lock FIAT 500E 2015 2.G Workshop Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2015, Model line: 500E, Model: FIAT 500E 2015 2.GPages: 367, PDF Size: 9.42 MB

Page 232 of 367

Brake Assist System (BAS)

The BAS is designed to optimize the vehicle’s braking

capability during emergency braking maneuvers. The

system detects an emergency braking situation by sens-

ing the rate and amount of brake application and then

applies optimum pressure to the brakes. This can help

reduce braking distances. The BAS complements the

Anti-Lock Brake System (ABS). Applying the brakes very

quickly results in the best BAS assistance. To receive the

benefit of the system, you must applycontinuousbrak-

ing pressure during the stopping sequence (do not

“pump” the brakes). Do not reduce brake pedal pressure

unless braking is no longer desired. Once the brake pedal

is released, the BAS is deactivated.

WARNING!

•The Brake Assist System (BAS) cannot prevent the

natural laws of physics from acting on the vehicle,

nor can it increase the traction afforded by prevail-

ing road conditions.

•The BAS cannot prevent collisions, including those

resulting from excessive speed in turns, driving on

very slippery surfaces, or hydroplaning.

•The capabilities of a BAS-equipped vehicle must

never be exploited in a reckless or dangerous

manner which could jeopardize the user ’s safety or

the safety of others.

230 STARTING AND OPERATING

Page 269 of 367

If the ignition switch is cycled, this sequence will repeat,

providing the system fault still exists. If the system fault

no longer exists, the “Tire Pressure Monitoring Telltale

Light” will no longer flash, and the “Service TPM Sys-

tem” message will no longer display, and a pressure

value will display in place of the dashes.

A system fault can occur due to any of the following:

1. Signal interference due to electronic devices or driving

next to facilities emitting the same radio frequencies as

the TPM sensors.

2. Installing aftermarket window tinting that contains

materials that may block radio wave signals.

3. Accumulation of snow or ice around the wheels or

wheel housings.

4. Using tire chains on the vehicle.

5. Using wheels/tires not equipped with TPM sensors.

The EVIC will also display a#Service Tire Pressure

Monitoring System#message for a minimum of five

seconds when a system fault related to an incorrect

sensor location fault is detected. In this case, the#Service

Tire Pressure Monitoring System#message is then fol-

lowed with a graphic display with pressure values still

Service TPM System Message

5

STARTING AND OPERATING 267

Page 276 of 367

HAZARD WARNING FLASHERS

The Hazard Warning flasher switch is located on the

instrument panel below the radio.

Push the switch to turn on the Hazard Warning

flashers. When the switch is activated, all direc-

tional turn signals will flash on and off to warn oncoming

traffic of an emergency. Push the switch a second time to

turn off the Hazard Warning flashers.

Do not use this emergency warning system when the

vehicle is in motion. Use it when your vehicle is disabled

and it is creating a safety hazard for other motorists.

If it is necessary to leave the vehicle to go for service, the

Hazard Warning flashers will continue to operate with

the ignition key removed and the vehicle locked.

NOTE:With extended use, the Hazard Warning flashers

may wear down your battery.

Range Projection Indicators

274 WHAT TO DO IN EMERGENCIES

Page 288 of 367

5. Remove the Speed Limit sticker from the instrument

panel after the tire has been repaired.

6. Replace the Sealant Bottle (1) and Sealant Hose (6)

assembly at your authorized dealer as soon as pos-

sible. Refer to (F) “Sealant Bottle and Hose Replace-

ment”.

NOTE:When having the tire serviced, advise the autho-

rized dealer or service center that the tire has been sealed

using the Tire Service Kit.

(F) Sealant Bottle And Hose Replacement:

1. Uncoil the Sealant Hose (6) (clear in color).

2. Locate the round Sealant Bottle release button in the

recessed area under the sealant bottle.

3. Push the Sealant Bottle release button. The Sealant

Bottle (1) will pop up. Remove the bottle and dispose

of it accordingly.

4. Clean any remaining sealant from the Tire Service Kit

housing.

5. Position the new Sealant Bottle (1) in the housing so

that the Sealant Hose (6) aligns with the hose slot in

the front of the housing. Push the bottle into the

housing. An audible click will be heard indicating the

bottle is locked into place.

