fuel pressure DODGE TRUCK 1993 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 21 of 1502

0 - 2

LUBRICATION

AND

MAINTENANCE

• Commercial service

When a vehicle is continuously subjected to severe

driving conditions, lubricate:

• Body components

• All the driveline coupling joints

• Steering linkage More often than normal driving conditions

DUSTY

AREAS

With this type of severe driving condition, special

care should be given to the:

• Engine air cleaner filter

• PCV filter

• Crankcase ventilation system

• Brake booster control valve air filter. Verify that the filters and the associated compo

nents are clean. Also verify that they are functioning

effectively. This will minimize the amount of abra sive particles that enter the engine.

OFF-ROAD

(4WD)

OPERATION

After off-road (4WD) operation, inspect the under

side of the vehicle. Inspect the:

• Tires

• Body structure

• Steering components

• Suspension components • Exhaust system

• Threaded fasteners

HARSH

SURFACE ENVIRONMENTS

After extended operation in harsh environments,

the brake drums, brake linings, and rear wheel bear ings should be inspected and cleaned. This will pre

vent wear and erratic brake action.

ROUTINE MAINTENANCE

The following routine maintenance is recommended

on a monthly basis: TIRES—Inspect the tires for unusual wear/damage.

Determine if the inflation pressure is adequate for

the vehicle load. BATTERY—Inspect and clean the terminals.

Tighten the terminals if necessary. FLUIDS—Determine if the component fluid levels

are acceptable. Add fluid, if necessary. LIGHTS/ELECTRICAL—Test all the electrical sys

tems in the vehicle for proper operation. It is also recommended that the engine oil and the

washer fluid level be determined at each fuel fill-up.

VEHICLE

NOISE CONTROL

Vehicles with a GVWR of 4 535 kg (10,000 lbs), or

more, are required to comply with Federal Exterior Noise Regulations (Fig. 2).

VEHICLE

NOISE

EMISSION

CONTROL INFORMATION

DATE

OF

VEHICLE

MANUFACTURE

THIS

VEHICLE CONFORMS

TO

U.S. EPA REGULATIONS FOR NOISE EMISSION

APPLICABLE

TO

MEDIUM

AND HEAVY

DUTY

TRUCKS. THE

FOLLOWING

ACTS OR THE CAUSING THEREOF BY ANY PERSON ARE PROHIBITED BY THE NOISE CONTROL ACT

OF 1972. (A) THE

REMOVAL

OR

RENDERING

INOPERATIVE, OTHER

THAN

FOR

PURPOSES

OF

MAINTENANCE,

REPAIR.

OR REPLACEMENT, OF ANY NOISE CONTROL DEVICE OR ELEMENT OF

DESIGN

(LISTED

IN

THE

OWNERS

MANUAL)

INCORPORATED

INTO

THIS

VEHICLE

IN COMPLIANCE

WITH

THE NOISE CONTROL

ACT:

(B) THE

USE

OF

THIS

VEHICLE

AFTER SUCH DEVICE

OR

ELEMENT

OF

DESIGN HAS BEEN REMOVED

OR

RENDERED

INOPERATIVE.

PU626D

Fig.

2 Vehicle

Noise

Emission

Control Information

Label

UNAUTHORIZED

DEFEAT

OF

NOISE

CONTROL COMPONENTS

Federal law prohibits removal, altering or other

wise defeating any noise control component. This in

cludes before or after the vehicle is in use. Federal

law also prohibits the use of a vehicle after a noise

control component is defeated.

REQUIRED MAINTENANCE/SERVICE

FOR

NOISE

CONTROL

The following maintenance is required after each

6-month or 9 600 km (6,000 miles) interval. This will

ensure that the vehicle noise control components are

operating properly.

EXHAUST SYSTEM

Inspect exhaust system for exhaust leaks and dam

aged components. The exhaust hangers, clamps and

U-bolts should be attached and in good condition.

Burned or ruptured mufflers, damaged exhaust pipes should be replaced. Refer to Group 11—Exhaust Sys

tem/Intake Manifold for service information.

AIR

FILTER

HOUSING/CANISTER

Inspect the air filter assembly for proper fit. Verify

the cover is securely attached to the housing/canis

ter. Inspect all the air filter housing hoses for con nections. The gasket between the air filter housing and throttle body must be in good condition. The air

filter element should be clean and serviced according

to the maintenance schedule.

FUEL

REQUIREMENTS

GASOLINE

ENGINES

All engines require the use of unleaded gasoline to

reduce the effects of lead to the environment. Also unleaded fuel is necessary to prevent damage to the

catalytic converter/02 sensor. The fuel must have a

minimum octane rating of 87 based on the (R + M)/2

calculation method.

Page 34 of 1502

•

LUBRICATION

AND

MAINTENANCE

0 - 15

DIESEL

ENGINES

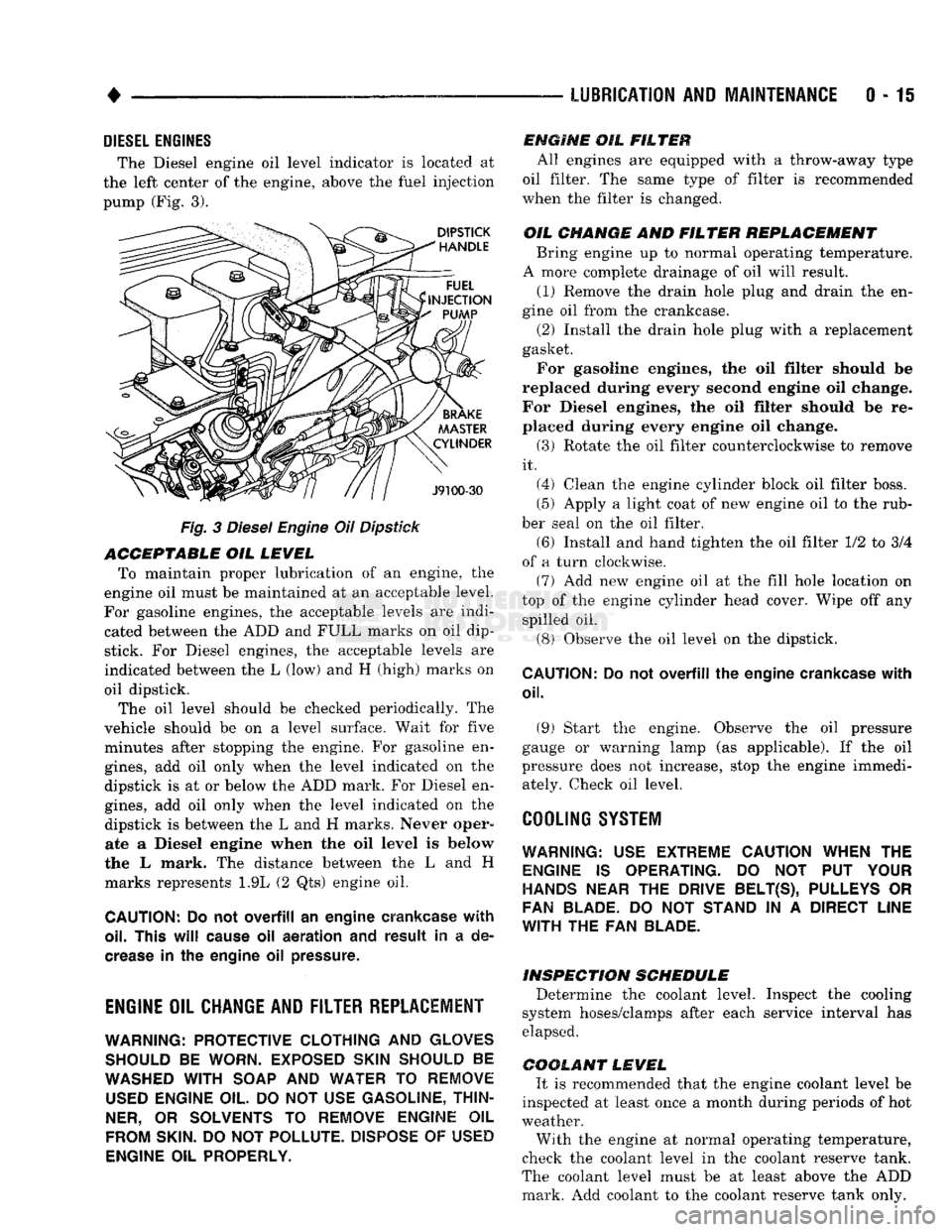

The Diesel engine oil level indicator is located at

the left center of the engine, above the

fuel

injection

pump (Fig. 3).

