brake FIAT DOBLO COMBI 2015 2.G Owner's Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2015, Model line: DOBLO COMBI, Model: FIAT DOBLO COMBI 2015 2.GPages: 323, PDF Size: 46.77 MB

Page 155 of 323

ACOUSTIC SIGNAL

When reverse gear is engaged an

intermittent acoustic signal is

automatically activated.

The frequency of the acoustic signal:

❒increases as the distance between

the vehicle and the obstacle

decreases;

❒becomes continuous when the

distance between the vehicle and the

obstacle is less than 30 cm and

stops immediately if the distance

increases;

❒is constant if the distance between

the vehicle and the obstacle is

unchanged;

❒whereas, if this situation occurs for

the side sensors, the indication will

stop after about 3 seconds to avoid,

for example, warning indications in

the event of manoeuvres alongside

walls.

Detection distances

If several obstacles are detected by

the sensors, only the nearest one

is considered.FAULT INDICATIONS

Any parking sensor faults will be

indicated when reverse is engaged

by the warning light in the

instrument panel switching on

together with the message in the

multifunction display, for

versions/markets, where provided

(see chapter "Warning lights and

messages”).

97)

OPERATION WITH

TRAILER

Parking sensor operation is

automatically deactivated when the

electric cable plug of the trailer is

inserted into the vehicle tow hook

socket. The sensors are

automatically reactivated when the

trailer's cable plug is removed.

IMPORTANT

If you wish to leave the tow hook

fitted without towing a trailer, it

is advisable to contact a Fiat

Dealership for the relevant system

update operations because the tow

hook could be detected as an

obstacle by the central sensors.GENERAL WARNINGS

98)

❒When parking, take the utmost care

over obstacles that may be above or

under the sensor.

❒Sometimes, objects located very

near the rear of the vehicle are not

detected and could therefore

damage the vehicle or be damaged

themselves.

The following conditions may

influence the performance of the

parking assistance system:

❒Reduced sensor sensitivity and a

reduction in the parking assistance

system performance could be due to

the presence on the surface of the

sensor of: ice, snow, mud, thick

paint.

❒The sensor may detect a non-

existent obstacle (echo noise) due to

mechanical noises, for example

when washing the vehicle, in case of

rain, strong wind, hail.

❒The signals sent out by the sensors

can be altered by dirt, snow or ice

deposited on the sensors or by

ultrasound systems (e.g. truck

pneumatic brakes or pneumatic drills)

near the vehicle.

151

Page 160 of 323

TOWING TRAILERS

IMPORTANT

The vehicle must be equipped with

a type-approved tow hook and

adequate electrical system to tow

trailers. Installation should be carried

out by specialised personnel who

will issue the required papers for

travelling on roads.

Install any specific and/or additional

door mirrors as specified by the

Highway Code.

Remember that when towing a

trailer, steep hills are harder to climb,

braking spaces increase and

overtaking takes longer depending

on the overall weight.

Engage a low gear when driving

downhill, rather than constantly

using the brake.

The weight of the trailer on the

vehicle tow hook will reduce the

loading capacity of the vehicle by

the same amount.To make sure that the maximum

towable weight is not exceeded

(given in the vehicle registration

document) account should be taken

of the fully laden trailer, including

accessories and luggage.

Do not exceed the speed limits

specific to each country you are

driving in, in the case of vehicles

towing trailers. In any case, the top

speed must not exceed 80 km/h.

99) 100)

WARNING

99) The ABS device with which the

vehicle is equipped will not

control the braking system of the

trailer. Particular caution is

required on slippery roads.

100) Never modify the braking

system of the vehicle to control

the trailer brake. The trailer

braking system must be fully

independent from the hydraulic

system of the vehicle.

SNOW TYRES

Fiat Dealerships will be happy to

provide advice concerning the most

suitable type of tyres for the

customer's requirements.

For the type of tyre to be used,

inflation pressures and the

specifications of snow tyres, follow

the instructions given in the

"Wheels" paragraph of the

"Technical specifications" section.

The winter features of these tyres

are reduced considerably when the

tread depth is below 4 mm. Replace

them in this case.

Due to snow tyre characteristics,

under normal conditions of use

or on long motorway journeys, the

performance of these tyres is lower

than that of standard tyres. Limit

performance according to the use

for which they were approved.