6. Verify that the cap is installed on the fitting at the end

of the Sealant Hose (6) and return the hose to its

storage area (located on the bottom of the air pump).

7. Return the Tire Service Kit to its storage location in the

vehicle.

286 WHAT TO DO IN EMERGENCIES

Page 290 of 367

WARNING!

•Take care to avoid the radiator cooling fan when-

ever the hood is raised. It can start anytime the

ignition switch is ON. You can be injured by

moving fan blades.

•Remove any metal jewelry such as rings, watch

bands and bracelets that could make an inadvertent

electrical contact. You could be seriously injured.

•Batteries contain sulfuric acid that can burn your

skin or eyes and generate hydrogen gas which is

flammable and explosive. Keep open flames or

sparks away from the battery.

1. Set the parking brake, place the transmission into

PARK and turn the ignition to LOCK.

2. Turn off the heater, radio, and all unnecessary electri-

cal accessories.

Battery Posts

1—Positive(+)Post(CoveredWithProtectiveCap)2 — Negative (-) Post

288 WHAT TO DO IN EMERGENCIES

Page 295 of 367

•Using a T25 driver bit, rotate the Manual Park Release

shaft (located just behind the rubber plug) clockwise,

at least 20 turns, to release the Park mechanism. The

vehicle is now out of PARK and can be moved.

•Reinstall the rubber plug.

•Release the parking brake only when a driver is in the

vehicle, or the vehicle is secured by other means. The

Manual Park Release will be reset automatically once

the vehicle is restarted.

TOWING A DISABLED VEHICLE

This section describes procedures for towing a disabled

vehicle using a commercial towing service.

Manual Park Release Location

6

WHAT TO DO IN EMERGENCIES 293

Page 311 of 367

WARNING!(Continued)

•The air conditioning system contains refrigerant

under high pressure. To avoid risk of personal

injury or damage to the system, adding refrigerant

or any repair requiring lines to be disconnected

should be done by an experienced technician.

Body Lubrication

Locks and all body pivot points, including such items as

seat tracks, door hinge pivot points and rollers, liftgate,

tailgate, decklid, sliding doors and hood hinges, should

be lubricated periodically with a lithium based grease,

such as MOPAR® Spray White Lube to assure quiet, easy

operation and to protect against rust and wear. Prior to

the application of any lubricant, the parts concerned

should be wiped clean to remove dust and grit; after

lubricating excess oil and grease should be removed.

Particular attention should also be given to hood latching

components to ensure proper function. When performing

other underhood services, the hood latch, release mecha-

nism and safety catch should be cleaned and lubricated.

The external lock cylinders should be lubricated twice a

year, preferably in the Fall and Spring. Apply a small

amount of a high quality lubricant, such as MOPAR®

Lock Cylinder Lubricant directly into the lock cylinder.

Wiper Blades

Clean the rubber edges of the wiper blades and the

windshield and rear window periodically with a sponge

or soft cloth and a mild nonabrasive cleaner. This will

remove accumulations of salt, waxes, or road film, and

help reduce streaking and smearing.

Operation of the wipers on dry glass for long periods

may cause deterioration of the wiper blades. Always use

washer fluid when using the wipers to remove salt or dirt

from a dry windshield or rear window.

