tail FIAT 500 1957 1.G Workshop Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1957, Model line: 500, Model: FIAT 500 1957 1.GPages: 128, PDF Size: 9.01 MB

Page 11 of 128

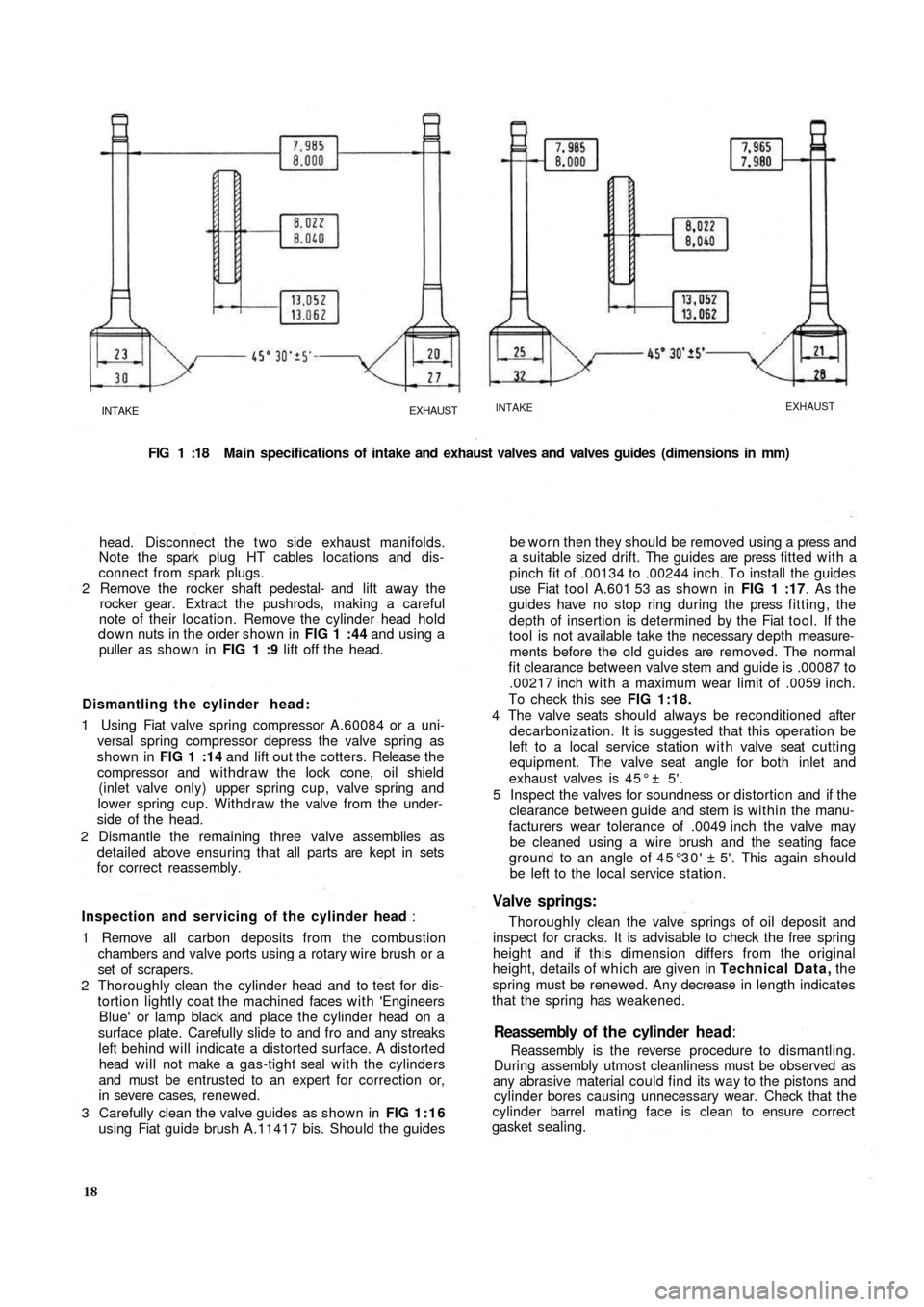

INTAKEEXHAUSTINTAKEEXHAUST

FIG 1 :18 Main specifications of intake and exhaust valves and valves guides (dimensions in mm)

head. Disconnect the t w o side exhaust manifolds.

Note the spark plug HT cables locations and dis-

connect from spark plugs.

2 Remove the rocker shaft pedestal- and lift away the

rocker gear. Extract the pushrods, making a careful

note of their location. Remove the cylinder head hold

down nuts in the order shown in FIG 1 :44 and using a

puller as shown in FIG 1 :9 lift off the head.

Dismantling the cylinder head:

1 Using Fiat valve spring compressor A.60084 or a uni-

versal spring compressor depress the valve spring as

shown in FIG 1 :14 and lift out the cotters. Release t h e

compressor and withdraw the lock cone, oil shield

(inlet valve only) upper spring cup, valve spring and

lower spring cup. Withdraw the valve from the under-

side of the head.

2 Dismantle the remaining three valve assemblies as

detailed above ensuring that all parts are kept in sets

for correct reassembly.

Inspection and servicing of the cylinder head :

1 Remove all carbon deposits from the combustion

chambers and valve ports using a rotary wire brush or a

set of scrapers.

2 Thoroughly clean the cylinder head and to test for dis-

tortion lightly coat the machined faces with 'Engineers

Blue' or lamp

black and place the cylinder head on a

surface plate. Carefully slide to and fro and any streaks

left behind will indicate a distorted surface. A distorted

head will not make a gas-tight seal with the cylinders

and must be entrusted to an expert for correction or,

in severe cases, renewed.

3 Carefully clean the valve guides as shown in FIG 1:16

using Fiat guide brush A.11417 bis. Should the guides

18Reassembly is the reverse procedure to dismantling.

During assembly utmost cleanliness must be observed as

any abrasive material could find its way to the pistons and

cylinder bores causing unnecessary wear. Check that the

cylinder barrel mating face is clean to ensure correct

gasket sealing.Reassembly of t h e cylinder head:

be worn then they should be removed using a press and

a suitable sized drift. The guides are press fitted with a

pinch fit of .00134 to .00244 inch. To install the guides

use Fiat tool A.601 53 as shown in FIG 1 :17. As the

guides have no stop ring during the press fitting, the

depth of insertion is determined by the Fiat tool. If the

tool is not available take the necessary depth measure-

ments before the old guides are removed. The normal

fit clearance between valve stem and guide is .00087 to

.00217 inch with a maximum wear limit of .0059 inch.

To check this see FIG 1:18.

4 The valve seats should always be reconditioned after

decarbonization. It is suggested that this operation be

left to a local service station with valve seat cutting

equipment. The valve seat angle for both inlet and

exhaust valves is 4 5 ° ± 5'.

5 Inspect the valves for soundness or distortion and if the

clearance between guide and stem is within the manu-

facturers wear tolerance of .0049 inch the valve may

be cleaned using a wire brush and the seating face

ground to an angle of 45°30' ± 5'. This again should

be left to the local service station.

Valve springs:

Thoroughly clean the valve springs of oil deposit and

inspect for cracks. It is advisable to check the free spring

height and if this dimension differs from the original

height, details of which are given in Technical Data, the

spring must be renewed. Any decrease in length indicates

that the spring has weakened.

Page 14 of 128

Insert a .0079 ± .00197 inch thick oil paper gasket

between the crankcase and cylinder bottom face and a

.0236 to .0275 inch thick graphitized asbestos gasket

between the cylinder and cylinder head. The compression

of the gaskets on assembly will eliminate any very small

differences between the t w o mating surfaces.

Inspection of tappet seats:

The tappet seats should be checked for scoring and

correct clearance which must not exceed .00315 inch.

Should the clearance be greater than the maximum

specified the seating may be reamed to oversize dimen-

sions as detailed in Technical Data. Tappets are avail-

able in .00197 and .00394 inch diameter oversize.

1 :9 Piston assembly

Inspection:

Before inspection the pistons must be thoroughly

cleaned and the ring grooves and piston head decarbo-

nized. Check for deep score marks and signs of distortion

or fracture especially around the skirt and piston pin areas.

