engine FIAT 500X 2017 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2017, Model line: 500X, Model: FIAT 500X 2017Pages: 284, PDF Size: 11.14 MB

Page 161 of 284

148)The space-saver wheel cannot be

fitted with snow chains. If a front (drive) tyre

is punctured and chains are needed, use a

standard wheel from the rear axle and

install the space-saver wheel on the rear

axle. In this way, with two normal drive

wheels at the front axle, it is possible to

use snow chains (this instruction is also

valid for 4x4 versions).

149)Never tamper with the inflation valve.

Never introduce tools of any kind between

the rim and the tyre. Check tyre and

space-saver wheel pressures regularly,

complying with the values given in the

"Technical specifications" chapter.150)The jack is a tool developed and

designed only for changing a wheel, if a

tyre gets punctured or damaged, on the

vehicle with which it is supplied or on other

vehicles of the same model. Any other use,

e.g. to jack up other vehicle models or

different things, is strictly prohibited. Never

use it to carry out maintenance or repairs

under the vehicle or to change

summer/winter wheels and vice versa: we

advise you to contact a Fiat Dealership.

Never go under the raised vehicle: use it

only in the positions indicated. Do not use

the jack for loads higher than the one

shown on its label. Never start the engine

with car raised. If the car is raised more

than necessary, everything can become

more unstable, with the risk of the car

dropping violently. Thus, lift the car only as

needed in order to access the space-saver

spare wheel.

151)When turning the jack handle make

sure that it can turn freely without scraping

your hand against the ground. The moving

components of the jack ("worm screw" and

joints) can also cause injuries: do not touch

them. If you come into contact with

lubricating grease, clean yourself

thoroughly.FIX&GO AUTOMATIC

KIT

(where provided)

DESCRIPTION

153) 154) 155) 156) 157) 158) 159)

68)

3)

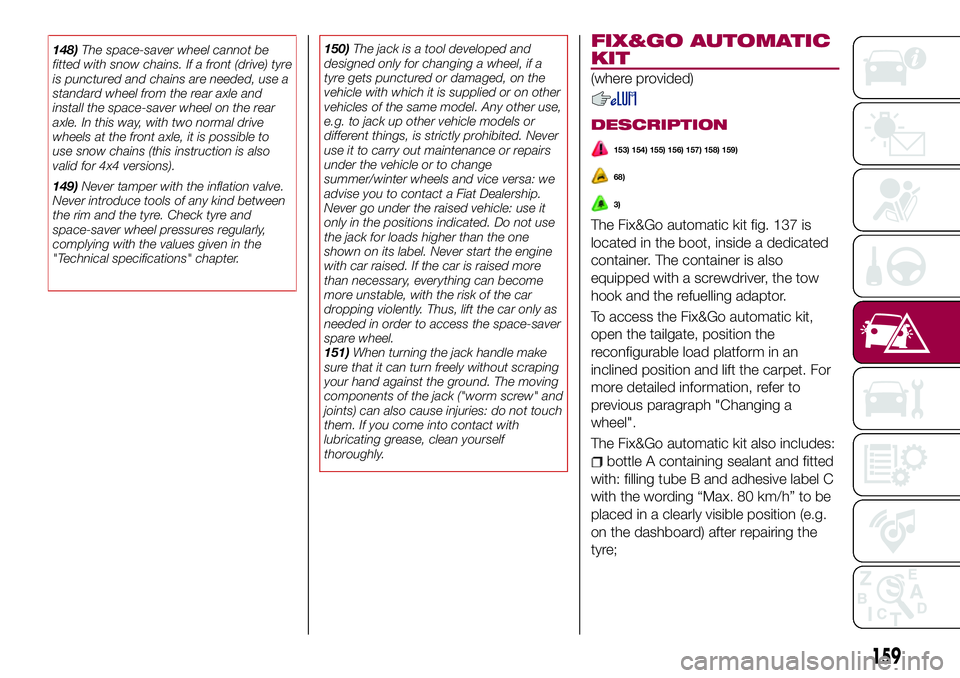

The Fix&Go automatic kit fig. 137 is

located in the boot, inside a dedicated

container. The container is also

equipped with a screwdriver, the tow

hook and the refuelling adaptor.

