check engine light FIAT 127 1981 2.G Workshop Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1981, Model line: 127, Model: FIAT 127 1981 2.GPages: 34, PDF Size: 6.87 MB

Page 12 of 34

Fiat 127 Internet Fan Club (http://fiat127.okruhy.cz) Fiat 127 - 1050

12/34

3. Engine

1049 cc engine - general

1 This engine is of overhead camshaft design,

using shims for valve clearance adjustment. The

crankshaft is supported in five main bearings,

the centre one incorporating the thrust washers

which control crankshaft endfloat.

2 An auxiliary shaft, driven by the toothed

camshaft belt, is used to drive the distributor and

the fuel pump. 3 Most major engine components

can be removed while the engine is in the car,

but operations on the crankshaft, main bearings

and flywheel can only be carried out after the

engine has been removed.

4 Engine removal and subsequent dismantling

follows closely the information given for the

overhead valve engine in Chapter 1, but the

following sequence for complete engine

dismantling is recommended:

(a) Engine ancillaries (alternator, fuel pump, distributor)

(b) Timing belt cover

(c) Water pump

(d) Timing belt tensioner and belt

(e) Manifolds

(f) Cylinder head complete with camshaft

(g) Crankshaft pulley

(h) Auxiliary shaft sprocket

(i) Sump

(j) Oil pump and auxiliary shaft

(k) Connecting rods and pistons

(l) Flywheel and crankshaft oil seal carriers

(m) Crankshaft and main bearings

5 If the cylinder head is to be dismantled, before

withdrawing the camshaft, have a suitably divided

container ready so that the valve clearance

adjusting shims can be extracted and kept in strict

originally installed order together with their

appropriate valves, springs etc.

6 All engine parts must be thoroughly cleaned

and examined as explained in Chapter 1. Where

required, all defective parts should be renewed

before reassembly starts.

