warning light FIAT DOBLO COMBI 2018 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2018, Model line: DOBLO COMBI, Model: FIAT DOBLO COMBI 2018Pages: 272, PDF Size: 23.75 MB

Page 114 of 272

The cold tyre inflation pressure must

not exceed the maximum inflation

pressure value printed on the side of

the tyre.

NOTE

The TPMS does not replace the

normal tyre maintenance service and

does not indicate any fault in a tyre.

Therefore, the TPMS should not be

used as pressure switch while adjusting

the tyre inflation pressure.

Driving with insufficient tyre pressure

causes their overheating and can

result in tyre failure. The low inflation

pressure reduces fuel efficiency and

tyre tread life and may also affect

handling and braking performance of

the vehicle.

The TPMS does not replace the

correct tyre maintenance. It is up to the

driver to maintain the correct tyre

pressure level measuring it with

a suitable pressure switch. This is

necessary even if the decrease in the

inflation pressure value does not cause

the tyre pressure control warning light

to switch on.

The TPMS warns the driver of any

condition of insufficient tyre pressure. If

this drops below the insufficient

pressure limit for any reason including

low temperature and normal pressure

loss of the tyre.

The seasonal temperature changes

affect tyre pressure.

IMPORTANT Monitoring and

maintaining the correct pressure in all

four tyres are particularly important.

Tyre pressure monitoring system

low pressure warning

IMPORTANT In the case of deflation of

more than one tyre sequentially, without

switching off and on the engine, from

the second tyre involved the acoustic

signal is not activated, only the

dedicated signal is shown on the

display.

To prevent the signal from being stored

in the event of pressure loss of a

subsequent tyre (with deactivation of

the acoustic signal), the ignition key

must be turned to MAR and then to

STOP, each time pressure is restored.

TPMS operation faults

The system fault is indicated by the

warning light

which first flashes for

75 seconds and then stays on steadily.

WARNING

101)The TPMS is optimised for the original

tyres and wheels provided. TPMS

pressures and alerts have been defined

according to the size of the tyres mounted

on the vehicle. Using equipment with

different size, type or kind may cause

irregular system operation or sensor

damage. Non-original spare wheels can

damage the sensor. Do not use tyre

sealant or balancing weights if the vehicle

is equipped with TPMS as these may

damage the sensors.

102)If the system signals a pressure

decrease on a specific tyre, it is

recommended to check the pressure on all

four tyres.

103)The TPMS does not relieve the driver

from the obligation to check the tyre

pressure every month; it is not even to be

considered a replacing system for

maintenance or a safety system

104)Tyre pressure must be checked with

tyres cold. Should it become necessary for

whatever reason to check pressure with

warm tyres, do not reduce pressure even

though it is higher than the prescribed

value, but repeat the check when tyres are

cold.

105)The TPMS cannot indicate sudden

tyre pressure drops (for example when

a tyre bursts). In this case, stop the vehicle,

braking with caution and avoiding abrupt

steering.

112

STARTING AND DRIVING

Page 115 of 272

106)The system only warns that the tyre

pressure is low: it is not able to inflate

them.

107)Insufficient tyre inflation increases fuel

consumption, reduces the tread duration

and may affect the capacity to drive safely.

108)Always refit the valve stem cap after

inspecting or adjusting tyre pressure.

This prevents dampness or dirt from

entering the valve stem and thus

the pressure control sensor from being

damaged.

109)The tyre repair kit (Fix&Go) provided

with the vehicle (for versions/markets,

where provided) is compatible with the

TPMS sensors; using sealants not

equivalent with that in the original kit may

adversely affect its operation. If sealants

not equivalent with the original ones are

used, it is recommended to have the

TPMS sensor operation checked by a

qualified repair centre.SPEED BLOCK

(for versions/markets, where provided)

The vehicle is equipped with a speed

limitation function that can be set at the

user's request to one of four predefined

values: 90, 100, 110, 130 km/h.

To activate/deactivate this function,

contact a Fiat Dealership.

Following the operation, a sticker will be

applied to the windscreen showing the

top speed setting.

IMPORTANT The speedometer could

indicate a higher maximum speed than

the effective one, set by the Dealership,

in accordance with the regulations in

force.

