clock FIAT 500L LIVING 2015 2.G Owners Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2015, Model line: 500L LIVING, Model: FIAT 500L LIVING 2015 2.GPages: 224, PDF Size: 5.92 MB

Page 26 of 224

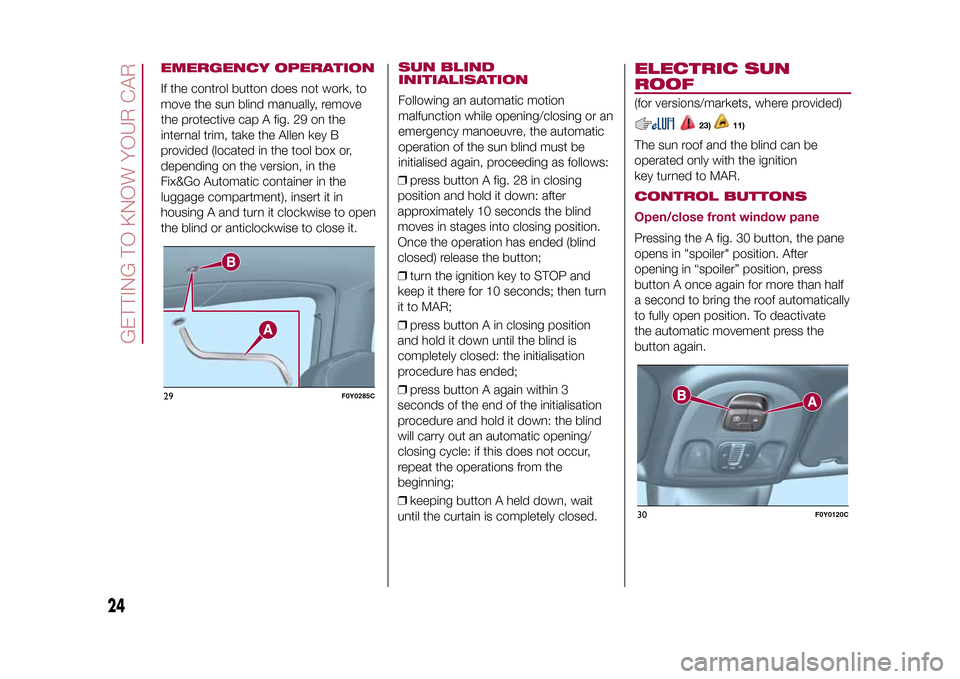

EMERGENCY OPERATIONIf the control button does not work, to

move the sun blind manually, remove

the protective cap A fig. 29 on the

internal trim, take the Allen key B

provided (located in the tool box or,

depending on the version, in the

Fix&Go Automatic container in the

luggage compartment), insert it in

housing A and turn it clockwise to open

the blind or anticlockwise to close it.

SUN BLIND

INITIALISATIONFollowing an automatic motion

malfunction while opening/closing or an

emergency manoeuvre, the automatic

operation of the sun blind must be

initialised again, proceeding as follows:

❒press button A fig. 28 in closing

position and hold it down: after

approximately 10 seconds the blind

moves in stages into closing position.

Once the operation has ended (blind

closed) release the button;

❒turn the ignition key to STOP and

keep it there for 10 seconds; then turn

it to MAR;

❒press button A in closing position

and hold it down until the blind is

completely closed: the initialisation

procedure has ended;

❒press button A again within 3

seconds of the end of the initialisation

procedure and hold it down: the blind

will carry out an automatic opening/

closing cycle: if this does not occur,

repeat the operations from the

beginning;

❒keeping button A held down, wait

until the curtain is completely closed.

ELECTRIC SUN

ROOF(for versions/markets, where provided)

23)

11)

