fuel pressure DODGE TRUCK 1993 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 373 of 1502

8D

- 22

IGNITION

SYSTEMS

• (1) Disconnect the wiring and secondary cable from

the ignition coil (Figs. 9 or 10).

WARNING:

(3.9L/5.2L/5.9L

LDC-GAS ENGINES)

DO

NOT REMOVE

THE

COIL MOUNTING BRACKET-TO-

CYLINDER HEAD MOUNTING BOLTS.

THE

COIL MOUNTING BRACKET

IS

UNDER ACCESSORY

DRIVE BELT TENSION.

IF

THIS BRACKET

IS TO BE

REMOVED

FOR ANY

REASON,

ALL

BELT TENSION

MUST FIRST

BE

RELIEVED. REFER

TO THE

BELT

SECTION

OF

GROUP

7,

COOLING SYSTEM.

(2) Remove ignition coil from coil mounting

bracket (two bolts).

INSTALLATION (1) Install the ignition coil to coil bracket. If nuts

and bolts are used to secure coil to coil bracket,

tighten to 11 N«m (100 in. lbs.) torque. If the coil mounting bracket has been tapped for coil mounting

bolts,

tighten bolts to 5 N«m (50 in. lbs.) torque.

(2) Connect all wiring to ignition coil.

INTAKE MANIFOLD CHARGE

AIR

TEMPERATURE

SENSOR

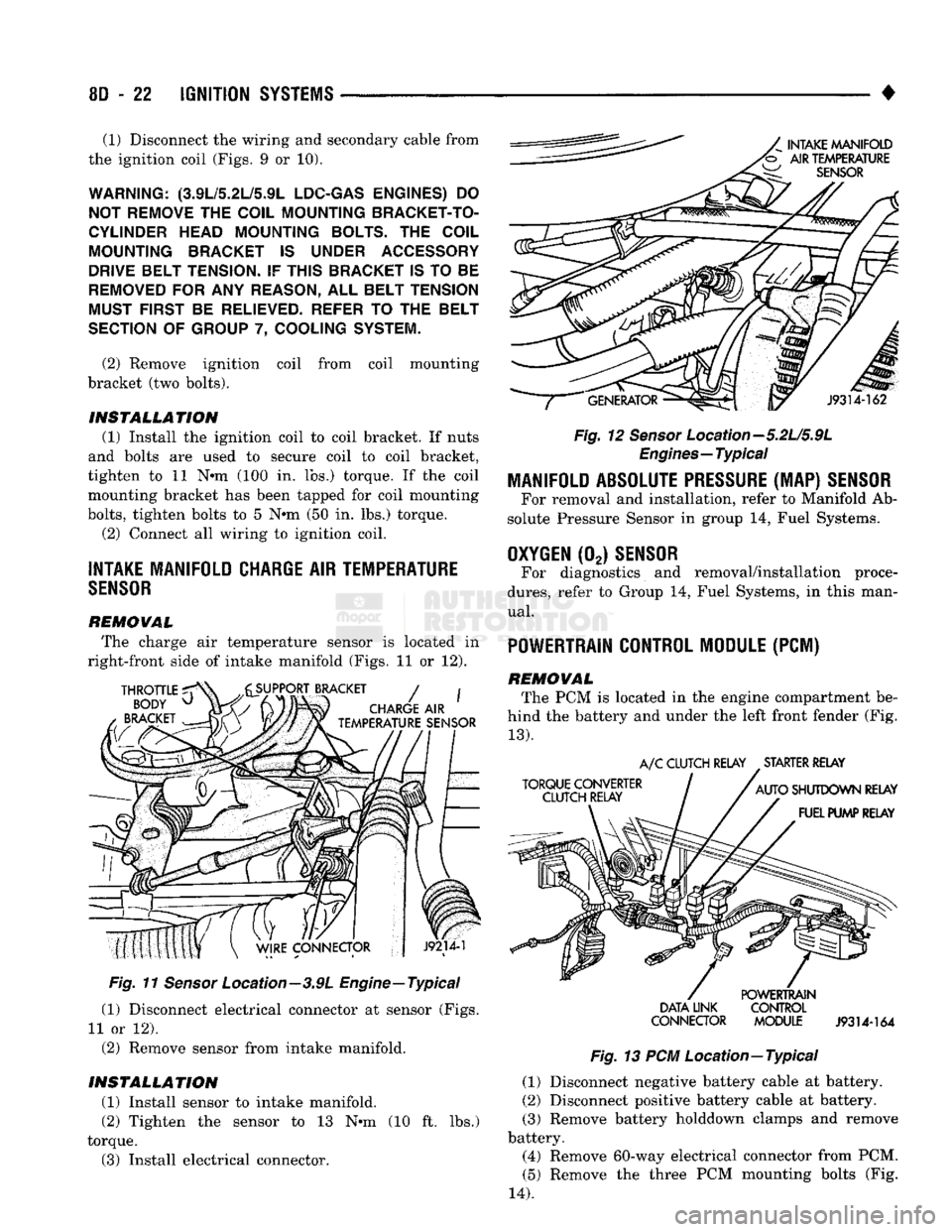

REMOVAL The charge air temperature sensor is located in

right-front side of intake manifold (Figs. 11 or 12).

Fig.