CRUISE CONTROL

(for versions/markets, where provided)

IN BRIEF

This is an electronic driving aid that

allows you to drive at a speed of

above 30 km/h on long and straight

dry roads (e.g. motorways) with

few driving changes at a preset

speed without having to press the

accelerator pedal. It is therefore not

recommended to use this device

on extra-urban roads with traffic. Do

not use it in town.

Activating the device

When the device is activated, warning

light

comes on together with the

relevant message in the instrument

panel (for versions/markets where

provided).

The speed adjustment function cannot

be activated in 1st or reverse gear; it

is advisable to activate the function

in 4th or higher gears.

When travelling downhill with the device

activated, the vehicle speed may

exceed the memorised one.

110) 111)

113

Page 117 of 272

by pressing the accelerator pedal (in

this case the system is not actually

turned off but the acceleration request

takes priority; the cruise control remains

activated, without the need to the

press button B fig. 133 to restore the

previous conditions once the

acceleration is over).

The device is automatically switched off

in the following cases:

if the ABS or ESC systems intervene

with the vehicle speed below the

set limit

in the event of system failure.

WARNING

110)When travelling with the device active,

never move the gear lever to neutral.

111)In the event of device faults or failures,

turn the ring nut A to OFF and contact a

Fiat Dealership.

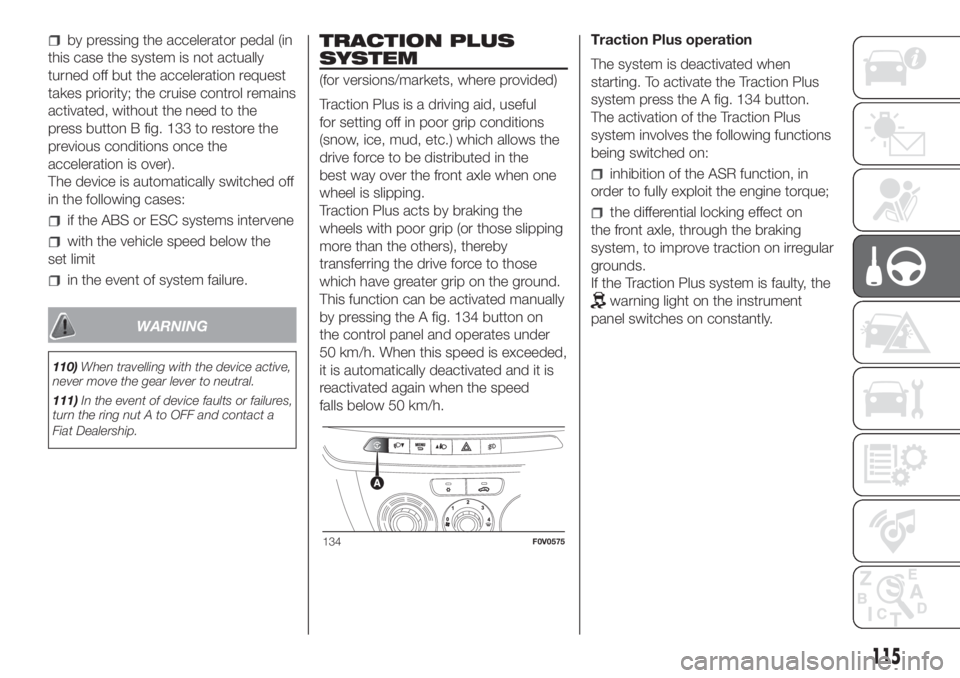

TRACTION PLUS

SYSTEM

(for versions/markets, where provided)

Traction Plus is a driving aid, useful

for setting off in poor grip conditions

(snow, ice, mud, etc.) which allows the

drive force to be distributed in the

best way over the front axle when one

wheel is slipping.

Traction Plus acts by braking the

wheels with poor grip (or those slipping

more than the others), thereby

transferring the drive force to those

which have greater grip on the ground.

This function can be activated manually

by pressing the A fig. 134 button on

the control panel and operates under

50 km/h. When this speed is exceeded,

it is automatically deactivated and it is

reactivated again when the speed

falls below 50 km/h.Traction Plus operation

The system is deactivated when

starting. To activate the Traction Plus

system press the A fig. 134 button.

