spare wheel FIAT DOBLO COMBI 2017 2.G Owners Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2017, Model line: DOBLO COMBI, Model: FIAT DOBLO COMBI 2017 2.GPages: 300, PDF Size: 24.91 MB

Page 139 of 300

The TPMS uses wireless devices with

electronic sensors mounted on the

wheel rims to constantly monitor the

value of tyre pressure. The sensors

mounted on each wheel as part of the

valve stem transmit various information

of the tyres to the receiver module, in

order to calculate the pressure.

IMPORTANT Monitoring and

maintaining the correct pressure in all

four tyres are particularly important.

Tyre pressure monitoring system

low pressure warning

The system warns the driver if one or

more tyres are flat by switching on

the warning light

on the instrument

panel (together with a warning message

and an acoustic signal).The TPMS continues to advise the

driver of the low tyre pressure condition

until this is corrected; the warning

continues until the pressure

corresponds or exceeds the pressure

prescribed for the cold tyres. When the

tyre low pressure control warning

light

switches on constantly, the

inflation pressure must be adjusted until

it reaches the pressure prescribed for

cold tyres. After the automatic update

of the system, the tyre pressure control

warning light switches off. You may

need to drive the vehicle for about 20

minutes at a speed higher than 20

km/h to allow the TPMS to receive this

information.

IMPORTANT In the case of deflation of

more than one tyre sequentially, without

switching off and on the engine, from

the second tyre involved the acoustic

signal is not activated, only the

dedicated signal is shown on the

display.

To prevent the signal from being stored

in the event of pressure loss of a

subsequent tyre (with deactivation of

the acoustic signal), the ignition key

must be turned to MAR and then to

STOP, each time pressure is restored.TPMS operation faults

The system fault is indicated by

warning light

which first flashes for

75 seconds and then stays on steadily.

This can occur in any of the following

situations:

interference caused by electronic

devices or radio frequency emissions

similar to those of the TPM sensors.

Application of tinted films which

interfere with the signals of the radio

waves.

Presence of snow or ice on the

wheels or the wheel arches.

Use of snow chains.

Use of wheels/tyres not equipped

with TPM sensors.

The space-saver wheel is not

equipped with the tyre pressure control

sensor. Therefore, the tyre pressure is

not controlled by the system.

NOTE The vehicle may be equipped

with FiX&Go Automatic tyre repair

kit, space-saver wheel or full size spare

wheel (with or without original TPMS

sensor to measure tyre pressure).

After the punctured tyre has been

repaired with the original tyre sealant

contained in the FiX&Go Automatic tyre

repair kit, the previous condition must

be restored, so that the

warning

light is off during normal driving.

135

Page 140 of 300

Space-saver wheel (for versions/

markets, where provided): the

space-saver wheel is not equipped with

a TPMS sensor. Once fitted, while

driving normally, the warning light

comes on (flashing for about 75

seconds, and then constantly). This

condition lasts until a wheel equipped

with an original TPMS sensor is fitted

on the vehicle.

Normal spare wheel (without TPMS

sensor): once fitted, while driving

normally, the

warning light comes on

(flashing for about 75 seconds, and

then constantly). This condition lasts

until a wheel equipped with an original

TPMS sensor is fitted on the vehicle.

The system is then restored and the

warning light switches off.

Normal spare wheel (with TPMS

sensor): once fitted, while driving

normally, the

warning light switches

off.

IMPORTANT In all the above-mentioned

cases, it is advisable to check the

spare wheel tyre pressure before

starting driving.

NOTE If the tyres are replaced, driving

the vehicle for short stretches, some

time might be needed before the

system is restored.IMPORTANT

WARNING

103)The TPMS is optimised for the

original tyres and wheels provided. TPMS

pressures and alerts have been defined

according to the size of the tyres mounted

on the vehicle. Using equipment with

different size, type or kind may cause

irregular system operation or sensor

damage. Non-original spare wheels can

damage the sensor. Do not use tyre

sealant or balancing weights if the vehicle

is equipped with TPMS as these may

damage the sensors.

104)If the system signals a pressure

decrease on a specific tyre, it is

recommended to check the pressure on all

four tyres.

105)TPMS does not relieve the driver from

the obligation to check the tyre pressure

every month; it is not to be considered

a replacing system for maintenance or a

safety system.

106)Tyre pressure must be checked with

tyres cold. Should it become necessary for

whatever reason to check pressure with

warm tyres, do not reduce pressure even if

it is higher than the prescribed value, but

repeat the check when tyres are cold.

107)The TPMS cannot indicate sudden

tyre pressure drops (for example when

a tyre bursts). In this case, stop the vehicle,

braking with caution and avoiding abrupt

steering.108)The system only warns that the tyre

pressure is low: it is not able to inflate

them.

109)Insufficient tyre inflation increases fuel

consumption, reduces the tread duration

and may affect the capacity to drive safely.

