tail FIAT 500 1957 1.G User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 1957, Model line: 500, Model: FIAT 500 1957 1.GPages: 128, PDF Size: 9.01 MB

Page 33 of 128

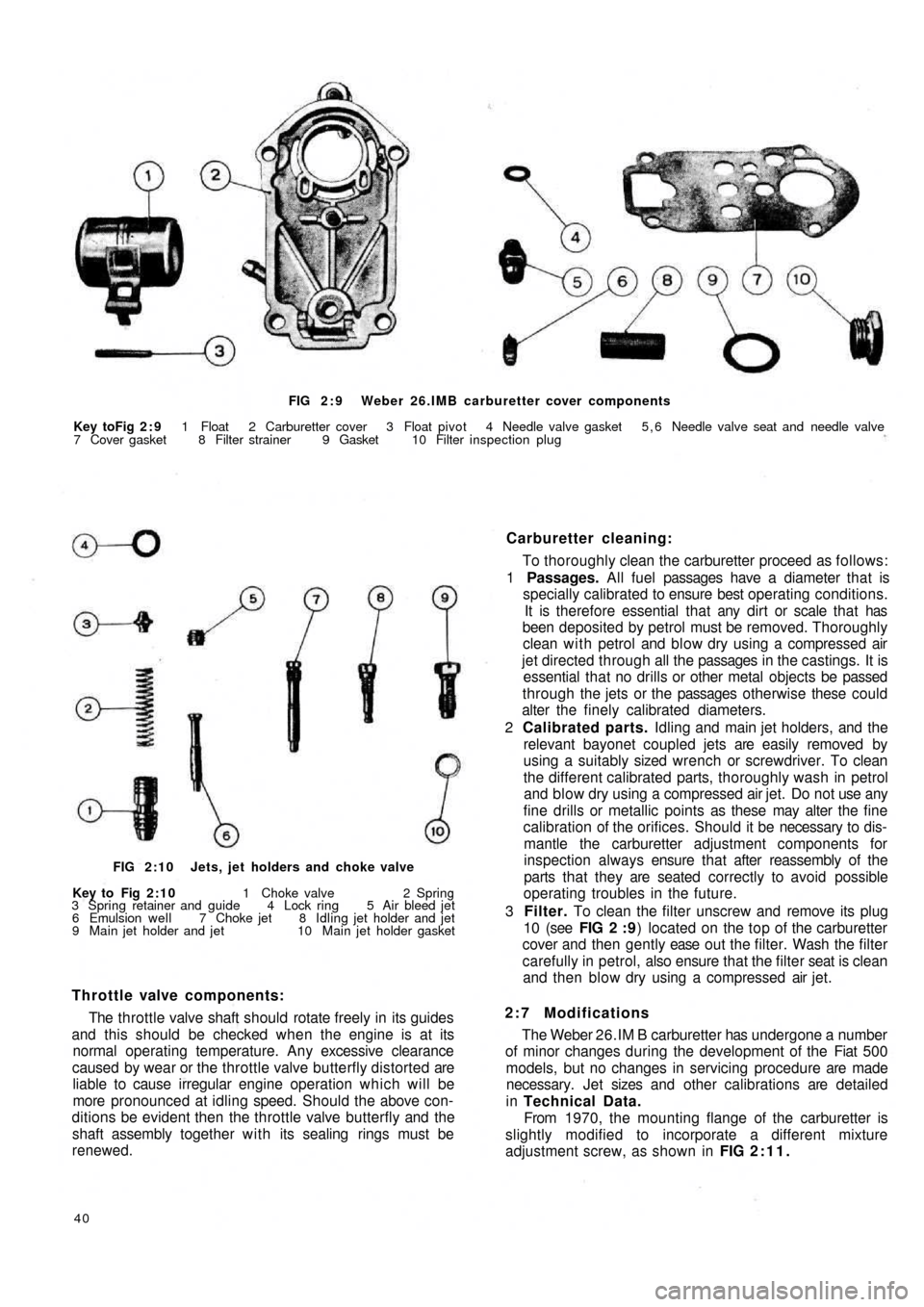

FIG 2 : 9 Weber 26.IMB carburetter cover components

Key toFig 2 : 9 1 Float 2 Carburetter cover 3 Float pivot 4 Needle valve gasket 5 , 6 Needle valve seat and needle valve

7 Cover gasket 8 Filter strainer 9 Gasket 10 Filter inspection plug

Carburetter cleaning:

To thoroughly clean the carburetter proceed as follows:

1 Passages. All fuel passages have a diameter that is

specially calibrated to ensure best operating conditions.

It is therefore essential that any dirt or scale that has

been deposited by petrol must be removed. Thoroughly

clean with petrol and blow dry using a compressed air

jet directed through all the passages in the castings. It is

essential that no drills or other metal objects be passed

through the jets or the passages otherwise these could

alter the finely calibrated diameters.

2 Calibrated parts. Idling and main jet holders, and the

relevant bayonet coupled jets are easily removed by

using a suitably sized wrench or screwdriver. To clean

the different calibrated parts, thoroughly wash in petrol

and blow dry using a compressed air jet. Do not use any

fine drills or metallic points as these may alter the fine

calibration of the orifices. Should it be necessary to dis-

mantle the carburetter adjustment components for

inspection always ensure that after reassembly of the

parts that they are seated correctly to avoid possible

operating troubles in the future.

3 Filter. To clean the filter unscrew and remove its plug

10 (see FIG 2 : 9) located on the top of the carburetter

cover and then gently ease o u t t h e filter. Wash the filter

carefully in petrol, also ensure that the filter seat is clean

and then blow dry using a compressed air jet.

2:7 Modifications

The Weber 26.IM B carburetter has undergone a number

of minor changes during the development of the Fiat 500

models, but no changes in servicing procedure are made

necessary. Jet sizes and other calibrations are detailed

in Technical Data.

From 1970, the mounting flange of the carburetter is

slightly modified to incorporate a different mixture

adjustment screw, as shown in FIG 2:11.

40

Throttle valve components:

The throttle valve shaft should rotate freely in its guides

and this should be checked when the engine is at its

normal operating temperature. Any excessive clearance

caused by wear or the throttle valve butterfly distorted are

liable to cause irregular engine operation which will be

more pronounced at idling speed. Should the above con-

ditions be evident then the throttle valve butterfly and the

shaft assembly together with its sealing rings must be

renewed.

