oil DODGE VIPER 2013 VX / 3.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2013, Model line: VIPER, Model: DODGE VIPER 2013 VX / 3.GPages: 100, PDF Size: 3.1 MB

Page 8 of 100

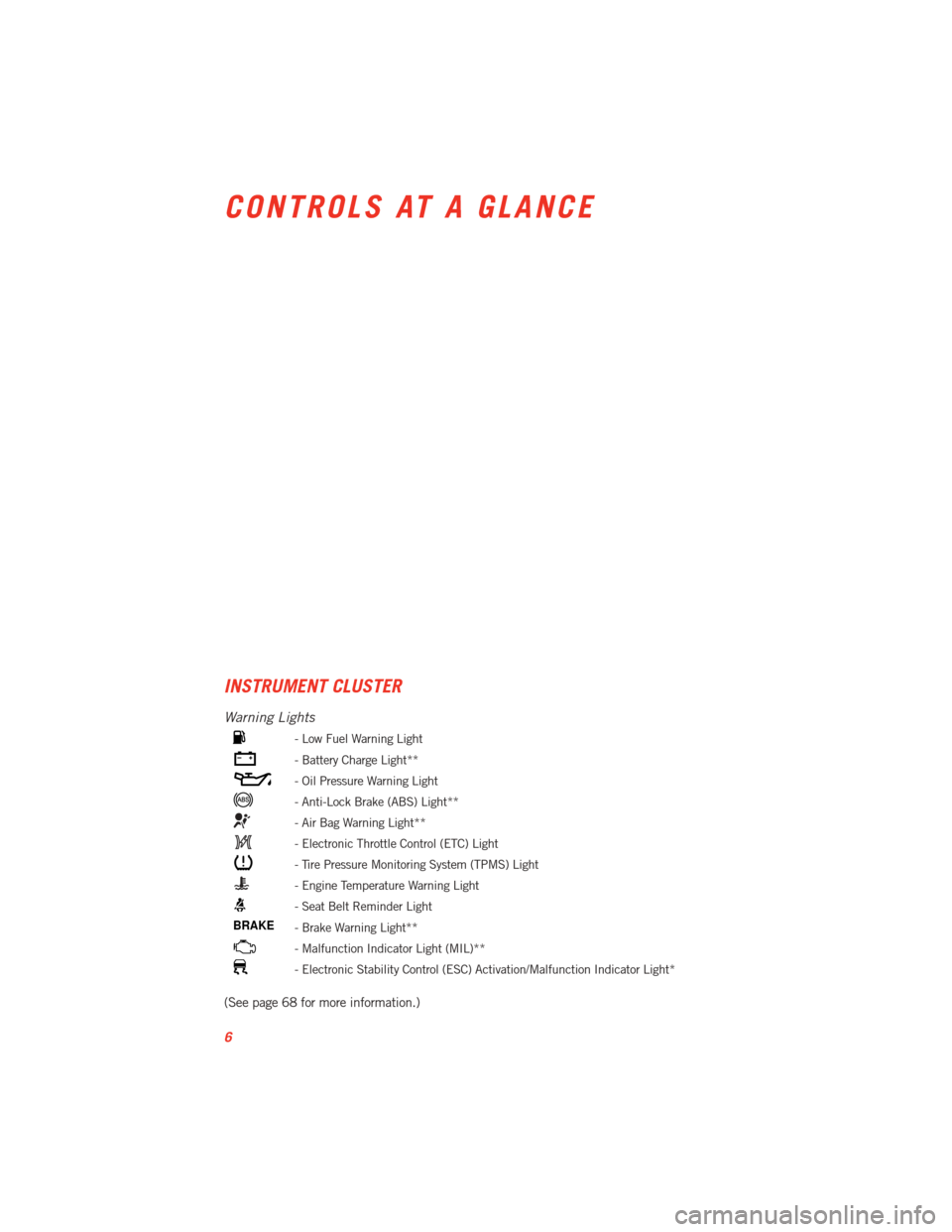

INSTRUMENT CLUSTER

Warning Lights

- Low Fuel Warning Light

- Battery Charge Light**

- Oil Pressure Warning Light

- Anti-Lock Brake (ABS) Light**

- Air Bag Warning Light**

- Electronic Throttle Control (ETC) Light

- Tire Pressure Monitoring System (TPMS) Light

- Engine Temperature Warning Light

- Seat Belt Reminder Light

BRAKE- Brake Warning Light**

- Malfunction Indicator Light (MIL)**

- Electronic Stability Control (ESC) Activation/Malfunction Indicator Light*

(See page 68 for more information.)