The sun roof and the blind can be

operated only with the ignition

key turned to MAR.CONTROL BUTTONS

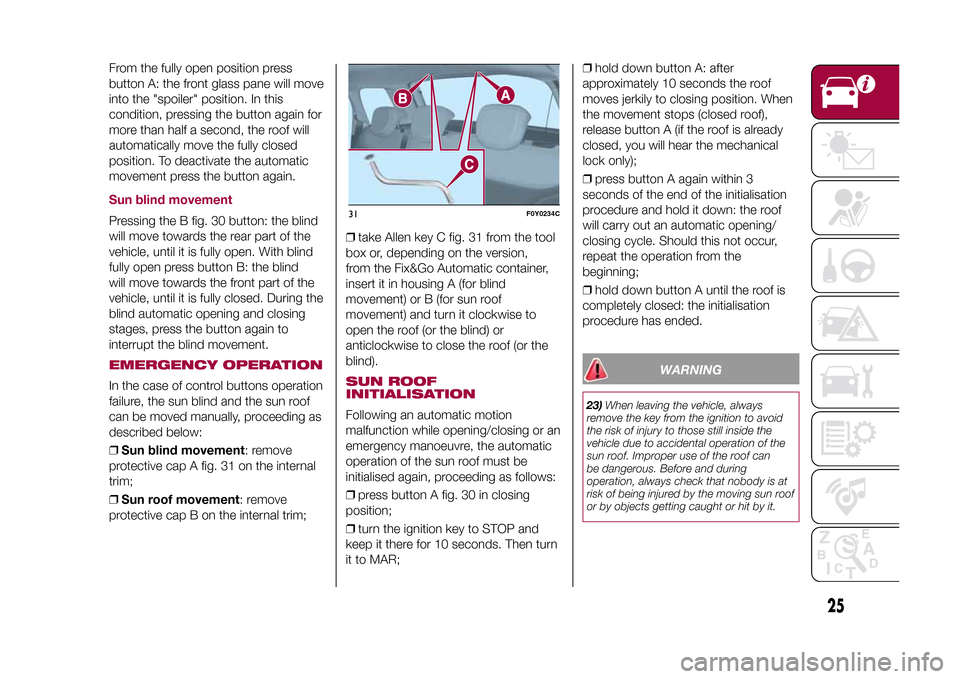

Open/close front window panePressing the A fig. 30 button, the pane

opens in "spoiler" position. After

opening in “spoiler” position, press

button A once again for more than half

a second to bring the roof automatically

to fully open position. To deactivate

the automatic movement press the

button again.

29

F0Y0285C

30

F0Y0120C

24

GETTING TO KNOW YOUR CAR

9-1-2015 12:9 Pagina 24

Page 27 of 224

From the fully open position press

button A: the front glass pane will move

into the "spoiler" position. In this

condition, pressing the button again for

more than half a second, the roof will

automatically move the fully closed

position. To deactivate the automatic

movement press the button again.Sun blind movementPressing the B fig. 30 button: the blind

will move towards the rear part of the

vehicle, until it is fully open. With blind

fully open press button B: the blind

will move towards the front part of the

vehicle, until it is fully closed. During the

blind automatic opening and closing

stages, press the button again to

interrupt the blind movement.EMERGENCY OPERATIONIn the case of control buttons operation

failure, the sun blind and the sun roof

can be moved manually, proceeding as

described below:

❒Sun blind movement: remove

protective cap A fig. 31 on the internal

trim;

❒Sun roof movement: remove

protective cap B on the internal trim;❒take Allen key C fig. 31 from the tool

box or, depending on the version,

from the Fix&Go Automatic container,

insert it in housing A (for blind

movement) or B (for sun roof

movement) and turn it clockwise to

open the roof (or the blind) or

anticlockwise to close the roof (or the

blind).

SUN ROOF

INITIALISATIONFollowing an automatic motion

malfunction while opening/closing or an

emergency manoeuvre, the automatic

operation of the sun roof must be

initialised again, proceeding as follows:

❒press button A fig. 30 in closing

position;

❒turn the ignition key to STOP and

keep it there for 10 seconds. Then turn

it to MAR;❒hold down button A: after

approximately 10 seconds the roof

moves jerkily to closing position. When

the movement stops (closed roof),

release button A (if the roof is already

closed, you will hear the mechanical

lock only);

❒press button A again within 3

seconds of the end of the initialisation

procedure and hold it down: the roof

will carry out an automatic opening/

closing cycle. Should this not occur,

repeat the operation from the

beginning;

❒hold down button A until the roof is

completely closed: the initialisation

procedure has ended.

WARNING

23)When leaving the vehicle, always

remove the key from the ignition to avoid

the risk of injury to those still inside the

vehicle due to accidental operation of the

sun roof. Improper use of the roof can

be dangerous. Before and during

operation, always check that nobody is at

risk of being injured by the moving sun roof

or by objects getting caught or hit by it.