FIG 2:10 Jets, jet holders and choke valve

Key to Fig 2:10 1 Choke valve 2 Spring

3 Spring retainer and guide 4 Lock ring 5 Air bleed jet

6 Emulsion well 7 Choke jet 8 Idling jet holder and jet

9 Main jet holder and jet 10 Main jet holder gasket

Page 34 of 128

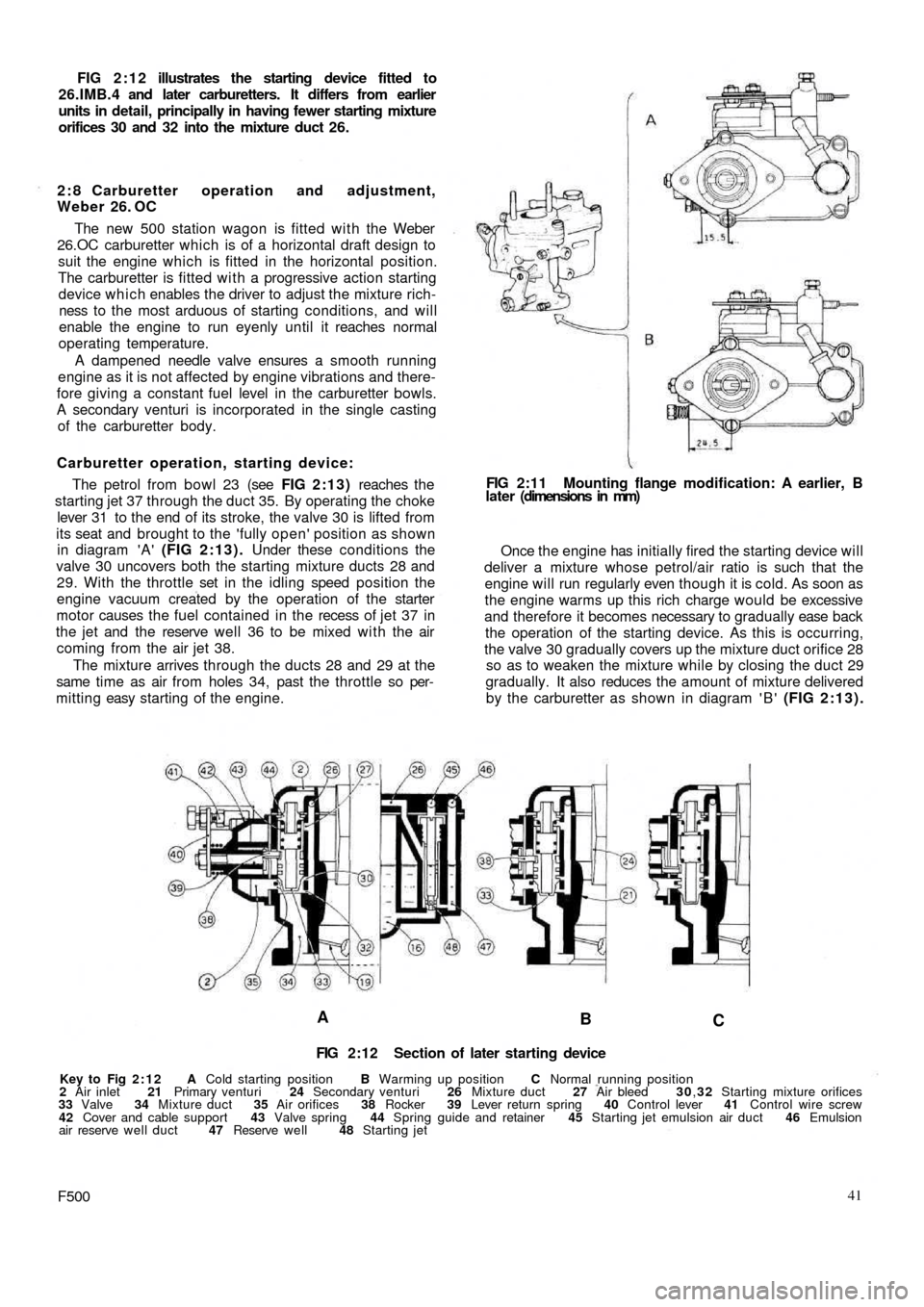

FIG 2:12 illustrates the starting device fitted to

26.IMB.4 and later carburetters. It differs from earlier

units in detail, principally in having fewer starting mixture

orifices 30 and 32 into the mixture duct 26.

2 : 8 Carburetter operation and adjustment,

Weber 26. OC

The new 500 station wagon is fitted with the Weber

26.OC carburetter which is of a horizontal draft design to

suit the engine which is fitted in the horizontal position.

The carburetter is fitted with a progressive action starting

device which enables the driver to adjust the mixture rich-

ness to the most arduous of starting conditions, and will

enable the engine to run eyenly until it reaches normal

operating temperature.

A dampened needle valve ensures a smooth running

engine as it is not affected by engine vibrations and there-

fore giving a constant fuel level in the carburetter bowls.

A secondary venturi is incorporated in the single casting

of the carburetter body.

Carburetter operation, starting device:

The petrol from bowl 23 (see FIG 2:13) reaches the

starting jet 37 through the duct 35. By operating the choke

lever 31 to the end of its stroke, the valve 30 is lifted from

its seat and brought to the 'fully open' position as shown

in diagram 'A' (FIG 2:13). Under these conditions the

valve 30 uncovers both the starting mixture ducts 28 and

29. With the throttle set in the idling speed position the

engine vacuum created by the operation of the starter

motor causes the fuel contained in the recess of j e t 37 in

the jet and the reserve

well 36 to be mixed with the air

coming from the air jet 38.

The mixture arrives through the ducts 28 and 29 at the

same time as air from holes 34, past the throttle so per-

mitting easy starting of the engine.

A

B

C

FIG 2:12 Section of later starting device

Key to Fig 2:12 A Cold starting position B Warming up position C Normal running position

2 Air inlet 21 Primary venturi 24 Secondary venturi 26 Mixture duct 27 Air bleed 30,32 Starting mixture orifices

33 Valve 34 Mixture duct 35 Air orifices 38 Rocker 39 Lever return spring 40 Control lever 41 Control wire screw

42 Cover and cable support 43 Valve spring 44 Spring guide and retainer 45 Starting jet emulsion air duct 46 Emulsion

air reserve well duct 47 Reserve well 48 Starting jet

F50041 Once the engine has initially fired the starting device will

deliver a mixture whose petrol/air ratio is such that the

engine will run regularly even though it is cold. As soon as

the engine warms up this rich charge would be excessive

and therefore it becomes necessary to gradually ease back

the operation of the starting device. As this is occurring,

the valve 30 gradually covers up the mixture duct orifice 28

so as to weaken the mixture while by closing the duct 29

gradually. It also reduces the amount of mixture delivered

by the carburetter as shown in diagram ' B ' (FIG 2:13). FIG 2:11 Mounting flange modification: A earlier, B

later (dimensions in mm)