To access the Fix&Go automatic kit,

open the tailgate, position the

reconfigurable load platform in an

inclined position and lift the carpet. For

more detailed information, refer to

previous paragraph "Changing a

wheel".

The Fix&Go automatic kit also includes:

bottle A containing sealant and fitted

with: filling tube B and adhesive label C

with the wording “Max. 80 km/h” to be

placed in a clearly visible position (e.g.

on the dashboard) after repairing the

tyre;

159

Page 162 of 284

a compressor D complete with

pressure gauge and connectors;

an instruction leaflet, to refer to for

prompt and correct use and that must

be then given to the personnel dealing

with the tyre treated with sealant;

a pair of gloves located in the side

compartment of the compressor;

some adaptors, for inflating different

elements.

IMPORTANT The sealing fluid is

effective with external temperatures of

between –20°C and +50°C. The sealing

fluid has an expiry date.

TYRE REPAIRING AND

PRESSURE RESTORING

PROCEDURE

Proceed as follows:

place the car in a safe and suitable

area, engaging the parking brake. Take

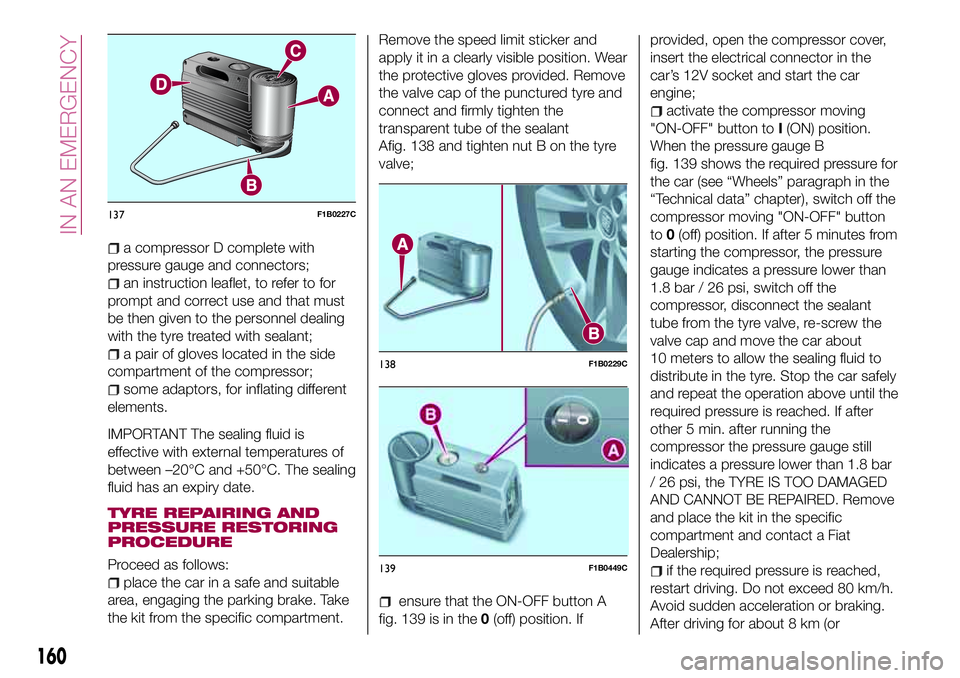

the kit from the specific compartment.Remove the speed limit sticker and

apply it in a clearly visible position. Wear

the protective gloves provided. Remove

the valve cap of the punctured tyre and

connect and firmly tighten the

transparent tube of the sealant

Afig. 138 and tighten nut B on the tyre

valve;

ensure that the ON-OFF button A

fig. 139 is in the0(off) position. Ifprovided, open the compressor cover,

insert the electrical connector in the

car’s 12V socket and start the car

engine;

activate the compressor moving

"ON-OFF" button toI(ON) position.