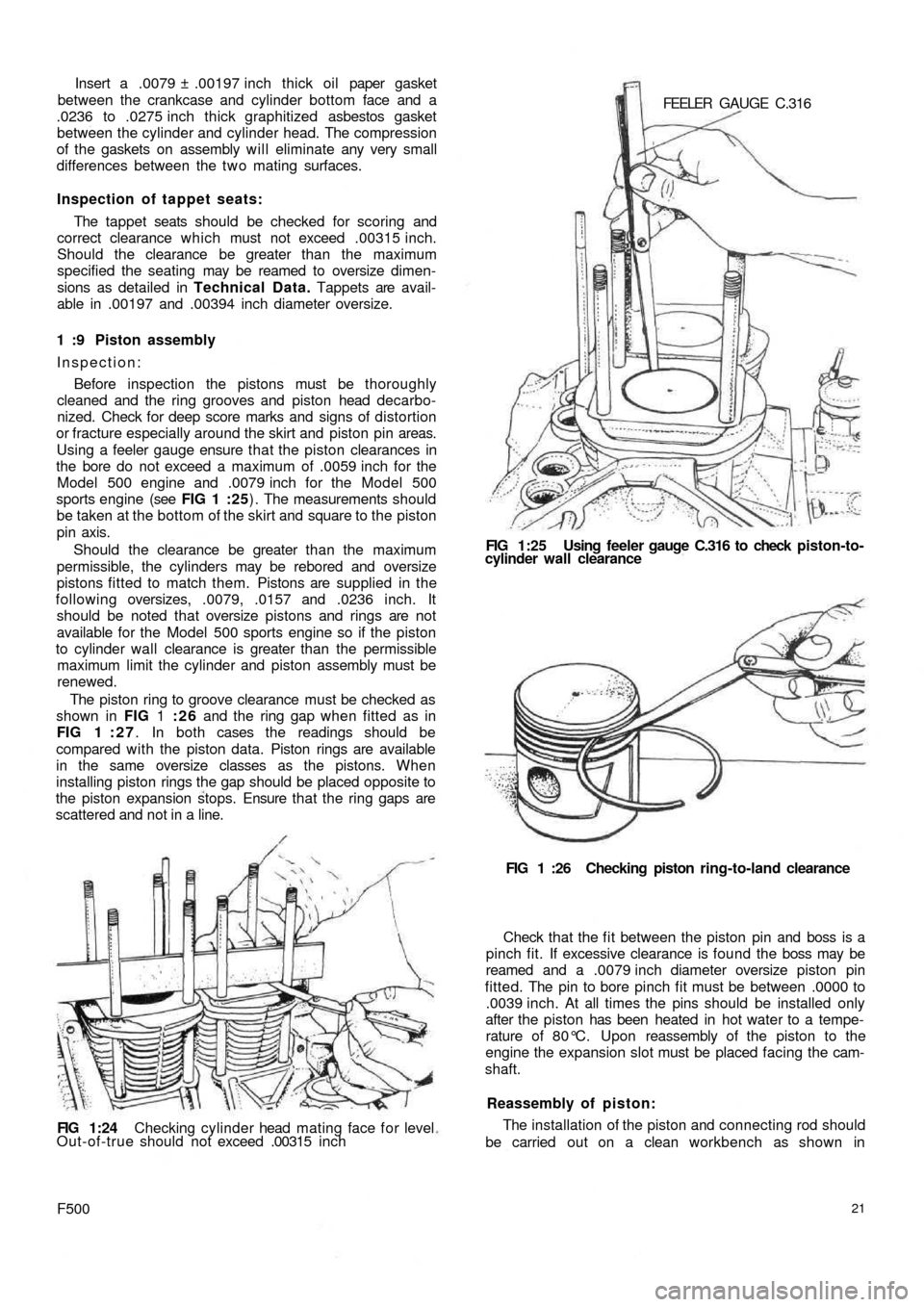

Using a feeler gauge ensure that the piston clearances in

the bore do not exceed a maximum of .0059 inch for the

Model 500 engine and .0079 inch for the Model 500

sports engine (see FIG 1 :25) . The measurements should

be taken at the bottom of the skirt and square to the piston

pin axis.

Should the clearance be greater than the maximum

permissible, the cylinders may be rebored and oversize

pistons fitted to m

atch them. Pistons are supplied in the

following oversizes, .0079, .0157 and .0236 inch. It

should be noted that oversize pistons and rings are not

available for the Model 500 sports engine so if the piston

to cylinder wall clearance is greater than the permissible

maximum limit the cylinder and piston assembly must be

renewed.

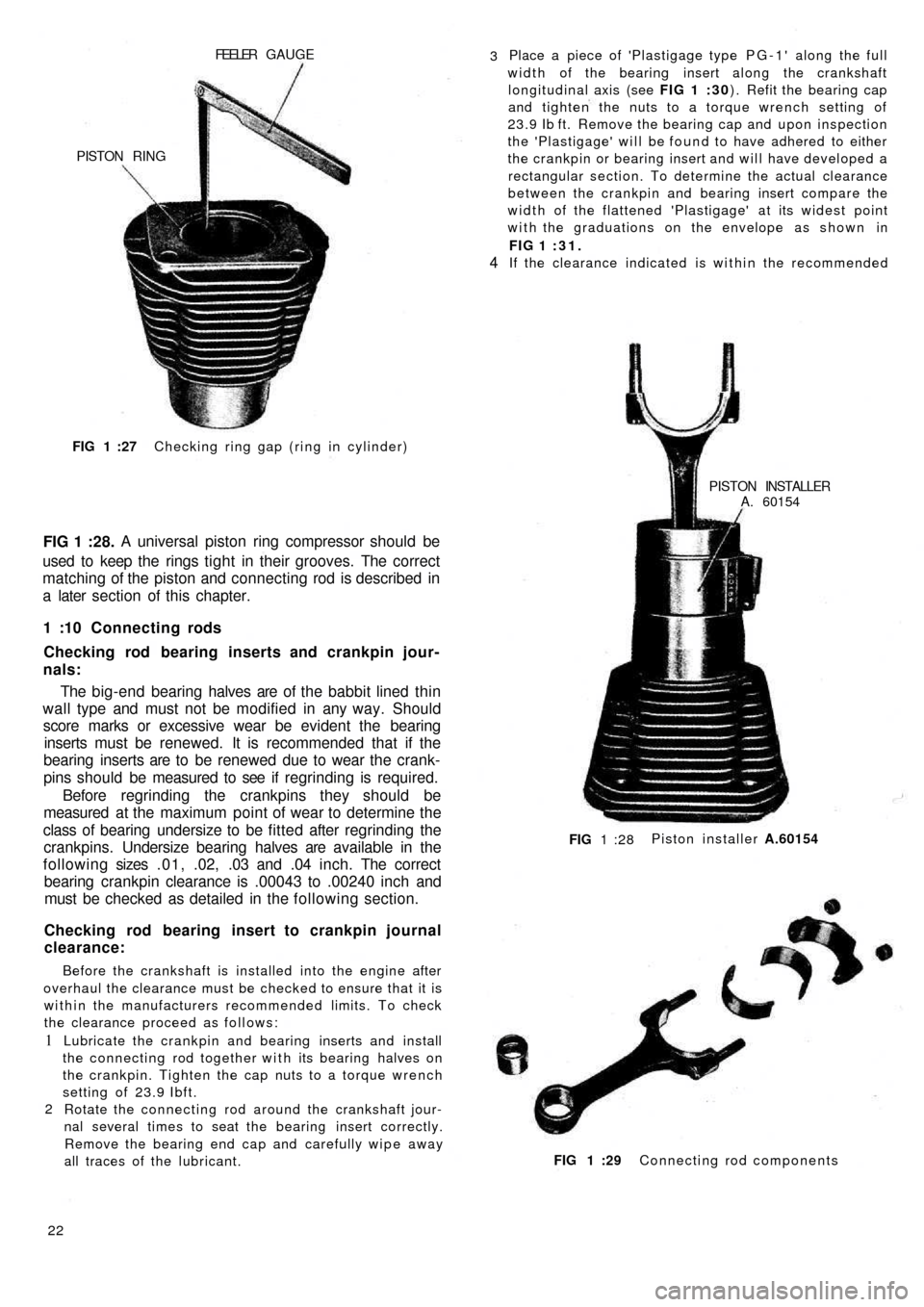

The piston ring to groove clearance must be checked as

shown in FIG 1 :26 and the ring gap when fitted as in

FIG 1 : 2 7. In both cases the readings should be

compared with the piston data. Piston rings are available

in the same oversize classes as the pistons. When

installing piston rings the gap should be placed opposite to

the piston expansion stops. Ensure that the ring gaps are

scattered and not in a line.