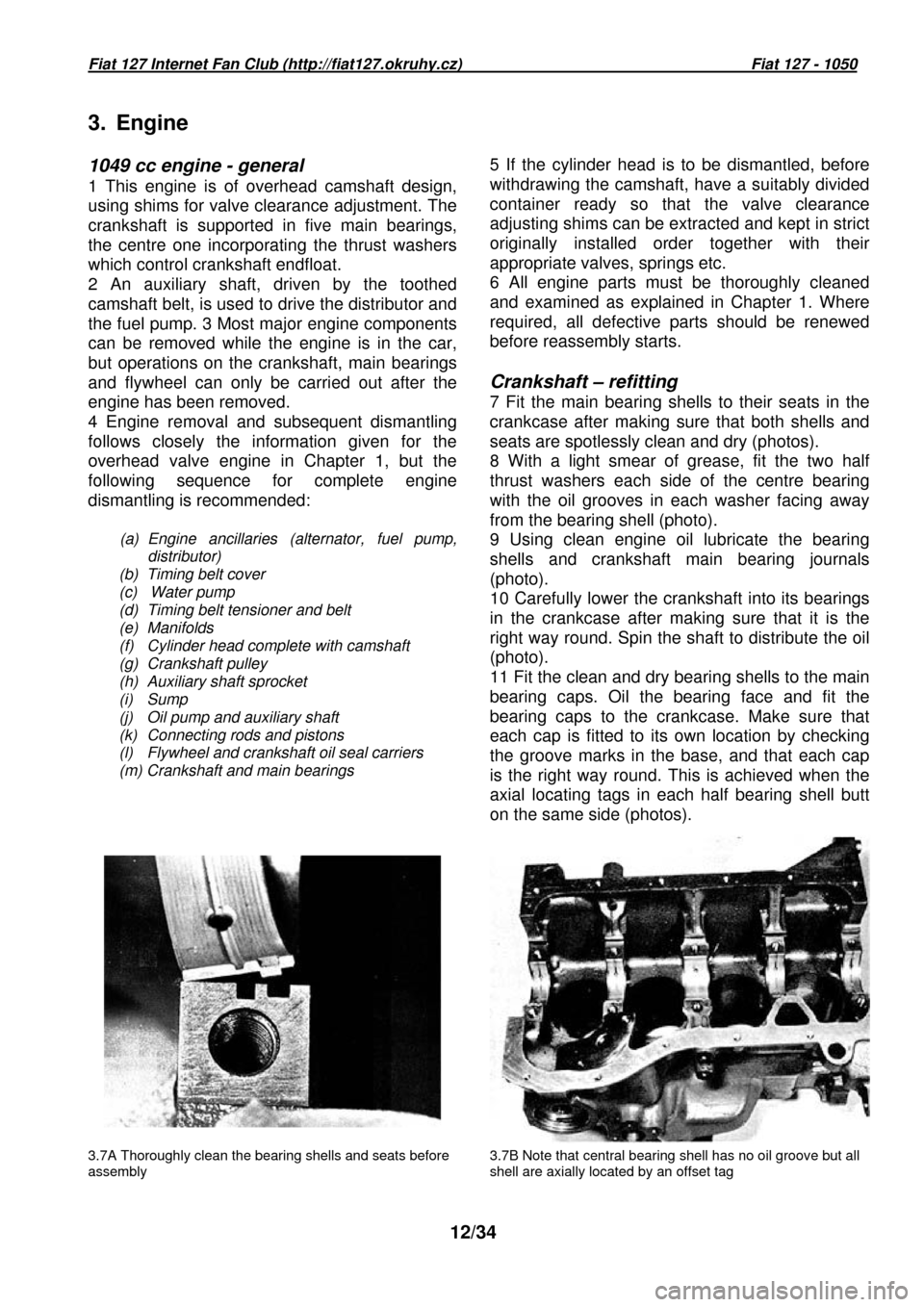

Crankshaft – refitting

7 Fit the main bearing shells to their seats in the

crankcase after making sure that both shells and

seats are spotlessly clean and dry (photos).

8 With a light smear of grease, fit the two half

thrust washers each side of the centre bearing

with the oil grooves in each washer facing away

from the bearing shell (photo).

9 Using clean engine oil lubricate the bearing

shells and crankshaft main bearing journals

(photo).

10 Carefully lower the crankshaft into its bearings

in the crankcase after making sure that it is the

right way round. Spin the shaft to distribute the o il

(photo).

11 Fit the clean and dry bearing shells to the main

bearing caps. Oil the bearing face and fit the

bearing caps to the crankcase. Make sure that

each cap is fitted to its own location by checking

the groove marks in the base, and that each cap

is the right way round. This is achieved when the

axial locating tags in each half bearing shell butt

on the same side (photos).

3.7A Thoroughly clean the bearing shells and seats

before

assembly 3.7B Note that central bearing shell has no oil gro ove but all

shell are axially located by an offset tag

Page 24 of 34

Fiat 127 Internet Fan Club (http://fiat127.okruhy.cz) Fiat 127 - 1050

24/34

progressively until the bearing halves meet.

53 Oil the camshaft seal and carefully fit it with

its carrier and a new gasket to the cylinder head

(photo).

54 Position the drivebelt guard backplate over

the camshaft seal carrier and fit the three bolts

and washers (photo). 55 Tighten the three bolts

retaining the backplate and seal carrier. Torque

load the four camshaft bearing securing nuts to

the specified setting.

56 Fit the camshaft toothed driving pulley with its

bolt and washer. Leave the final tightening until

the drivebelt is fitted (photo).

57 Check the valve clearances; the camshaft

can be turned by a spanner on the pulley

retaining bolt. Readjust any clearance if

necessary, as described later in this Section.

58 Owing to the small clearance between a

piston at TDC and the open valves during

exhaust/inlet overlap, it is imperative to get the

crankshaft and camshaft in their correct related

positions before turning the engine after fitting

the cylinder head. If this relationship is out then

serious damage could be done to the valves or

pistons by turning the crankshaft, as the pistons

will impinge on the valve heads. To avoid this

the following sequence should be observed. Set

the crankshaft as described in paragraph 59,

and the camshaft (before assembling the

cylinder head to the block) also as described in

paragraph 59. Fit the head to the block taking

care not to disturb the set positions and, finally,

fit the toothed drivebelt. Then the crankshaft can

be turned with no likelihood of damage.

59 Set the crankshaft by using a spanner on the

pulley retaining nut and aligning the mark on the

pulley with the long pointer on the timing

indicator bracket. Then set the camshaft by

aligning the hole in the camshaft pulley with the

cast ridge on the top of the camshaft seal carrier

just behind the toothed pulley (photo).