When the pressure gauge B

fig. 139 shows the required pressure for

the car (see “Wheels” paragraph in the

“Technical data” chapter), switch off the

compressor moving "ON-OFF" button

to0(off) position. If after 5 minutes from

starting the compressor, the pressure

gauge indicates a pressure lower than

1.8 bar / 26 psi, switch off the

compressor, disconnect the sealant

tube from the tyre valve, re-screw the

valve cap and move the car about

10 meters to allow the sealing fluid to

distribute in the tyre. Stop the car safely

and repeat the operation above until the

required pressure is reached. If after

other 5 min. after running the

compressor the pressure gauge still

indicates a pressure lower than 1.8 bar

/ 26 psi, the TYRE IS TOO DAMAGED

AND CANNOT BE REPAIRED. Remove

and place the kit in the specific

compartment and contact a Fiat

Dealership;

if the required pressure is reached,

restart driving. Do not exceed 80 km/h.

Avoid sudden acceleration or braking.

After driving for about 8 km (or

137F1B0227C

138F1B0229C

139F1B0449C

160

IN AN EMERGENCY

Page 164 of 284

EMERGENCY

STARTING

69)

If the battery is flat, a jump starting can

be performed using the battery and the

cables of another vehicle, or using an

auxiliary battery. In all cases, the battery

used must have a capacity equal to or

a little higher than the flat one.

IMPORTANT

Do not use an auxiliary battery or any

other source of external supply with a

voltage above 12 V: the battery, the

starter, the alternator and the electrical

system of the vehicle could be

damaged.

Do not attempt jump starting if the

battery is frozen. The battery could

break and explode!

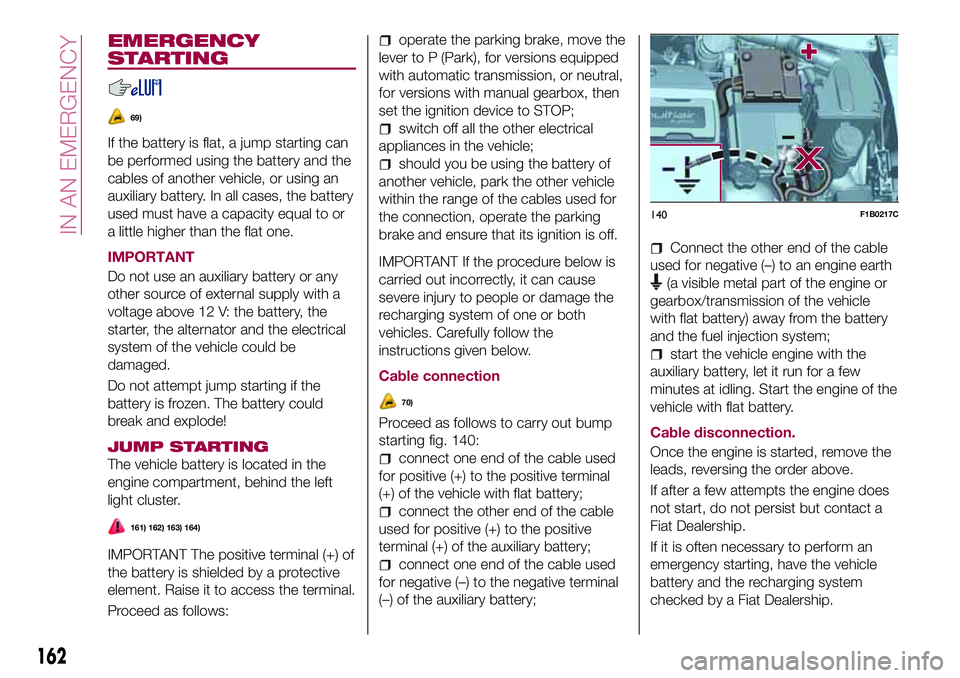

JUMP STARTING

The vehicle battery is located in the

engine compartment, behind the left

light cluster.

