diagram FIAT 500 1957 1.G User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 1957, Model line: 500, Model: FIAT 500 1957 1.GPages: 128, PDF Size: 9.01 MB

Page 49 of 128

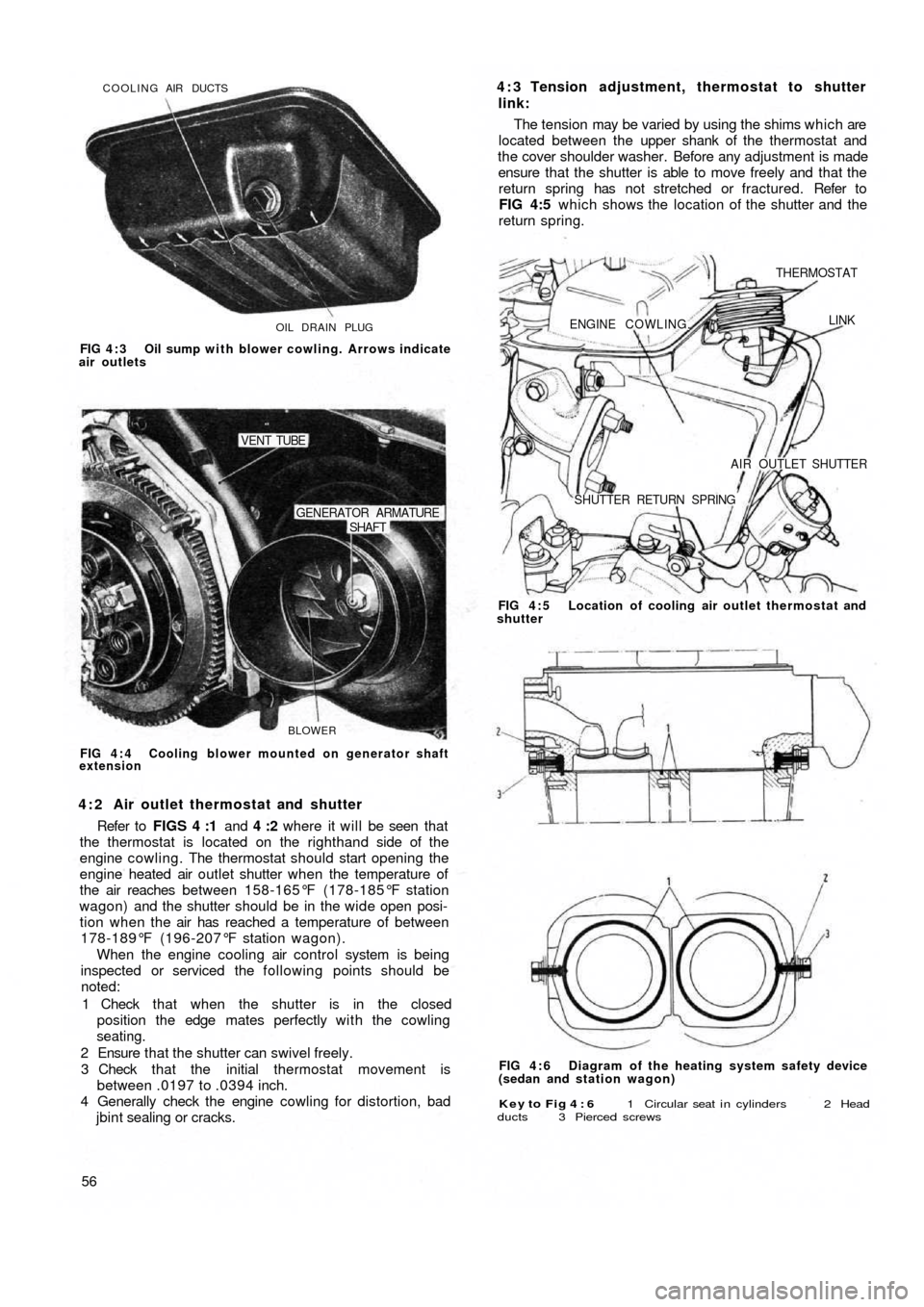

OIL DRAIN PLUG COOLING AIR DUCTS

FIG 4 : 3 Oil sump with blower cowling. Arrows indicate

air outlets

BLOWER

SHAFT GENERATOR ARMATURE

VENT TUBE

FIG 4 : 4 Cooling blower mounted on generator shaft

extension

4 : 2 Air outlet thermostat and shutter

Refer to FIGS 4 :1 and 4 :2 where it will be seen that

the thermostat is located on the righthand side of the

engine cowling. The thermostat should start opening the

engine heated air outlet shutter when the temperature of

the air reaches between 158-165°F (178-185°F station

wagon) and the shutter should be in the wide open posi-

tion when the air has reached a temperature of between

178-189°F (196-207°F station wagon).

When the engine cooling air control system is being

inspected or serviced the following points should be

noted:

1 Check that when the shutter is in the closed

position the edge mates perfectly with the cowling

seating.

2 Ensure that the shutter can swivel freely.

3 Check that the initial thermostat movement is

between .0197 to .0394 inch.

4 Generally check the engine cowling for distortion, bad

jbint sealing or cracks.

56

Key to Fig 4 : 6 1 Circular seat i n cylinders 2 Head

ducts 3 Pierced screws

FIG 4 : 6 Diagram of the heating system safety device

(sedan and station wagon) FIG 4 : 5 Location of cooling air outlet thermostat and

shutter

ENGINE COWLING.

THERMOSTAT

LINK

AIR OUTLET SHUTTER

SHUTTER RETURN SPRING

4 : 3 Tension adjustment, thermostat to shutter

link:

The tension may be varied by using the shims which are

located between the upper shank of the thermostat and

the cover shoulder washer. Before any adjustment is made

ensure that the shutter is able to move freely and that the

return spring has not stretched or fractured. Refer to

FIG 4:5 which shows the location of the shutter and the

return spring.

