and ring gear backlash are adjusted by the use

of shims located between the differential bearing

cones and case.

Page 158 of 1502

•

REAR

SUSPENSION

AND

AXLE

3 - 31

LUBRICANT

Hypoid gear lubricant, as defined by MIL-L-2105-B

and API GL 5 is the specified lube. MOPAR Hypoid

Gear Lubricant conforms with both of these specifica

tions and is highly recommended.

CAUTION:

If a

rear

axle

is

submerged

in

water,

the

axle

lubricant

must

be

replaced

immediately,

DRAIN

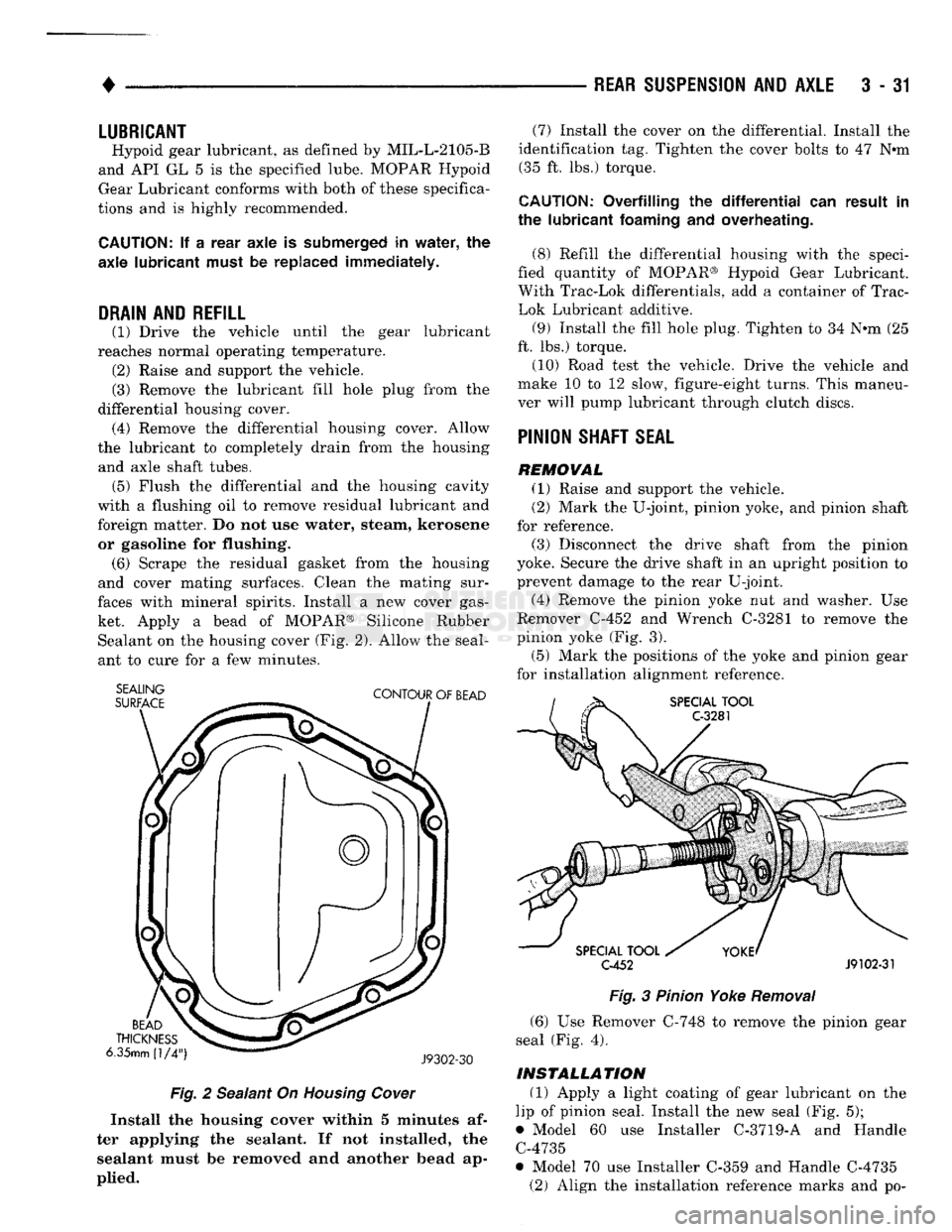

AND

REFILL

(1) Drive the vehicle until the gear lubricant

reaches normal operating temperature. (2) Raise and support the vehicle. (3) Remove the lubricant fill hole plug from the