The activation of the Traction Plus

system involves the following functions

being switched on:

inhibition of the ASR function, in

order to fully exploit the engine torque;

the differential locking effect on

the front axle, through the braking

system, to improve traction on irregular

grounds.

If the Traction Plus system is faulty, the

warning light on the instrument

panel switches on constantly.

134F0V0575

115

Page 123 of 272

IN AN EMERGENCY

A punctured tyre or a burnt-out bulb?

At times, a problem may interfere

with our journey.

The pages on emergencies can help

you to deal with critical situations

independently and with calm.

In an emergency we recommend that

you call the freephone number found in

the Warranty Booklet.

It is also possible to call the 00 800

3428 0000 freephone number to

search the nearest Fiat Dealership.HAZARD WARNING LIGHTS...........122

REPLACING A BULB ......................122

REPLACING AN EXTERIOR BULB ..125

REPLACING INTERIOR BULBS ......128

REPLACING FUSES........................129

REPLACING A WHEEL ...................134

FIX&GO AUTOMATIC KIT ................138

EMERGENCY STARTING ................141

FUEL CUT-OFF SYSTEM ................142

LIFTING THE VEHICLE....................142

TOWING THE VEHICLE ..................143

121

Page 124 of 272

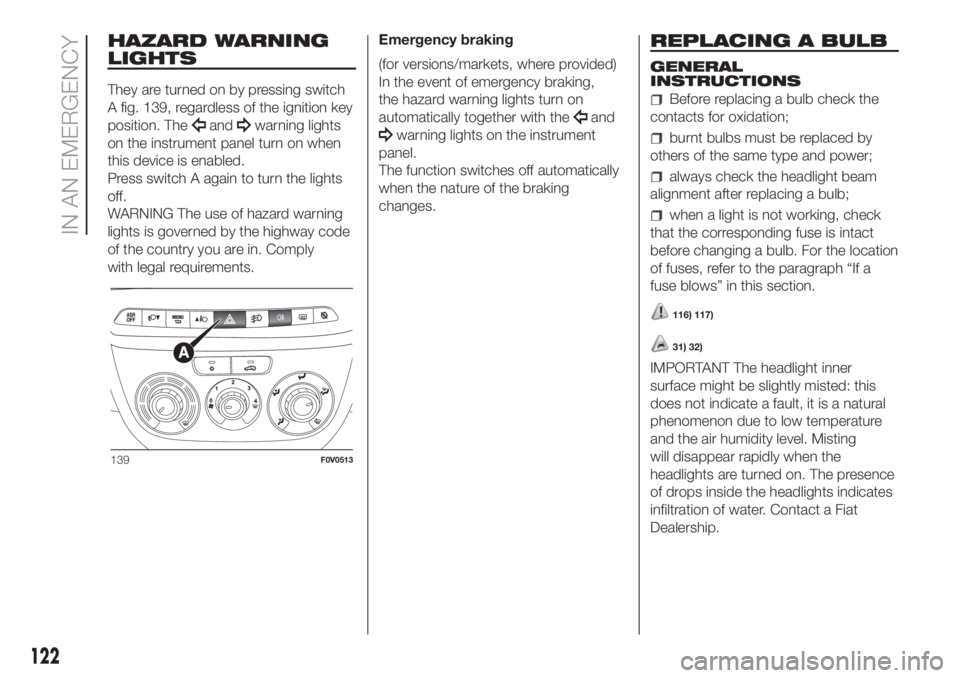

HAZARD WARNING

LIGHTS

They are turned on by pressing switch

A fig. 139, regardless of the ignition key

position. The

andwarning lights

on the instrument panel turn on when

this device is enabled.

Press switch A again to turn the lights

off.

WARNING The use of hazard warning

lights is governed by the highway code

of the country you are in. Comply

with legal requirements.Emergency braking

(for versions/markets, where provided)

In the event of emergency braking,

the hazard warning lights turn on

automatically together with theand

warning lights on the instrument

panel.

The function switches off automatically

when the nature of the braking

changes.

REPLACING A BULB

GENERAL

INSTRUCTIONS

Before replacing a bulb check the

contacts for oxidation;

burnt bulbs must be replaced by

others of the same type and power;

always check the headlight beam

alignment after replacing a bulb;

when a light is not working, check

that the corresponding fuse is intact

before changing a bulb. For the location

of fuses, refer to the paragraph “If a

fuse blows” in this section.