CONTROLS AT A GLANCE

6

Page 20 of 100

ENGINE BREAK-IN RECOMMENDATIONS — SRT 10 VERSIONS

• A long break-in period is not required for the drivetrain (engine, transmission, and rearaxle) in your new vehicle.

•

Drive moderately during the first 500 miles (800 km). After the initial 60 miles (100 km),

speeds up to 50 or 55 mph (80 or 90 km/h) are desirable.

• While cruising, brief full-throttle acceleration within the limits of local traffic laws contributes to a good break-in. However, wide-open throttle acceleration in low gear can

be detrimental and should be avoided.

• The engine oil is a high performance synthetic lubricant, the transmission fluid, and axle lubricant installed at the factory is high-quality and energy-conserving. Oil, fluid,

and lubricant changes should be consistent with anticipated climate and conditions

under which vehicle operations will occur. For the recommended viscosity and quality

grades, refer to “Maintaining Your Vehicle”.

NOTE:

A new engine may consume some oil during its first few thousand miles (kilometers) of

operation. This should be considered a normal part of the break-in and not interpreted as

an indication of difficulty.

CAUTION!

Never use Non-Detergent Oil or Straight Mineral Oil in the engine or damage may

result.

OPERATING YOUR VEHICLE

18

Page 71 of 100

malfunction telltale after replacing one or more tires or wheels on your vehicle, to

ensure that the replacement or alternate tires and wheels allow the TPMS to continue

to function properly.

NOTE:

Tire pressures change by approximately 1 psi (7 kPa) per 12° F (7° C) of air temperature

change. Keep this in mind when checking tire pressure inside a garage, especially in the

Winter. Example: If garage temperature is 68°F (20°C) and the outside temperature is

32°F (0°C), then the cold tire inflation pressure should be increased by 3 psi (21 kPa),

which equals 1 psi (7 kPa) for every 12°F (7°C) for this outside temperature condition.

CAUTION!

The TPMS has been optimized for the original equipment tires and wheels. TPMS

pressures and warning have been established for the tire size equipped on your vehicle.

Undesirable system operation or sensor damage may result when using replacement

equipment that is not of the same size, type, and/or style. Aftermarket wheels can

cause sensor damage. Do not use tire sealant from a can, or balance beads if your

vehicle is equipped with a TPMS, as damage to the sensors may result.

- Engine Temperature Warning Light

• This light warns of an overheated engine condition.

• If the light turns on or flashes continuously while driving, safely pull over and stop the vehicle. If the A/C system is on, turn it off. Also, shift the transmission into NEUTRAL

and idle the vehicle. If the temperature reading does not return to normal, turn the

engine off immediately.

• We recommend that you do not operate the vehicle or engine damage will occur. Have the vehicle serviced immediately.

WARNING!

A hot engine cooling system is dangerous. You or others could be badly burned by

steam or boiling coolant. You may want to call an authorized dealer for service if your

vehicle overheats.

BRAKE- Brake Warning Light

• The Brake Warning light illuminates when there is either a system malfunction or theparking brake is applied. If the light is on and the parking brake is not applied, it

indicates a possible brake hydraulic malfunction, brake booster problem or an Anti-

Lock Brake System problem.

• Please have your vehicle serviced immediately.

WHAT TO DO IN EMERGENCIES

69

Page 72 of 100

WARNING!

Driving a vehicle with the red brake light on is dangerous. Part of the brake system may

have failed. It will take longer to stop the vehicle. You could have a collision. Have the

vehicle checked immediately.

- Malfunction Indicator Light (MIL)

• Certain conditions, such as a poor fuel quality, etc., may illuminate the MIL afterengine start. The vehicle should be serviced if the light stays on through several typical

driving cycles. In most situations, the vehicle will drive normally and not require towing.

• If the MIL flashes when the engine is running, serious conditions may exist that could lead to immediate loss of power or severe catalytic converter damage. We recommend

you do not operate the vehicle. Have the vehicle serviced immediately.

- Electronic Stability Control (ESC) OFF Indicator Light

• This light indicates the Electronic Stability Control (ESC) is off.

