wheel size DODGE TRUCK 1993 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 6 of 1502

INTRODUCTION

INTRODUCTION

DESIGNATIONS,

LABELS/PLATES/DECALS,

CODES

AND DIMENSIONS/WEIGHTS .

CONTENTS

page

MEASUREMENT

AND TORQUE

... 1 SPECIFICATIONS

page

. 11

DESIGNATIONS, LABELS/PLATES/DECALS, CODES

AND

DIMENSIONS/WEIGHTS

INDEX

page

Engine

and

Transmission/Transfer

Case

Identification

2

Engine/Transmission/GVWR

4

Equipment

Identification

Plate

3

International

Vehicle Control

and

Display

Symbols

10

Major Component

Identification 3

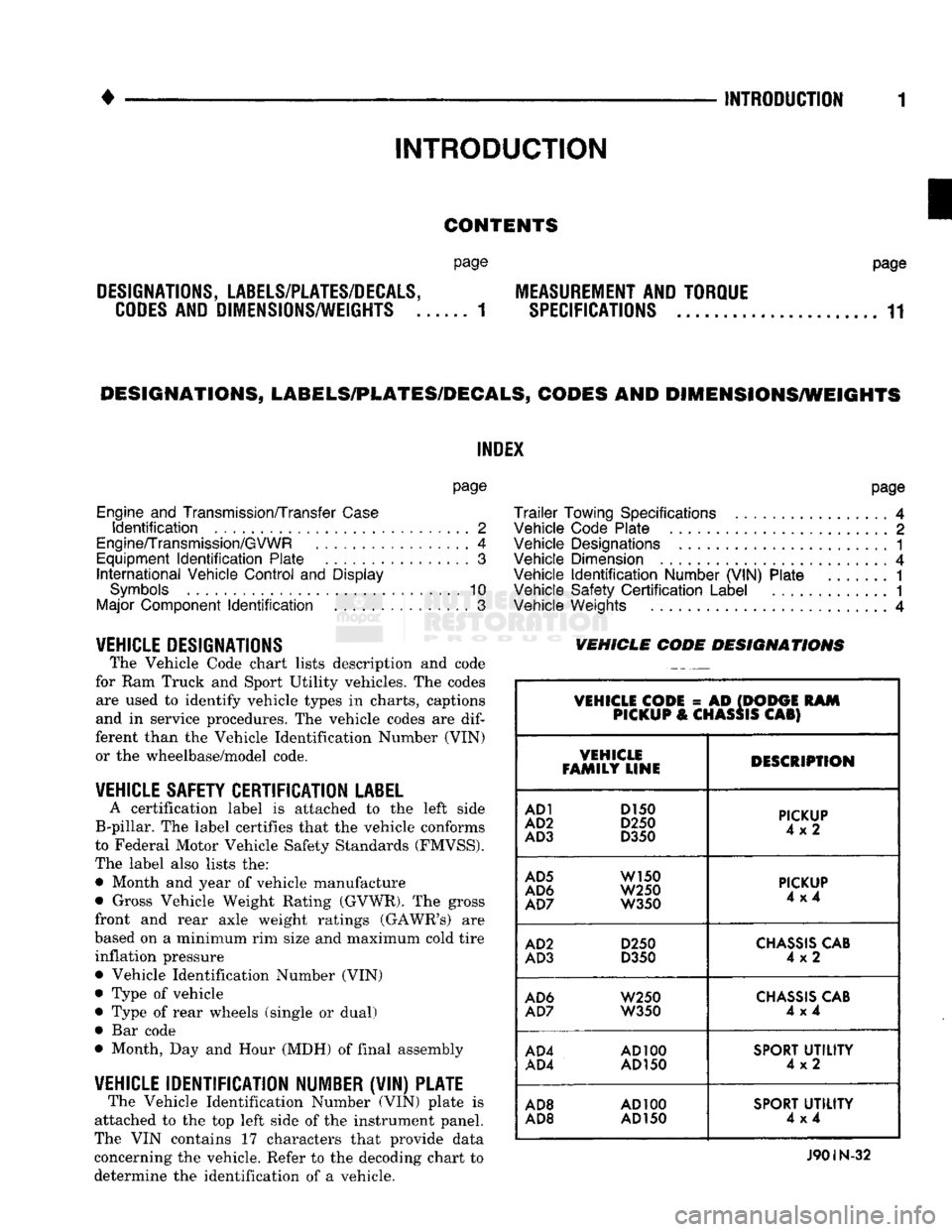

VEHICLE DESIGNATIONS The Vehicle Code chart lists description and code

for Ram Truck and Sport Utility vehicles. The codes are used to identify vehicle types in charts, captions

and in service procedures. The vehicle codes are

dif

ferent than the Vehicle Identification Number (VIN) or the wheelbase/model code.

VEHICLE SAFETY CERTIFICATION

LABEL

A certification label is attached to the left side

B-pillar. The label certifies that the vehicle conforms

to Federal Motor Vehicle Safety Standards (FMVSS).

The label also lists the: • Month and year of vehicle manufacture

• Gross Vehicle Weight Rating (GVWR). The gross

front and rear axle weight ratings (GAWR's) are

based on a minimum rim size and maximum cold tire inflation pressure Vehicle Identification Number (VIN)

Type of vehicle

Type of rear wheels (single or dual) Bar code

Month, Day and Hour (MDH) of final assembly

VEHICLE IDENTIFICATION NUMBER (VIN) PLATE The Vehicle Identification Number (VIN) plate is

attached to the top left side of the instrument panel.

The VIN contains 17 characters that provide data

concerning the vehicle. Refer to the decoding chart to

determine the identification of a vehicle.

page

Trailer

Towing Specifications

4

Vehicle Code Plate

2

Vehicle Designations

1

Vehicle Dimension

4

Vehicle

Identification

Number (VIN) Plate

1

Vehicle Safety

Certification

Label

............. 1

Vehicle Weights

4

VEHICLE CODE

DESIGNATIONS

VEHICLE CODE

= AD

(DODGE

RAM

PICKUP

&

CHASSIS

CAB)

VEHICLE

FAMILY LINE DESCRIPTION

AD1

D150

AD2

D250

AD3

D350

PICKUP

4x2

AD5

W150

AD6

W250

AD7

W350

PICKUP

4x4

AD2

D250

AD3

D350

CHASSIS

CAB

4x2

AD6

W250

AD7

W350

CHASSIS

CAB

4x4

AD4

AD100

AD4

AD150

SPORT

UTILITY

4x2

AD8

AD100

AD8 AD

150

SPORT

UTILITY

4x4

J90IN-32

Page 56 of 1502

FRONT SUSPENSION

AND

AXLE

2 - 3

FRONT

WHEEL

ALIGNMENT

GENERAL

INFORMATION

Front wheel alignment involves

the

correct posi

tioning

of the

tire contact patch

in

relation

to the

pavement.

The

positioning

is

accomplished through

the suspension

and

steering linkage adjustments.

An

alignment

is

essential

for

efficient steering

and

direc

tional stability.

The

most important factors

of

front

end alignment

are

camber, caster

and toe

position. Routine inspection

of

the front

suspension

and

steering components

is a

good

preventative

maintenance practice.

Inspection

also

helps

to

ensure

safe operation

of the

vehicle.