Page 36 of 128

1

14,5

7,52 9 48 35

76

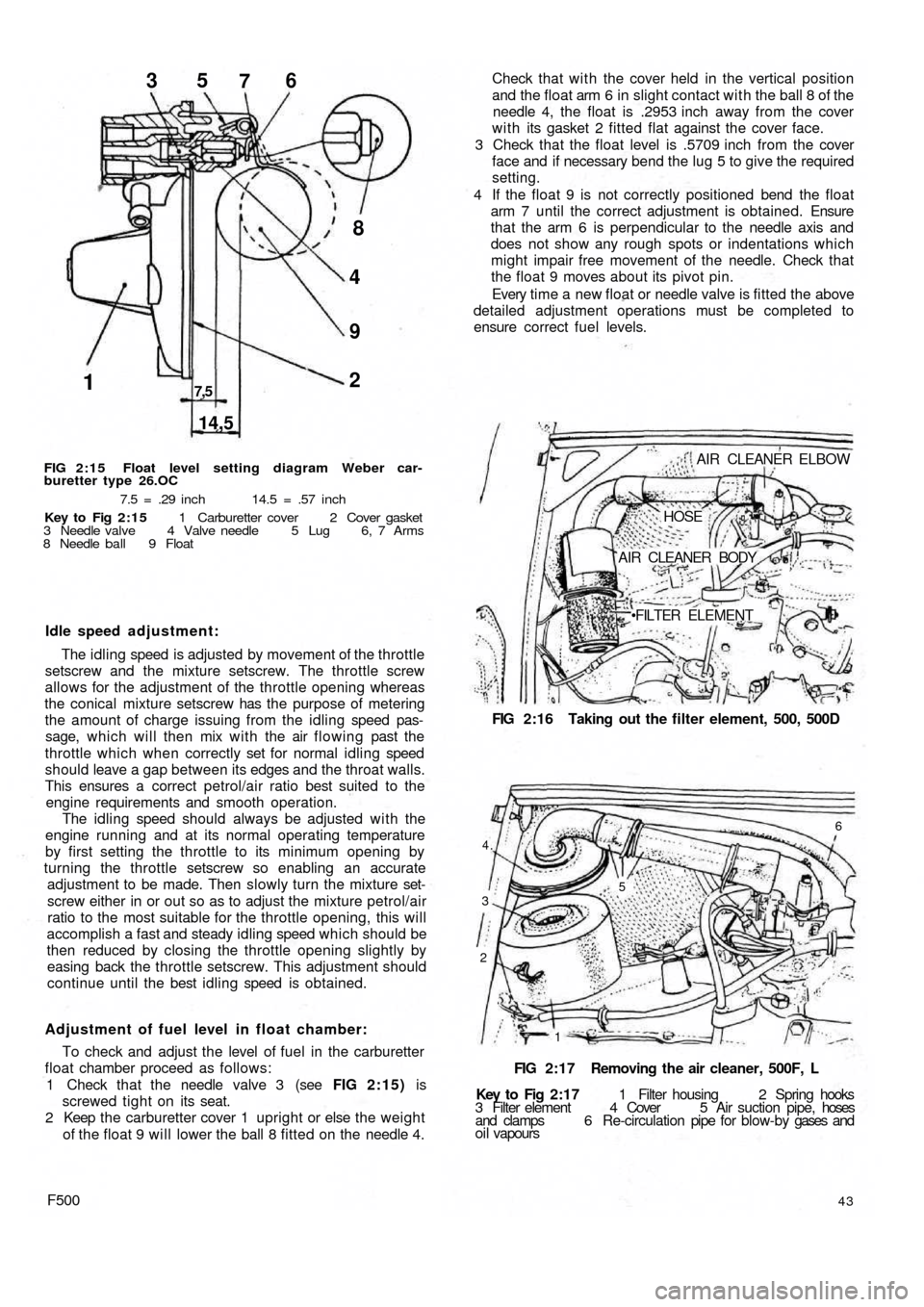

FIG 2:15 Float level setting diagram Weber car-

buretter type 26.OC

7.5 = .29 inch 14.5 = .57 inch

Key to Fig 2:15 1 Carburetter cover 2 Cover gasket

3 Needle valve 4 Valve needle 5 Lug 6, 7 Arms

8 Needle ball 9 Float

Idle speed adjustment:

The idling speed is adjusted by movement of the throttle

setscrew and the mixture setscrew. The throttle screw

allows for the adjustment of the throttle opening whereas

the conical mixture setscrew has the purpose of metering

the amount of charge issuing from the idling speed pas-

sage, which will then mix with the air flowing past the

throttle which when correctly set for normal idling speed

should leave a gap between its edges and the throat walls.

This ensures a correct petrol/air ratio best suited to the

engine requirements and smooth operation.

The idling speed should always be adjusted with the

engine running and at its normal operating temperature

by first setting the throttle to its minimum opening by

turning the throttle setscrew so enabling an accurate

adjustment to be made. Then slowly turn the mixture set-

screw either in or out so as to adjust the mixture petrol/air

ratio to the most suitable for the throttle opening, this will

accomplish a fast and steady idling speed which should be

then reduced by closing the throttle opening slightly by

easing back the throttle setscrew. This adjustment should

continue until the best idling speed is obtained.

Adjustment of fuel level in float chamber:

To check and adjust the level of fuel in the carburetter

float chamber proceed as follows:

1 Check that the needle valve 3 (see FIG 2:15) is

screwed tight on its seat.

2 Keep the carburetter cover 1 upright or else the weight

of the float 9 will lower the ball 8 fitted on the needle 4.

F50043

Key to Fig 2:17 1 Filter housing 2 Spring hooks

3 Filter element 4 Cover 5 Air suction pipe, hoses

and clamps 6 Re-circulation pipe for blow-by gases and

oil vapoursFIG 2:17 Removing the air cleaner, 500F, L

2

1 3

4.

6

5

FIG 2:16 Taking out the filter element, 500, 500D AIR CLEANER ELBOW

HOSE

AIR CLEANER BODY

FILTER ELEMENT Check that with the cover held in the vertical position

and the float arm 6 in slight contact with the ball 8 of the

needle 4, the float is .2953 inch away from the cover

w i t h its gasket 2 fitted flat against the cover face.

3 Check that the float level is .5709 inch from the cover

face and if necessary bend the lug 5 to give the required

setting.

4 If the float 9 is not correctly positioned bend the float

arm 7 until the correct adjustment is obtained. Ensure

that the arm 6 is perpendicular to the needle axis and

does not show any rough spots or indentations which

might impair free movement of the needle. Check that

the float 9 moves about its pivot pin.

Every time a new float or needle valve is fitted the above

detailed adjustment operations must be completed to

ensure correct fuel levels.