31

F0Y0234C

25

9-1-2015 12:9 Pagina 25

Page 29 of 224

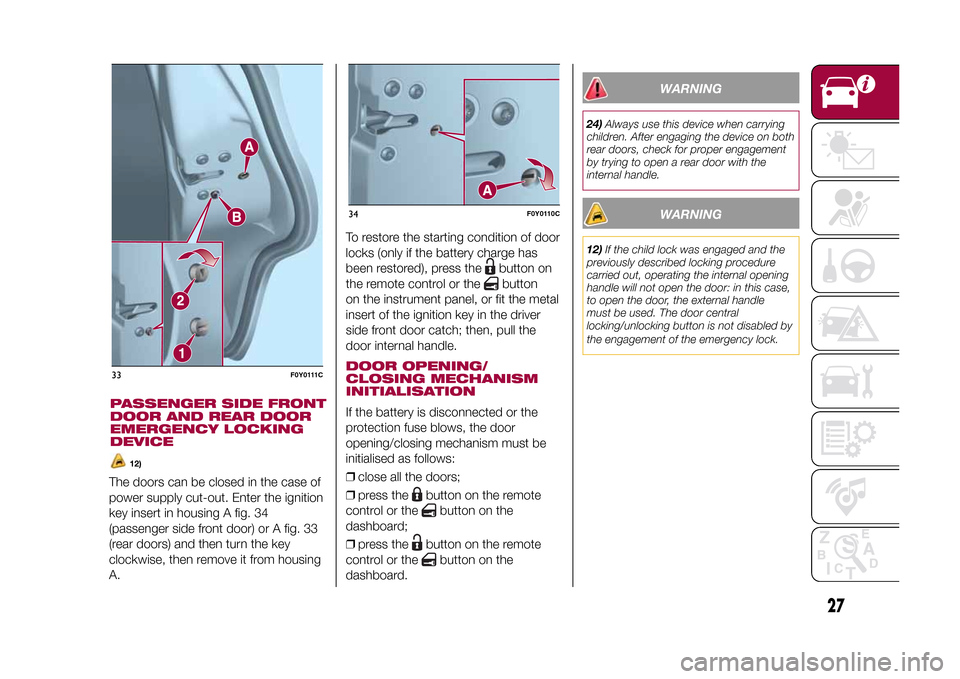

The doors can be closed in the case of

power supply cut-out. Enter the ignition

key insert in housing A fig. 34

(passenger side front door) or A fig. 33

(rear doors) and then turn the key

clockwise, then remove it from housing

A.To restore the starting condition of door

locks (only if the battery charge has

been restored), press the

button on

the remote control or thebutton

on the instrument panel, or fit the metal

insert of the ignition key in the driver

side front door catch; then, pull the

door internal handle.

DOOR OPENING/

CLOSING MECHANISM

INITIALISATIONIf the battery is disconnected or the

protection fuse blows, the door

opening/closing mechanism must be

initialised as follows:

❒close all the doors;

❒press the

button on the remote

control or the

button on the

dashboard;

❒press the

button on the remote

control or the

button on the

dashboard.

WARNING

24)Always use this device when carrying

children. After engaging the device on both

rear doors, check for proper engagement

by trying to open a rear door with the

internal handle.

WARNING

12)If the child lock was engaged and the

previously described locking procedure

carried out, operating the internal opening

handle will not open the door: in this case,

to open the door, the external handle

must be used. The door central

locking/unlocking button is not disabled by

the engagement of the emergency lock.

33

F0Y0111C

34

F0Y0110C

27

9-1-2015 12:9 Pagina 27

PASSENGER SIDE FRONT

DOOR AND REAR DOOR

EMERGENCY LOCKING

DEVICE

12)

Page 35 of 224

IMPORTANT The Dualdrive electric

power steering has an electronic

damping effect while approaching the

end of stroke. In some manoeuvring

conditions, the steering wheel might

rotate a bit before touching its

mechanical stop. This behaviour is

standard as it takes place to prevent

strong impacts on the mechanical

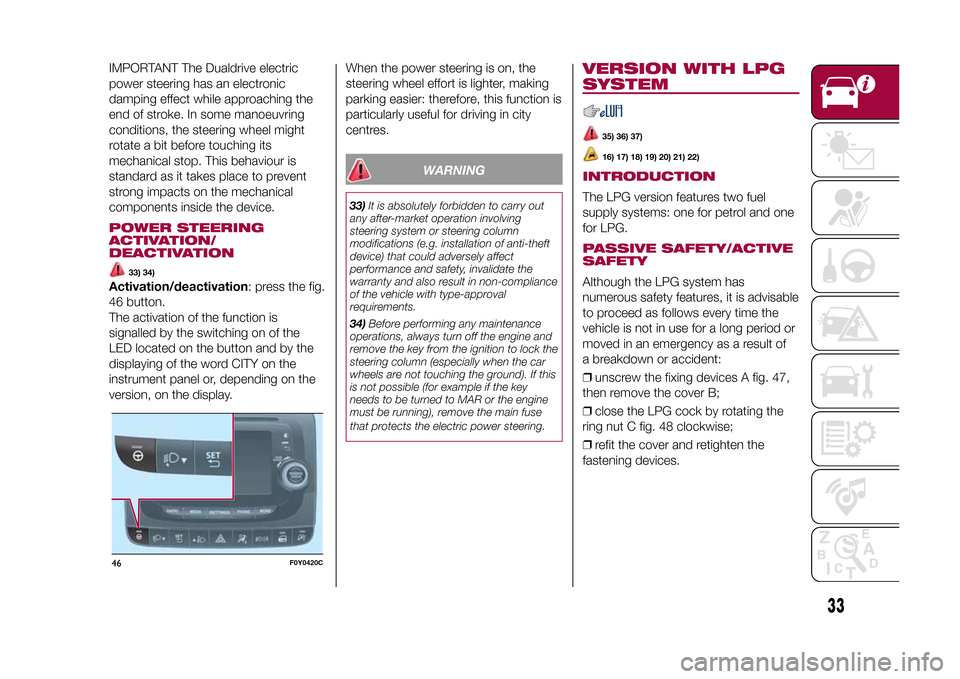

components inside the device.POWER STEERING

ACTIVATION/

DEACTIVATION

33) 34)

Activation/deactivation: press the fig.

