engine FIAT 500X 2017 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2017, Model line: 500X, Model: FIAT 500X 2017Pages: 284, PDF Size: 11.14 MB

Page 132 of 284

DRIVE MODE

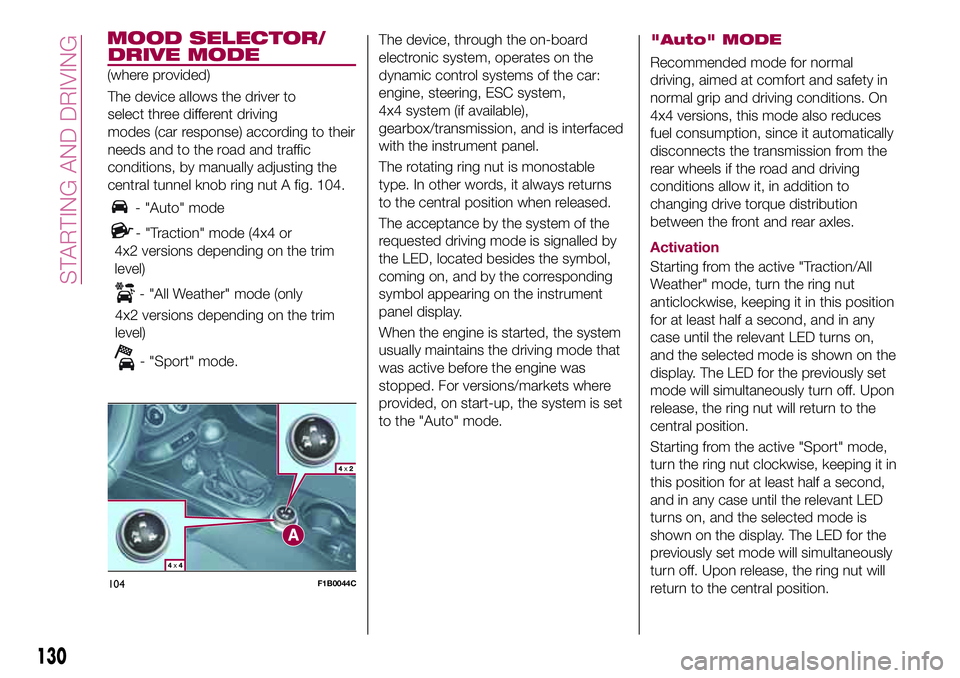

The device allows the driver to

select three different driving

modes (car response) according to their

needs and to the road and traffic

conditions, by manually adjusting the

central tunnel knob ring nut A fig. 104.

- "Auto" mode

- "Traction" mode (4x4 or

4x2 versions depending on the trim

level)

- "All Weather" mode (only

4x2 versions depending on the trim

level)

- "Sport" mode.The device, through the on-board

electronic system, operates on the

dynamic control systems of the car:

engine, steering, ESC system,

4x4 system (if available),

gearbox/transmission, and is interfaced

with the instrument panel.

The rotating ring nut is monostable

type. In other words, it always returns

to the central position when released.

The acceptance by the system of the

requested driving mode is signalled by

the LED, located besides the symbol,

coming on, and by the corresponding

symbol appearing on the instrument

panel display.

When the engine is started, the system

usually maintains the driving mode that

was active before the engine was

stopped. For versions/markets where

provided, on start-up, the system is set

to the "Auto" mode.

"Auto" MODE

Recommended mode for normal

driving, aimed at comfort and safety in

normal grip and driving conditions. On

4x4 versions, this mode also reduces

fuel consumption, since it automatically

disconnects the transmission from the

rear wheels if the road and driving

conditions allow it, in addition to

changing drive torque distribution

between the front and rear axles.

Activation

Starting from the active "Traction/All

Weather" mode, turn the ring nut

anticlockwise, keeping it in this position

for at least half a second, and in any

case until the relevant LED turns on,

and the selected mode is shown on the

display. The LED for the previously set

mode will simultaneously turn off. Upon

release, the ring nut will return to the

central position.

Starting from the active "Sport" mode,

turn the ring nut clockwise, keeping it in

this position for at least half a second,

and in any case until the relevant LED

turns on, and the selected mode is

shown on the display. The LED for the

previously set mode will simultaneously

turn off. Upon release, the ring nut will

return to the central position.