Page 37 of 128

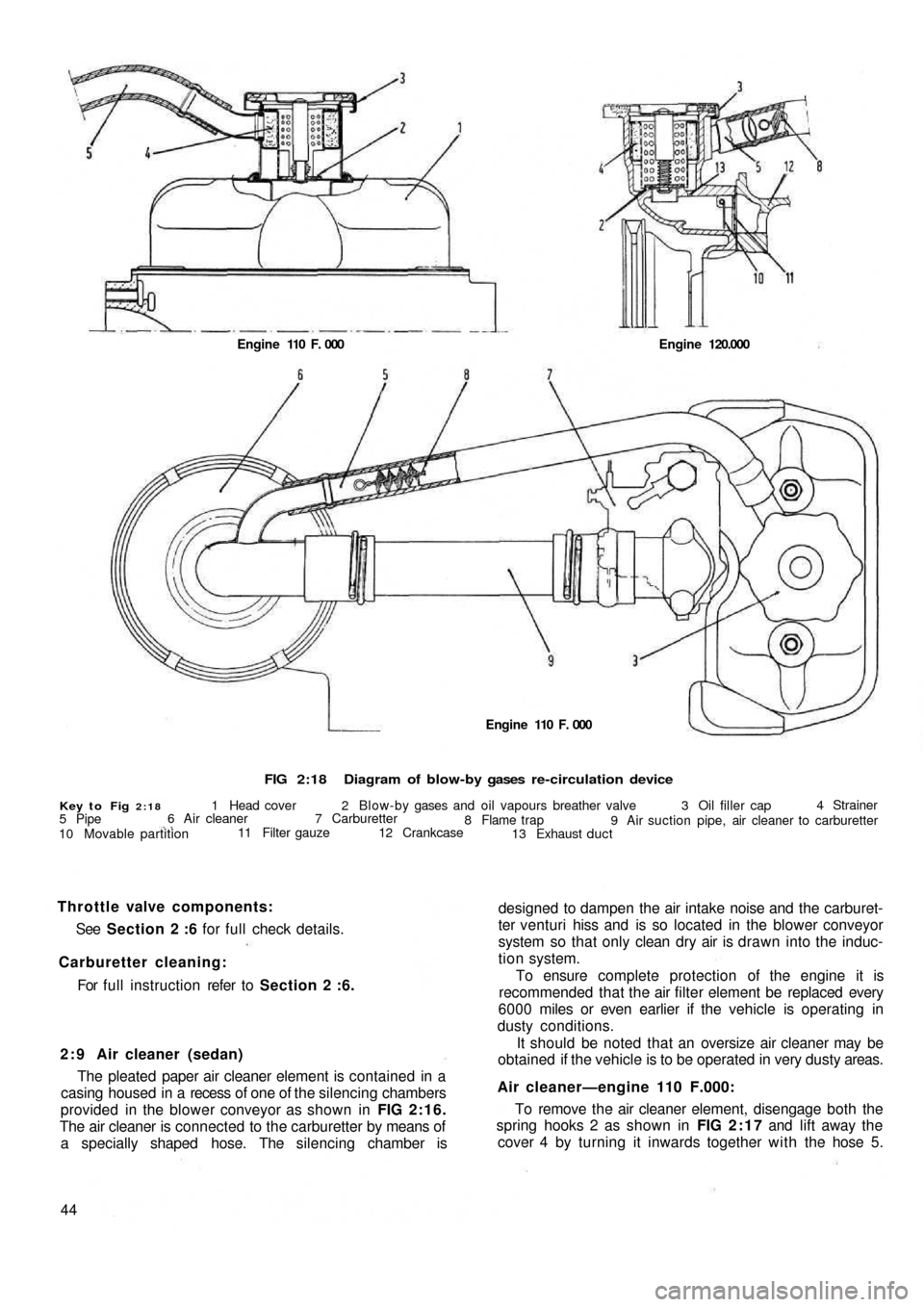

FIG 2:18Diagram of blow-by gases re-circulation device

Key to Fig 2:181 Head cover 2 Blow-by gases and oil vapours breather valve 3 Oil filler cap4 Strainer

9 Air suction pipe, air cleaner to carburetter 8 Flame trap

13 Exhaust duct 12 Crankcase 7 Carburetter 6 Air cleaner

11 Filter gauze

10 Movable partition 5 PipeEngine 110 F. 000 Engine 120.000

designed to dampen the air intake noise and the carburet-

ter venturi hiss and is so located in the blower conveyor

system so that only clean dry air is drawn into the induc-

tion system.

To ensure complete protection of the engine it is

recommended that the air filter element be replaced every

6000 miles or even earlier if the vehicle is operating in

dusty conditions.

It should be noted that an oversize air cleaner may be

obtained if the vehicle is to be operated in very dusty areas.

Air cleaner—engine 110 F.000:

To remove the air cleaner element, disengage both the

spring hooks 2 as shown in FIG 2:17 and lift away the

cover 4 by turning it inwards together with the hose 5. 2 : 9 Air cleaner (sedan)

The pleated paper air cleaner element is contained in a

casing housed in a recess of one of the silencing chambers

provided in the blower conveyor as shown in FIG 2:16.

The air cleaner is connected to the carburetter by means of

a specially shaped hose. The silencing chamber is

44For full instruction refer to Section 2 :6. Carburetter cleaning:See Section 2 :6 for full check details. Throttle valve components:

Engine 110 F. 000

Page 50 of 128

4 : 4 Heating system safety device

110F series sedan engines and later station wagon

engines incorporate a modification to the cylinder head

designed so that in the event of cylinder head gasket

failure exhaust gases are expelled outside the engine and

not leaked into the heating system.

The safety device comprises a square section circular

seat 1 (see FIG 4 :6) which is formed in the upper face of

the cylinder, a special duct in the cylinder head and a

pierced screw 3 for each cylinder.

The system is so designed that the exhaust gases are

released to the atmosphere from the circular seat in the

cylinder via the duct 2 and the pierced screw 3. It should

be noted that the screw 3 is also used for securing the

conveyor.

4 : 5 Maintenance

Due to the simple design of the air cooling system

maintenance has been kept to an absolute minimum and

should consist of the following checks:1 Inspect all the air conveyor system joints and ensure

that all the joint nuts and bolts are tight and that there

is no distortion between two joint faces.

2 Check that the tension of the generator and fan drive

belt is correct: with a hand pressure of approximately

22 Ib the belt should sag 13/32 inch. Adjust if necessary

as detailed in Chapter 1.

3 Ensure that the shutter can swivel freely and that the

spring is in a serviceable condition.

4 : 6 Fault diagnosis

(a) Engine overheating

1 Generator and fan drive belt slipping

2 Shutter control thermostat defective

3 Shutter unable to swivel freely

4 Shutter return spring broken

5 Leaking joints in conveyor system

F50057

Page 60 of 128

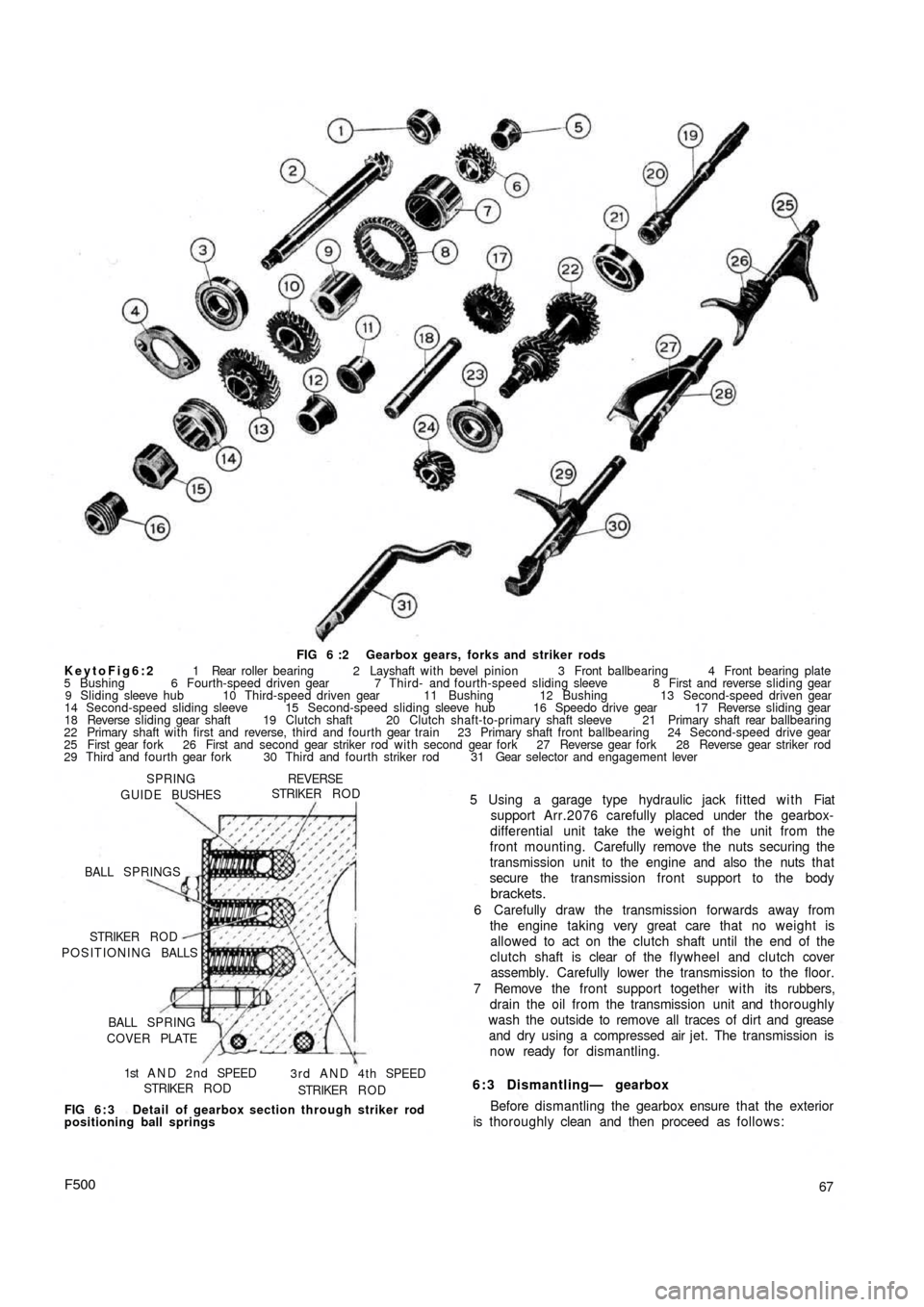

FIG 6 :2 Gearbox gears, forks and striker rods

KeytoFig6:2 1 Rear roller bearing 2 Layshaft with bevel pinion 3 Front ballbearing 4 Front bearing plate