156

STARTING AND DRIVING

Page 166 of 323

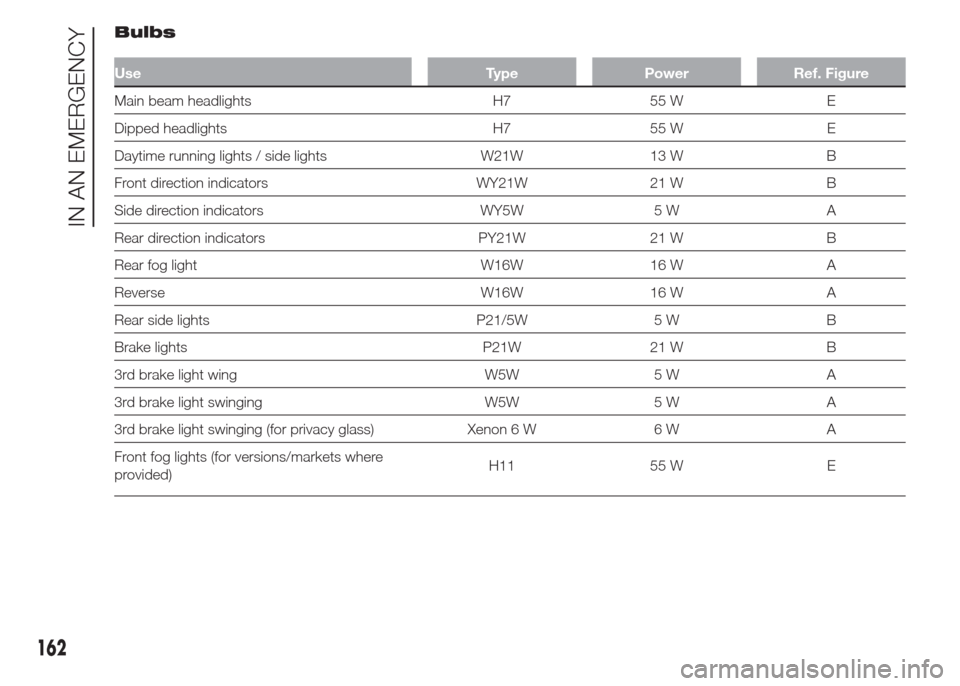

Bulbs

Use Type Power Ref. Figure

Main beam headlights H7 55 W E

Dipped headlights H7 55 W E

Daytime running lights / side lights W21W 13 W B

Front direction indicators WY21W 21 W B

Side direction indicators WY5W 5 W A

Rear direction indicators PY21W 21 W B

Rear fog light W16W 16 W A

Reverse W16W 16 W A

Rear side lights P21/5W 5 W B

Brake lights P21W 21 W B

3rd brake light wing W5W 5 W A

3rd brake light swinging W5W 5 W A

3rd brake light swinging (for privacy glass) Xenon 6 W 6 W A

Front fog lights (for versions/markets where

provided)H11 55 W E

162

IN AN EMERGENCY

Page 168 of 323

DIRECTION

INDICATORS

Front

To replace the bulb, proceed as

follows:

❒remove the protective cover C fig.

152;

❒turn bulb holder A fig. 155

anticlockwise and remove it;

❒extract the bulb, pushing it gently

and turning it anticlockwise;

❒replace the bulb and refit the bulb

holder A fig. 155 by turning it

clockwise and locking it properly into

place;

❒refit the protective cover C fig. 152.

Side

IMPORTANT Go to a Fiat Dealership

to have bulbs for the side direction

indicators replaced, because they

are located inside the wing mirror.