60 Fit a new cylinder head gasket with the word

ALTO upwards (photo). Do not use grease or

any other jointing compound. 61 Taking care not

to disturb the crankshaft or camshaft lower the

cylinder head onto the block (photo).

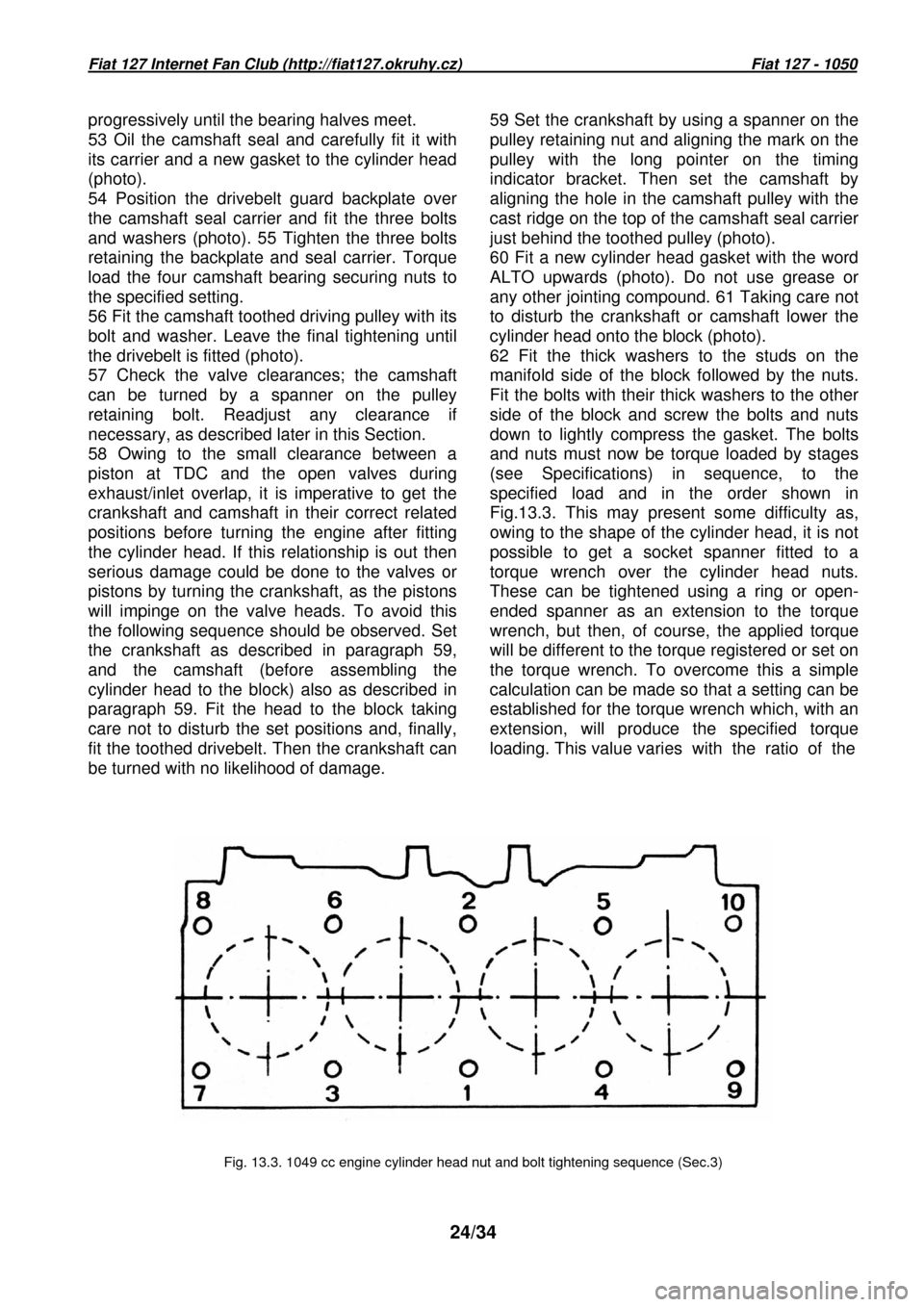

62 Fit the thick washers to the studs on the

manifold side of the block followed by the nuts.