116) 117)

31) 32)

IMPORTANT The headlight inner

surface might be slightly misted: this

does not indicate a fault, it is a natural

phenomenon due to low temperature

and the air humidity level. Misting

will disappear rapidly when the

headlights are turned on. The presence

of drops inside the headlights indicates

infiltration of water. Contact a Fiat

Dealership.

139F0V0513

122

IN AN EMERGENCY

Page 125 of 272

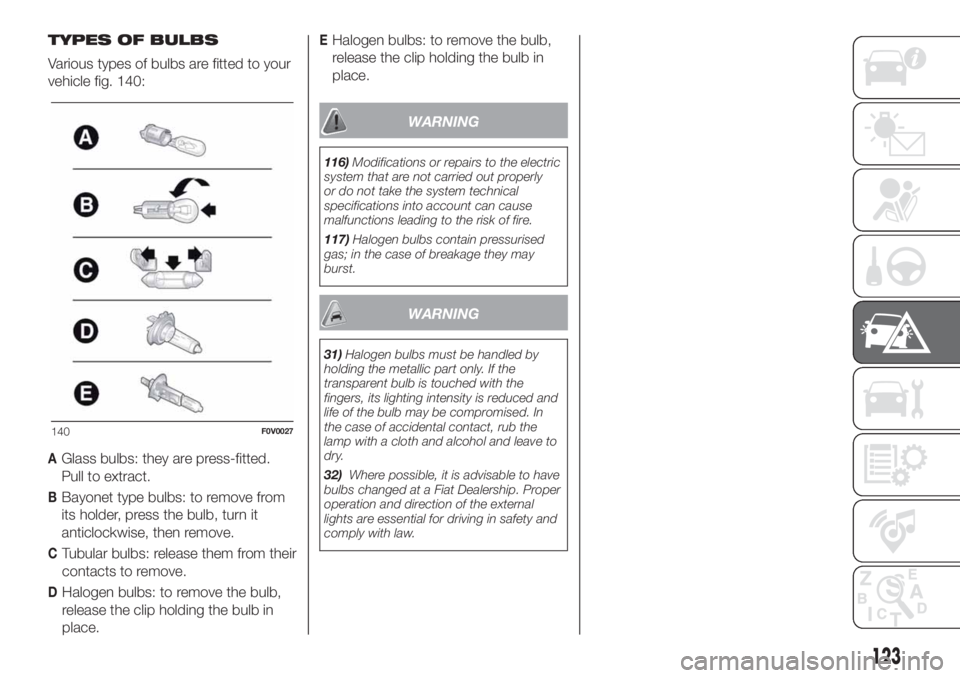

TYPES OF BULBS

Various types of bulbs are fitted to your

vehicle fig. 140:

AGlass bulbs: they are press-fitted.

Pull to extract.

BBayonet type bulbs: to remove from

its holder, press the bulb, turn it

anticlockwise, then remove.

CTubular bulbs: release them from their

contacts to remove.

DHalogen bulbs: to remove the bulb,

release the clip holding the bulb in

place.

EHalogen bulbs: to remove the bulb,

release the clip holding the bulb in

place.

WARNING

116)Modifications or repairs to the electric

system that are not carried out properly

or do not take the system technical

specifications into account can cause

malfunctions leading to the risk of fire.

117)Halogen bulbs contain pressurised

gas; in the case of breakage they may

burst.

WARNING

31)Halogen bulbs must be handled by

holding the metallic part only. If the

transparent bulb is touched with the

fingers, its lighting intensity is reduced and

life of the bulb may be compromised. In

the case of accidental contact, rub the

lamp with a cloth and alcohol and leave to

dry.

32)Where possible, it is advisable to have

bulbs changed at a Fiat Dealership. Proper

operation and direction of the external

lights are essential for driving in safety and

comply with law.