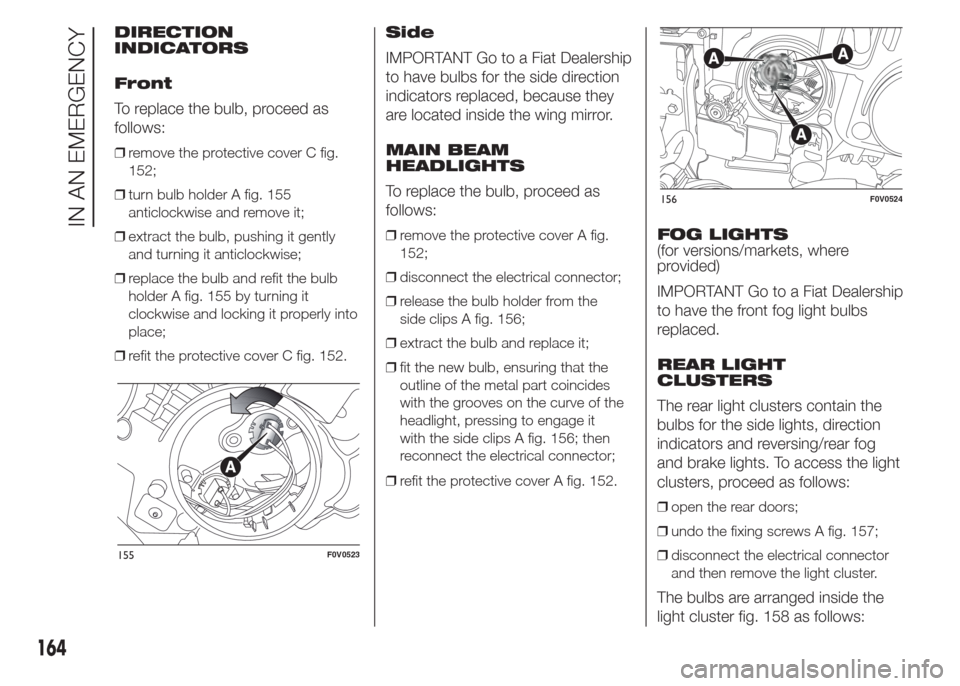

MAIN BEAM

HEADLIGHTS

To replace the bulb, proceed as

follows:

❒remove the protective cover A fig.

152;

❒disconnect the electrical connector;

❒release the bulb holder from the

side clips A fig. 156;

❒extract the bulb and replace it;

❒fit the new bulb, ensuring that the

outline of the metal part coincides

with the grooves on the curve of the

headlight, pressing to engage it

with the side clips A fig. 156; then

reconnect the electrical connector;

❒refit the protective cover A fig. 152.FOG LIGHTS

(for versions/markets, where

provided)

IMPORTANT Go to a Fiat Dealership

to have the front fog light bulbs

replaced.

REAR LIGHT

CLUSTERS

The rear light clusters contain the

bulbs for the side lights, direction

indicators and reversing/rear fog

and brake lights. To access the light

clusters, proceed as follows:

❒open the rear doors;

❒undo the fixing screws A fig. 157;

❒disconnect the electrical connector

and then remove the light cluster.

The bulbs are arranged inside the

light cluster fig. 158 as follows:

155F0V0523

156F0V0524

164

IN AN EMERGENCY

Page 169 of 323

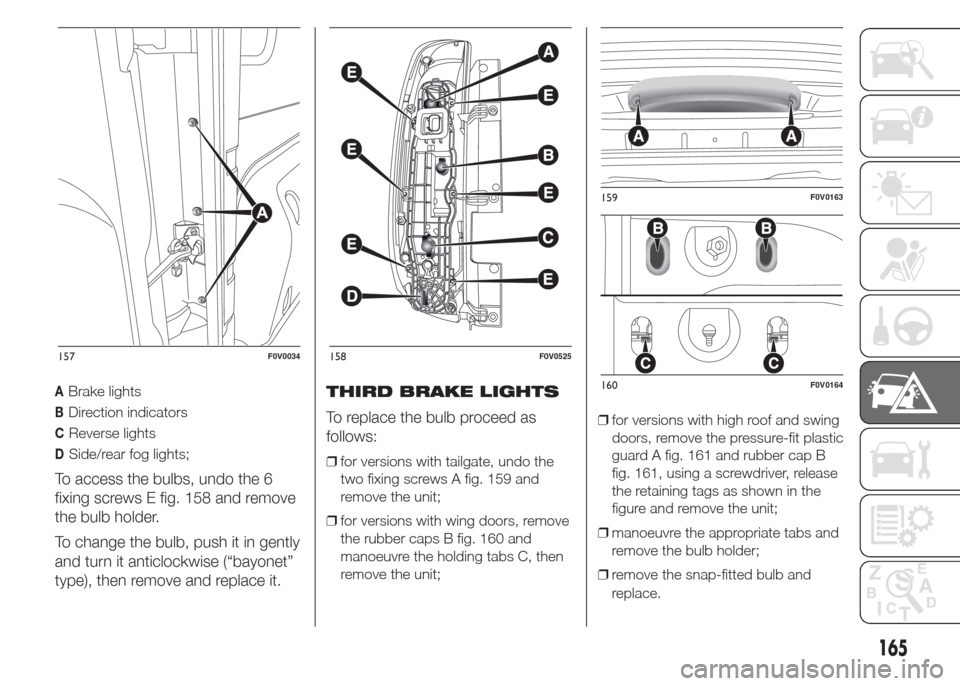

ABrake lights

BDirection indicators

CReverse lights

DSide/rear fog lights;

To access the bulbs, undo the 6

fixing screws E fig. 158 and remove

the bulb holder.

