boot FIAT BARCHETTA 2003 1.G User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 2003, Model line: BARCHETTA, Model: FIAT BARCHETTA 2003 1.GPages: 170, PDF Size: 3.55 MB

Page 77 of 170

76

Here are some suggestions which

may help you to keep the running

costs of your vehicle down and low-

er the amount of toxic emissions re-

leased into the atmosphere.

GENERAL

CONSIDERATIONS

Car maintenance

The overall state of the car is an im-

portant factor which has a marked in-

fluence over fuel consumption and dri-

ving comfort and on the life span of

your car. For this reason care should

be taken to maintain your car by car-

rying out the necessary checks and

regulations in accordance with the

specifications given in the Scheduled

Maintenance Programme (see sec-

tions... spark plugs, idle, air filter, tim-

ing).

CONTAINING RUNNING COSTS

AND POLLUTION

Tyres

Tyres should be checked at least

every four weeks: if the pressure is

too low fuel consumption increases as

the resistance to the rolling movement

of the tyre is greater. In this state, tyre

wear is increased and car handling suf-

fers which will affect safety.

Unnecessary loads

Do not travel with too much luggage

stowed in the boot. The weight of the

vehicle (especially when driving in

town) and its trim greatly affects con-

sumption and stability. To get the most out of ABS:

– During emergency stops or when

grip conditions are poor, you will feel

a slight pulsation on the brake pedal.

This is the sign that the ABS is in ac-

tion. Do not release the brake pedal

but continue to press so as not to in-

terrupt the braking action.

– ABS prevents the wheels from

locking but it does not increase actu-

al grip conditions between tyre and

road. Therefore, even if your car is fit-

ted with ABS, respect the safety dis-

tance from the car in front of you and

keep your speed down when driving

into bends.

– ABS serves to increase the con-

trollability of the car, not to enable you

to go faster.

Page 89 of 170

88

CHANGING A WHEEL

Please note:

– the jack weighs 1.85 kg;

– the jack requires no adjustments;

– the jack cannot be repaired. If it

breaks it must be replaced with a new

jack;

– no other tool, part from the han-

dle shown in this chapter can be fitted

to the jack.

Change the wheel as follows:

1)Stop the vehicle so that it is not

a hazard for other road users or your-

self when changing the wheel. The

ground should be as flat and firm as

possible.2)Stop the engine and engage the

handbrake.

3)Engage first gear or reverse.

4)Lift the boot carpet.

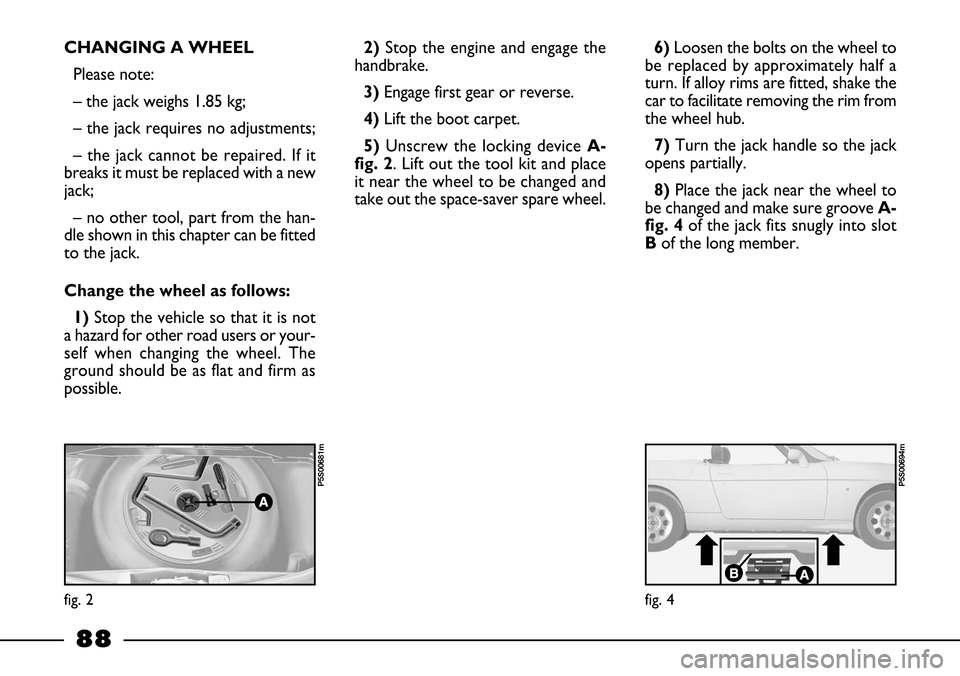

5)Unscrew the locking device A-

fig. 2. Lift out the tool kit and place

it near the wheel to be changed and

take out the space-saver spare wheel.6)Loosen the bolts on the wheel to

be replaced by approximately half a

turn. If alloy rims are fitted, shake the

car to facilitate removing the rim from

the wheel hub.

