engine FIAT 500 ABARTH 2013 2.G Owner's Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2013, Model line: 500 ABARTH, Model: FIAT 500 ABARTH 2013 2.GPages: 84, PDF Size: 4.63 MB

Page 51 of 84

CAUTION!

Driving with a hot cooling system could damage your vehicle. If the temperature

gauge reads hot, pull over and stop the vehicle. Idle the vehicle with the air condi-

tioner turned off until the pointer drops back into the normal range. If the pointer

remains on hot, turn the engine off immediately and call for service.

WARNING!

You or others can be badly burned by hot engine coolant (antifreeze) or steam

from your radiator. If you see or hear steam coming from under the hood, do not

open the hood until the radiator has had time to cool. Never try to open a cooling

system pressure cap when the radiator or coolant bottle is hot.

TIREFIT KIT

• Your vehicle may be equipped with a TIREFIT kit. The TIREFIT kit is located under

the front driver’s seat.

• Small punctures up to 1/4 in (6 mm) in the tire tread can be sealed with TIREFIT.

Foreign objects (e.g., screws or nails) should not be removed from the tire.

TIREFIT can be used in outside temperatures down to approximately -4°F

(-20°C).

• This kit will provide a temporary tire seal, allowing you to drive your vehicle up to

100 miles (160 km) with a maximum speed of 55 mph (88 km/h).