Page 55 of 128

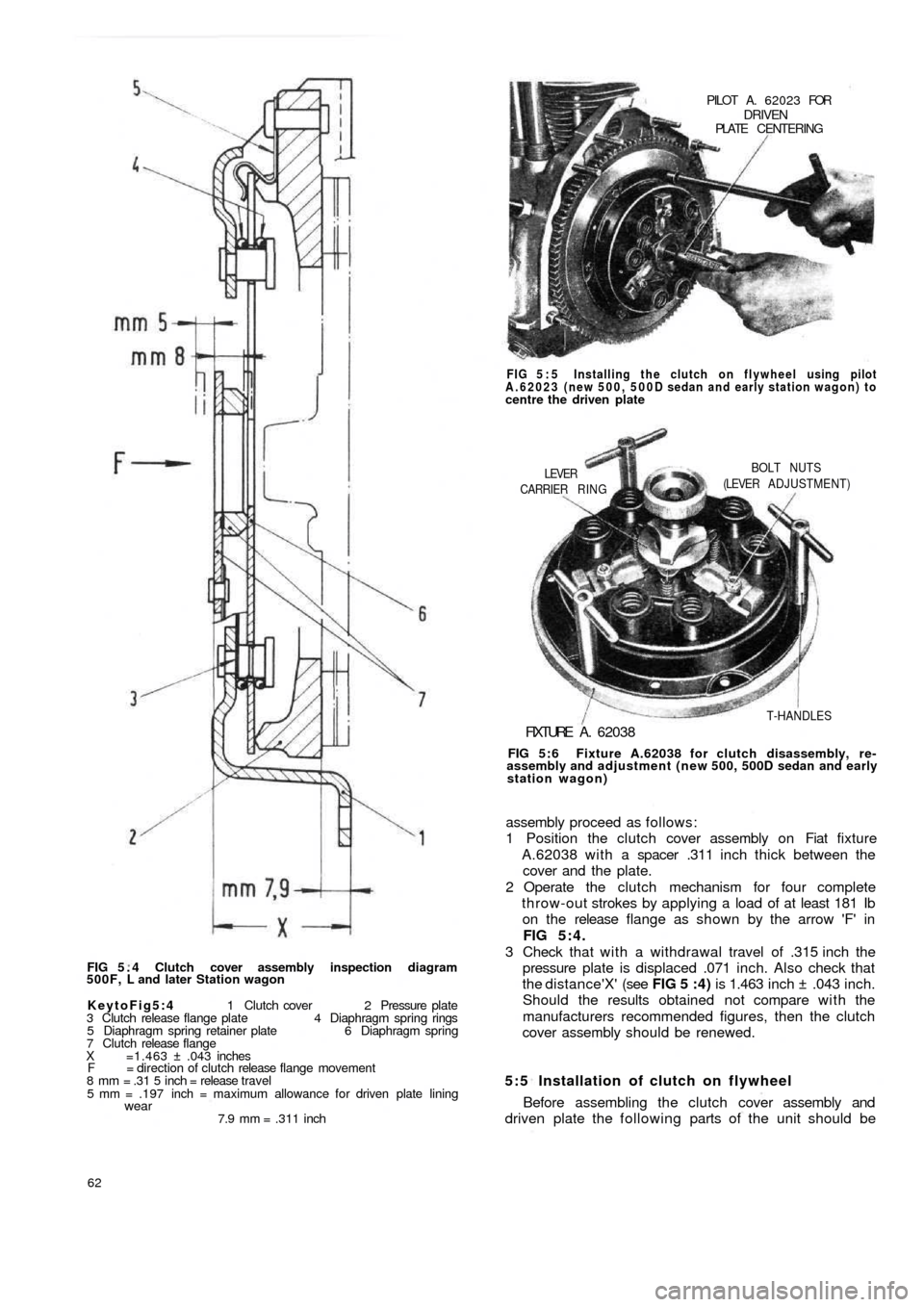

FIG 5 . 4 Clutch cover assembly inspection diagram

500F, L and later Station wagon

KeytoFig5:4 1 Clutch cover 2 Pressure plate

3 Clutch release flange plate 4 Diaphragm spring rings

5 Diaphragm spring retainer plate 6 Diaphragm spring

7 Clutch release flange

X =1.463 ± .043 inches

F = direction of clutch release flange movement

8 mm = .31 5 inch = release travel

5 mm = .197 inch = maximum allowance for driven plate lining

wear7.9 mm = .311 inch

62

5:5 Installation of clutch on flywheel

Before assembling the clutch cover assembly and

driven plate the following parts of the unit should be assembly proceed as follows:

1 Position the clutch cover assembly on Fiat fixture

A.62038 with a spacer .311 inch thick between the

cover and the plate.

2 Operate the clutch mechanism for four complete

throw-out strokes by applying a load of at least 181 Ib

on the release flange as shown by the arrow 'F' in

FIG 5:4.

3 Check that w i t h a withdrawal travel of .315 inch the

pressure plate is displaced .071 inch. Also check that

the distance'X' (see FIG 5 :4) is 1.463 inch ± .043 inch.

Should the results obtained not compare w i t h the

manufacturers recommended figures, then the clutch

cover assembly should be renewed.

FIG 5:6 Fixture A.62038 for clutch disassembly, re-

assembly and adjustment (new 500, 500D sedan and early

station wagon)

FIXTURE A . 62038

T-HANDLES CARRIER RING

LEVERBOLT NUTS

(LEVER ADJUSTMENT) FIG 5 : 5 Installing the clutch on flywheel using pilot

A.62023 (new 500, 500D sedan and early station wagon) to

centre the driven platePILOT A. 62023 FOR

DRIVENPLATE CENTERING

Page 66 of 128

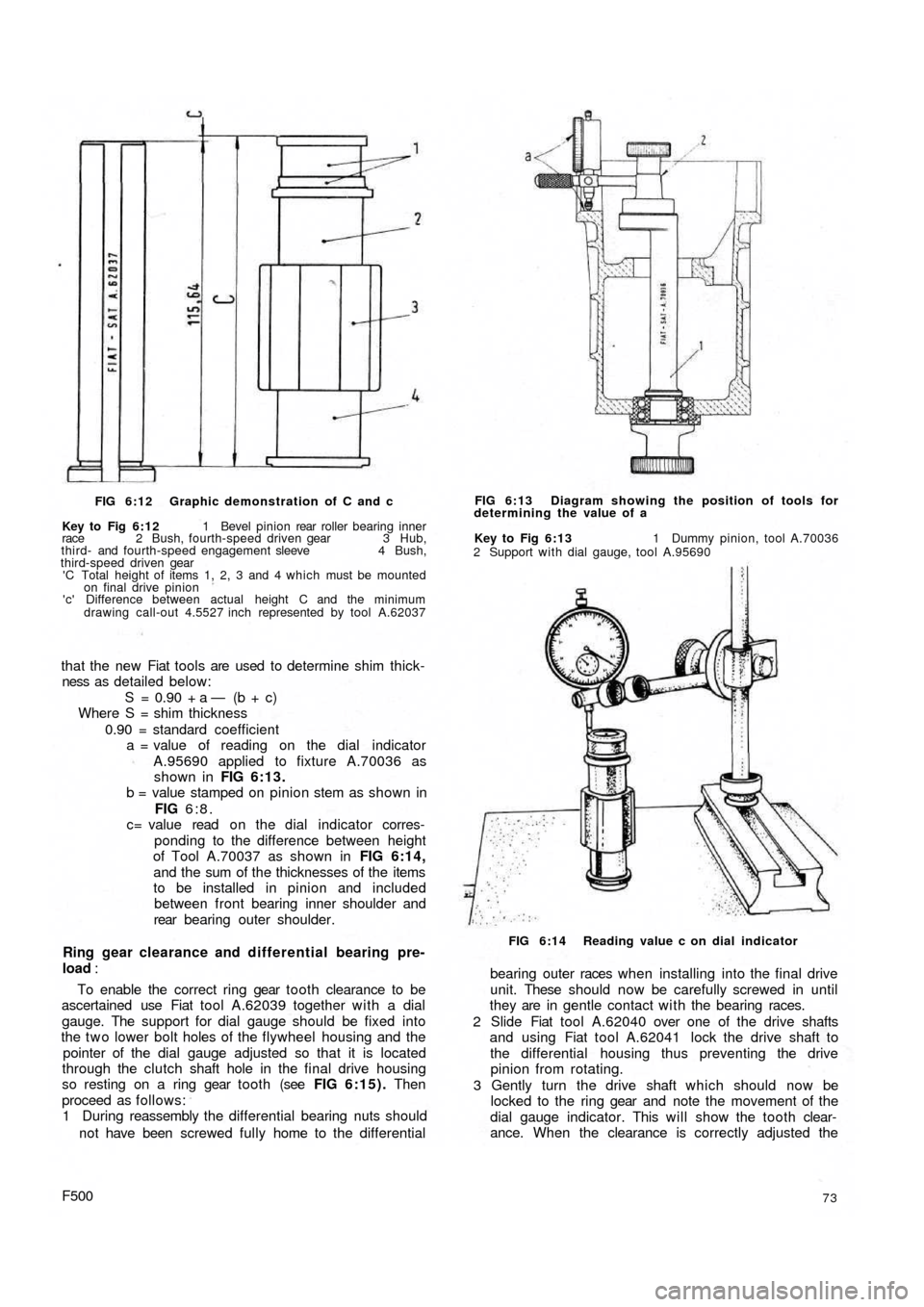

FIG 6:12 Graphic demonstration of C and c

Key to Fig 6:12 1 Bevel pinion rear roller bearing inner

race 2 Bush, fourth-speed driven gear 3 Hub,

third- and fourth-speed engagement sleeve 4 Bush,

third-speed driven gear

'C Total height of items 1, 2, 3 and 4 which must be mounted

on final drive pinion

'c' Difference between actual height C and the minimum

drawing call-out 4.5527 inch represented by tool A.62037

that the new Fiat tools are used to determine shim thick-

ness as detailed below:

S = 0.90 + a — (b + c)

Where S = shim thickness

0.90 = standard coefficient

a = value of reading on the dial indicator

A.95690 applied to fixture A.70036 as

shown in FIG 6:13.

b = value stamped on pinion stem as shown in

FIG 6:8.

c= value read o n the dial indicator corres-

ponding to the difference between height

of Tool A.70037 as shown in FIG 6:14,

and the sum of the thicknesses of the items

to be installed in pinion and included

between front bearing inner shoulder and

rear bearing outer shoulder.