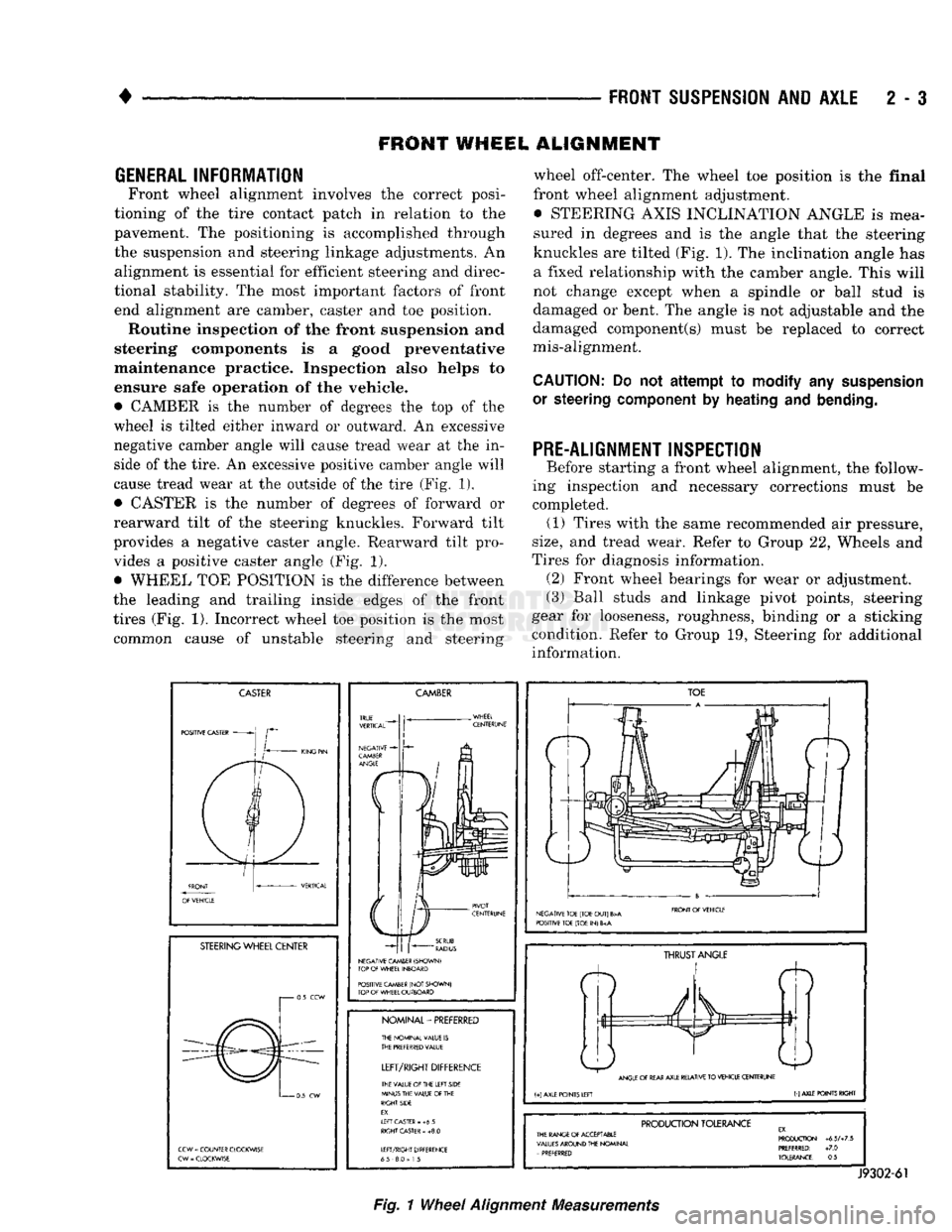

• CAMBER

is the

number

of

degrees

the top of the

wheel

is

tilted either inward

or

outward.

An

excessive

negative camber angle will cause tread wear

at the in

side

of

the tire.

An

excessive positive camber angle will

cause tread wear

at the

outside

of

the tire (Fig.

1),

• CASTER

is the

number

of

degrees

of

forward

or

rearward tilt

of the

steering knuckles. Forward tilt

provides

a

negative caster angle. Rearward tilt pro vides

a

positive caster angle

(Fig. 1).

• WHEEL

TOE

POSITION

is the

difference between

the leading

and

trailing inside edges

of the

front

tires (Fig.

1).

Incorrect wheel

toe

position

is the

most common cause

of

unstable steering

and

steering wheel off-center.

The

wheel

toe

position

is the

final

front wheel alignment adjustment. • STEERING AXIS INCLINATION ANGLE

is

mea

sured

in

degrees

and is the

angle that

the

steering

knuckles

are

tilted (Fig. 1).

The

inclination angle

has

a fixed relationship with

the

camber angle. This will

not change except when

a

spindle

or

ball stud

is

damaged

or

bent.

The

angle

is not

adjustable

and the

damaged component(s) must

be

replaced

to

correct

mis-alignment.

CAUTION:

Do not

attempt to modify

any

suspension

or steering

component

by

heating

and

bending.

PRE-ALIGNMENT INSPECTION

Before starting

a

front wheel alignment,

the

follow

ing inspection

and

necessary corrections must

be

completed.

(1)

Tires with

the

same recommended

air

pressure,

size,

and

tread wear. Refer

to

Group

22,

Wheels

and

Tires

for

diagnosis information. (2) Front wheel bearings

for

wear

or

adjustment.

(3) Ball studs

and

linkage pivot points, steering

gear

for

looseness, roughness, binding

or a

sticking

condition. Refer

to

Group

19,

Steering

for

additional information.

CASTER

POSITIVE CASTER

STEERING

WHEEL CENTER

i 0.5

CCW

0

5

CW

CCW

=

COUNTER CLOCKWISE

CW

-

CLOCKWISE

CAMBER

NEGATIVE CAMBER (SHOWN)

TOP

OF

WHEEL INBOARD

POSITIVE CAMBER

(NOT

SHOWN)

TOP

OF

WHEEL OUTBOARD

NOMINAL-PREFERRED

THE NOMINAL VALUE

IS

THE

PREFERRED

VALUE

LEFT/RIGHT

DIFFERENCE

THE VALUE

Of

THE LEFT SIDE

MINUS THE VALUE

OF

THE

RIGHT SIDE

EX.

If

FT CASTER

- +6 5

RIGHT

CASTER

»

+8.0

LEFT/RIGHT DIFFERENCE

65 8.0

=

1

5

TOE

NEGATIVE TOE (TOE

OUT)

B>A

POSITIVE TOE (TOE

IN) 6

FRONT

Of

VEHICLE

ft

THRUST

ANGLE

ANGLE

OF

REAR

AXLE RELATIVE

TO

VEHICLE CENTERUNE

(+)

AXLE POINTS LEFT

(-)

AXLE POINTS RIGHT

PRODUCTION

TOLERANCE

THE RANGE

Of

ACCEPTABLE

VALUES

AROUND THE NOMINAL

-

PREFERRED PRODUCTION

+6.5A7.5

PREFERRED:

+7.0

TOLERANCE:

0.5

J9302-61

Fig.

1

Wheel

Alignment

Measurements

Page 64 of 1502

•

FRONT

SUSPENSION

AND

AXLE

2 - 11 (2) Position the seal over the ball stud (if neces

sary, use a replacement seal). Force portion of the

seal downward on the ball stud housing with an ap

propriate size socket wrench until it is securely locked in place.

(3) Install lower suspension arm using procedure

under Lower Suspension Arm Installation.

LOWER SUSPENSION

ARM

BUSHING

REMOVAL (1) Follow procedure under Coil Spring and Lower

Suspension Arm Removal.

(2) Use an arbor press and an appropriate size

sleeve to force the original bushing from the lower

suspension arm bore.

INSTALLATION (1) Use an arbor press and an appropriate size

sleeve to force the replacement bushing into the

lower suspension arm bore. Ensure that it is com

pletely seated in the bore.

(2) Install the lower suspension arm according to in

structions provided within the installation procedure.

UPPER SUSPENSION

ARM REMOVAL (1) Raise the vehicle. Position support stands un

der the frame rail and lower the front of the hoist.

Remove the wheel/tire.

(2) Remove shock absorber, refer to above proce

dures.

(3) Install Spring Compressor DD-1278 (Fig. 5).

Tighten the nut finger-tight and then loosen it 1/2 of- a-turn.

(4) Remove the cotter pins and the ball stud nuts.