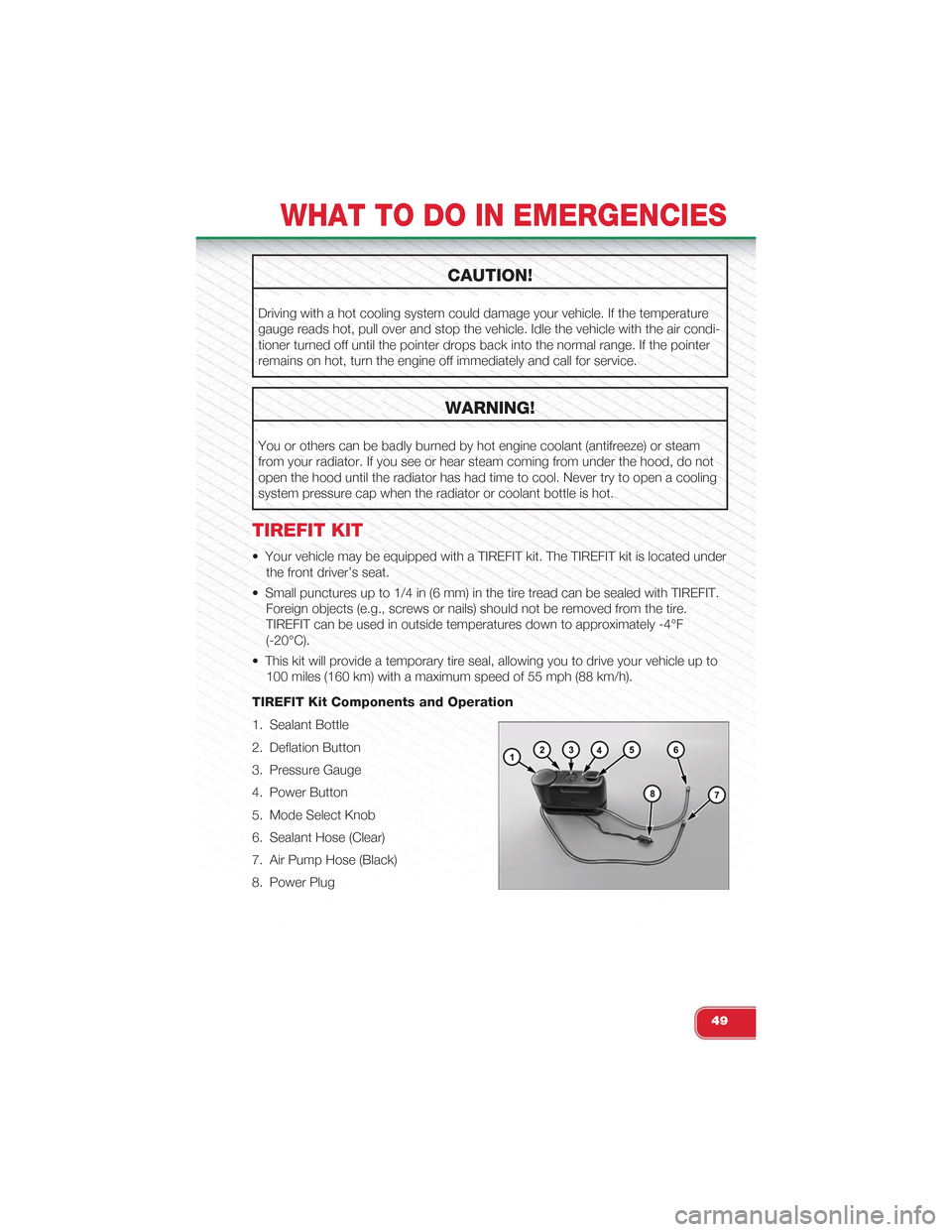

TIREFIT Kit Components and Operation

1. Sealant Bottle

2. Deflation Button

3. Pressure Gauge

4. Power Button

5. Mode Select Knob

6. Sealant Hose (Clear)

7. Air Pump Hose (Black)

8. Power Plug

WHAT TO DO IN EMERGENCIES

49

Page 53 of 84

Sealing A Tire With TIREFIT

(A) Whenever You Stop To Use TIREFIT:

1. Pull over to a safe location and turn on the vehicle’s Hazard Warning flashers.

2. Verify that the valve stem (on the wheel with the deflated tire) is in a position that

is near to the ground. This will allow the TIREFIT Hoses (6) and (7) to reach the

valve stem and keep the TIREFIT kit flat on the ground. This will provide the best

positioning of the kit when injecting the sealant into the deflated tire and running

the air pump. Move the vehicle as necessary to place the valve stem in this posi-

tion before proceeding.

3. Place the transmission in PARK (auto transmission) or in Gear (manual transmis-

sion) and cycle the ignition to the OFF position.

4. Set the parking brake.

(B) Setting Up To Use TIREFIT:

1. Turn the Mode Select Knob (5) to the Sealant Mode position.

2. Uncoil the Sealant Hose (6) and then remove the cap from the fitting at the end

of the hose.

3. Place the TIREFIT kit flat on the ground next to the deflated tire.

4. Remove the cap from the valve stem and then screw the fitting at the end of the

Sealant Hose (6) onto the valve stem.

5. Uncoil the Power Plug (8) and insert the plug into the vehicle’s 12 Volt power

outlet.

6. Do not remove foreign objects (e.g., screws or nails) from the tire.

(C) Injecting TIREFIT Sealant Into The Deflated Tire:

• Always start the engine before turning ON the TIREFIT kit.

NOTE:Manual transmission vehicles must have the parking brake engaged and the shift lever inNEUTRAL.

• After pressing the Power Button (4), the sealant (white fluid) will flow from the

Sealant Bottle (1) through the Sealant Hose (6) and into the tire.

NOTE:Sealant may leak out through the puncture in the tire.

•If the sealant (white fluid) does not flow within 0 – 10seconds

through the Sealant Hose (6):

1.Press the Power Button (4) to turn Off the TIREFIT kit. Disconnect the Sealant Hose

(6) from the valve stem. Make sure the valve stem is free of debris. Reconnect the

Sealant Hose (6) to the valve stem. Check that the Mode Select Knob (5) is in the

Sealant Mode position and not Air Mode. Press the Power Button (4) to turn On the

TIREFIT kit.

WHAT TO DO IN EMERGENCIES

51

Page 54 of 84

2. Connect the Power Plug (8) to a different 12 Volt power outlet in your vehicle or

another vehicle, if available. Make sure the engine is running before turning ON

the TIREFIT kit.

3. The Sealant Bottle (1) may be empty due to previous use. Call for assistance.

NOTE:If the Mode Select Knob (5) is on Air Mode and the pump is operating, air will dispensefrom the Air Pump Hose (7) only, not the Sealant Hose (6).

•If the sealant (white fluid) does flow through the Sealant Hose (6):

1. Continue to operate the pump until sealant is no longer flowing through the hose

(typically takes 30 - 70 seconds). As the sealant flows through the Sealant Hose

(6), the Pressure Gauge (3) can read as high as 70 psi (5 kPa). The Pressure

Gauge (3) will decrease quickly from approximately 70 psi (5 kPa) to the actual

tire pressure when the Sealant Bottle (1) is empty.

2. The pump will start to inject air into the tire immediately after the Sealant Bottle

(1) is empty. Continue to operate the pump and inflate the tire to the pressure

indicated on the tire pressure label on the driver-side latch pillar (recommended

pressure). Check the tire pressure by looking at the Pressure Gauge (3).

•If the tire does not inflate to at least 26 psi (1.8 kPa) pressure within

15 minutes:

• The tire is too badly damaged. Do not attempt to drive the vehicle further. Call

for assistance.