110)Always refit the valve stem cap after

inspecting or adjusting tyre pressure.

This prevents dampness or dirt from

entering the valve stem and thus

the pressure control sensor from being

damaged.

111)The tyre repair kit (Fix&Go) provided

with the vehicle (for versions/markets,

where provided) is compatible with the

TPMS sensors; using sealants not

equivalent with that in the original kit may

adversely affect its operation. If sealants

not equivalent with the original one are

used, it is recommended to have the

TPMS sensor operation checked by a

qualified repair centre.

136

STARTING AND DRIVING

Page 166 of 300

CHANGING A WHEEL

The vehicle is originally equipped with

the Fix&Go automatic quick tyre repair

kit (see instructions in the next section).

As an alternative, the vehicle may

have a normal-sized spare wheel.

Wheel changing and correct use of the

jack and spare wheel call for some

precautions, as listed below.

125) 126) 127) 128)

Note for one-way tyres

One-way tyres have a few arrows on

the side indicating the rotation direction.

If a wheel is changed (when punctured,

for example) the direction of the arrows

on the spare wheel tyre may not

coincide with the rotation direction of

the wheel to be replaced.

In these conditions, too, the tyre still

maintains its safety features.

Anyway, it is recommended to have the

wheel repaired and refitted as soon as

possible, as the best performance is

achieved when the rotation direction of

all tyres coincides with the one

indicated by the arrows.

Please note that:

the jack weight is 4 kg;

the jack requires no adjustment;

the jack cannot be repaired and in

the event of a fault it must be replaced

by another original one;

no tool other than its cranking

device may be fitted on the jack.

To change a wheel, proceed as follows:

stop the vehicle in a position that is

not dangerous for oncoming traffic

where you can change the wheel safely.

The ground should be flat if possible,

and sufficiently firm;

stop the engine and pull the

handbrake;

engage first gear or reverse;

wear the reflective safety jacket

(compulsory by law in certain countries)

before getting out of the vehicle;

indicate that the vehicle has broken

down using the devices required by

the law in the current country (e.g.

warning triangle, hazard lights, etc.);

for Cargo versions fig. 187: move

the left front seat forward and operate

lever A to access the tool bag; take it to

the wheel that needs replacing;

for Doblò/Doblò Combi versions fig.

188: open the rear doors, inside the

compartment on the rear right side,

take the tool bag, unhooking the elastic

band from the buckle, and take it next

to the wheel to be changed;

take wheel spanner B fig. 189 and

the extension with pentagonal fitting C;

inside the load area, fit extension C

on bolt A; use spanner B to lower the

wheel by unwinding the wire;

use the wheel dismantling spanner B

to remove the wheel from the vehicle

fig. 190;

unscrew knob D fig. 191 and release

the rim from bracket E, removing it

from the hole of the rim;

187F0V0149

188F0V0148

162

IN AN EMERGENCY

Page 168 of 300

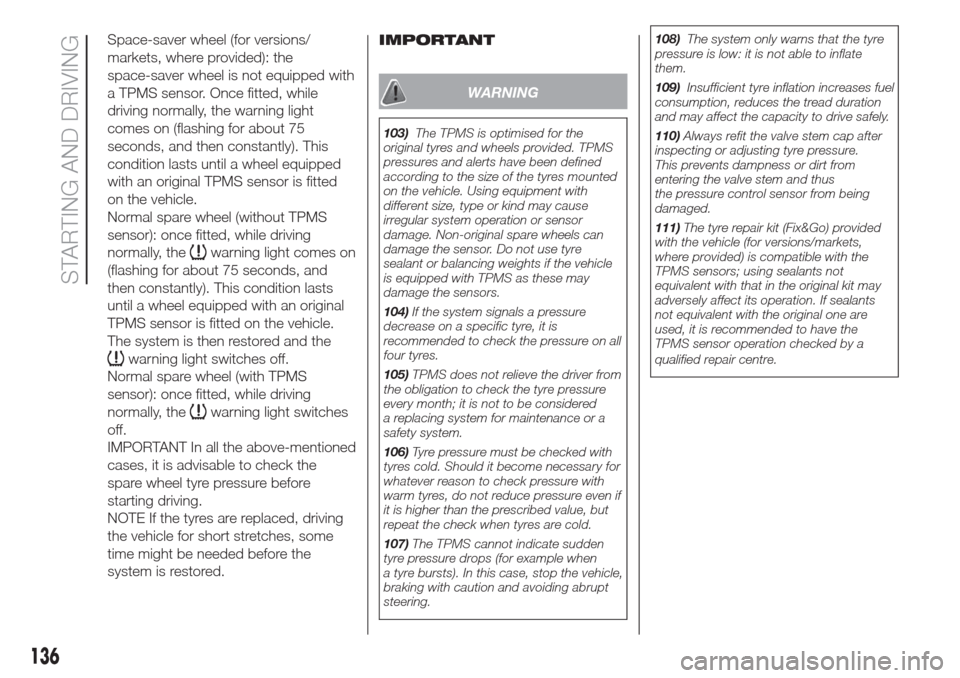

warn anybody nearby that the

vehicle is about to be lifted. They must

stay clear and not touch the vehicle

until it is back on the ground.

