lock FIAT 500 2020 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2020, Model line: 500, Model: FIAT 500 2020Pages: 228, PDF Size: 6.01 MB

Page 104 of 228

129)Before starting any servicing

operation, stop the engine and remove the

key from the ignition switch to operate

the steering lock, particularly when the

wheels do not touch the ground. If this is

not possible (for example if the key needs

to be turned to MAR or the engine must be

running), remove the main fuse that

protects the electric power steering.START&STOP

SYSTEM

130) 131) 132) 133)

46)

(for versions/markets, where provided)

The Start&Stop system automatically

stops the engine each time the car

is stationary and starts it again when

the driver wants to move off.

In this way, the vehicle efficiency is

increased, by reducing consumption,

dangerous gas emissions and sound

pollution.

OPERATING MODE

Stopping the engine

With manual transmission: with the car

stationary, the engine stops with the

transmission in neutral and the clutch

pedal released.

With Dualogic gearbox: the engine

stops if the car is at a standstill and the

brake pedal is pressed. This condition

can be maintained even if the brake

pedal is not depressed, if the gear lever

is in position N (Neutral).NOTE The engine can only be stopped

automatically over about 10 km/h, to

prevent the engine from being

repeatedly stopped when driving at

walking pace.

Stopping of the engine is indicated by

the warning light or the symbol

on

the instrument panel switching on

(on some versions, together with a

message on the display).

Restarting the engine

With manual transmission: press the

clutch pedal.

With Dualogic gearbox: if the gear lever

is in position N (Neutral), place it in

any other gear, otherwise release the

brake pedal or move the gear lever

to+,–or R (Reverse).

MANUAL SYSTEM

ACTIVATION/

DEACTIVATION

The system can be activated/

deactivated by pressing the button A

fig. 79 on the dashboard.

With the system off, the warning light or

the symbol

appear on the

instrument panel (with a message for

versions with colour display).

Start&Stop mode will be active

whenever the engine is started.

102

STARTING AND DRIVING

Page 112 of 228

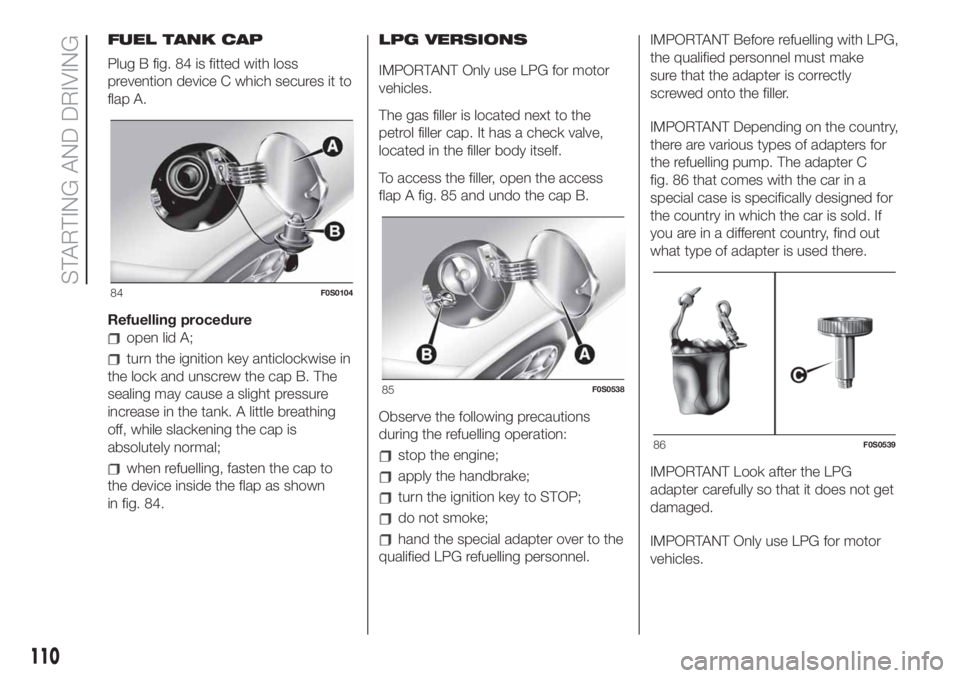

FUEL TANK CAP

Plug B fig. 84 is fitted with loss

prevention device C which secures it to

flap A.