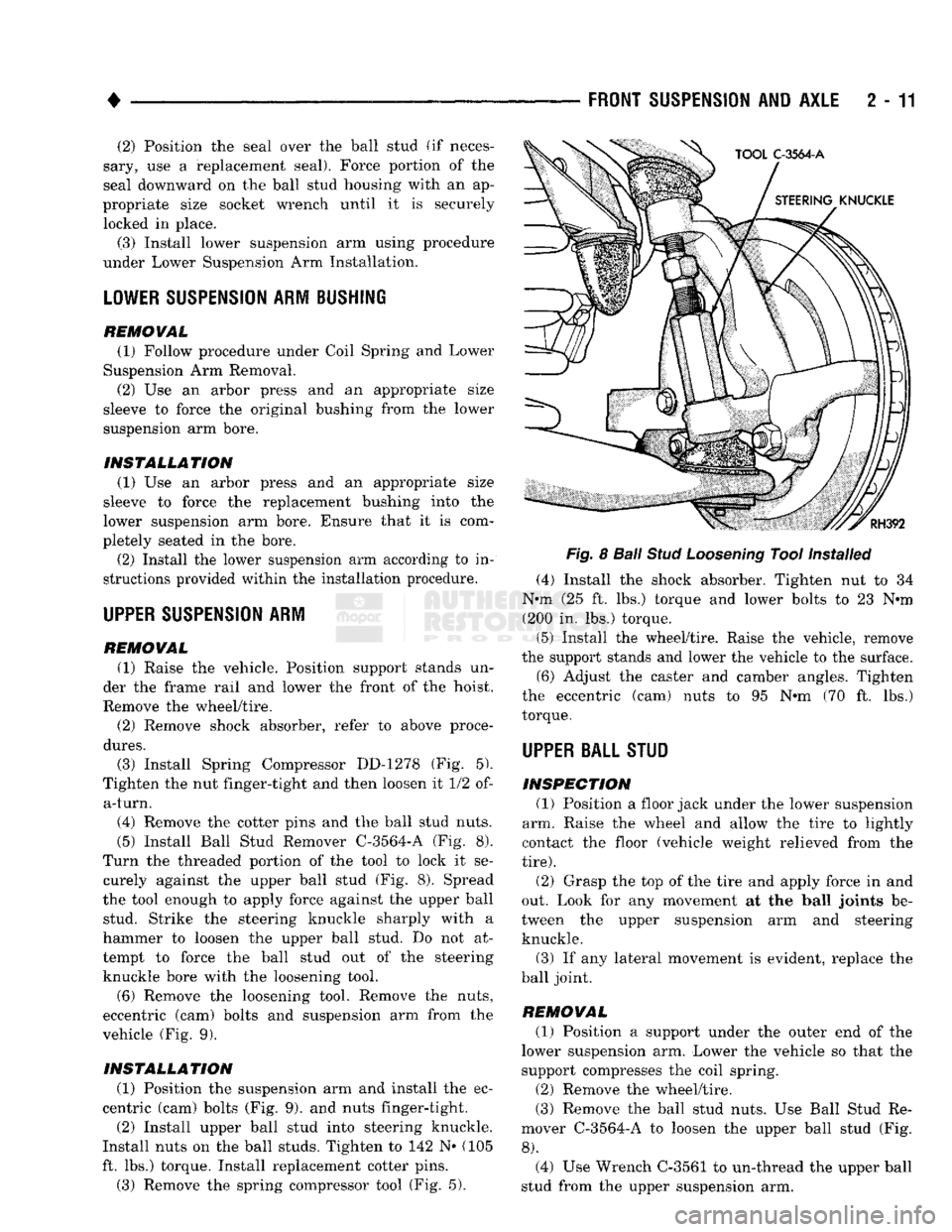

(5) Install Ball Stud Remover C^3564-A (Fig. 8).

Turn the threaded portion of the tool to lock it se curely against the upper ball stud (Fig. 8). Spread

the tool enough to apply force against the upper ball stud. Strike the steering knuckle sharply with a

hammer to loosen the upper ball stud. Do not at

tempt to force the ball stud out of the steering knuckle bore with the loosening tool.

(6) Remove the loosening tool. Remove the nuts,

eccentric (cam) bolts and suspension arm from the

vehicle (Fig. 9).

INSTALLATION (1) Position the suspension arm and install the ec

centric (cam) bolts (Fig. 9). and nuts finger-tight.

(2) Install upper ball stud into steering knuckle.

Install nuts on the ball studs. Tighten to 142 N« (105

ft. lbs.) torque. Install replacement cotter pins.

(3) Remove the spring compressor tool (Fig. 5).

Fig.

8

Ball

Stud

Loosening

Tool Installed

(4) Install the shock absorber. Tighten nut to 34

N*m (25 ft. lbs.) torque and lower bolts to 23 N*m (200 in. lbs.) torque.

(5) Install the wheel/tire. Raise the vehicle, remove

the support stands and lower the vehicle to the surface.

(6) Adjust the caster and camber angles. Tighten

the eccentric (cam) nuts to 95 N*m (70 ft. lbs.)

torque.

UPPER BALL STUD

INSPECTION (1) Position a floor jack under the lower suspension

arm. Raise the wheel and allow the tire to lightly

contact the floor (vehicle weight relieved from the

tire).

(2) Grasp the top of the tire and apply force in and

out. Look for any movement at the ball joints be

tween the upper suspension arm and steering knuckle.

(3) If any lateral movement is evident, replace the

ball joint.

REMOVAL (1) Position a support under the outer end of the

lower suspension arm. Lower the vehicle so that the

support compresses the coil spring.

(2) Remove the wheel/tire.

(3) Remove the ball stud nuts. Use Ball Stud Re

mover C-3564-A to loosen the upper ball stud (Fig.

8).

(4) Use Wrench C-3561 to un-thread the upper ball

stud from the upper suspension arm.

Page 230 of 1502

•

BRAKES

5 - 43

CAMPER

ASSEMBLY

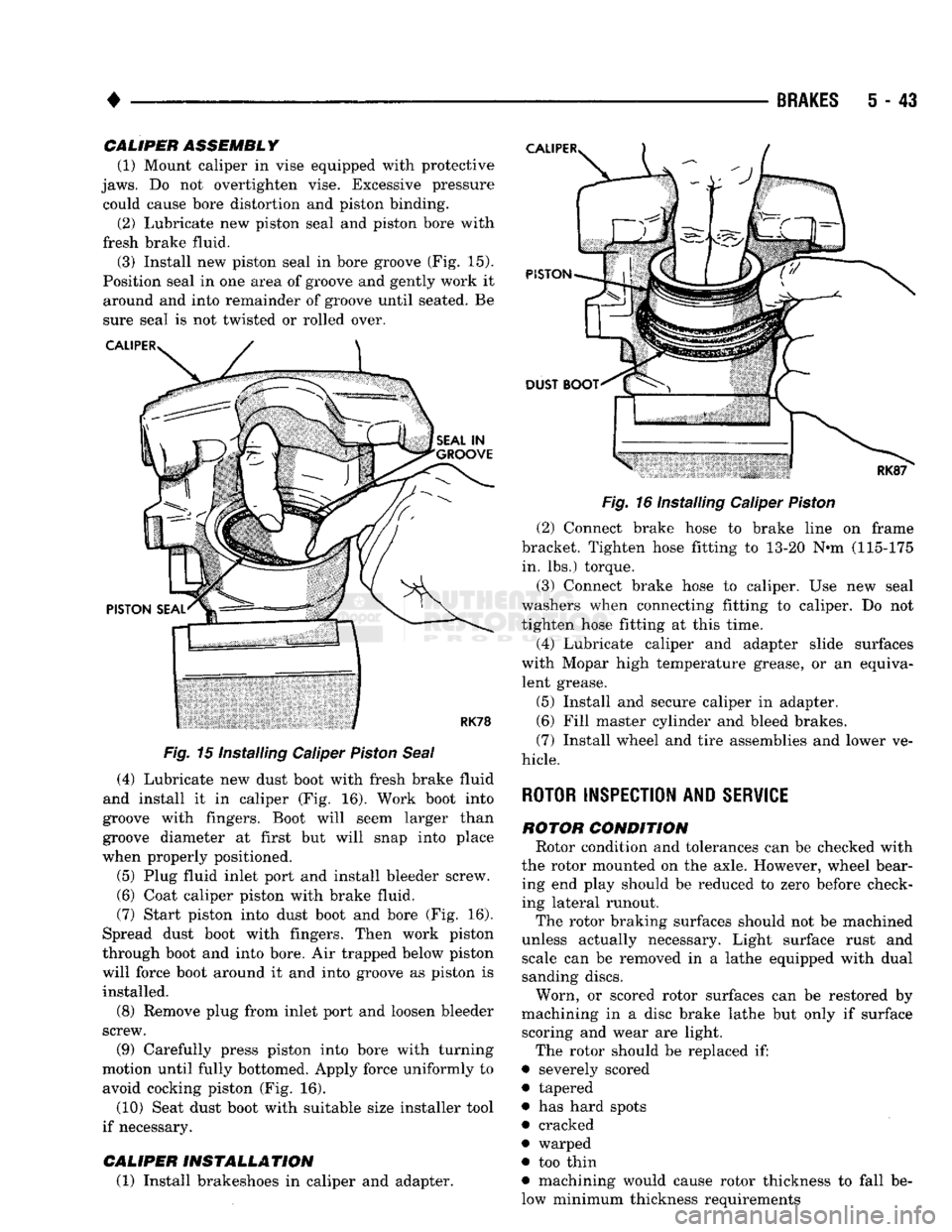

(1) Mount caliper in vise equipped with protective

jaws.

Do not overtighten vise. Excessive pressure could cause bore distortion and piston binding. (2) Lubricate new piston seal and piston bore with

fresh brake fluid. (3) Install new piston seal in bore groove (Fig. 15).

Position seal in one area of groove and gently work it around and into remainder of groove until seated. Be

sure seal is not twisted or rolled over.

Fig.

15 Installing Caliper

Piston

Seal

(4) Lubricate new dust boot with fresh brake fluid

and install it in caliper (Fig. 16). Work boot into

groove with fingers. Boot will seem larger than

groove diameter at first but will snap into place

when properly positioned.

(5) Plug fluid inlet port and install bleeder screw. (6) Coat caliper piston with brake fluid.

(7) Start piston into dust boot and bore (Fig. 16).

Spread dust boot with fingers. Then work piston

through boot and into bore. Air trapped below piston

will force boot around it and into groove as piston is installed.