introduce the handle in the hole on

the nut and the plastic clip, then

operate the jack and raise the vehicle,

until the wheel is a few centimetres

off the ground. When turning the crank,

ensure that it rotates freely in order to

avoid grazing your hands against the

ground. The moving components of the

jack (screws and joints) can also cause

injuries: avoid touching them. If you

become soiled with the lubricating

grease, clean it off thoroughly;

fully loosen the fixing bolts and

remove the wheel;

make sure the contact surfaces

between spare wheel and hub are

clean so that the fastening bolts will not

come loose;

fit the standard wheel by inserting

the first bolt B fig. 197 two threads into

the hole closest to the inflation valve

A;

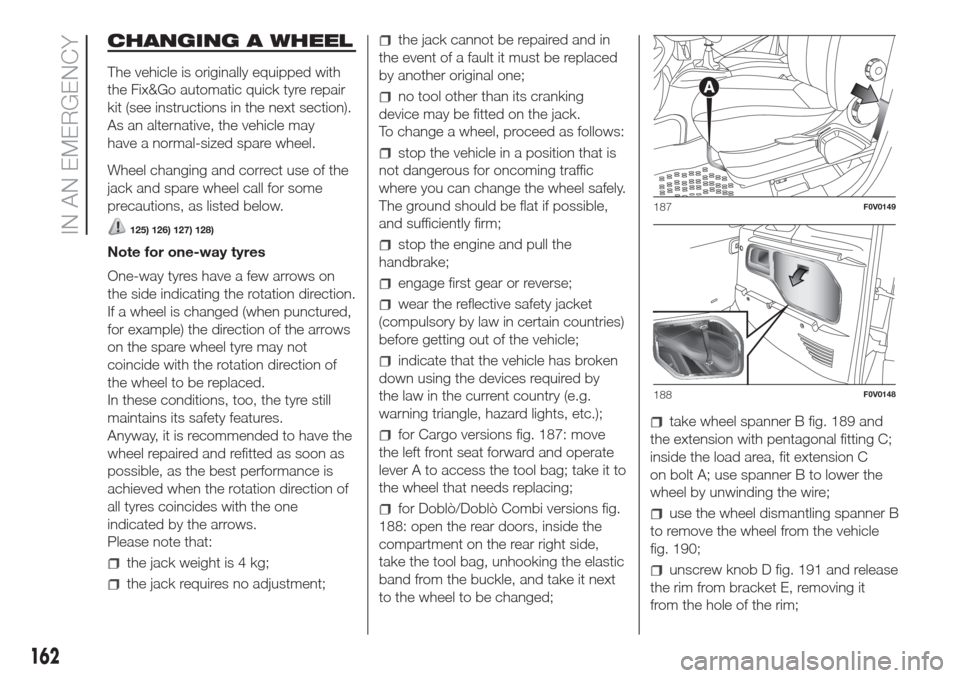

fit the hubcap, making sure that the

symbol

aligns with the inflation

valve, and then insert the other three

bolts.

tighten the bolts using the spanner

provided;

turn the jack handle to lower the

vehicle, and remove the jack;

use the wrench provided to fully

tighten the bolts, passing alternately

from one bolt to the opposite one,

as per the numerical sequence

illustrated in fig. 198.

At the end of the operation

fix bracket A fig. 199 to the wheel

after passing it through the hole, insert

the threaded pin into one of the bolt

holes and secure by tightening knob B;