- Charging System Light

• This light shows the status of the electrical charging system. If the charging systemlight remains on, it means that the vehicle is experiencing a problem with the charging

system.

• We recommend you do not continue driving if the charging system light is on. Have the vehicle serviced immediately.

- Oil Pressure Warning Light

• This light indicates low engine oil pressure. If the light turns on while driving, stop thevehicle and shut off the engine as soon as possible. A chime will sound when this light

turns on.

• We recommend you do not operate the vehicle or engine damage will occur. Have the vehicle serviced immediately.

- Anti-Lock Brake (ABS) Light

• This light monitors the Anti-Lock Brake System (ABS).

• If the light is not on during starting, stays on, or turns on while driving, we recommendyou drive to the nearest service center and have the vehicle serviced immediately.

- Electronic Throttle Control (ETC) Indicator Light

• This light informs you of a problem with the Electronic Throttle Control (ETC) system.

• If a problem is detected, the light will come on while the engine is running. Cycle theignition when the vehicle has completely stopped and the shift lever is placed in the

NEUTRAL position; the light should turn off.

WHAT TO DO IN EMERGENCIES

70

Page 75 of 100

Using The Deflation Button

• Press the Deflation Button (2) to reduce the air pressure in the tire if it becomes over-inflated.

TIREFIT Usage Precautions

• Replace the TIREFIT Sealant Bottle (1) and Sealant Hose (6) prior to the expirationdate (printed on the bottle label) to assure optimum operation of the system. Refer to

“Sealing a Tire with TIREFIT” section (F) “Sealant Bottle and Hose Replacement”.

• The Sealant Bottle (1) and Sealant Hose (6) are a one tire application use. After each use, always replace these components immediately at an authorized dealer.

• When the TIREFIT sealant is in a liquid form, clean water, and a damp cloth will remove the material from the vehicle or tire and wheel components. Once the sealant dries, it

can easily be peeled off and properly discarded.

• For optimum performance, make sure the valve stem on the wheel is free of debris before connecting the TIREFIT kit.

• You can use the TIREFIT air pump to inflate bicycle tires. The kit also comes with two needles, located in the Accessory Storage Compartment (on the bottom of the air

pump) for inflating sport balls, rafts, or similar inflatable items. However, use only the

Air Pump Hose (7) and make sure the Mode Select Knob (5) is in the Air Mode when

inflating such items to avoid injecting sealant into them. The TIREFIT Sealant is only

intended to seal punctures less than 1/4 in (6 mm) diameter in the tread of your

vehicle.

• Do not lift or carry the TIREFIT kit by the hoses.

Sealing A Tire With TIREFIT

(A) Whenever You Stop To Use TIREFIT:

1. Pull over to a safe location and turn on the vehicle’s Hazard Warning flashers.

2. Verify that the valve stem (on the wheel with the deflated tire) is in a position that is near to the ground. This will allow the TIREFIT Hoses (6) and (7) to reach the valve

stem and keep the TIREFIT kit flat on the ground. This will provide the best positioning

of the kit when injecting the sealant into the deflated tire and running the air pump.

Move the vehicle as necessary to place the valve stem in this position before

proceeding.

3. Place the transmission in PARK (auto transmission) or in Gear (manual transmission) and turn Off the ignition.

4. Set the parking brake.

(B) Setting Up To Use TIREFIT:

1. Turn the Mode Select Knob (5) to the Sealant Mode position.

2. Uncoil the Sealant Hose (6) and then remove the cap from the fitting at the end of the hose.

WHAT TO DO IN EMERGENCIES

73

Page 76 of 100

3. Place the TIREFIT kit flat on the ground next to the deflated tire.

4. Remove the cap from the valve stem and then screw the fitting at the end of theSealant Hose (6) onto the valve stem.

5. Uncoil the Power Plug (8) and insert the plug into the vehicle’s 12 Volt power outlet.

6. Do not remove foreign objects (e.g., screws or nails) from the tire.

(C) Injecting TIREFIT Sealant Into The Deflated Tire:

• Always start the engine before turning ON the TIREFIT kit.

NOTE:

Manual transmission vehicles must have the parking brake engaged and the shift lever in

NEUTRAL.

• After pressing the Power Button (4), the sealant (white fluid) will flow from the Sealant Bottle (1) through the Sealant Hose (6) and into the tire.