7)Turn the jack handle so the jack

opens partially.

8)Place the jack near the wheel to

be changed and make sure groove A-

fig. 4of the jack fits snugly into slot

Bof the long member.

fig. 2

P5S00681m

fig. 4

P5S00694m

Page 91 of 170

90

3)Screw up the bolts with the span-

ner provided.

4) Lower the vehicle and remove the

jack.

5)Tighten up the bolts in the same

order as shown above.When you have finished

1)Put the space-saver spare wheel

back in the boot.

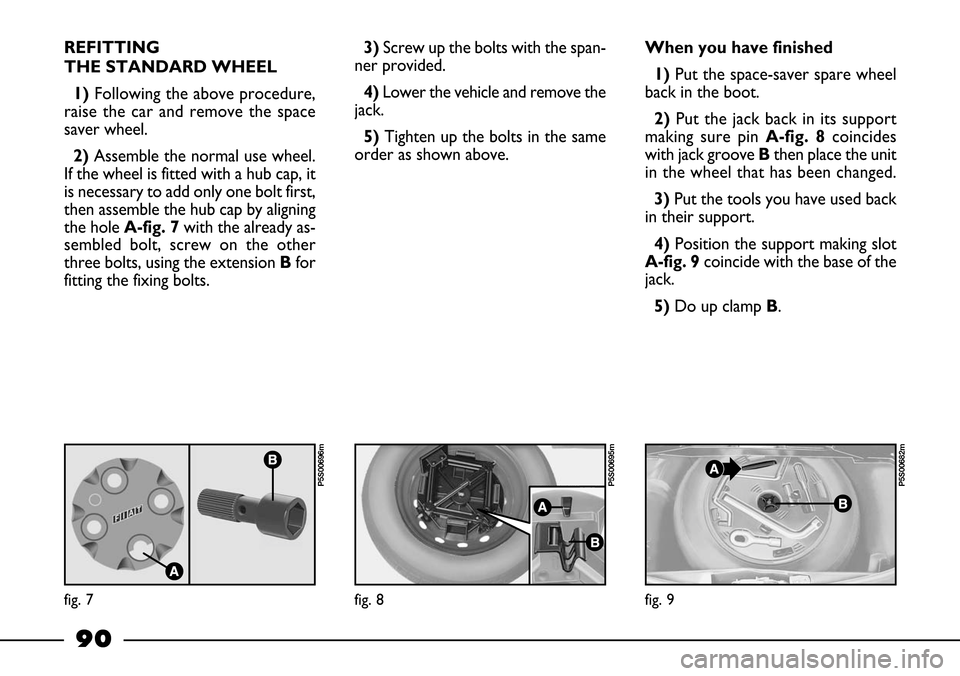

2) Put the jack back in its support

making sure pin A-fig. 8coincides

with jack groove Bthen place the unit

in the wheel that has been changed.

3) Put the tools you have used back

in their support.

4)Position the support making slot

A-fig. 9coincide with the base of the

jack.

5)Do up clamp B. REFITTING

THE STANDARD WHEEL

1) Following the above procedure,

raise the car and remove the space

saver wheel.

2)Assemble the normal use wheel.