195F0V0155

196F0V0156

197F0V0157

198F0V0158

164

IN AN EMERGENCY

Page 169 of 300

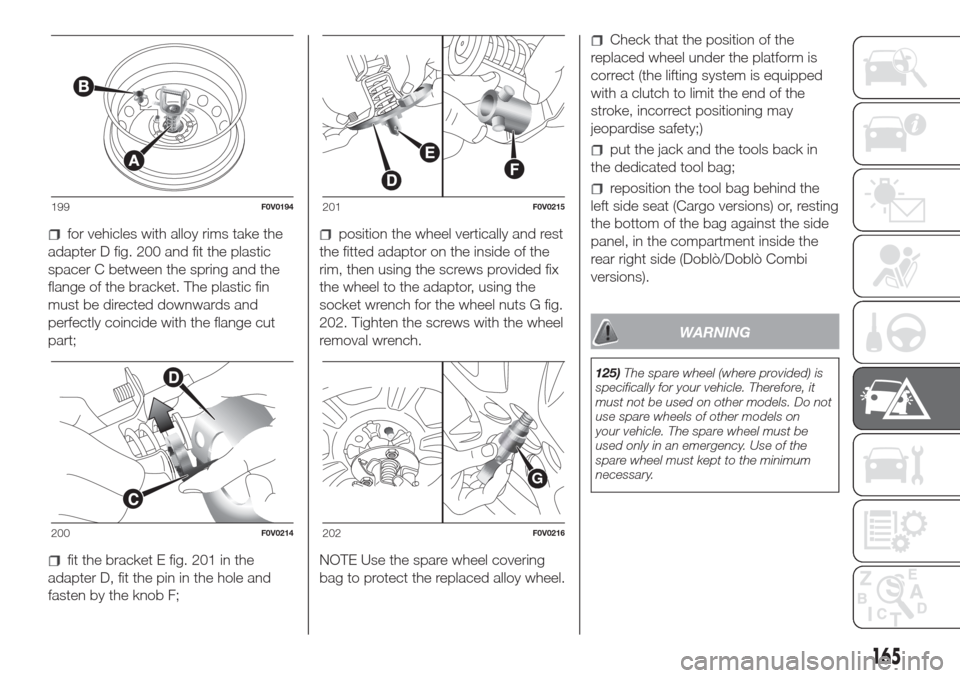

for vehicles with alloy rims take the

adapter D fig. 200 and fit the plastic

spacer C between the spring and the

flange of the bracket. The plastic fin

must be directed downwards and

perfectly coincide with the flange cut

part;

fit the bracket E fig. 201 in the

adapter D, fit the pin in the hole and

fasten by the knob F;

position the wheel vertically and rest

the fitted adaptor on the inside of the

rim, then using the screws provided fix

the wheel to the adaptor, using the

socket wrench for the wheel nuts G fig.

202. Tighten the screws with the wheel

removal wrench.

NOTE Use the spare wheel covering

bag to protect the replaced alloy wheel.

Check that the position of the

replaced wheel under the platform is

correct (the lifting system is equipped

with a clutch to limit the end of the

stroke, incorrect positioning may

jeopardise safety;)

put the jack and the tools back in

the dedicated tool bag;

reposition the tool bag behind the

left side seat (Cargo versions) or, resting

the bottom of the bag against the side

panel, in the compartment inside the

rear right side (Doblò/Doblò Combi

versions).

WARNING

125)The spare wheel (where provided) is

specifically for your vehicle. Therefore, it

must not be used on other models. Do not

use spare wheels of other models on

your vehicle. The spare wheel must be

used only in an emergency. Use of the

spare wheel must kept to the minimum

necessary.

199F0V0194

200F0V0214

201F0V0215

G

202F0V0216

165

Page 170 of 300

126)Use your hazard lights, warning

triangle, etc. to show that your vehicle is

stationary according to the regulations

in force. Passengers should get out of the

vehicle, particularly if it is heavily loaded,

and wait for the wheel to be changed away

from the traffic. If you are on a slope or

uneven surface, place wedges or other

suitable objects under the wheels to secure

the vehicle. Have the wheel repaired and

refitted as soon as possible. Do not apply

grease to the bolt threads before

assembly: they might spontaneously

unscrew.

127)Use the jack only to replace wheels

on the vehicle with which it is supplied

or on other vehicles of the same model.

Never use the jack for other purposes,

such as lifting other models. Never use the

jack to carry out repairs under the vehicle.

Incorrect positioning of the jack may cause

the lifted vehicle to fall. Do not use the

jack for loads higher than those shown on

the label.

128)Incorrect hub cap assembly may

cause it to come off when the vehicle is

moving. Never tamper with the inflation

valve. Never introduce tools of any kind

between rim and tyre. Check tyre and

spare wheel pressures regularly, referring to

the values shown in the "Technical

specifications" section.FIX&GO AUTOMATIC

KIT

129) 130)

28)