104F1B0044C

130

STARTING AND DRIVING

(where provided)

MOOD SELECTOR/

Page 136 of 284

LANE ASSIST

SYSTEM (lane

crossing warning)

DESCRIPTION

57) 58) 59) 60) 61) 62)

The Lane Assist system makes use of a

camera located on the windscreen to

detect the lane limits and calculate the

position of the vehicle within such limits,

in order to make sure that it remains

inside the lane.

When both limits of the lane are

detected and the vehicle crosses one of

them without the awareness of the

driver (direction indicator off), the Lane

Assist system provides a tactile warning

by applying torque to the steering wheel

(vibration), thus advising the driver that

he must take an action to remain in the

lane.

IMPORTANT The torque applied to the

steering wheel by the system is

sufficient for the driver to notice it, but

always limited, so that they can easily

override it, and the driver always

maintains control of the vehicle. The

driver can therefore turn the steering

wheel as required at all times.

If the vehicle continues going beyond

the line of the lane without anyintervention from the driver, the

warning light (or the icon on the

display) will be displayed on the

instrument panel to urge the driver to

bring the vehicle back into the limits of

the lane.

IMPORTANT The system monitors the

presence of the driver's hands on the

steering wheel. If they are not detected,

the system emits an acoustic signal and

deactivates until it is reactivated by

pressing the dedicated button (see

description below).

When one limit of the lane is detected

and the vehicle crosses it (direction

indicator off), warning light

(or the

icon on the display) will be displayed on

the instrument panel to urge the driver

to bring the vehicle back into the lane.

In this case, the tactile warning

(vibration on the steering wheel) is not

provided.

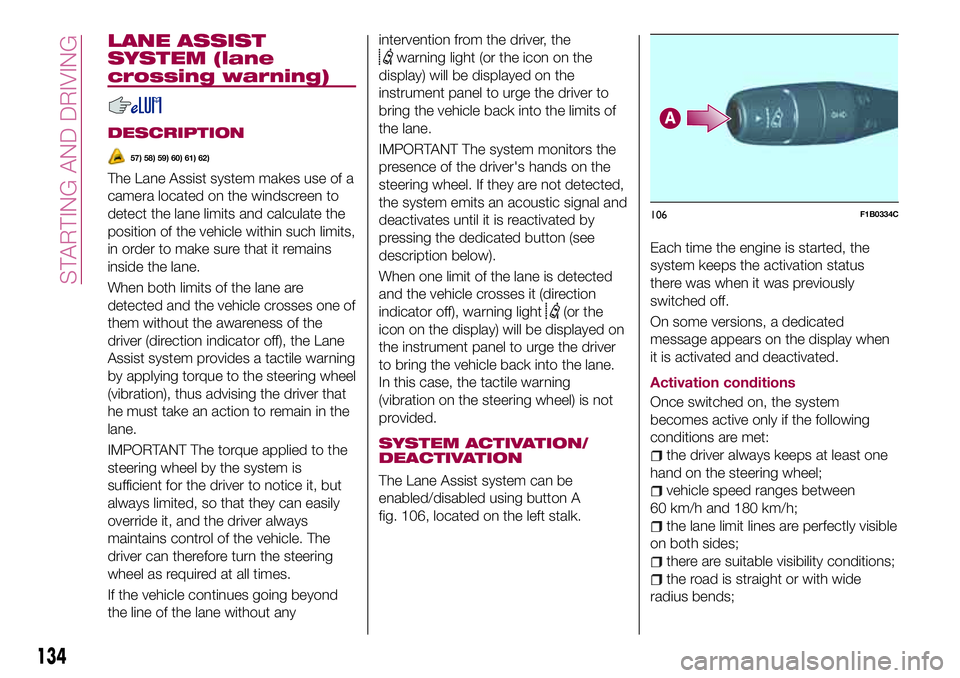

SYSTEM ACTIVATION/

DEACTIVATION

The Lane Assist system can be

enabled/disabled using button A

fig. 106, located on the left stalk.Each time the engine is started, the

system keeps the activation status

there was when it was previously

switched off.

On some versions, a dedicated

message appears on the display when

it is activated and deactivated.

Activation conditions

Once switched on, the system

becomes active only if the following

conditions are met:

the driver always keeps at least one

hand on the steering wheel;

vehicle speed ranges between

60 km/h and 180 km/h;

the lane limit lines are perfectly visible

on both sides;

there are suitable visibility conditions;

the road is straight or with wide

radius bends;

106F1B0334C

134

STARTING AND DRIVING

Page 139 of 284

Do not exceed the speed limits specific

to each country you are driving in, in the

case of vehicles towing trailers. In any

case, the top speed must not exceed

100 km/h.