(8) Remove plug from inlet port and loosen bleeder

screw.

(9) Carefully press piston into bore with turning

motion until fully bottomed. Apply force uniformly to avoid cocking piston (Fig. 16).

(10) Seat dust boot with suitable size installer tool

if necessary.

CALIPER

INSTALLATION

(1) Install brakeshoes in caliper and adapter.

Fig.

16 Installing Caliper

Piston

(2) Connect brake hose to brake line on frame

bracket. Tighten hose fitting to 13-20 N«m (115-175 in. lbs.) torque.

(3) Connect brake hose to caliper. Use new seal

washers when connecting fitting to caliper. Do not

tighten hose fitting at this time.

(4) Lubricate caliper and adapter slide surfaces

with Mopar high temperature grease, or an equiva lent grease.

(5) Install and secure caliper in adapter.

(6) Fill master cylinder and bleed brakes.

(7) Install wheel and tire assemblies and lower ve

hicle.

ROTOR INSPECTION AND

SERVICE

ROTOR

CONDITION

Rotor condition and tolerances can be checked with

the rotor mounted on the axle. However, wheel bear ing end play should be reduced to zero before check

ing lateral runout.

The rotor braking surfaces should not be machined

unless actually necessary. Light surface rust and scale can be removed in a lathe equipped with dual

sanding discs.

Worn, or scored rotor surfaces can be restored by

machining in a disc brake lathe but only if surface scoring and wear are light.

The rotor should be replaced if:

• severely scored

• tapered

• has hard spots

• cracked

• warped

• too thin

• machining would cause rotor thickness to fall be

low minimum thickness requirements

Page 235 of 1502

5

- 48

BRAKES

•

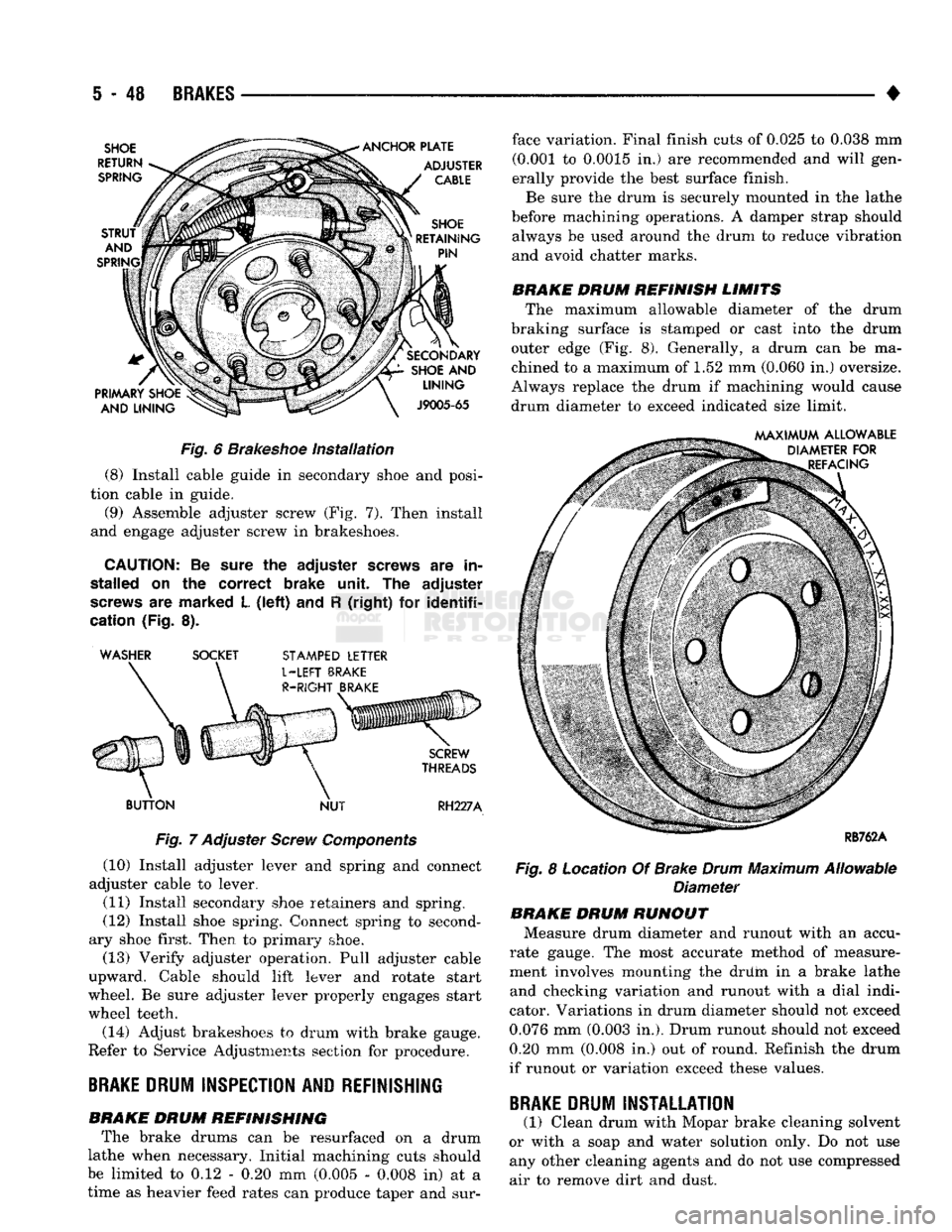

Fig.

6

Brakeshoe

Installation

(8) Install cable guide in secondary shoe and posi

tion cable in guide. (9) Assemble adjuster screw (Fig. 7). Then install

and engage adjuster screw in brakeshoes.

CAUTION:

Be sure the

adjuster

screws

are in

stalled

on the

correct

brake unit. The

adjuster

screws

are marked L

(left)

and R

(right)

for

identifi

cation

(Fig. 8). ' WASHER SOCKET

STAMPED

LETTER

BUTTON

NUT

RH227A

Fig.

7 Adjuster

Screw

Components

(10) Install adjuster lever and spring and connect

adjuster cable to lever.

(11) Install secondary shoe retainers and spring.

(12) Install shoe spring. Connect spring to second

ary shoe first. Then to primary shoe. (13) Verify adjuster operation. Pull adjuster cable

upward. Cable should lift lever and rotate start

wheel. Be sure adjuster lever properly engages start

wheel teeth.

(14) Adjust brakeshoes to drum with brake gauge.

Refer to Service Adjustments section for procedure.

BRAKE

DRUM

INSPECTION

AND

REFINISHING

BRAKE DRUM REFINISHING The brake drums can be resurfaced on a drum

lathe when necessary. Initial machining cuts should

be limited to 0.12 - 0.20 mm (0.005 - 0.008 in) at a

time as heavier feed rates can produce taper and sur face variation. Final finish cuts of 0.025 to 0.038 mm

(0.001 to 0.0015 in.) are recommended and will gen

erally provide the best surface finish.

Be sure the drum is securely mounted in the lathe

before machining operations. A damper strap should always be used around the drum to reduce vibration

and avoid chatter marks.