Fit the bolts with their thick washers to the other

side of the block and screw the bolts and nuts

down to lightly compress the gasket. The bolts

and nuts must now be torque loaded by stages

(see Specifications) in sequence, to the

specified load and in the order shown in

Fig.13.3. This may present some difficulty as,

owing to the shape of the cylinder head, it is not

possible to get a socket spanner fitted to a

torque wrench over the cylinder head nuts.

These can be tightened using a ring or open-

ended spanner as an extension to the torque

wrench, but then, of course, the applied torque

will be different to the torque registered or set o n

the torque wrench. To overcome this a simple

calculation can be made so that a setting can be

established for the torque wrench which, with an

extension, will produce the specified torque

loading. This value varies with the ratio of t he

Fig. 13.3. 1049 cc engine cylinder head nut and bol t tightening sequence (Sec.3)

Page 28 of 34

Fiat 127 Internet Fan Club (http://fiat127.okruhy.cz) Fiat 127 - 1050

28/34

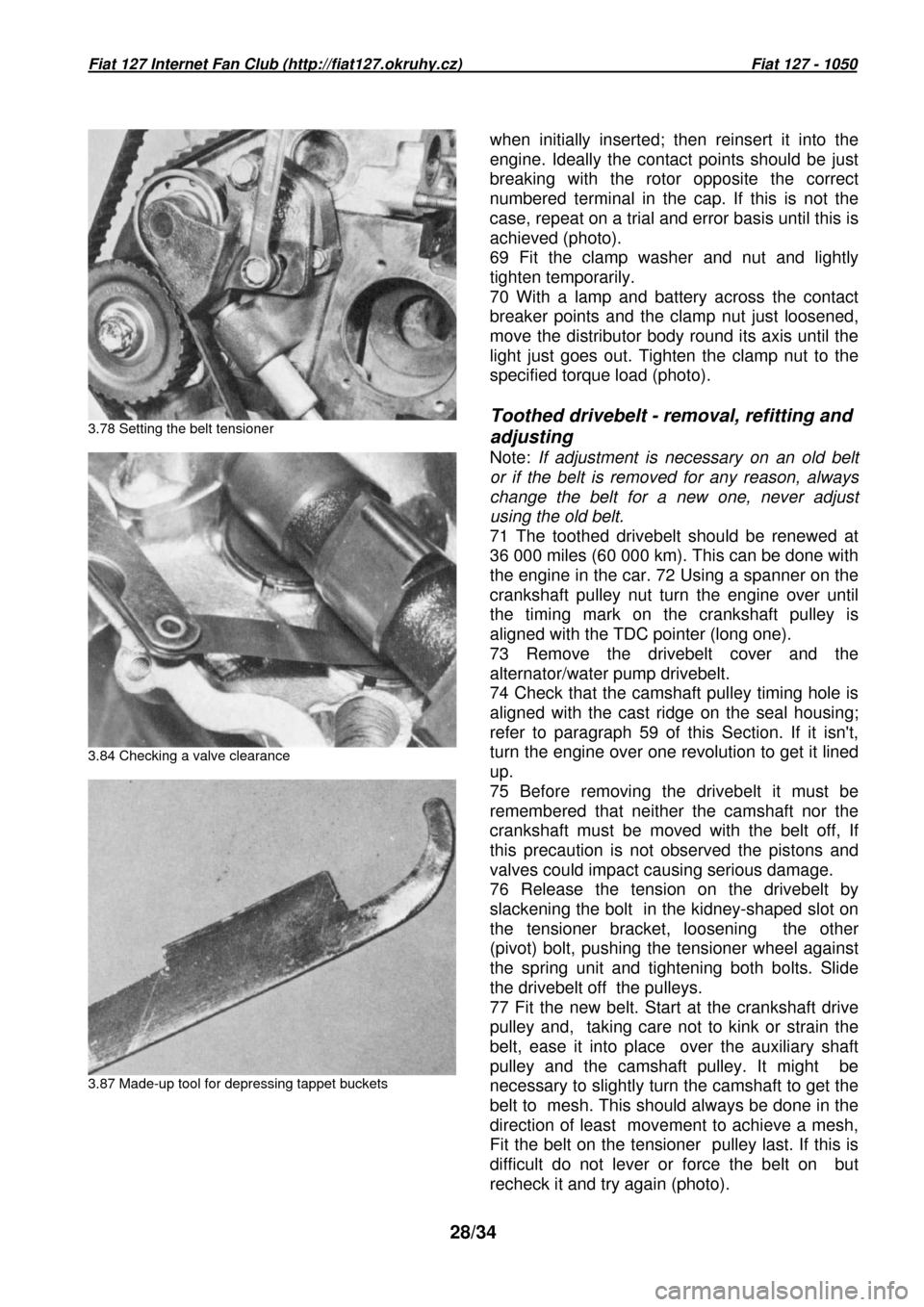

3.78 Setting the belt tensioner

3.84 Checking a valve clearance

3.87 Made-up tool for depressing tappet buckets

when initially inserted; then reinsert it into the

engine. Ideally the contact points should be just

breaking with the rotor opposite the correct

numbered terminal in the cap. If this is not the

case, repeat on a trial and error basis until this

is

achieved (photo).

69 Fit the clamp washer and nut and lightly

tighten temporarily.

70 With a lamp and battery across the contact

breaker points and the clamp nut just loosened,

move the distributor body round its axis until the

light just goes out. Tighten the clamp nut to the

specified torque load (photo).

Toothed drivebelt - removal, refitting and

adjusting

Note: If adjustment is necessary on an old belt

or if the belt is removed for any reason, always

change the belt for a new one, never adjust

using the old belt.

71 The toothed drivebelt should be renewed at

36 000 miles (60 000 km). This can be done with

the engine in the car. 72 Using a spanner on the

crankshaft pulley nut turn the engine over until

the timing mark on the crankshaft pulley is

aligned with the TDC pointer (long one).

73 Remove the drivebelt cover and the

alternator/water pump drivebelt.

74 Check that the camshaft pulley timing hole is

aligned with the cast ridge on the seal housing;

refer to paragraph 59 of this Section. If it isn't,

turn the engine over one revolution to get it lined

up.