Any electric brake must be powered

directly by the battery through a cable

with a cross-section of no less than

2.5 mm

2. In addition to the electrical

branches, the vehicle electrical system

can only be connected to the supply

cable for an electric brake and to the

cable for an internal light for the trailer,

not exceeding 15 W. For connections,

use the preset control unit with a

battery cable with section not less than

2.5 mm

2. The use of auxiliary loads

other than external lights (e.g. electric

brake) must take place with engine

running.

INSTALLING A TOW

HOOK

The towing device should be fastened

to the body by specialised personnel

according to any additional and/or

integrative information supplied by the

Manufacturer of the device. It must also

meet current regulations with reference

to Directive 94/20/EC and subsequent

amendments.

For any version the towing device used

must be right for the towable weight of

the vehicle on which it is to be installed.

For the electrical connection a standard

connector should be used which is

generally placed on a special bracket

normally fastened to the towing device,

and a special ECU for external trailer

light control must be installed on the

vehicle. 7 or 13-pin 12 V DC

connections should be used

(CUNA/UNI and ISO/DIN Standards).

Follow any instructions provided by the

vehicle manufacturer and/or the towing

device manufacturer.

137

Page 142 of 284

REFUELLING THE

VEHICLE

133) 134) 135)

PETROL ENGINES

Only use unleaded petrol with a number

of octanes (R.O.N.) not lower than 95

(EN 228 specification).

DIESEL ENGINES

64)

Only use Diesel for motor vehicles (EN

590 specification).

When using or parking the vehicle for a

long time in the mountains or cold

areas, it is advisable to refuel using

locally available diesel. In this case, it is

also advisable to keep the tank over

50% full.

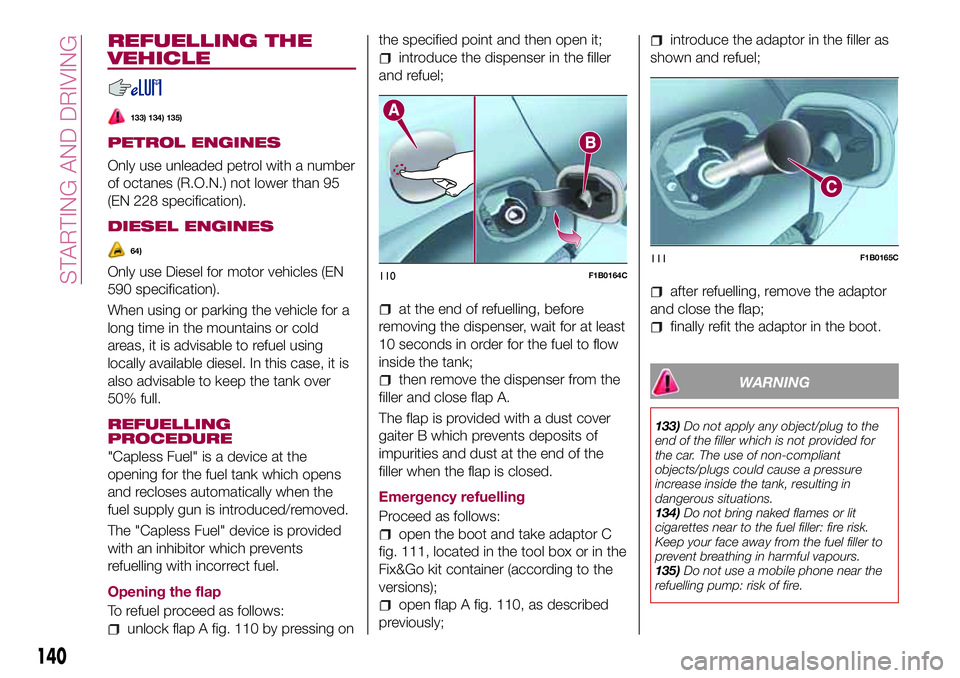

REFUELLING

PROCEDURE

"Capless Fuel" is a device at the

opening for the fuel tank which opens

and recloses automatically when the

fuel supply gun is introduced/removed.

The "Capless Fuel" device is provided

with an inhibitor which prevents

refuelling with incorrect fuel.