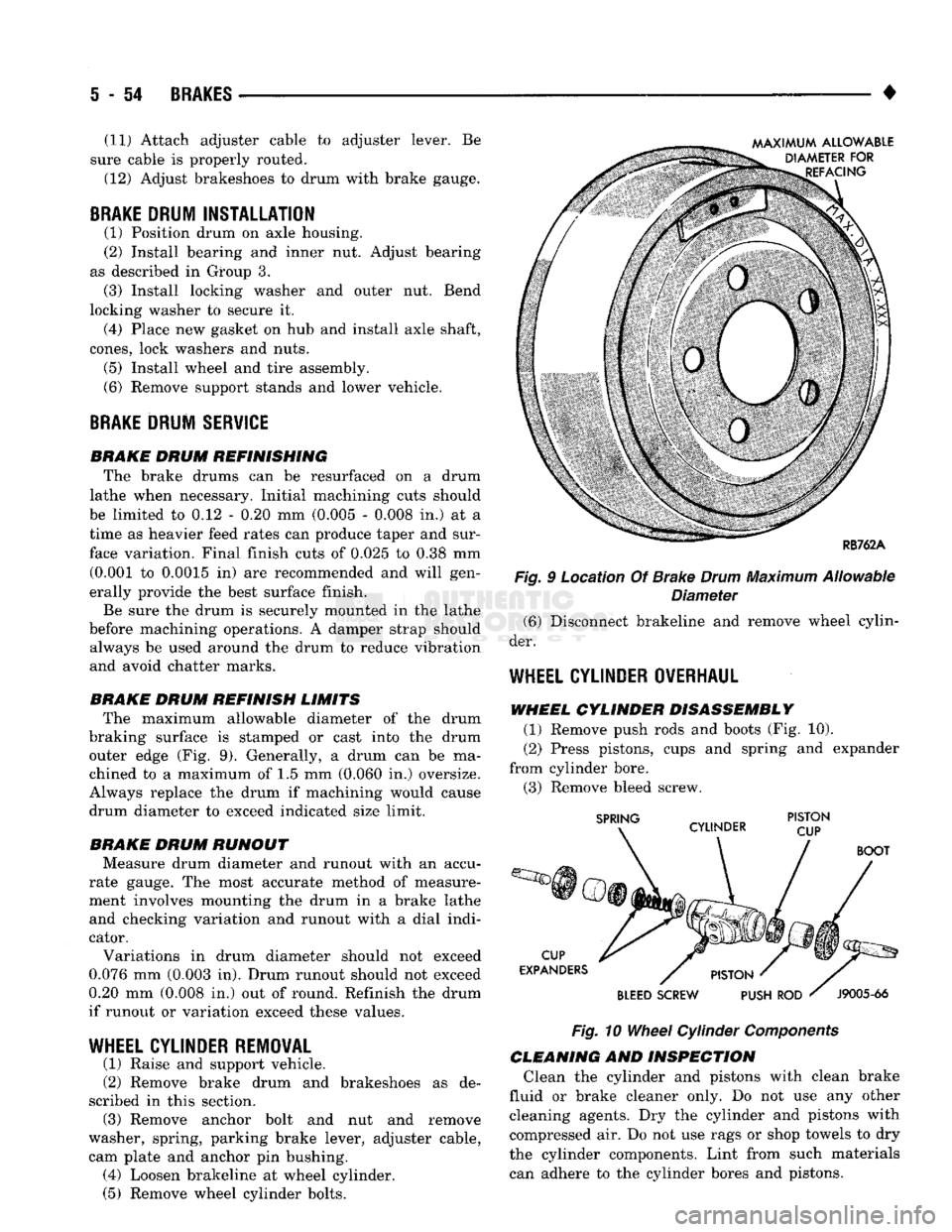

BRAKE DRUM REFINISH LIMITS The maximum allowable diameter of the drum

braking surface is stamped or cast into the drum outer edge (Fig. 8). Generally, a drum can be ma

chined to a maximum of 1.52 mm (0.060 in.) oversize.

Always replace the drum if machining would cause

drum diameter to exceed indicated size limit.

Fig.

8 Location Of Brake

Drum

Maximum Allowable

Diameter BRAKE DRUM RUNOUT

Measure drum diameter and runout with an accu

rate gauge. The most accurate method of measure

ment involves mounting the driim in a brake lathe

and checking variation and runout with a dial indi

cator. Variations in drum diameter should not exceed

0.076 mm (0.003 in.). Drum runout should not exceed 0.20 mm (0.008 in.) out of round. Refinish the drum

if runout or variation exceed these values.

BRAKE

DRUM

INSTALLATION

(1) Clean drum with Mopar brake cleaning solvent

or with a soap and water solution only. Do not use any other cleaning agents and do not use compressed

air to remove dirt and dust.

Page 241 of 1502

5

- 54

BRAKES

• (11) Attach adjuster cable to adjuster lever. Be

sure cable is properly routed.

(12) Adjust brakeshoes to drum with brake gauge.

BRAKE

DRUM INSTALLATION

(1) Position drum on axle housing.

(2) Install bearing and inner nut. Adjust bearing

as described in Group 3. (3) Install locking washer and outer nut. Bend

locking washer to secure it. (4) Place new gasket on hub and install axle shaft,

cones,

lock washers and nuts. (5) Install wheel and tire assembly.

(6) Remove support stands and lower vehicle.

BRAKE

DRUM

SERVICE

BRAKE DRUM REFINISHING The brake drums can be resurfaced on a drum

lathe when necessary. Initial machining cuts should

be limited to 0.12 - 0.20 mm (0.005 - 0.008 in.) at a time as heavier feed rates can produce taper and sur

face variation. Final finish cuts of 0.025 to 0.38 mm (0.001 to 0.0015 in) are recommended and will gen

erally provide the best surface finish.

Be sure the drum is securely mounted in the lathe

before machining operations. A damper strap should always be used around the drum to reduce vibration

and avoid chatter marks.

BRAKE DRUM REFINISH LIMITS The maximum allowable diameter of the drum

braking surface is stamped or cast into the drum outer edge (Fig. 9). Generally, a drum can be ma

chined to a maximum of 1.5 mm (0.060 in.) oversize.

Always replace the drum if machining would cause

drum diameter to exceed indicated size limit.

BRAKE DRUM RUNOUT Measure drum diameter and runout with an accu

rate gauge. The most accurate method of measure

ment involves mounting the drum in a brake lathe and checking variation and runout with a dial indi

cator.

Variations in drum diameter should not exceed

0.076 mm (0.003 in). Drum runout should not exceed

0.20 mm (0.008 in.) out of round. Refinish the drum

if runout or variation exceed these values.

WHEEL

CYLINDER REMOVAL

(1) Raise and support vehicle.

(2) Remove brake drum and brakeshoes as de

scribed in this section. (3) Remove anchor bolt and nut and remove

washer, spring, parking brake lever, adjuster cable, cam plate and anchor pin bushing. (4) Loosen brakeline at wheel cylinder.

(5) Remove wheel cylinder bolts. Fig. 9 Location Of Brake

Drum

Maximum Allowable

Diameter (6) Disconnect brakeline and remove wheel cylin

der.

WHEEL

CYLINDER OVERHAUL

WHEEL CYLINDER DISASSEMBLY (1) Remove push rods and boots (Fig. 10).

(2) Press pistons, cups and spring and expander

from cylinder bore. (3) Remove bleed screw.

Fig.

10

Wheel

Cylinder

Components

CLEANING AND INSPECTION Clean the cylinder and pistons with clean brake

fluid or brake cleaner only. Do not use any other cleaning agents. Dry the cylinder and pistons with

compressed air. Do not use rags or shop towels to dry

the cylinder components. Lint from such materials can adhere to the cylinder bores and pistons.

Page 256 of 1502

•

CLUTCH

6 - 3 Check condition of the clutch before installation. A

warped cover or diaphragm spring will cause grab and incomplete release or engagement.

Be careful when handling the cover and disc. Im

pact can distort the cover, diaphragm spring, release

fingers and the hub of the clutch disc.

Use an alignment tool when positioning the disc on

the flywheel. The tool prevents accidental misalign ment which could result in cover distortion and disc

damage.

A frequent cause of clutch cover distortion (and

consequent misalignment) is improper bolt tighten

ing. To avoid warping the cover, tighten the bolts al

ternately (in a diagonal pattern) and evenly (2-3

threads at a time) to specified torque.

Clutch

Housing

Misalignment And Runout Clutch housing alignment is important to proper

operation. The housing bore maintains alignment be

tween the crankshaft and transmission input shaft.

Misalignment can cause noise, incomplete clutch

release and chatter. It can also result in premature

wear of the pilot bearing, cover release fingers and

clutch disc. In severe cases, misalignment can also cause premature wear of the transmission input

shaft and bearing.

Housing face misalignment is generally caused by

incorrect seating on the engine or transmission, loose

housing bolts, missing alignment dowels or housing damage. Infrequently, misalignment may also be

caused by housing mounting surfaces that are not

parallel. If housing misalignment is suspected, housing bore

and face runout can be checked with a dial indicator

as described in the following two procedures:

MEASURING

CLUTCH HOUSING BORE

RUNOUT

(1) Remove the clutch housing and strut.

(2) Remove the clutch cover and disc.

(3) Replace one of the flywheel bolts with a 7/16-20

threaded rod that is 10 in. (25.4 cm) long (Fig. 1).

The rod will be used to mount the dial indicator.

(4) Remove the release fork from the clutch hous

ing. (5) Reinstall the clutch housing. Tighten the hous

ing bolts nearest the alignment dowels first. (6) Mount the dial indicator on the threaded rod

and position the indicator plunger on the surface of

the clutch housing bore (Fig. 2).

(7) Rotate the crankshaft until the indicator

plunger is at the top center of the housing bore. Zero the indicator at this point.

(8) Rotate the crankshaft and record the indicator

readings at eight points (45° apart) around the bore (Fig. 3). Repeat the measurement at least twice for

accuracy. (9) Subtract each reading from the one 180° oppo

site to determine magnitude and direction of runout.

Refer to Figure 3 and following example.

Bore runout example: 0.000 - (-0.007) = 0.007 in. + 0.002 - (-0.010) = 0.012 in.

+ 0.004 - (-0.005) = 0.009 in.

-0.001 -

(

+ 0.001) = -0.002 in. (= 0.002 inch)

In the above example, the largest difference is

0.012 in. and is called the total indicator reading

(TIR).