FIG 1:24 Checking cylinder head mating face f o r level

Out-of-true should not exceed .00315 i n c h

F50021

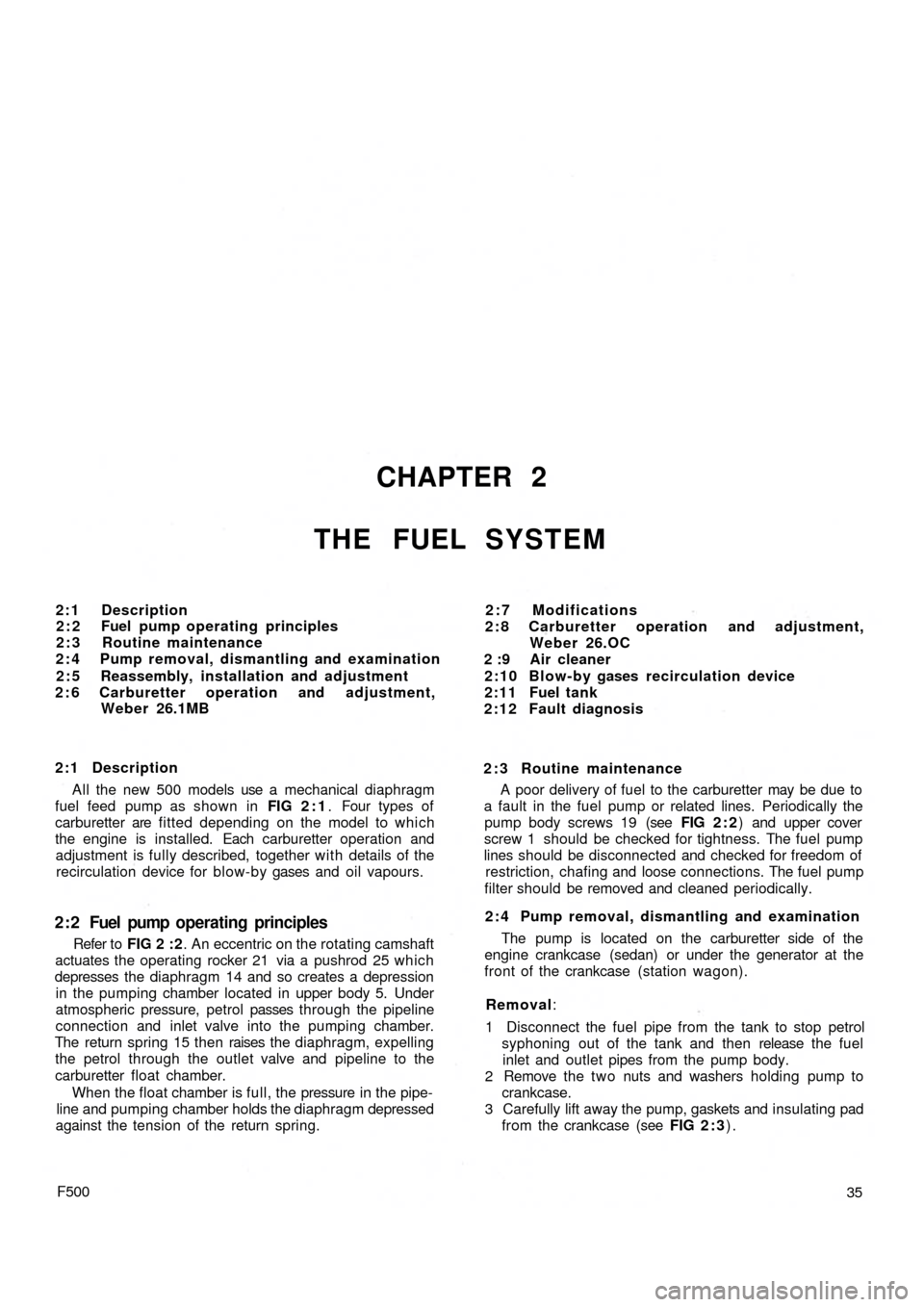

The installation of the piston and connecting rod should

be carried out on a clean workbench as shown in Reassembly of piston: Check that the f i t between the piston pin and boss is a

pinch fit. If excessive clearance is found the boss may be

reamed and a .0079 inch diameter oversize piston pin

fitted. The pin to bore pinch fit must be between .0000 to

.0039 inch. At all times the pins should be installed only

after the piston has been heated in hot water to a tempe-

rature of 80°C. Upon reassembly of the piston to the

engine the expansion slot must be placed facing the cam-

shaft.FIG 1 :26 Checking piston ring-to-land clearance FEELER GAUGE C.316

FIG 1:25 Using feeler gauge C.316 to check piston-to-

cylinder wall clearance

Page 15 of 128

FEELER GAUGE

Checking ring gap (ring in cylinder) FIG 1 :27

FIG 1 :28.A universal piston ring compressor should be

used to keep the rings t i g h t in their grooves. The correct

matching of the piston and connecting rod is described in

a later section of this chapter.

1 :10 Connecting rods

Checking rod bearing inserts and crankpin jour-

nals:

The big-end bearing halves are of the babbit lined thin

wall type and must not be modified in any way. Should

score marks or excessive wear be evident the bearing

inserts must be renewed. It is recommended that if the

bearing inserts are to be renewed due to wear the crank-

pins should be measured to see if regrinding is required.

Before regrinding the crankpins they should be

measured at the maximum point of wear to determine the

class of bearing undersize to be fitted after regrinding the

crankpins. Undersize bearing halves are available in the

f o l l o w i n g sizes .01, .02, .03 and .04 inch. The correct

bearing crankpin clearance is .00043 to .00240 inch and

must be checked as detailed in the following section.

Checking rod bearing insert to crankpin journal

clearance:

Before the crankshaft is installed into the engine after

overhaul the clearance must be checked to ensure that it is

within the manufacturers recommended limits. To check

the clearance proceed as follows:

1

2Lubricate the crankpin and bearing inserts and install

the connecting rod together with its bearing halves on

the crankpin. Tighten the cap nuts to a torque wrench

setting of 23.9 Ibft.

Rotate the connecting rod around the crankshaft jour-

nal several times to seat the bearing insert correctly.

Remove the bearing end cap and carefully wipe away

all traces of the lubricant.