Opening the flap

To refuel proceed as follows:

unlock flap A fig. 110 by pressing onthe specified point and then open it;

introduce the dispenser in the filler

and refuel;

at the end of refuelling, before

removing the dispenser, wait for at least

10 seconds in order for the fuel to flow

inside the tank;

then remove the dispenser from the

filler and close flap A.

The flap is provided with a dust cover

gaiter B which prevents deposits of

impurities and dust at the end of the

filler when the flap is closed.

Emergency refuelling

Proceed as follows:

open the boot and take adaptor C

fig. 111, located in the tool box or in the

Fix&Go kit container (according to the

versions);

open flap A fig. 110, as described

previously;

introduce the adaptor in the filler as

shown and refuel;

after refuelling, remove the adaptor

and close the flap;

finally refit the adaptor in the boot.

WARNING

133)Do not apply any object/plug to the

end of the filler which is not provided for

the car. The use of non-compliant

objects/plugs could cause a pressure

increase inside the tank, resulting in

dangerous situations.

134)Do not bring naked flames or lit

cigarettes near to the fuel filler: fire risk.

Keep your face away from the fuel filler to

prevent breathing in harmful vapours.

135)Do not use a mobile phone near the

refuelling pump: risk of fire.

110F1B0164C111F1B0165C

140

STARTING AND DRIVING

Page 143 of 284

IMPORTANT

64)Vehicles with a diesel engine must only

be filled with diesel fuel for motor vehicles,

in compliance with European Standard EN

590. The use of other products or mixtures

may damage the engine beyond repair and

consequently invalidate the warranty, due

to the damage caused. If you accidentally

introduce other types of fuel into the tank,

do not start the engine. Empty the tank. If

the engine has been run for even an

extremely limited amount of time, you must

not only drain the fuel tank, but the rest of

the supply circuit as well.

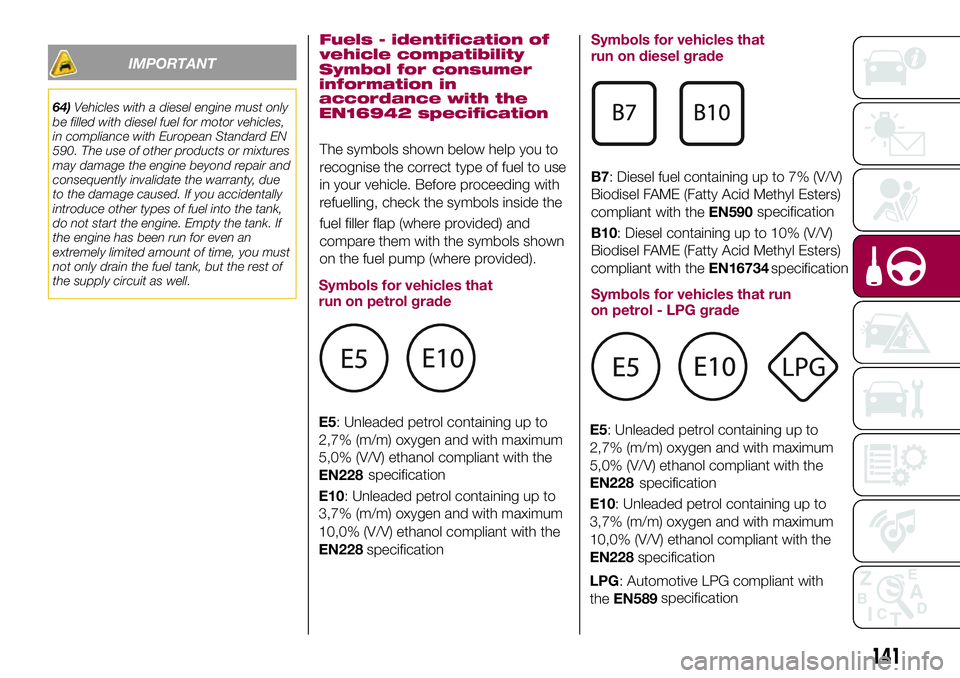

Fuels - identification of

vehicle compatibility

Symbol for consumer

information in

accordance with the

EN16942 specification

The symbols shown below help you to

recognise the correct type of fuel to use

in your vehicle. Before proceeding with

refuelling, check the symbols inside the

fuel filler flap (where provided) and

compare them with the symbols shown

on the fuel pump (where provided).