NOTE:If the tire becomes over-inflated, press the Deflation Button to reduce the tire pressure tothe recommended inflation pressure before continuing.

•If the tire inflates to the recommended pressure or is at least 26 psi

(1.8 Bar) pressure within 15 minutes:

1. Press the Power Button (4) to turn off the TIREFIT kit.

2. Remove the Speed Limit sticker from the top of the Sealant Bottle (1) and place

the sticker on the instrument panel.

3. Immediately disconnect the Sealant Hose (6) from the valve stem, reinstall the

cap on the fitting at the end of the hose, and place the TIREFIT kit in the vehicle

storage location. Quickly proceed to (D) “Drive Vehicle”.

(D) Drive Vehicle:

• Immediately after injecting sealant and inflating the tire, drive the vehicle 5 miles

(8 km) or 10 minutes to ensure distribution of the TIREFIT Sealant within the tire.

Do not exceed 55 mph (88 km/h).

WHAT TO DO IN EMERGENCIES

52

Page 57 of 84

JUMP-STARTING PROCEDURE

• If your vehicle has a discharged battery, it can be jump-started using a set of

jumper cables and a battery in another vehicle or by using a portable battery

booster pack. Jump-starting can be dangerous if done improperly so please fol-

low the procedures in this section carefully.

NOTE:When using a portable battery booster pack, follow the manufacturer’s operating instruc-tions and precautions.