Refuelling procedure

open lid A;

turn the ignition key anticlockwise in

the lock and unscrew the cap B. The

sealing may cause a slight pressure

increase in the tank. A little breathing

off, while slackening the cap is

absolutely normal;

when refuelling, fasten the cap to

the device inside the flap as shown

in fig. 84.LPG VERSIONS

IMPORTANT Only use LPG for motor

vehicles.

The gas filler is located next to the

petrol filler cap. It has a check valve,

located in the filler body itself.

To access the filler, open the access

flap A fig. 85 and undo the cap B.

Observe the following precautions

during the refuelling operation:stop the engine;

apply the handbrake;

turn the ignition key to STOP;

do not smoke;

hand the special adapter over to the

qualified LPG refuelling personnel.IMPORTANT Before refuelling with LPG,

the qualified personnel must make

sure that the adapter is correctly

screwed onto the filler.

IMPORTANT Depending on the country,

there are various types of adapters for

the refuelling pump. The adapter C

fig. 86 that comes with the car in a

special case is specifically designed for

the country in which the car is sold. If

you are in a different country, find out

what type of adapter is used there.

IMPORTANT Look after the LPG

adapter carefully so that it does not get

damaged.

IMPORTANT Only use LPG for motor

vehicles.

84F0S0104

85F0S0538

86F0S0539

110

STARTING AND DRIVING

Page 119 of 228

REPLACING AN

EXTERNAL BULB

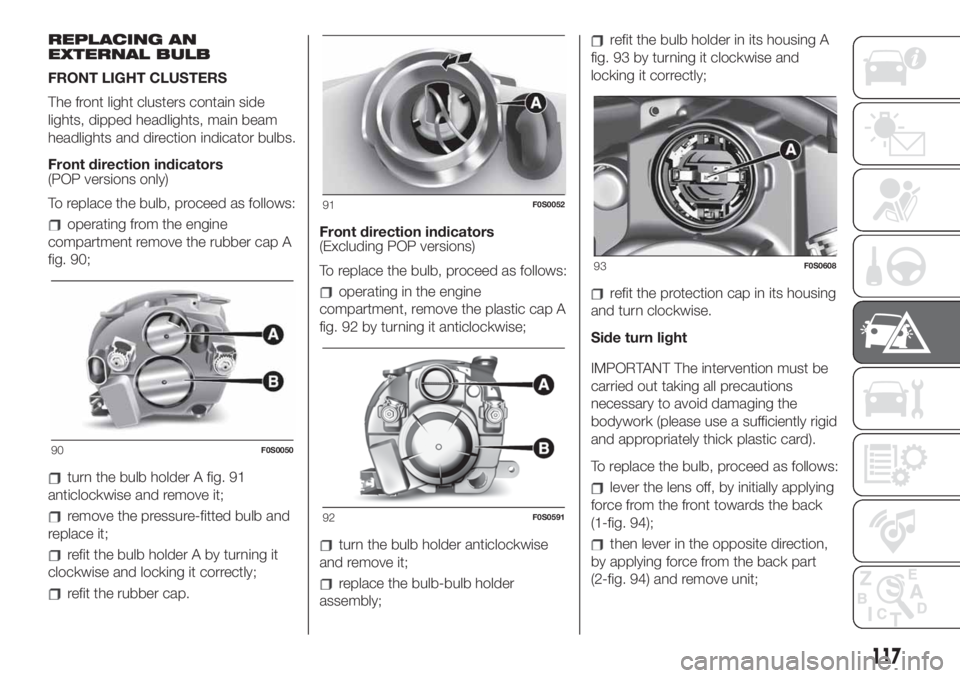

FRONT LIGHT CLUSTERS

The front light clusters contain side

lights, dipped headlights, main beam

headlights and direction indicator bulbs.