11

Sensor

Location—3.9L Engine—Typical

(1) Disconnect electrical connector at sensor (Figs.

11 or 12).

(2) Remove sensor from intake manifold.

INSTALLATION (1) Install sensor to intake manifold. (2) Tighten the sensor to 13 N-m (10 ft. lbs.)

torque. (3) Install electrical connector.

Fig.

12

Sensor

Location—5.2L/5.9L

Engines—Typical

MANIFOLD ABSOLUTE

PRESSURE

(MAP)

SENSOR

For removal and installation, refer to Manifold Ab

solute Pressure Sensor in group 14, Fuel Systems.

OXYGEN

(02)

SENSOR

For diagnostics and removal/installation proce

dures,

refer to Group 14, Fuel Systems, in this man

ual.

POWERTRAIN CONTROL MODULE

(PCM)

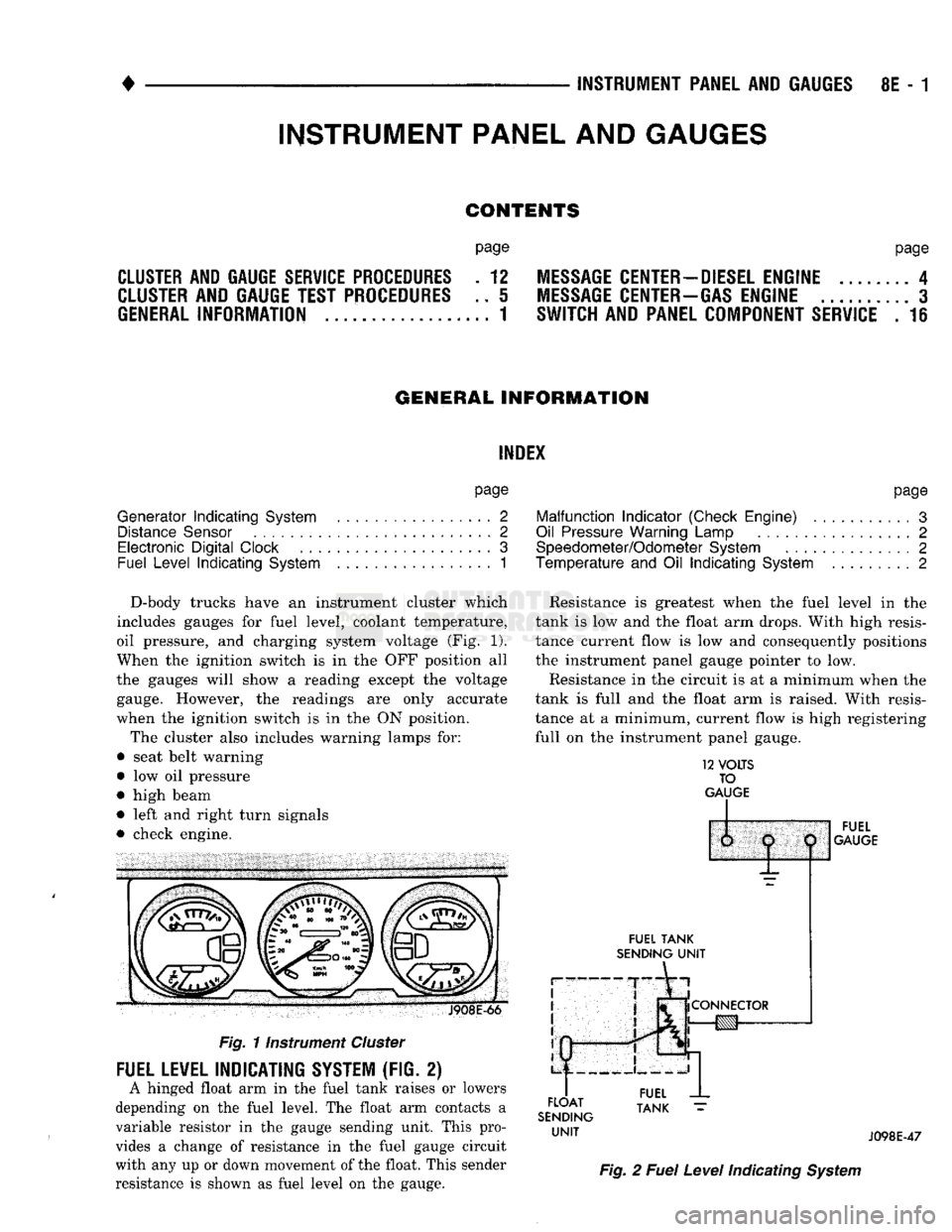

REMOVAL The PCM is located in the engine compartment be

hind the battery and under the left front fender (Fig.

13).

DATA

UNK CONTROL

CONNECTOR MODULE

J9314-164

Fig.

13 PCM Location—Typical (1) Disconnect negative battery cable at battery.

(2) Disconnect positive battery cable at battery.

(3) Remove battery holddown clamps and remove

battery.

(4) Remove 60-way electrical connector from PCM.

(5) Remove the three PCM mounting bolts (Fig.

14).