If the wheel is fitted with a hub cap, it

is necessary to add only one bolt first,

then assemble the hub cap by aligning

the hole A-fig. 7with the already as-

sembled bolt, screw on the other

three bolts, using the extension Bfor

fitting the fixing bolts.

fig. 7

P5S00696m

fig. 8

P5S00695m

fig. 9

P5S00682m

Page 114 of 170

113

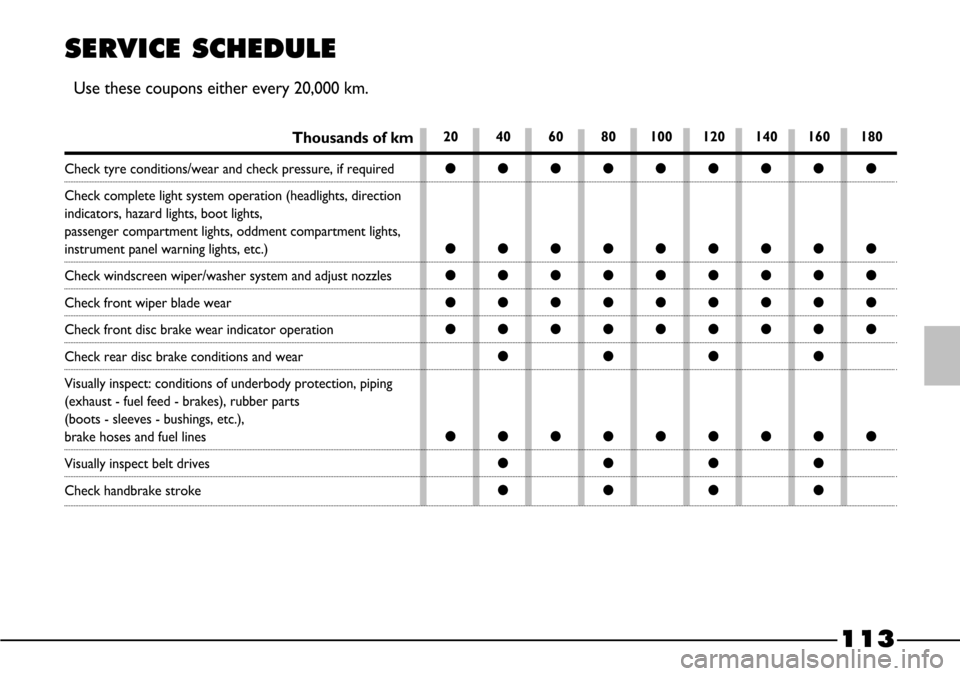

SERVICE SCHEDULE

Use these coupons either every 20,000 km.

Thousands of km20 40 60 80 100 120 140 160 180

Check tyre conditions/wear and check pressure, if required

Check complete light system operation (headlights, direction

indicators, hazard lights, boot lights,

passenger compartment lights, oddment compartment lights,

instrument panel warning lights, etc.)

Check windscreen wiper/washer system and adjust nozzles

Check front wiper blade wear

Check front disc brake wear indicator operation

Check rear disc brake conditions and wear

Visually inspect: conditions of underbody protection, piping

(exhaust - fuel feed - brakes), rubber parts

(boots - sleeves - bushings, etc.),

brake hoses and fuel lines

Visually inspect belt drives

Check handbrake stroke

ççççççççç

ççççççççç

ççççççççç

ççççççççç

ççççççççç

çççç

ççççççççç

çççç

çççç

Page 116 of 170

115

ANNUAL

INSPECTION

SCHEDULE

The following annual inspection

schedule is required for cars travelling

less than 20,000 km a year (e.g. ap-

proximately 10,000 km). The schedule

includes the following operations:

– Check tyre condition and wear and

adjust pressure, if required (including

spare-saver spare wheel).

– Check operation of lights (head-

lights, direction indicators, hazard

lights, boot light, passenger compart-

ment ceiling light, glove compartment

light, instrument panel lights, etc.).

– Check windscreen wiper/washer

and adjust nozzles.

– Check position wear of windscreen

window wiper blades.

ADDITIONAL

OPERATIONS

Every 1,000 kmor before long

trips, check and top up as necessary:

– coolant level

– brake fluid level

– power steering fluid level

– electrolyte level

– windscreen washer liquid level

– tyre condition and pressure.

We advise you to use FL Selenia

products, which have been designed

and produced expressly for the Fiat

vehicles (see the table “Capacities” giv-

en in the “Technical specifications”

section).

Every 3,000 km check and top up

as necessary: engine oil level. – Check rear brake pad conditions

and wear.

– Inspect conditions of. engine, gear-

box, transmission, piping (exhaust - fu-

el feed - brakes), rubber parts (boots

- sleeves - bushings - etc.), brake and

fuel line hoses.

– Check battery charge status.

– Check conditions of various con-

trol belts.

– Check and top up fluid levels (en-

gine coolant, brakes, windscreen

washer, battery, etc.).