161) 162) 163) 164)

IMPORTANT The positive terminal (+) of

the battery is shielded by a protective

element. Raise it to access the terminal.

Proceed as follows:

operate the parking brake, move the

lever to P (Park), for versions equipped

with automatic transmission, or neutral,

for versions with manual gearbox, then

set the ignition device to STOP;

switch off all the other electrical

appliances in the vehicle;

should you be using the battery of

another vehicle, park the other vehicle

within the range of the cables used for

the connection, operate the parking

brake and ensure that its ignition is off.

IMPORTANT If the procedure below is

carried out incorrectly, it can cause

severe injury to people or damage the

recharging system of one or both

vehicles. Carefully follow the

instructions given below.

Cable connection

70)

Proceed as follows to carry out bump

starting fig. 140:

connect one end of the cable used

for positive (+) to the positive terminal

(+) of the vehicle with flat battery;

connect the other end of the cable

used for positive (+) to the positive

terminal (+) of the auxiliary battery;

connect one end of the cable used

for negative (–) to the negative terminal

(–) of the auxiliary battery;

Connect the other end of the cable

used for negative (–) to an engine earth

(a visible metal part of the engine or

gearbox/transmission of the vehicle

with flat battery) away from the battery

and the fuel injection system;

start the vehicle engine with the

auxiliary battery, let it run for a few

minutes at idling. Start the engine of the

vehicle with flat battery.

Cable disconnection.

Once the engine is started, remove the

leads, reversing the order above.

If after a few attempts the engine does

not start, do not persist but contact a

Fiat Dealership.

If it is often necessary to perform an

emergency starting, have the vehicle

battery and the recharging system

checked by a Fiat Dealership.

140F1B0217C

162

IN AN EMERGENCY

Page 165 of 284

IMPORTANT Any accessories (e.g.

mobile phones, etc.) connected to the

vehicle power sockets, draw current

even if they are not used. These

devices, if left connected too much time

with engine off, may cause the battery

to drain with following reduction of its

life and/or failure to start the engine.

WARNING

161)Before opening the bonnet, make

sure that the engine is off and that the

ignition key is in the STOP position. Follow

the indications on the plate underneath the

bonnet. We recommend that you remove

the key from the ignition if other people

remain in the vehicle. The vehicle should

always be left after the key has been

removed or turned to the STOP position.

During refuelling, make sure that the engine

is off (and that the ignition key is in the

STOP position).

162)Do not get too close to the radiator

cooling fan: the electric fan may start;

danger of injury. Scarves, ties and other

loose clothing might be pulled by moving

parts.

163)Remove any metal objects (e.g. rings,

watches, bracelets), that might cause an

accidental electrical contact and cause

serious injury.

164)The batteries contain acid that can

burn skin or eyes. Batteries produce

hydrogen, which is easily flammable and

explosive. Therefore, keep away flames or

devices which may cause sparks.

IMPORTANT

69)Never use a fast battery-charger to

start the engine as this could damage the

electronic systems of your vehicle,

particularly the ignition and engine fuel

supply control units.

70)Do not connect the cable to the

negative terminal (–) of the flat battery. The

following spark could lead to battery

explosion and cause serious harm. Only

use the specific earth point; do not use any

other exposed metallic part.

FUEL CUT-OFF

SYSTEM

DESCRIPTION

This intervenes in the case of an impact

causing:

the interruption of the fuel supply

with the engine consequently switching

off;

the automatic unlocking of the

doors;

turning on of the lights inside the

vehicle;

deactivation of climate control

system ventilation;

switching on of the hazard warning

lights (to deactivate the lights press the

button on the dashboard).

On some versions, the intervention of

the system is indicated by a message

shown on the display. In the same way,

a dedicated message on the display

warns the driver if system operation is

compromised.

IMPORTANT Carefully check the vehicle

for fuel leaks, for instance in the engine

compartment, under the vehicle or near

the tank area. After a collision, bring the

ignition device to STOP to prevent the

battery from running down.