Fig.

3

Diesel

Engine

Oil

Dipstick

ACCEPTABLE

OIL

LEVEL

To maintain proper lubrication of an engine, the

engine oil must be maintained at an acceptable level.

For gasoline engines, the acceptable levels are indi cated between the ADD and

FULL

marks on oil

dip

stick. For Diesel engines, the acceptable levels are

indicated between the L (low) and H

(high) marks

on

oil dipstick. The oil level should be checked periodically. The

vehicle should be on a level surface. Wait for

five

minutes after stopping the engine. For gasoline en

gines,

add oil only when the level indicated on the

dipstick is at or below the ADD mark. For Diesel en

gines,

add oil only when the level indicated on the

dipstick is between the L and H marks.

Never oper

ate a Diesel

engine when

the oil

level

is below

the L mark. The distance between the L and H

marks represents 1.9L (2 Qts) engine oil.

CAUTION:

Do not

overfill

an

engine crankcase

with

oil. This

will

cause

oil

aeration

and

result

in a de

crease

in the

engine

oil

pressure.

ENGINE

OIL

CHANGE AND FILTER REPLACEMENT

WARNING: PROTECTIVE CLOTHING

AND

GLOVES SHOULD

BE

WORN. EXPOSED SKIN SHOULD

BE

WASHED

WITH

SOAP

AND

WATER

TO

REMOVE

USED

ENGINE

OIL.

DO NOT

USE

GASOLINE, THIN

NER,

OR

SOLVENTS

TO

REMOVE ENGINE

OIL

FROM

SKIN.

DO NOT

POLLUTE. DISPOSE

OF

USED

ENGINE

OIL

PROPERLY.

ENGINE

OIL

FILTER

All engines are equipped with a throw-away type

oil filter. The same type of filter is recommended

when the filter is changed.

OIL CHANGE

AND

FILTER

REPLACEMENT

Bring engine up to normal operating temperature.

A more complete drainage of oil will result.

(1) Remove the drain hole plug and drain the en

gine oil from the crankcase.

(2) Install the drain hole plug with a replacement

gasket. For gasoline engines, the oil filter should be

replaced during every second engine oil change.

For Diesel engines, the oil filter should be re

placed during every engine oil change.

(3) Rotate the oil filter counterclockwise to remove

it.

(4) Clean the engine cylinder block oil filter boss. (5) Apply a light coat of new engine oil to the rub

ber seal on the oil filter.

(6) Install and hand tighten the oil filter 1/2 to 3/4

of a turn clockwise. (7) Add new engine oil at the fill hole location on

top of the engine cylinder head cover. Wipe off any spilled oil.

(8) Observe the oil level on the dipstick.

CAUTION:

Do not

overfill

the

engine crankcase

with

oil.

(9)

Start the engine. Observe the oil pressure

gauge or warning lamp (as applicable). If the oil

pressure does not increase, stop the engine immedi ately. Check oil level.

COOLING SYSTEM

WARNING:

USE

EXTREME CAUTION WHEN

THE

ENGINE

IS

OPERATING.

DO NOT PUT

YOUR

HANDS NEAR

THE

DRIVE BELT(S), PULLEYS

OR

FAN BLADE.

DO NOT

STAND

IN A

DIRECT LINE

WITH

THE FAN

BLADE.

INSPECTION SCHEDULE

Determine the coolant level. Inspect the cooling

system hoses/clamps after each service interval has

elapsed.

COOLANT LEVEL

It is recommended that the engine coolant level be

inspected at least once a month during periods of hot

weather.

With the engine at normal operating temperature,

check the coolant level in the coolant reserve tank.

The coolant level must be at least above the ADD mark. Add coolant to the coolant reserve tank only.

Page 191 of 1502

5

- 4

BRAKES

• (3) During road test, make normal and firm brake

stops in 25-40 mph (40-64 Km/h) range. Note faulty

brake operation such as pull, grab, drag, noise, low

pedal, etc.

(4) Inspect suspect brake components and refer to

problem diagnosis information for causes of various

brake conditions.

COMPONENT

INSPECTION

Fluid leak points and dragging brake units can usu

ally be located without removing any components. The

area around a leak point will be wet with fluid. The

components at a dragging brake unit (wheel, tire, rotor)

will be quite warm or hot to the touch.

Other brake problem conditions will require compo

nent removal for proper inspection. Raise the vehicle and remove the necessary wheels for better visual ac

cess.

DIAGNOSING BRAKE

PROBLEMS

PEDAL FALLS

AWAY

A

brake pedal that falls away under steady foot

pressure is the result of a system leak. The leak

point could be at a brakeline, fitting, hose, or caliper. Internal leakage in the master cylinder caused by

worn or damaged piston cups, may also be the prob lem cause.

If leakage is severe, fluid will be evident at or around

the leaking component. However, internal leakage in

the master cylinder may not be physically evident. Re fer to the cylinder test procedure in this section.

LOW PEDAL

If a low pedal is experienced, pump the pedal sev

eral times. If the pedal comes back up, worn lining

and worn rotors or drums are the likely causes.

A decrease in fluid level in the master cylinder res

ervoirs may only be the result of normal lining wear.

Fluid level can be expected to decrease in proportion to wear. It is a result of the outward movement of

caliper and wheel cylinder pistons to compensate for

normal wear. Top off the reservoir fluid level and

check brake operation to verify proper brake action.

SPONGY PEDAL. A spongy pedal is most often caused by air in the sys

tem. Thin brake drums or substandard brake lines and

hoses can also cause a spongy pedal. The proper course

of action is to bleed the system and replace thin drums and suspect quality brake lines and hoses.

HARD PEDAL

OR

HIGH

PEDAL

EFFORT

A hard pedal or high pedal effort may be due to

lining that is water soaked, contaminated, glazed, or

badly worn. The power booster or check valve could also be faulty. On diesel engine models, high pedal effort may be

the result of a low vacuum condition. If the booster and check valve are OK, the problem may be related

to a vacuum pump hose, hose connection, hose fit

ting, pump diaphragm, or drive gear. Vacuum pump output can be checked with a standard vacuum

gauge. Vacuum output should range from 8.5 to 25 inches vacuum. If vacuum pump output is within

limits,

check the power booster and check valve as

described in this section.

BRAKE DRAG

Brake drag occurs when the lining is in constant

contact with the rotor or drum. Drag can occur at

one wheel, all wheels, fronts only, or rears only. It is a product of incomplete brakeshoe release. Drag can

be minor or severe enough to overheat the linings,

rotors and drums.

Brake drag can also effect fuel economy. If undetec

ted, minor brake drag can be misdiagnosed as an en gine or transmission/torque converter problem.

Minor drag will usually cause slight surface charring

of the lining. It can also generate hard spots in rotors and drums from the overheat-cool down process. In most

cases,

the rotors, drums, wheels and tires are quite

warm to the touch after the vehicle is stopped.

Severe drag can char the brake lining all the way

through. It can also distort and score rotors and drums to the point of replacement. The wheels, tires and brake components will be extremely hot. In se

vere cases, the lining may generate smoke as it chars

from overheating.

Some common causes of brake drag are:

• seized or improperly adjusted parking brake cables

• loose/worn wheel bearing

• seized caliper or wheel cylinder piston

• caliper binding on corroded bushings or rusted

slide surfaces

• loose caliper mounting bracket

• drum brakeshoes binding on worn or damaged sup

port plates

• misassembled components. If brake drag occurs at all wheels, the problem may

be related to a blocked master cylinder return port, or faulty power booster that binds and does not release.