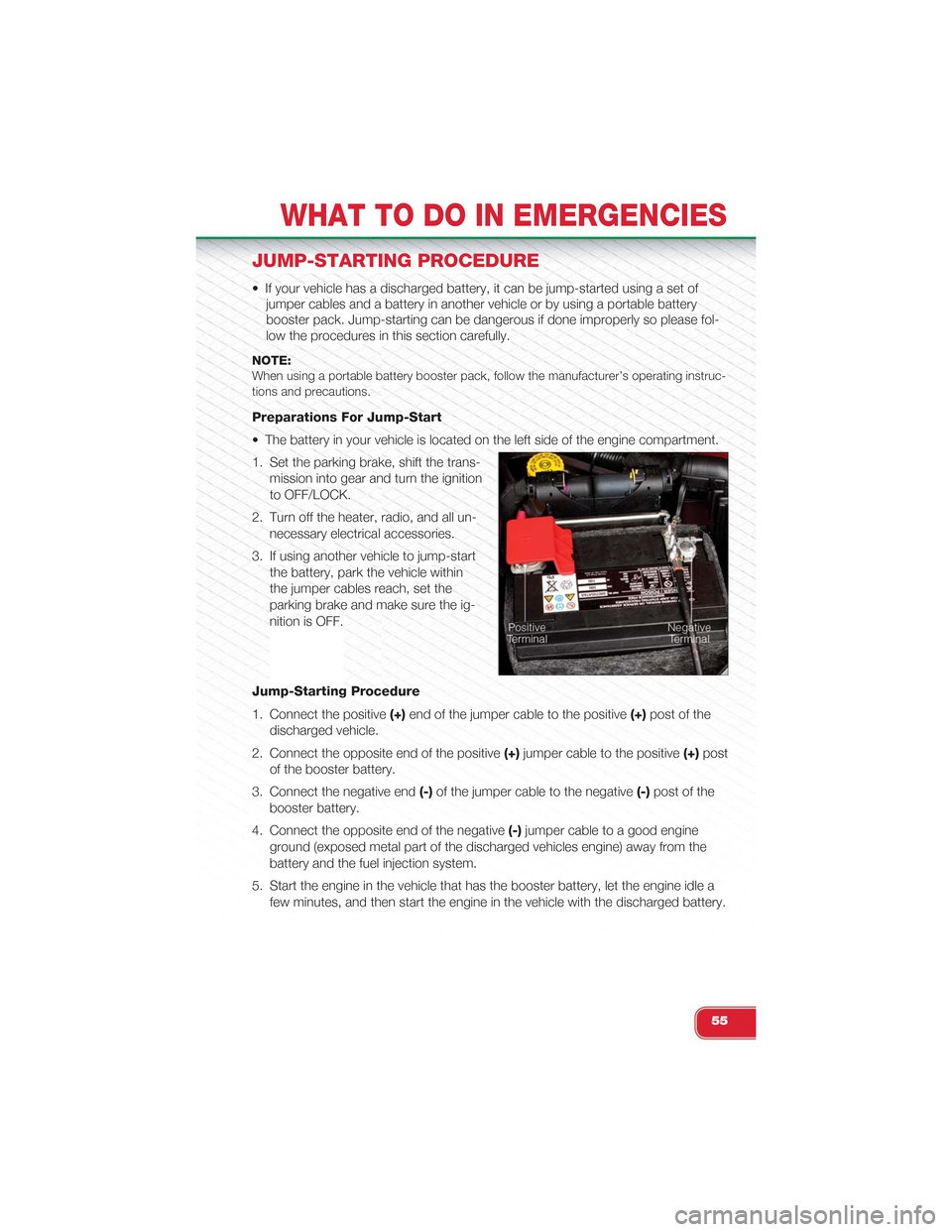

Preparations For Jump-Start

• The battery in your vehicle is located on the left side of the engine compartment.

1. Set the parking brake, shift the trans-

mission into gear and turn the ignition

to OFF/LOCK.

2. Turn off the heater, radio, and all un-

necessary electrical accessories.

3. If using another vehicle to jump-start

the battery, park the vehicle within

the jumper cables reach, set the

parking brake and make sure the ig-

nition is OFF.

Jump-Starting Procedure

1. Connect the positive(+)end of the jumper cable to the positive(+)post of the

discharged vehicle.

2. Connect the opposite end of the positive(+)jumper cable to the positive(+)post

of the booster battery.

3. Connect the negative end(-)of the jumper cable to the negative(-)post of the

booster battery.

4. Connect the opposite end of the negative(-)jumper cable to a good engine

ground (exposed metal part of the discharged vehicles engine) away from the

battery and the fuel injection system.

5. Start the engine in the vehicle that has the booster battery, let the engine idle a

few minutes, and then start the engine in the vehicle with the discharged battery.

WHAT TO DO IN EMERGENCIES

55

Page 58 of 84

Once the engine is started, remove the jumper cables in the reverse sequence:

1. Disconnect the negative(-)jumper cable from the engine ground(-)of the ve-

hicle with the discharged battery.

2. Disconnect the negative end(-)of the jumper cable from the negative(-)post of

the booster battery.

3.Disconnect the opposite end of the positive(+)jumper cable from the positive(+)

post of the booster battery.

4. Disconnect the positive(+)end of the jumper cable from the positive(+)post of

the discharged vehicle.

• If frequent jump-starting is required to start your vehicle, you should have the bat-

tery and charging system inspected at your authorized studio.

CAUTION!

• Accessories that can be plugged into the vehicle power outlets draw powerfrom the vehicle’s battery, even when not in use (i.e., cellular phones, etc.).Eventually, if plugged in long enough, the vehicle’s battery will discharge suf-ficiently to degrade battery life and/or prevent the engine from starting.

• Do not use a portable battery booster pack or any other booster source with

a system voltage greater than 12 Volts or damage to the battery, starter mo-

tor, alternator or electrical system may occur.

• Failure to follow these procedures could result in damage to the charging

system of the booster vehicle or the discharged vehicle.

WARNING!

• Do not attempt jump-starting if the battery is frozen. It could rupture or ex-

plode and cause personal injury.

•Take care to avoid the radiator cooling fan whenever the hood is raised. It can

start anytime the ignition switch is on. You can be injured by moving fan blades.

• Remove any metal jewelry such as watch bands or bracelets that might

make an inadvertent electrical contact. You could be seriously injured.

• Batteries contain sulfuric acid that can burn your skin or eyes and generate

hydrogen gas which is flammable and explosive. Keep open flames or

sparks away from the battery.

• Do not allow vehicles to touch each other as this could establish a ground

connection and personal injury could result.

• Failure to follow this procedure could result in personal injury or property

damage due to battery explosion.

•Do not connect the cable to the negative post (-)

of the discharged battery. The resulting electrical spark could cause the bat-

tery to explode and could result in personal injury.

WHAT TO DO IN EMERGENCIES

56

Page 59 of 84

TOWING A DISABLED VEHICLE

With Ignition Key

Manual Transmission

• Vehicle can be flat towed (all four wheels on the ground) with the transmission in

NEUTRAL.

• Vehicle can be towed with the front wheels elevated.

• Vehicle can be towed on a flatbed truck (all wheels off the ground).

NOTE:If it is necessary to use the accessories while being towed (wipers, defrosters, etc.), the keymust be in the ON/RUN position. Make certain the transmission remains in NEUTRAL.

Without The Ignition Key

• Special care must be taken when the vehicle is towed with the ignition in the

OFF/LOCK position. A dolly should be used under the front wheels if the rear

wheels are raised. Proper towing equipment is necessary to prevent damage to

the vehicle.