140F0V0027

123

Page 134 of 272

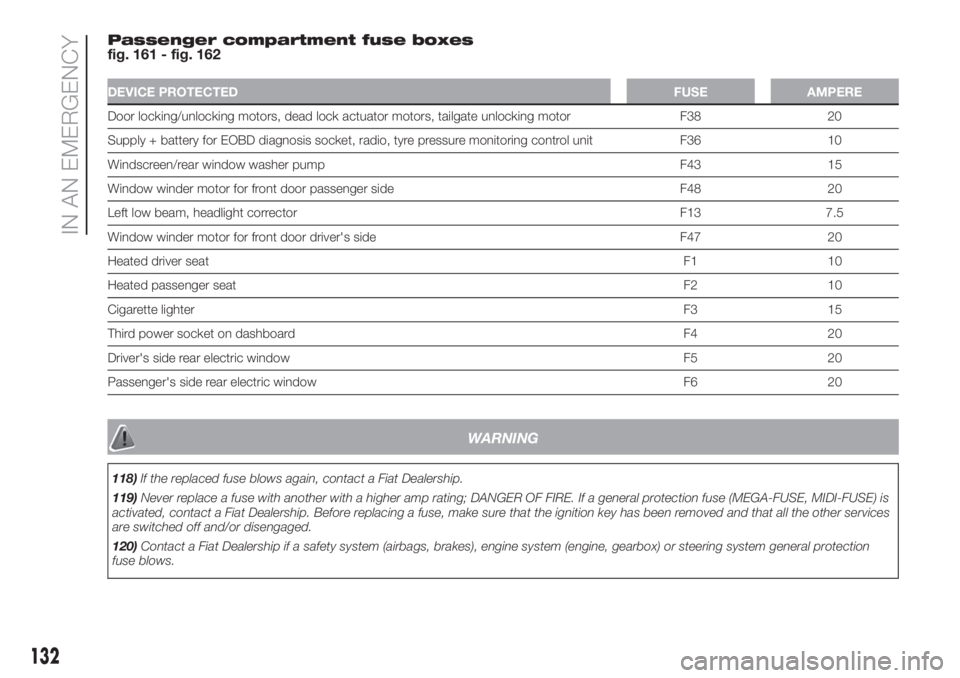

Passenger compartment fuse boxes

fig. 161 - fig. 162

DEVICE PROTECTEDFUSE AMPERE

Door locking/unlocking motors, dead lock actuator motors, tailgate unlocking motor F38 20

Supply + battery for EOBD diagnosis socket, radio, tyre pressure monitoring control unit F36 10

Windscreen/rear window washer pump F43 15

Window winder motor for front door passenger side F48 20

Left low beam, headlight corrector F13 7.5

Window winder motor for front door driver's side F47 20

Heated driver seatF1 10

Heated passenger seatF2 10

Cigarette lighterF3 15

Third power socket on dashboard F4 20

Driver's side rear electric window F5 20

Passenger's side rear electric window F6 20

WARNING

118)If the replaced fuse blows again, contact a Fiat Dealership.

119)Never replace a fuse with another with a higher amp rating; DANGER OF FIRE. If a general protection fuse (MEGA-FUSE, MIDI-FUSE) is

activated, contact a Fiat Dealership. Before replacing a fuse, make sure that the ignition key has been removed and that all the other services

are switched off and/or disengaged.

120)Contact a Fiat Dealership if a safety system (airbags, brakes), engine system (engine, gearbox) or steering system general protection

fuse blows.