BRAKE FADE

Brake fade is a product of overheating caused by

brake drag. However, brake overheating and subse quent fade can also be caused by riding the brake

pedal, making repeated high deceleration stops in a short time span, or constant braking on steep moun

tain roads. Refer to the Brake Drag information in

this section for additional causes.

PEDAL

PULSA

TION

Pedal pulsation is caused by components that are

loose, out of round, or worn beyond tolerance limits.

Page 291 of 1502

7 - 20

COOLING

SYSTEM

•

HOSE

CLAMP

HOSE

J9207-36

Fig.

16

Hose

Clamp

Tool

WITH AIR

CONDITIONING

(A/C)

REMOVAL

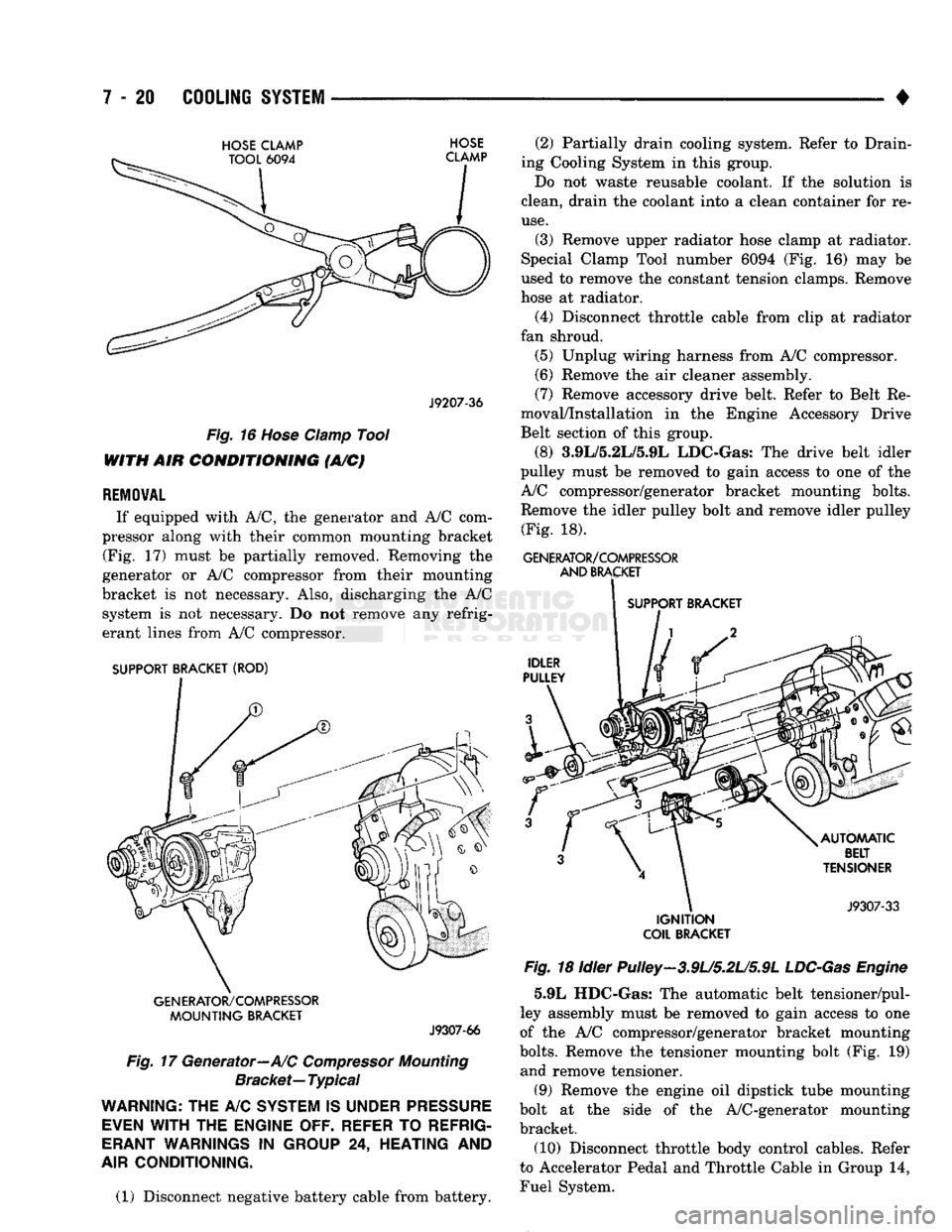

If equipped with A/C, the generator and A/C com

pressor along with their common mounting bracket (Fig. 17) must be partially removed. Removing the

generator or A/C compressor from their mounting

bracket is not necessary. Also, discharging the A/C system is not necessary. Do not remove any refrig

erant lines from A/C compressor.

SUPPORT BRACKET (ROD)

GENERATOR/COMPRESSOR

MOUNTING

BRACKET

J9307-66

Fig.

17 Generator—A/C

Compressor

Mounting

Bracket—

Typical

WARNING;

THE A/C

SYSTEM

IS

UNDER

PRESSURE

EVEN

WITH

THE

ENGINE OFF. REFER

TO

REFRIG

ERANT

WARNINGS

IN

GROUP

24,

HEATING

AND

AIR

CONDITIONING.

(1) Disconnect negative battery cable from battery. (2) Partially drain cooling system. Refer to Drain

ing Cooling System in this group.

Do not waste reusable coolant. If the solution is

clean, drain the coolant into a clean container for re

use.

(3) Remove upper radiator hose clamp at radiator.

Special Clamp Tool number 6094 (Fig. 16) may be

used to remove the constant tension clamps. Remove

hose at radiator.

(4) Disconnect throttle cable from clip at radiator

fan shroud. (5) Unplug wiring harness from A/C compressor.

(6) Remove the air cleaner assembly.

(7) Remove accessory drive belt. Refer to Belt Re

moval/Installation in the Engine Accessory Drive

Belt section of this group.

(8) 3.9L/5.2L/5.9L LDC-Gas: The drive belt idler

pulley must be removed to gain access to one of the

A/C compressor/generator bracket mounting bolts. Remove the idler pulley bolt and remove idler pulley (Fig. 18).

GENERATOR/COMPRESSOR

AND

BRACKET

SUPPORT BRACKET

IGNITION

COIL

BRACKET

Fig.

18 Idler Pulley-3.9U5.2U5.9L

LDC-Gas

Engine

5.9L HDC-Gas: The automatic belt tensioner/pul-

ley assembly must be removed to gain access to one

of the A/C compressor/generator bracket mounting

bolts.

Remove the tensioner mounting bolt (Fig. 19) and remove tensioner.

(9) Remove the engine oil dipstick tube mounting

bolt at the side of the A/C-generator mounting

bracket.

(10) Disconnect throttle body control cables. Refer

to Accelerator Pedal and Throttle Cable in Group 14,

Fuel System.

Page 352 of 1502

•

IGNITION

SYSTEMS

8D

- 1

CONTENTS

page page

COMPONENT IDENTIFICATION/SYSTEM DIAGNOSTICS/SERVICE PROCEDURES

7

OPERATION

1

IGNITION SWITCH

25

COMPONENT REMOVAL/INSTALLATION

..... 18

SPECIFICATIONS

28

COMPONENT

IDENTIFICATION/SYSTEM OPERATION

INDEX

page

Automatic

Shut Down (ASD) Relay

1

Camshaft Position Sensor

2

Crankshaft Position Sensor

2

Distributors

3

Engine Coolant

Temperature

Sensor

...........

4

General

Information

1

page

Ignition

Coil

3

Intake

Manifold Charge

Air

Temperature

Sensor

. . 4

Manifold Absolute Pressure (MAP) Sensor

4

Powertrain

Control

Module (PCM)

. 5

Throttle

Position Sensor

5

GENERAL

INFORMATION

Throughout this group, references

are

made

to

par

ticular vehicle models

by

alphabetical designation

or

by

the

particular vehicle nameplate.

A

chart showing a breakdown

of

alphabetical designations

is

included

in

the

Introduction group

at the

beginning

of

this

manual. 5.9L

gas

powered engines will

be

referred

to as ei

ther: LDC (Light Duty Cycle),

or

HDC (Heavy Duty Cycle). This section

of the

group, Component Identifica

tion/System Operation, will discuss ignition system operation

and

will identify ignition system compo

nents.