Front direction indicators

(POP versions only)

To replace the bulb, proceed as follows:

operating from the engine

compartment remove the rubber cap A

fig. 90;

turn the bulb holder A fig. 91

anticlockwise and remove it;

remove the pressure-fitted bulb and

replace it;

refit the bulb holder A by turning it

clockwise and locking it correctly;

refit the rubber cap.Front direction indicators

(Excluding POP versions)

To replace the bulb, proceed as follows:

operating in the engine

compartment, remove the plastic cap A

fig. 92 by turning it anticlockwise;

turn the bulb holder anticlockwise

and remove it;

replace the bulb-bulb holder

assembly;

refit the bulb holder in its housing A

fig. 93 by turning it clockwise and

locking it correctly;

refit the protection cap in its housing

and turn clockwise.

Side turn light

IMPORTANT The intervention must be

carried out taking all precautions

necessary to avoid damaging the

bodywork (please use a sufficiently rigid

and appropriately thick plastic card).

To replace the bulb, proceed as follows:

lever the lens off, by initially applying

force from the front towards the back

(1-fig. 94);

then lever in the opposite direction,

by applying force from the back part

(2-fig. 94) and remove unit;

90F0S0050

91F0S0052

92F0S0591

93F0S0608

117

Page 120 of 228

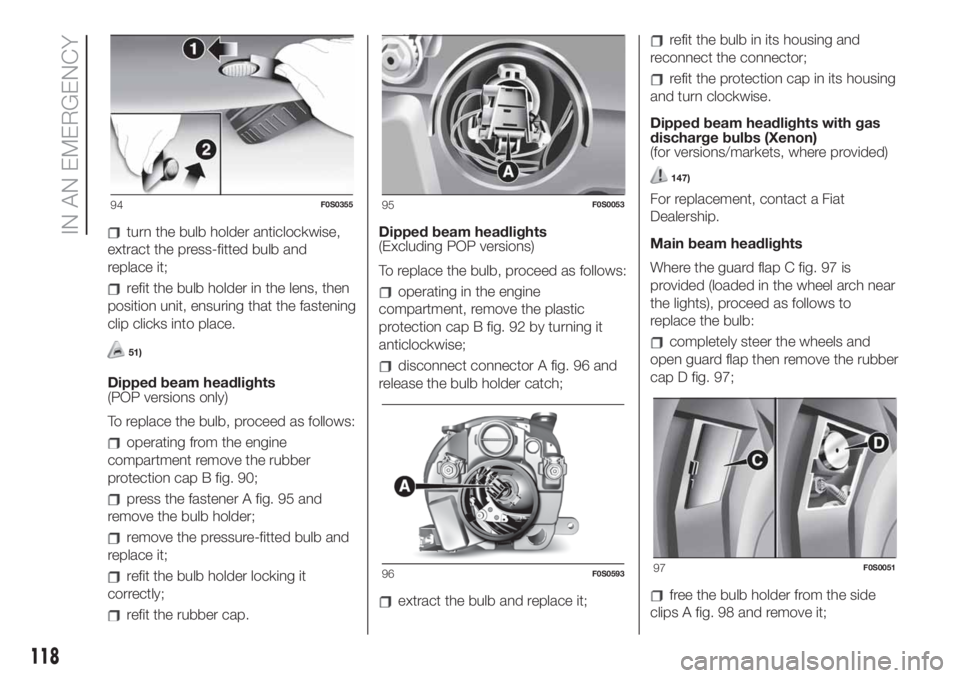

turn the bulb holder anticlockwise,

extract the press-fitted bulb and

replace it;

refit the bulb holder in the lens, then

position unit, ensuring that the fastening

clip clicks into place.

51)

Dipped beam headlights

(POP versions only)

To replace the bulb, proceed as follows:

operating from the engine

compartment remove the rubber

protection cap B fig. 90;

press the fastener A fig. 95 and

remove the bulb holder;

remove the pressure-fitted bulb and

replace it;

refit the bulb holder locking it

correctly;

refit the rubber cap.Dipped beam headlights

(Excluding POP versions)

To replace the bulb, proceed as follows:

operating in the engine

compartment, remove the plastic

protection cap B fig. 92 by turning it

anticlockwise;

disconnect connector A fig. 96 and

release the bulb holder catch;

extract the bulb and replace it;

refit the bulb in its housing and

reconnect the connector;

refit the protection cap in its housing

and turn clockwise.