Symbols for vehicles that

run on petrol grade

E5: Unleaded petrol containing up to

2,7% (m/m) oxygen and with maximum

5,0% (V/V) ethanol compliant with the

EN228

E10: Unleaded petrol containing up to

3,7% (m/m) oxygen and with maximum

10,0% (V/V) ethanol compliant with the

EN228Symbols for vehicles that

run on diesel grade

B7: Diesel fuel containing up to 7% (V/V)

Biodisel FAME (Fatty Acid Methyl Esters)

compliant with theEN590

B10: Diesel containing up to 10% (V/V)

Biodisel FAME (Fatty Acid Methyl Esters)

compliant with theEN16734

Symbols for vehicles that run

on petrol - LPG grade

LPG: Automotive LPG compliant with

theEN589

141

specification

specificationspecification

specification

E5: Unleaded petrol containing up to

2,7% (m/m) oxygen and with maximum

5,0% (V/V) ethanol compliant with the

EN228

E10: Unleaded petrol containing up to

3,7% (m/m) oxygen and with maximum

10,0% (V/V) ethanol compliant with the

EN228specification

specification

specification

Page 148 of 284

REPLACING AN

EXTERNAL BULB

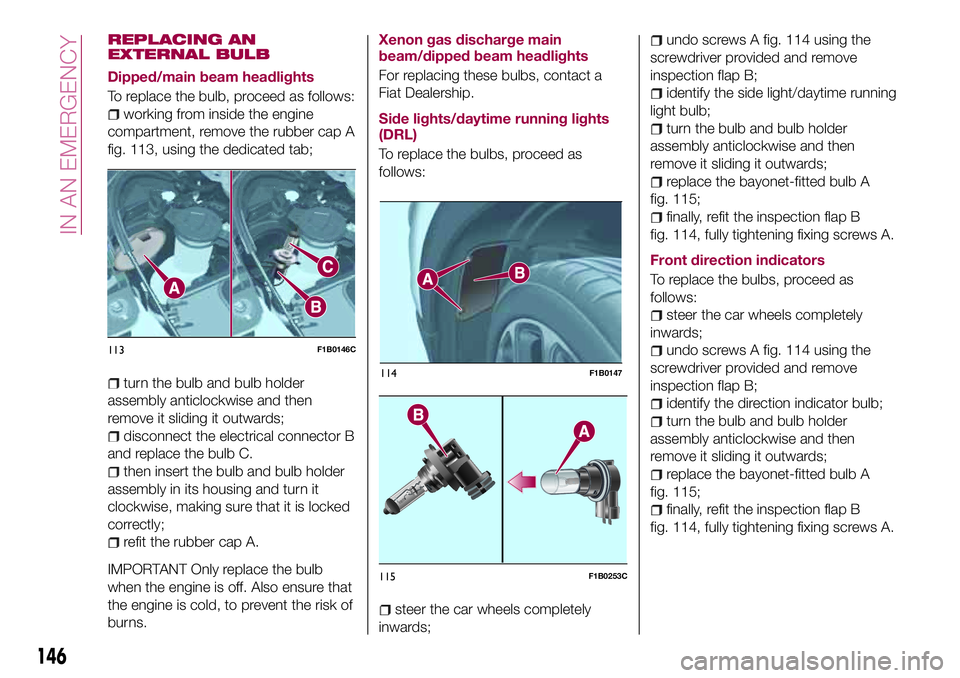

Dipped/main beam headlights

To replace the bulb, proceed as follows:

working from inside the engine

compartment, remove the rubber cap A

fig. 113, using the dedicated tab;

turn the bulb and bulb holder

assembly anticlockwise and then

remove it sliding it outwards;

disconnect the electrical connector B

and replace the bulb C.

then insert the bulb and bulb holder

assembly in its housing and turn it

clockwise, making sure that it is locked

correctly;

refit the rubber cap A.

IMPORTANT Only replace the bulb

when the engine is off. Also ensure that

the engine is cold, to prevent the risk of

burns.

Xenon gas discharge main

beam/dipped beam headlights

For replacing these bulbs, contact a

Fiat Dealership.

Side lights/daytime running lights

(DRL)

To replace the bulbs, proceed as

follows:

steer the car wheels completely

inwards;

undo screws A fig. 114 using the

screwdriver provided and remove

inspection flap B;

identify the side light/daytime running

light bulb;

turn the bulb and bulb holder

assembly anticlockwise and then

remove it sliding it outwards;

replace the bayonet-fitted bulb A

fig. 115;

finally, refit the inspection flap B

fig. 114, fully tightening fixing screws A.