For diagnostic procedures

and

adjustments, refer

to

the Diagnostics/Service Procedures section

of

this

group.

For removal

and

installation

of

ignition system

components, refer

to the

Component Removal/Instal

lation section

of

this group. For other useful information, refer

to

On-Board

Di

agnostics

in the

General Diagnosis sections

of

Group

14,

Fuel System

in

this manual. For operation

of the DRB II

Diagnostic Scan Tool,

refer

to the

appropriate Powertrain Diagnostic Proce

dures service manual.

An Ignition specifications section

is

included

at the

end

of

this group.

A

general Maintenance Schedule (mileage intervals)

for

ignition related items

can be

found

in

Group

0,

Lubrication and Maintenance. This

schedule

can

also

be

found

in the

Owners Manual.

IGNITION

SYSTEMS

The ignition systems used

on all

engines

are

basi

cally identical. Similarities

and

differences between

the systems will

be

discussed.

A sequential multi-port fuel injection system

is

used

on all gas

powered engines.

The ignition system

is

controlled

by the

powertrain

control module (PCM)

on all

engines.

The

PCM

was

formerly referred

to as the

SBEC

or

engine control ler.

The ignition system consists

of:

• Spark Plugs

• Ignition Coil

• Secondary Ignition Cables

• Ignition distributor. Contains rotor

and

camshaft

position sensor • Powertrain Control Module (PCM)

• Crankshaft Position Sensor

AUTOMATIC SHUT DOWN (ASD) RELAY

The automatic shut down (ASD) relay

is

located

in

the engine compartment (Fig.

1). As one of its

func

tions,

the ASD

relay will supply battery voltage

to

the ignition coil.

The

ground circuit

for the

ASD

re

lay

is

controlled

by the

powertrain control module (PCM).

The PCM

regulates

ASD

relay operation

by

switching

the

ground circuit on-and-off.

IGNITION

SYSTEMS

Page 355 of 1502

8D

- 4

IGNITION

SYSTEMS

•

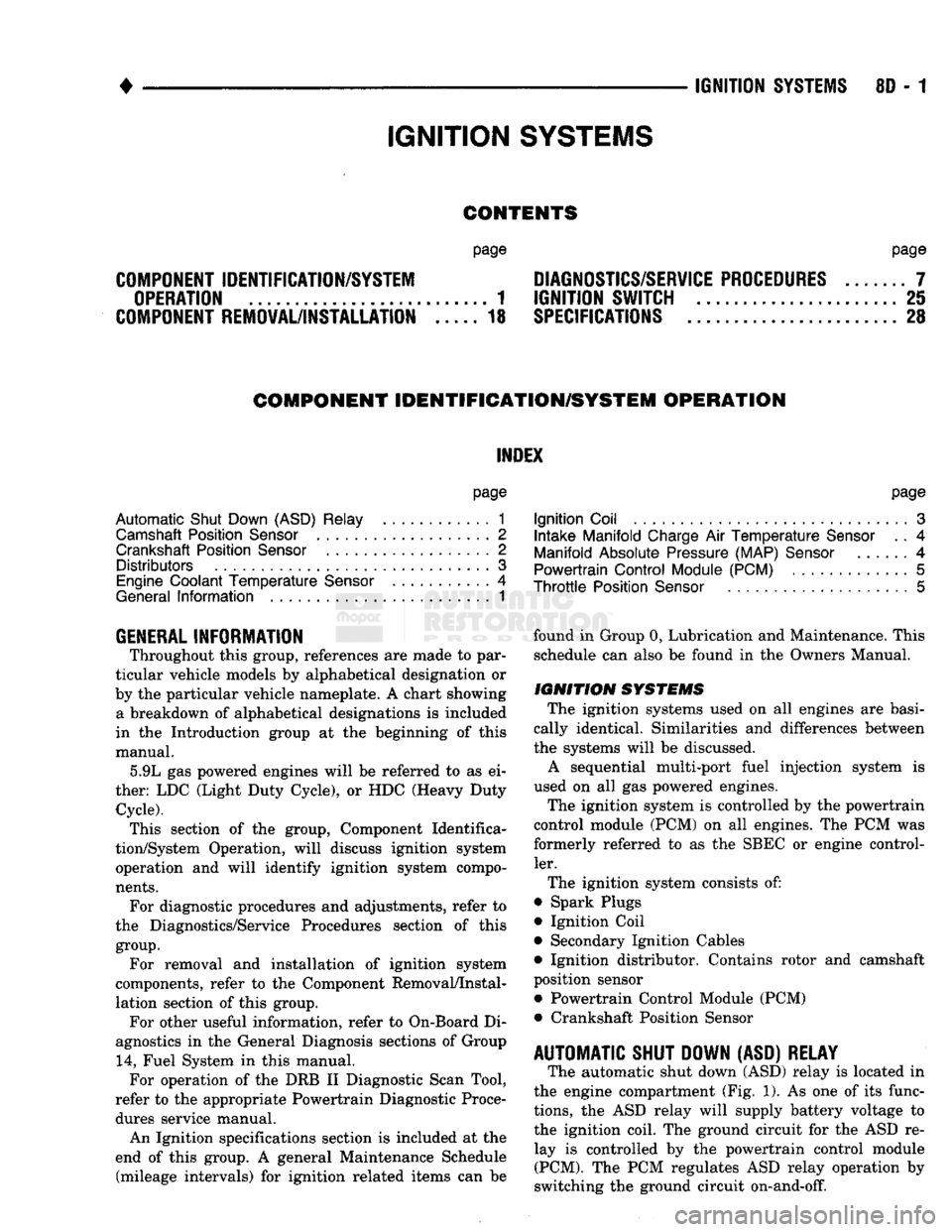

Fig. 6 ignition Coil—3.9L/5.2L/5.9L

LDC-Gas

Engines Fig. 7 Ignition Coil—5.9L

HDC-Gas

Engine

• 5.9L HDC-Gas Engines: The coil is mounted to a

bracket that is bolted to the automatic belt tensioner mounting bracket (Fig. 7).

For component testing, refer to the Diagnostics/Ser

vice Procedures section of this group.

For removal and installation of this component, re

fer to the Component Removal/Installation section of

this group.

ENGINE COOLANT TEMPERATURE

SENSOR

The sensor provides an input voltage to the power-

train control module (PCM) relating coolant temper ature. The PCM uses this input, along with inputs

from other sensors, to determine injector pulse width and ignition timing. As coolant temperature varies,

the coolant temperature sensor resistance will

change, resulting in a different input voltage to the

PCM. When the engine is cold, the PCM will operate in

the Open Loop Cycle. It will demand slightly richer air-fuel mixtures and higher idle speeds, until nor mal operating temperatures are reached. Refer to

Modes Of Operation in Group 14, Fuel System for a

description of Open and Closed Loop operation.