Page 382 of 1502

• • ^ ^ ^ INSTRUMENT PANEL AND GAUGES 8E - 1

CONTENTS

page

CLUSTER AND GAUGE SERVICE PROCEDURES . 12

CLUSTER AND GAUGE TEST PROCEDURES .. i

GENERAL INFORMATION . 1

page

MESSAGE CENTER-DIESEL ENGINE ........ 4

MESSAGE CENTER-GAS ENGINE .......... 3

SWITCH

AND PANEL COMPONENT SERVICE . 16

GENERAL

INFORMATION

INDEX

page

Generator

Indicating

System

2

Distance

Sensor

2

Electronic

Digital

Clock

3

Fuel

Level

Indicating

System

1

page

Malfunction

Indicator

(Check

Engine)

3

Oil

Pressure

Warning

Lamp

................. 2

Speedometer/Odometer

System

2

Temperature

and Oil

Indicating

System

......... 2

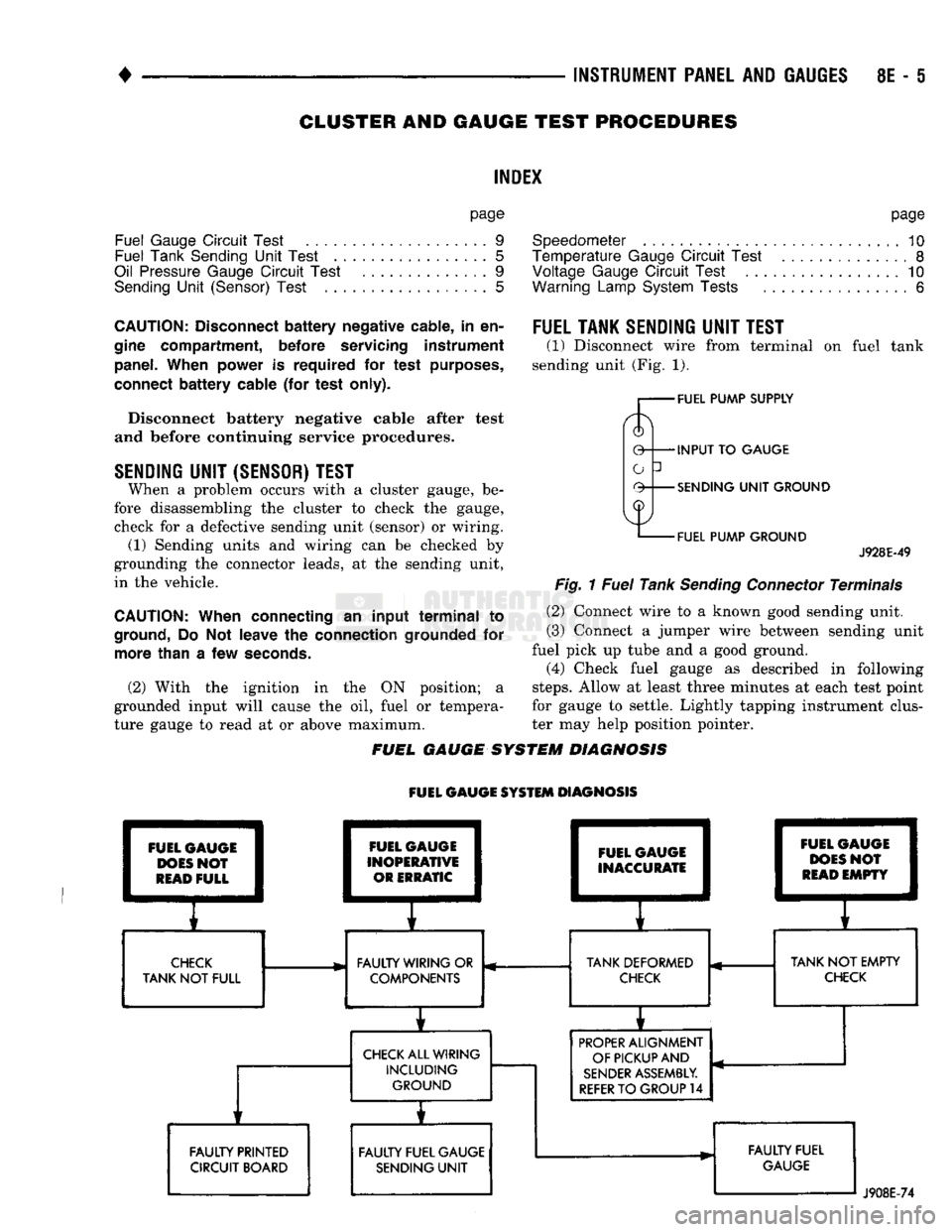

D-body trucks have an instrument cluster which

includes gauges for fuel level, coolant temperature,

oil pressure, and charging system voltage (Fig. 1).

When the ignition switch is in the OFF position all

the gauges will show a reading except the voltage gauge. However, the readings are only accurate

when the ignition switch is in the ON position.

The cluster also includes warning lamps for:

• seat belt warning

• low oil pressure

• high beam

• left and right turn signals

• check engine. J908E-66

Fig.

11nstrument

Cluster

FUEL LEVEL INDICATING SYSTEM (FIG. 2)

A hinged float arm in the fuel tank raises or lowers

depending on the fuel level. The float arm contacts a

variable resistor in the gauge sending unit. This pro

vides a change of resistance in the fuel gauge circuit

with any up or down movement of the float. This sender

resistance is shown as fuel level on the gauge. Resistance is greatest when the fuel level in the

tank is low and the float arm drops. With high resis

tance current flow is low and consequently positions

the instrument panel gauge pointer to low.