To change the bulb, push it in gently

and turn it anticlockwise (“bayonet”

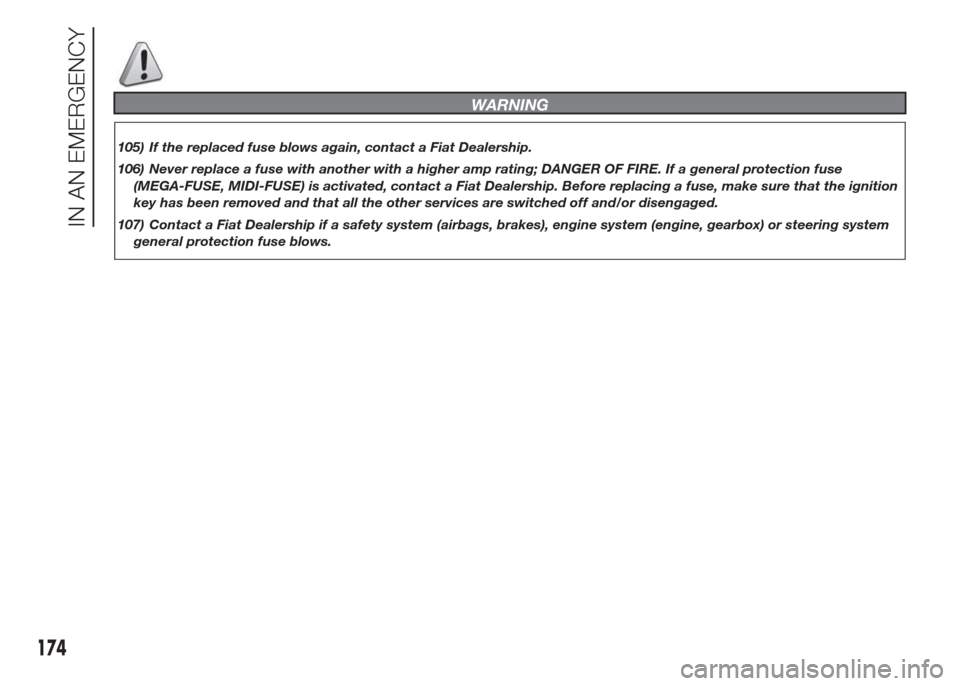

type), then remove and replace it.THIRD BRAKE LIGHTS

To replace the bulb proceed as

follows:

❒for versions with tailgate, undo the

two fixing screws A fig. 159 and

remove the unit;

❒for versions with wing doors, remove

the rubber caps B fig. 160 and

manoeuvre the holding tabs C, then

remove the unit;❒for versions with high roof and swing

doors, remove the pressure-fit plastic

guard A fig. 161 and rubber cap B

fig. 161, using a screwdriver, release

the retaining tags as shown in the

figure and remove the unit;

❒manoeuvre the appropriate tabs and

remove the bulb holder;

❒remove the snap-fitted bulb and

replace.

157F0V0034158F0V0525

159F0V0163

160F0V0164

165

Page 178 of 323

WARNING

105) If the replaced fuse blows again, contact a Fiat Dealership.

106) Never replace a fuse with another with a higher amp rating; DANGER OF FIRE. If a general protection fuse

(MEGA-FUSE, MIDI-FUSE) is activated, contact a Fiat Dealership. Before replacing a fuse, make sure that the ignition

key has been removed and that all the other services are switched off and/or disengaged.

107) Contact a Fiat Dealership if a safety system (airbags, brakes), engine system (engine, gearbox) or steering system

general protection fuse blows.

174

IN AN EMERGENCY

Page 179 of 323

CHANGING A WHEEL

The vehicle is originally equipped

with the Fix&Go automatic quick

tyre repair kit (see instructions in the

next section). As an alternative,

the vehicle may have a normal-sized

spare wheel.

Wheel changing and correct use of

the jack and spare wheel call for

some precautions, as listed below.