Ring gear clearance and differential bearing pre-

load :

To enable the correct ring gear tooth clearance to be

ascertained use Fiat tool A.62039 together with a dial

gauge. The support for dial gauge should be fixed into

the t w o lower bolt holes of the flywheel housing and the

pointer of the dial gauge adjusted so that it is located

through the clutch shaft hole in the final drive housing

so resting on a ring gear tooth (see FIG 6:15). Then

proceed as follows:

1 During reassembly the differential bearing nuts should

not have been screwed fully home to the differential

F50073

bearing outer races w h e n installing into the f i n a l drive

unit. These should now be carefully screwed in until

they are in gentle contact with the bearing races.

2 Slide Fiat tool A.62040 over one of the drive shafts

and using Fiat tool A.62041 lock the drive shaft to

the differential housing thus preventing the drive

pinion from rotating.

3 Gently turn the drive shaft which should now be

locked to the ring gear and note the movement of the

dial gauge indicator. This will show the tooth clear-

ance. When the clearance is correctly adjusted the

FIG 6:14 Reading value c on dial indicator Key to Fig 6:13 1 Dummy pinion, tool A.70036

2 Support with dial gauge, tool A.95690 FIG 6:13 Diagram showing the position of tools for

determining the value of a

Page 94 of 128

reassembling and during assembly liberally lubricated

using Fiat W90/M oil (SAE90 EP).

2 The pitman arm nut should be correctly positioned on

reassembly to the sector shaft and both are marked

with notches or a master tooth on the sector will mate

with a double tooth on the pitman arm which will

prevent incorrect reassembly.

3 The pitman arm nut must be tightened to a torque

wrench setting of 72 Ib/ft.

4 Fill the box up to the level and filler plug with SAE90 EP

gear oil.

Refitting the steering box:

To refit the steering box to the vehicle proceed as

follows:

1 Engage the w o r m screw f r o m the steering shaft by

gently manipulating the steering box.

2 Replace the steering box to body nuts and tighten to a

torque wrench setting of 14 to 18 Ib/ft.

3 Replace the t w o track rod pins in their seatings in the

pitman arm and tighten the self-locking nuts to a

torque wrench setting of 18 to 21 Ib/ft.

4 Replace the steering shaft to worm screw mounting

bolt, lock washer and nut.

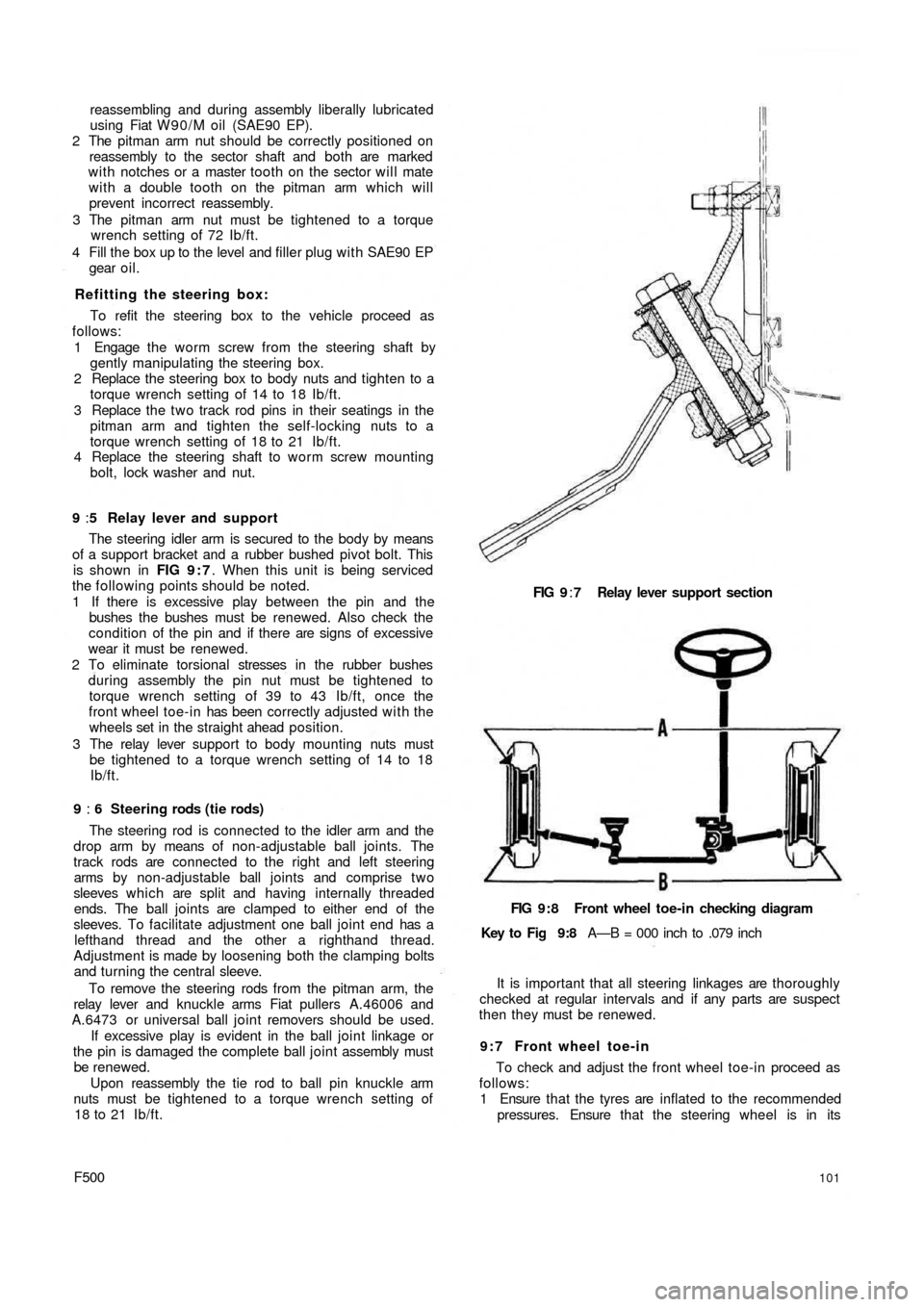

9 :5 Relay lever and support

The steering idler arm is secured to the body by means

of a support bracket and a rubber bushed pivot bolt. This

is shown in FIG 9 : 7. When this unit is being serviced

the following points should be noted.

1 If there is excessive play between the pin and the

bushes the bushes must be renewed. Also check the

condition of the pin and if there are signs of excessive

wear it must be renewed.

2 To eliminate torsional stresses in the rubber bushes

during assembly the pin nut must be tightened to

torque wrench setting of 39 to 43 Ib/ft, once the

front wheel toe-in has been correctly adjusted w i t h the

wheels set in the straight ahead position.

3 The relay lever support to body mounting nuts must

be tightened to a torque wrench setting of 14 to 18

Ib/ft.

9 : 6 Steering rods (tie rods)

The steering rod is connected to the idler arm and the

drop arm by means of non-adjustable ball joints. The

track rods are connected to the right and left steering

arms by non-adjustable ball joints and comprise t w o

sleeves which are split and having internally threaded

ends. The ball joints are clamped to either end of the

sleeves. To facilitate adjustment one ball joint end has a

lefthand thread and the other a righthand thread.

Adjustment is made by loosening both the clamping bolts

and turning the central sleeve.

To remove the steering rods from the pitman arm, the

relay lever and knuckle arms Fiat pullers A.46006 and

A.6473 or universal ball joint removers should be used.

If excessive play is evident in the ball joint linkage or

the pin is damaged the complete ball joint assembly must

be renewed.

Upon reassembly the tie rod to ball pin knuckle arm

nuts must be tightened to a torque wrench setting of

18 to 21 Ib/ft.

F500101

FIG 9:7 Relay lever support section

FIG 9:8 Front wheel toe-in checking diagram

Key to Fig 9:8 A—B = 000 inch to .079 inch

It is important that all steering linkages are thoroughly

checked at regular intervals and if any parts are suspect

then they must be renewed.