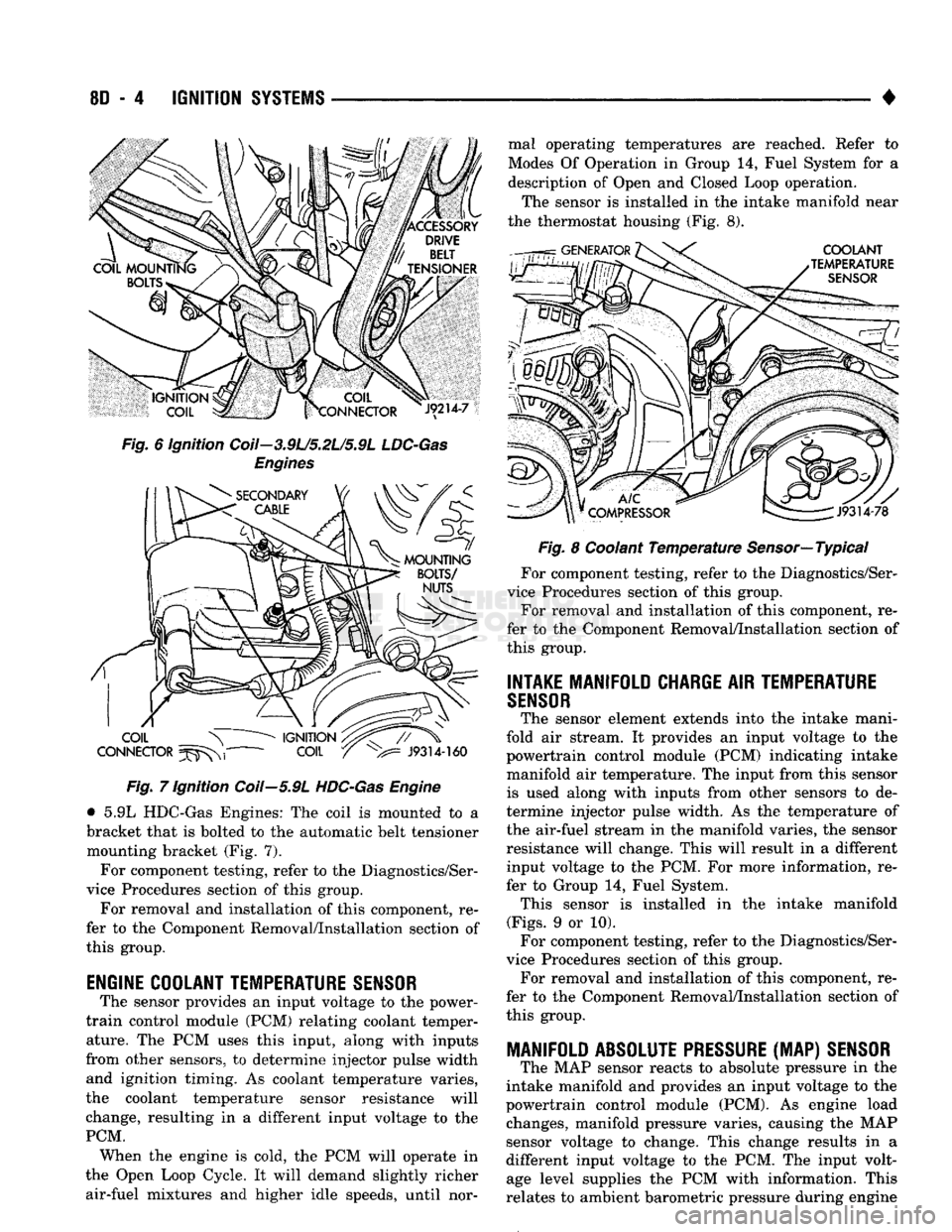

The sensor is installed in the intake manifold near

the thermostat housing (Fig. 8).

Fig. 8 Coolant Temperature Sensor—Typical

For component testing, refer to the Diagnostics/Ser

vice Procedures section of this group. For removal and installation of this component, re

fer to the Component Removal/Installation section of

this group.

INTAKE MANIFOLD CHARGE

AIR

TEMPERATURE

SENSOR

The sensor element extends into the intake mani

fold air stream. It provides an input voltage to the

powertrain control module (PCM) indicating intake

manifold air temperature. The input from this sensor is used along with inputs from other sensors to de

termine injector pulse width. As the temperature of

the air-fuel stream in the manifold varies, the sensor

resistance will change. This will result in a different input voltage to the PCM. For more information, re

fer to Group 14, Fuel System. This sensor is installed in the intake manifold

(Figs.

9 or 10). For component testing, refer to the Diagnostics/Ser

vice Procedures section of this group. For removal and installation of this component, re

fer to the Component Removal/Installation section of

this group.

MANIFOLD ABSOLUTE

PRESSURE

(MAP)

SENSOR

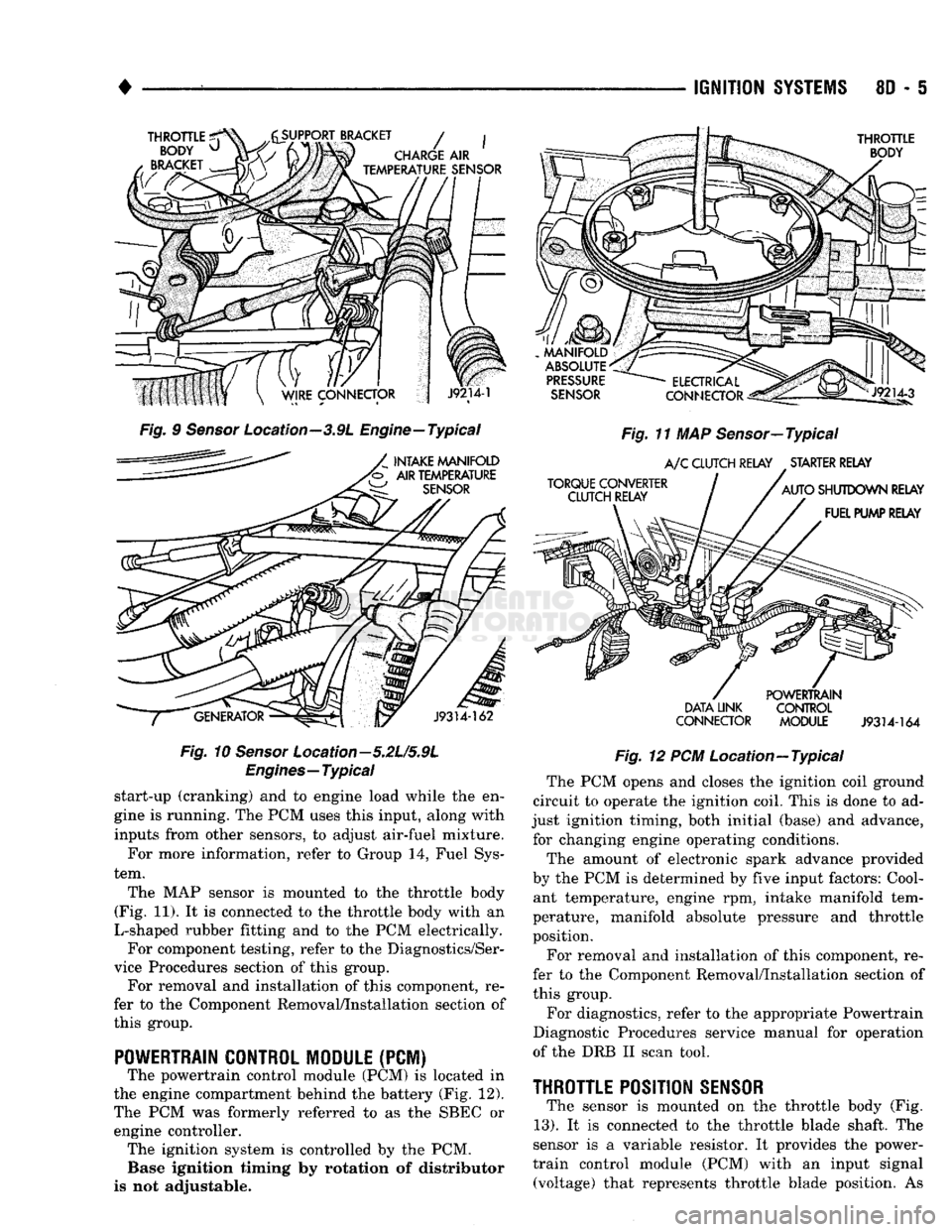

The MAP sensor reacts to absolute pressure in the

intake manifold and provides an input voltage to the

powertrain control module (PCM). As engine load changes, manifold pressure varies, causing the MAP

sensor voltage to change. This change results in a

different input voltage to the PCM. The input volt age level supplies the PCM with information. This

relates to ambient barometric pressure during engine

Page 356 of 1502

•

IGNITION

SYSTEMS

8D - 5

THROTTLE

^

BODY

u

BRACKET

y^SUPPORT

BRACKET

/ |

CHARGE

AIR

ijmmmmk

TEMPERATURE

SENSOR

THROTTLE

BODY

Fig.

9

Sensor

Location—3.9L Engine—Typical

INTAKE MANIFOLD

'b AIR TEMPERATURE

SENSOR

J9314-162

Fig.