7

MAINTAINING YOUR VEHICLE 309

Page 324 of 367

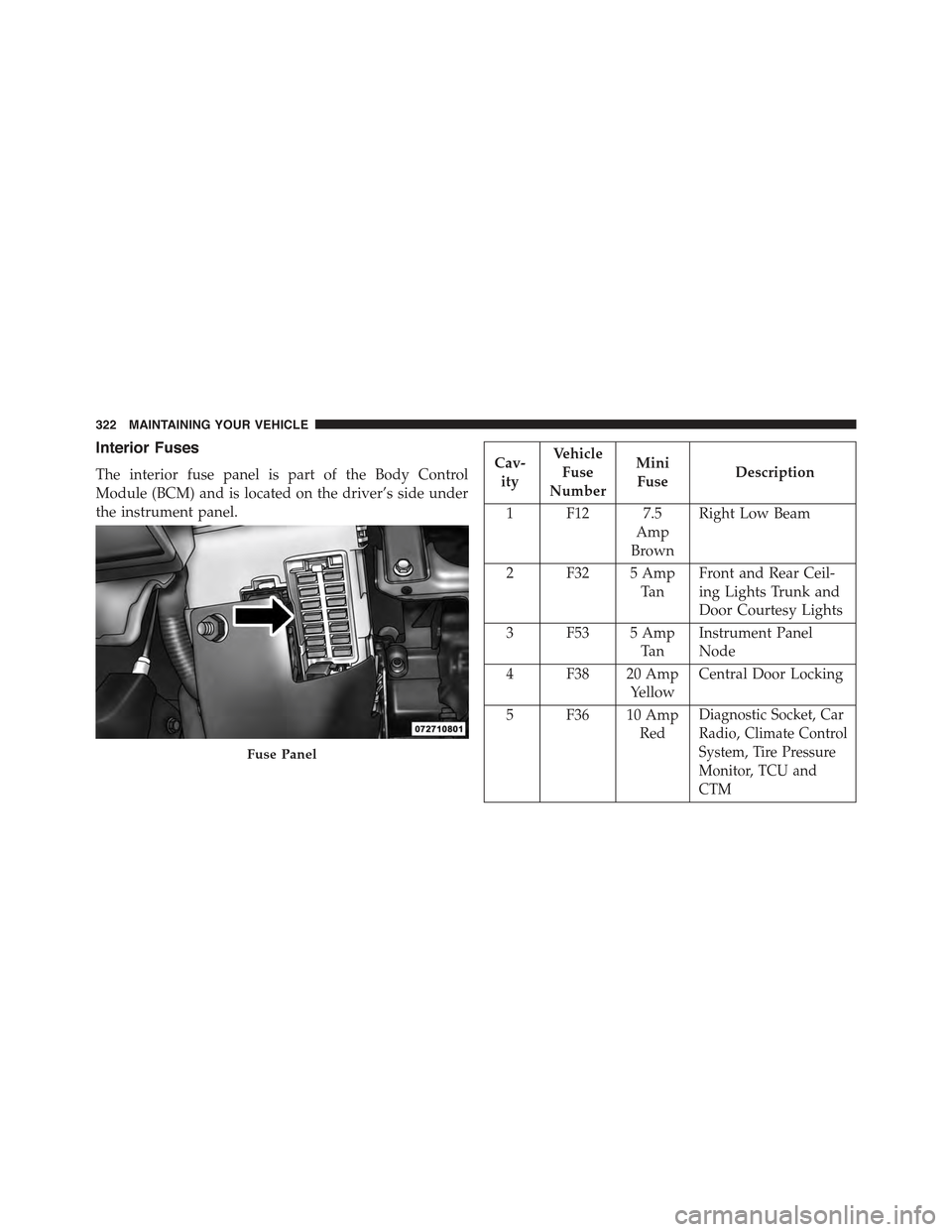

Interior Fuses

The interior fuse panel is part of the Body Control

Module (BCM) and is located on the driver’s side under

the instrument panel.