22FIG 1 :29 Connecting rod components Piston installer A.60154

FIG 1 :28PISTON INSTALLER

A. 60154 If the clearance indicated is within the recommended FIG 1 :31.

4

Place a piece of 'Plastigage type PG-1' along the full

width of the bearing insert along the crankshaft

longitudinal axis (see FIG 1 :30) . Refit the bearing cap

and tighten the nuts to a torque wrench setting of

23.9 Ib ft. Remove the bearing cap and upon inspection

the 'Plastigage' will be found to have adhered to either

the crankpin or bearing insert and will have developed a

rectangular section. To determine the actual clearance

between the crankpin and bearing insert compare the

width of the flattened 'Plastigage' at its widest point

with the graduations on the envelope as shown in 3

PISTON RING

Page 21 of 128

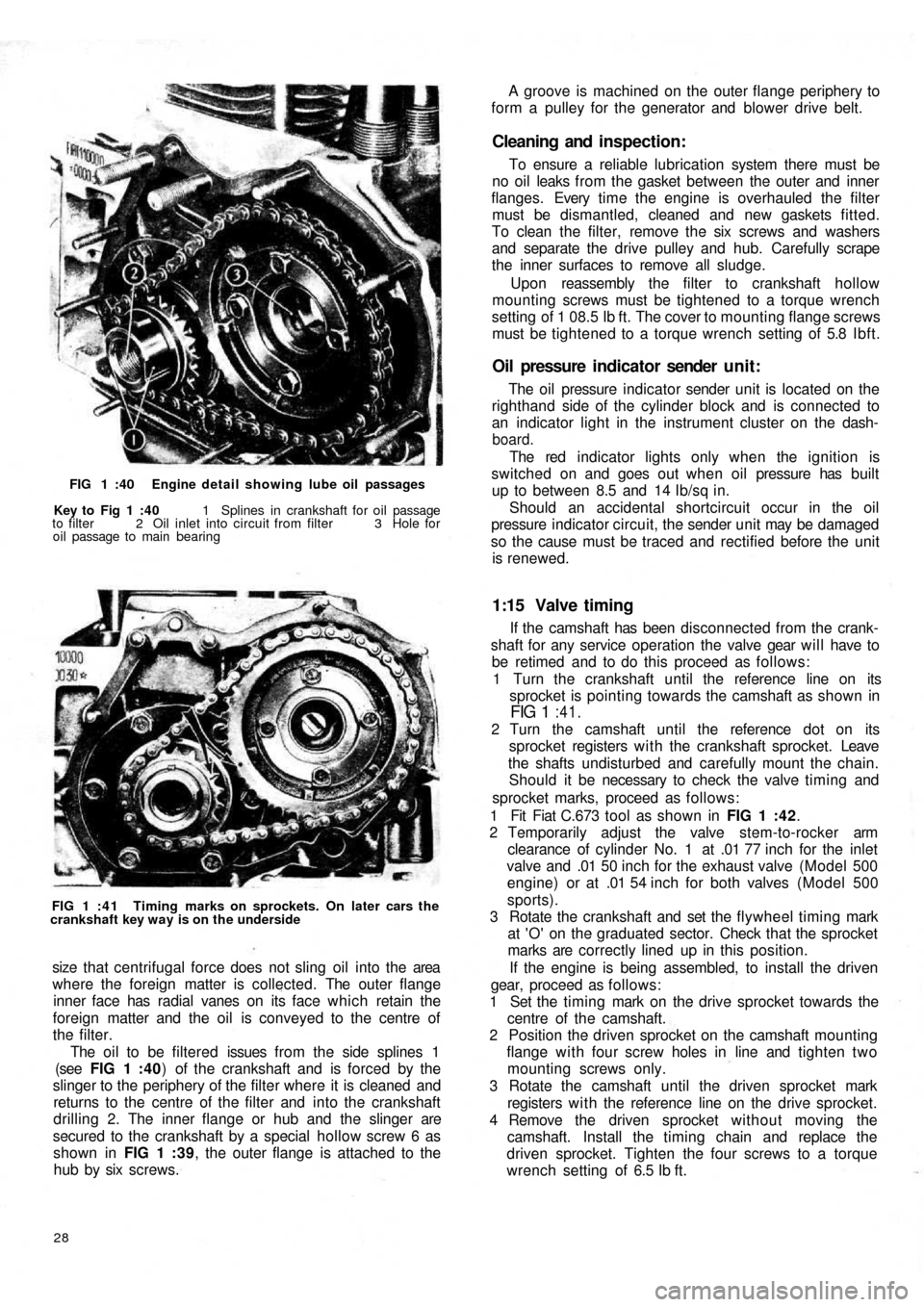

FIG 1 :40 Engine detail showing lube oil passages

Key to Fig 1 :40 1 Splines in crankshaft for oil passage

to filter 2 Oil inlet into circuit from filter 3 Hole for

oil passage to main bearing

FIG 1 : 4 1 Timing marks on sprockets. On later cars the

crankshaft key way is on the underside

size that centrifugal force does not sling oil into the area

where the foreign matter is collected. The outer flange

inner face has radial vanes on its face which retain the

foreign matter and the oil is conveyed to the centre of

the filter.

The oil to be filtered issues from the side splines 1

(see FIG 1 :40) of the crankshaft and is forced by the

slinger to the periphery of the filter where it is cleaned and

returns to the centre of the filter and into the crankshaft

drilling 2. The inner flange or hub and the slinger are

secured to the crankshaft by a special hollow screw 6 as

shown in FIG 1 :39, the outer flange is attached to the

hub by six screws.

28

If the camshaft has been disconnected from the crank-

shaft for any service operation the valve gear will have to

be retimed and to do this proceed as follows:

1 Turn the crankshaft until the reference line on its

sprocket is pointing towards the camshaft as shown in

FIG 1 :41.

2 Turn the camshaft until the reference dot on its

sprocket registers w i t h the crankshaft sprocket. Leave

the shafts undisturbed and carefully mount the chain.

Should it be necessary to check the valve timing and

sprocket marks, proceed as follows:

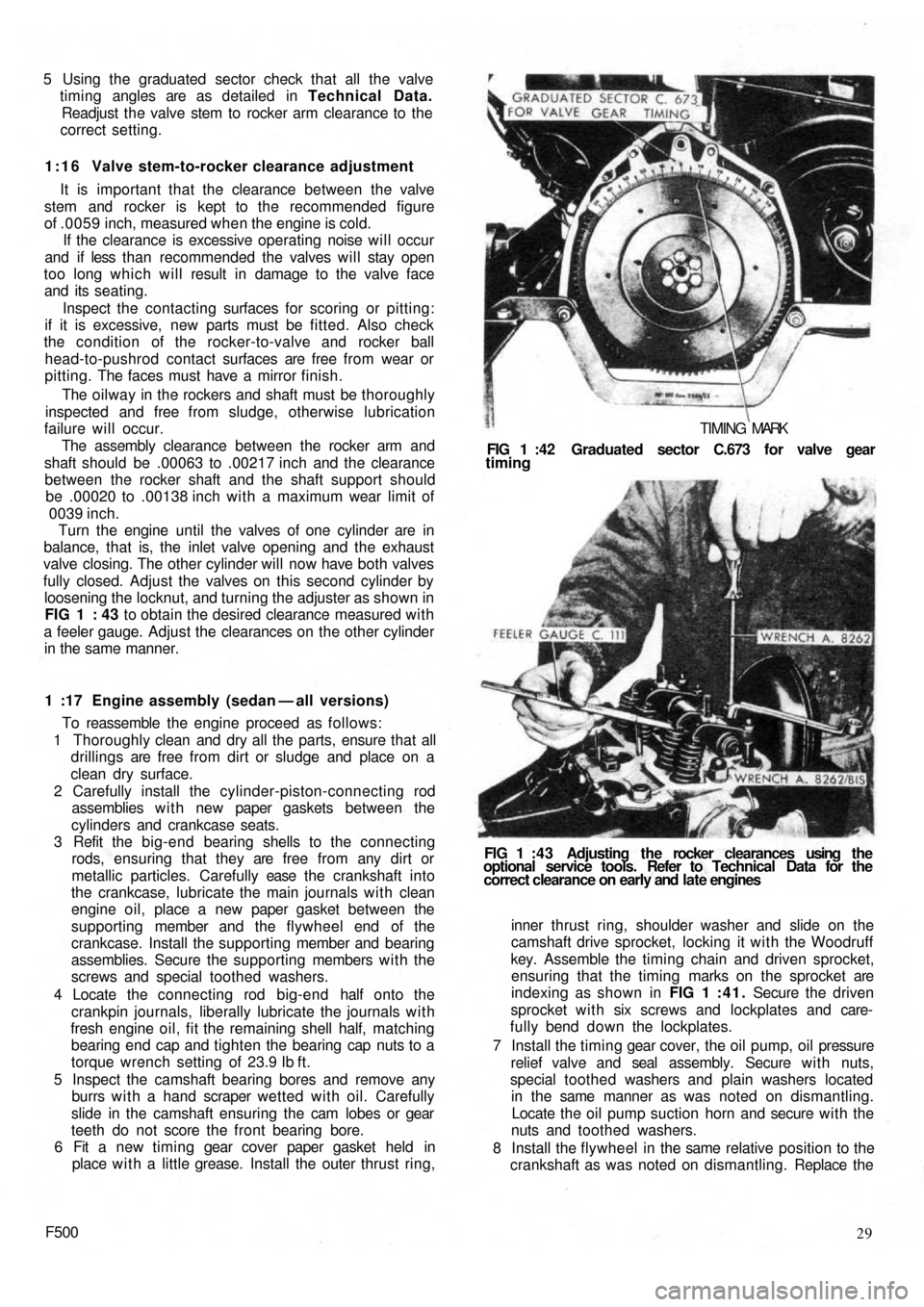

1 Fit Fiat C.673 tool as shown in FIG 1 :42.

2 Temporarily adjust the valve stem-to-rocker arm

clearance of cylinder No. 1 at .01 77 inch for the inlet

valve and .01 50 inch for the exhaust valve (Model 500

engine) or at .01 54 inch for both valves (Model 500

sports).

3 Rotate the crankshaft and set the flywheel timing mark

at 'O' on the graduated sector. Check that the sprocket

marks are correctly lined up in this position.

If the engine is being assembled, to install the driven

gear, proceed as follows:

1 Set the timing mark on the drive sprocket towards the

centre of the camshaft.

2 Position the driven sprocket on the camshaft mounting

flange with four screw holes in line and tighten two

mounting screws only.

3 Rotate the camshaft until the driven sprocket mark

registers w i t h the reference line on the drive sprocket.

4 Remove the driven sprocket without moving the

camshaft. Install the timing chain and replace the

driven sprocket. Tighten the four screws to a torque

wrench setting of 6.5 Ib ft.

1:15 Valve timing

The oil pressure indicator sender unit is located on the

righthand side of the cylinder block and is connected to

an indicator light in the instrument cluster on the dash-

board.

The red indicator lights only when the ignition is

switched on and goes out when o i l pressure has built

up to between 8.5 and 14 Ib/sq in.

Should an accidental shortcircuit occur in the oil

pressure indicator circuit, the sender unit may be damaged

so the cause must be traced and rectified before the unit

is renewed.

Oil pressure indicator sender unit:

To ensure a reliable lubrication system there must be

no oil leaks from the gasket between the outer and inner

flanges. Every t i m e t h e engine is overhauled the filter

must be dismantled, cleaned and new gaskets fitted.

To clean the filter, remove the six screws and washers

and separate the drive pulley and hub. Carefully scrape

the inner surfaces to remove all sludge.