46 button.

The activation of the function is

signalled by the switching on of the

LED located on the button and by the

displaying of the word CITY on the

instrument panel or, depending on the

version, on the display.When the power steering is on, the

steering wheel effort is lighter, making

parking easier: therefore, this function is

particularly useful for driving in city

centres.

WARNING

33)It is absolutely forbidden to carry out

any after-market operation involving

steering system or steering column

modifications (e.g. installation of anti-theft

device) that could adversely affect

performance and safety, invalidate the

warranty and also result in non-compliance

of the vehicle with type-approval

requirements.

34)Before performing any maintenance

operations, always turn off the engine and

remove the key from the ignition to lock the

steering column (especially when the car

wheels are not touching the ground). If this

is not possible (for example if the key

needs to be turned to MAR or the engine

must be running), remove the main fuse

that protects the electric power steering.

VERSION WITH LPG

SYSTEM

35) 36) 37)16) 17) 18) 19) 20) 21) 22)

INTRODUCTIONThe LPG version features two fuel

supply systems: one for petrol and one

for LPG.PASSIVE SAFETY/ACTIVE

SAFETYAlthough the LPG system has

numerous safety features, it is advisable

to proceed as follows every time the

vehicle is not in use for a long period or

moved in an emergency as a result of

a breakdown or accident:

❒unscrew the fixing devices A fig. 47,

then remove the cover B;

❒close the LPG cock by rotating the

ring nut C fig. 48 clockwise;

❒refit the cover and retighten the

fastening devices.

46

F0Y0420C

33

9-1-2015 12:9 Pagina 33

Page 37 of 224

IMPORTANT In order to avoid

inconsistent information by the LPG

gauge on the instrument panel, it is

recommended to refill with at least 10

litres each time.

WARNING

35)Please note that in some countries

(including Italy) there are legal restrictions

in force for parking/garaging motor

vehicles with gas that has a higher density

than air; LPG comes under this category.

36)Do not switch between the two

operating modes whilst starting the engine.

37)If gas is smelled, switch from methane

operation to petrol operation and

immediately go to a Fiat Dealership to have

the vehicle checked and possible system

faults excluded.

WARNING

16)The vehicle is equipped with a gaseous

LPG injection system designed specifically

for it: it is therefore absolutely forbidden

to alter the configuration of the system or

its components. The use of other

components or materials could cause

malfunctions and lead to a reduction

in safety; therefore, in the case of

problems, contact a Fiat Dealership. When

towing or lifting the car, follow the

instructions in the paragraph on "Towing

the car" to prevent damage to the gas

methane system parts.17)The system operates at temperatures

ranging between −20 °C and 100 °C.

18)When painting in an oven, the LPG

tank must be removed from the vehicle and

later refitted by a Fiat Dealership. Although

the LPG system has numerous safety

features, it is advisable to proceed

as follows every time the car is not in use

for a long period or moved in an

emergency as a result of a breakdown or

accident: unscrew the fastening devices of

the LPG tank, then remove it. Close the

LPG cock rotating the ring nut C clockwise

(see "Passive/active Safety"). Refit the

cover and retighten the fastening devices.

19)Only use LPG fuel for motor vehicles.

20)It is strictly forbidden to use any

additive in the LPG. Periodically (at least

once every six months) it is advisable to let

the LPG in the tank run out and, at the

first refuelling, to check that it does not

exceed the maximum capacity of 38.4 litres

(reserve included) (with a tolerance of 2

litres excess). If the level is above 38.4 litres

(reserve included) contact a Fiat

Dealership immediately.

21)When switching from petrol to methane

is requested, a metal noise is heard from

the valves which pressurise the circuit. As a

result of the switching logic described

above, the delay between the ticking of the

valve and the switching off of the warning

on the instrument panel is entirely normal.22)In particular usage conditions, such as

starting and operation at low ambient

temperature or supply of LPG with low

content of propane, the system may

temporarily switch to petrol operation,

without indicating the performed switching

on the instrument panel. In the event of

low LPG levels in the tank or request for

high performance (e.g. overtaking, car fully

laden, steep hills) the system may

automatically switch to petrol operation to

guarantee the engine power requested; the

green warning light on the instrument

panel switches on to indicate this. When

the above conditions are no longer

present, the system automatically restores

LPG operation; the green warning light

switches off. To achieve the above

automatic switching, make sure that there

is enough fuel in the petrol tank.