Cav-

ity

Vehicle

Fuse

Number

Mini

FuseDescription

1 F12 7.5

Amp

Brown

Right Low Beam

2 F32 5 Amp

Ta n

Front and Rear Ceil-

ing Lights Trunk and

Door Courtesy Lights

3 F53 5 Amp

Ta n

Instrument Panel

Node

4 F38 20 Amp

Yellow

Central Door Locking

5 F36 10 Amp

Red

Diagnostic Socket, Car

Radio, Climate Control

System, Tire Pressure

Monitor, TCU and

CTM

Fuse Panel

322 MAINTAINING YOUR VEHICLE

Page 327 of 367

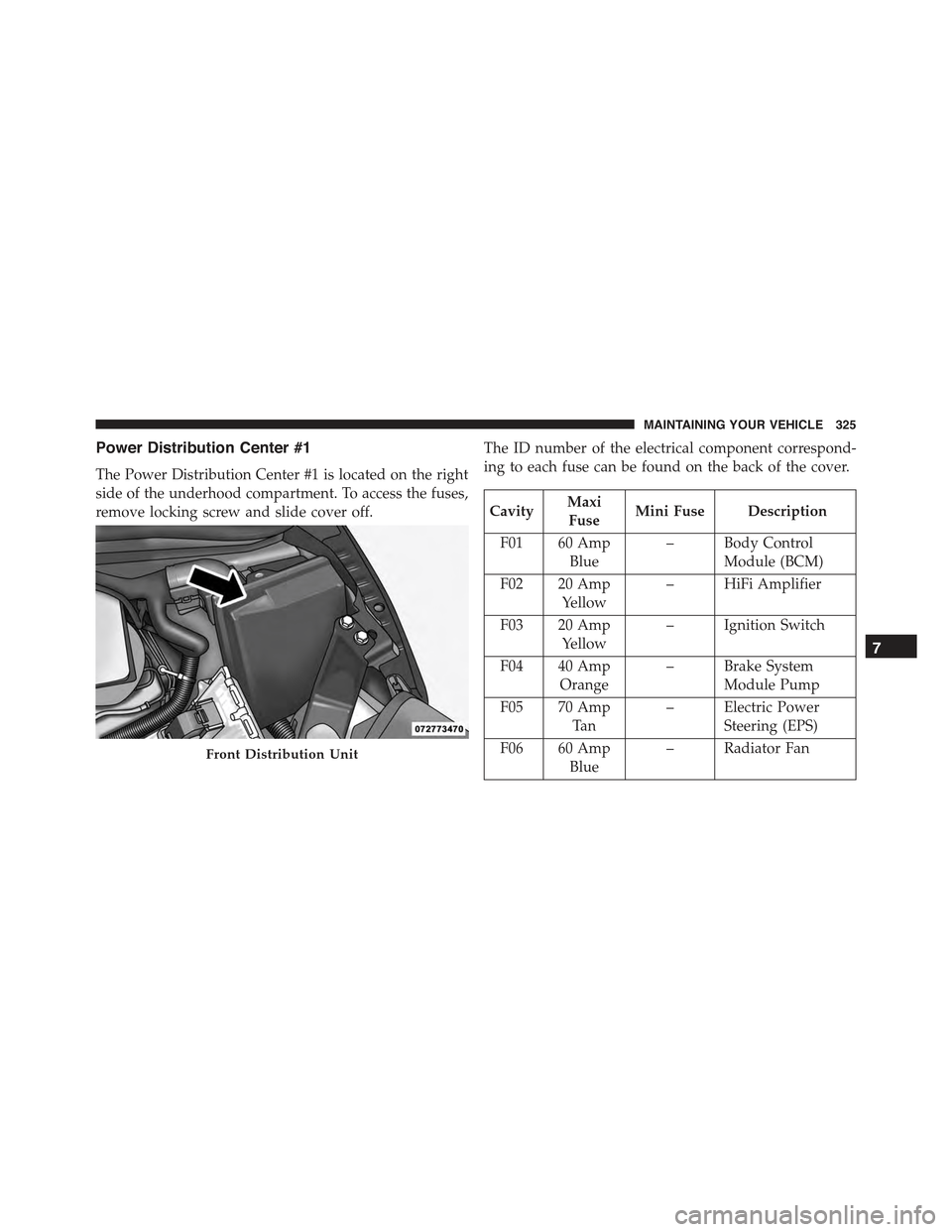

Power Distribution Center #1

The Power Distribution Center #1 is located on the right

side of the underhood compartment. To access the fuses,

remove locking screw and slide cover off.

The ID number of the electrical component correspond-

ing to each fuse can be found on the back of the cover.

CavityMaxi

FuseMini Fuse Description

F01 60 Amp

Blue

– Body Control

Module (BCM)

F02 20 Amp

Yellow

– HiFi Amplifier

F03 20 Amp

Yellow

– Ignition Switch

F04 40 Amp

Orange

– Brake System

Module Pump

F05 70 Amp

Ta n

– Electric Power

Steering (EPS)