differential housing cover. (4) Remove the differential housing cover. Allow

the lubricant to completely drain from the housing and axle shaft tubes. (5) Flush the differential and the housing cavity

with a flushing oil to remove residual lubricant and

foreign matter. Do not use water,

steam,

kerosene

or

gasoline for

flushing,

(6) Scrape the residual gasket from the housing

and cover mating surfaces. Clean the mating sur

faces with mineral spirits. Install a new cover gas

ket. Apply a bead of MOPAR® Silicone Rubber Sealant on the housing cover (Fig. 2). Allow the seal

ant to cure for a few minutes.

SEALING

SURFACE

CONTOUR

OF

BEAD

BEAD

THICKNESS

6.35mm

(1/4")

J9302-30

Fig.

2 Sealant On Housing Cower

Install

the

housing

cover

within 5

minutes

af

ter

applying

the

sealant.

If not

installed,

the

sealant

must be

removed

and another

bead

ap

plied.

(7) Install the cover on the differential. Install the

identification tag. Tighten the cover bolts to 47 Nem (35 ft. lbs.) torque.

CAUTION:

Overfilling

the differential" can

result

in

the

lubricant

foaming

and

overheating.

(8) Refill the differential housing with the speci

fied quantity of MOPAR® Hypoid Gear Lubricant.

With Trac-Lok differentials, add a container of Trac-

Lok Lubricant additive.

(9) Install the fill hole plug. Tighten to 34 N-m (25

ft. lbs.) torque.

(10) Road test the vehicle. Drive the vehicle and

make 10 to 12 slow, figure-eight turns. This maneu

ver will pump lubricant through clutch discs.

PINION

SHAFT

SEAL

REMOVAL

(1) Raise and support the vehicle.

(2) Mark the U-joint, pinion yoke, and pinion shaft

for reference.

(3) Disconnect the drive shaft from the pinion

yoke. Secure the drive shaft in an upright position to

prevent damage to the rear U-joint.

(4) Remove the pinion yoke nut and washer. Use

Remover C-452 and Wrench C-3281 to remove the

pinion yoke (Fig. 3).

(5) Mark the positions of the yoke and pinion gear

for installation alignment reference.

SPECIAL

TOOL

C-3281

SPECIAL

TOOL

C-452

J9102-31

Fig.

3 Pinion Yoke

Removal

(6) Use Remover C-748 to remove the pinion gear

seal (Fig. 4).

INSTALLATION

(1) Apply a light coating of gear lubricant on the

lip of pinion seal. Install the new seal (Fig. 5);

• Model 60 use Installer C-3719-A and Handle C-4735

• Model 70 use Installer C-359 and Handle C-4735 (2) Align the installation reference marks and po-

Page 161 of 1502

3

- 34

REAR SUSPENSION

AND

AXLE

• (4) Install the spring U-bolts and tighten the nuts

with the specified torque.

(5) Install the shock absorbers.

(6) Connect the parking brake cables.

(7) Connect the brake lines. Install the hubs and

brake drums. Adjust the wheel bearings (refer to Wheel Bearing Adjustment).

(8) Remove the block from the brake pedal. Bleed

and adjust the brakes.

(9) Connect the drive shaft to the pinion yoke with

the reference marks aligned. Tighten the U-joint clamp bolts to 21 N-m (16 ft. lbs./186 in. lbs.) torque.