NOTE:

Sealant may leak out through the puncture in the tire.

• If the sealant (white fluid) does not flow within 0 – 10 seconds through the Sealant

Hose (6):

1. Press the Power Button (4) to turn Off the TIREFIT kit. Disconnect the Sealant Hose (6) from the valve stem. Make sure the valve stem is free of debris. Reconnect the

Sealant Hose (6) to the valve stem. Check that the Mode Select Knob (5) is in the

Sealant Mode position and not Air Mode. Press the Power Button (4) to turn On the

TIREFIT kit.

2. Connect the Power Plug (8) to a different 12 Volt power outlet in your vehicle or another vehicle, if available. Make sure the engine is running before turning ON the

TIREFIT kit.

3. The Sealant Bottle (1) may be empty due to previous use. Call for assistance.

NOTE:

If the Mode Select Knob (5) is on Air Mode and the pump is operating, air will dispense

from the Air Pump Hose (7) only, not the Sealant Hose (6).

• If the sealant (white fluid) does flow through the Sealant Hose (6):

1. Continue to operate the pump until sealant is no longer flowing through hose (typically takes 30 - 70 seconds). As the sealant flows through the Sealant Hose (6), the

Pressure Gauge (3) can read as high as 70 psi (5 kPa). The Pressure Gauge (3) will

decrease quickly from approximately 70 psi (5 kPa) to the actual tire pressure when

the Sealant Bottle (1) is empty.

2. The pump will start to inject air into the tire immediately after the Sealant Bottle (1) is empty. Continue to operate the pump and inflate the tire to the pressure indicated

on the tire pressure label on the driver-side latch pillar (recommended pressure).

Check the tire pressure by looking at the Pressure Gauge (3).

WHAT TO DO IN EMERGENCIES

74

Page 77 of 100

•If the tire does not inflate to at least 26 psi (1.8 kPa) pressure within 15 minutes:

• The tire is too badly damaged. Do not attempt to drive the vehicle further. Call for assistance.

NOTE:

If the tire becomes over-inflated, press the Deflation Button to reduce the tire pressure to

the recommended inflation pressure before continuing.

• If the tire does not inflate to at least 26 psi (1.8 kPa) pressure within 15 minutes:

1. Press the Power Button (4) to turn off the TIREFIT kit.

2. Remove the Speed Limit sticker from the top of the Sealant Bottle (1) and place the sticker on the instrument panel.

3. Immediately disconnect the Sealant Hose (6) from the valve stem, reinstall the cap on the fitting at the end of the hose, and place the TIREFIT kit in the vehicle storage

location. Quickly proceed to (D) “Drive Vehicle”.

(D) Drive Vehicle:

• Immediately after injecting sealant and inflating the tire, drive the vehicle 5 miles (8 km) or 10 minutes to ensure distribution of the TIREFIT Sealant within the tire.

Do not exceed 55 mph (88 km/h).

(E) After Driving:

Pull over to a safe location. Refer to “Whenever You Stop to Use TIREFIT” before continuing.

1. Turn the Mode Select Knob (5) to the Air Mode position.

2. Uncoil the Air Pump Hose (7) (black in color) and screw the fitting at the end of hose (7) onto the valve stem.

3. Uncoil the power plug and insert the plug into the vehicles 12 Volt power outlet.

4. Check the pressure in the tire by reading the Pressure Gauge (3).

• If tire pressure is less than 19 psi (1.3 kPa), the tire is too badly damaged. Do not

attempt to drive the vehicle further. Call for assistance.

If the tire pressure is 19 psi (1.3 kPa) or higher:

1. Press the Power Button (4) to turn on TIREFIT and inflate the tire to the pressure indicated on the tire and loading information label on the driver-side door opening.

2. Disconnect the TIREFIT kit from the valve stem, reinstall the cap on the valve stem and unplug from 12 Volt outlet.

3. Place the TIREFIT kit in its proper storage area in the vehicle.

4. Have the tire inspected and repaired or replaced at the earliest opportunity at an authorized dealer or tire service center.

5. Replace the Sealant Bottle (1) and Sealant Hose (6) assembly at your authorized dealer as soon as possible. Refer to “(F) Sealant Bottle and Hose Replacement.”

WHAT TO DO IN EMERGENCIES

75

Page 78 of 100

NOTE:

If the tire becomes over-inflated, press the Deflation Button to reduce the tire pressure to

the recommended inflation pressure before continuing.