9 : 7 Front wheel toe-in

To check and adjust the front wheel toe-in proceed as

follows:

1 Ensure that the tyres are inflated to the recommended

pressures. Ensure that the steering wheel is in its

Page 97 of 128

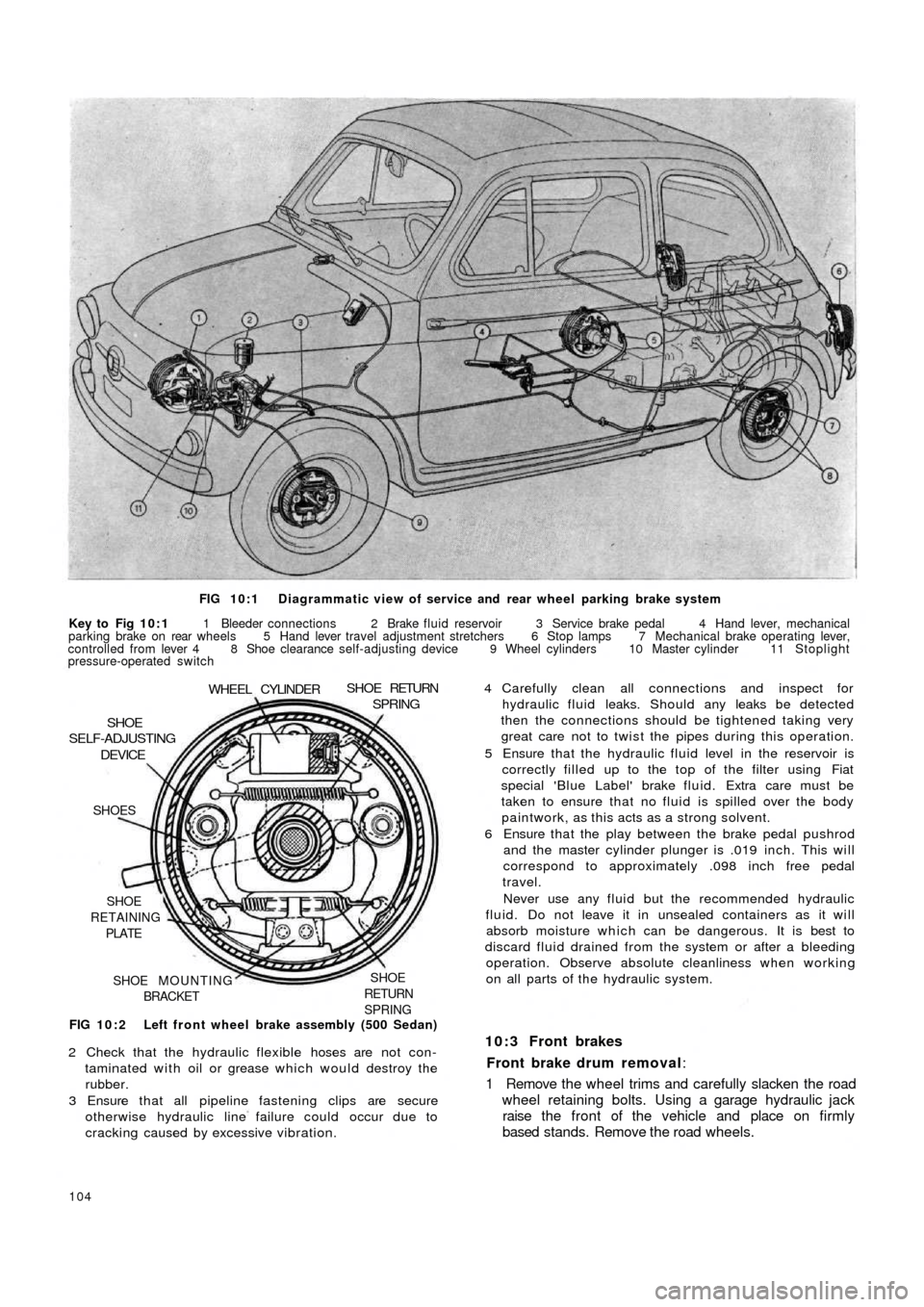

FIG 10:1 Diagrammatic view of service and rear wheel parking brake system

Key to Fig 10:1 1 Bleeder connections 2 Brake fluid reservoir 3 Service brake pedal 4 Hand lever, mechanical

parking brake on rear wheels 5 Hand lever travel adjustment stretchers 6 Stop lamps 7 Mechanical brake operating lever,

controlled from lever 4 8 Shoe clearance self-adjusting device 9 Wheel cylinders 10 Master cylinder 11 Stoplight

pressure-operated switch

FIG 10:2 Left front wheel brake assembly (500 Sedan)

SHOE

RETURN

SPRINGSHOE MOUNTING

BRACKET SHOE

RETAINING

PLATE SHOES

DEVICESHOE

SELF-ADJUSTING

WHEEL CYLINDERSHOE RETURNSPRING

2 Check that the hydraulic flexible hoses are not con-

taminated with oil or grease which would destroy the

rubber.

3 Ensure that all pipeline fastening clips are secure

otherwise hydraulic line failure could occur due to

cracking caused by excessive vibration.

104

4 Carefully clean all connections and inspect for

hydraulic fluid leaks. Should any leaks be detected

then the connections should be tightened taking very

great care not to twist the pipes during this operation.

5 Ensure that the hydraulic fluid level in the reservoir is

correctly filled up to the top of the filter using Fiat

special 'Blue Label' brake fluid. Extra care must be

taken to ensure that no fluid is spilled over the body

paintwork, as this acts as a strong solvent.

6 Ensure that the play between the brake pedal pushrod

and the master cylinder plunger is .019 inch. This will

correspond to approximately .098 inch free pedal

travel.

Never use any fluid but the recommended hydraulic

fluid. Do not leave it in unsealed containers as it will

absorb moisture which can be dangerous. It is best to

discard fluid drained from the system or after a bleeding

operation. Observe absolute cleanliness when working

on all parts of the hydraulic system.

10:3 Front brakes

Front brake drum removal:

1 Remove the wheel trims and carefully slacken the road

wheel retaining bolts. Using a garage hydraulic jack

raise the front of the vehicle and place on firmly

based stands. Remove the road wheels.

Page 104 of 128

CHAPTER 11

THE ELECTRICAL EQUIPMENT

11:1 Description

11:2 Battery

11:3 The generator

11:4 The starter

11:5 The control box

1 1 : 6 Fuses

1 1 : 7 Flasher unit

11:1 Description

All models covered by this manual have 12 volts

electrical systems in which the negative battery terminal

is earthed. There are three units in the regulator box to

control the charging circuit; a cut-out, a current regulator

and a voltage regulator. These are adjustable but it must

be stressed that accurate moving coil meters are required

when checking or altering the settings. Cheap and

unreliable instruments will make accurate adjustments

impossible.

There are wiring diagrams in Technical Data at the end

of this manual to enable those with electrical experience

to trace and correct wiring faults.

For t h e U.K. Market the headlamps are of the double

filament dipping renewable bulb type with adjustments

for individual beam settings.

The battery is located in the front compartment

forward of the petrol tank and the fuses to the rear o f the

petrol tank.

Detailed instructions for servicing the electrical equip-

ment will be found in this chapter, but it must be pointed

out that it is not sensible to try to repair that which is

seriously defective, electrically or mechanically. Such

equipment should be replaced by new units which can

be obtained on an exchange basis.

F500111

11 :8 Windscreen wipers

1 1 : 9 The lighting system

11:10 Panel and warning lights

11:11 The horn

11:12 Lighting and flasher switch

1 1 : 1 3 Fault diagnosis

11.2 The battery

This of the 12-volt lead/acid type and has to meet

heavy demands for current particularly in the winter. To

maintain the performance of the battery at its maximum

it is essential to carry out the following operations.

Keep the top of the battery and surrounding parts dry

and clean, as dampness can cause leakage between the

securing clamps and the battery terminals. Clean off any

corrosion from the metal parts of the battery mounting

with diluted ammonia and paint them with an anti-

sulphuric paint. If the terminal posts are corroded,

remove the cables and clean w i t h diluted ammonia.