Dipped beam headlights with gas

discharge bulbs (Xenon)

(for versions/markets, where provided)

147)

For replacement, contact a Fiat

Dealership.

Main beam headlights

Where the guard flap C fig. 97 is

provided (loaded in the wheel arch near

the lights), proceed as follows to

replace the bulb:

completely steer the wheels and

open guard flap then remove the rubber

cap D fig. 97;

free the bulb holder from the side

clips A fig. 98 and remove it;

94F0S035595F0S0053

96F0S059397F0S0051

118

IN AN EMERGENCY

Page 121 of 228

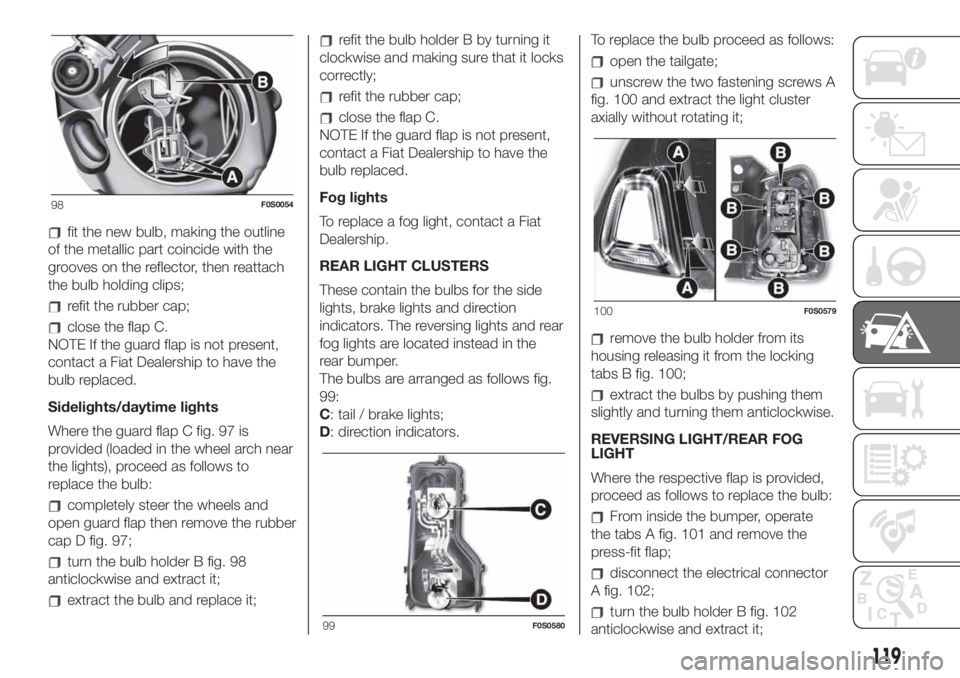

fit the new bulb, making the outline

of the metallic part coincide with the

grooves on the reflector, then reattach

the bulb holding clips;

refit the rubber cap;

close the flap C.

NOTE If the guard flap is not present,

contact a Fiat Dealership to have the

bulb replaced.

Sidelights/daytime lights

Where the guard flap C fig. 97 is

provided (loaded in the wheel arch near

the lights), proceed as follows to

replace the bulb:

completely steer the wheels and

open guard flap then remove the rubber

cap D fig. 97;

turn the bulb holder B fig. 98

anticlockwise and extract it;

extract the bulb and replace it;

refit the bulb holder B by turning it

clockwise and making sure that it locks

correctly;

refit the rubber cap;

close the flap C.

NOTE If the guard flap is not present,

contact a Fiat Dealership to have the

bulb replaced.

Fog lights

To replace a fog light, contact a Fiat

Dealership.

REAR LIGHT CLUSTERS

These contain the bulbs for the side

lights, brake lights and direction

indicators. The reversing lights and rear

fog lights are located instead in the

rear bumper.