NOTE:

When having the tire serviced, advise the authorized dealer or service center that the tire

has been sealed using the TIREFIT service kit.

(F) Sealant Bottle And Hose Replacement:

1. Uncoil the Sealant Hose (6) (clear in color).

2. Locate the round Sealant Bottle release button in the recessed area under the sealantbottle.

3. Press the Sealant Bottle release button. The Sealant Bottle (1) will pop up. Remove the bottle and dispose of it accordingly.

4. Clean any remaining sealant from the TIREFIT housing.

5. Position the new Sealant Bottle (1) in the housing so that the Sealant Hose (6) aligns with the hose slot in the front of the housing. Press the bottle into the housing.

An audible click will be heard indicating the bottle is locked into place.

6. Verify that the cap is installed on the fitting at the end of the Sealant Hose (6) and return the hose to its storage area (located on the bottom of the air pump).

7. Return the TIREFIT kit to its storage location in the vehicle.

CAUTION!

• The metal end fitting from Power Plug (8) may get hot after use, so it should be handled carefully.

• Failure to reinstall the cap on the fitting at the end of the Sealant Hose (6) can result

in sealant contacting your skin, clothing, and the vehicle’s interior. It can also result

in sealant contacting internal TIREFIT kit components which may cause perma-

nent damage to the kit.