Smear the posts w i t h petroleum jelly before remaking the

connections and fit the terminals securely. High electrical

resistance due to corrosion at the terminal posts is often

responsible for lack of sufficient current to operate the

starter motor.

Ensure t h a t the filler plugs are in good condition and

show no signs of cracks. This may cause leakage of

electrolyte and consequent corrosion. Test the condition

of the cells after topping-up the electrolyte level with

distilled water to just above the tops of the separators as

shown in FIG 11 :2 . Never add neat acid. If it is

necessary to make a new electrolyte due to loss by

spillage add sulphuric acid to the

distilled water.

It is highly dangerous to add water to acid.

Page 109 of 128

4

53 2 1

7

6

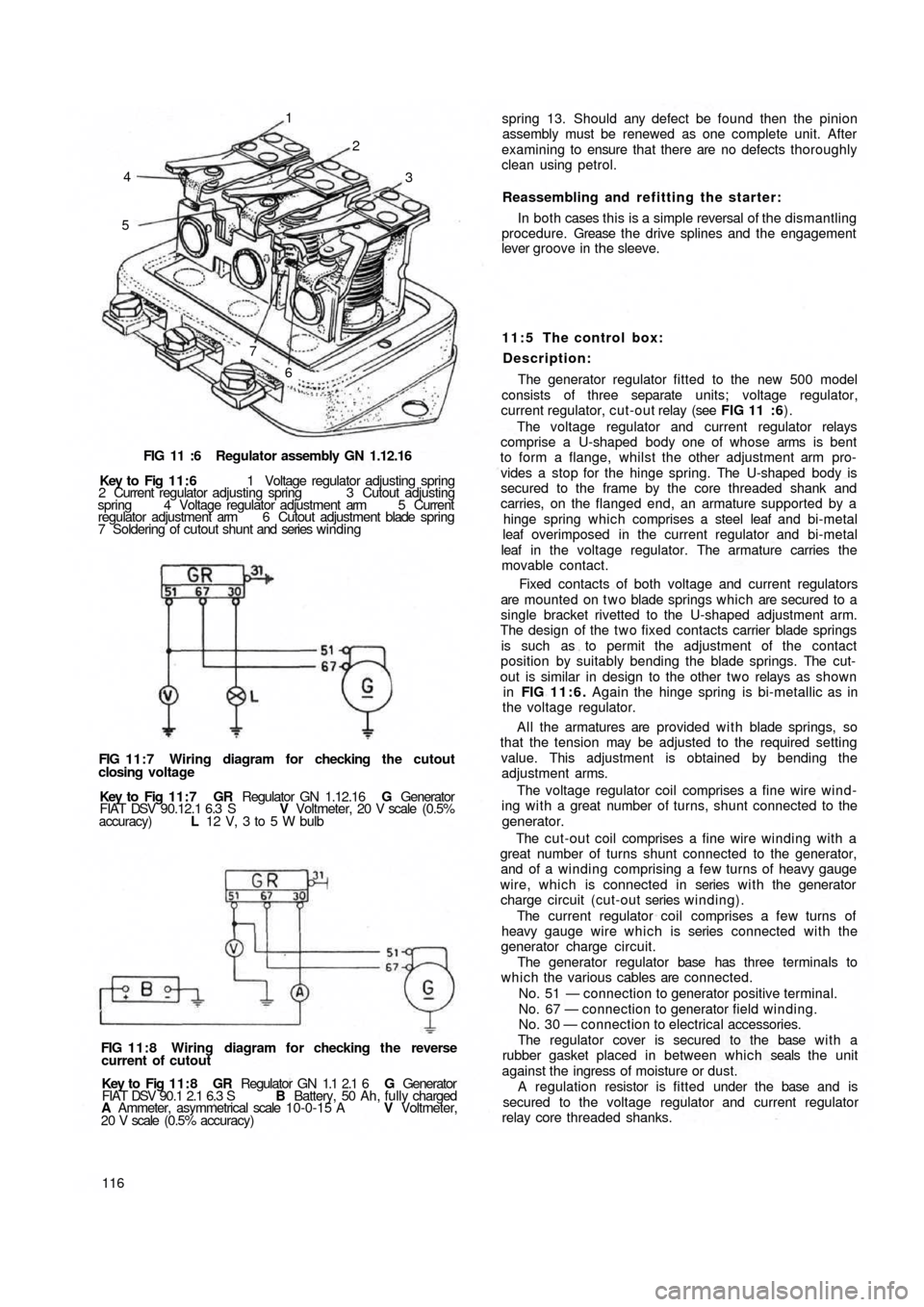

FIG 11 :6 Regulator assembly GN 1.12.16

Key to Fig 11:6 1 Voltage regulator adjusting spring

2 Current regulator adjusting spring 3 Cutout adjusting

spring 4 Voltage regulator adjustment arm 5 Current

regulator adjustment arm 6 Cutout adjustment blade spring

7 Soldering of cutout shunt and series winding

FIG 11:7 Wiring diagram for checking the cutout

closing voltage

Key to Fig 1 1 : 7 GR Regulator GN 1.12.16 G Generator

FIAT DSV 90.12.1 6.3 S V Voltmeter, 20 V scale (0.5%

accuracy) L 12 V, 3 to 5 W bulb

FIG 11:8 Wiring diagram for checking the reverse

current of cutout

Key to Fig 11:8 GR Regulator GN 1.1 2.1 6 G Generator

FIAT DSV 90.1 2.1 6.3 S B Battery, 50 Ah, fully charged

A Ammeter, asymmetrical scale 10-0-15 A V Voltmeter,

20 V scale (0.5% accuracy)

116spring 13. Should any defect be found then the pinion

assembly must be renewed as one complete unit. After

examining to ensure that there are no defects thoroughly

clean using petrol.

Reassembling and refitting the starter:

In both cases this is a simple reversal of the dismantling

procedure. Grease t h e drive splines and the engagement

lever groove in the sleeve.

11:5 The control box:

Description:

The generator regulator fitted to the new 500 model

consists of three separate

units; voltage regulator,

current regulator, cut-out relay (see FIG 11 :6).

The voltage regulator and current regulator relays

comprise a U-shaped body one of whose arms is bent

to form a flange, whilst the other adjustment arm pro-

vides a stop for the hinge spring. The U-shaped body is

secured to the frame by the core threaded shank and

carries, on the flanged end, an armature supported by a

hinge spring which comprises a steel leaf and bi-metal

leaf overimposed in the current regulator and bi-metal

leaf in the voltage regulator. The armature carries the

movable contact.

Fixed contacts of both voltage and current regulators

are mounted on t w o blade springs which are secured to a

single bracket rivetted to the U-shaped adjustment arm.

The design of the t w o fixed contacts carrier blade springs

is such as to permit the adjustment of the contact

position by suitably bending the blade springs. The cut-

out is similar in design to the other two relays as shown

in FIG 11:6. Again the hinge spring is bi-metallic as in

the voltage regulator.

All the armatures are provided w i t h blade springs, so

that the tension may be adjusted to the required setting

value. This adjustment is obtained by bending the

adjustment arms.

The voltage regulator coil comprises a fine wire wind-

ing w i t h a great number of turns, shunt connected to the

generator.

The cut-out coil comprises a fine wire winding with a

great number of turns shunt connected to the generator,

and of a winding comprising a few turns of heavy gauge

wire, which is connected in series w i t h the generator

charge circuit (cut-out series winding).

The current regulator coil comprises a few turns of

heavy gauge wire which is series connected with the

generator charge circuit.

The generator regulator base has three terminals to

which the various cables are connected.

No. 51 — connection to generator positive terminal.

No. 67 — connection to generator field winding.

No. 30 — connection to electrical accessories.

The regulator cover is secured to the base w i t h a

rubber gasket placed in between which seals the unit

against the ingress of moisture or dust.

A regulation resistor is fitted under the base and is

secured to the voltage regulator and current regulator

relay core threaded shanks.