Resistance in the circuit is at a minimum when the

tank is full and the float arm is raised. With resis

tance at a minimum, current flow is high registering

full on the instrument panel gauge.

12

VOLTS

TO

GAUGE

IP

FUEL

TANK

SENDING

UNIT

FLOAT

SENDING

UNIT

1:

1

j

^

fCONNECTOR

!g|yj-»—

FUEL

GAUGE

FUEL

TANK

J098E-47

Fig.

2

Fuel

Level

Indicating

System

INSTRUMENT PANEL AND GAUGES

Page 386 of 1502

•

INSTRUMENT PANEL

AND

GAUGES

8E - 5

CLUSTER

AND

GAUGE TEST

PROCEDURES

INDEX

page

Fuel Gauge

Circuit

Test

9

Fuel Tank Sending

Unit

Test

5

Oil Pressure Gauge

Circuit

Test

..............

9

Sending

Unit

(Sensor) Test

5

page

Speedometer

10

Temperature

Gauge

Circuit

Test

8

Voltage Gauge

Circuit

Test

10

Warning Lamp System Tests

6

CAUTION:

Disconnect

battery

negative cable,

in

en

gine compartment, before servicing instrument panel. When power

is

required

for

test purposes,

connect

battery

cable

(for

test only).

Disconnect battery negative cable after test

and before continuing service procedures.

SENDING

UNIT

(SENSOR) TEST

When

a

problem occurs with

a

cluster gauge,

be

fore disassembling

the

cluster

to

check

the

gauge, check

for a

defective sending unit (sensor)

or

wiring.

(1) Sending units

and

wiring

can be

checked

by

grounding

the

connector leads,

at the

sending unit,

in

the

vehicle.

CAUTION:

When connecting

an

input

terminal

to

ground,

Do Not

leave

the

connection grounded

for

more than

a

few

seconds.

(2) With

the

ignition

in the ON

position;

a

grounded input will cause

the oil,

fuel

or

tempera

ture gauge

to

read

at or

above maximum.

FUEL TANK SENDING

UNIT

TEST

(1) Disconnect wire from terminal

on

fuel tank

sending unit (Fig.

1).

FUEL PUMP SUPPLY

INPUT

TO

GAUGE

SENDING

UNIT

GROUND

FUEL PUMP GROUND

J928E-49

Fig.

1

Fuel

Tank

Sending

Connector

Terminals

(2) Connect wire

to a

known good sending unit.

(3) Connect

a

jumper wire between sending unit

fuel pick

up

tube

and a

good ground.

(4) Check fuel gauge

as

described

in

following

steps.

Allow

at

least three minutes

at

each test point

for gauge

to

settle. Lightly tapping instrument clus

ter

may

help position pointer.