132

IN AN EMERGENCY

Page 136 of 272

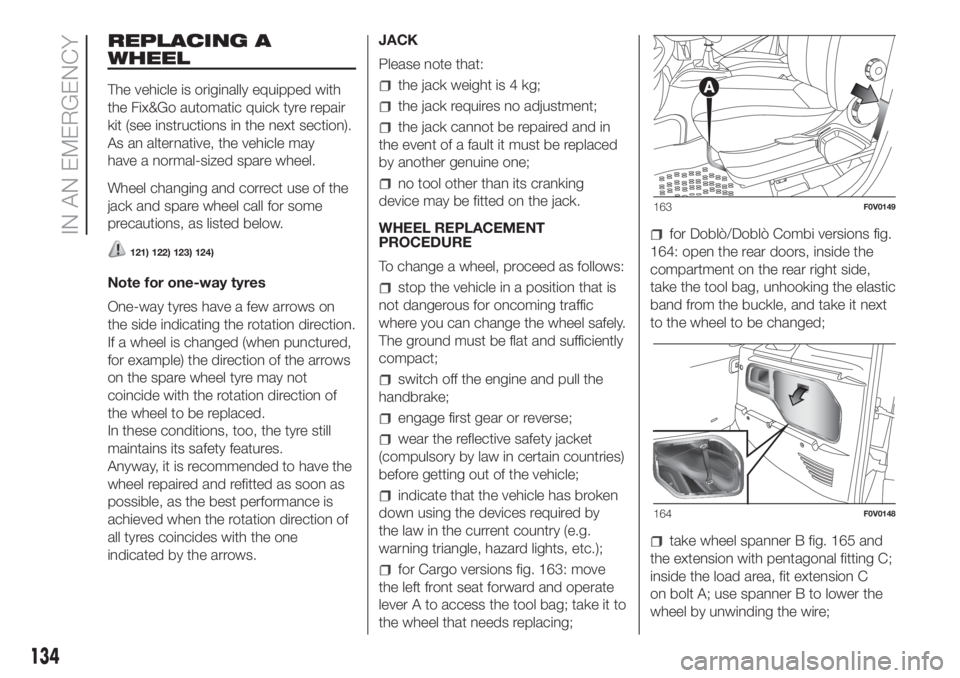

REPLACING A

WHEEL

The vehicle is originally equipped with

the Fix&Go automatic quick tyre repair

kit (see instructions in the next section).

As an alternative, the vehicle may

have a normal-sized spare wheel.

Wheel changing and correct use of the

jack and spare wheel call for some

precautions, as listed below.

121) 122) 123) 124)

Note for one-way tyres

One-way tyres have a few arrows on

the side indicating the rotation direction.

If a wheel is changed (when punctured,

for example) the direction of the arrows

on the spare wheel tyre may not

coincide with the rotation direction of

the wheel to be replaced.

In these conditions, too, the tyre still

maintains its safety features.

Anyway, it is recommended to have the

wheel repaired and refitted as soon as

possible, as the best performance is

achieved when the rotation direction of

all tyres coincides with the one

indicated by the arrows.JACK

Please note that:

the jack weight is 4 kg;

the jack requires no adjustment;

the jack cannot be repaired and in

the event of a fault it must be replaced

by another genuine one;

no tool other than its cranking

device may be fitted on the jack.

WHEEL REPLACEMENT

PROCEDURE

To change a wheel, proceed as follows:

stop the vehicle in a position that is

not dangerous for oncoming traffic

where you can change the wheel safely.

The ground must be flat and sufficiently

compact;

switch off the engine and pull the

handbrake;

engage first gear or reverse;

wear the reflective safety jacket

(compulsory by law in certain countries)

before getting out of the vehicle;

indicate that the vehicle has broken

down using the devices required by

the law in the current country (e.g.

warning triangle, hazard lights, etc.);

for Cargo versions fig. 163: move

the left front seat forward and operate

lever A to access the tool bag; take it to

the wheel that needs replacing;

for Doblò/Doblò Combi versions fig.

164: open the rear doors, inside the

compartment on the rear right side,

take the tool bag, unhooking the elastic

band from the buckle, and take it next

to the wheel to be changed;

take wheel spanner B fig. 165 and

the extension with pentagonal fitting C;

inside the load area, fit extension C

on bolt A; use spanner B to lower the

wheel by unwinding the wire;

163F0V0149

164F0V0148

134

IN AN EMERGENCY

Page 140 of 272

check that the position of the

replaced wheel under the platform is

correct (the lifting system is equipped

with a clutch to limit the end of the

stroke, incorrect positioning may

jeopardise safety;)

put the jack and the tools back in

the dedicated tool bag;

reposition the tool bag behind the

left side seat (Cargo versions) or, resting

the bottom of the bag against the side

panel, in the compartment inside the

rear right side (Doblò/Doblò Combi

versions).

WARNING

121)The spare wheel (where provided) is

specifically for your vehicle. Therefore, it

must not be used on other models. Do not

use spare wheels of other models on

your vehicle. The spare wheel must be

used only in an emergency. Use of the

spare wheel must kept to the minimum

necessary.122)Use your hazard lights, warning

triangle, etc to show that your vehicle is

stationary. Passengers should get out

of the vehicle, particularly if it is heavily

loaded, and wait for the wheel to be

changed away from the traffic. If you are on

a slope or uneven surface, place wedges

or other suitable objects under the wheels

to secure the vehicle. Have the wheel

repaired and refitted as soon as possible.