108) 109) 110) 111)

Note for one-way

tyres

One-way tyres have a few arrows on

the side indicating the rotation

direction. If a wheel is changed

(when punctured, for example) the

direction of the arrows on the spare

wheel tyre may not coincide with

the rotation direction of the wheel to

be replaced.

In these conditions, too, the tyre still

maintains its safety features.Anyway, it is recommended to have

the wheel repaired and refitted as

soon as possible, as the best

performance is achieved when the

rotation direction of all tyres

coincides with the one indicated by

the arrows.

Please note that:

❒the jack weight is 4 kg;

❒the jack requires no adjustment;

❒the jack cannot be repaired and in

the event of a fault it must be

replaced by another original one;

❒no tool other than its cranking device

may be fitted on the jack.

To change a wheel, proceed as

follows:

❒stop the vehicle in a position that is

not dangerous for oncoming traffic

where you can change the wheel

safely. The ground should be flat

if possible, and sufficiently firm;

❒stop the engine and pull the

handbrake;

❒engage first gear or reverse;

❒wear the reflective safety jacket

(compulsory by law in certain

countries) before getting out of the

vehicle;❒indicate that the vehicle has broken

down using the devices required by

the law in the current country (e.g.

warning triangle, hazard lights, etc.);

❒for Cargo versions fig. 180: move the

left front seat forward and operate

lever A to access the tool bag; take it

to the wheel that needs replacing;

❒for Doblò/Doblò Combi versions fig.

181: open the rear doors, inside the

compartment on the rear right side,

take the tool bag, unhooking the

elastic band from the buckle, and

take it next to the wheel to be

changed;

❒take wheel spanner B fig. 182 and

the extension with pentagonal fitting

C; inside the load area, fit extension

C on bolt A; use spanner B to lower

the wheel by unwinding the wire;

180F0V0149

175

Page 184 of 323

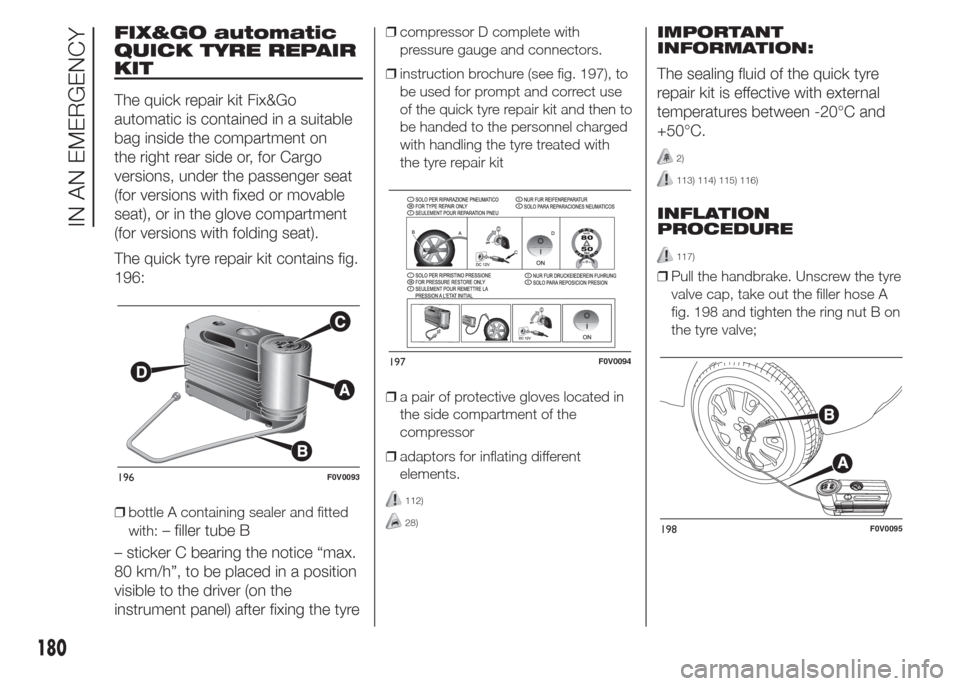

FIX&GO automatic

QUICK TYRE REPAIR

KIT

The quick repair kit Fix&Go

automatic is contained in a suitable

bag inside the compartment on

the right rear side or, for Cargo

versions, under the passenger seat

(for versions with fixed or movable

seat), or in the glove compartment

(for versions with folding seat).

The quick tyre repair kit contains fig.

196:

❒bottle A containing sealer and fitted

with:

– filler tube B

– sticker C bearing the notice “max.