5 Bushing 6 Fourth-speed driven gear 7 Third- and fourth-speed sliding sleeve 8 First and reverse sliding gear

9 Sliding sleeve hub 10 Third-speed driven gear 11 Bushing 12 Bushing 13 Second-speed driven gear

14 Second-speed sliding sleeve 15 Second-speed sliding sleeve hub 16 Speedo drive gear 17 Reverse sliding gear

18 Reverse sliding gear shaft 19 Clutch shaft 20 Clutch shaft-to-primary shaft sleeve 21 Primary shaft rear ballbearing

22 Primary shaft with first and reverse, third and fourth gear train 23 Primary shaft front ballbearing 24 Second-speed drive gear

25 First gear fork 26 First and second gear striker rod with second gear fork 27 Reverse gear fork 28 Reverse gear striker rod

29 Third and fourth gear fork 30 Third and fourth striker rod 31 Gear selector and engagement lever

SPRING

GUIDE BUSHES

REVERSESTRIKER R O D

BALL SPRINGS

POSITIONING BALLS STRIKER R O D

BALL SPRING

COVER PLATE

1st A N D 2 n d SPEED

STRIKER R O D3 r d A N D 4 t h SPEED

STRIKER R O D

FIG 6 : 3 Detail of gearbox section through striker rod

positioning ball springs

F50067 5 Using a garage type hydraulic jack fitted with Fiat

support Arr.2076 carefully placed under the gearbox-

differential unit take the weight of the unit from the

front mounting. Carefully remove the nuts securing the

transmission unit to the engine and also the nuts that

secure the transmission front support to the body

brackets.

6 Carefully draw the transmission forwards away from

the engine taking very great care that no weight is

allowed to act on the clutch shaft until the end of the

clutch shaft is clear of the flywheel and clutch cover

assembly. Carefully lower the transmission to the floor.

7 Remove the front support together with its rubbers,

drain the oil from the transmission unit and thoroughly

wash the outside to remove all traces of dirt and grease

and dry using a compressed air jet. The transmission is

now ready for dismantling.

6:3 Dismantling— gearbox

Before dismantling the gearbox ensure that the exterior

is thoroughly clean and then proceed as follows:

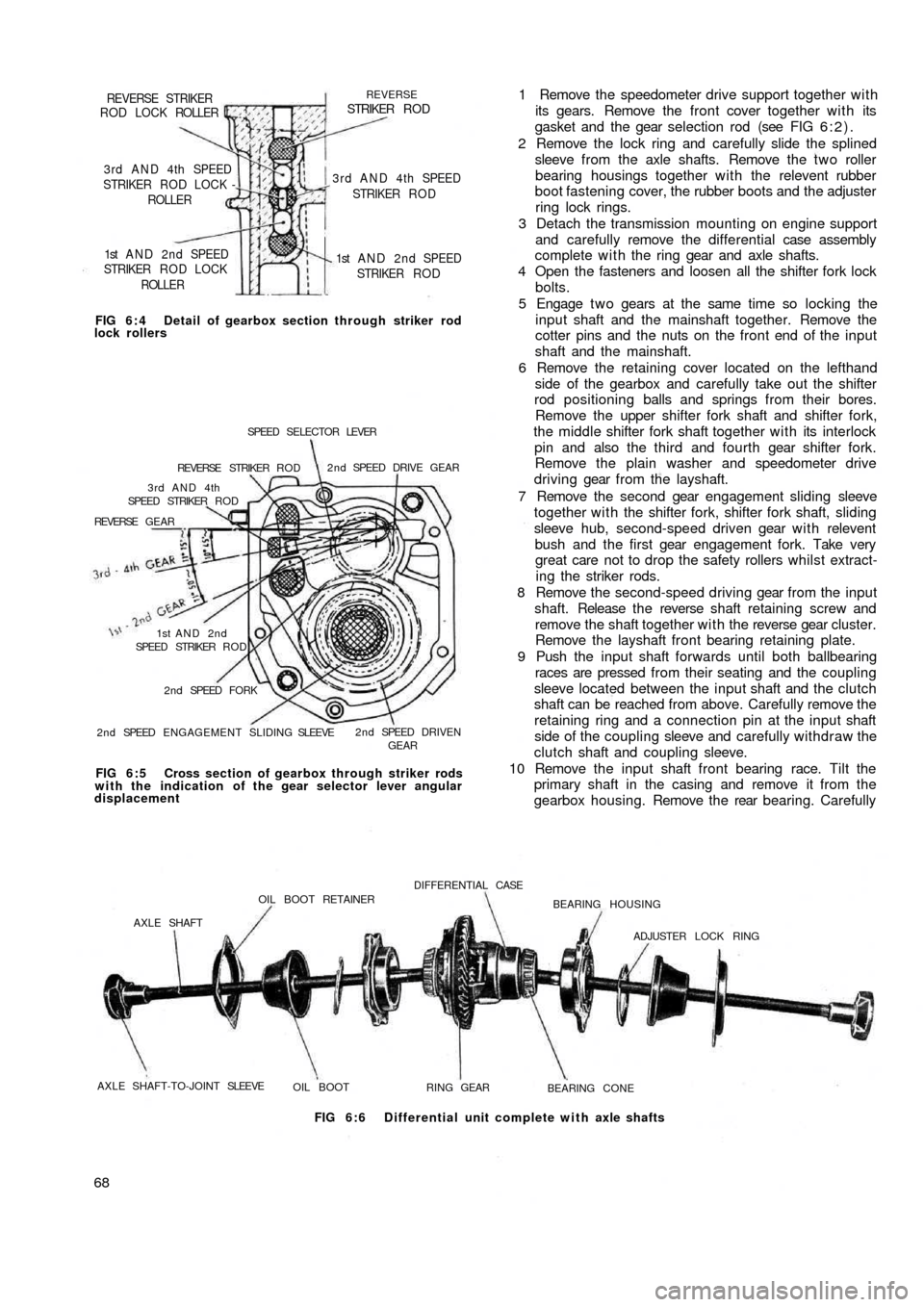

Page 61 of 128

1st A N D 2 n d SPEED

STRIKER R O D LOCK

ROLLER1st A N D 2 n d SPEED

STRIKER R O D 3 r d A N D 4 t h SPEED

STRIKER R O D 3 r d A N D 4 t h SPEED

STRIKER R O D LOCK -

ROLLER REVERSE STRIKER

ROD LOCK ROLLER

REVERSESTRIKER R O D

FIG 6 : 4 Detail of gearbox section through striker rod

lock rollers

2 n d SPEED DRIVENGEAR2 n d SPEED ENGAGEMENT SLIDING SLEEVE 2 n d SPEED FORK 1st A N D 2 n d

SPEED STRIKER R O D REVERSE GEAR3rd AND 4th

SPEED STRIKER R O DREVERSE STRIKER R O D2 n d SPEED DRIVE GEAR SPEED SELECTOR LEVER

FIG 6 : 5 Cross section of gearbox through striker rods

with the indication of the gear selector lever angular

displacement

68

AXLE SHAFT-TO-JOINT SLEEVE

OIL BOOT

RING GEAR

FIG 6:6 Differential unit complete with axle shafts

BEARING CONEADJUSTER LOCK RING BEARING HOUSING DIFFERENTIAL CASE

OIL BOOT RETAINER

AXLE SHAFT

1 Remove the speedometer drive support together with

its gears. Remove the front cover together with its

gasket and the gear selection rod (see FIG 6:2).