Upon reassembly the filter to crankshaft hollow

mounting screws must be tightened to a torque wrench

setting of 1 08.5 Ib ft. The cover to mounting flange screws

must be tightened to a torque wrench setting of 5.8 Ibft.

Cleaning and inspection:

A groove is machined on the outer flange periphery to

form a pulley for the generator and blower drive belt.

Page 22 of 128

5 Using the graduated sector check that all the valve

timing angles are as detailed in Technical Data.

Readjust the valve stem to rocker arm clearance to the

correct setting.

1:16 Valve stem-to-rocker clearance adjustment

It is important that the clearance between the valve

stem and rocker is kept to the recommended figure

of .0059 inch, measured when the engine is cold.

If the clearance is excessive operating noise will occur

and if less than recommended the valves will stay open

too long which will result in damage to the valve face

and its seating.

Inspect the contacting surfaces for scoring or pitting:

if it is excessive, new parts must be fitted. Also check

the condition of the rocker-to-valve and rocker ball

head-to-pushrod contact surfaces are free from wear or

pitting. The faces must have a mirror finish.

The oilway in the rockers and shaft must be thoroughly

inspected and free from sludge, otherwise lubrication

failure will occur.

The assembly clearance between the rocker arm and

shaft should be .00063 to .00217 inch and the clearance

between the rocker shaft and the shaft support should

be .00020 to .00138 inch with a maximum wear limit of

0039 inch.

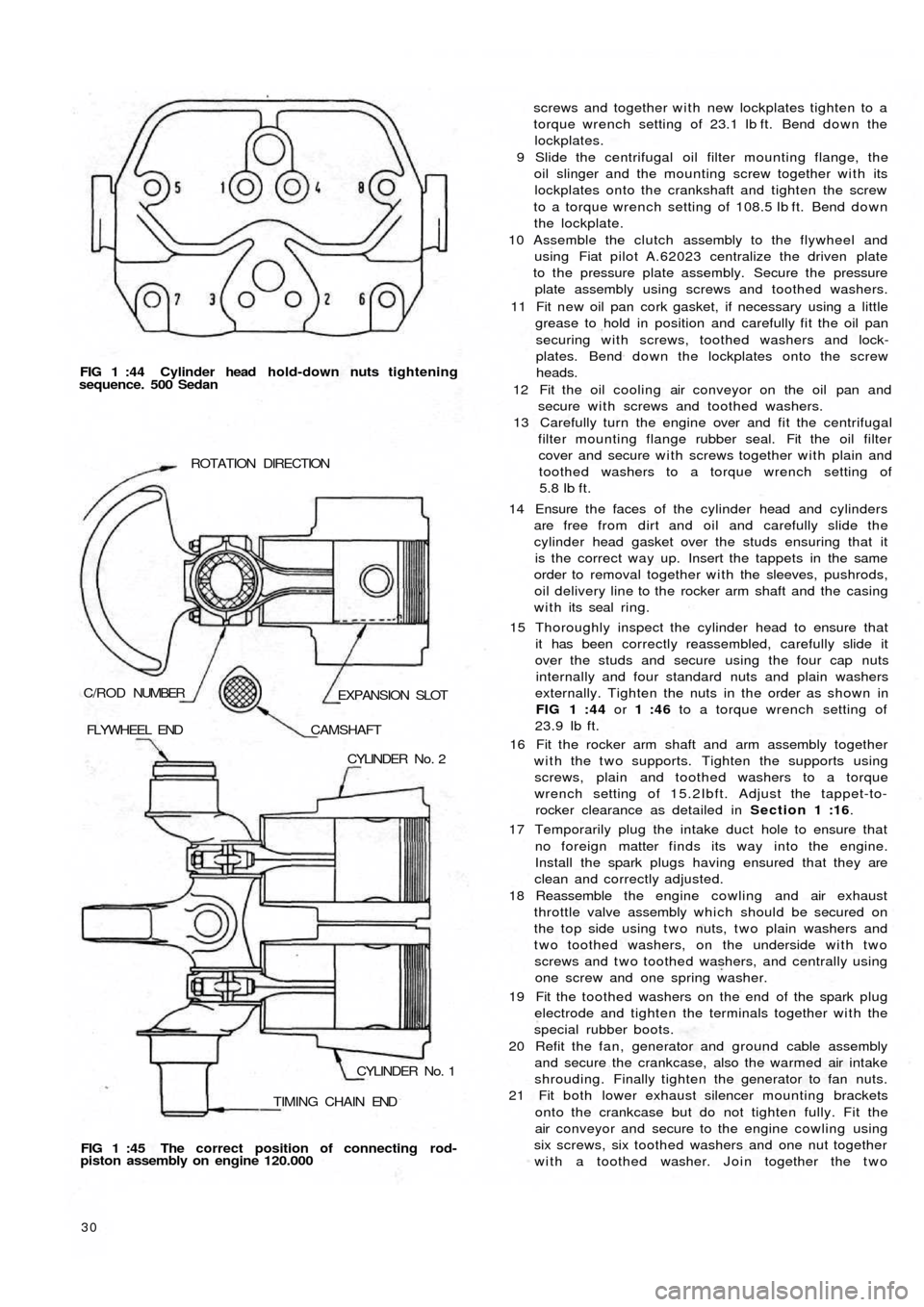

Turn the engine until the valves of one cylinder are in

balance, that is, the inlet valve opening and the exhaust

valve closing. The other cylinder will now have both valves

fully closed. Adjust the valves on this second cylinder by

loosening the locknut, and turning the

adjuster as shown in

FIG 1 : 43 to obtain the desired clearance measured with

a feeler gauge. Adjust the clearances on the other cylinder

in the same manner.

1 :17 Engine assembly (sedan — all versions)

To reassemble the engine proceed as follows:

1 Thoroughly clean and dry all the parts, ensure that all

drillings are free from dirt or sludge and place on a

clean dry surface.

2 Carefully install the cylinder-piston-connecting rod

assemblies w i t h new paper gaskets between the

cylinders and crankcase seats.

3 Refit the big-end bearing shells to the connecting

rods, ensuring that they are free from any dirt or

metallic particles. Carefully ease t h e crankshaft into

the crankcase, lubricate the main journals with clean

engine oil, place a new paper gasket between the

supporting member and the flywheel end of the

crankcase. Install the supporting member and bearing

assemblies. Secure the supporting members with the

screws and special toothed washers.

4 Locate the connecting rod big-end half onto the

crankpin journals, liberally lubricate the journals with

fresh engine oil, fit the remaining shell half, matching

bearing end cap and tighten the bearing cap nuts to a

torque wrench setting of 23.9 Ib ft.

5 Inspect the camshaft bearing bores and remove any

burrs w i t h a hand scraper wetted with oil. Carefully

slide in the camshaft ensuring the cam lobes or gear

teeth do not score the front bearing bore.

6 Fit a new timing gear cover paper gasket held in

place w i t h a little grease. Install the outer thrust ring,

F50029 inner thrust ring, shoulder washer and slide on the

camshaft drive sprocket, locking it with the Woodruff

key. Assemble the timing chain and driven sprocket,

ensuring that the timing marks on the sprocket are

indexing as shown in FIG 1 :41. Secure the driven

sprocket with six screws and lockplates and care-

fully bend down the lockplates.

7 Install the timing gear cover, the oil pump, oil pressure

relief valve and seal assembly. Secure w i t h nuts,

special toothed washers and plain washers located

in the same manner as was noted on dismantling.

Locate the oil pump suction horn and secure with the

nuts and toothed washers.