35

9-1-2015 12:9 Pagina 35

Page 108 of 224

Emergency refuellingProceed as follows:

❒open the luggage compartment and

take the adapter, located in the tool box

or in the Fix&Go Automatic container

(according to the versions);

❒open the flap A pulling it outwards, fit

the dispenser in the filler as shown in

fig. 101 and start refuelling;

❒after refuelling, remove the adapter

and close the flap;

❒reintroduce the adapter in the box

and put this back in the luggage

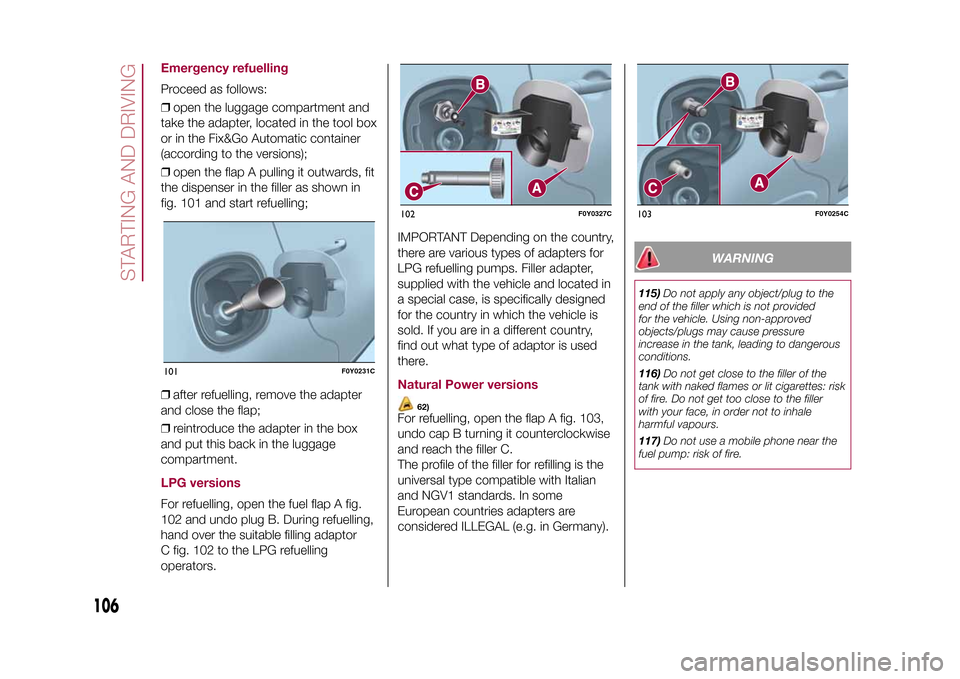

compartment.LPG versionsFor refuelling, open the fuel flap A fig.

102 and undo plug B. During refuelling,

hand over the suitable filling adaptor

C fig. 102 to the LPG refuelling

operators.IMPORTANT Depending on the country,

there are various types of adapters for

LPG refuelling pumps. Filler adapter,

supplied with the vehicle and located in

a special case, is specifically designed

for the country in which the vehicle is

sold. If you are in a different country,

find out what type of adaptor is used

there.

Natural Power versions

62)

For refuelling, open the flap A fig. 103,

undo cap B turning it counterclockwise

and reach the filler C.

The profile of the filler for refilling is the

universal type compatible with Italian

and NGV1 standards. In some

European countries adapters are

considered ILLEGAL (e.g. in Germany).

WARNING

115)Do not apply any object/plug to the

end of the filler which is not provided

for the vehicle. Using non-approved

objects/plugs may cause pressure

increase in the tank, leading to dangerous

conditions.

116)Do not get close to the filler of the

tank with naked flames or lit cigarettes: risk

of fire. Do not get too close to the filler

with your face, in order not to inhale

harmful vapours.

117)Do not use a mobile phone near the

fuel pump: risk of fire.