– Change engine oil.

– Replace engine oil filter.

– Replace pollen filter (where fitted).

Page 125 of 170

124

USEFUL ADVICE

FOR LENGTHENING THE

LIFE OF YOUR BATTERY

When you park the car, ensure the

doors, boot and bonnet are closed

properly. The courtesy light must be

off.

Do not keep accessories (e.g. radio,

hazard lights etc.) switched on for a

long time when the engine is not run-

ning.

IMPORTANT A battery which is

kept at a charge of less than 50% for

any length of time will be damaged by

sulphation leading to a reduction in

cranking power and a higher risk of

the battery electrolyte freezing (this

may even occur at –10°C).

If the car is inactive for a long peri-

od of time, refer to “Storing the car”

in the “Driving your car” chapter.If, after purchasing your car you

would like to add electrical accessories

that require a permanent power sup-

ply (alarm systems, hands-free phone,

radio navigator with satellite anti-theft

system, etc.), visit a Fiat Dealership.

The staff of experts, besides suggest-

ing the most suitable accessories in the

Lineaccessori range, will also check

whether the car electrical system can

support the required load or if a larg-

er size battery needs to be installed.

These devices will, in fact, run off the

battery even when the key is not in-

serted (car parked) and can deploy the

battery.

Incorrect fitting of elec-

trical and electronic ac-

cessories can seriously

damage the car.Batteries contain sub-

stances that are very

harmful for the environ-

ment. You are advised to have the

battery changed at a Fiat Dealer-

ship. It is properly equipped for

disposing of used batteries in an

environmentally-friendly way that

complies with the law.

Do not attempt to recharge

a frozen battery. Thaw it

first otherwise it could explode. If

the battery froze, make sure the in-

ternal elements are not broken

(short-circuit risk) and that the cas-

ing is not cracked (risk of spilling

the poisonous and corrosive fluid).

WARNING

Page 133 of 170

132

Windows

Use specific window cleaners to

clean the windows. Use very clean

cloths to avoid scratching the glass or

damaging its transparency.

Engine compartment

At the end of each winter season,

carefully clean the engine compart-

ment. Have this done at a garage.Detergents pollute wa-

ter. The car must there-

fore be washed in an area

equipped for the collection and

purification of the liquids used

while washing.

IMPORTANTThe car should be

washed while the engine is cold and

with the ignition key at STOP. After

washing the car, make sure that the

various protections (e.g. rubber boots

and various guards) have not been re-

moved or damaged. Outside plastic parts must be cleaned

following the usual car washing pro-

cedure.

Avoid parking your car under trees;

the resinous substances that often

drop will dull the paintwork and in-

crease the possibility of corrosion.

IMPORTANT Bird droppings must

be washed off immediately and with

great care as their acid is particularly

aggressive.