8 Install the flywheel in the same relative position to the

crankshaft as was noted on dismantling. Replace the FIG 1 : 4 3 Adjusting the rocker clearances using the

optional service tools. Refer to Technical Data for the

correct clearance on early and late engines FIG 1 :42 Graduated sector C.673 for valve gear

timing

TIMING MARK

Page 23 of 128

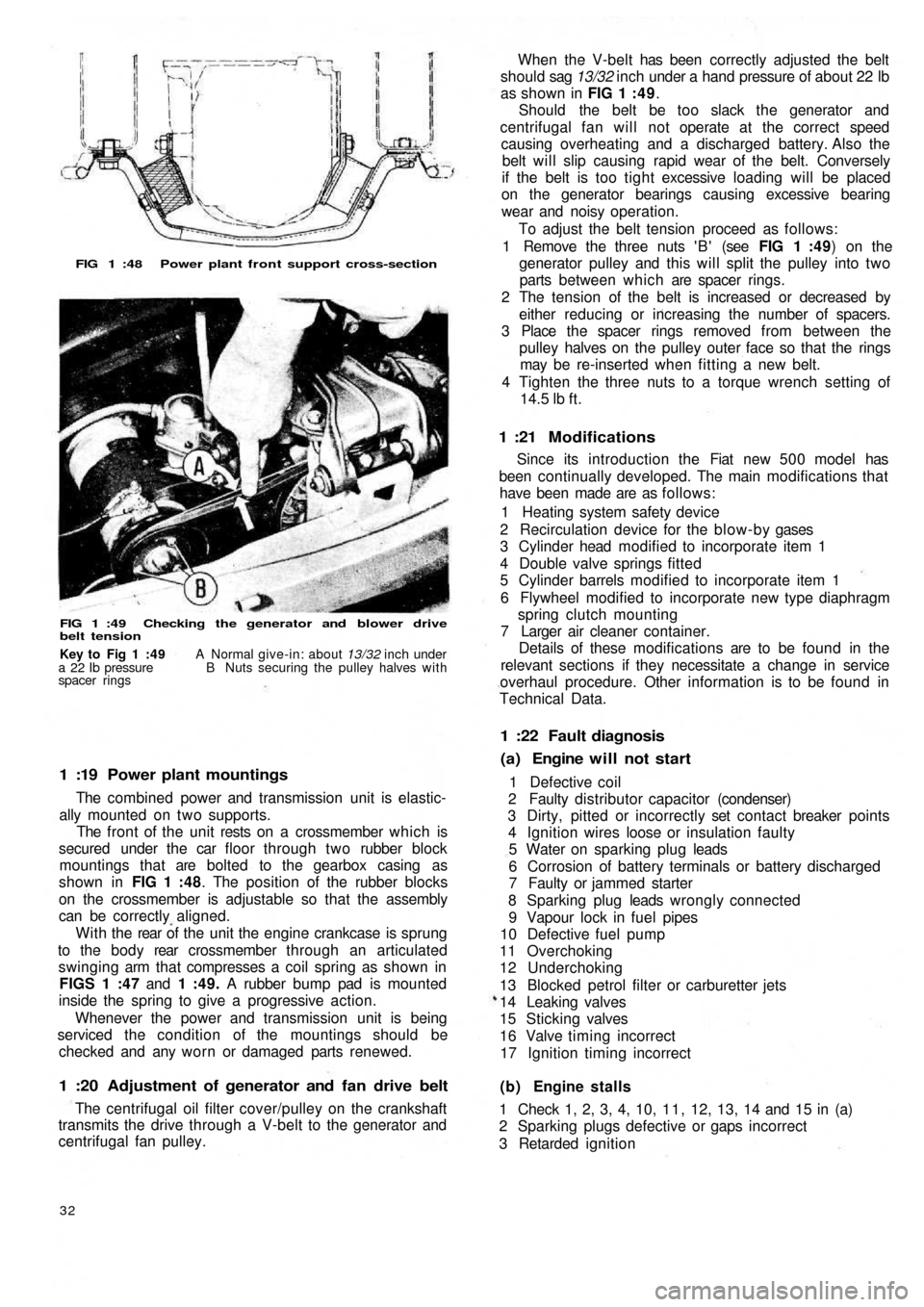

FIG 1 :44 Cylinder head h o ld-down nuts tightening

sequence. 500 Sedan

TIMING CHAIN ENDCYLINDER No. 1 CYLINDER No. 2 FLYWHEEL END

CAMSHAFT

EXPANSION SLOT C/ROD NUMBERROTATION DIRECTION

FIG 1 :45 The correct position of connecting rod-

piston assembly on engine 120.000

30

screws and together with new lockplates tighten to a

torque wrench setting of 23.1 Ib ft. Bend down the

lockplates.

9 Slide the centrifugal oil filter mounting flange, the

oil slinger and the mounting screw together with its

lockplates onto the crankshaft and tighten the screw

to a torque wrench setting of 108.5 Ib ft. Bend down

the lockplate.

10 Assemble the clutch assembly to the flywheel and

using Fiat pilot A.62023 centralize the driven plate

to the pressure plate assembly. Secure the pressure

plate assembly using screws and toothed washers.

11 Fit new oil pan cork gasket, if necessary using a little

grease to hold in position and carefully fit the oil pan

securing with screws, toothed washers and lock-

plates. Bend down the lockplates onto the screw

heads.

12 Fit the oil cooling air conveyor on the oil pan and

secure with screws and toothed washers.

13 Carefully turn the engine over and fit the centrifugal

filter mounting flange rubber seal. Fit the oil filter

cover and secure with screws together with plain and

toothed washers to a torque wrench setting of

5.8

Ib ft.

14 Ensure t h e faces of the cylinder head and cylinders

are free from dirt and oil and carefully slide the

cylinder head gasket over the studs ensuring that it

is the correct way up. Insert the tappets in the same

order to removal together with the sleeves, pushrods,

oil delivery line to the rocker arm shaft and the casing

with its seal ring.

15 Thoroughly inspect the cylinder head to ensure that

it has been correctly reassembled, carefully slide it

over the studs and secure using the four cap nuts

internally and four standard nuts and plain washers

externally. Tighten the nuts in the order as shown in

FIG 1 :44 or 1 :46 to a torque wrench setting of

23.9 Ib ft.

16 Fit the rocker arm shaft and arm assembly together

with the two supports. Tighten the supports using

screws, plain and toothed washers to a torque

wrench setting of 15.2Ibft. Adjust the tappet-to-

rocker clearance as detailed in Section 1 :16.

17 Temporarily plug the intake duct hole to ensure that

no foreign matter finds its way into the engine.

Install the spark plugs having ensured that they are

clean and correctly adjusted.

18 Reassemble the engine cowling and air

exhaust

throttle valve assembly which should be secured on

the top side using t w o nuts, t w o plain washers and

two toothed washers, on the underside with two

screws and t w o toothed washers, and centrally using

one screw and one spring washer.

19 Fit the toothed washers on the end of the spark plug

electrode and tighten the terminals together with the

special rubber boots.

20 Refit the fan, generator and ground cable assembly

and secure the crankcase, also the warmed air intake

shrouding. Finally tighten the generator to fan nuts.

21 Fit both lower exhaust silencer mounting brackets

onto the crankcase but do not tighten fully. Fit the

air conveyor and secure to the engine cowling using

six screws, six toothed washers and one nut together

with a toothed washer. Join together the t w o

Page 25 of 128

FIG 1 :48 Power plant front support cross-section

FIG 1 :49 Checking the generator and blower drive

belt tension

1 :19 Power plant mountings

The combined power and transmission unit is elastic-

ally mounted on two supports.

The front of the unit rests on a crossmember which is

secured under the car floor through two rubber block

mountings that are bolted to the gearbox casing as

shown in FIG 1 :48. The position of the rubber blocks

on the crossmember is adjustable so that the assembly

can be correctly aligned.

W i t h t h e rear of the unit the engine crankcase is sprung

to the b o d y rear crossmember through an articulated

swinging arm that compresses a coil spring as shown in

FIGS 1 :47 and 1 :49. A rubber bump pad is mounted

inside the spring to give a progressive action.

Whenever the power and transmission unit is being

serviced the condition of the mountings should be

checked and any worn or damaged parts renewed.

1 :20 Adjustment of generator and fan drive belt

The centrifugal oil filter cover/pulley on the crankshaft

transmits the drive through a V-belt to the generator and

centrifugal fan pulley.

32

(b) Engine stalls

1 Check 1, 2, 3, 4, 10, 1 1 , 12, 13, 14 and 15 in (a)

2 Sparking plugs defective or gaps incorrect

3 Retarded ignition 1 Defective coil

2 Faulty distributor capacitor (condenser)

3 Dirty, pitted or incorrectly set contact breaker points

4 Ignition wires loose or insulation faulty

5 Water on sparking plug leads

6 Corrosion of battery terminals or battery discharged

7 Faulty or jammed starter

8 Sparking plug leads wrongly connected

9 Vapour lock in fuel pipes

10 Defective fuel pump

11 Overchoking

12 Underchoking

13 Blocked petrol filter or carburetter jets

14 Leaking valves

15 Sticking valves

16 Valve timing incorrect

17 Ignition timing incorrect

(a) Engine will not start 1 :22 Fault diagnosis

Since its introduction the Fiat new 5 0 0 model has

been continually developed. The main modifications that

have been made are as follows:

1 Heating system safety device

2 Recirculation device for the blow-by gases

3 Cylinder head modified to incorporate item 1

4 Double valve springs fitted

5 Cylinder barrels modified to incorporate item 1

6 Flywheel modified to incorporate new type diaphragm

spring clutch mounting

7 Larger air cleaner container.

Details of these modifications are to be found in the

relevant sections if they necessitate a change in service

overhaul procedure. Other information is to be found in

Technical Data.