The bulbs are arranged as follows fig.

99:

C: tail / brake lights;

D: direction indicators.To replace the bulb proceed as follows:

open the tailgate;

unscrew the two fastening screws A

fig. 100 and extract the light cluster

axially without rotating it;

remove the bulb holder from its

housing releasing it from the locking

tabs B fig. 100;

extract the bulbs by pushing them

slightly and turning them anticlockwise.

REVERSING LIGHT/REAR FOG

LIGHT

Where the respective flap is provided,

proceed as follows to replace the bulb:

From inside the bumper, operate

the tabs A fig. 101 and remove the

press-fit flap;

disconnect the electrical connector

A fig. 102;

turn the bulb holder B fig. 102

anticlockwise and extract it;

98F0S0054

99F0S0580

100F0S0579

119

Page 122 of 228

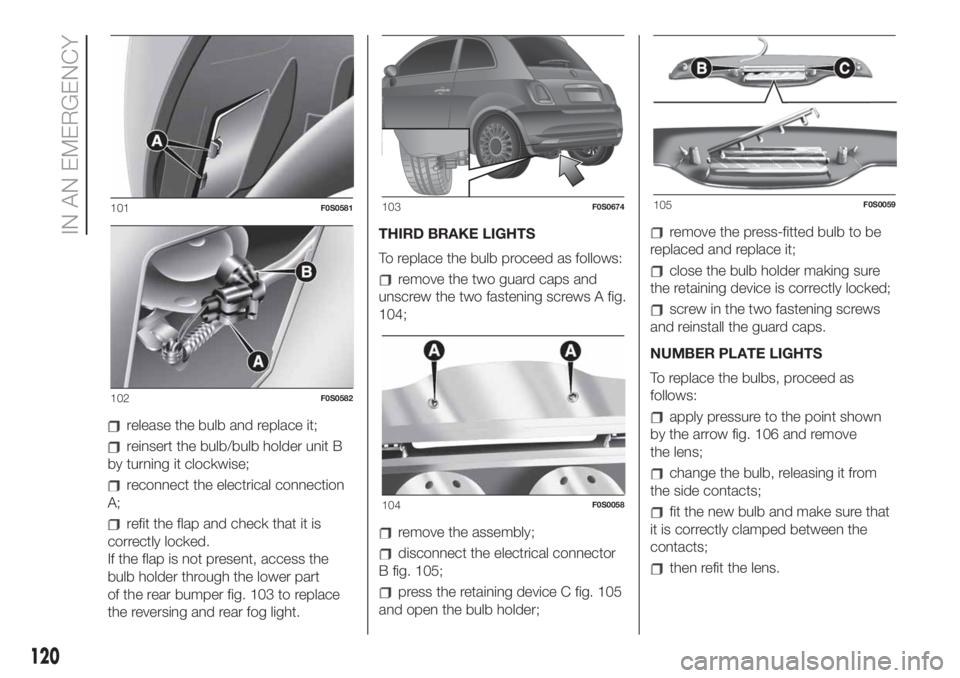

release the bulb and replace it;

reinsert the bulb/bulb holder unit B

by turning it clockwise;

reconnect the electrical connection

A;

refit the flap and check that it is

correctly locked.

If the flap is not present, access the

bulb holder through the lower part

of the rear bumper fig. 103 to replace

the reversing and rear fog light.THIRD BRAKE LIGHTS

To replace the bulb proceed as follows:

remove the two guard caps and

unscrew the two fastening screws A fig.

104;

remove the assembly;

disconnect the electrical connector

B fig. 105;

press the retaining device C fig. 105

and open the bulb holder;

remove the press-fitted bulb to be

replaced and replace it;

close the bulb holder making sure

the retaining device is correctly locked;

screw in the two fastening screws

and reinstall the guard caps.

NUMBER PLATE LIGHTS

To replace the bulbs, proceed as

follows:

apply pressure to the point shown

by the arrow fig. 106 and remove

the lens;

change the bulb, releasing it from

the side contacts;

fit the new bulb and make sure that

it is correctly clamped between the

contacts;

then refit the lens.