Front direction indicators

To replace the bulbs, proceed as

follows:

steer the car wheels completely

inwards;

undo screws A fig. 114 using the

screwdriver provided and remove

inspection flap B;

identify the direction indicator bulb;

turn the bulb and bulb holder

assembly anticlockwise and then

remove it sliding it outwards;

replace the bayonet-fitted bulb A

fig. 115;

finally, refit the inspection flap B

fig. 114, fully tightening fixing screws A.

113F1B0146C

115F1B0253C

146

IN AN EMERGENCY

114F1B0147

Page 151 of 284

NOTE Before removing the lens unit,

put a protection (e.g. cloth) on the tip of

the screwdriver, in order not to damage

the lens itself.

WARNING

136)Before replacing the bulb, wait for the

exhaust ducts to cool down: DANGER OF

SCALDING!

137)Modifications or repairs to the electric

system that are not carried out properly or

do not take the system technical

specifications into account can cause

malfunctions leading to the risk of fire.

138)Halogen bulbs contain pressurised

gas, in the case of breakage they may

burst causing glass fragments to be

projected outwards.

IMPORTANT

65)Halogen bulbs must be handled

holding the metallic part only. Touching the

transparent part of the bulb with your

fingers may reduce the intensity of the

emitted light and even reduce the lifespan

of the bulb. In the event of accidental

contact, wipe the bulb with a cloth

moistened with alcohol and let the bulb dry.

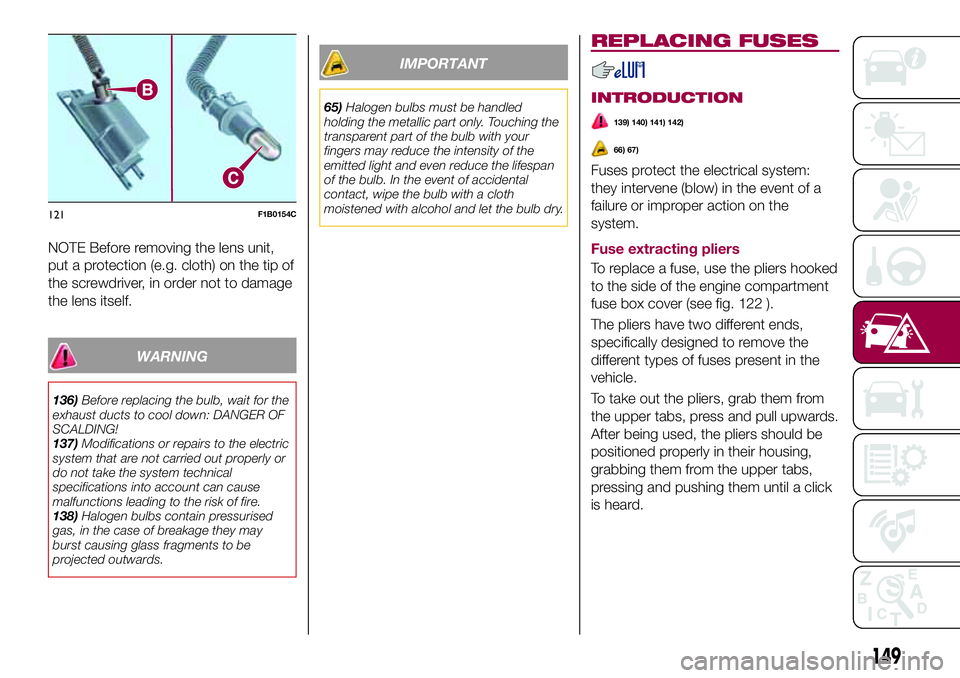

REPLACING FUSES

INTRODUCTION

139) 140) 141) 142)

66) 67)

Fuses protect the electrical system:

they intervene (blow) in the event of a

failure or improper action on the

system.

Fuse extracting pliers

To replace a fuse, use the pliers hooked

to the side of the engine compartment

fuse box cover (see fig. 122 ).

The pliers have two different ends,

specifically designed to remove the

different types of fuses present in the

vehicle.

To take out the pliers, grab them from

the upper tabs, press and pull upwards.

After being used, the pliers should be

positioned properly in their housing,

grabbing them from the upper tabs,

pressing and pushing them until a click

is heard.