F06 60 Amp

Blue

– Radiator FanFront Distribution Unit

7

MAINTAINING YOUR VEHICLE 325

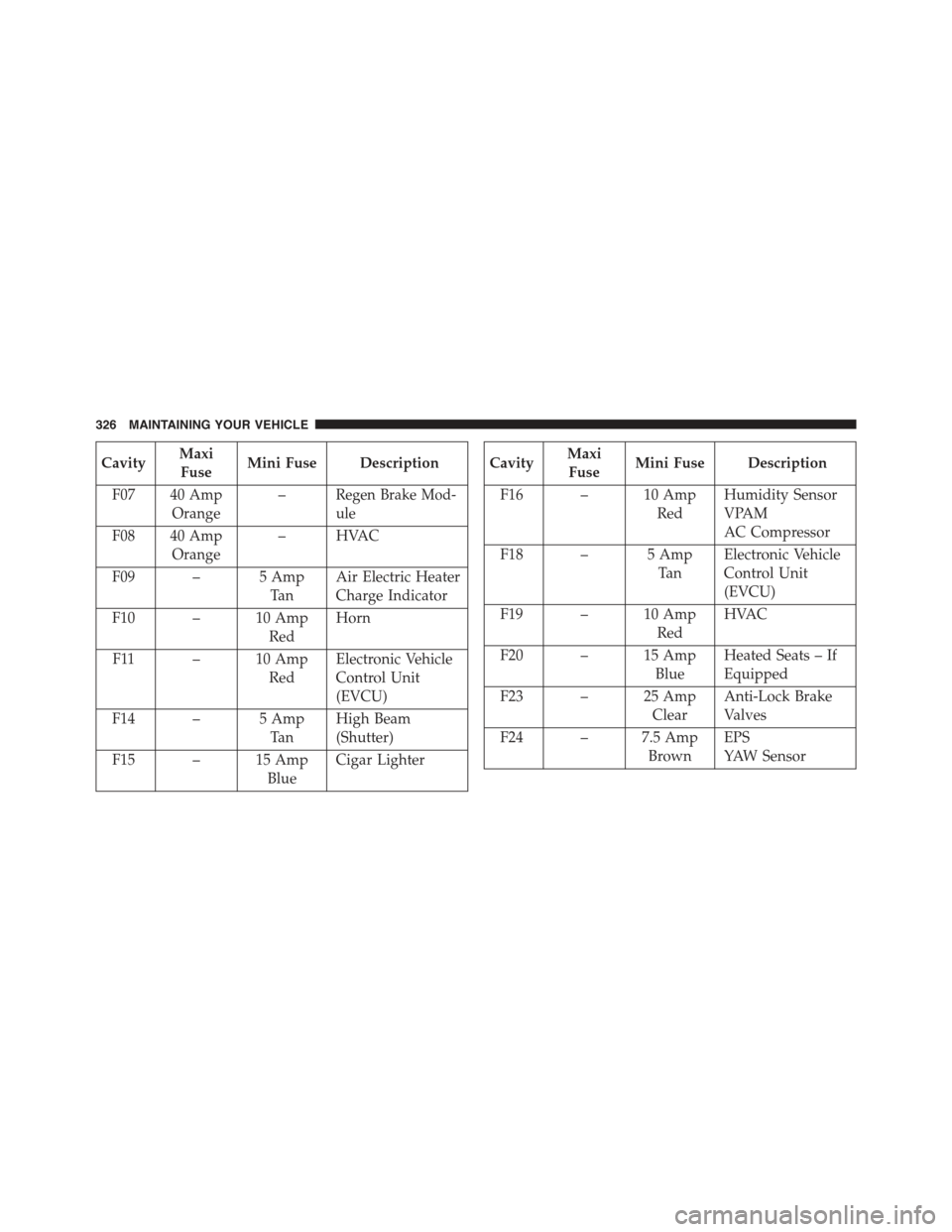

Page 328 of 367

CavityMaxi

FuseMini Fuse Description

F07 40 Amp

Orange

–Regen Brake Mod-

ule

F08 40 Amp

Orange

–HVAC

F09 – 5 Amp

Ta n

Air Electric Heater

Charge Indicator

F10 – 10 Amp

Red

Horn

F11 – 10 Amp

Red

Electronic Vehicle

Control Unit

(EVCU)

F14 – 5 Amp

Ta n

High Beam

(Shutter)

F15 – 15 Amp

Blue

Cigar Lighter

CavityMaxi

FuseMini Fuse Description

F16 – 10 Amp

Red

Humidity Sensor

VPAM

AC Compressor

F18 – 5 Amp

Ta n

Electronic Vehicle

Control Unit

(EVCU)

F19 – 10 Amp

Red

HVAC

F20 – 15 Amp

Blue

Heated Seats – If

Equipped

F23 – 25 Amp

Clear

Anti-Lock Brake

Valves

F24 – 7.5 Amp

Brown

EPS

YAW Sensor

326 MAINTAINING YOUR VEHICLE