(10) Install the rear wheels and tighten the lug

nuts with the specified torque (refer to Group 22,

Wheels And Tires). (11) Raise the rear of the vehicle, remove the sup

ports,

level the vehicle and position the supports. (12) Remove the fill hole plug from the differential

housing cover. Fill the differential housing to the correct level with MOPAR Hypoid Gear Lubricant, or

an equivalent product. Add 4 ounces of MOPAR Hypoid Gear Lubri

cant Additive for Trac-Lok equipped axles. (13) Install the fill hole plug. Remove the supports

and lower the vehicle. (14) Road test the vehicle to evaluate the results of

the repair.

DIFFERENTIAL

DISASSEMBLY

RE MO VA

L/DISA

SSEMBL Y

Remove the RWAL brake sensor

hold-down

bolt and pull the sensor from the differential

housing. The sensor must be removed to prevent damage when disassembling or assembling the differential components.

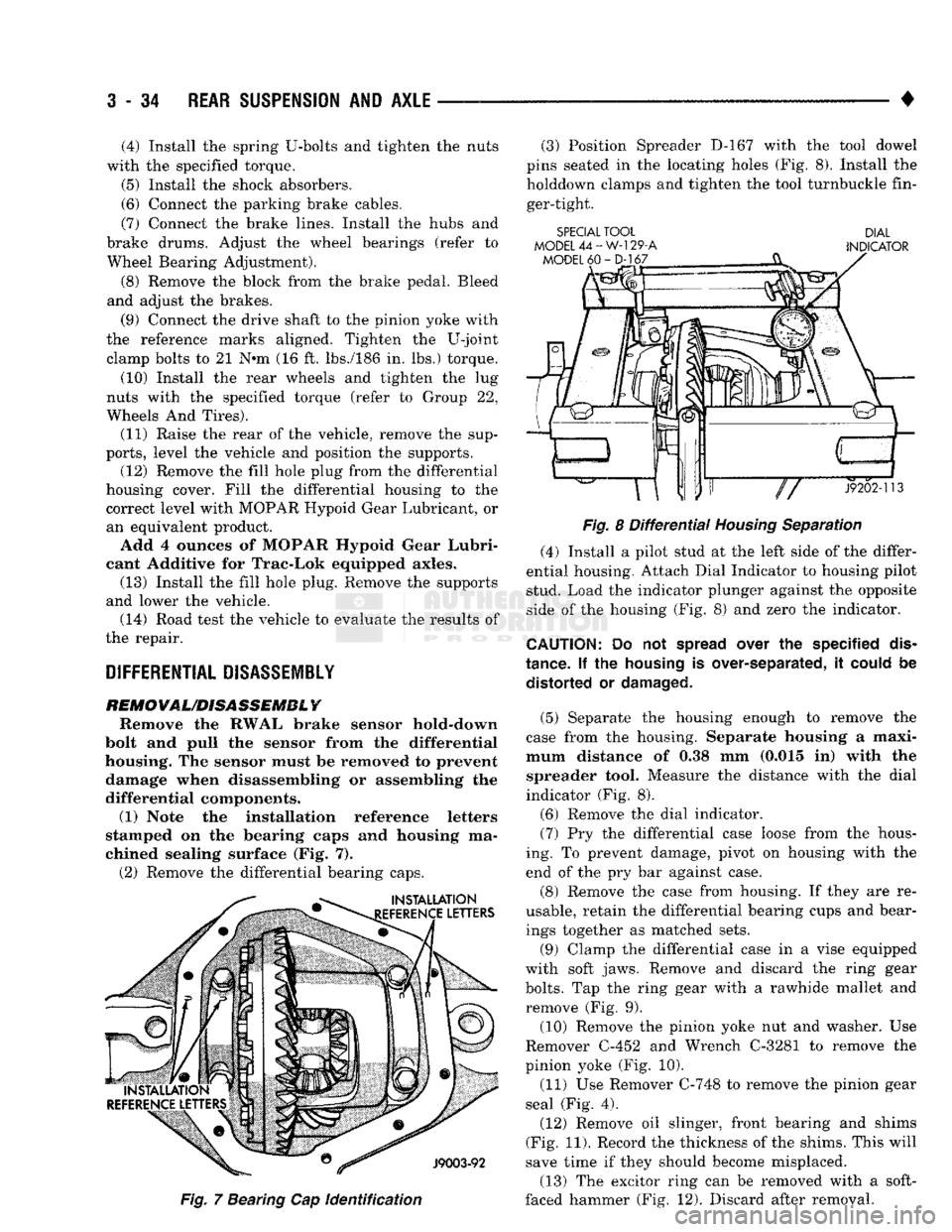

(1) Note the installation reference letters

stamped on the bearing caps and housing ma

chined sealing surface (Fig. 7). (2) Remove the differential bearing caps.

Fig.

7 Bearing Cap

identification

(3) Position Spreader D-167 with the tool dowel

pins seated in the locating holes (Fig. 8). Install the holddown clamps and tighten the tool turnbuckle fin

ger-tight.

SPECIAL TOOL DIAL

MODEL

44-W-129-A

INDICATOR

Fig.

8

Differential

Housing

Separation

(4) Install a pilot stud at the left side of the differ

ential housing. Attach Dial Indicator to housing pilot

stud. Load the indicator plunger against the opposite

side of the housing (Fig. 8) and zero the indicator.

CAUTION:

Do not

spread

over the specified

dis

tance. If the

housing

is over-separated, it

could

be distorted or

damaged.

(5) Separate the housing enough to remove the

case from the housing. Separate housing a maxi

mum distance of 0.38 mm (0.015 in) with the spreader tool. Measure the distance with the dial

indicator (Fig. 8).

(6) Remove the dial indicator. (7) Pry the differential case loose from the hous

ing. To prevent damage, pivot on housing with the

end of the pry bar against case.

(8) Remove the case from housing. If they are re

usable, retain the differential bearing cups and bear ings together as matched sets.

(9) Clamp the differential case in a vise equipped

with soft jaws. Remove and discard the ring gear

bolts.

Tap the ring gear with a rawhide mallet and

remove (Fig. 9).