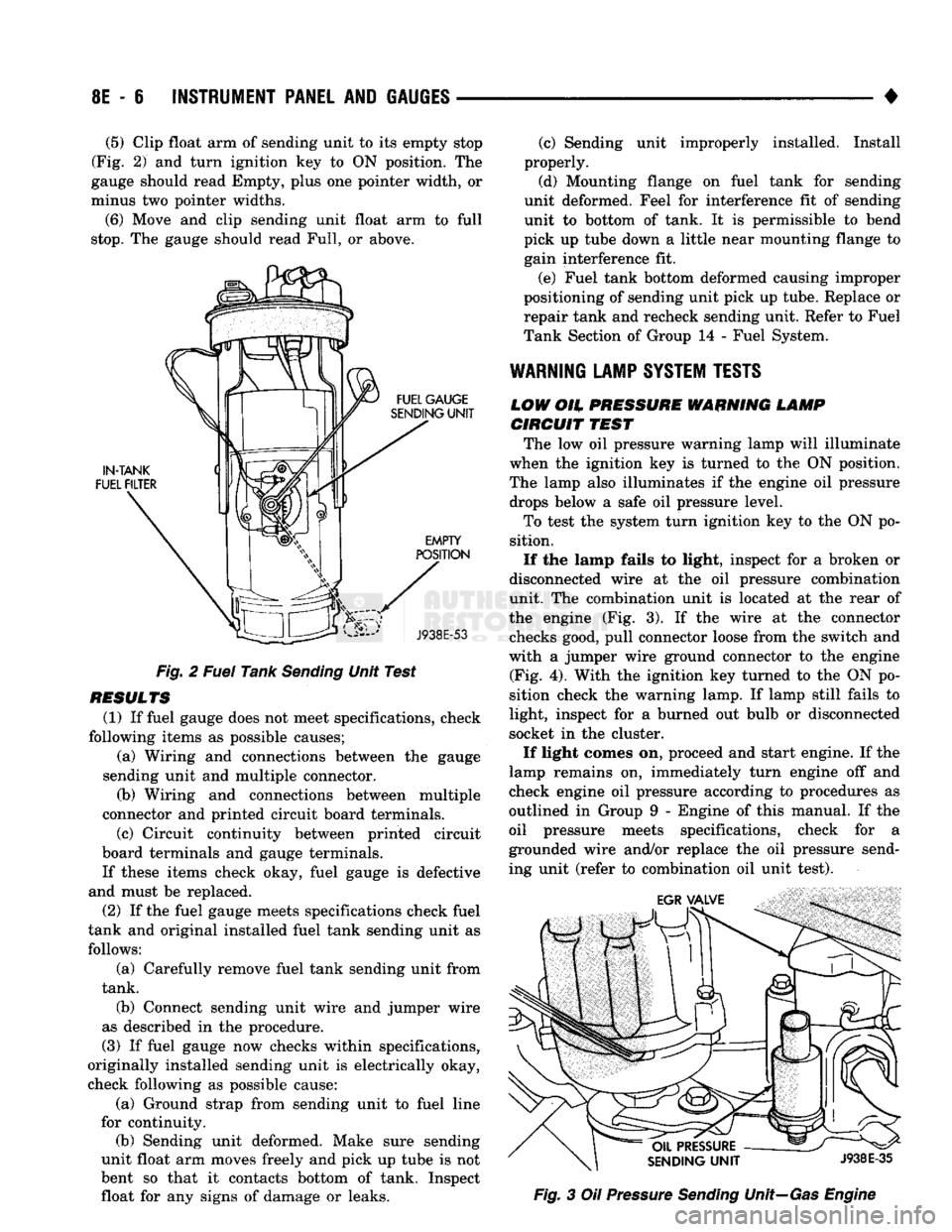

FUEL GAUGE SYSTEM DIAGNOSIS

FUEL GAUGE SYSTEM DIAGNOSIS FUEL GAUGE

DOES

NOT

READ

FULL FAULTY PRINTED

CIRCUIT BOARD FUEL GAUGE

INOPERATIVE OR ERRATIC FUEL GAUGE

INACCURATE

E

1

I

CHECK

FAULTY WIRING

OR

TANK DEFORMED

TANK

NOT

FULL COMPONENTS

CHECK

CHECK

ALL WIRING INCLUDING GROUND

i

FAULTY FUEL GAUGE SENDING

UNIT

i 1

FUEL

C

1

DOES

1

READ

1

pAUGE

I

>N0?

1

EMPTY

1

r

TANK

NOT

EMPTY

CHECK

PROPER

ALIGNMENT

OF PICKUP AND

SENDER

ASSEMBLY.

REFER

TO

GROUP

14

FAULTY FUEL

GAUGE

J908E-74

Page 387 of 1502

8E

- 6

INSTRUMENT PANEL

AND

GAUGES

•

(5)

Clip float arm of sending unit to its empty stop

(Fig. 2) and turn ignition key to ON position. The

gauge should read Empty, plus one pointer width, or

minus two pointer widths.

(6) Move and clip sending unit float arm to full

stop.

The gauge should read Full, or above.

Fig. 2 Fuel Tank Sending Unit Test

RESULTS (1) If fuel gauge does not meet specifications, check

following items as possible causes; (a) Wiring and connections between the gauge

sending unit and multiple connector. (b) Wiring and connections between multiple

connector and printed circuit board terminals.

(c) Circuit continuity between printed circuit

board terminals and gauge terminals.

If these items check okay, fuel gauge is defective

and must be replaced.

(2) If the fuel gauge meets specifications check fuel

tank and original installed fuel tank sending unit as follows:

(a) Carefully remove fuel tank sending unit from

tank.

(b) Connect sending unit wire and jumper wire

as described in the procedure.

(3) If fuel gauge now checks within specifications,

originally installed sending unit is electrically okay,

check following as possible cause:

(a) Ground strap from sending unit to fuel line

for continuity. (b) Sending unit deformed. Make sure sending

unit float arm moves freely and pick up tube is not

bent so that it contacts bottom of tank. Inspect float for any signs of damage or leaks. (c) Sending unit improperly installed. Install

properly.

(d) Mounting flange on fuel tank for sending

unit deformed. Feel for interference fit of sending

unit to bottom of tank. It is permissible to bend

pick up tube down a little near mounting flange to gain interference fit.

(e) Fuel tank bottom deformed causing improper

positioning of sending unit pick up tube. Replace or

repair tank and recheck sending unit. Refer to Fuel

Tank Section of Group 14 - Fuel System.

WARNING

LAMP

SYSTEM

TESTS

LOW

OH.

PRESSURE WARNING LAMP CIRCUIT

TEST

The low oil pressure warning lamp will illuminate

when the ignition key is turned to the ON position.

The lamp also illuminates if the engine oil pressure drops below a safe oil pressure level.

To test the system turn ignition key to the ON po

sition.

If the lamp fails to light, inspect for a broken or

disconnected wire at the oil pressure combination

unit. The combination unit is located at the rear of

the engine (Fig. 3). If the wire at the connector checks good, pull connector loose from the switch and

with a jumper wire ground connector to the engine (Fig. 4). With the ignition key turned to the ON po

sition check the warning lamp. If lamp still fails to

light, inspect for a burned out bulb or disconnected

socket in the cluster.