75 Before removing the drivebelt it must be

remembered that neither the camshaft nor the

crankshaft must be moved with the belt off, If

this precaution is not observed the pistons and

valves could impact causing serious damage.

76 Release the tension on the drivebelt by

slackening the bolt in the kidney-shaped slot on

the tensioner bracket, loosening the other

(pivot) bolt, pushing the tensioner wheel against

the spring unit and tightening both bolts. Slide

the drivebelt off the pulleys.

77 Fit the new belt. Start at the crankshaft drive

pulley and, taking care not to kink or strain the

belt, ease it into place over the auxiliary shaft

pulley and the camshaft pulley. It might be

necessary to slightly turn the camshaft to get the

belt to mesh. This should always be done in the

direction of least movement to achieve a mesh,

Fit the belt on the tensioner pulley last. If this is

difficult do not lever or force the belt on but

recheck it and try again (photo).

Page 29 of 34

Fiat 127 Internet Fan Club (http://fiat127.okruhy.cz) Fiat 127 - 1050

29/34

78 Slacken the tensioner bolts to tension the belt

and retighten the bolts (photo).

79 Turn the engine over for two complete

revolutions to even out belt tension. Then again

slacken the tensioner bolts to let the tensioner

take up any slack and

retighten the bolts. Never

turn the engine backwards or rock the camshaft

when tensioning the belt, as slack could develop

in the belt and it might jump a tooth.

80 Refit and tension the alternator/water pump

V-belt. Refit the drivebelt cover.

Valve clearances - adjustment

81 Checking the valve clearances should be

done at the 6000 miles servicing, or whenever

the cylinder head has been removed and

refitted for any reason. It is important that the

clearances are set correctly, otherwise the

timing will be wrong and the engine

performance will be poor. If there is no

clearance at all, the valves and seats will soon

get burnt. Set the clearances with the engine

cold.

82 Remove the camshaft cover. The engine can

be turned over by either using a spanner on the

crankshaft pulley nut, or by jacking up a front

wheel, engaging top gear and using the wheel

to turn the engine.

83 Each tappet must be checked when its

operating cam is pointing upwards, 1800 away

from the tappet. Check the clearances in the

firing order, No. 1 cylinder first and then 3, 4

and 2. Do the exhaust of one cylinder and the

inlet of the one after, at the same time to

minimise the amount of engine turning. Counting

from the timing belt end, exhaust valves are

1-4-5-8, inlet valves 2-3-6-7.