CAUTION!

• Failure to follow these towing methods can cause severe transmission dam-

age. Such damage is not covered by the New Vehicle Limited Warranty.

• If the vehicle being towed requires steering, the ignition switch must be in the

ON/RUN position.

• Do not attempt to use sling-type equipment when towing. When securing

the vehicle to a flatbed truck, do not attach to front or rear suspension com-

ponents. Damage to your vehicle may result from improper towing.

ENHANCED ACCIDENT RESPONSE SYSTEM

• In the event of an impact causing air bag deployment, if the communication net-

work remains intact, and the power remains intact, depending on the nature of

the event the Occupant Restraint Controller (ORC) will determine whether to have

the Enhanced Accident Response System perform the following functions:

• Cut off fuel to the engine.

• Flash hazard lights as long as the battery has power or until the ignition key is

turned off.

• Turn on the interior lights, which remain on as long as the battery has power or

until the ignition key is removed.

• Unlock the doors automatically.

WHAT TO DO IN EMERGENCIES

57

Page 60 of 84

• After the event occurs, when the system is active, the message "Fuel Cutoff See

Handbook" is displayed.

• Carefully check the vehicle for fuel leaks in the engine compartment and on the

ground near the engine compartment and fuel tank before resetting the system

and starting the engine.

NOTE:

In order to start the engine and move the vehicle to a safe location after an impact, the

System Reset Procedure must be completed.