DESCRIPTION

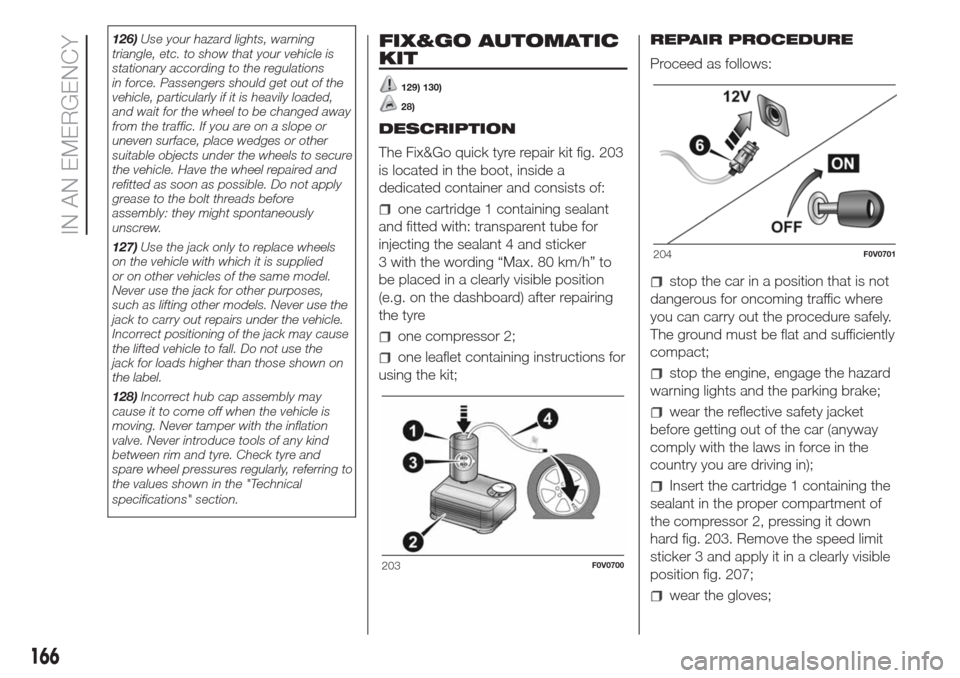

The Fix&Go quick tyre repair kit fig. 203

is located in the boot, inside a

dedicated container and consists of:

one cartridge 1 containing sealant

and fitted with: transparent tube for

injecting the sealant 4 and sticker

3 with the wording “Max. 80 km/h” to

be placed in a clearly visible position

(e.g. on the dashboard) after repairing

the tyre

one compressor 2;

one leaflet containing instructions for

using the kit;REPAIR PROCEDURE

Proceed as follows:

stop the car in a position that is not

dangerous for oncoming traffic where

you can carry out the procedure safely.

The ground must be flat and sufficiently

compact;

stop the engine, engage the hazard

warning lights and the parking brake;

wear the reflective safety jacket

before getting out of the car (anyway

comply with the laws in force in the

country you are driving in);

Insert the cartridge 1 containing the

sealant in the proper compartment of

the compressor 2, pressing it down

hard fig. 203. Remove the speed limit

sticker 3 and apply it in a clearly visible

position fig. 207;

wear the gloves;

203F0V0700

204F0V0701

166

IN AN EMERGENCY

Page 203 of 300

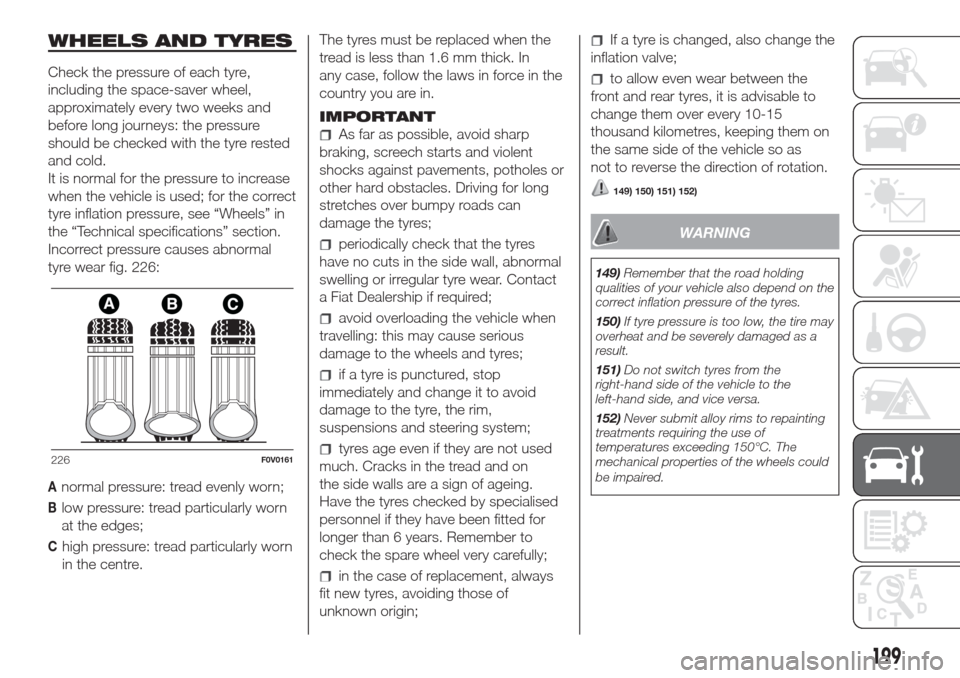

WHEELS AND TYRES

Check the pressure of each tyre,

including the space-saver wheel,

approximately every two weeks and

before long journeys: the pressure

should be checked with the tyre rested

and cold.

It is normal for the pressure to increase

when the vehicle is used; for the correct

tyre inflation pressure, see “Wheels” in

the “Technical specifications” section.