84 Insert the feeler gauge for the appropriate

valve. See the Specifications for correct

settings. The feeler should slide in readily

between cam and shim, but with slight frictional

drag. Try one a size thicker and one a size

thinner. The thick one should not go in and the

thinner one should be too loose (photo).

85 If the clearance is wrong, measure the

clearance and write it down with the number of

the valve. When all the clearances have been

checked, it will be necessary to remove those

shims which are fitted where the clearances are

wrong, and renew them with different thickness

shims. If a clearance is too big, use a thicker

shim. If a clearance is too small use a thinner

shim. Calculate by simple subtraction. 86 To change a shim, turn the engine until the

relevant cam is pointing upwards, then turn the

tappet in its housing so that the slot in the rim is

accessible.

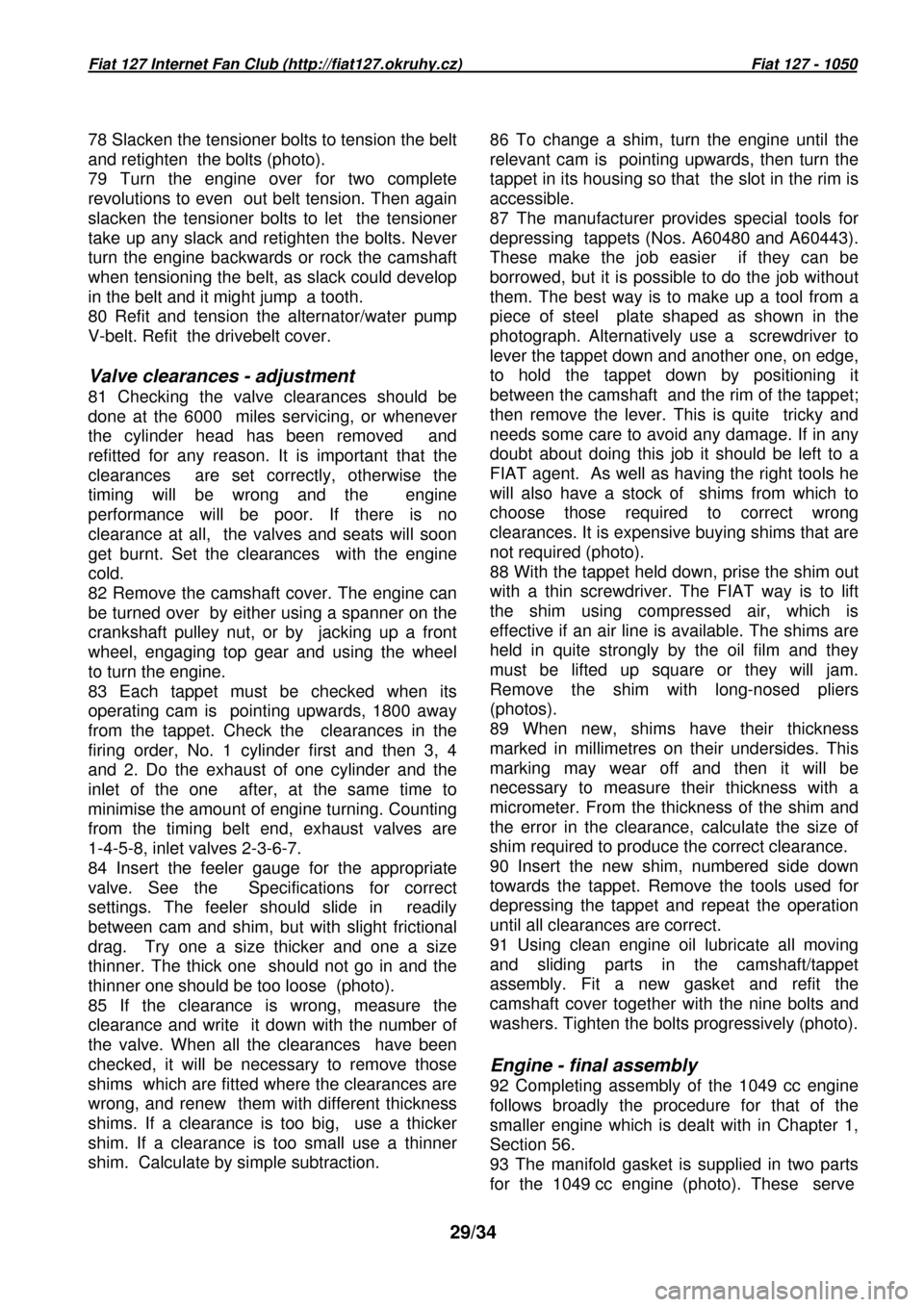

87 The manufacturer provides special tools for

depressing tappets (Nos. A60480 and A60443).