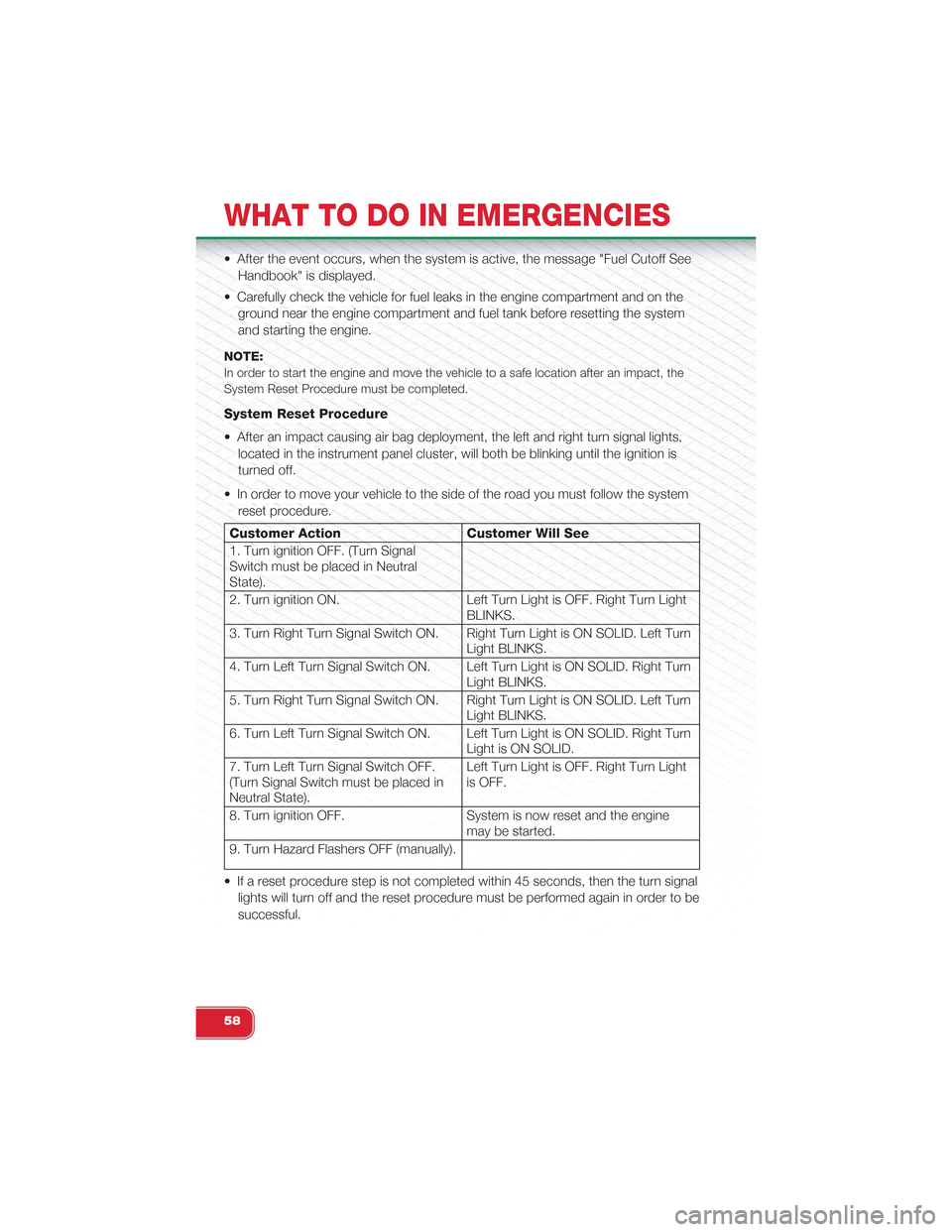

System Reset Procedure

• After an impact causing air bag deployment, the left and right turn signal lights,

located in the instrument panel cluster, will both be blinking until the ignition is

turned off.

• In order to move your vehicle to the side of the road you must follow the system

reset procedure.

Customer Action Customer Will See

1. Turn ignition OFF. (Turn SignalSwitch must be placed in NeutralState).

2. Turn ignition ON. Left Turn Light is OFF. Right Turn LightBLINKS.

3. Turn Right Turn Signal Switch ON. Right Turn Light is ON SOLID. Left TurnLight BLINKS.

4. Turn Left Turn Signal Switch ON. Left Turn Light is ON SOLID. Right TurnLight BLINKS.

5. Turn Right Turn Signal Switch ON. Right Turn Light is ON SOLID. Left TurnLight BLINKS.

6. Turn Left Turn Signal Switch ON. Left Turn Light is ON SOLID. Right TurnLight is ON SOLID.

7. Turn Left Turn Signal Switch OFF.(Turn Signal Switch must be placed inNeutral State).

Left Turn Light is OFF. Right Turn Lightis OFF.

8. Turn ignition OFF. System is now reset and the enginemay be started.

9. Turn Hazard Flashers OFF (manually).

• If a reset procedure step is not completed within 45 seconds, then the turn signal

lights will turn off and the reset procedure must be performed again in order to be

successful.

WHAT TO DO IN EMERGENCIES

58

Page 61 of 84

FREEING A STUCK VEHICLE

• If your vehicle becomes stuck in mud, sand or snow, it can often be moved by a

rocking motion. Turn your steering wheel right and left to clear the area around

the front wheels. Then shift back and forth between 1st gear and REVERSE. Us-

ing minimal accelerator pedal pressure to maintain the rocking motion, without

spinning the wheels, is most effective.

NOTE:If your vehicle is equipped with Traction Control or Electronic Stability Control (ESC), turnthe system OFF before attempting to “rock” the vehicle.

CAUTION!

• Racing the engine or spinning the wheels may lead to transmission overheat-

ing and failure. Allow the engine to idle with the shift lever in NEUTRAL for at

least one minute after every five rocking-motion cycles. This will minimize

overheating and reduce the risk of transmission failure during prolonged ef-

forts to free a stuck vehicle.

• When “rocking” a stuck vehicle by moving between 1st and REVERSE, do

not spin the wheels faster than 15 mph (24 km/h), or drivetrain damage may

result.

• Revving the engine or spinning the wheels too fast may lead to transmission

overheating and failure. It can also damage the tires. Do not spin the wheels

above 30 mph (48 km/h) while in gear (no transmission shifting occurring).

WARNING!

Fast spinning tires can be dangerous. Forces generated by excessive wheel

speeds may cause tire damage or failure. A tire could explode and injure some-

one. Do not spin your vehicle's wheels faster than 30 mph (48 km/h) when you

are stuck. Do not let anyone near a spinning wheel, no matter what the speed.