This means that the housing bore is offset

from the crankshaft centerline by 0.006 in. (which is 1/2 of 0.012 in.).

On gas engines, the acceptable maximum TIR for

housing bore runout is 0.010 inch. If measured TIR is more than 0.010 in. (as in the example), bore runout

will have to be corrected with offset dowels. Offset dowels are available in 0.007, 0.014 and 0.021 in.

sizes for this purpose (Fig. 4). Refer to Correcting

Housing Bore Runout for dowel installation.

On diesel engines, the acceptable maximum

TIR for housing bore runout is 0.015 inch. How

ever, unlike gas engines, offset dowels are not available to correct runout on diesel engines. If

bore runout exceeds the stated maximum on a diesel engine, it may be necessary to replace ei

ther the clutch housing, or transmission adapter

plate.

CORRECTING CLUTCH HOUSING BORE

RUNOUT

(GAS

ENGINE

ONLY)

On gas engine vehicles, clutch housing bore runout

is corrected with offset dowels. However, if bore

runout exceeds 0.015 in. TIR on a diesel equipped model, the clutch housing, or transmission adapter

plate may have to be replaced. Offset dowels are not available for diesel models.

The dial indicator reads positive when the plunger

moves inward (toward indicator) and negative when it moves outward (away from indicator). As a result,

the lowest or most negative reading determines the

direction of housing bore offset (runout).

In the sample readings shown in Figure 3 and in

step (7) above, the bore is offset toward the 0.010

inch reading. To correct this, remove the housing and

original dowels. Then install the new offset dowels in

the direction needed to center the bore with the crankshaft centerline.

In the example, TIR was 0.012 inch. The dowels

needed for correction would have an offset of 0.007

in. (Fig. 4).

Install the dowels with the slotted side facing out

so they can be turned with a screwdriver. Then in

stall the housing, remount the dial indicator and

check bore runout again. Rotate the dowels until the

TIR is less than 0.010 in. if necessary.

If a TIR of 0.053 in. or greater is encountered, it

may be necessary to replace the clutch housing.

Page 258 of 1502

•

CLUTCH

6 - 5

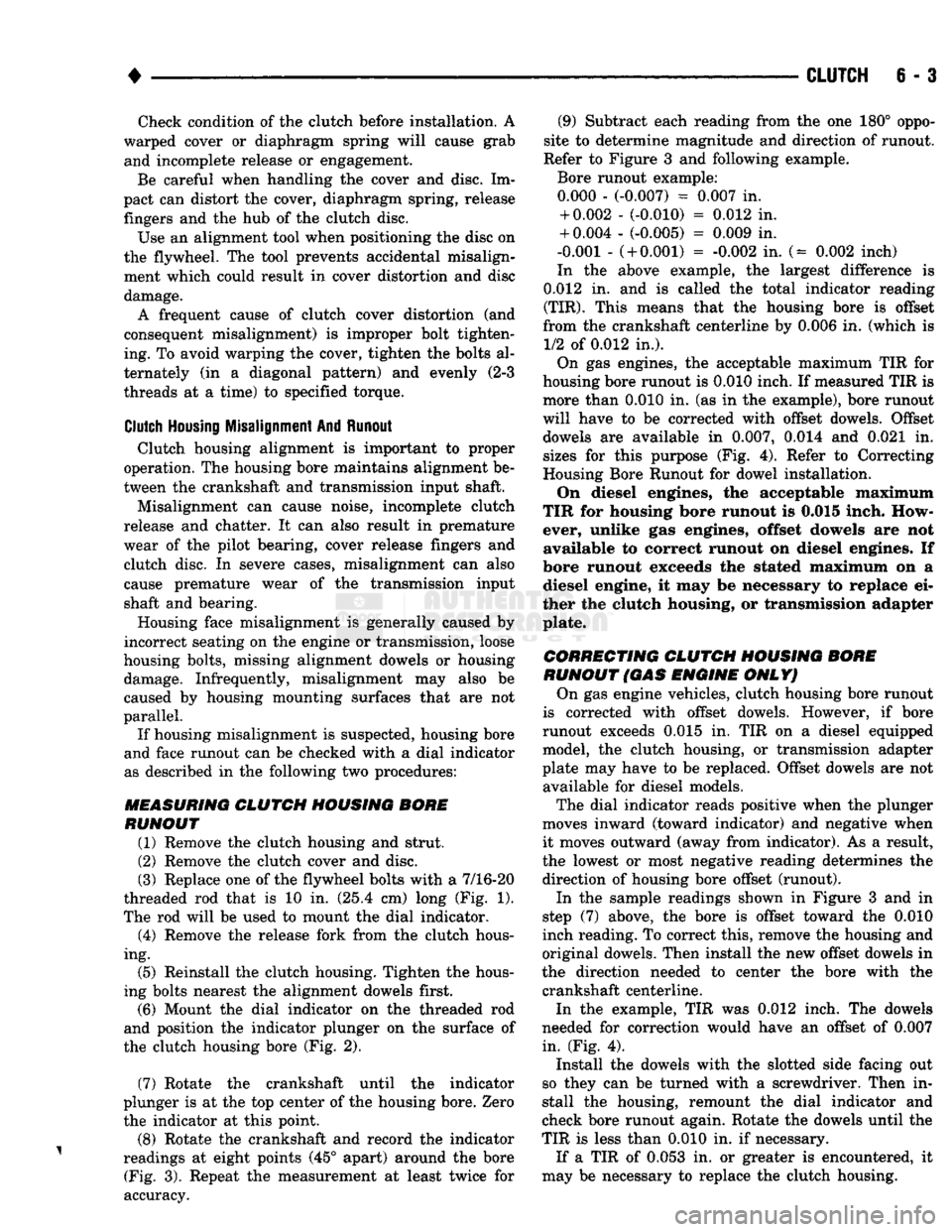

INDICATOR

PLUNGER

DIAL INDICATOR

CLUTCH

HOUSING

FACE

INDICATOR MOUNTING

„

STUD OR ROD

J9006-29

Fig.

5

Measuring

Clutch

Housing

Face

Runout

+

.009 CLUTCH

HOUSING

FACE

CIRCLE

(AT RIM

OF BORE)

,004

(SAMPLE

READINGS)

J9006-30

Fig.

6

Housing

Face Measurement

Points

And

Sample

Readings

INSTALLATION

METHODS

AND

PARTS

USAGE

Distortion of clutch components during installation

and the use of non-standard components are addi

tional causes of clutch malfunction.