2 Remove the lock ring and carefully slide the splined

sleeve from the axle shafts. Remove the t w o roller

bearing housings together with the relevent rubber

boot fastening cover, the rubber boots and the adjuster

ring lock rings.

3 Detach the transmission mounting on engine support

and carefully remove the differential case assembly

complete w i t h the ring gear and axle shafts.

4 Open the fasteners and loosen all the shifter fork lock

bolts.

5 Engage t w o gears at the same time so locking the

input shaft and the mainshaft together. Remove the

cotter pins and the nuts on the front end of the input

shaft and the mainshaft.

6 Remove the retaining cover located on the lefthand

side of the gearbox and carefully take out the shifter

rod positioning balls and springs from their bores.

Remove the upper shifter fork shaft and shifter fork,

the middle shifter fork shaft together with its interlock

pin and also the third and fourth gear shifter fork.

Remove the plain washer and speedometer drive

driving gear from the layshaft.

7 Remove the second gear engagement sliding sleeve

together with the shifter fork, shifter fork shaft, sliding

sleeve hub, second-speed driven gear with relevent

bush and the first gear engagement

fork. Take very

great care not to drop the safety rollers whilst extract-

ing the striker rods.

8 Remove the second-speed driving gear from the input

shaft. Release the reverse shaft retaining screw and

remove the shaft together with the reverse gear cluster.

Remove the layshaft front bearing retaining plate.

9 Push the input shaft forwards until both ballbearing

races are pressed from their seating and the coupling

sleeve located between the input shaft and the clutch

shaft can be reached from above. Carefully remove the

retaining ring and a connection pin at the input shaft

side of the coupling sleeve and carefully withdraw the

clutch shaft and coupling sleeve.

10 Remove the input shaft front bearing race. Tilt the

primary shaft in the casing and remove it from the

gearbox housing. Remove the rear bearing. Carefully

Page 65 of 128

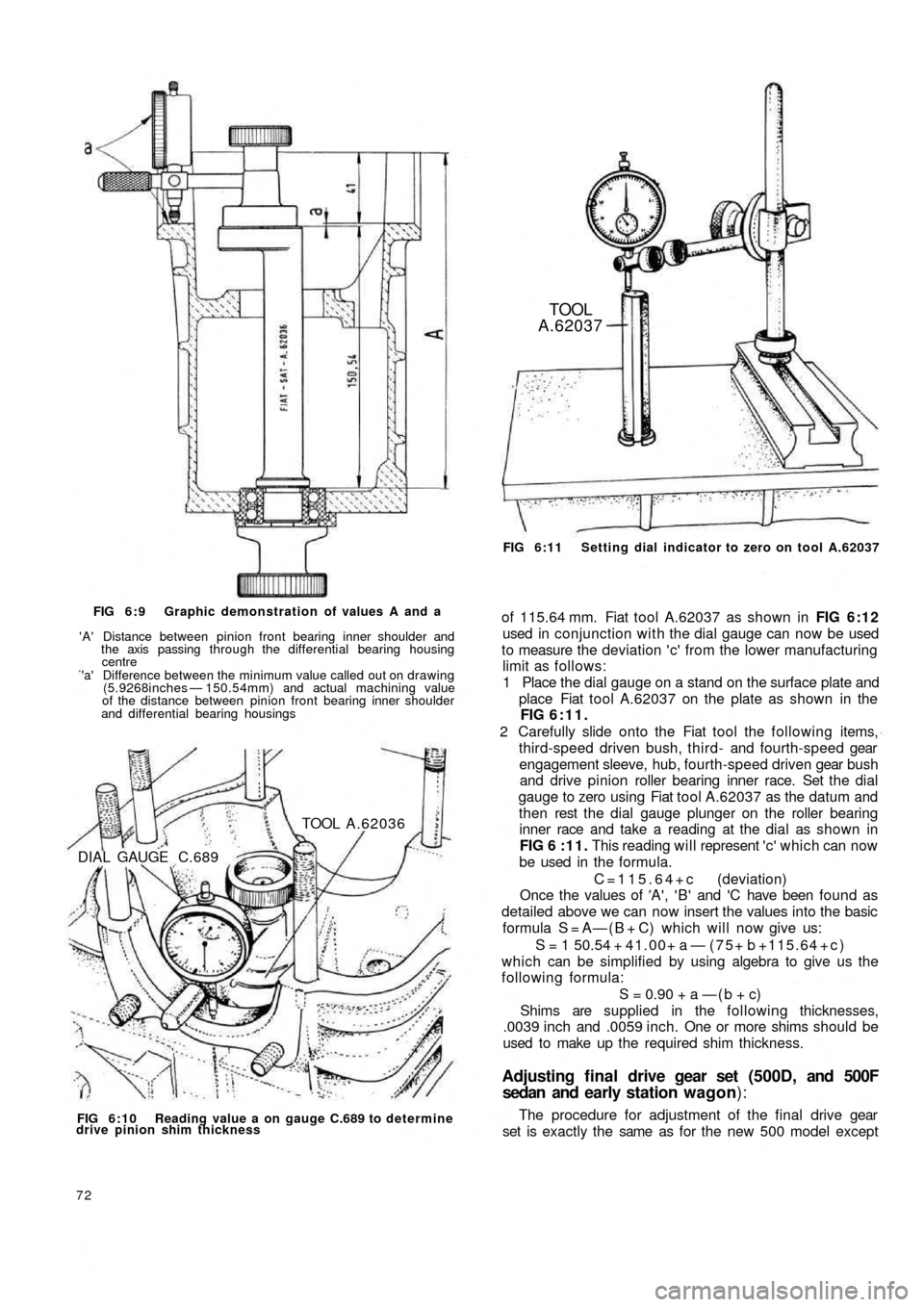

FIG 6:9 Graphic demonstration of values A and a

'A' Distance between pinion front bearing inner shoulder and

the axis passing through the differential bearing housing

centre'a' Difference between the minimum value called out on drawing

(5.9268inches — 150.54mm) and actual machining value

of the distance between pinion front bearing inner shoulder

and differential bearing housings

DIAL GAUGE C.689TOOL A.62036

FIG 6:10 Reading value a on gauge C.689 to determine

drive pinion shim thickness

72The procedure for adjustment of the final drive gear

set is exactly the same as for the new 500 model except of 115.64 mm. Fiat tool A.62037 as shown in FIG 6:12

used in conjunction with the dial gauge can now be used

to measure the deviation 'c' from the lower manufacturing

limit as follows:

1 Place the dial gauge on a stand on the surface plate and

place Fiat tool A.62037 on the plate as shown in the

FIG 6 : 1 1 .

2 Carefully slide onto the Fiat tool the following items,

third-speed driven bush, third- and fourth-speed gear

engagement sleeve, hub, fourth-speed driven gear bush

and drive pinion roller bearing inner race. Set the dial

gauge to zero using Fiat tool A.62037 as the datum and

then rest the dial gauge plunger on the roller bearing

inner race and take a reading at the dial as shown in

FIG 6 :11. This reading will represent 'c' which can now

be used in the formula.