101

F0Y0231C

102

F0Y0327C

103

F0Y0254C

106

STARTING AND DRIVING

9-1-2015 12:9 Pagina 106

Page 111 of 224

HAZARD WARNING

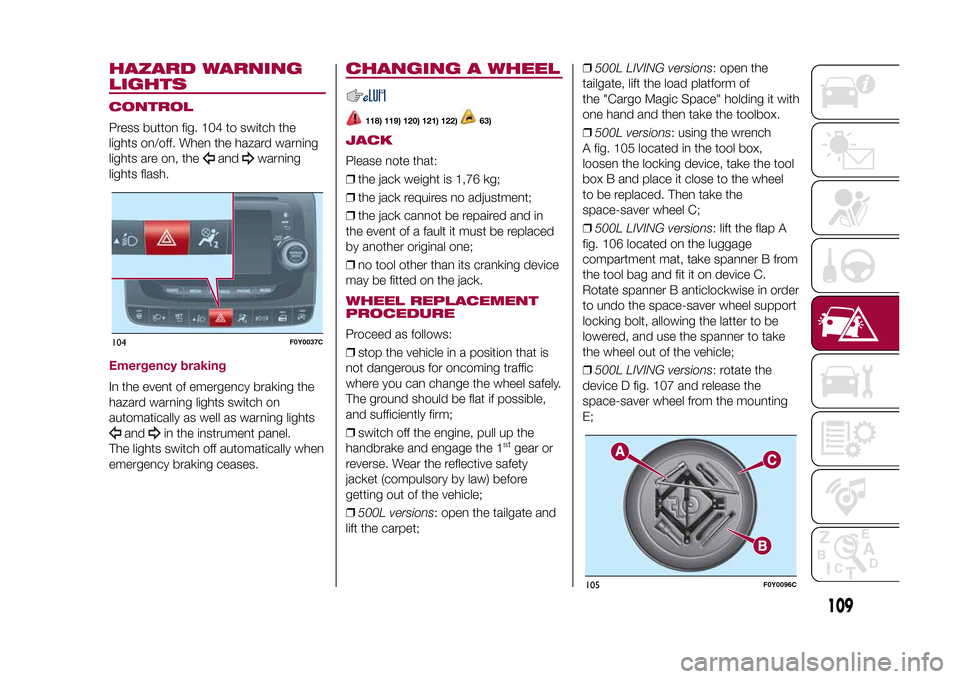

LIGHTSCONTROLPress button fig. 104 to switch the

lights on/off. When the hazard warning

lights are on, the

and

warning

lights flash.

Emergency brakingIn the event of emergency braking the

hazard warning lights switch on

automatically as well as warning lights

and

in the instrument panel.

The lights switch off automatically when

emergency braking ceases.

CHANGING A WHEEL

118) 119) 120) 121) 122)

63)

JACKPlease note that:

❒the jack weight is 1,76 kg;

❒the jack requires no adjustment;

❒the jack cannot be repaired and in

the event of a fault it must be replaced

by another original one;

❒no tool other than its cranking device

may be fitted on the jack.WHEEL REPLACEMENT

PROCEDUREProceed as follows:

❒stop the vehicle in a position that is

not dangerous for oncoming traffic

where you can change the wheel safely.

The ground should be flat if possible,

and sufficiently firm;

❒switch off the engine, pull up the

handbrake and engage the 1

stgear or

reverse. Wear the reflective safety

jacket (compulsory by law) before

getting out of the vehicle;

❒500L versions: open the tailgate and

lift the carpet;❒500L LIVING versions: open the

tailgate, lift the load platform of

the "Cargo Magic Space" holding it with

one hand and then take the toolbox.

❒500L versions: using the wrench

A fig. 105 located in the tool box,

loosen the locking device, take the tool

box B and place it close to the wheel

to be replaced. Then take the

space-saver wheel C;

❒500L LIVING versions: lift the flap A

fig. 106 located on the luggage

compartment mat, take spanner B from

the tool bag and fit it on device C.

Rotate spanner B anticlockwise in order

to undo the space-saver wheel support

locking bolt, allowing the latter to be

lowered, and use the spanner to take

the wheel out of the vehicle;

❒500L LIVING versions: rotate the

device D fig. 107 and release the

space-saver wheel from the mounting

E;

104

F0Y0037C

105

F0Y0096C

109

9-1-2015 12:9 Pagina 109

Page 113 of 224

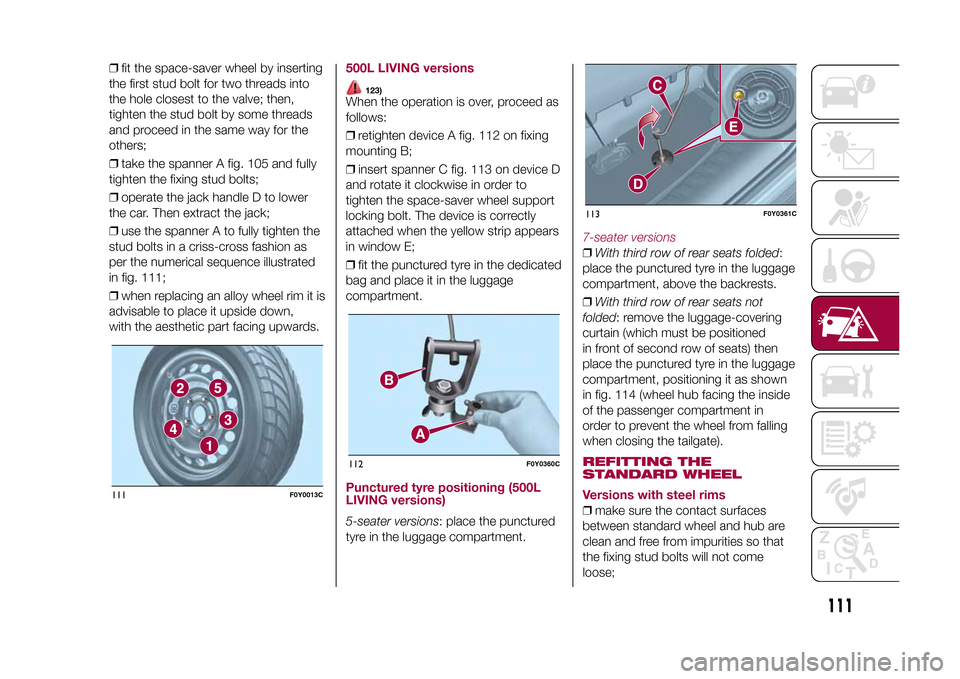

❒fit the space-saver wheel by inserting

the first stud bolt for two threads into

the hole closest to the valve; then,

tighten the stud bolt by some threads

and proceed in the same way for the

others;