101F0S0581

102F0S0582

103F0S0674

104F0S0058

105F0S0059

120

IN AN EMERGENCY

Page 124 of 228

The dashboard fuse box shown is

located in the lower area next to the

pedal board.

ENGINE COMPARTMENT

JUNCTION BOX

52)

The fusebox is located on the right side

of the engine compartment. To access

the fuses, proceed as follows:

Fully press screw A fig. 109;

at the same time slowly rotate the

screw anticlockwise, until resistance is

encountered (do not overtighten);

slowly release the screw;

opening is indicated by the entire

screw head coming out of its seat;

remove cover B, sliding it upwards

on the side guides, as indicated in

the figure.Once the fuse has been replaced,

proceed as follows:

correctly refit the cover B in the side

guides of the casing;

slide it down completely from the

top;

fully tighten screw A using the

screwdriver provided;

at the same time slowly rotate the

screw clockwise, until resistance is

encountered (do not overtighten);

slowly release the screw;

closure is indicated by the securing

of the entire screw head in its housing.

The number identifying the electrical

component corresponding to each fuse

is shown on the control unit cover.

LPG versions

The LPG system components are

protected by specific fuses. Contact a

Fiat Dealership for replacement.

109F0S0606

122

IN AN EMERGENCY

Page 125 of 228

DASHBOARD FUSE BOX

USERSFUSE AMPERE

Headlight alignment corrector F13

5(*)

Diagnosis socket, radio, climate control, EOBD F36 15

Brake light switch, instrument panel node F37 5

Central door locking F38 15

Windscreen/rear window washer pump F43 15

Driver side electric window F47 20

Passenger side electric window F48 20

(*)(for versions/markets, where provided)

110F0S0172

123

Page 132 of 228

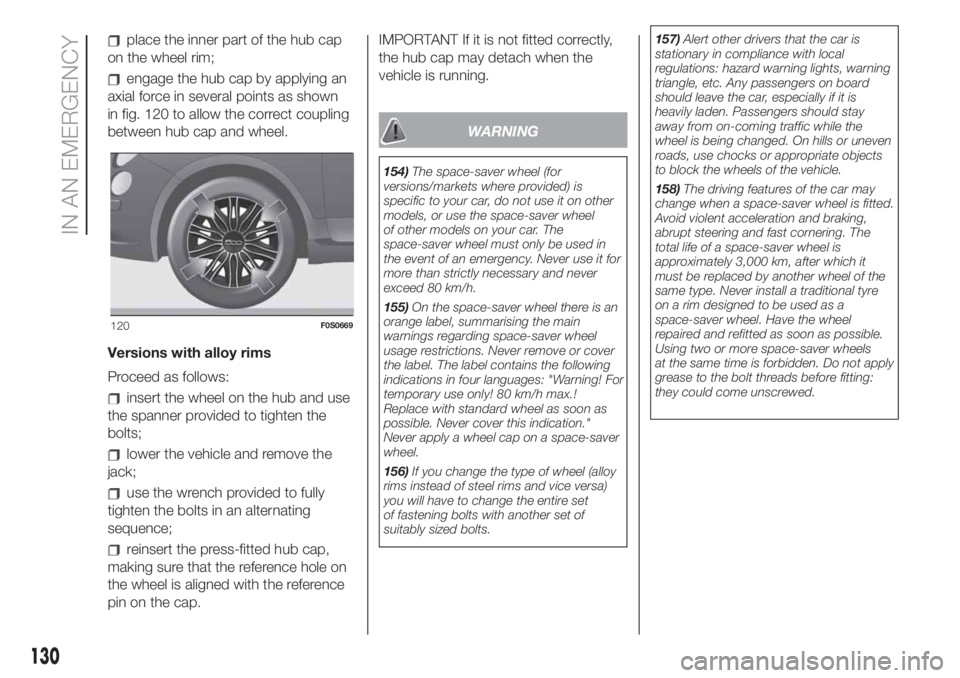

place the inner part of the hub cap

on the wheel rim;

engage the hub cap by applying an

axial force in several points as shown

in fig. 120 to allow the correct coupling

between hub cap and wheel.