121F1B0154C

149

Page 152 of 284

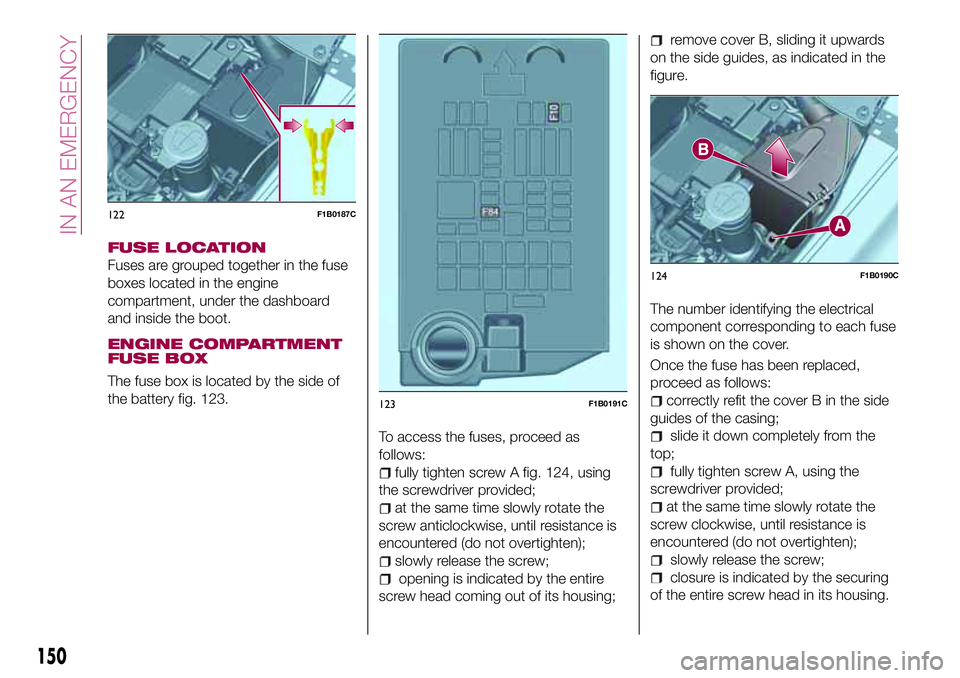

FUSE LOCATION

Fuses are grouped together in the fuse

boxes located in the engine

compartment, under the dashboard

and inside the boot.

ENGINE COMPARTMENT

FUSE BOX

The fuse box is located by the side of

the battery fig. 123.

To access the fuses, proceed as

follows:

fully tighten screw A fig. 124, using

the screwdriver provided;

at the same time slowly rotate the

screw anticlockwise, until resistance is

encountered (do not overtighten);

slowly release the screw;

opening is indicated by the entire

screw head coming out of its housing;

remove cover B, sliding it upwards

on the side guides, as indicated in the

figure.

The number identifying the electrical

component corresponding to each fuse

is shown on the cover.

Once the fuse has been replaced,

proceed as follows:

correctly refit the cover B in the side

guides of the casing;

slide it down completely from the

top;

fully tighten screw A, using the

screwdriver provided;

at the same time slowly rotate the

screw clockwise, until resistance is

encountered (do not overtighten);

slowly release the screw;

closure is indicated by the securing

of the entire screw head in its housing.