Do not apply grease to the bolt threads

before fitting: they could come unscrewed.

123)Use the jack only to replace wheels

on the vehicle with which it is supplied

or on other vehicles of the same model.

Never use the jack for other purposes,

such as lifting other models. Never use the

jack to carry out repairs under the vehicle.

Incorrect positioning of the jack may cause

the lifted vehicle to fall. Do not use the

jack for loads higher than the one shown

on its label.

124)Incorrect hub cap assembly may

cause it to come off when the vehicle is

moving. Never tamper with the inflation

valve. Never introduce tools of any kind

between rim and tyre. Check tyre and

space-saver wheel pressures regularly,

complying with the values given in the

"Technical specifications" chapter.

FIX&GO AUTOMATIC

KIT

125) 126)

37)

DESCRIPTION

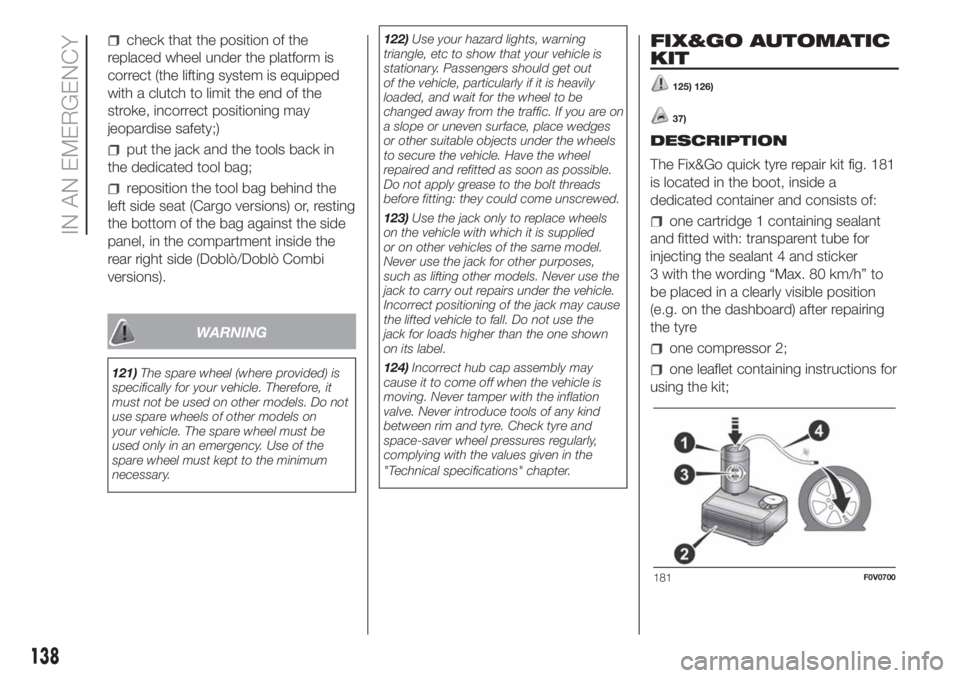

The Fix&Go quick tyre repair kit fig. 181

is located in the boot, inside a

dedicated container and consists of:

one cartridge 1 containing sealant

and fitted with: transparent tube for

injecting the sealant 4 and sticker

3 with the wording “Max. 80 km/h” to

be placed in a clearly visible position

(e.g. on the dashboard) after repairing

the tyre

one compressor 2;

one leaflet containing instructions for

using the kit;