80 km/h”, to be placed in a position

visible to the driver (on the

instrument panel) after fixing the tyre

❒compressor D complete with

pressure gauge and connectors.

❒instruction brochure (see fig. 197), to

be used for prompt and correct use

of the quick tyre repair kit and then to

be handed to the personnel charged

with handling the tyre treated with

the tyre repair kit

❒a pair of protective gloves located in

the side compartment of the

compressor

❒adaptors for inflating different

elements.

112)

28)

IMPORTANT

INFORMATION:

The sealing fluid of the quick tyre

repair kit is effective with external

temperatures between -20°C and

+50°C.

2)

113) 114) 115) 116)

INFLATION

PROCEDURE

117)

❒Pull the handbrake. Unscrew the tyre

valve cap, take out the filler hose A

fig. 198 and tighten the ring nut B on

the tyre valve;

196F0V0093

197F0V0094

198F0V0095

180

IN AN EMERGENCY

Page 185 of 323

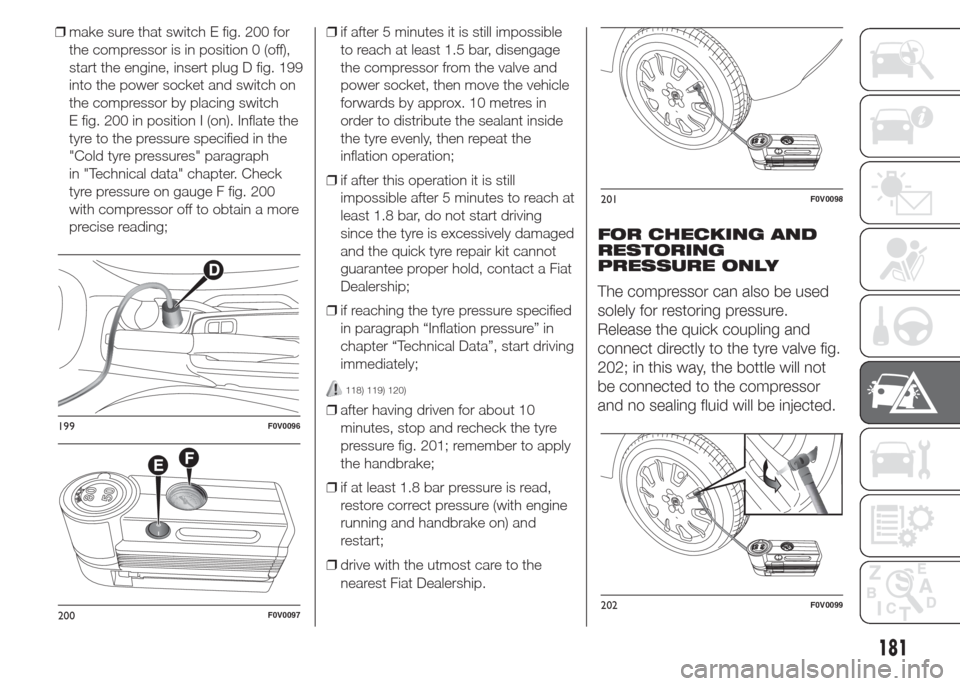

❒make sure that switch E fig. 200 for

the compressor is in position 0 (off),

start the engine, insert plug D fig. 199

into the power socket and switch on

the compressor by placing switch

E fig. 200 in position I (on). Inflate the

tyre to the pressure specified in the

"Cold tyre pressures" paragraph

in "Technical data" chapter. Check

tyre pressure on gauge F fig. 200

with compressor off to obtain a more

precise reading;❒if after 5 minutes it is still impossible

to reach at least 1.5 bar, disengage

the compressor from the valve and

power socket, then move the vehicle

forwards by approx. 10 metres in

order to distribute the sealant inside

the tyre evenly, then repeat the

inflation operation;

❒if after this operation it is still

impossible after 5 minutes to reach at

least 1.8 bar, do not start driving

since the tyre is excessively damaged

and the quick tyre repair kit cannot

guarantee proper hold, contact a Fiat

Dealership;

❒if reaching the tyre pressure specified

in paragraph “Inflation pressure” in

chapter “Technical Data”, start driving

immediately;

118) 119) 120)