10

Sensor

Location—5.2L/5.9L

Engines—Typical

start-up (cranking) and to engine load while the en

gine is running. The PCM uses this input, along with

inputs from other sensors, to adjust air-fuel mixture.

For more information, refer to Group 14, Fuel Sys

tem.

The MAP sensor is mounted to the throttle body

(Fig. 11). It is connected to the throttle body with an

L-shaped rubber fitting and to the PCM electrically. For component testing, refer to the Diagnostics/Ser

vice Procedures section of this group. For removal and installation of this component, re

fer to the Component Removal/Installation section of

this group.

POWERTRAIN CONTROL MODULE

(PCM) The powertrain control module (PCM) is located in

the engine compartment behind the battery (Fig. 12).

The PCM was formerly referred to as the SBEC or engine controller. The ignition system is controlled by the PCM. Base ignition timing by rotation of distributor

is not adjustable.

MANIFOLD

ABSOLUTE

PRESSURE

SENSOR

TORQUE CONVERTER CLUTCH RELAY

ELECTRICAL

Jlp^

CONNECTOR

^gis!—

Fig.

11 MAP Sensor—Typical

A/C

CLUTCH RELAY STARTER RELAY

AUTO

SHUTDOWN RELAY FUEL PUMP RELAY

DATA LINK

CONNECTOR POWERTRAIN

CONTROL

MODULE

J9314-164

Fig.

12 PCM Location—Typical The PCM opens and closes the ignition coil ground

circuit to operate the ignition coil. This is done to ad

just ignition timing, both initial (base) and advance, for changing engine operating conditions.

The amount of electronic spark advance provided

by the PCM is determined by five input factors: Cool ant temperature, engine rpm, intake manifold tem

perature, manifold absolute pressure and throttle

position.

For removal and installation of this component, re

fer to the Component Removal/Installation section of

this group.

For diagnostics, refer to the appropriate Powertrain

Diagnostic Procedures service manual for operation

of the DRB II scan tool.

THROTTLE

POSITION

SENSOR

The sensor is mounted on the throttle body (Fig.

13).

It is connected to the throttle blade shaft. The

sensor is a variable resistor. It provides the power-

train control module (PCM) with an input signal (voltage) that represents throttle blade position. As

Page 358 of 1502

•

IGNITION

SYSTEMS

80 - 7

DIAGNOSTICS/SERW1CE

PROCEDURES

INDEX

page

Automatic Shut Down (ASD) Relay

7

Camshaft Position

Sensor

Test

...............

7

Crankshaft Position

Sensor

Test

8

Distributor

Cap

8

Distributor

Rotor

8

Engine

Coolant Temperature

Sensor

Test

10

General

Information

7

Ignition

Coil

8

Ignition

Secondary

Circuit

Diagnosis

10

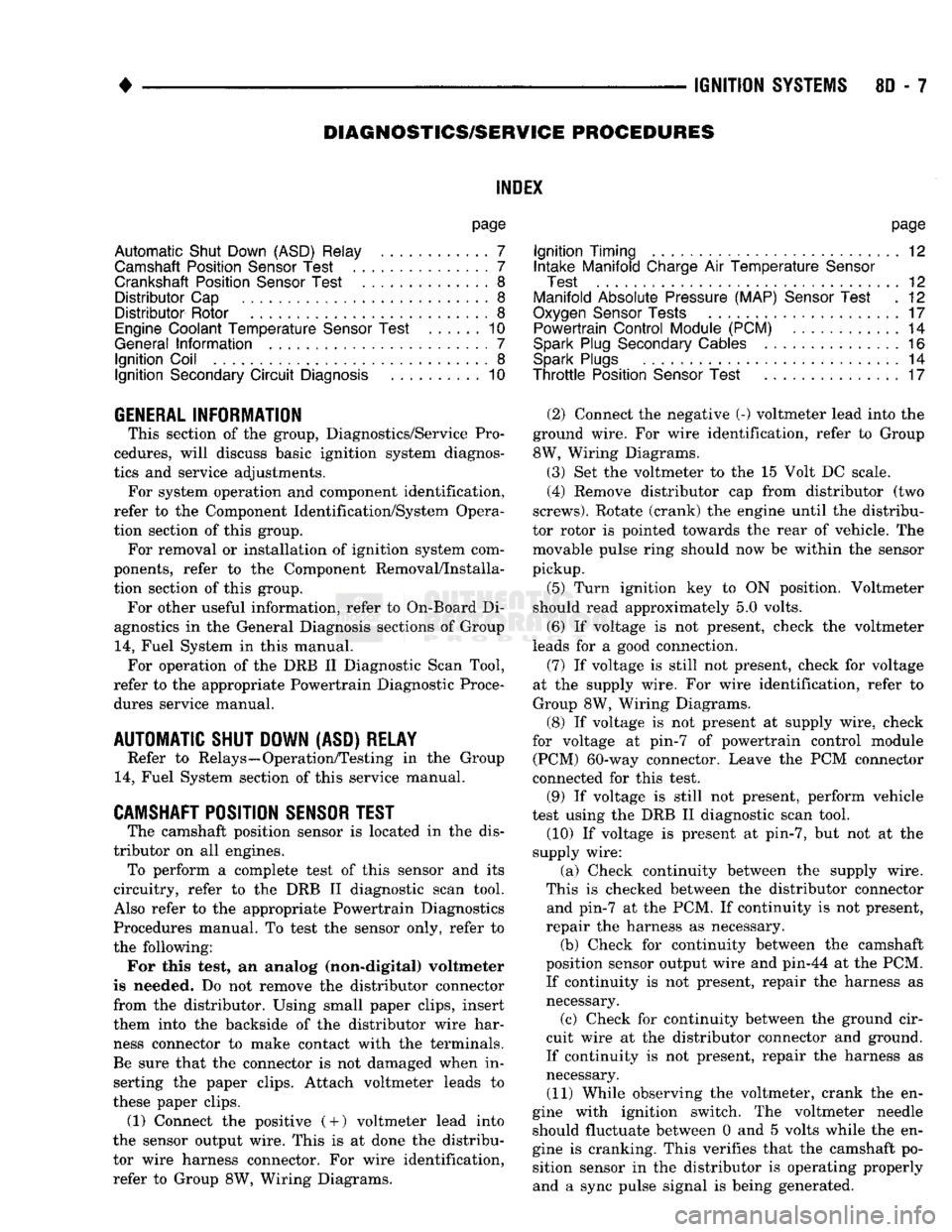

GENERAL

INFORMATION

This section

of the

group, Diagnostics/Service Pro

cedures, will discuss basic ignition system diagnos

tics

and

service adjustments. For system operation

and

component identification,

refer

to the

Component Identification/System Opera

tion section

of

this group. For removal

or

installation

of

ignition system com

ponents, refer

to the

Component Removal/Installa

tion section

of

this group. For other useful information, refer

to

On-Board

Di

agnostics

in the

General Diagnosis sections

of

Group

14,

Fuel System

in

this manual. For operation

of the DRB II

Diagnostic Scan Tool,

refer

to the

appropriate Powertrain Diagnostic Proce

dures service manual.

AUTOMATIC SHUT DOWN

(ASD)

RELAY

Refer

to

Relays—Operation/Testing

in the

Group

14,

Fuel System section

of

this service manual.

CAMSHAFT POSITION SENSOR TEST

The camshaft position sensor

is

located

in the

dis

tributor

on all

engines. To perform

a

complete test

of

this sensor

and its

circuitry, refer

to the DRB II

diagnostic scan tool.

Also refer

to the

appropriate Powertrain Diagnostics

Procedures manual.

To

test

the

sensor only, refer

to

the following: For this test,

an

analog (non-digital) voltmeter

is needed.

Do not

remove

the

distributor connector from

the

distributor. Using small paper clips, insert

them into

the

backside

of the

distributor wire har ness connector

to

make contact with

the

terminals.

Be sure that

the

connector

is not

damaged when

in

serting

the

paper clips. Attach voltmeter leads

to

these paper clips. (1) Connect

the

positive (

+

)

voltmeter lead into

the sensor output wire. This

is at

done

the

distribu tor wire harness connector.