C=115.64+c (deviation)

Once the values of A', ' B ' and 'C have been found as

detailed above we can now insert the values into the basic

formula S = A—(B + C) which will now give us:

S = 1 50.54 + 41.00+ a — (75+ b +115.64 + c )

which can be simplified by using algebra to give us the

following formula:

S = 0.90 + a — ( b + c)

Shims are supplied in the following thicknesses,

.0039 inch and .0059 inch. One or more shims should be

used to make up the

required shim thickness.

Adjusting final drive gear set (500D, and 500F

sedan and early station wagon):

FIG 6:11 Setting dial indicator to zero on tool A.62037

TOOL

A.62037

Page 66 of 128

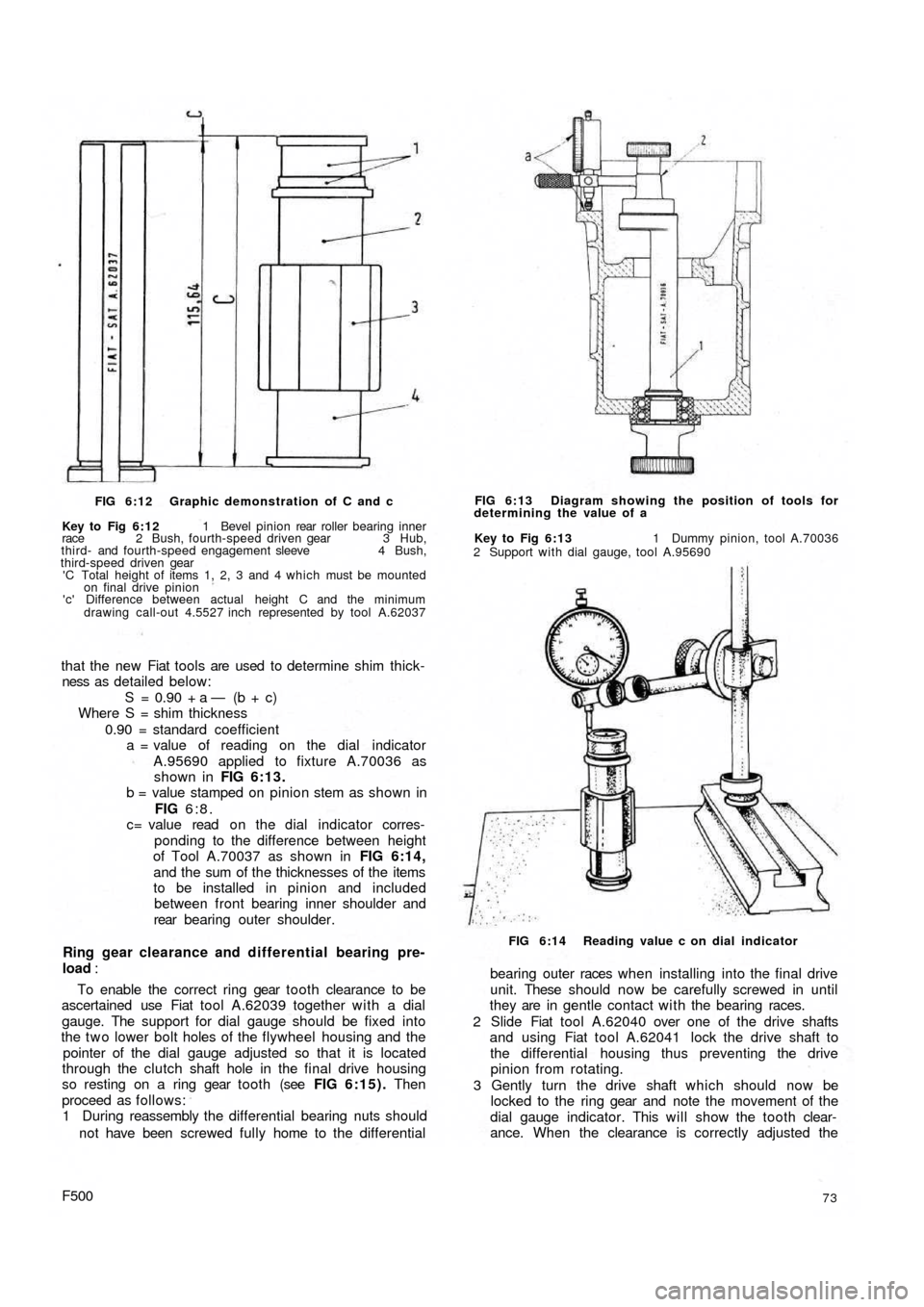

FIG 6:12 Graphic demonstration of C and c

Key to Fig 6:12 1 Bevel pinion rear roller bearing inner

race 2 Bush, fourth-speed driven gear 3 Hub,

third- and fourth-speed engagement sleeve 4 Bush,

third-speed driven gear

'C Total height of items 1, 2, 3 and 4 which must be mounted

on final drive pinion

'c' Difference between actual height C and the minimum

drawing call-out 4.5527 inch represented by tool A.62037

that the new Fiat tools are used to determine shim thick-

ness as detailed below:

S = 0.90 + a — (b + c)

Where S = shim thickness

0.90 = standard coefficient

a = value of reading on the dial indicator

A.95690 applied to fixture A.70036 as

shown in FIG 6:13.

b = value stamped on pinion stem as shown in

FIG 6:8.

c= value read o n the dial indicator corres-

ponding to the difference between height

of Tool A.70037 as shown in FIG 6:14,

and the sum of the thicknesses of the items

to be installed in pinion and included

between front bearing inner shoulder and

rear bearing outer shoulder.

Ring gear clearance and differential bearing pre-

load :

To enable the correct ring gear tooth clearance to be

ascertained use Fiat tool A.62039 together with a dial

gauge. The support for dial gauge should be fixed into

the t w o lower bolt holes of the flywheel housing and the

pointer of the dial gauge adjusted so that it is located

through the clutch shaft hole in the final drive housing

so resting on a ring gear tooth (see FIG 6:15). Then

proceed as follows:

1 During reassembly the differential bearing nuts should

not have been screwed fully home to the differential

F50073

bearing outer races w h e n installing into the f i n a l drive

unit. These should now be carefully screwed in until

they are in gentle contact with the bearing races.

2 Slide Fiat tool A.62040 over one of the drive shafts

and using Fiat tool A.62041 lock the drive shaft to

the differential housing thus preventing the drive

pinion from rotating.