Incorrect pressure causes abnormal

tyre wear fig. 226:

Anormal pressure: tread evenly worn;

Blow pressure: tread particularly worn

at the edges;

Chigh pressure: tread particularly worn

in the centre.The tyres must be replaced when the

tread is less than 1.6 mm thick. In

any case, follow the laws in force in the

country you are in.

IMPORTANT

As far as possible, avoid sharp

braking, screech starts and violent

shocks against pavements, potholes or

other hard obstacles. Driving for long

stretches over bumpy roads can

damage the tyres;

periodically check that the tyres

have no cuts in the side wall, abnormal

swelling or irregular tyre wear. Contact

a Fiat Dealership if required;

avoid overloading the vehicle when

travelling: this may cause serious

damage to the wheels and tyres;

if a tyre is punctured, stop

immediately and change it to avoid

damage to the tyre, the rim,

suspensions and steering system;

tyres age even if they are not used

much. Cracks in the tread and on

the side walls are a sign of ageing.

Have the tyres checked by specialised

personnel if they have been fitted for

longer than 6 years. Remember to

check the spare wheel very carefully;

in the case of replacement, always

fit new tyres, avoiding those of

unknown origin;

If a tyre is changed, also change the

inflation valve;

to allow even wear between the

front and rear tyres, it is advisable to

change them over every 10-15

thousand kilometres, keeping them on

the same side of the vehicle so as

not to reverse the direction of rotation.

149) 150) 151) 152)

WARNING

149)Remember that the road holding

qualities of your vehicle also depend on the

correct inflation pressure of the tyres.

150)If tyre pressure is too low, the tire may

overheat and be severely damaged as a

result.

151)Do not switch tyres from the

righthand side of the vehicle to the

lefthand side, and vice versa.

152)Never submit alloy rims to repainting

treatments requiring the use of

temperatures exceeding 150°C. The

mechanical properties of the wheels could

be impaired.

226F0V0161

199

Page 219 of 300

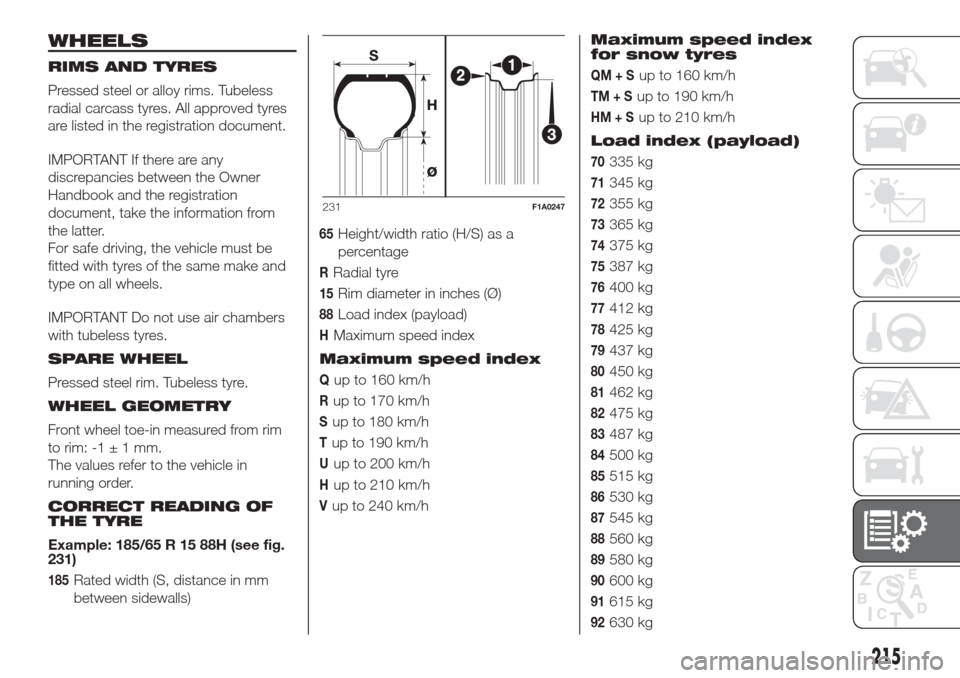

WHEELS

RIMS AND TYRES

Pressed steel or alloy rims. Tubeless

radial carcass tyres. All approved tyres

are listed in the registration document.

IMPORTANT If there are any

discrepancies between the Owner

Handbook and the registration

document, take the information from

the latter.

For safe driving, the vehicle must be

fitted with tyres of the same make and

type on all wheels.

IMPORTANT Do not use air chambers

with tubeless tyres.

SPARE WHEEL

Pressed steel rim. Tubeless tyre.

WHEEL GEOMETRY

Front wheel toe-in measured from rim

to rim: -1±1mm.

The values refer to the vehicle in

running order.

CORRECT READING OF

THE TYRE

Example: 185/65 R 15 88H (see fig.