Versions with alloy rims

Proceed as follows:

insert the wheel on the hub and use

the spanner provided to tighten the

bolts;

lower the vehicle and remove the

jack;

use the wrench provided to fully

tighten the bolts in an alternating

sequence;

reinsert the press-fitted hub cap,

making sure that the reference hole on

the wheel is aligned with the reference

pin on the cap.IMPORTANT If it is not fitted correctly,

the hub cap may detach when the

vehicle is running.

WARNING

154)The space-saver wheel (for

versions/markets where provided) is

specific to your car, do not use it on other

models, or use the space-saver wheel

of other models on your car. The

space-saver wheel must only be used in

the event of an emergency. Never use it for

more than strictly necessary and never

exceed 80 km/h.

155)On the space-saver wheel there is an

orange label, summarising the main

warnings regarding space-saver wheel

usage restrictions. Never remove or cover

the label. The label contains the following

indications in four languages: "Warning! For

temporary use only! 80 km/h max.!

Replace with standard wheel as soon as

possible. Never cover this indication."

Never apply a wheel cap on a space-saver

wheel.

156)If you change the type of wheel (alloy

rims instead of steel rims and vice versa)

you will have to change the entire set

of fastening bolts with another set of

suitably sized bolts.157)Alert other drivers that the car is

stationary in compliance with local

regulations: hazard warning lights, warning

triangle, etc. Any passengers on board

should leave the car, especially if it is

heavily laden. Passengers should stay

away from on-coming traffic while the

wheel is being changed. On hills or uneven

roads, use chocks or appropriate objects

to block the wheels of the vehicle.

158)The driving features of the car may

change when a space-saver wheel is fitted.

Avoid violent acceleration and braking,

abrupt steering and fast cornering. The

total life of a space-saver wheel is

approximately 3,000 km, after which it

must be replaced by another wheel of the

same type. Never install a traditional tyre

on a rim designed to be used as a

space-saver wheel. Have the wheel

repaired and refitted as soon as possible.

Using two or more space-saver wheels

at the same time is forbidden. Do not apply

grease to the bolt threads before fitting:

they could come unscrewed.

120F0S0669

130

IN AN EMERGENCY

Page 137 of 228

WARNING

166)This starting procedure must be

performed by expert personnel because

incorrect actions could cause electrical

discharge of considerable intensity.

Furthermore, battery fluid is poisonous and

corrosive: avoid contact with skin and

eyes. Keep naked flames and lighted

cigarettes away from the battery and do

not cause sparks.

167)Remove any metal objects (e.g. rings,

watches, bracelets), that might cause an

accidental electrical contact and cause

serious injury.

168)Do not attempt to charge a frozen

battery: it must be thawed first, otherwise it

may explode. If freezing has occurred, the

battery should be checked by skilled

personnel to make sure that the internal

elements are not damaged and that the

body is not cracked, with the risk of leaking

poisonous and corrosive acid.

WARNING

56)Never use a fast battery-charger to

start the engine as this could damage the

electronic systems of your vehicle,

particularly the ignition and engine fuel

supply control units.57)Do not connect the cable to the

negative terminal (–) of the flat battery. The

following spark could lead to battery

explosion and cause serious harm. Only

use the specific earth point; do not use any

other exposed metallic part.

58)Never bump start the engine by

pushing, towing or coasting downhill. This

could cause fuel to flow into the catalytic

converter and damage it beyond repair.

FUEL CUT-OFF

SYSTEM

169)

This intervenes in the case of an impact

causing:

the fuel supply cut-off with the

engine consequently switching off

the automatic unlocking of the doors

turning on of the lights inside the

vehicle;

The intervention of the system is

indicated by a message shown on the

display.

IMPORTANT Carefully check the car for

fuel leaks, for instance in the engine

compartment, under the car or near the

tank area. After a collision, turn the

ignition key to STOP position to prevent

the battery from running down.

To restore the correct operation of the

vehicle, proceed as follows:

turn the ignition key to the MAR-ON

position

activate the right direction indicator

deactivate the right direction

indicator

activate the left direction indicator

deactivate the left direction indicator

135