3 Gently turn the drive shaft which should now be

locked to the ring gear and note the movement of the

dial gauge indicator. This will show the tooth clear-

ance. When the clearance is correctly adjusted the

FIG 6:14 Reading value c on dial indicator Key to Fig 6:13 1 Dummy pinion, tool A.70036

2 Support with dial gauge, tool A.95690 FIG 6:13 Diagram showing the position of tools for

determining the value of a

Page 67 of 128

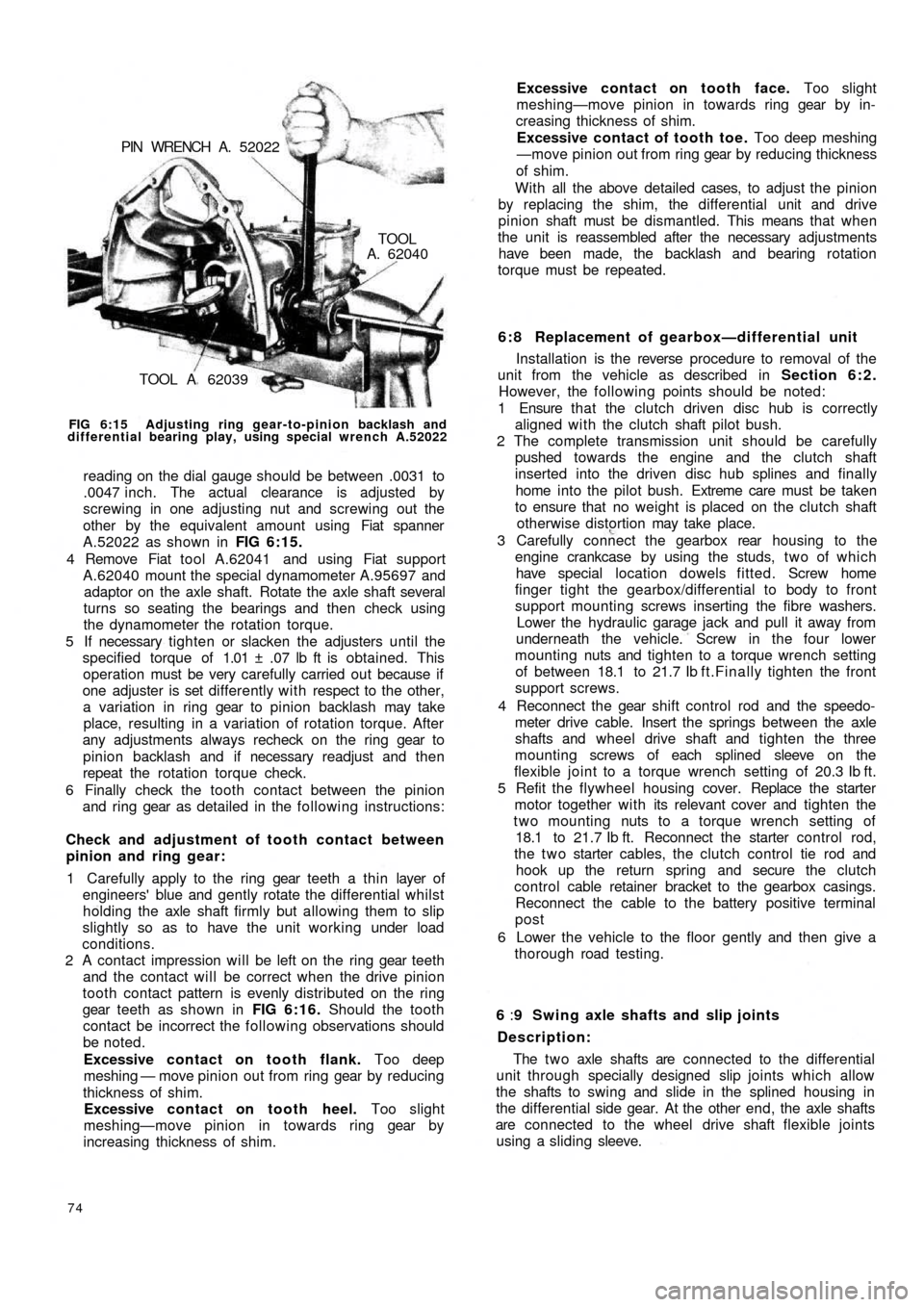

TOOL A 62039

TOOLA. 62040 PIN WRENCH A. 52022

FIG 6:15 Adjusting ring gear-to-pinion backlash and

differential bearing play, using special wrench A.52022

reading on the dial gauge should be between .0031 to

.0047 inch. The actual clearance is adjusted by

screwing in one adjusting nut and screwing out the

other by the equivalent amount using Fiat spanner

A.52022 as shown in FIG 6:15.

4 Remove Fiat tool A.62041 and using Fiat support

A.62040 mount the special dynamometer A.95697 and

adaptor on the axle shaft. Rotate the axle shaft several

turns so seating the bearings and then check using

the dynamometer the rotation torque.

5 If necessary tighten or slacken the adjusters until the

specified torque of 1.01 ± .07 lb ft is obtained. This

operation must be very carefully carried out because if

one adjuster is set differently with respect to the other,

a variation in ring gear to pinion backlash may take

place, resulting in a variation of rotation torque. After

any adjustments always recheck on the ring gear to

pinion backlash and if necessary readjust and then

repeat the rotation torque check.

6 Finally check the tooth contact between the pinion

and ring gear as detailed in the following instructions:

Check and adjustment of tooth contact between

pinion and ring gear:

1 Carefully apply to the ring gear teeth a thin layer of

engineers' blue and gently rotate the differential whilst

holding the axle shaft firmly but allowing them to slip

slightly so as to have the unit working under load

conditions.

2 A contact impression will be left on the ring gear teeth

and the contact will be correct when the drive pinion

tooth contact pattern is evenly distributed on the ring

gear teeth as shown in FIG 6:16. Should the tooth

contact be incorrect the following observations should

be noted.

Excessive contact on tooth flank. Too deep

meshing — move pinion out from ring gear by reducing

thickness of shim.

Excessive contact on tooth heel. Too slight

meshing—move pinion in towards ring gear by

increasing thickness of shim.

74

6 : 8 Replacement of gearbox—differential unit

Installation is the reverse procedure to removal of the

unit from the vehicle as described in Section 6:2.

However, the following points should be noted:

1 Ensure that the clutch driven disc hub is correctly

aligned with the clutch shaft pilot bush.

2 The complete transmission unit should be carefully

pushed towards the engine and the clutch shaft

inserted into the driven disc hub splines and finally

home into the pilot bush. Extreme care must be taken

to ensure that no weight is placed on the clutch shaft

otherwise distortion may take place.

3 Carefully connect the gearbox rear housing to the

engine crankcase by using the studs, t w o of which

have special location dowels fitted. Screw home

finger tight the gearbox/differential to body to front

support mounting screws inserting the fibre washers.

Lower the hydraulic garage jack and pull it away from

underneath the vehicle. Screw in the four lower

mounting nuts and tighten to a torque wrench setting

of between 18.1 to 21.7 Ib f t.Finally tighten the front

support screws.

4 Reconnect the gear shift control rod and the speedo-

meter drive cable. Insert the springs between the axle

shafts and wheel drive shaft and tighten the

three

mounting screws of each splined sleeve on the

flexible joint to a torque wrench setting of 20.3 Ib ft.

5 Refit the flywheel housing cover. Replace the starter

motor together with its relevant cover and tighten the

two mounting nuts to a torque wrench setting of

18.1 to 21.7 Ib ft. Reconnect the starter control rod,

the t w o starter cables, the clutch control tie rod and

hook up the return spring and secure the clutch

control cable retainer bracket to the gearbox casings.

Reconnect the cable to the battery positive terminal

post

6 Lower the vehicle to the floor gently and then give a

thorough road testing.

6 :9 Swing axle shafts and slip joints

Description:

The t w o axle shafts are connected to the differential

unit through specially designed slip joints which allow

the shafts to swing and slide in the splined housing in

the differential side gear. At the other end, the axle shafts

are connected to the wheel drive shaft flexible joints

using a sliding sleeve. Excessive contact on tooth face. Too slight

meshing—move pinion in towards ring gear by in-

creasing thickness of shim.

Excessive contact of tooth toe. Too deep meshing

—move pinion out from ring gear by reducing thickness

of shim.

With all the above detailed cases, to adjust the pinion

by replacing the shim, the differential unit and drive

pinion shaft must be dismantled. This means that when

the unit is reassembled after the necessary adjustments

have been made, the backlash and bearing rotation

torque must be repeated.