If light comes on, proceed and start engine. If the

lamp remains on, immediately turn engine off and

check engine oil pressure according to procedures as

outlined in Group 9 - Engine of this manual. If the

oil pressure meets specifications, check for a

grounded wire and/or replace the oil pressure send

ing unit (refer to combination oil unit test). Fig. 3 Oil Pressure Sending Unit—Gas Engine

Page 390 of 1502

INSTRUMENT

PANEL

AND

GAUGES

8E - S

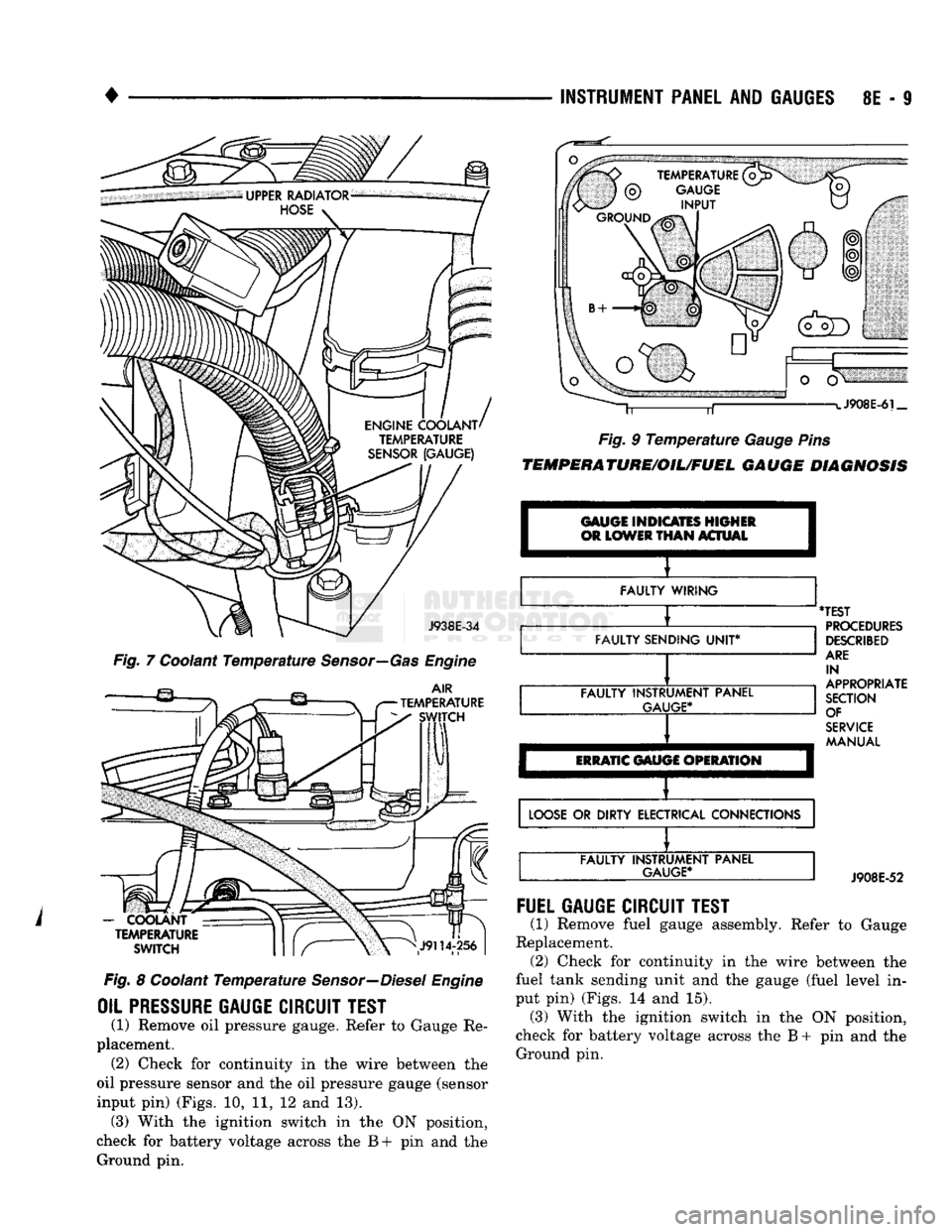

J938E-34

Fig. 7 Coolant Temperature Sensor—Gas Engine

AIR

TEMPERATURE SWITCH

-

COOLANT TEMPERATURE

SWITCH

Fig. 8 Coolant Temperature Sensor—Diesel Engine

OIL PRESSURE

GAUGE

CIRCUIT

TEST

(1) Remove oil pressure gauge. Refer to Gauge Re

placement. (2) Check for continuity in the wire between the

oil pressure sensor and the oil pressure gauge (sensor

input pin) (Figs. 10, 11, 12 and 13). (3) With the ignition switch in the ON position,

check for battery voltage across the B+ pin and the Ground pin. J908E-6i_

Fig. 9 Temperature Gauge Pins

TEMPERATURE/OIL/FUEL

GAUGE

DIAGNOSIS

GAUGE INDICATES HIGHER

OR

LOWER

THAN

ACTUAL I

FAULTY WIRING

FAULTY SENDING

UNIT*

FAULTY INSTRUMENT PANEL

GAUGE*

ERRATIC

GAUGE OPERATION

'TEST

PROCEDURES

DESCRIBED

ARE

IN

APPROPRIATE

SECTION OF

SERVICE

MANUAL

LOOSE

OR DIRTY ELECTRICAL CONNECTIONS FAULTY INSTRUMENT PANEL

GAUGE*

J908E-52

FUEL

GAUGE

CIRCUIT

TEST

(1) Remove fuel gauge assembly. Refer to Gauge

Replacement. (2) Check for continuity in the wire between the

fuel tank sending unit and the gauge (fuel level in

put pin) (Figs. 14 and 15). (3) With the ignition switch in the ON position,

check for battery voltage across the B + pin and the Ground pin.