163

Page 166 of 284

FUEL CUT-OFF SYSTEM

RESET

165)

To restore correct operation of the car,

carry out the following procedure (this

procedure must be started and

completed within less than 1 minute):

with direction indicator lever in

neutral position, turn the ignition device

to STOP;

turn the ignition device to MAR;

activate the right direction indicator

and then the left one;

activate the right direction indicator

and then the left one again;

deactivate the left direction indicator;

turn the ignition device to STOP and

then to MAR.

WARNING

165)If, after an impact, you smell fuel or

notice leaks from the fuel system, do not

reactivate the system to avoid the risk of

fire.

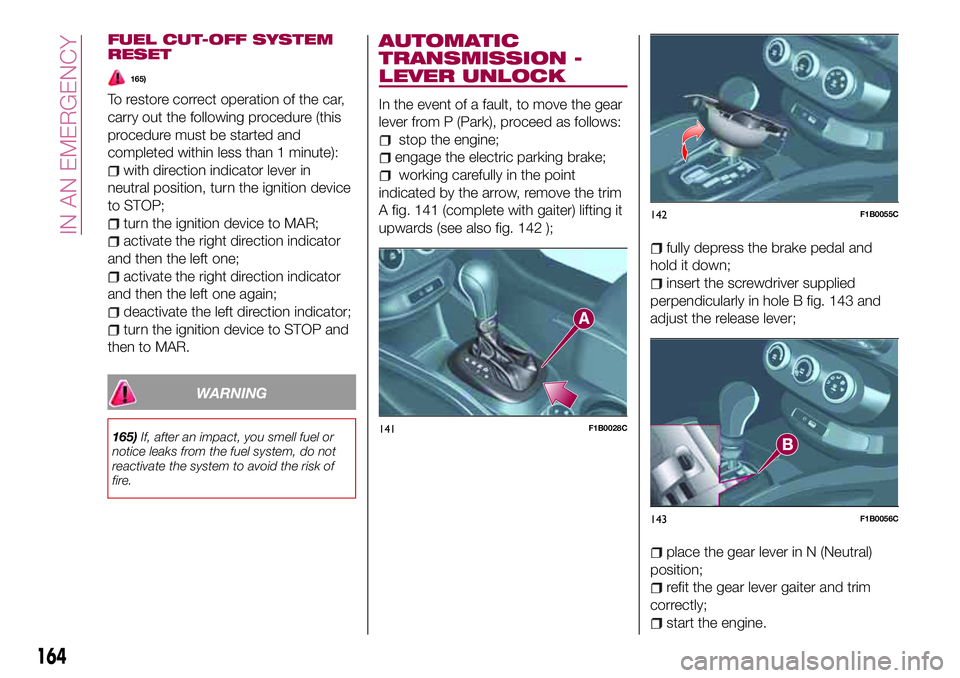

AUTOMATIC

TRANSMISSION -

LEVER UNLOCK

In the event of a fault, to move the gear

lever from P (Park), proceed as follows:

stop the engine;

engage the electric parking brake;

working carefully in the point

indicated by the arrow, remove the trim

A fig. 141 (complete with gaiter) lifting it

upwards (see also fig. 142 );

fully depress the brake pedal and

hold it down;

insert the screwdriver supplied

perpendicularly in hole B fig. 143 and

adjust the release lever;

place the gear lever in N (Neutral)

position;

refit the gear lever gaiter and trim

correctly;

start the engine.

141F1B0028C

142F1B0055C

143F1B0056C

164

IN AN EMERGENCY

Page 168 of 284

IMPORTANT

71)It is advisable to contact a Fiat

Dealership to have the refitting procedure

carried out. If you would like to proceed

autonomously, special attention must be

paid to the correct coupling of the retaining

clips. Otherwise, noise might be heard due

to an incorrect fastening of the lower cover

with the upper cover.