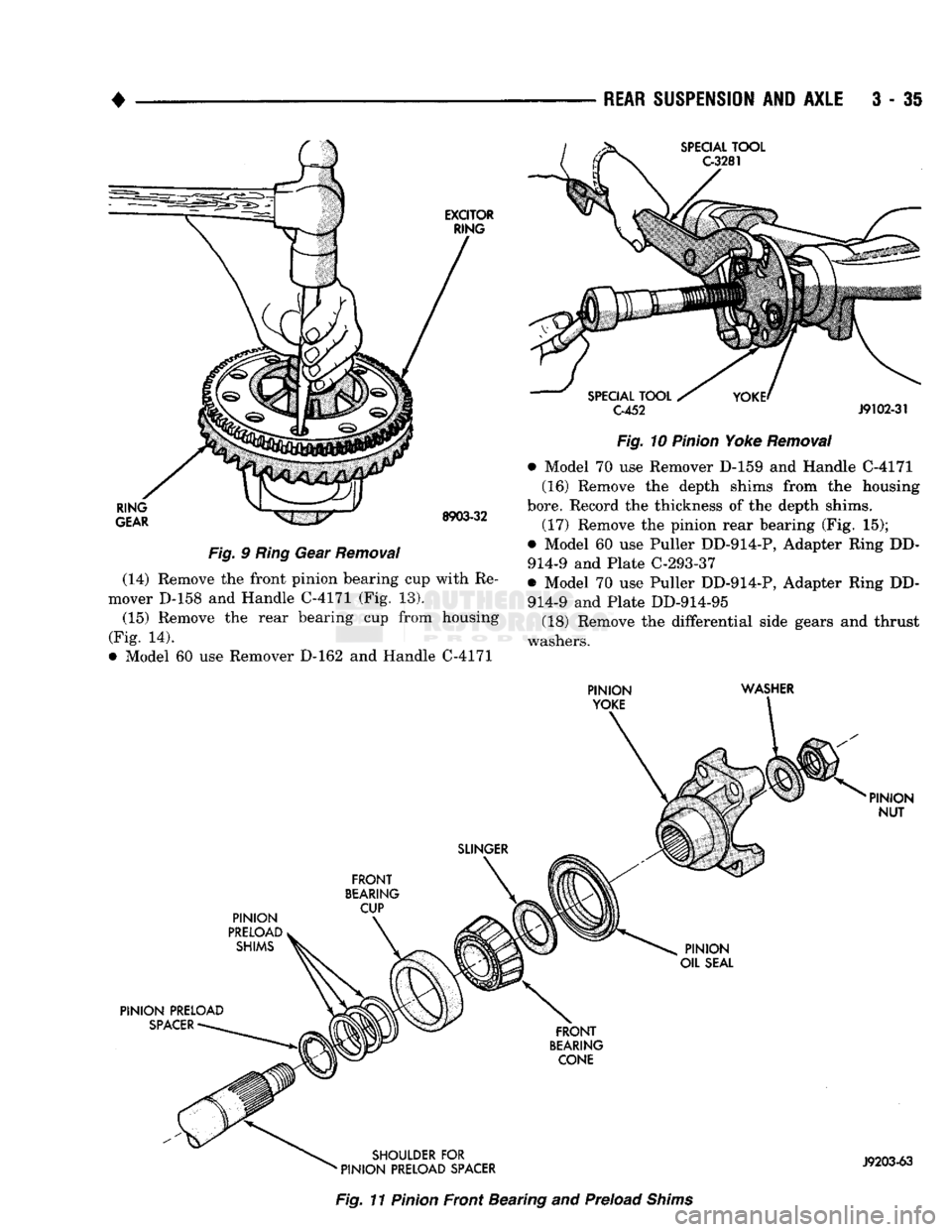

(10) Remove the pinion yoke nut and washer. Use

Remover C-452 and Wrench C-3281 to remove the

pinion yoke (Fig. 10).

(11) Use Remover C-748 to remove the pinion gear

seal (Fig. 4).

(12) Remove oil slinger, front bearing and shims

(Fig. 11). Record the thickness of the shims. This will

save time if they should become misplaced.

(13) The excitor ring can be removed with a soft-

faced hammer (Fig. 12). Discard after removal.

Page 162 of 1502

REAR SUSPENSION

AND

AXLE

3 - 35

SPECIAL

TOOL

C-3281

EXCITOR

RING RING

GEAR

8903-32

Fig.

9

Ring

Gear

Removal

(14) Remove the front pinion bearing cup with Re

mover D-158 and Handle C-4171 (Fig. 13).

(15) Remove the rear bearing cup from housing

(Fig.

14).

• Model 60 use Remover D-162 and Handle C-4171

SPECIAL

TOOL

C-452

J9102-31

Fig.

10

Pinion

Yoke

Removal

• Model 70 use Remover D-159 and Handle C-4171

(16) Remove the depth shims from the housing

bore.

Record the thickness of the depth shims.

(17) Remove the pinion rear bearing (Fig. 15);

• Model 60 use Puller DD-914-P, Adapter Ring DD-

914-9 and Plate C-293-37

• Model 70 use Puller DD-914-P, Adapter Ring DD-

914-9 and Plate DD-914-95 (18) Remove the differential side gears and thrust

washers.

PINION

YOKE

WASHER

SLINGER

PINION

PRELOAD

SHIMS

FRONT

BEARING

CUP

PINION

NUT

PINION

OIL

SEAL

PINION PRELOAD

SPACER

FRONT

BEARING

CONE

SHOULDER

FOR

'

PINION

PRELOAD

SPACER

J9203-63

Fig.

11

Pinion

Front Bearing and Preload

Shims