122F1B0187C

123F1B0191C

124F1B0190C

150

IN AN EMERGENCY

Page 155 of 284

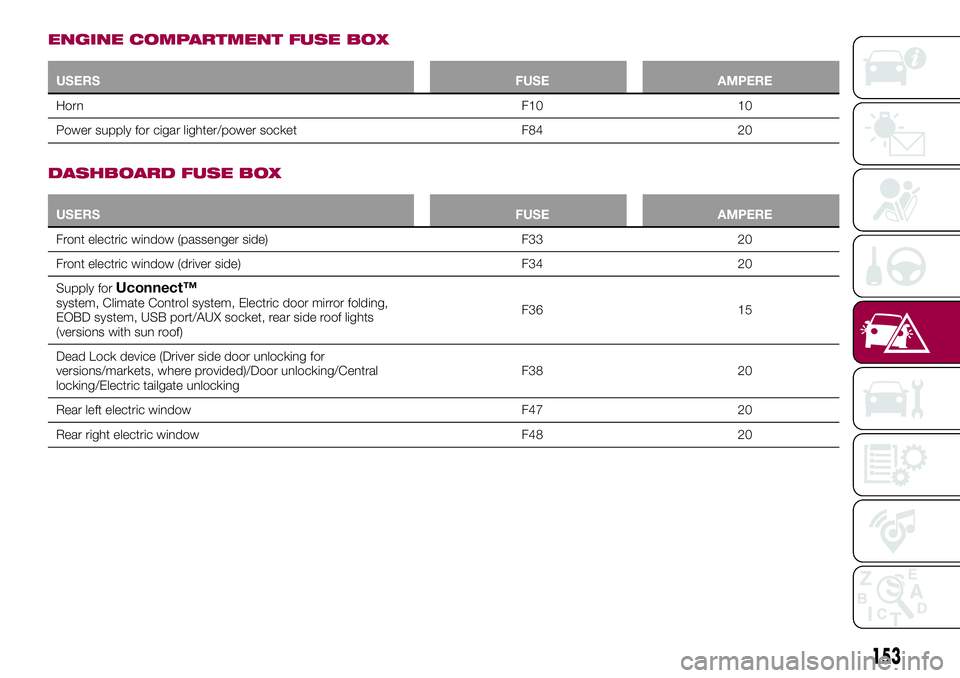

ENGINE COMPARTMENT FUSE BOX

USERSFUSE AMPERE

HornF10 10

Power supply for cigar lighter/power socket F84 20

DASHBOARD FUSE BOX

USERSFUSE AMPERE

Front electric window (passenger side) F33 20

Front electric window (driver side) F34 20

Supply for

Uconnect™system, Climate Control system, Electric door mirror folding,

EOBD system, USB port/AUX socket, rear side roof lights

(versions with sun roof)F36 15

Dead Lock device (Driver side door unlocking for

versions/markets, where provided)/Door unlocking/Central

locking/Electric tailgate unlockingF38 20

Rear left electric window F47 20

Rear right electric window F48 20

153

Page 157 of 284

WARNING

139)If the replaced fuse blows again,

contact a Fiat Dealership.

140)Never replace a fuse with another

with a higher amp rating; DANGER OF

FIRE

141)If a fuse NOT indicated in this or the

previous page is used, contact a Fiat

Dealership.

142)Before replacing a fuse, make sure

that the ignition device is at STOP, that the

key, if mechanical, has been removed and

that all devices are switched off and/or

disconnected.

IMPORTANT

66)Never replace a fuse with metal wires

or anything else.

67)If it is necessary to wash the engine

compartment, take care not to directly hit

the fuse box and the window wiper motor

with the water jet.

CHANGING A WHEEL

JACK

150) 151)

Please note that:

the jack weight is 2.8 kg;

the jack requires no adjustment;

the jack cannot be repaired and in

the event of a fault it must be replaced

by another genuine one;

no tool other than its cranking device

may be fitted on the jack.

Maintenance

prevent any dirt from depositing on

the "worm screw";

keep the "worm screw" lubricated;

never modify the jack.

Conditions for non-use

temperatures below −40°C;

on sandy or muddy ground;

on uneven ground;

on steep roads;

in extreme weather conditions:

thunderstorms, typhoons, hurricanes,

blizzards, storms, etc...

in direct contact with the engine or

for repairs under the car;

on boats.

CHANGING PROCEDURE

143) 144) 145) 146) 147) 148) 149)

Proceed as follows:

stop the vehicle in a position that is

not dangerous for oncoming traffic

where you can change the wheel safely.

The ground should be flat if possible,

and sufficiently firm;

stop the engine, engage the hazard

warning lights and the electric parking

brake;

engage first gear or reverse or, for

versions with automatic transmission,

move the lever to position P (Park);

wear the reflective safety jacket

(compulsory by law in certain countries)

before getting out of the vehicle;

open the boot and position the

reconfigurable load platform in an

inclined position (see "Boot" in the

"Knowing your vehicle" chapter);

take the tool bag provided, which is

secured to the luggage compartment

cover with specific fastenings. This bag

contains fig. 128: jack A; screwdriver B;

adaptor C for refuelling in the event of

an emergency; pin D for centring the

wheel (where provided, to be used in

the spare wheel fitting procedure);

special anti-theft nut E (where provided,

to be used in the wheel stud bolt

fitting/removal procedure); wedge F

wheels and the vehicle;

155

(where provided) for blocking the