Page 143 of 170

142

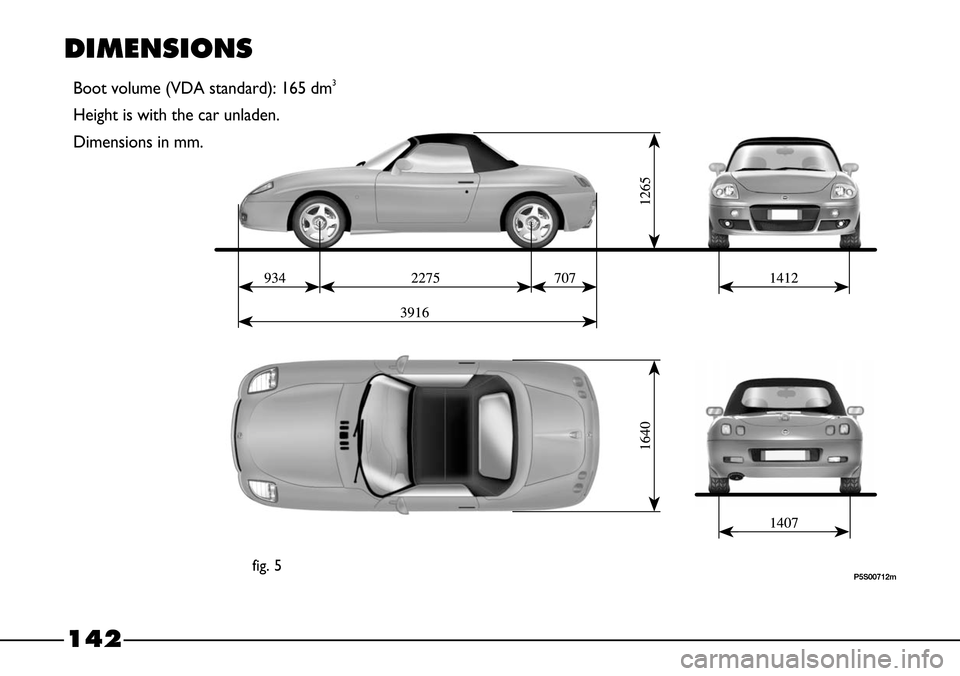

fig. 5P5S00712m

DIMENSIONS

Boot volume (VDA standard): 165 dm3

Height is with the car unladen.

Dimensions in mm.

Page 144 of 170

143

Kerb weight

(including fuel, space-saver spare wheel, tools and accessories):

Payload (*) including the driver:

Maximum loads permitted (**)

– front axle:

– rear axle:

– total:

Towable weight

– trailer with brakes:

– trailer without brakes:

Maximum load on the ball joint

(trailer with brakes):

(*) If special equipment is fitted (tow hitch etc.) the unladen weight increases, thus reducing the payload as specified in the maximum loads allowed.

(**) Loads not to be exceeded: the driver must arrange the goods in the boot so that they comply with these limits.

WEIGHTS

Weights (kg)

1060

200

850

700

1260

450

400

35

Page 151 of 170

150

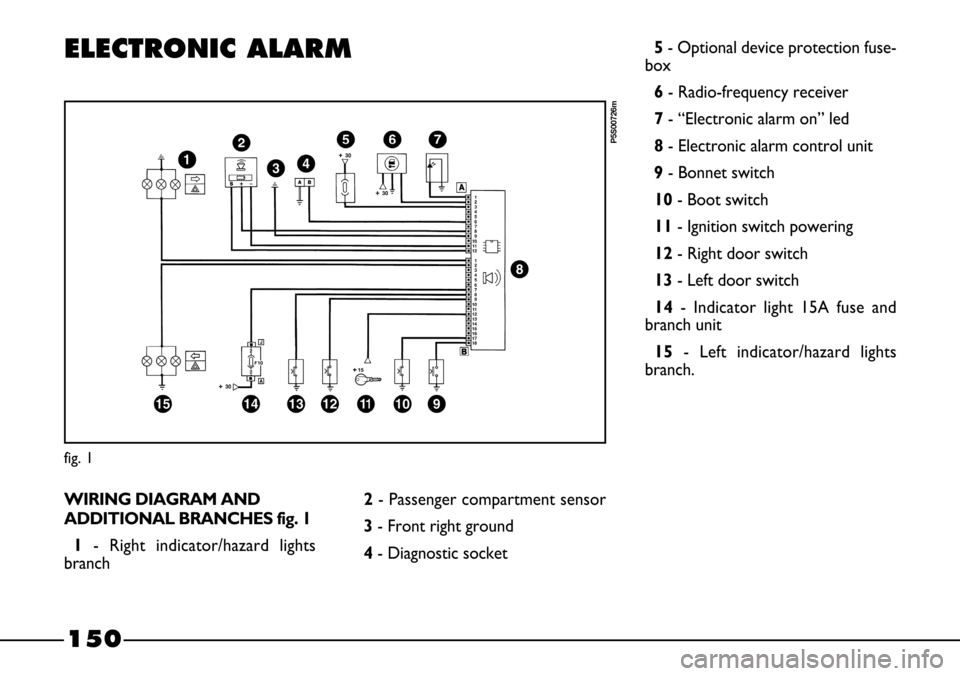

ELECTRONIC ALARM

WIRING DIAGRAM AND

ADDITIONAL BRANCHES fig. 1

1- Right indicator/hazard lights

branch

fig. 1

P5S00726m

2- Passenger compartment sensor

3- Front right ground

4- Diagnostic socket5- Optional device protection fuse-

box

6- Radio-frequency receiver

7- “Electronic alarm on” led

8- Electronic alarm control unit

9- Bonnet switch

10- Boot switch

11- Ignition switch powering

12- Right door switch

13- Left door switch

14- Indicator light 15A fuse and

branch unit

15 - Left indicator/hazard lights

branch.