For

wire identification,

refer

to

Group

8W,

Wiring Diagrams.

page

Ignition

Timing

12

Intake Manifold Charge

Air

Temperature

Sensor

Test

12

Manifold Absolute Pressure (MAP)

Sensor

Test

. 12

Oxygen

Sensor

Tests

17

Powertrain Control Module (PCM)

............

14

Spark

Plug Secondary Cables

16

Spark

Plugs

............................

14

Throttle

Position

Sensor

Test

17

(2) Connect

the

negative

(-)

voltmeter lead into

the

ground wire.

For

wire identification, refer

to

Group

8W, Wiring Diagrams.

(3)

Set the

voltmeter

to the 15

Volt

DC

scale. (4) Remove distributor

cap

from distributor

(two

screws). Rotate (crank)

the

engine until

the

distribu

tor rotor

is

pointed towards

the

rear

of

vehicle.

The

movable pulse ring should

now be

within

the

sensor

pickup.

(5) Turn ignition

key to ON

position. Voltmeter

should read approximately

5.0

volts.

(6)

If

voltage

is not

present, check

the

voltmeter

leads

for a

good connection.

(7)

If

voltage

is

still

not

present, check

for

voltage

at

the

supply wire.

For

wire identification, refer

to

Group

8W,

Wiring Diagrams.

(8)

If

voltage

is not

present

at

supply wire, check

for voltage

at

pin-7

of

powertrain control module (PCM) 60-way connector. Leave

the PCM

connector

connected

for

this test. (9)

If

voltage

is

still

not

present, perform vehicle

test using

the DRB II

diagnostic scan tool. (10)

If

voltage

is

present

at

pin-7,

but not at the

supply wire: (a) Check continuity between

the

supply wire.

This

is

checked between

the

distributor connector and pin-7

at the PCM. If

continuity

is not

present,

repair

the

harness

as

necessary. (b) Check

for

continuity between

the

camshaft

position sensor output wire

and

pin-44

at the PCM.

If continuity

is not

present, repair

the

harness

as

necessary. (c) Check

for

continuity between

the

ground cir

cuit wire

at the

distributor connector

and

ground.

If continuity

is not

present, repair

the

harness

as

necessary. (11) While observing

the

voltmeter, crank

the en

gine with ignition switch.

The

voltmeter needle should fluctuate between

0 and 5

volts while

the en

gine

is

cranking. This verifies that

the

camshaft

po

sition sensor

in the

distributor

is

operating properly

and

a

sync pulse signal

is

being generated.

Page 363 of 1502

8D

- 12

IGNITION

SYSTEMS

•

XX

oooooooooo

,0000000000

\2141

3%

lOOOOOOOOOO

OOOOOOOOOO

si

20

fcji^OQOOOOOOJ

«r

~

• • -

•

- - #

•oooooooooo.

CONNECTOR

TERMINAL

SIDE

SHOWN

J908D-42

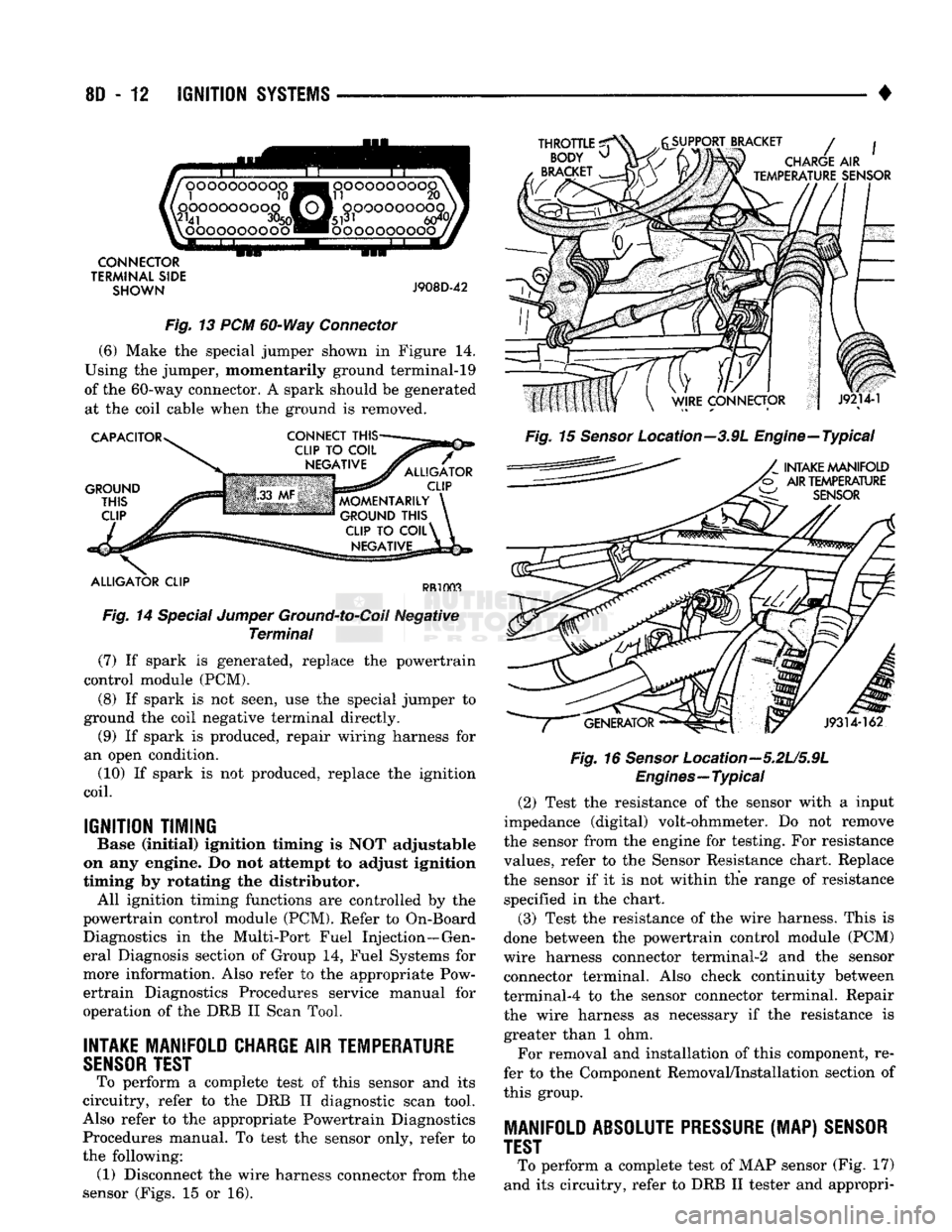

Fig. 13 PCM 60-Way Connector

(6) Make the special jumper shown in Figure 14.

Using the jumper, momentarily ground terminal-19

of the 60-way connector. A spark should be generated at the coil cable when the ground is removed.

CAPACITOR

GROUND

THIS

CLIP

CONNECT

THIS-

ALLIGATOR

CLIP

MOMENTARILY

GROUND

THIS

CLIP

TO

COIL^

NEGATIVE

ALLIGATOR

CLIP

PR1003

Fig. 14 Special Jumper Ground-to-Coil Negative Terminal (7) If spark is generated, replace the powertrain

control module (PCM).

(8) If spark is not seen, use the special jumper to

ground the coil negative terminal directly. (9) If spark is produced, repair wiring harness for

an open condition. (10) If spark is not produced, replace the ignition

coil.

IGNITION TIMING

Base (Initial) ignition timing Is NOT adjustable

on any engine. Do not attempt to adjust Ignition

timing by rotating the distributor. All ignition timing functions are controlled by the

powertrain control module (PCM). Refer to On-Board Diagnostics in the Multi-Port Fuel Injection—Gen

eral Diagnosis section of Group 14, Fuel Systems for

more information. Also refer to the appropriate Pow ertrain Diagnostics Procedures service manual for

operation of the DRB II Scan Tool.

INTAKE

MANIFOLD

CHARGE

AIR

TEMPERATURE

SENSOR

TEST

To perform a complete test of this sensor and its

circuitry, refer to the DRB II diagnostic scan tool.

Also refer to the appropriate Powertrain Diagnostics Procedures manual. To test the sensor only, refer to

the following: (1) Disconnect the wire harness connector from the

sensor (Figs. 15 or 16).