Page 391 of 1502

8E

- 10

INSTRUMENT

PANEL

AND

GAUGES

GROUND

OIL

PRESSURE

SENSOR

INPUT

J908E-70

Fig.

10 Oil Pressure

Sending

Unit—Gas Engine

STEERING

PUMP

ENGINE

BLOCK

J9119-74

Fig.

11 Oil Pressure

Sending

Unit—Diesel Engine

SENDING

UNIT

(GAUGE)

SWITCH

(LIGHT)

898E-2

Fig.

12 Combination Oil Unit Terminals

VOLTAGE

GAUGE

CIRCUIT

TEST

(1) Remove voltage gauge. Refer to Gauge Replace

ment.

Fig.

13 Oil Pressure

Gauge

Pins

r— FUEL

PUMP

SUPPLY

0 INPUT TO

GAUGE

-SENDING

UNIT

GROUND

-FUEL

PUMP

GROUND

J928E-49

Fig.

14 Fuel Tank

Sending

Connector Terminals

FUEL

GAUGE

INPUT

^

GROUND

y

J908E-71

Fig.

15 Fuel

Gauge

Pins

(2) With the ignition switch in the ON position,

check for battery voltage across the B+ pin and the Ground pin (Fig. 16).

The instrument panel voltmeter indicates elec

trical system battery voltage.

SPEEDOMETER

(1) Remove speedometer assembly. Refer to Gauge

Replacement.

Page 394 of 1502

INSTRUMENT PANEL

AND

GAUGES

8E - 13

INSTRUMENT

PANEL MAP LAMP

BRACKET

HEADLAMP

SWITCH

CLUSTER

ASSEMBLY

HEADLAMP

SWITCH

MOUNTING

NUT CARGO LAMP

SWITCH

BEZEL

AND

APPLIQUE

HEADLAMP

KNOB

AND

STEM

BRACKET-AAAP LAMP

MOUNTING

Fig.

2 Instrument

Panel

(6) Position lower steering cover and install 4

screws.

(7)

Install bezel.

(8)

Remove protective cover from steering column.

(9) Connect negative cable to battery. (10) Check to see that all instruments are func

tioning properly.

PRINTED CIRCUIT BOARD

A visual inspection of the conductors should be

made for cracks or damaged circuits. If no visual

damage is evident, each circuit should be tested for continuity with an ohmmeter or a test light. Should an open circuit be detected, the printed circuit board

should be replaced.

REMOVAL (FIG. 3J (1) Remove instrument cluster. See cluster re

moval.

(2)

Remove lamp socket assemblies.

(3) Remove gauge mounting screws and remove

gauges.

(4) Remove printed circuit board mounting screws.

(5)

Remove printed circuit board from cluster hous

ing.

HEADLAMP

SWITCH

BEZEL

CLUSTER MASK AND LENS

J928E-46

Cluster

and

Switches

INSTALLATION

CAUTION:

Do not overtighten mounting

screws

or

damage

to circuit

board

and/or

cluster

housing

will

occur.

(1) Position printed circuit board on cluster hous

ing, install mounting screws and tighten.

(2)

Install gauges.

(3) Install lamp socket assemblies. Be sure illumi

nation lamp diffusers are installed. (4) Install instrument cluster.

FUEL GAUGE

TEMPERATURE

GAUGE VOLTAGE GAUGE

OIL

PRESSURE

GAUGE

It is not necessary to remove instrument clus

ter from vehicle for gauge replacement. When removing gauge assemblies (Fig. 4) from

cluster, gauge must be pulled straight out, not

twisted, or damage to gauge pin and/or printed cir cuit board may result. (1) Disconnect negative cable from battery.

(2)

Remove bezel. Refer to Cluster Bezel Removal. (3) Remove cluster mask and lens. Refer to Cluster

Mask and Lens Removal.

Page 395 of 1502

8E

- 14

INSTRUMENT

PANEL

AND

GAUGES

•

VOLTAGE

GAUGE

Fig. 3 instrument Cluster Printed Circuit Board

SPEEDOMETER OIL

PRESSURE

GAUGE

TEMPERATURE GAUGE

FUEL

GAUGE

Fig. 4 Cluster With Mask Removed

J908E-69

(4)

Remove gauge mounting screws.

(5) Pull gauge rearward to remove.

For Installation, reverse Removal procedures.

SPEEDOMETER/ODOMETER

It is not necessary to remove instrument clus

ter from vehicle for speedometer replacement. When removing speedometer (Fig. 4) from cluster,

gauge must be pulled straight out, not twisted, or

damage to gauge pin and/or printed circuit board

may result. (1) Disconnect negative cable from battery.

(2) Remove bezel. Refer to Cluster Bezel Removal.

(3) Remove cluster mask and lens. Refer to Cluster

Mask and Lens Removal. (4) Remove mounting screws retaining speedome

ter/odometer to housing.