Page 110 of 128

Checking cut-out:

1 Closing voltage:

This test should be carried out at a temperature of

25°±10°C and the regulator should be connected to a

generator test bed as shown in FIG 11:7. The unit should

be operated under no load conditions for between 15 -

18 minutes with the cover installed and w i t h a voltage of

between 16.5 volts for an initial operating temperature of

15-20°C or 15 volts for an initial operating temperature

of 20-35°C. This will enable thermal stabilization of the

unit to be obtained so that the temperature of both the

cut-out shunt windings and the bymetallic springs

increase due to the heat developed by the windings and

reaches the normal operating setting.

Once thermal stabilization has been obtained the

generator should be restarted and the speed gradually

increased so that immediately the test lamp starts to

glow the voltmeter reading may be taken. This will be

the value of the cut-out contact closing voltage.

2 Reverse current:

This check should be carried out at a temperature range

of between 25°±10°C and it is recommended that it is

performed as soon as possible after the closing voltage

test so that the thermal stabilization remains unaltered.

Connect the regulator as shown in FIG 11:8 and

gradually speed up the generator to 4500 rev/min for

approximately 5 minutes. Ensure that the voltmeter reads

at least 14.5 volts and then gradually reduce the generator

speed carefully watching the movement of the ammeter

needle which should at first indicate a charging current

and then gradually move to zero and then to the other side

of the scale to indicate reverse current value. If the

generator speed is reduced further the reverse current

reading will increase to a given value and then suddenly

fall to zero which will indicate that the cut-out contact

has opened. This limit indicates the maximum reverse

current value which should not, under any circumstances,

exceed 16 amps.

During this test, to obtain the maximum reverse

current possible the reduction in generator speed must

not take more than 10 seconds otherwise the battery

voltage will drop excessively.

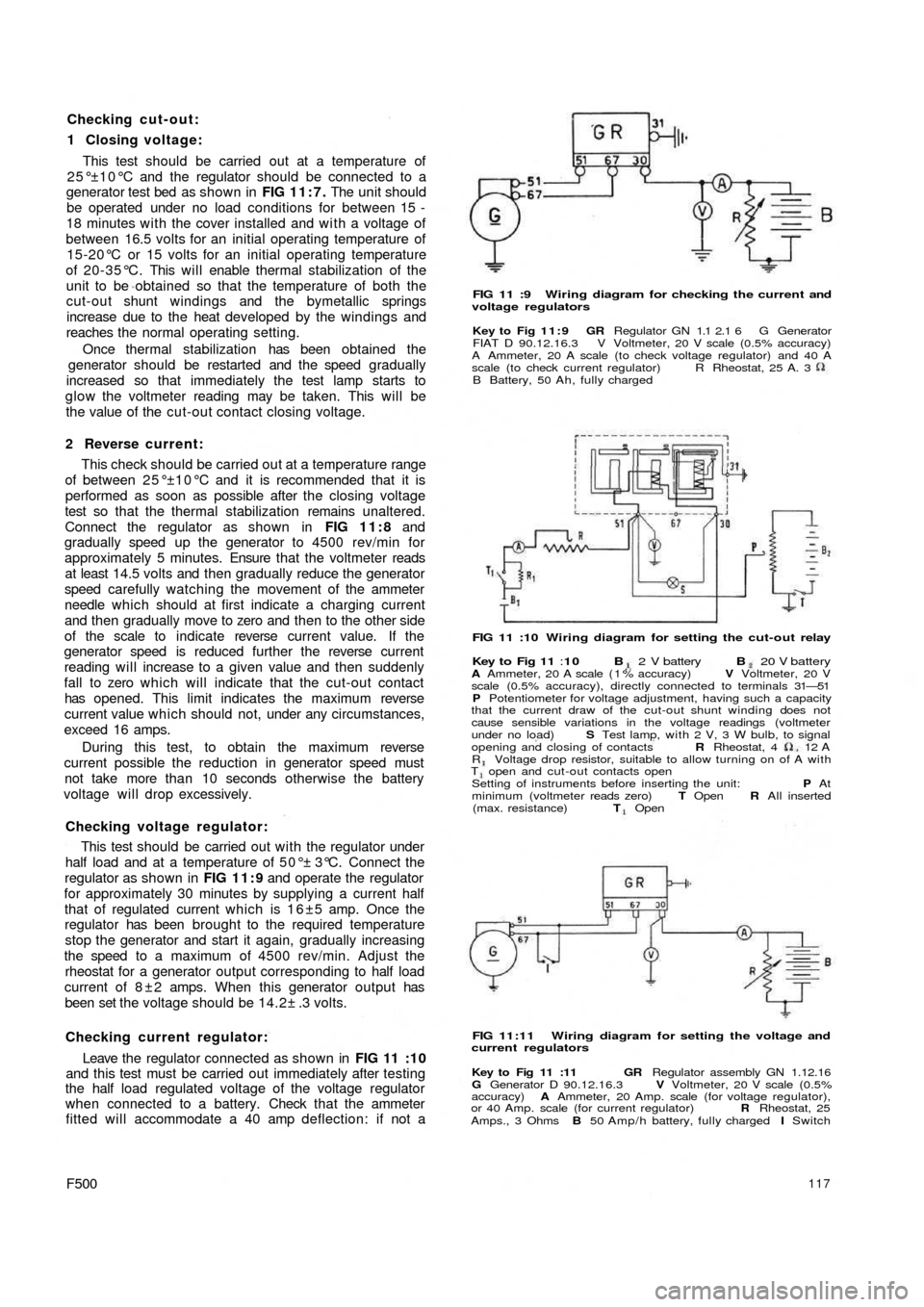

Checking voltage regulator:

This test should be carried out w i t h the regulator under

half load and at a temperature of 50°± 3°C. Connect the

regulator as shown in FIG 11:9 and operate the regulator

for approximately 30 minutes by supplying a current half

that of regulated current which is 1 6 ±5 amp. Once the

regulator has been brought to the required temperature

stop the generator and start it again, gradually increasing

the speed to a maximum of 4500 rev/min. Adjust the

rheostat for a generator output corresponding to half load

current of 8 ± 2 amps. When this generator output has

been set the voltage should be 14.2± .3 volts.

Checking current regulator:

Leave the regulator connected as shown in

FIG 11 :10

and this test must be carried out immediately after testing

the half load regulated voltage of the voltage regulator

when connected to a battery. Check that the ammeter

fitted will accommodate a 40 amp deflection: if not a

F500117

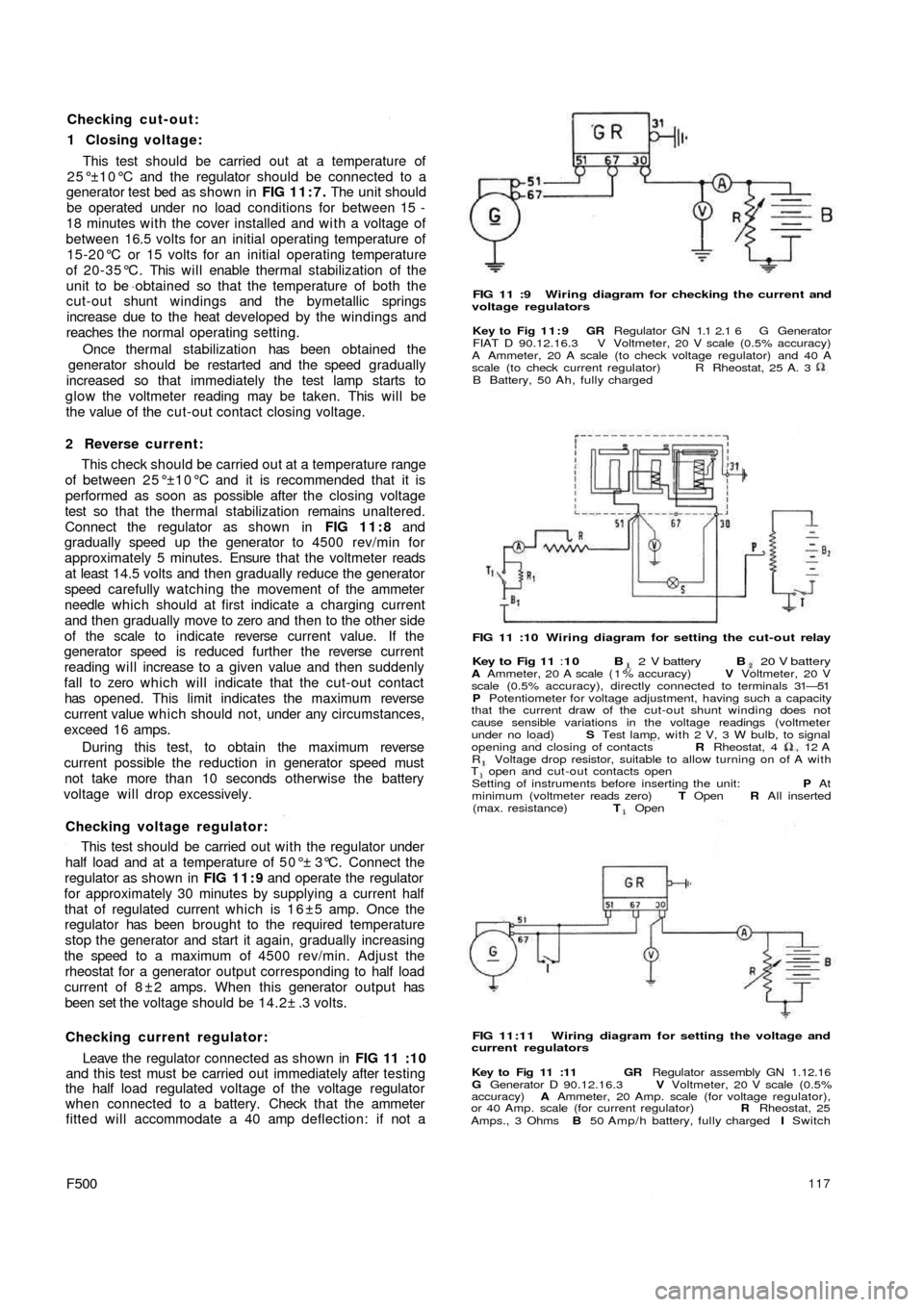

FIG 11 :9 Wiring diagram for checking the current and

voltage regulators

Key to Fig 11:9 GR Regulator GN 1.1 2.1 6 G Generator

FIAT D 90.12.16.3 V Voltmeter, 20 V scale (0.5% accuracy)

A Ammeter, 20 A scale (to check voltage regulator) and 40 A

scale (to check current regulator)

B Battery, 50 Ah, fully chargedR Rheostat, 25 A. 3

FIG 11 :10 Wiring diagram for setting the cut-out relay

Key to Fig 11 :10 B 2 V battery B 20 V batteryA Ammeter, 20 A scale ( 1 % accuracy) V Voltmeter, 20 V

scale (0.5% accuracy), directly connected to terminals 31—51

P Potentiometer for voltage adjustment, having such a capacity

that the current draw of the cut-out shunt winding does not

cause sensible variations in the voltage readings (voltmeter

under no load) S Test lamp, with 2 V, 3 W bulb, to signal

opening and closing of contacts R Rheostat, 4 12

AR Voltage drop resistor, suitable to allow turning on of A withT open and cut-out contacts open

Setting of instruments before inserting the unit: P At

minimum (voltmeter reads zero) T Open R All inserted

(max. resistance) T Open

FIG 11:11 Wiring diagram for setting the voltage and

current regulators

Key to Fig 11 :11 GR Regulator assembly GN 1.12.16

G Generator D 90.12.16.3 V Voltmeter, 20 V scale (0.5%

accuracy) A Ammeter, 20 Amp. scale (for voltage regulator),

or 40 Amp. scale (for current regulator) R Rheostat, 25

Amps., 3 Ohms B 50 Amp/h battery, fully charged I Switch

Page 111 of 128

Checking cut-out:

1 Closing voltage:

This test should be carried out at a temperature of

25°±10°C and the regulator should be connected to a

generator test bed as shown in FIG 11:7. The unit should

be operated under no load conditions for between 15 -

18 minutes with the cover installed and w i t h a voltage of

between 16.5 volts for an initial operating temperature of

15-20°C or 15 volts for an initial operating temperature

of 20-35°C. This will enable thermal stabilization of the

unit to be obtained so that the temperature of both the

cut-out shunt windings and the bymetallic springs

increase due to the heat developed by the windings and

reaches the normal operating setting.

Once thermal stabilization has been obtained the

generator should be restarted and the speed gradually

increased so that immediately the test lamp starts to

glow the voltmeter reading may be taken. This will be

the value of the cut-out contact closing voltage.

2 Reverse current:

This check should be carried out at a temperature range

of between 25°±10°C and it is recommended that it is

performed as soon as possible after the closing voltage

test so that the thermal stabilization remains unaltered.

Connect the regulator as shown in FIG 11:8 and

gradually speed up the generator to 4500 rev/min for

approximately 5 minutes. Ensure that the voltmeter reads

at least 14.5 volts and then gradually reduce the generator

speed carefully watching the movement of the ammeter

needle which should at first indicate a charging current

and then gradually move to zero and then to the other side

of the scale to indicate reverse current value. If the

generator speed is reduced further the reverse current

reading will increase to a given value and then suddenly

fall to zero which will indicate that the cut-out contact

has opened. This limit indicates the maximum reverse

current value which should not, under any circumstances,

exceed 16 amps.

During this test, to obtain the maximum reverse

current possible the reduction in generator speed must

not take more than 10 seconds otherwise the battery

voltage will drop excessively.

Checking voltage regulator:

This test should be carried out w i t h the regulator under

half load and at a temperature of 50°± 3°C. Connect the

regulator as shown in FIG 11:9 and operate the regulator

for approximately 30 minutes by supplying a current half

that of regulated current which is 1 6 ±5 amp. Once the

regulator has been brought to the required temperature

stop the generator and start it again, gradually increasing

the speed to a maximum of 4500 rev/min. Adjust the

rheostat for a generator output corresponding to half load

current of 8 ± 2 amps. When this generator output has

been set the voltage should be 14.2± .3 volts.

Checking current regulator:

Leave the regulator connected as shown in

FIG 11 :10

and this test must be carried out immediately after testing

the half load regulated voltage of the voltage regulator

when connected to a battery. Check that the ammeter

fitted will accommodate a 40 amp deflection: if not a

F500117

FIG 11 :9 Wiring diagram for checking the current and

voltage regulators

Key to Fig 11:9 GR Regulator GN 1.1 2.1 6 G Generator

FIAT D 90.12.16.3 V Voltmeter, 20 V scale (0.5% accuracy)

A Ammeter, 20 A scale (to check voltage regulator) and 40 A

scale (to check current regulator)

B Battery, 50 Ah, fully chargedR Rheostat, 25 A. 3

FIG 11 :10 Wiring diagram for setting the cut-out relay

Key to Fig 11 :10 B 2 V battery B 20 V batteryA Ammeter, 20 A scale ( 1 % accuracy) V Voltmeter, 20 V

scale (0.5% accuracy), directly connected to terminals 31—51

P Potentiometer for voltage adjustment, having such a capacity

that the current draw of the cut-out shunt winding does not

cause sensible variations in the voltage readings (voltmeter

under no load) S Test lamp, with 2 V, 3 W bulb, to signal

opening and closing of contacts R Rheostat, 4 12

AR Voltage drop resistor, suitable to allow turning on of A withT open and cut-out contacts open