THROTTLE

^

BODY

^

BRACKET

SUPPORT BRACKET

/

CHARGE

AIR

TEMPERATURE

SENSOR

Fig. 15 Sensor Location--3.9L Engine—Typical

INTAKE

MANIFOLD

AIR

TEMPERATURE

W

SENSOR

J9314-162

Fig. 16

Sensor

Location—5.2U5.9L

Engines—Typical

(2) Test the resistance of the sensor with a input

impedance (digital) volt-ohmmeter. Do not remove

the sensor from the engine for testing. For resistance

values, refer to the Sensor Resistance chart. Replace

the sensor if it is not within the range of resistance specified in the chart.

(3) Test the resistance of the wire harness. This is

done between the powertrain control module (PCM)

wire harness connector terminal-2 and the sensor connector terminal. Also check continuity between

terminal-4 to the sensor connector terminal. Repair

the wire harness as necessary if the resistance is greater than 1 ohm.

For removal and installation of this component, re

fer to the Component Removal/Installation section of

this group.

MANIFOLD

ABSOLUTE PRESSURE

(MAP)

SENSOR

TEST

To perform a complete test of MAP sensor (Fig. 17)

and its circuitry, refer to DRB II tester and appropri-

Page 369 of 1502

8D

- 18

IGNITION

SYSTEMS

•

COMPONENT REMGWAL/INSTALLATION

INDEX

page

Automatic

Shut Down (ASD) Relay

18

Camshaft

Position

Sensor

, 18

Crankshaft Position

Sensor

18

Distributor

Service

20

Engine

Coolant Temperature

Sensor

20

General

Information

18

Ignition

Coil

21

page

Intake

Manifold Charge

Air

Temperature

Sensor

. 22

Manifold Absolute Pressure (MAP)

Sensor

..... 22

Oxygen

(02)

Sensor

22

Powertrain

Control

Module (PCM)

22

Spark

Plug Secondary Cables

24

Spark

Plugs

23

Throttle

Position

Sensor

(TPS)

24

GENERAL

INFORMATION

This section

of the

group, Component Removal/In

stallation, will discuss

the

removal

and

installation

of ignition system components. For basic ignition system diagnostics

and

service

adjustments, refer

to the

Diagnostics/Service Proce

dures section

of

this group. For system operation

and

component identification,

refer

to the

Component Identification/System Opera

tion section

of

this group.

AUTOMATIC

SHUT DOWN

(ASb)

RELAY

The automatic shut down

(ASD)

relay

is

located

in

the engine compartment

(Fig. 1).

TORQUE CONVERTER

CLUTCH RELAY

A/C

CLUTCH RELAY STARTER RELAY

AUTO

SHUTDOWN RELAY FUEL PUMP RELAY DATA UNK

CONNECTOR POWERTRAIN

CONTROL

MODULE

J9314-164

Fig.

1

Auto

Shut Down

Relay

REMOVAL

(1) Disconnect negative battery cable

at

battery.

(2)

Remove

the

relay

by

pulling from connector.

INSTALLATION

(1) Check

the

terminals

in the

relay connector

for

corrosion

or

damage before installation.

(2)

Push

the

relay into

the

connector.

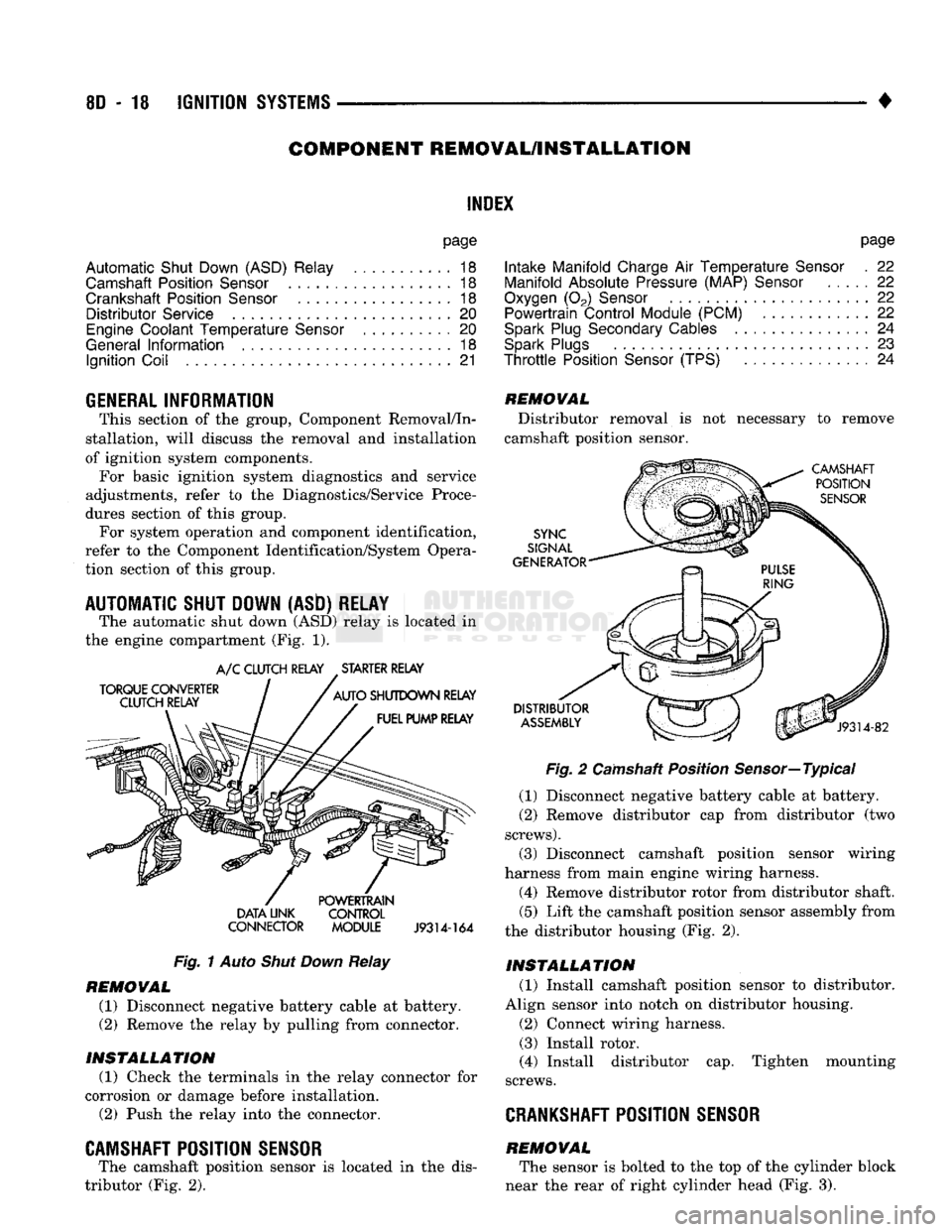

CAMSHAFT POSITION SENSOR

The camshaft position sensor

is

located

in the

dis

tributor

(Fig. 2).

REMOVAL

Distributor removal

is not

necessary

to

remove

camshaft position sensor.

CAMSHAFT POSITION

SENSOR

SYNC

SIGNAL

GENERATOR

DISTRIBUTOR

ASSEMBLY

J9314-82

Fig.

2

Camshaft Position Sensor—Typical

(1) Disconnect negative battery cable

at

battery.

(2)

Remove distributor

cap

from distributor

(two

screws).

(3) Disconnect camshaft position sensor wiring

harness from main engine wiring harness.

(4) Remove distributor rotor from distributor shaft.

(5)

Lift

the

camshaft position sensor assembly from

the distributor housing

(Fig. 2).

INSTALLATION

(1) Install camshaft position sensor

to

distributor.

Align sensor into notch

on

distributor housing.

(2)

Connect wiring harness.

(3) Install rotor.

(4) Install distributor

cap.

Tighten mounting

screws.

CRANKSHAFT

POSITION SENSOR

REMOVAL The sensor

is

bolted

to the top of the

cylinder block

near

the

rear

of

right cylinder head

(Fig. 3).