231)

185Rated width (S, distance in mm

between sidewalls)

65Height/width ratio (H/S) as a

percentage

RRadial tyre

15Rim diameter in inches (Ø)

88Load index (payload)

HMaximum speed index

Maximum speed index

Qup to 160 km/h

Rup to 170 km/h

Sup to 180 km/h

Tup to 190 km/h

Uup to 200 km/h

Hup to 210 km/h

Vup to 240 km/hMaximum speed index

for snow tyres

QM+Sup to 160 km/h

TM+Sup to 190 km/h

HM+Sup to 210 km/h

Load index (payload)

70335 kg

71345 kg

72355 kg

73365 kg

74375 kg

75387 kg

76400 kg

77412 kg

78425 kg

79437 kg

80450 kg

81462 kg

82475 kg

83487 kg

84500 kg

85515 kg

86530 kg

87545 kg

88560 kg

89580 kg

90600 kg

91615 kg

92630 kg

231F1A0247

215

Page 221 of 300

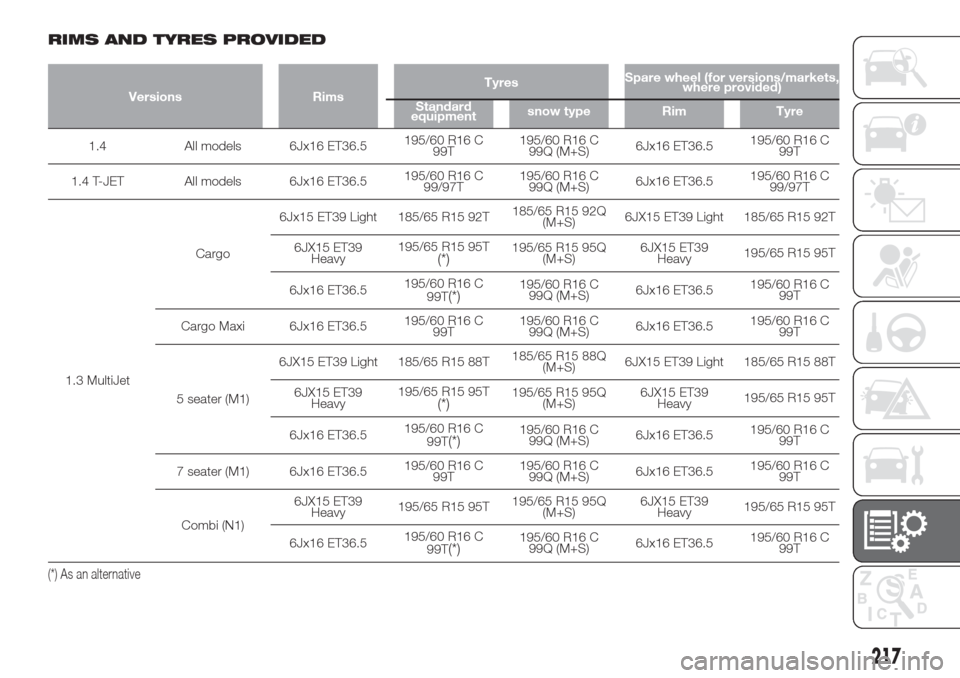

RIMS AND TYRES PROVIDED

Versions RimsTyresSpare wheel (for versions/markets,

where provided)