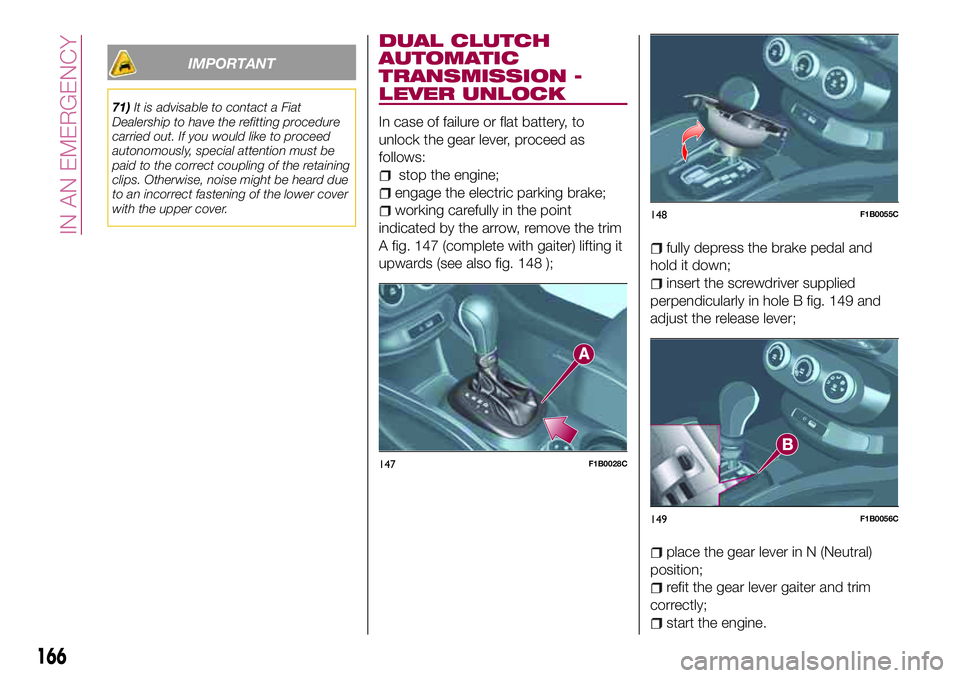

DUAL CLUTCH

AUTOMATIC

TRANSMISSION -

LEVER UNLOCK

In case of failure or flat battery, to

unlock the gear lever, proceed as

follows:

stop the engine;

engage the electric parking brake;

working carefully in the point

indicated by the arrow, remove the trim

A fig. 147 (complete with gaiter) lifting it

upwards (see also fig. 148 );

fully depress the brake pedal and

hold it down;

insert the screwdriver supplied

perpendicularly in hole B fig. 149 and

adjust the release lever;

place the gear lever in N (Neutral)

position;

refit the gear lever gaiter and trim

correctly;

start the engine.

147F1B0028C

148F1B0055C

149F1B0056C

166

IN AN EMERGENCY

Page 171 of 284

167)The brake servo and the

electromechanical power steering will not

work while the vehicle is being towed. You

will therefore need to apply more force on

the brake pedal and steering wheel. Do not

use flexible ropes when towing, and avoid

jerky movements. During towing, make

sure that the trailer hitch does not damage

any components it is touching. When

towing the car, you must comply with all

specific traffic regulations and adopt an

appropriate driving behaviour. Do not start

the engine while towing the car. Before

tightening the ring, clean the threaded

housing thoroughly. Make sure that the ring

is fully screwed into the housing before

towing the car.

168)The front and rear tow hooks should

be used only for emergencies on the road.

You are allowed to tow the vehicle for short

distances using an appropriate device in

accordance with the highway code (a rigid

bar), to move the vehicle on the road in

readiness for towing or transport via a

breakdown vehicle. Tow hooks MUST NOT

be used to tow vehicles off the road or

where there are obstacles and/or for

towing operations using cables or other

non-rigid devices. In compliance with the

above conditions, towing must take place

with the two vehicles (one towing, the other

towed) aligned as much as possible along

the same centre line.