❒take the spanner A fig. 105 and fully

tighten the fixing stud bolts;

❒operate the jack handle D to lower

the car. Then extract the jack;

❒use the spanner A to fully tighten the

stud bolts in a criss-cross fashion as

per the numerical sequence illustrated

in fig. 111;

❒when replacing an alloy wheel rim it is

advisable to place it upside down,

with the aesthetic part facing upwards.

500L LIVING versions

123)

When the operation is over, proceed as

follows:

❒retighten device A fig. 112 on fixing

mounting B;

❒insert spanner C fig. 113 on device D

and rotate it clockwise in order to

tighten the space-saver wheel support

locking bolt. The device is correctly

attached when the yellow strip appears

in window E;

❒fit the punctured tyre in the dedicated

bag and place it in the luggage

compartment.Punctured tyre positioning (500L

LIVING versions)5-seater versions: place the punctured

tyre in the luggage compartment.

7-seater versions❒With third row of rear seats folded:

place the punctured tyre in the luggage

compartment, above the backrests.

❒With third row of rear seats not

folded: remove the luggage-covering

curtain (which must be positioned

in front of second row of seats) then

place the punctured tyre in the luggage

compartment, positioning it as shown

in fig. 114 (wheel hub facing the inside

of the passenger compartment in

order to prevent the wheel from falling

when closing the tailgate).REFITTING THE

STANDARD WHEEL

Versions with steel rims❒make sure the contact surfaces

between standard wheel and hub are

clean and free from impurities so that

the fixing stud bolts will not come

loose;

111

F0Y0013C

112

F0Y0360C

113

F0Y0361C

111

9-1-2015 12:9 Pagina 111

Page 120 of 224

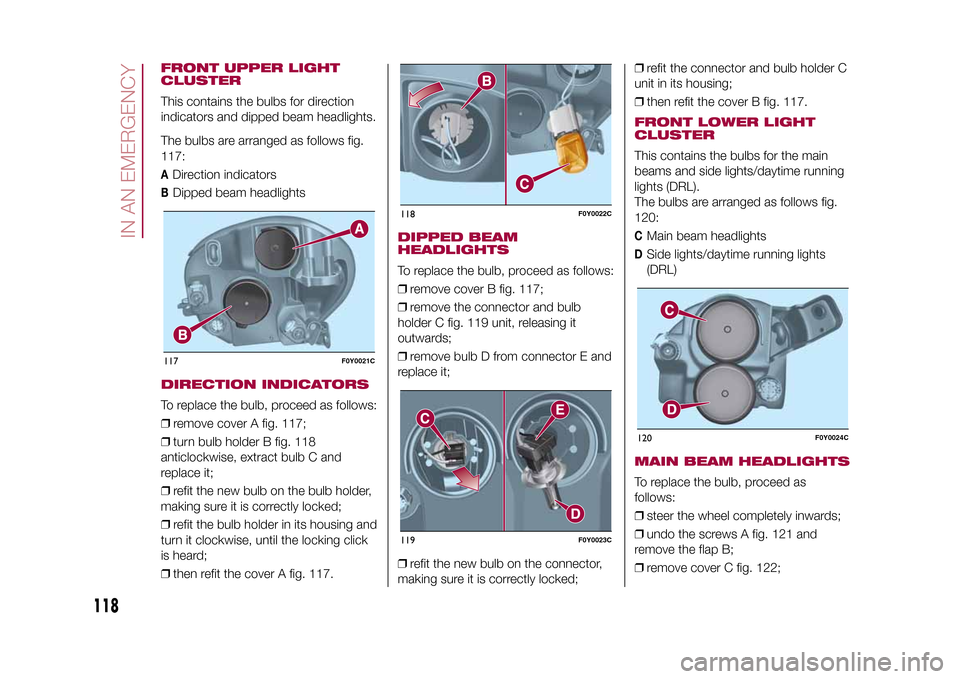

FRONT UPPER LIGHT

CLUSTERThis contains the bulbs for direction

indicators and dipped beam headlights.

The bulbs are arranged as follows fig.

117:A

Direction indicators

B

Dipped beam headlights

DIRECTION INDICATORSTo replace the bulb, proceed as follows:

❒remove cover A fig. 117;

❒turn bulb holder B fig. 118

anticlockwise, extract bulb C and

replace it;

❒refit the new bulb on the bulb holder,

making sure it is correctly locked;

❒refit the bulb holder in its housing and

turn it clockwise, until the locking click

is heard;

❒then refit the cover A fig. 117.