1 :21 Modifications

When the V-belt has been correctly adjusted the belt

should sag 13/32 inch under a hand pressure of about 22 lb

as shown in FIG 1 : 4 9.

Should the belt be too slack the generator and

centrifugal fan will not operate at the correct speed

causing overheating and a discharged battery. Also the

belt will slip causing rapid wear of the belt. Conversely

if the belt is too tight excessive loading will be placed

on the generator bearings causing excessive bearing

wear and noisy operation.

To adjust the belt tension proceed as follows:

1 Remove the three nuts ' B ' (see FIG 1 :49) on the

generator pulley and this will split the pulley into two

parts between which are spacer rings.

2 The tension of the belt is increased or decreased by

either reducing or increasing the number of spacers.

3 Place the spacer rings removed from between the

pulley halves on the pulley outer face so that the rings

may be re-inserted when fitting a new belt.

4 Tighten the three nuts to a torque wrench setting of

14.5

lb ft.

Key to Fig 1 :49 A Normal give-in: about 13/32 inch under

a 22 Ib pressure B Nuts securing the pulley halves with

spacer rings

Page 28 of 128

CHAPTER 2

THE FUEL SYSTEM

2:1 Description

2 : 2 Fuel pump operating principles

2 : 3 Routine maintenance

2 : 4 Pump removal, dismantling and examination

2 : 5 Reassembly, installation and adjustment

2 : 6 Carburetter operation and adjustment,

Weber 26.1MB2 : 7 Modifications

2 : 8 Carburetter operation and adjustment,

Weber 26.OC

2 :9 Air cleaner

2 : 1 0 B l o w - b y gases recirculation device

2:11 Fuel tank

2:12 Fault diagnosis

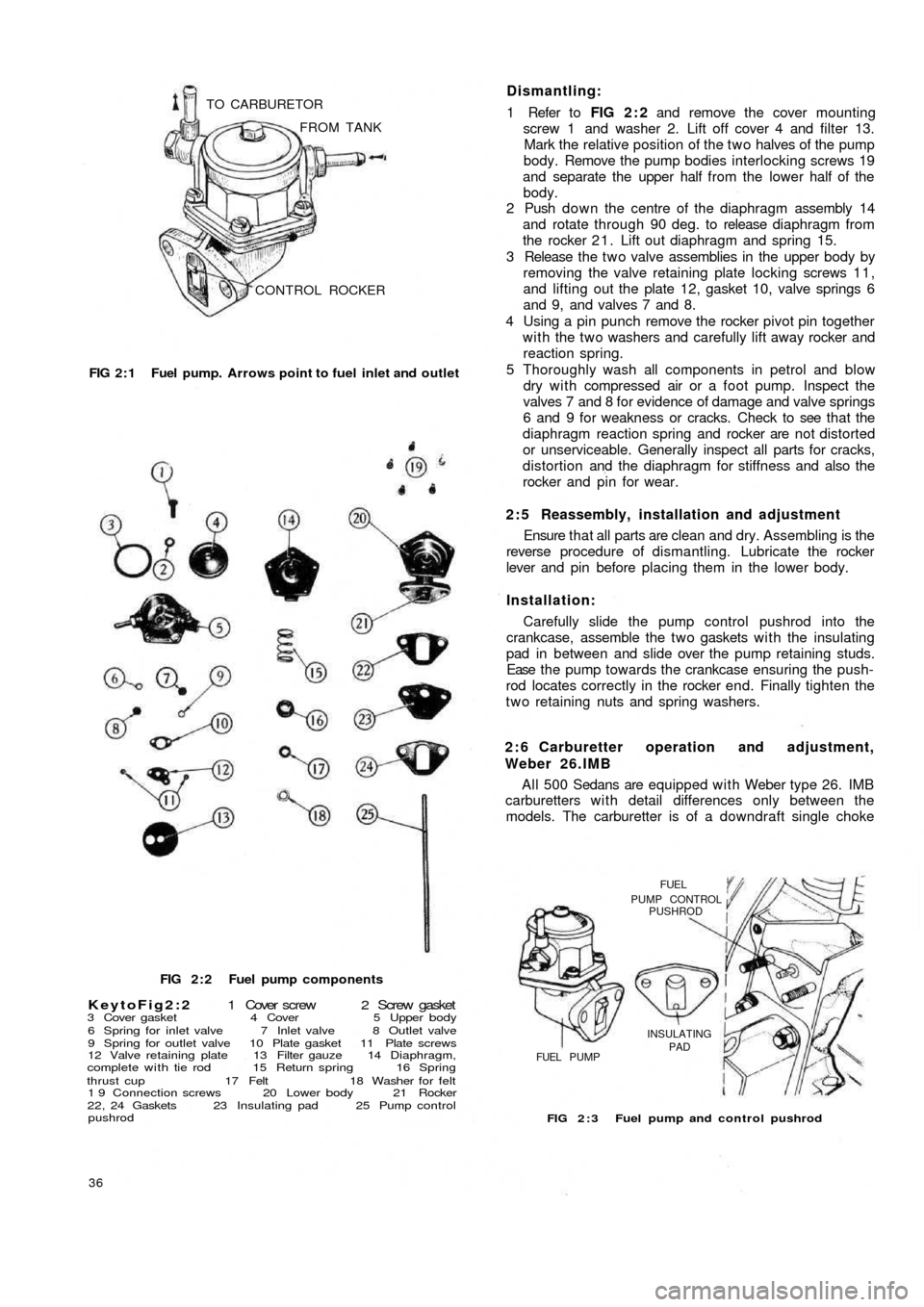

2:1 Description

All the new 500 models use a mechanical diaphragm

fuel feed pump as shown in FIG 2 : 1. Four types of

carburetter are fitted depending on the model to which

the engine is installed. Each carburetter operation and

adjustment is fully described, together with details of the

recirculation device for blow-by gases and o i l vapours.

2 : 2 Fuel pump operating principles

Refer to FIG 2 : 2. An eccentric on the rotating camshaft

actuates the operating rocker 21 via a pushrod 25 which

depresses the diaphragm 14 and so creates a depression

in the pumping chamber located in upper body 5. Under

atmospheric pressure, petrol passes through the pipeline

connection and inlet valve into the pumping chamber.

The return spring 15 then raises the diaphragm, expelling

the petrol through the outlet valve and pipeline to the

carburetter float chamber.

When the float chamber is full, the pressure in the pipe-

line and pumping chamber holds the diaphragm depressed

against the tension of the return spring.2 : 3 Routine maintenance

A poor delivery of fuel to the carburetter may be due to

a fault in the fuel pump or related lines. Periodically the

pump body screws 19 (see FIG 2 : 2) and upper cover

screw 1 should be checked for tightness. The fuel pump

lines should be disconnected and checked for freedom of

restriction, chafing and loose connections. The fuel pump

filter should be removed and cleaned periodically.

2:4 Pump removal, dismantling and examination

The pump is located on the carburetter side of the

engine crankcase (sedan) or under the generator at the

front of the crankcase (station wagon).

Removal:

1 Disconnect the fuel pipe from the tank to stop petrol

syphoning out of the tank and then release the fuel

inlet and outlet pipes from the pump body.

2 Remove the t w o nuts and washers holding pump to

crankcase.

3 Carefully lift away the pump, gaskets and insulating pad

from the crankcase (see FIG 2 : 3).

F50035

Page 29 of 128

CONTROL ROCKER FROM TANK TO CARBURETOR

FIG 2 : 1 Fuel pump. Arrows point to fuel inlet and outlet

FIG 2 : 2 Fuel pump components

KeytoFig2:2 1 Cover screw 2 Screw gasket3 Cover gasket 4 Cover 5 Upper body

6 Spring for inlet valve 7 Inlet valve 8 Outlet valve

9 Spring for outlet valve 10 Plate gasket 11 Plate screws

12 Valve retaining plate 13 Filter gauze 14 Diaphragm,

complete with tie rod 15 Return spring 16 Spring

thrust cup 17 Felt 18 Washer for felt

1 9 Connection screws 20 Lower body 21 Rocker

22, 24 Gaskets 23 Insulating pad 25 Pump control

pushrod

36

FIG 2 : 3 Fuel pump and control pushrod

FUELPUMP CONTROLPUSHROD

INSULATING

PAD

FUEL PUMP

A l l 500 Sedans are equipped with Weber type 26. IMB

carburetters w i t h detail differences only between the

models. The carburetter is of a downdraft single choke 2 : 6 Carburetter operation and adjustment,

Weber 26.IMB Carefully slide the pump control pushrod into the

crankcase, assemble the t w o gaskets w i t h the insulating

pad in between and slide over the pump retaining studs.