WHAT TO DO IN EMERGENCIES

59

Page 64 of 84

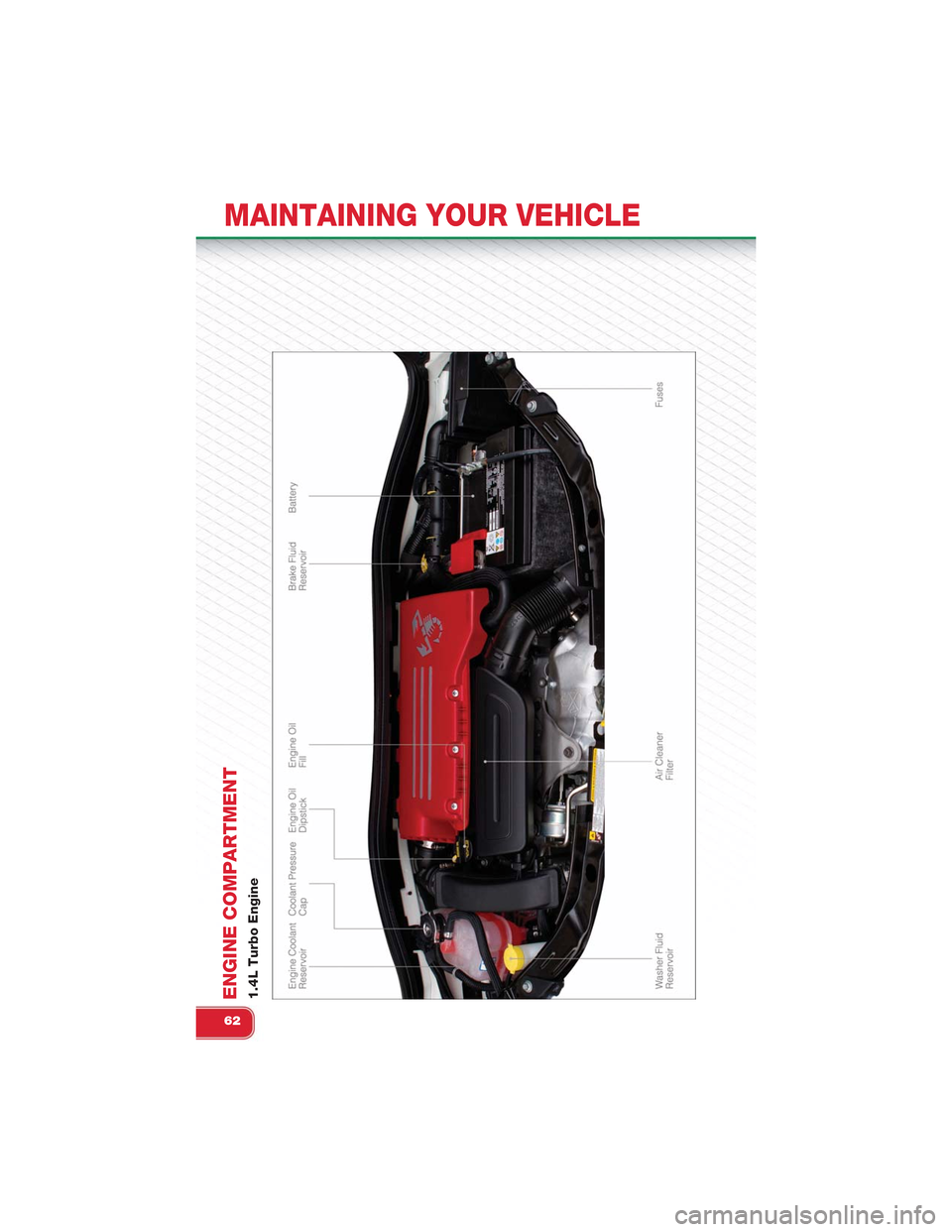

ENGINE COMPARTMENT1.4L Turbo Engine

MAINTAINING YOUR VEHICLE

62

Page 65 of 84

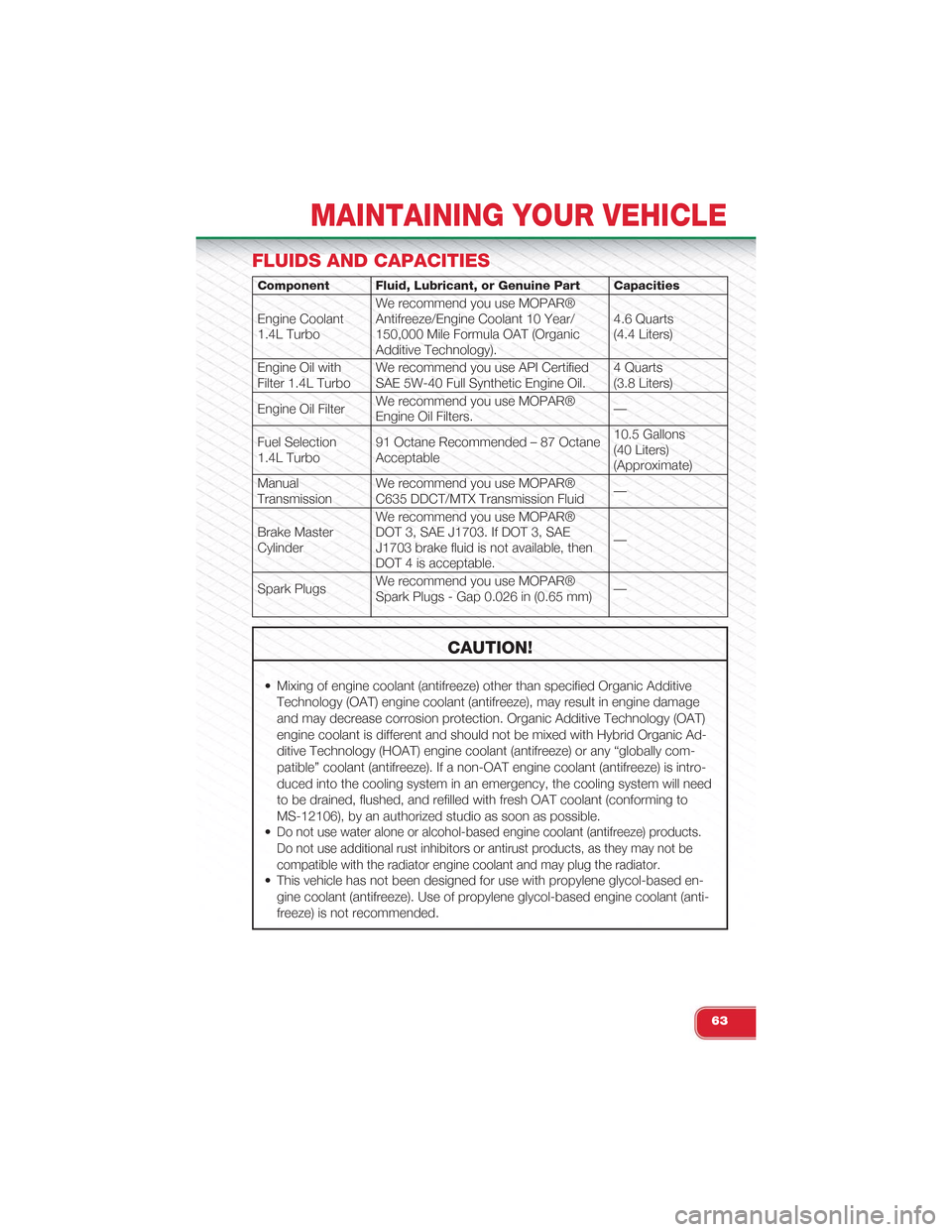

FLUIDS AND CAPACITIES

Component Fluid, Lubricant, or Genuine Part Capacities

Engine Coolant1.4L Turbo

We recommend you use MOPAR®Antifreeze/Engine Coolant 10 Year/150,000 Mile Formula OAT (OrganicAdditive Technology).

4.6 Quarts(4.4 Liters)

Engine Oil withFilter 1.4L TurboWe recommend you use API CertifiedSAE 5W-40 Full Synthetic Engine Oil.4 Quarts(3.8 Liters)

Engine Oil FilterWe recommend you use MOPAR®Engine Oil Filters.—

Fuel Selection1.4L Turbo91 Octane Recommended – 87 OctaneAcceptable

10.5 Gallons(40 Liters)(Approximate)

ManualTransmissionWe recommend you use MOPAR®C635 DDCT/MTX Transmission Fluid—

Brake MasterCylinder

We recommend you use MOPAR®DOT 3, SAE J1703. If DOT 3, SAEJ1703 brake fluid is not available, thenDOT 4 is acceptable.

—

Spark PlugsWe recommend you use MOPAR®Spark Plugs - Gap 0.026 in (0.65 mm)—

CAUTION!

• Mixing of engine coolant (antifreeze) other than specified Organic Additive

Technology (OAT) engine coolant (antifreeze), may result in engine damage

and may decrease corrosion protection. Organic Additive Technology (OAT)

engine coolant is different and should not be mixed with Hybrid Organic Ad-

ditive Technology (HOAT) engine coolant (antifreeze) or any “globally com-

patible” coolant (antifreeze). If a non-OAT engine coolant (antifreeze) is intro-

duced into the cooling system in an emergency, the cooling system will need

to be drained, flushed, and refilled with fresh OAT coolant (conforming to

MS-12106), by an authorized studio as soon as possible.

•Do not use water alone or alcohol-based engine coolant (antifreeze) products.

Do not use additional rust inhibitors or antirust products, as they may not be

compatible with the radiator engine coolant and may plug the radiator.

• This vehicle has not been designed for use with propylene glycol-based en-

gine coolant (antifreeze). Use of propylene glycol-based engine coolant (anti-

freeze) is not recommended.

MAINTAINING YOUR VEHICLE

63