WHAT TO DO IN EMERGENCIES

76

Page 85 of 100

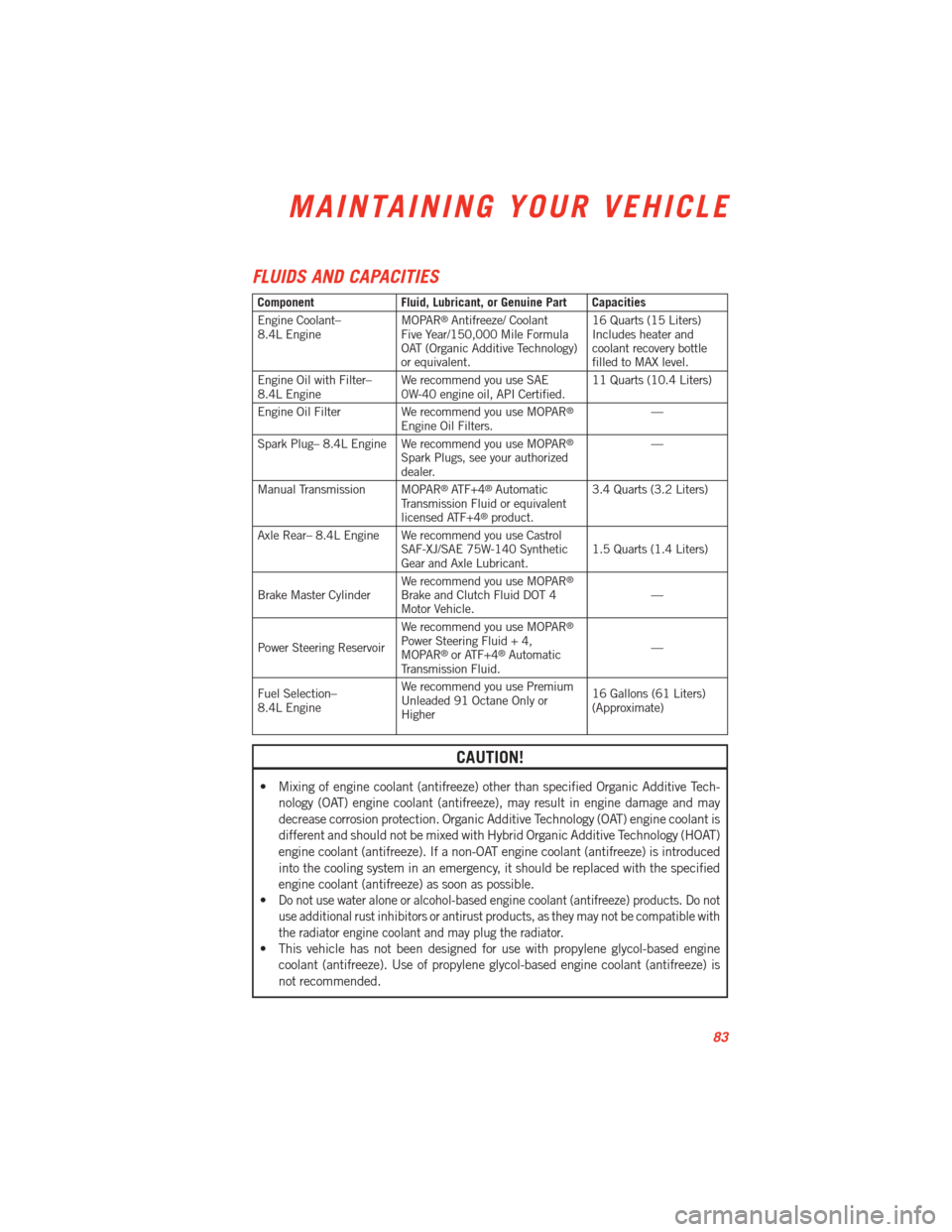

FLUIDS AND CAPACITIES

ComponentFluid, Lubricant, or Genuine Part Capacities

Engine Coolant–

8.4L Engine MOPAR®Antifreeze/ Coolant

Five Year/150,000 Mile Formula

OAT (Organic Additive Technology)

or equivalent. 16 Quarts (15 Liters)

Includes heater and

coolant recovery bottle

filled to MAX level.

Engine Oil with Filter–

8.4L Engine We recommend you use SAE

0W-40 engine oil, API Certified. 11 Quarts (10.4 Liters)

Engine Oil Filter We recommend you use MOPAR

®

Engine Oil Filters. —

Spark Plug– 8.4L Engine We recommend you use MOPAR®

Spark Plugs, see your authorized

dealer. —

Manual Transmission MOPAR

®ATF+4®Automatic

Transmission Fluid or equivalent

licensed ATF+4

®product. 3.4 Quarts (3.2 Liters)

Axle Rear– 8.4L Engine We recommend you use Castrol SAF-XJ/SAE 75W-140 Synthetic

Gear and Axle Lubricant. 1.5 Quarts (1.4 Liters)

Brake Master Cylinder We recommend you use MOPAR

®

Brake and Clutch Fluid DOT 4

Motor Vehicle. —

Power Steering Reservoir We recommend you use MOPAR

®

Power Steering Fluid + 4,

MOPAR®or ATF+4®Automatic

Transmission Fluid. —

Fuel Selection–

8.4L Engine We recommend you use Premium

Unleaded 91 Octane Only or

Higher 16 Gallons (61 Liters)

(Approximate)

CAUTION!

• Mixing of engine coolant (antifreeze) other than specified Organic Additive Tech-

nology (OAT) engine coolant (antifreeze), may result in engine damage and may

decrease corrosion protection. Organic Additive Technology (OAT) engine coolant is

different and should not be mixed with Hybrid Organic Additive Technology (HOAT)

engine coolant (antifreeze). If a non-OAT engine coolant (antifreeze) is introduced

into the cooling system in an emergency, it should be replaced with the specified

engine coolant (antifreeze) as soon as possible.

•

Do not use water alone or alcohol-based engine coolant (antifreeze) products. Do not

use additional rust inhibitors or antirust products, as they may not be compatible with

the radiator engine coolant and may plug the radiator.

• This vehicle has not been designed for use with propylene glycol-based engine

coolant (antifreeze). Use of propylene glycol-based engine coolant (antifreeze) is

not recommended.