169

Page 172 of 284

SERVICING AND MAINTENANCE

Correct maintenance permits the

performance of the vehicle to be

maintained over time, as well as limited

running costs and safeguarding the

efficiency of the safety systems.

This chapter explains how.SCHEDULED SERVICING.......171

ENGINE COMPARTMENT......181

BATTERY RECHARGING.......190

SERVICING PROCEDURES.....191

LIFTING THE VEHICLE.........194

WHEELS AND TYRES.........194

BODYWORK...............196

INTERIORS................197

170

SERVICING AND MAINTENANCE

Page 174 of 284

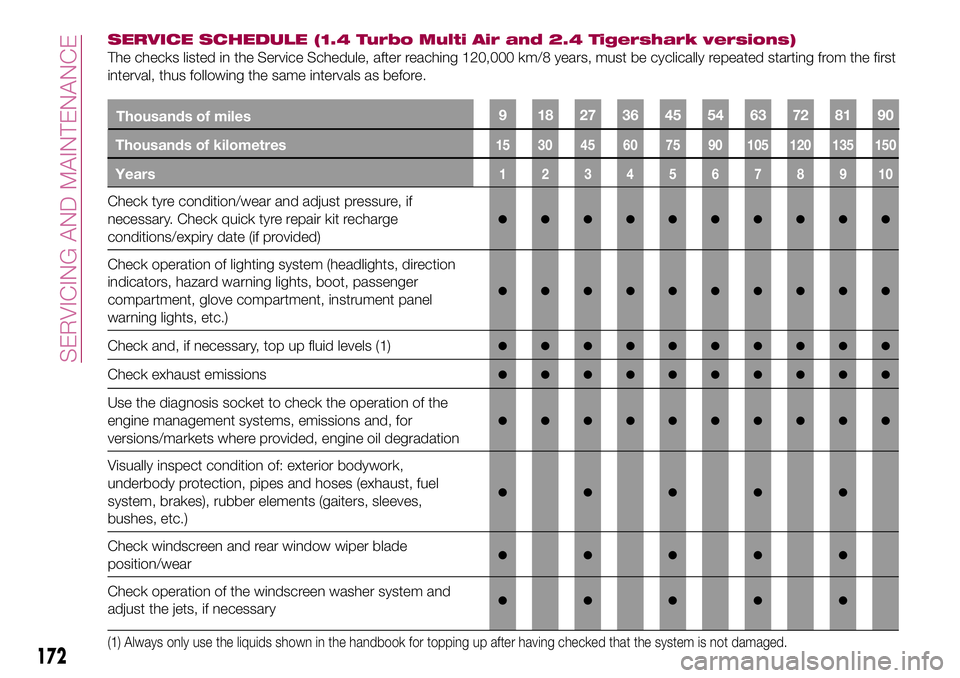

SERVICE SCHEDULE (1.4 Turbo Multi Air and 2.4 Tigershark versions)

The checks listed in the Service Schedule, after reaching 120,000 km/8 years, must be cyclically repeated starting from the first

interval, thus following the same intervals as before.

Thousands of kilometres15 30 45 60 75 90 105 120 135 150

Years12345678910

Check tyre condition/wear and adjust pressure, if

necessary. Check quick tyre repair kit recharge

conditions/expiry date (if provided)

●●●●●●●●●●

Check operation of lighting system (headlights, direction

indicators, hazard warning lights, boot, passenger

compartment, glove compartment, instrument panel

warning lights, etc.)

●●●●●●●●●●

Check and, if necessary, top up fluid levels (1)●●●●●●●●●●

Check exhaust emissions●●●●●●●●●●

Use the diagnosis socket to check the operation of the

engine management systems, emissions and, for

versions/markets where provided, engine oil degradation

●●●●●●●●●●

Visually inspect condition of: exterior bodywork,

underbody protection, pipes and hoses (exhaust, fuel

system, brakes), rubber elements (gaiters, sleeves,

bushes, etc.)