Ease t h e p u m p towards the crankcase ensuring the push-

rod locates correctly in the rocker end. Finally tighten the

two retaining nuts and spring washers. Installation:Ensure t h a t all parts are clean and dry. Assembling is the

reverse procedure of dismantling. Lubricate the rocker

lever and pin before placing them in the lower body. 2 : 5 Reassembly, installation and adjustment 1 Refer to FIG 2 : 2 and remove the cover mounting

screw 1 and washer 2. Lift off cover 4 and filter 13.

Mark the relative position of the two halves of the pump

body. Remove the pump bodies interlocking screws 19

and separate the upper half from the lower half of the

body.

2 Push down the centre of the diaphragm assembly 14

and rotate through 90 deg. to release diaphragm from

the rocker 2 1 . Lift out diaphragm and spring 15.

3 Release the t w o valve assemblies in the upper body by

removing the valve retaining plate locking screws 1 1 ,

and lifting out the plate 12, gasket 10, valve springs 6

and 9, and valves 7 and 8.

4 Using a pin punch remove the rocker pivot pin together

w i t h the t w o washers and carefully lift away rocker and

reaction spring.

5 Thoroughly wash all components in petrol and

blow

dry with compressed air or a foot pump. Inspect the

valves 7 and 8 for evidence of damage and valve springs

6 and 9 for weakness or cracks. Check to see that the

diaphragm reaction spring and rocker are not distorted

or unserviceable. Generally inspect all parts for cracks,

distortion and the diaphragm for stiffness and also the

rocker and pin for wear. Dismantling:

Page 32 of 128

3 Engine warm-up:

As the engine begins to warm up to its normal operating

temperature, gradually push home the starting device

lever so as only to supply the engine with the richened

charge enabling the cold engine operation to be smooth

and regular. Position ' B ' (FIG 2:6).

4 Normal car driving:

Once the engine has reached its normal operating

temperature the starting device should be completely

brought out of operation by bringing the control lever to

the position 'C (FIG 2:6).

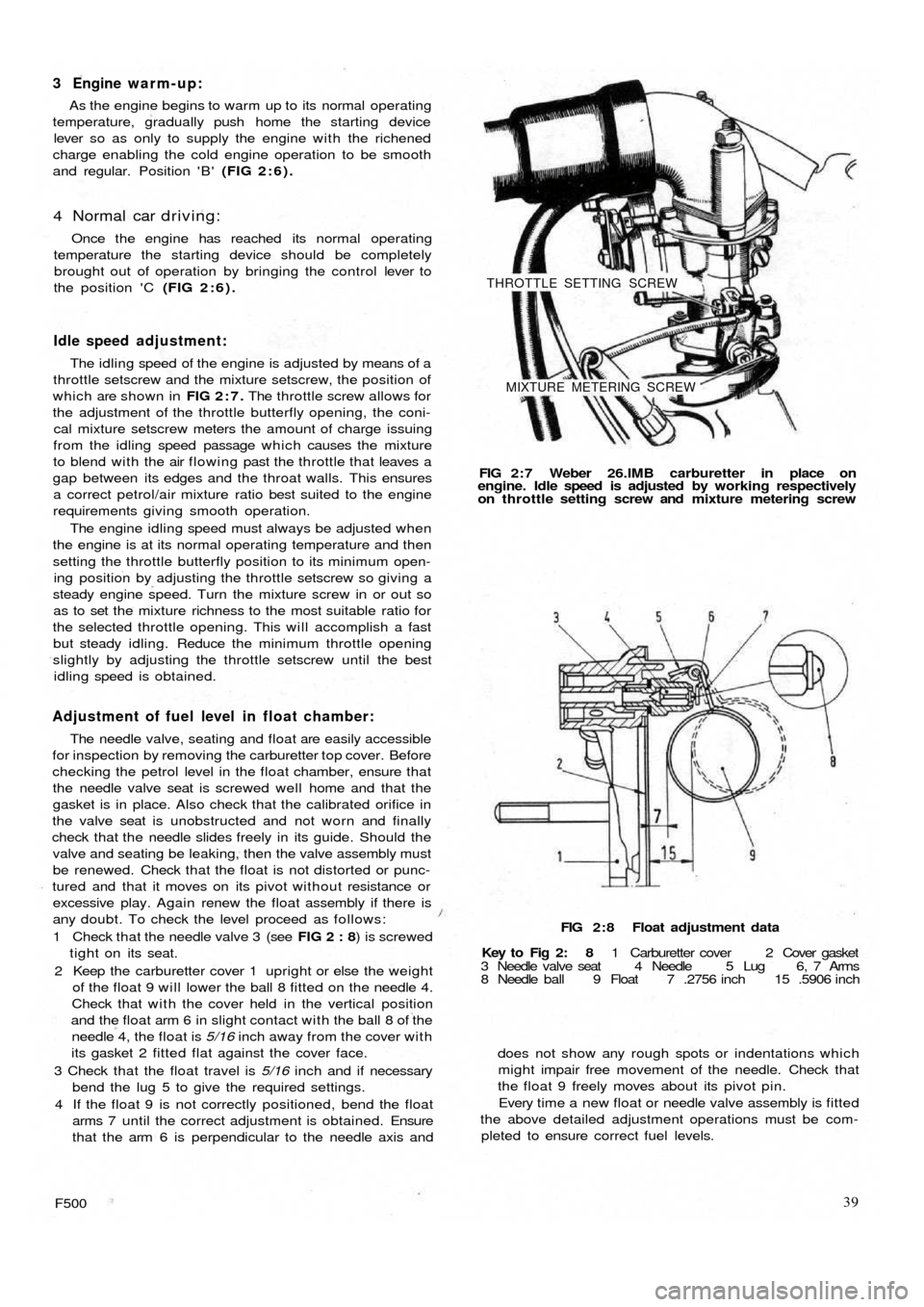

Idle speed adjustment:

The idling speed of the engine is adjusted by means of a

throttle setscrew and the mixture setscrew, the position of

which are shown in FIG 2:7. The throttle screw allows for

the adjustment of the throttle butterfly opening, the coni-

cal mixture setscrew meters the amount of charge issuing

from the idling speed passage which causes the mixture

to blend with the air flowing past the throttle that leaves a

gap between its edges and the throat walls. This ensures

a correct petrol/air mixture ratio best suited to the engine

requirements giving smooth operation.

The engine idling speed must always be adjusted when

the engine is at its normal operating temperature and then

setting the throttle butterfly position to its minimum open-

ing position by adjusting the throttle setscrew so giving a

steady engine speed. Turn the mixture screw in or out so

as to set the mixture richness to the most suitable ratio for

the selected throttle opening. This will accomplish a fast

but steady idling. Reduce the minimum throttle opening

slightly by adjusting the throttle setscrew until the best

idling speed is obtained.

Adjustment of fuel level in float chamber:

The needle valve, seating and float are easily accessible

for inspection by removing the carburetter top cover. Before

checking the petrol level in the float chamber, ensure that

the needle valve seat is screwed well home and that the

gasket is in place. Also check that the calibrated orifice in

the valve seat is unobstructed and not worn and finally

check that the needle slides freely in its guide. Should the

valve and seating be leaking, then the valve assembly must

be renewed. Check that the float is not distorted or punc-

tured and that it moves on its pivot without resistance or

excessive play. Again renew the float assembly if there is

any doubt. To check the level proceed as follows:

1 Check that the needle valve 3 (see FIG 2 : 8) is screwed

tight on its seat.

2 Keep the carburetter cover 1 upright or else the weight

of the float 9 will lower the ball 8 fitted on the needle 4.

Check that with the cover held in the vertical position

and the float arm 6 in slight contact with the ball 8 of the

needle 4, the float is 5/16 inch away from the cover with

its gasket 2

fitted flat against the cover face.

3 Check that the float travel is 5/16 inch and if necessary

bend the lug 5 to give the required settings.

4 If the float 9 is not correctly positioned, bend the float

arms 7 until the correct adjustment is obtained. Ensure

that the arm 6 is perpendicular to the needle axis and

F50039

does not show any rough spots or indentations which

might impair free movement of the needle. Check that

the float 9 freely moves about its pivot pin.

Every time a new float or needle valve assembly is fitted

the above detailed adjustment operations must be com-

pleted to ensure correct fuel levels. FIG 2 : 8 Float adjustment data

Key to Fig 2: 8 1 Carburetter cover 2 Cover gasket

3 Needle valve seat 4 Needle 5 Lug 6, 7 Arms

8 Needle ball 9 Float 7 .2756 inch 15 .5906 inch FIG 2 : 7 Weber 26.IMB carburetter in place on

engine. Idle speed is adjusted by working respectively

on throttle setting screw and mixture metering screw

THROTTLE SETTING SCREW

MIXTURE METERING SCREW