These make the job easier if they can be

borrowed, but it is possible to do the job without

them. The best way is to make up a tool from a

piece of steel plate shaped as shown in the

photograph. Alternatively use a screwdriver to

lever the tappet down and another on

e, on edge,

to hold the tappet down by positioning it

between the camshaft and the rim of the tappet;

then remove the lever. This is quite tricky and

needs some care to avoid any damage. If in any

doubt about doing this job it should be left to a

FIAT agent. As well as having the right tools he

will also have a stock of shims from which to

choose those required to correct wrong

clearances. It is expensive buying shims that are

not required (photo).

88 With the tappet held down, prise the shim out

with a thin screwdriver. The FIAT way is to lift

the shim using compressed air, which is

effective if an air line is available. The shims are

held in quite strongly by the oil film and they

must be lifted up square or they will jam.

Remove the shim with long-nosed pliers

(photos).

89 When new, shims have their thickness

marked in millimetres on their undersides. This

marking may wear off and then it will be

necessary to measure their thickness with a

micrometer. From the thickness of the shim and

the error in the clearance, calculate the size of

shim required to produce the correct clearance.

90 Insert the new shim, numbered side down

towards the tappet. Remove the tools used for

depressing the tappet and repeat the operation

until all clearances are correct.

91 Using clean engine oil lubricate all moving

and sliding parts in the camshaft/tappet

assembly. Fit a new gasket and refit the

camshaft cover together with the nine bolts and

washers. Tighten the bolts progressively (photo).

Engine - final assembly

92 Completing assembly of the 1049 cc engine

follows broadly the procedure for that of the

smaller engine which is dealt with in Chapter 1,

Section 56.