Standard

equipmentsnow type Rim Tyre

1.4 All models 6Jx16 ET36.5195/60 R16 C

99T195/60 R16 C

99Q (M+S)6Jx16 ET36.5195/60 R16 C

99T

1.4 T-JET All models 6Jx16 ET36.5195/60 R16 C

99/97T195/60 R16 C

99Q (M+S)6Jx16 ET36.5195/60 R16 C

99/97T

1.3 MultiJetCargo6Jx15 ET39 Light 185/65 R15 92T185/65 R15 92Q

(M+S)6JX15 ET39 Light 185/65 R15 92T

6JX15 ET39

Heavy195/65 R15 95T

(*)195/65 R15 95Q

(M+S)6JX15 ET39

Heavy195/65 R15 95T

6Jx16 ET36.5195/60 R16 C

99T

(*)195/60 R16 C

99Q (M+S)6Jx16 ET36.5195/60 R16 C

99T

Cargo Maxi 6Jx16 ET36.5195/60 R16 C

99T195/60 R16 C

99Q (M+S)6Jx16 ET36.5195/60 R16 C

99T

5 seater (M1)6JX15 ET39 Light 185/65 R15 88T185/65 R15 88Q

(M+S)6JX15 ET39 Light 185/65 R15 88T

6JX15 ET39

Heavy195/65 R15 95T

(*)195/65 R15 95Q

(M+S)6JX15 ET39

Heavy195/65 R15 95T

6Jx16 ET36.5195/60 R16 C

99T

(*)195/60 R16 C

99Q (M+S)6Jx16 ET36.5195/60 R16 C

99T

7 seater (M1) 6Jx16 ET36.5195/60 R16 C

99T195/60 R16 C

99Q (M+S)6Jx16 ET36.5195/60 R16 C

99T

Combi (N1)6JX15 ET39

Heavy195/65 R15 95T195/65 R15 95Q

(M+S)6JX15 ET39

Heavy195/65 R15 95T

6Jx16 ET36.5195/60 R16 C

99T

(*)195/60 R16 C

99Q (M+S)6Jx16 ET36.5195/60 R16 C

99T

(*) As an alternative

217

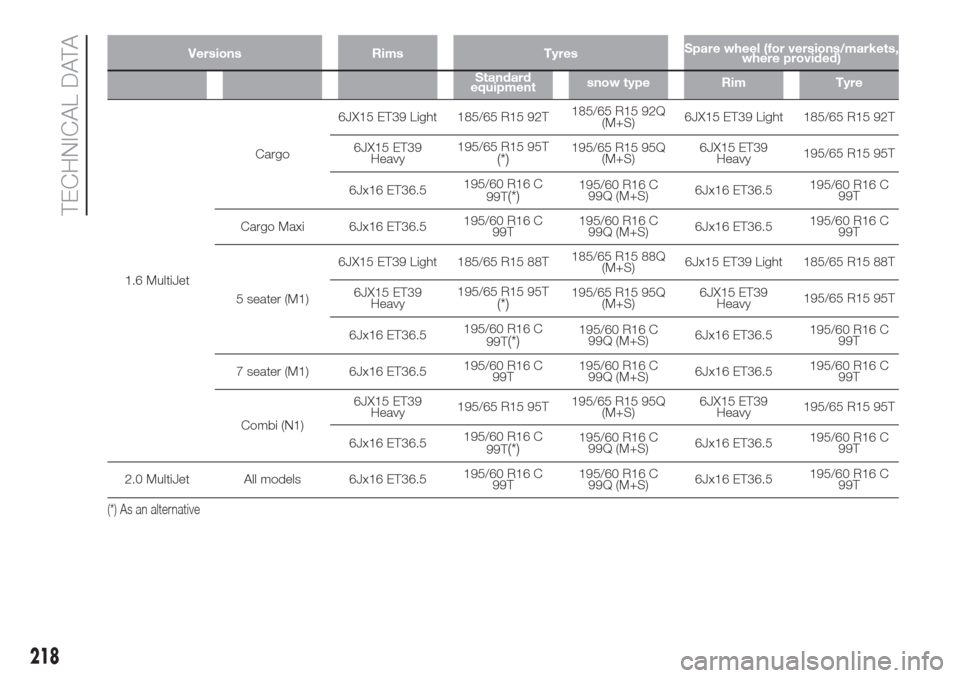

Page 222 of 300

Versions Rims TyresSpare wheel (for versions/markets,

where provided)

Standard

equipmentsnow type Rim Tyre

1.6 MultiJetCargo6JX15 ET39 Light 185/65 R15 92T185/65 R15 92Q

(M+S)6JX15 ET39 Light 185/65 R15 92T

6JX15 ET39

Heavy195/65 R15 95T

(*)195/65 R15 95Q

(M+S)6JX15 ET39

Heavy195/65 R15 95T

6Jx16 ET36.5195/60 R16 C

99T

(*)195/60 R16 C

99Q (M+S)6Jx16 ET36.5195/60 R16 C

99T

Cargo Maxi 6Jx16 ET36.5195/60 R16 C

99T195/60 R16 C

99Q (M+S)6Jx16 ET36.5195/60 R16 C

99T

5 seater (M1)6JX15 ET39 Light 185/65 R15 88T185/65 R15 88Q

(M+S)6Jx15 ET39 Light 185/65 R15 88T

6JX15 ET39

Heavy195/65 R15 95T

(*)195/65 R15 95Q

(M+S)6JX15 ET39

Heavy195/65 R15 95T

6Jx16 ET36.5195/60 R16 C

99T

(*)195/60 R16 C

99Q (M+S)6Jx16 ET36.5195/60 R16 C

99T

7 seater (M1) 6Jx16 ET36.5195/60 R16 C

99T195/60 R16 C

99Q (M+S)6Jx16 ET36.5195/60 R16 C

99T

Combi (N1)6JX15 ET39

Heavy195/65 R15 95T195/65 R15 95Q

(M+S)6JX15 ET39

Heavy195/65 R15 95T

6Jx16 ET36.5195/60 R16 C

99T

(*)195/60 R16 C

99Q (M+S)6Jx16 ET36.5195/60 R16 C

99T

2.0 MultiJet All models 6Jx16 ET36.5195/60 R16 C

99T195/60 R16 C

99Q (M+S)6Jx16 ET36.5195/60 R16 C

99T

(*) As an alternative

218

TECHNICAL DATA