Improper clutch cover bolt tightening can distort

the cover. The usual result is clutch grab, chatter

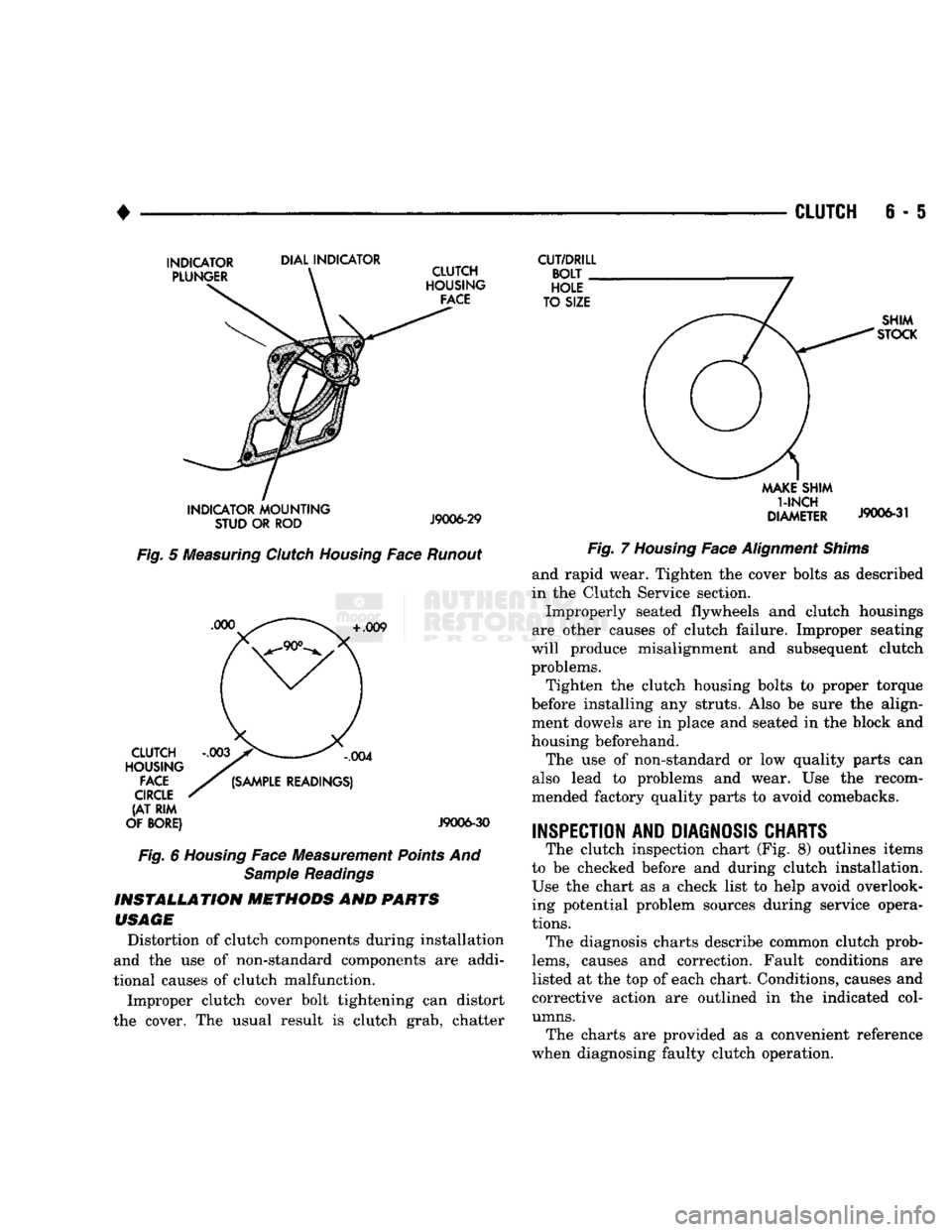

CUT/DRILL

BOLT

HOLE

TO SIZE SHIM

STOCK

MAKE

SHIM

1-INCH

DIAMETER

J9006-31

Fig.

7

Housing

Face

Alignment

Shims

and rapid wear. Tighten the cover bolts as described

in the Clutch Service section.

Improperly seated flywheels and clutch housings

are other causes of clutch failure. Improper seating

will produce misalignment and subsequent clutch problems.

Tighten the clutch housing bolts to proper torque

before installing any struts. Also be sure the align ment dowels are in place and seated in the block and

housing beforehand.

The use of non-standard or low quality parts can

also lead to problems and wear. Use the recom

mended factory quality parts to avoid comebacks.

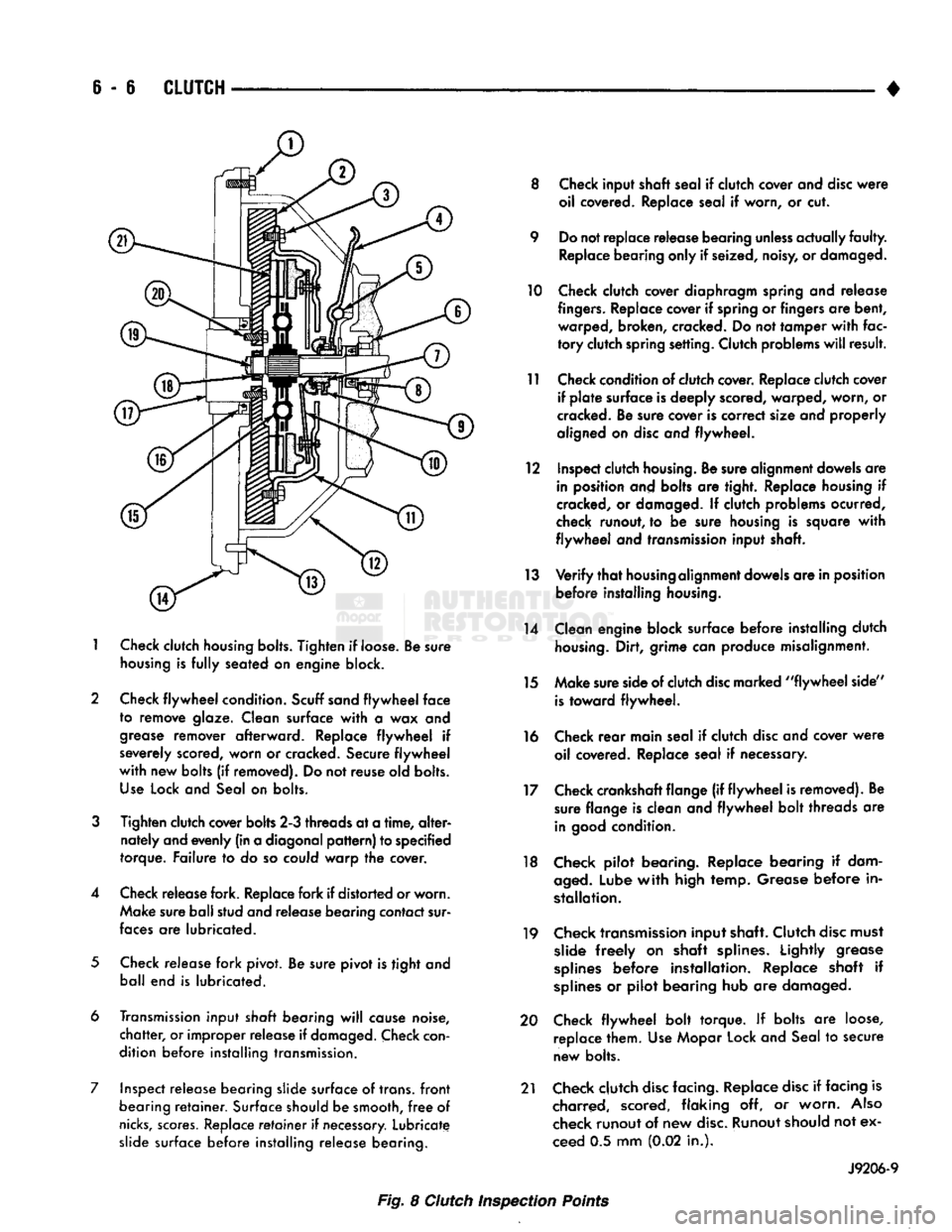

INSPECTION AND DIAGNOSIS CHARTS

The clutch inspection chart (Fig. 8) outlines items

to be checked before and during clutch installation. Use the chart as a check list to help avoid overlooking potential problem sources during service opera

tions.

The diagnosis charts describe common clutch prob

lems,

causes and correction. Fault conditions are

listed at the top of each chart. Conditions, causes and

corrective action are outlined in the indicated col

umns.

The charts are provided as a convenient reference

when diagnosing faulty clutch operation.

Page 259 of 1502

6 - 6

CLUTCH

1

Check

clutch

housing bolts.

Tighten

if loose. Be sure

housing

is

fully

seated on engine block.

2 Check

flywheel

condition.

Scuff sand

flywheel

face

to remove glaze. Clean surface

with

a wax and

grease

remover afterward. Replace

flywheel

if

severely scored, worn or cracked. Secure

flywheel

with

new bolts (if removed). Do not reuse old bolts.

Use

Lock and Seal on bolts.

3

Tighten clutch cover bolts 2-3 threads at a

time,

alter

nately and evenly (in a diagonal

pattern)

to specified

torque. Failure to do so could warp the cover.

4 Check release fork. Replace fork if distorted or worn. Make sure ball stud and release bearing contact sur

faces

are lubricated.

5

Check release fork pivot. Be sure pivot is tight and ball end is lubricated.

6 Transmission input

shaft

bearing

will

cause noise,

chatter,

or improper release if

damaged.

Check

con

dition before installing transmission.

7 Inspect release bearing slide surface of trans,

front

bearing

retainer.

Surface should be smooth,

free

of

nicks,

scores.

Replace

retainer

if

necessary.

Lubricate slide surface before installing release bearing. 8 Check input shaft seal if clutch cover and

disc

were

oil covered. Replace seal if worn, or cut.

9 Do not replace release bearing

unless

actually

faulty.

Replace bearing only if seized, noisy, or damaged.

10 Check clutch cover diaphragm spring and release

fingers.

Replace cover if spring or fingers are bent, warped, broken, cracked. Do not tamper

with

fac

tory

clutch spring setting. Clutch problems

will

result.

11 Check condition of clutch cover. Replace clutch cover if

plate

surface is deeply scored, warped, worn, or

cracked. Be sure cover is correct size and properly

aligned on

disc

and flywheel.

12 Inspect clutch

housing.

Be sure alignment dowels are in position and bolts are tight. Replace housing if

cracked, or damaged. If clutch problems ocurred,

check runout, to be sure housing is square

with

flywheel

and transmission input shaft.

13

Verify

that

housing

alignment dowels are in position before installing

housing.

14 Clean engine block surface before installing clutch

housing.

Dirt, grime can produce misalignment.

15 Make sure side of clutch

disc

marked

"flywheel

side"

is

toward flywheel.

16 Check

rear

main seal if clutch

disc

and cover

were

oil covered. Replace seal if necessary.