(5) Pull speedometer/odometer rearward to remove.

For Installation, reverse Removal procedures.

Page 396 of 1502

•

INSTRUMENT PANEL

AND

GAUGES

8E - 15

PRND21 INDICATOR

REMOVAL

(1) Remove bezel. Refer to Cluster Bezel Removal.

(2)

Remove cluster mask and lens. Refer to Cluster

Mask and Lens Removal. (3) Remove cluster assembly. Refer to Instrument

Cluster Removal. (4) Remove screws attaching PRND21 mechanism

to cluster housing.

(5)

Remove PRND21 mechanism.

INSTALLATION (1) Position PRND21 mechanism to cluster hous

ing. (2) Install mounting screws.

(3)

Install cluster assembly. (4) Install mask-lens.

(5)

Install bezel.

LAMP BULBS

CLUSTER ILLUMINATION LAMPS TURN SIGNAL INDICATOR LAMPS

LOW OIL PRESSURE INDICATOR LAMP

HIGH BEAM INDICATOR LAMP CHECK ENGINE LAMP

SEAT BELT WARNING LAMP

REMOVAL (1) Disconnect negative cable from battery.

(2) Remove instrument cluster. See cluster re

moval.

(3)

Twist lamp socket assembly and remove from

printed circuit board. (4) Remove bulb from socket.

INSTALLATION (1) Install bulb into socket.

(2) Install socket assembly into printed circuit

board.

(3)

Position cluster into place in panel. See cluster

installation. (4) Connect battery negative cable.

LAMP BULB REPLACEMENT—MESSAGE CENTER

REMOVAL (1) Disconnect battery negative cable.

(2) Remove instrument cluster bezel assembly. Re

fer to Instrument Cluster removal.

(3)

Twist lamp socket assembly and remove from

printed circuit board. (4) Remove bulb from socket.

INSTALLATION (1) Install bulb into socket assembly. (2) Install lamp socket assembly into printed cir

cuit board.

(3)

Install Instrument Cluster bezel assembly to

instrument panel. Refer to Instrument Cluster instal

lation.

(4) Connect negative cable from battery.

FOUR WHEEL DRIVE INDICATOR LAMP (1) Pull bulb and socket assembly from rear of

housing. (2) Remove bulb from socket.

(3)

Reverse removal procedures to install.

SPECIFICATIONS

Fuel

Gauge Calibration

Mntar Position Resistance

Empty Graduation 90

ohms

± 3

ohms

Empty Stop

Greater

than

96.5 ohms

Full

Graduation 12 ohm

± 3

ohms

Full

Stop

Less

than

8

ohms

1/2

45.3 ohms

± 3

ohms

Temperature

Gauge

Calibration

Pointer

Position Resistance

Cold Graduation 655 ohms

Hot Graduation 64 ohms

Oil Pressure Gauge Calibration

Pointer

Position Resistance

Low Graduation 100 ohms

High Graduation 12 ohms

J908E-58

Page 454 of 1502

•

LAMPS

8L - 11

BULB

APPLICATION

GENERAL

INFORMATION

The following Bulb Application Table lists

the

lamp title

on the

left side

of the

column

and

part

number

on the

right.

CAUTION:

Do not use

bulbs

that

have

a

higher

can

dle power than

the

bulb

listed

in the

Bulb

Applica

tion Table.

Damage

to

lamp

can

result.

EXTERIOR LAMPS

Auxiliary Turn Signal (Snow Plow) 2057

Auxiliary Headlamps (Snow Plow) .6054

Back-up....................... .......1156 Cargo Lamp..

922

Clearance Lamps

194

Front Side Marker

168

Headlamp/Sealed Beam .6052

License Plate

168

Park/Turn Signal 2057

TaiyStop/Turn Signal ...2057

INTERIOR LAMPS

DIMMER CONTROLLED LAMPS Service procedures

for

most

of the

lamps

in the in

strument panel

are

located

in

Group

8E,

Instrument

Panel

and

Gauges. Some components have lamps

that

can

only

be

serviced

by an

Authorized Service Center (ASC). These components must

be

removed

from

the

vehicle

for

service. Contact local dealer

for

location

of

nearest

ASC.

A/C Heater Control

158

Ash Receiver

..158

Gear Shift Selector...........................................PC194

Heater Control

158

Instrument Cluster.. PC 194

Radio

ASC

Snow Plow Control

.158

INDICATOR LAMPS Service procedures

for

most

of the

lamps

in the in

strument panel,

and

switches

are

located

in

Group

8E,

Instrument Panel

and

Gauges. Anti-lock Brake PC194

Brake Warning PC194 Check Engine PC194

Engine

Oil

Pressure

158

Fasten Seat Belts.. PC 194 Four Wheel Drive ....158

Hazard Flasher

194

High Beam PC194

Low Fuel....... JPC194

Maintenance Required PC 194

Transmission Temperature ..PC 194 Turn Signal PC194

NON-DIMMING LAMPS Service procedures

for

most

of the

lamps

in the

fol

lowing list

can be

found

in

Group

23,

Body.

Dome

1004

Engine Compartment ...105 Glove Compartment....

1891

Ignition Lock

ASC

Reading Lamp

912