MAINTAINING YOUR VEHICLE

83

Page 86 of 100

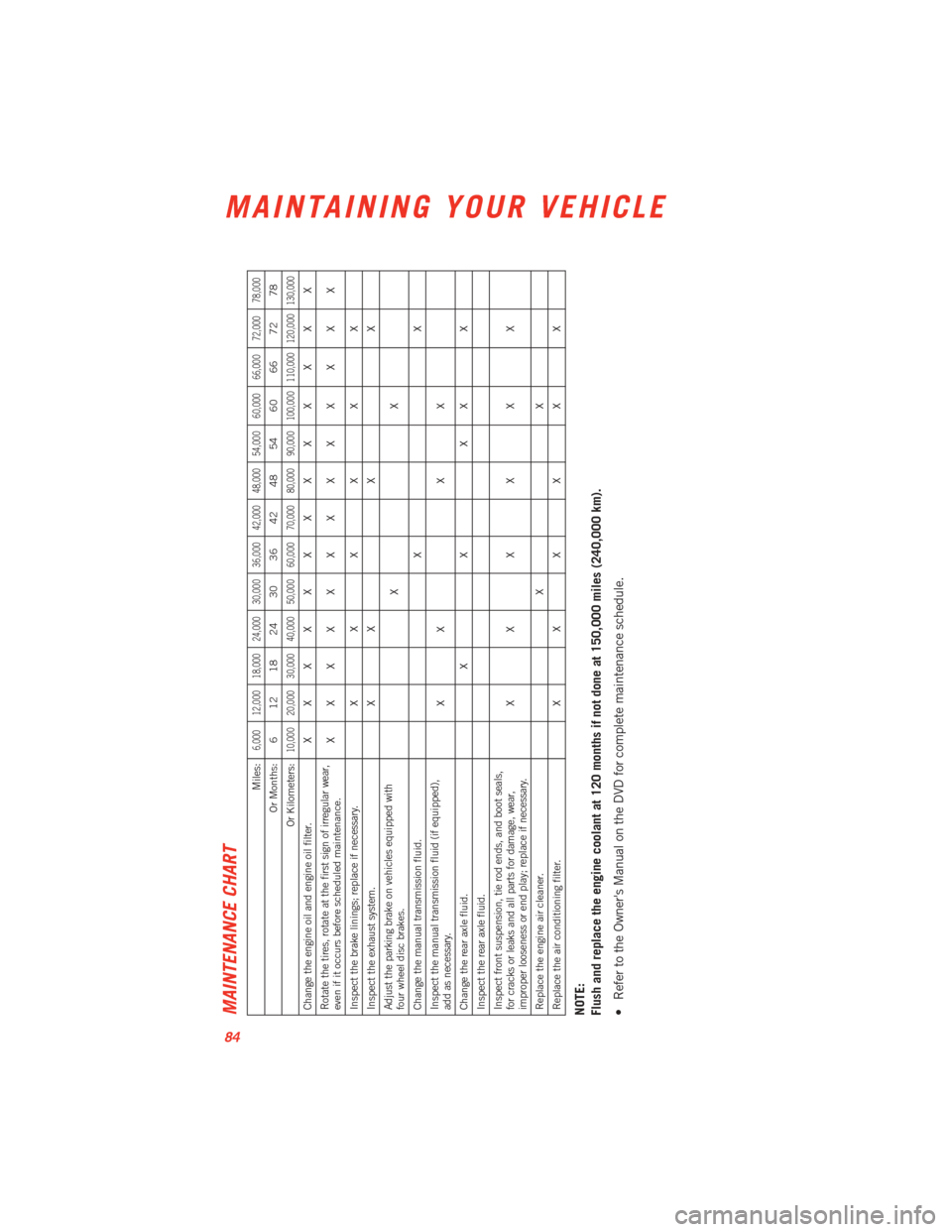

MAINTENANCE CHART

Miles:

6,000 12,000 18,000 24,000 30,000 36,000 42,000 48,000 54,000 60,000 66,000 72,000 78,000

Or Months: 6 12 18 24 30 36 42 48 54 60 66 72 78

Or Kilometers:

10,000 20,000 30,000 40,000 50,000 60,000 70,000 80,000 90,000 100,000 110,000 120,000 130,000

Change the engine oil and engine oil filter. XXXXXXXXX X X X X

Rotate the tires, rotate at the first sign of irregular wear,

even if it occurs before scheduled maintenance. XXXXXXXXX X X X X

Inspect the brake linings; replace if necessary. X X X X X X

Inspect the exhaust system. X X X X

Adjust the parking brake on vehicles equipped with

four wheel disc brakes. XX

Change the manual transmission fluid. X X

Inspect the manual transmission fluid (if equipped),

add as necessary. XX X X

Change the rear axle fluid. X X X X X

Inspect the rear axle fluid.

Inspect front suspension, tie rod ends, and boot seals,

for cracks or leaks and all parts for damage, wear,

improper looseness or end play; replace if necessary. XXXX X X

Replace the engine air cleaner. X X

Replace the air conditioning filter. X X X X X XNOTE:

Flush and replace the engine coolant at 120 months if not done at 150,000 miles (240,000 km).

• Refer to the Owner's Manual on the DVD for complete maintenance schedule.

MAINTAINING YOUR VEHICLE

84