17 Check crankshaft flange (if

flywheel

is removed). Be sure flange is clean and

flywheel

bolt threads are

in

good

condition.

18 Check pilot bearing. Replace bearing if dam

aged.

Lube

with

high temp. Grease before in

stallation.

19 Check transmission input shaft. Clutch

disc

must slide

freely

on shaft splines. Lightly grease

splines

before installation. Replace shaft if

splines

or pilot bearing hub are damaged.

20 Check

flywheel

bolt torque. If bolts are loose, replace them. Use Mopar Lock and Seal to secure

new bolts.

21 Check clutch

disc

facing. Replace

disc

if facing is charred, scored, flaking off, or worn.

Also

check runout of new

disc.

Runout should not ex

ceed 0.5 mm (0.02 in.).

J9206-9

Fig. 8 Clutch Inspection Points

Page 612 of 1502

•

ENGINES

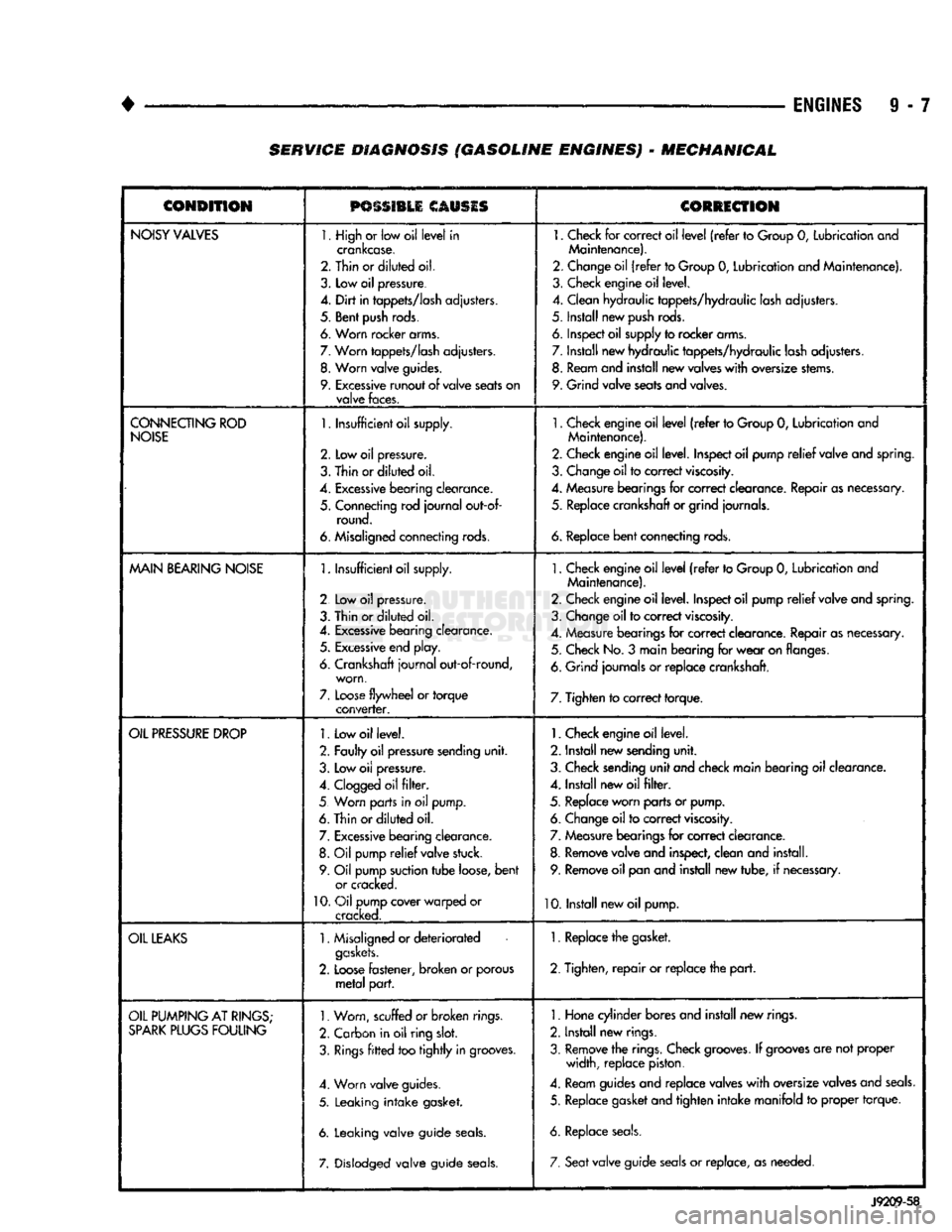

9 - 7 SERVICE DIAGNOSIS (GASOLINE ENGINES) - MECHANICAL

CONDITION

PSSSI1LI

CAUSIS

CORRECTION

NOISY

VALVES

1. High

or

low oil

level

in

crankcase.

2. Thin or

diluted

oil.

3.

Low

oil

pressure.

4.

Dirt

in

tappets/lash

adjusters.

5. Bent

push

rods.

6. Worn rocker arms.

7.

Worn

tappets/lash

adjusters.

8.

Worn

valve

guides.

9.

Excessive

runout

of

valve

seats

on

valve

faces.

1.

Check

for

correct oil

level

(refer

to

Group

0,

Lubrication and

Maintenance).

2. Change oil

(refer

to Group

0,

Lubrication and Maintenance).

3. Check engine oil level.

4. Clean hydraulic tappets/hydraulic lash adjusters.

5. Install new

push

rods.

6. Inspect oil supply to rocker arms.

7. Install new hydraulic tappets/hydraulic lash adjusters. 8. Ream and install new valves

with

oversize stems.

9. Grind valve seats and valves.

CONNECTING

ROD

NOISE

1.

Insufficient oil supply.

2.

Low oil

pressure.

3.

Thin

or

diluted

oil.

4.

Excessive

bearing

clearance.

5. Connecting rod

journal

out-of- round.

6. Misaligned connecting rods.

1.

Check engine oil

level

(refer

to Group

0,

Lubrication and

Maintenance).

2. Check engine oil level. Inspect oil pump

relief

valve and spring.

3. Change oil to correct

viscosity.

4. Measure bearings for correct clearance. Repair as necessary, 5. Replace crankshaft or grind journals.

6.

Replace

bent

connecting rods.

MAIN

BEARING

NOISE

1.

Insufficient oil supply.

2 Low

oil

pressure.

3. Thin or

diluted

oil.

4.

Excessive

bearing clearance. 5.

Excessive

end play.

6. Crankshaft

journal

out-of-round, worn,

7.

Loose

flywheel

or

torque

converter.

1.

Check engine oil

level

(refer

to Group

0,

Lubrication and

Maintenance).

2. Check engine oil level. Inspect oil pump

relief

valve and spring.

3. Change oil to correct

viscosity.

4. Measure bearings for correct clearance. Repair as necessary. 5. Check No.

3

main bearing for

wear

on flanges.

6. Grind journals

or

replace crankshaft.

7. Tighten to correct torque.

OIL

PRESSURE

DROP

1.

Low oil level.

2. Faulty oil pressure sending

unit.

3. Low

oil

pressure.

4.

Clogged

oil

filter.

5 Worn parts in

oil

pump.

6. Thin or

diluted

oil.

7.

Excessive

bearing clearance. 8.

Oil

pump

relief

valve stuck.

9. Oil pump suction

tube

loose,

bent

or cracked.

10.

Oil pump cover warped

or

cracked.

1.

Check engine oil level.

2. Install new sending

unit.

3. Check sending

unit

and check main bearing oil clearance.

4. Install new oil

filter.

5. Replace worn parts or pump. 6. Change oil to correct

viscosity.

7. Measure bearings for correct clearance.

8. Remove valve and inspect, clean and install. 9. Remove oil pan and install new tube,

if

necessary.

10. Install new oil pump.

OIL

LEAKS

1.

Misaligned or

deteriorated

gaskets.

2.

Loose

fastener, broken

or

porous

metal

part.

1. Replace the gasket.

2. Tighten,

repair

or replace the

part.

OIL

PUMPING

AT

RINGS;

SPARK

PLUGS

FOULING

1.

Worn, scuffed

or broken

rings.

2. Carbon in oil ring

slot.

3.

Rings

fitted

too

tightly

in grooves.

4. Worn valve guides.

5. Leaking

intake

gasket.

6. Leaking valve guide

seals.

7. Dislodged valve guide

seals.

1.

Hone cylinder bores and install new rings.

2. Install new rings.

3. Remove the rings. Check

grooves.

If

grooves

are not proper width, replace piston.

4. Ream guides and replace valves

with

oversize valves and

seals.

5. Replace gasket and tighten

intake

manifold

to

proper torque.

6. Replace

seals.

7. Seat

valve guide

seals

or

replace, as needed.

J9209-58