DIPPED BEAM

HEADLIGHTSTo replace the bulb, proceed as follows:

❒remove cover B fig. 117;

❒remove the connector and bulb

holder C fig. 119 unit, releasing it

outwards;

❒remove bulb D from connector E and

replace it;

❒refit the new bulb on the connector,

making sure it is correctly locked;❒refit the connector and bulb holder C

unit in its housing;

❒then refit the cover B fig. 117.

FRONT LOWER LIGHT

CLUSTERThis contains the bulbs for the main

beams and side lights/daytime running

lights (DRL).

The bulbs are arranged as follows fig.

120:C

Main beam headlights

D

Side lights/daytime running lights

(DRL)

MAIN BEAM HEADLIGHTSTo replace the bulb, proceed as

follows:

❒steer the wheel completely inwards;

❒undo the screws A fig. 121 and

remove the flap B;

❒remove cover C fig. 122;

117

F0Y0021C

118

F0Y0022C

119

F0Y0023C

120

F0Y0024C

118

IN AN EMERGENCY

9-1-2015 12:9 Pagina 118

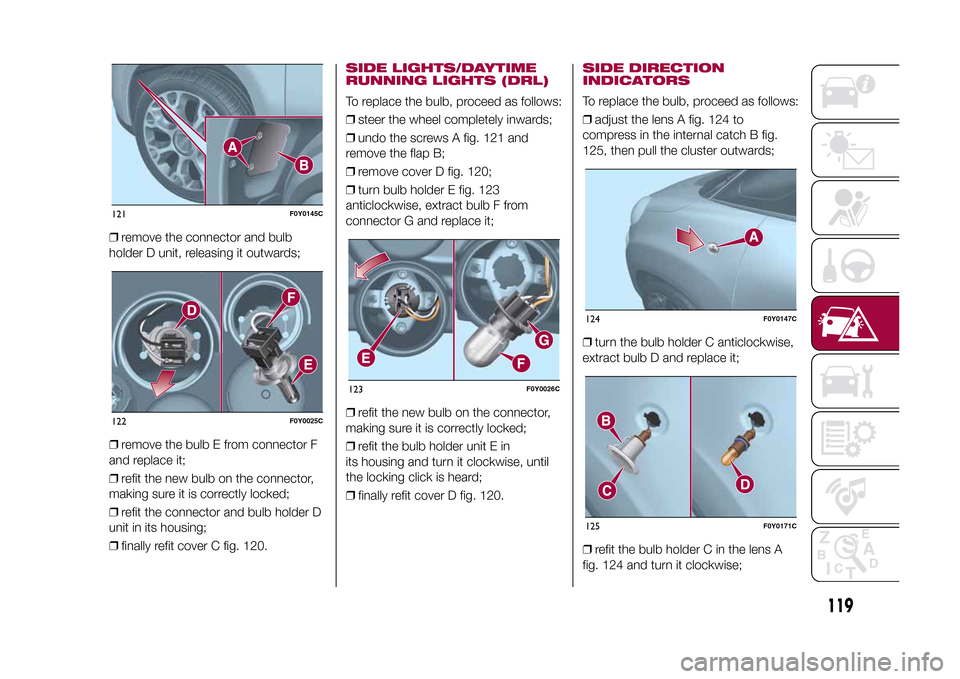

Page 121 of 224

❒remove the connector and bulb

holder D unit, releasing it outwards;

❒remove the bulb E from connector F

and replace it;

❒refit the new bulb on the connector,

making sure it is correctly locked;

❒refit the connector and bulb holder D

unit in its housing;

❒finally refit cover C fig. 120.

SIDE LIGHTS/DAYTIME

RUNNING LIGHTS (DRL)To replace the bulb, proceed as follows:

❒steer the wheel completely inwards;

❒undo the screws A fig. 121 and

remove the flap B;

❒remove cover D fig. 120;

❒turn bulb holder E fig. 123

anticlockwise, extract bulb F from

connector G and replace it;

❒refit the new bulb on the connector,

making sure it is correctly locked;

❒refit the bulb holder unit E in

its housing and turn it clockwise, until

the locking click is heard;

❒finally refit cover D fig. 120.

SIDE DIRECTION

INDICATORSTo replace the bulb, proceed as follows:

❒adjust the lens A fig. 124 to

compress in the internal catch B fig.

125, then pull the cluster outwards;

❒turn the bulb holder C anticlockwise,

extract bulb D and replace it;

❒refit the bulb holder C in the lens A

fig. 124 and turn it clockwise;

121

F0Y0145C

122

F0Y0025C

123

F0Y0026C

124

F0Y0147C

125

F0Y0171C

119

9-1-2015 12:9 Pagina 119