Setting of instruments before inserting the unit: P At

minimum (voltmeter reads zero) T Open R All inserted

(max. resistance) T Open

FIG 11:11 Wiring diagram for setting the voltage and

current regulators

Key to Fig 11 :11 GR Regulator assembly GN 1.12.16

G Generator D 90.12.16.3 V Voltmeter, 20 V scale (0.5%

accuracy) A Ammeter, 20 Amp. scale (for voltage regulator),

or 40 Amp. scale (for current regulator) R Rheostat, 25

Amps., 3 Ohms B 50 Amp/h battery, fully charged I Switch

Page 112 of 128

FIG 11:12 Wiring diagram for setting the cutout relay

Key to Fig 11 :12 B 2 V battery B 20 V battery

A Ammeter, 15 A scale ( 1 % accuracy) V Voltmeter, 20 V

scale (0.5% accuracy), directly connected to terminals 31-51

P Potentiometer for voltage adjustment, having such a capacity

that the current draw of the cutout shunt winding does not cause

sensible variations in the voltage readings (voltmeter under no

load) S Test lamp, with 2 V, 3 W bulb, to signal opening

and closing of contacts R Rheostat, 4 , 1 2 A R Voltagedrop rheostat, suitable to allow turning on of S with T open and

cutout contacts open

Setting of instruments before inserting the unit: P At

minimum (Voltmeter reads zero) T Open R All inserted

(max. resistance) T Open

1

2

3

4

5

6

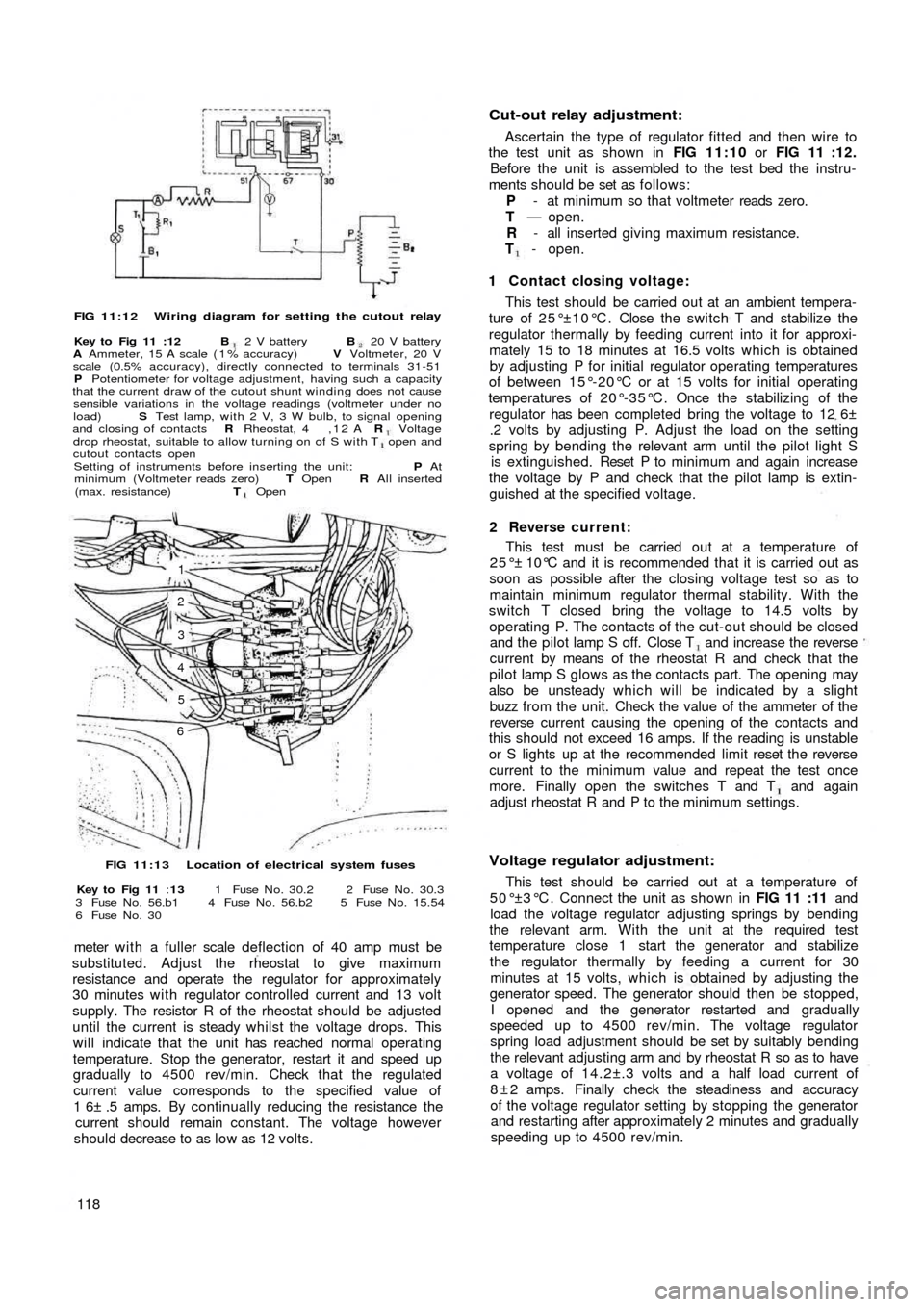

FIG 11:13 Location of electrical system fuses

Key to Fig 11 :13 1 Fuse N o . 30.2 2 Fuse N o . 30.3

3 Fuse N o . 56.b1 4 Fuse N o . 56.b2 5 Fuse N o . 15.54

6 Fuse N o . 30

meter w i t h a fuller scale deflection of 40 amp must be

substituted. Adjust the rheostat to give maximum

resistance and operate the regulator for approximately

30 minutes with regulator controlled current and 13 volt

supply. The resistor R of the rheostat should be adjusted

until the current is steady whilst the voltage drops. This

will indicate that the unit has reached normal operating

temperature. Stop the generator, restart it and speed up

gradually to 4500 rev/min. Check that the regulated

current value corresponds to the specified value of

1 6± .5 amps. By continually reducing the resistance the

current should remain constant. The voltage however

should decrease to as l o w as 12 volts.

118

Cut-out relay adjustment:

Ascertain the type of regulator fitted and then wire to

the test unit as shown in FIG 11:10 or FIG 11 :12.

Before the unit is assembled to the test bed the instru-

ments should be set as follows:

P - at minimum so that voltmeter reads zero.

T — open.

R - all inserted giving maximum resistance.

T - open.

1 Contact closing voltage:

This test should be carried out at an ambient tempera-

ture of 25°±10°C. Close the switch T and stabilize the

regulator thermally by feeding current into it for approxi-

mately 15 to 18 minutes at 16.5 volts which is obtained

by adjusting P for initial regulator operating temperatures

of between 15°-20°C or at 15 volts for initial operating

temperatures of 20°-35°C. Once the stabilizing of the

regulator has been completed bring the voltage to 12 6±

.2 volts by adjusting P. Adjust the load on the setting

spring by bending the relevant arm until the pilot light S

is extinguished. Reset P to m inimum and again increase

the voltage by P and check that the pilot lamp is extin-

guished at the specified voltage.

2 Reverse current:

This test must be carried out at a temperature of

25°± 10°C and it is recommended that it is carried out as

soon as possible after the closing voltage test so as to

maintain minimum regulator thermal stability. With the

switch T closed bring the voltage to 14.5 volts by

operating P. The contacts of the cut-out should be closed

and the pilot lamp S off. Close T and increase the reverse

current by means of the rheostat R and check that the

pilot lamp S glows as the contacts part. The opening may

also be unsteady which will be indicated by a slight

buzz from the unit. Check the value of the ammeter of the

reverse current causing the opening of the contacts and

this should not exceed 16 amps. If the reading is unstable

or S lights up at the recommended limit reset the reverse

current to the minimum value and repeat the test once

more. Finally open the switches T and T and again

adjust rheostat R and P to the minimum settings.

Voltage regulator adjustment:

This test should be carried out at a temperature of

5 0 ° ±3 ° C . Connect the unit as shown in FIG 11 :11 and

load the voltage regulator adjusting springs by bending

the relevant arm. With the unit at the required test

temperature close 1 start the generator and stabilize

the regulator thermally by feeding a current for 30

minutes at 15 volts, which is obtained by adjusting the

generator speed. The generator should then be stopped,

I opened and the generator restarted and gradually

speeded up to 4500 rev/min. The voltage regulator

spring load adjustment should be set by suitably bending

the relevant adjusting arm and by rheostat R so as to have

a voltage of 14.2±.3 volts and a half load current of

8 ± 2 amps. Finally check the steadiness and accuracy

of the voltage regulator setting by stopping the generator

and restarting after approximately 2 minutes and gradually

speeding up to 4500 rev/min.