93 The manifold gasket is supplied in two parts

for the 1049 cc engine (photo). These serve

Page 31 of 34

Fiat 127 Internet Fan Club (http://fiat127.okruhy.cz) Fiat 127 - 1050

31/34

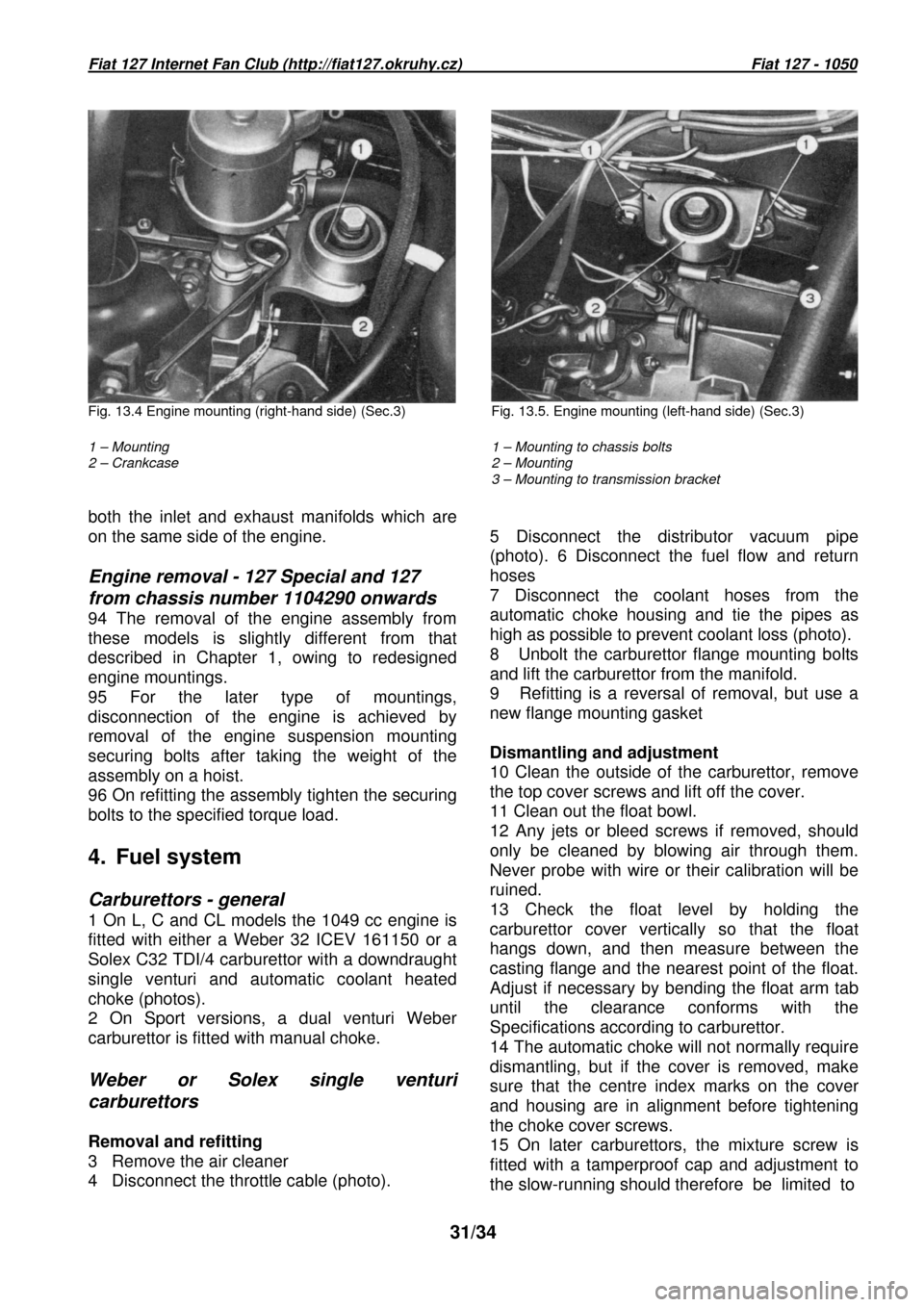

Fig. 13.4 Engine mounting (right-hand side) (Sec.3) Fig. 13.5. Engine mounting (left-hand side) (Sec.3)

1 – Mounting

2 – Crankcase

1 – Mounting to chassis bolts

2 – Mounting

3 – Mounting to transmission bracket

both the inlet and exhaust manifolds which are

on the same side of the engine.

Engine removal - 127 Special and 127

from chassis number 1104290 onwards

94 The removal of the engine assembly from

these models is slightly different from that

described in Chapter 1, owing to redesigned

engine mountings.

95 For the later type of mountings,

disconnection of the engine is achieved by

removal of the engine suspension mounting

securing bolts after taking the weight of the

assembly on a hoist.

96 On refitting the assembly tighten the securing

bolts to the specified torque load.

4. Fuel system

Carburettors - general

1 On L, C and CL models the 1049 cc engine is

fitted with either a Weber 32 ICEV 161150 or a

Solex C32 TDI/4 carburettor with a downdraught

single venturi and automatic coolant heated

choke (photos).

2 On Sport versions, a dual venturi Weber

carburettor is fitted with manual choke.

Weber or Solex single venturi

carburettors

Removal and refitting

3 Remove the air cleaner

4 Disconnect the throttle cable (photo).

5 Disconnect the distributor vacuum pipe

(photo). 6 Disconnect the fuel flow and return

hoses 7 Disconnect the coolant hoses from the

automatic choke housing and tie the pipes as

high as possible to prevent coolant loss (photo).

8 Unbolt the carburettor flange mounting bolts

and lift the carburettor from the manifold.

9 Refitting is a reversal of removal, but use a

new flange mounting gasket

Dismantling and adjustment

10 Clean the outside of the carburettor, remove

the top cover screws and lift off the cover.

11 Clean out the float bowl.

12 Any jets or bleed screws if removed, should

only be cleaned by blowing air through them.

Never probe with wire or their calibration will be

ruined.

13 Check the float level by holding the

carburettor cover vertically so that the float

hangs down, and then measure between the

casting flange and the nearest point of the float.

Adjust if necessary by bending the float arm tab

until the clearance conforms with the

Specifications according to carburettor.

14 The automatic choke will not normally require

dismantling, but if the cover is removed, make

sure that the centre index marks on the cover

and housing are in alignment before tightening

the choke cover screws.

15 On later carburettors, the mixture screw is

fitted with a tamperproof cap and adjustment to

the slow-running should therefore be limited to