181F0V0700

138

IN AN EMERGENCY

Page 141 of 272

TYRE REPAIRING AND

PRESSURE RESTORING

PROCEDURE

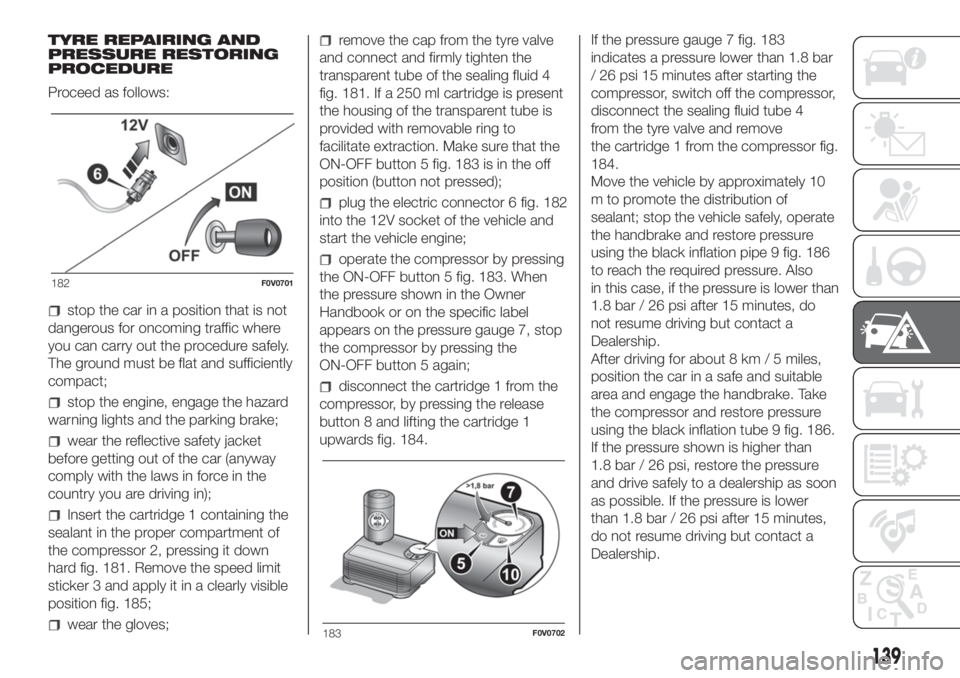

Proceed as follows:

stop the car in a position that is not

dangerous for oncoming traffic where

you can carry out the procedure safely.

The ground must be flat and sufficiently

compact;

stop the engine, engage the hazard

warning lights and the parking brake;

wear the reflective safety jacket

before getting out of the car (anyway

comply with the laws in force in the

country you are driving in);

Insert the cartridge 1 containing the

sealant in the proper compartment of

the compressor 2, pressing it down

hard fig. 181. Remove the speed limit

sticker 3 and apply it in a clearly visible

position fig. 185;

wear the gloves;

remove the cap from the tyre valve

and connect and firmly tighten the

transparent tube of the sealing fluid 4

fig. 181. If a 250 ml cartridge is present

the housing of the transparent tube is

provided with removable ring to

facilitate extraction. Make sure that the

ON-OFF button 5 fig. 183 is in the off

position (button not pressed);

plug the electric connector 6 fig. 182

into the 12V socket of the vehicle and

start the vehicle engine;

operate the compressor by pressing

the ON-OFF button 5 fig. 183. When

the pressure shown in the Owner

Handbook or on the specific label

appears on the pressure gauge 7, stop

the compressor by pressing the

ON-OFF button 5 again;

disconnect the cartridge 1 from the

compressor, by pressing the release

button 8 and lifting the cartridge 1

upwards fig. 184.If the pressure gauge 7 fig. 183

indicates a pressure lower than 1.8 bar

/ 26 psi 15 minutes after starting the

compressor, switch off the compressor,

disconnect the sealing fluid tube 4

from the tyre valve and remove

the cartridge 1 from the compressor fig.

184.

Move the vehicle by approximately 10

m to promote the distribution of

sealant; stop the vehicle safely, operate

the handbrake and restore pressure

using the black inflation pipe 9 fig. 186

to reach the required pressure. Also

in this case, if the pressure is lower than

1.8 bar / 26 psi after 15 minutes, do

not resume driving but contact a

Dealership.

After driving for about 8 km / 5 miles,

position the car in a safe and suitable

area and engage the handbrake. Take

the compressor and restore pressure

using the black inflation tube 9 fig. 186.

If the pressure shown is higher than

1.8 bar / 26 psi, restore the pressure

and drive safely to a dealership as soon

as possible. If the pressure is lower

than 1.8 bar / 26 psi after 15 minutes,

do not resume driving but contact a

Dealership.

182F0V0701

183F0V0702

139