●●●●●

Check windscreen and rear window wiper blade

position/wear●●●●●

Check operation of the windscreen washer system and

adjust the jets, if necessary●●●●●

(1) Always only use the liquids shown in the handbook for topping up after having checked that the system is not damaged.

172

SERVICING AND MAINTENANCE

Thousands of miles9 182736455463728190

Page 175 of 284

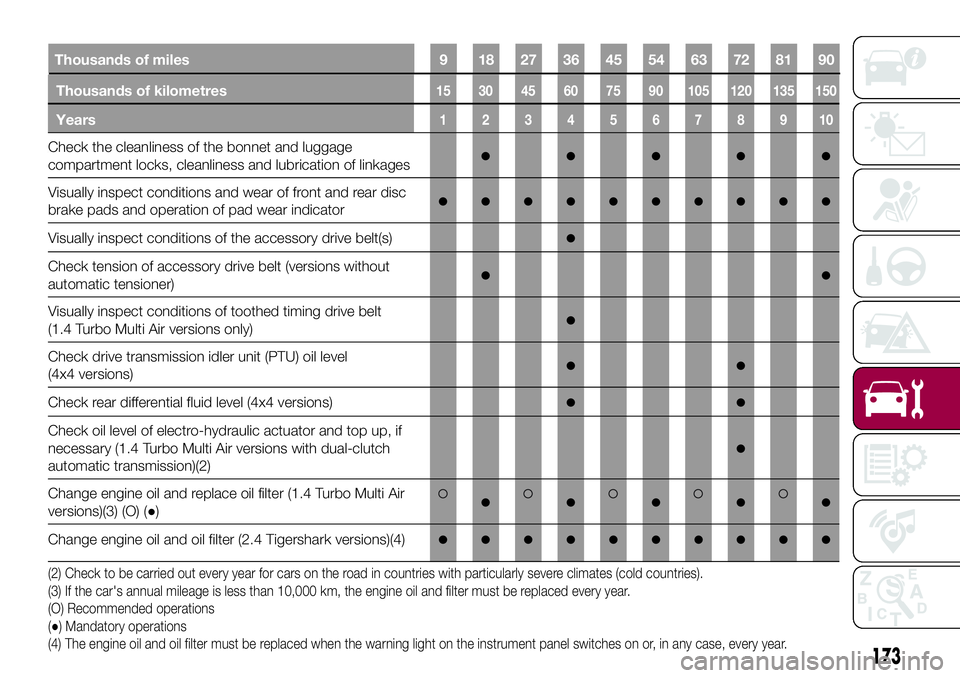

Thousands of kilometres15 30 45 60 75 90 105 120 135 150

Years12345678910

Check the cleanliness of the bonnet and luggage

compartment locks, cleanliness and lubrication of linkages●●●●●

Visually inspect conditions and wear of front and rear disc

brake pads and operation of pad wear indicator●●●●●●●●●●

Visually inspect conditions of the accessory drive belt(s)●

Check tension of accessory drive belt (versions without

automatic tensioner)●●

Visually inspect conditions of toothed timing drive belt

(1.4 Turbo Multi Air versions only)●

Check drive transmission idler unit (PTU) oil level

(4x4 versions)●●

Check rear differential fluid level (4x4 versions)●●

Check oil level of electro-hydraulic actuator and top up, if

necessary (1.4 Turbo Multi Air versions with dual-clutch

automatic transmission)(2)

●

Change engine oil and replace oil filter (1.4 Turbo Multi Air

versions)(3) (O) (●)●●●●●

Change engine oil and oil filter (2.4 Tigershark versions)(4)●●●●●●●●●●

(2) Check to be carried out every year for cars on the road in countries with particularly severe climates (cold countries).

(3) If the car's annual mileage is less than 10,000 km, the engine oil and filter must be replaced every year.

(O) Recommended operations

(●) Mandatory operations

(4) The engine oil and oil filter must be replaced when the warning light on the instrument panel switches on or, in any case, every year.

173

Thousands of miles 9 18 27 36 45 54 63 72 81 90