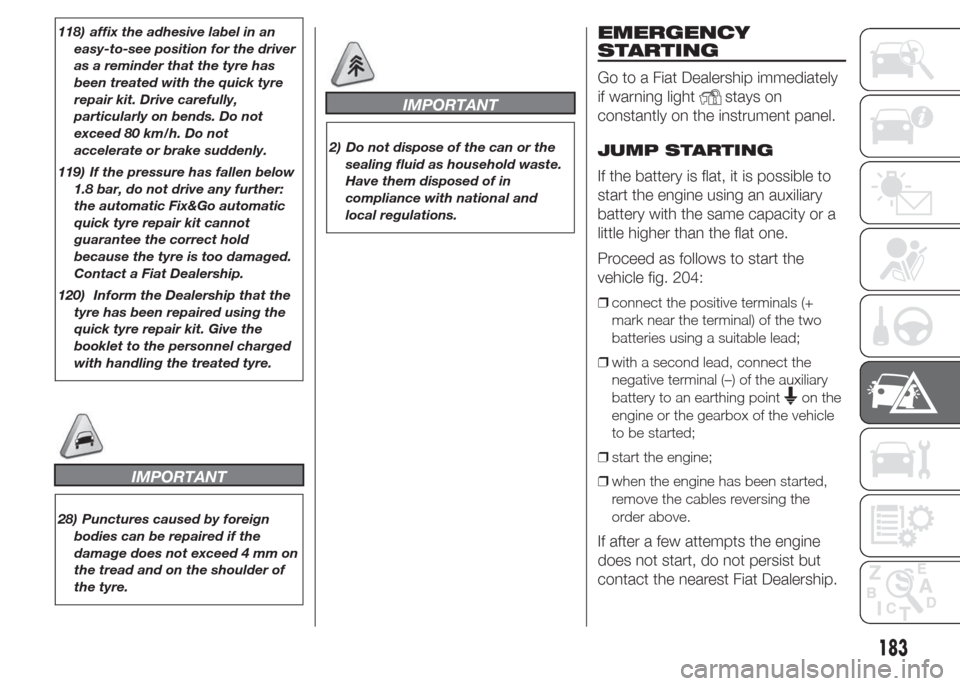

❒after having driven for about 10

minutes, stop and recheck the tyre

pressure fig. 201; remember to apply

the handbrake;

❒if at least 1.8 bar pressure is read,

restore correct pressure (with engine

running and handbrake on) and

restart;

❒drive with the utmost care to the

nearest Fiat Dealership.

FOR CHECKING AND

RESTORING

PRESSURE ONLY

The compressor can also be used

solely for restoring pressure.

Release the quick coupling and

connect directly to the tyre valve fig.

202; in this way, the bottle will not

be connected to the compressor

and no sealing fluid will be injected.

199F0V0096

200F0V0097

201F0V0098

202F0V0099

181

Page 187 of 323

118) affix the adhesive label in an

easy-to-see position for the driver

as a reminder that the tyre has

been treated with the quick tyre

repair kit. Drive carefully,

particularly on bends. Do not

exceed 80 km/h. Do not

accelerate or brake suddenly.

119) If the pressure has fallen below

1.8 bar, do not drive any further:

the automatic Fix&Go automatic

quick tyre repair kit cannot

guarantee the correct hold

because the tyre is too damaged.

Contact a Fiat Dealership.

120) Inform the Dealership that the

tyre has been repaired using the

quick tyre repair kit. Give the

booklet to the personnel charged

with handling the treated tyre.

IMPORTANT

28) Punctures caused by foreign

bodies can be repaired if the

damage does not exceed 4 mm on

the tread and on the shoulder of

the tyre.

IMPORTANT

2) Do not dispose of the can or the

sealing fluid as household waste.

Have them disposed of in

compliance with national and

local regulations.

EMERGENCY

STARTING

Go to a Fiat Dealership immediately

if warning light

stays on

constantly on the instrument panel.

JUMP STARTING

If the battery is flat, it is possible to

start the engine using an auxiliary

battery with the same capacity or a

little higher than the flat one.

Proceed as follows to start the

vehicle fig. 204:

❒connect the positive terminals (+

mark near the terminal) of the two

batteries using a suitable lead;

❒with a second lead, connect the

negative terminal (–) of the auxiliary

battery to an earthing point

on the

engine or the gearbox of the vehicle

to be started;

❒start the engine;

❒when the engine has been started,

remove the cables reversing the

order above.

If after a few attempts the engine

does not start, do not persist but

contact the nearest Fiat Dealership.

183